Page 1

Built-In Central Cleaning System

MODELS: CV554, CV556, and CV570

SYSTEM PLANNING AND LAYOUT . . . . . . . . . . . . . . . . . . . . . .2

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Locating the Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tubing and Wall Inlet Location . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Locating Access Keys in Existing Construction . . . . . . . . . . . . . . .3

INSTALLATION IN NEW CONSTRUCTION . . . . . . . . . . . . . . . .4-8

Wall Inlet Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installing the Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wall Inlet Installation

Model 360 Wall Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Model 330 Wall Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Model CI390 Wall Inlet (Electrified Inlet) . . . . . . . . . . . . . . . . . .7

POWER UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Dimensional Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Tubing Connections at Power Unit . . . . . . . . . . . . . . . . . . . . . . .8

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

INSTALLATION IN EXISTING CONSTRUCTION . . . . . . . . . . .9-10

Wall Inlet Installation

Model 360 Wall Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Model 330 Wall Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

FLOOR INLET INSTALLATION . . . . . . . . . . . . . . . . . . . . . . .10-11

FINAL SYSTEM CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

INSTALLATION

INSTRUCTIONS

Page 2

2

SYSTEM PLANNING AND LAYOUT

The NuTone Central Cleaning System consists of a Power Unit,

PVC Tubing and Fittings, Wall Inlets, a flexible Hose and various

cleaning Attachments.

The Power Unit is designed to be wall-mounted away from the

living area of the home and connected to the living area by

means of permanently installed in-wall tubing, fittings and inlets.

Generally, an installation will require 3 to 4 inlets and 16 to 20

feet of tubing per inlet. It is suggested that a floor plan be used to

more accurately determine the quantity of materials needed.

As an aid in planning the installation in either new or existing

construction, look at the following examples. You should be able

to adapt the examples shown to your specific home layout.

Here the power unit is mounted

in the garage. The intake and

exhaust tubing, the only exposed

tubing in the installation, runs up

the garage wall and into the attic.

The trunk line runs horizontally

through the attic from the power

unit to the farthest inlet location.

Branch lines spread throughout the

attic, connecting the trunk line to the

inlet tubing. Each inlet tube is

threaded vertically through an inside wall.

Located in hallways, and in large rooms, the inlets are placed to

provide maximum access to all cleaning areas. See Figure 1.

EXHAUST

TRUNK LINE

BRANCH LINE

INLETS

POWER

UNIT

INTAKE

INLET LINE

FIGURE 2

FIGURE 1

Like the two-story house, the split level installation

commonly calls for a two-level trunk line. Here,

the power unit is located in the garage.

The intake tubing runs exposed up the

garage wall and into the ground level

section's attic. Two branch lines

connect this part of the trunk

line to inlet lines which are

dropped inside interior walls. A

vertical branch line runs to the

upstairs attic, where the trunk

line branches into a T-shape.

This trunk line connects to two

upstairs inlet lines and to one

inlet line which drops through

an upstairs wall and down into

the third-level utility room to service

this entire level. See Figure 3.

EXHAUST

POWER

UNIT

INTAKE

TRUNK

LINE

VERTICAL

BRANCH

LINE

BRANCH

LINES

INLET

LINE

INLET

INLET

BRANCH

LINE

THE RANCH STYLE HOUSE

THE TWO-STORY HOUSE

THE SPLIT-LEVEL HOUSE

A double-trunk line system is commonly used in two-story houses.

In the installation shown at left, the power unit is mounted in the

basement. The intake tubing runs up the basement wall and

connects to the main trunk line, which runs along the unfinished

basement ceiling. Two first-floor inlets are connected to the basement

trunk line by vertical inlet lines run through interior walls. In the center

of the house, a vertical branch line runs from the basement trunk line,

through stacked closets, up into the attic. A second trunk line runs across

the attic and two branch lines connect to inlet lines which are dropped

down through upstairs interior walls. See Figure 2.

FIGURE 3

ATTIC

TRUNK

LINE

INLET

VERTICAL

BRANCH

LINE

INTAKE

POWER

UNIT

EXHAUST

BASEMENT

TRUNK LINE

LINE

INLET

Page 3

3

• Locate the power unit away from the general living area in an

accessible location for emptying the lower dirt cannister and

periodically cleaning the filter.

• When planning, remember the power unit is equipped with

an inlet to service a garage, basement, utility room, etc.,

wherever it is located.

• Locate the power unit within six feet of a grounded electrical

outlet. The power unit requires a 120vAC power source.

• Do not locate the power unit close to a source of extreme

heat (i.e., water heater) or in an area with a high ambient

temperature (i.e., attic, furnace room).

• If the power unit is located in a closet or a small utility room,

make sure the area is well-ventilated (i.e., with door louvers).

• Exhausting the power unit to the outside is recommended for

optimal performance but is not required. The exhaust should

not be vented into a wall, a ceiling or a concealed space in

the house. If the exhaust line is vented outside the home,

Model 393 Wall Cap or a roof vent are recommended.

WARNING: Power unit must not be mounted in a high

ambient temperature area such as attic, furnace room, etc.

TUBING AND WALL INLET LOCATIONS

1. Locate inlets on interior walls, choosing central locations

which allow several rooms to be cleaned from a single inlet

using a 30 foot long hose.

2. The tubing installation should consist of a main trunk line

running from the farthest wall inlet to the power unit

location, with branch lines running to each additional inlet.

Keep all tubing lines as straight as possible and use as few

fittings as possible. Beginning at the area farthest from the

power unit, choose a tentative inlet location. Measure 30

feet from the proposed inlet location to the farthest corner of

the rooms to be cleaned by that inlet to determine if inlet

location is proper.

3. If working from blueprints (or building plans drawn at

1

⁄4" = 1 ft. scale), use a 71⁄2" chain as your guide to

determine inlet locations.

4. Move tentative inlet location if necessary. Use the same

procedure to determine each additional inlet location,

always working toward the power unit.

5. Be sure tubing will not interfere with electrical, plumbing or

other mechanical installations.

6. Locate inlets within six feet of an electrical receptacle to

allow use of optional current-carrying hose.

7. Be sure inlets will not be blocked by doors or furniture.

LOCATING THE POWER UNIT

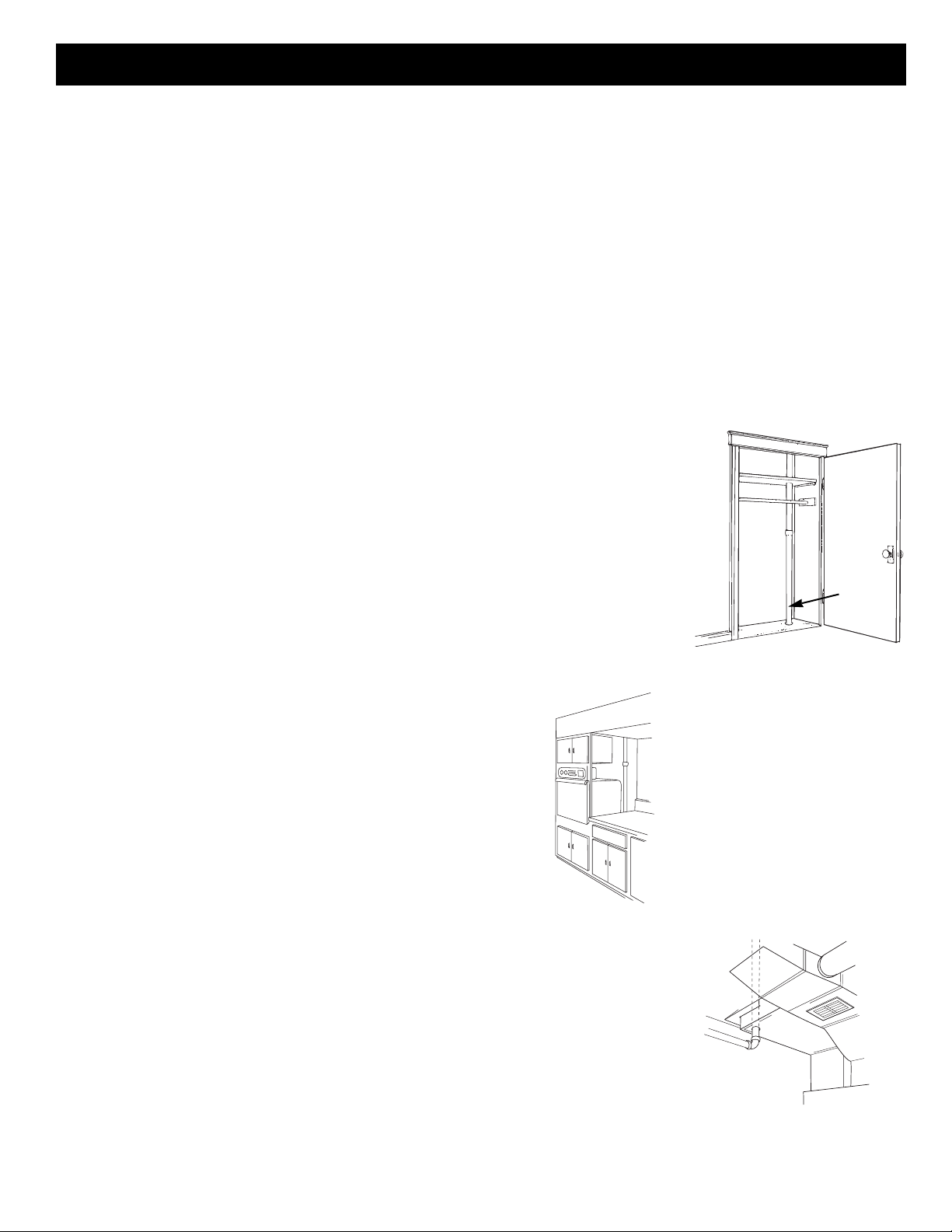

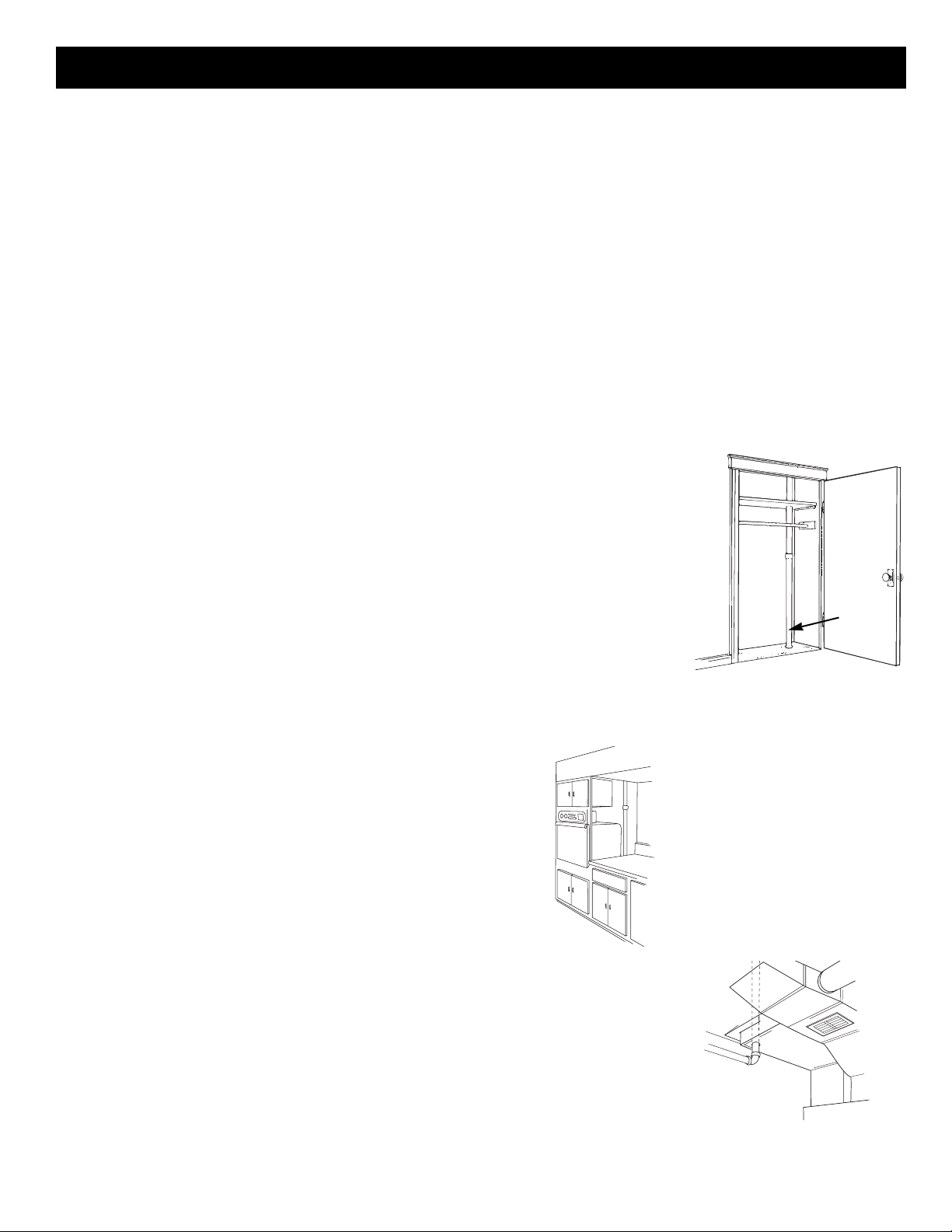

Built-In Appliances. You will often

find a hollow space behind built-in

kitchen appliances. If this space lines

up with an obstruction-free interior wall

above or a closet, this might be a key

to your installation. See Figure 5.

You may also want to consider

running exposed tubing through

cabinets or cupboards.

Cold-Air Return. A cold-air

return often provides a straight

run from basement to other levels

of the house. See Figure 6.

The ductwork is easily cut for

access. Seal around the tube

when completing the installation.

FIGURE 5

FIGURE 6

LOCATING ACCESS KEYS IN

EXISTING CONSTRUCTION

Let's say, for example, you have a two-story house and you want

to locate the power unit in the basement. If you can't find interior

walls on both the first and second floors which line up and are free

from obstacles. How do you get from the basement to the attic?

Unless your home is a ranch-style house where a single trunk

line can run directly through the attic or basement, you should first

investigate your house to find the key to running your tubing from

level to level. Look for an accessible area free from obstructions

that will accommodate the 2" tubing.

If you understand how your existing home is constructed, it can

be relatively easy to find access routes to run the tubing. Refer

again to the illustration on page 2 as you consider your home

construction.

Some of the keys you might find in your home are illustrated here.

FIGURE 4

Stacked Closets or Laundry

Chute. Many homes will have

an upstairs closet located

directly above a downstairs

closet. It is easy to run the

tubing from one floor level to

another inside these stacked

closets. In these installations

the tubing is often left exposed

inside the closets. See Figure

4. A laundry chute could also

provide access from basement

to upper floors.

TUBING

Page 4

4

INSTALLATION IN NEW CONSTRUCTION

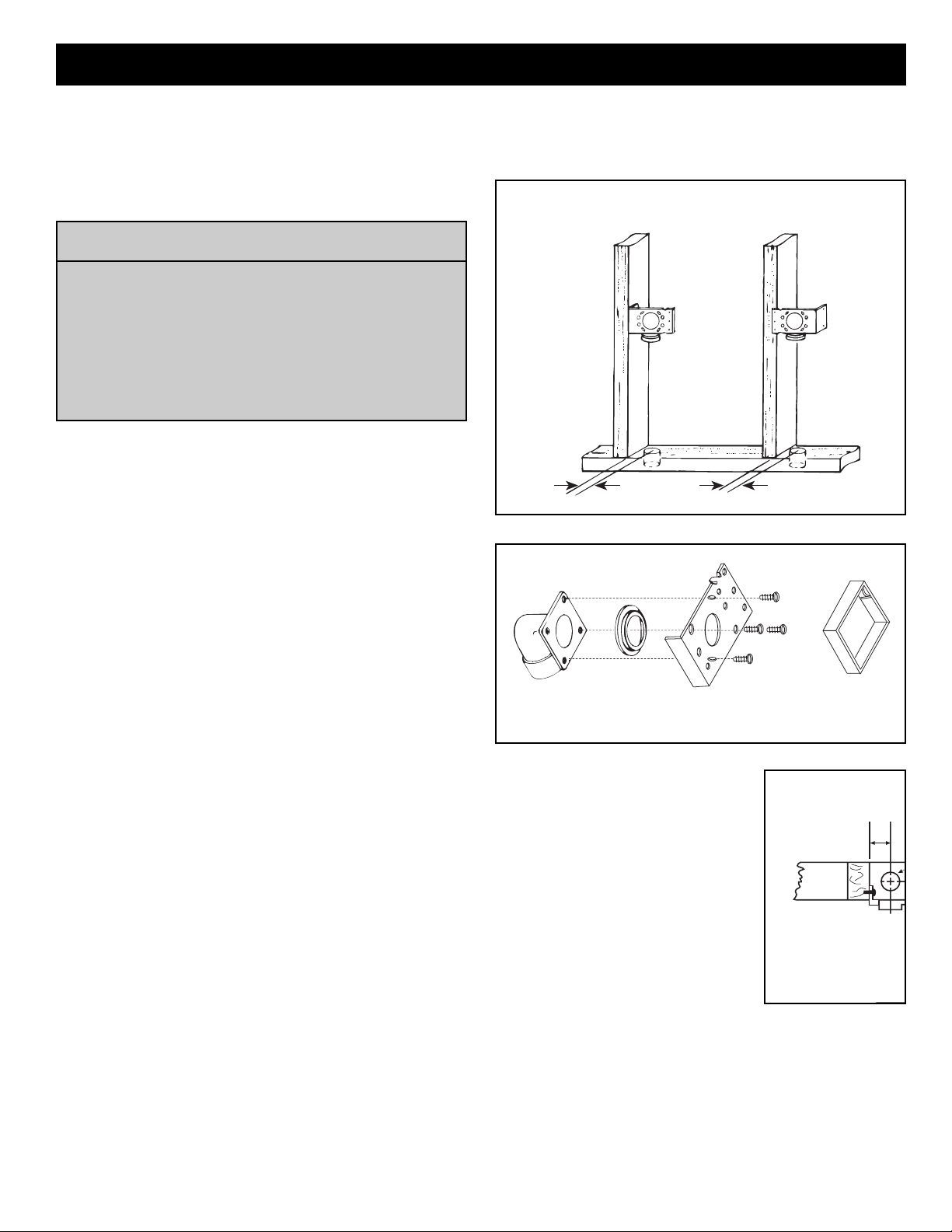

Once the locations for wall inlets have been determined, mount

all inlet brackets.

1. Choose the appropriate mounting bracket for the inlet being

installed. (See chart.)

2. To locate bracket on wall stud, measure approximately 18" up

from finished floor level. (Height may vary according to

individual preference.)

MODEL 361 (FOR USE WITH 360 INLETS)

3. Refer to Figure 7. Nail bracket to side of stud so that front

edge of bracket is flush to front of stud. (The bracket may also

be nailed to the front edge of the stud. See face mounting

illustrated. For face mounting, use locating tabs on bracket for

proper alignment.)

4. Refer to Figure 8. Remove cardboard from plaster guard

frame. Using four (4) provided screws, attach the appropriate

flanged fitting and inlet seal to back of inlet.

5. Replace cardboard in plaster guard frame.

MODEL 329 (FOR USE WITH 330 INLETS)

6. When using Model 329, glue elbow to mounting plate. Attach

to stud as shown in Figure 9.

SIDE

MOUNTING

FACE

MOUNTING

MODEL 361

23/8"

1

13

/16"

FIGURE 7

FIGURE 8

WALL INLET ROUGH-IN

SIDE

MOUNTING

M

TH

2

3

/8"

M

FIGURE 9

NuTone Inlet Rough-in

330 Series 329

360 Series 361

CI390 Series Electrified Inlet CI390RK

Page 5

5

INSTALLATION IN NEW CONSTRUCTION

(continued)

Use the following installation guidelines when installing tubing.

1. Start tubing installation at farthest inlet and work toward the

power unit.

2. Tubing run to the power unit should be as straight as

possible.

3. When assembling sections with elbows and tees, make

sure the curve in the fitting is aligned so that the air flows

toward the power unit.

4. Branch lines should always join the trunk line from above or

from the same level. Never join a branch line from an angle

below the trunk line.

5. Refer to Figure 28 on page 8. Run low voltage wiring

(Model 376-UL) and secure wiring to tubing as tubing is

installed. Model CF-380 Pipe Support can be used to

support long runs of tubing (position near joists) and to clip

wire along tubing. Secure tubing to joists or studs. Leave

approximately 6" of wire for connection to each inlet.

6. Cut a 2

1

⁄2" diameter hole in sole plate, header or stud

directly in line with opening of inlet bracket fitting.

Note Figure 6 for center line dimensions.

7. Refer to Figure 11. Measure length of tubing needed to

connect inlet to trunk line. Allow approximately

3

⁄4" of tubing

for inserting into fittings.

8. Refer to Figure 12. Cut tubing, keeping cut square.

9. Refer to Figure 13. Remove burrs from both inside and

outside of tubing.

10. Before cementing, pre-assemble section to inlet fitting,

check for proper length.

11. Refer to Figure 14. Apply PVC cement (Model 379) to

outside of tubing. Coat tubing approximately 1" back. Take

care to keep cement from inside of tube.

12. Refer to Figure 15. Insert tubing into fitting with a twisting

motion to evenly spread cement. Be sure tubing is firmly

seated in fitting.

13. If fittings have been attached to tubing at the end opposite

the inlet bracket, be sure alignment is proper before

cement sets.

14. Refer to Figure 16. Tape wire to tubing to hold in place

and insert through hole in inlet bracket.

15. Connect each inlet line and branch line into main trunk line.

Complete low voltage wiring as main trunk line is continued

back to power unit.

INSTALLING THE TUBING

SIDE

MOUNTING

FACE

MOUNTING

MODEL 361 MOUNTING

2

1

/2" DIA. HOLE

THROUGH SOLE PLATE

2

3

/8"

1

13

/16"

MODEL 329 MOUNTING

2"

FACE

MOUNTING

1

13

/16"

1

13

/16"

2

1

/2" DIA. HOLE

THROUGH SOLE PLATE

1

13

/16"

FIGURE 10

FIGURE 11

FIGURE 12 FIGURE 13

FIGURE 14 FIGURE 15

FIGURE 16

2" - 382S

2

5

⁄8" - 382

Caution: When tubing is run

through the wall stud, sole plate,

headers - or anywhere that

building materials will be

attached - place a nail plate

(Model 378) over that area

(on both sides if necessary)

to prevent nails from piercing

tubing.

3

/4"

FITTING

INCLUDE FITTING

RECESS IN

MEASUREMENT

TUBING MEASUREMENT

PVC TUBING

3

/4"

FITTING

Page 6

6

INSTALLATION IN NEW CONSTRUCTION

(continued)

FIGURE 19

FIGURE 21

FIGURE 17

MODEL 360 WALL INLET (361 Rough-In)

1. Remove the cardboard plaster guard.

2. Refer to Figure 17. For some drywall or panel construction, the

plaster frame will extend beyond the finished wall. In this case,

remove plaster frame from mounting bracket by removing

mounting screws.

NOTE: When using the Model 361 inlet bracket on walls thinner

than

1

⁄2", use a 1⁄4" spacer (not furnished) between the wall and the

inlet bracket. See Figure 20. Spacer may be made from plywood,

Masonite™, etc. Contact cement may be used to hold spacer in

place during assembly. Configuration of spacer may vary

depending upon installation.

3. Refer to Figure 18. Connect 2-conductor low voltage wire to

terminal screws on back of wall inlet. Cap off both wires using

wire nut (supplied).

4. Guide excess wire back through the hole in inlet bracket and

flanged fitting

5. Refer to Figure 19. Place inlet into mounting bracket and

secure.

NOTE: when wall inlets are installed in walls that are less

than

1

⁄2" thick or when inlets are installed back-to-back in a

wall, the tube of the wall inlet may extend into elbow area of

the flanged fitting and cause blockage. Shorten the wall inlet

tube to prevent this condition. Refer to Figure 21.

For extra thick walls, use Model 399 Extension Sleeve to connect

inlet to the flanged fitting.

MODEL 330 WALL INLET (329 Rough-in)

See Figure 23.

1. Connect 2-conductor low voltage wire to terminal screws on

back of wall inlet.

2. Align inlet mounting holes with holes in mounting plate.

3. Place inlet into mounting plate and secure with two provided

screws.

MOUNTING

PLATE

INLET

FIGURE 22

WALL INLET INSTALLATION

FIGURE 20

FIGURE 18

INLET MOUNTING

BRACKET

21/4"

SPACER

1

/4"

31/4"

MODEL 365

DOUBLE FLANGED

TEE

PLASTER

WALL LESS THAN

GUARD

HOLE

WALL

INLET

1

/2" THICK.

WALL

SHORTEN

MOUNTING

BRACKET

Page 7

7

INSTALLATION IN NEW CONSTRUCTION

(continued)

1. See Figure 23. Fasten the mounting plate to a stud within

three studs (48") of an electrical outlet box. Measure and

mark the wire 10" from the plug (A). Feed the wire through

the top hole in the mounting plate (just above the circular

opening). Snap the molded plug into the mounting plate as

pictured (B). This will keep it secure and out of harm’s way

during drywalling and finishing. Line up the wire at the

previously measured 10" mark with the strain of relief

channel on the back of the mounting plate. Secure it in

place with the supplied wire tie (C).

2. Run the inlet wire to the adjacent electric box. If you must

run wire through a stud, drill directly through the center of

the stud (D).

3. See Figure 24. Place the exposed ends of the two wires

into the electrical box through a strain relief channel (E).

Tighten the strain relief channel (do not overtighten) on the

white sheathing leaving 1/2" of this sheathing exposed

inside of the outlet box.

Fold the 6" of black and white wire into the outlet box.

Leave the wires to be connected by the electrician when

plug receptacles are being installed. (Attention: Power

tools such as routers are not recommended for use with

the inlet installation, as removal of drywall with these

devices may cause damage to the mounting plate and/or

inlet plug).

4. Once drywall and finishing processes have been

completed, remove molded plug from mounting plate (with

the aid of a slot screwdriver) and snap it into the wing slot

at the back of the inlet (F). (Please note: molded plug fits

one way only, with the narrow opening at the top). Insert

inlet into the mounting plate and secure inlet to mounting

plate with screws provided.

NOTE: All electrical devices such as the electrified inlet

should be reported to the construction electrician for listing

on the inspection report for building inspection purposes.

NOTE: Plumb inlet to tubing using NuTone

Model 382-S 90° Ell fitting.

CI-390 ELECTRAVALVE™ ELECTRIFIED INLET INSTALLATION (CI-390RK Rough-In)

(Not available in Canada)

D

E

FIGURE 23

FIGURE 24

Page 8

8

1. Use black rubber connectors and hose clamps to connect intake

and exhaust tubing.

2. Connect intake tubing to intake tube on power unit.

3. Connect exhaust tubing to upper exhaust tube on power unit.

4. Make sure all tubing connections are securely fastened.

5. An optional muffler (Model 392) may be installed to reduce

motor noise.

6. The exhaust should not be vented into a wall, ceiling or concealed

space in the house. Exterior vented exhaust lines should be terminated using Model 393 Wall Caps or appropriate louvered

exhaust vents.

POWER UNIT INSTALLATION

FIGURE 26

FIGURE 27

TUBING CONNECTIONS AT POWER UNIT

MOUNTING See Figure 25. Also refer to page 3.

1. Locate power unit within six feet of a grounded electrical outlet.

2. Remove mounting bracket from power unit and attach to wall,

following minimum clearances noted in Figure 25. Screws must be

secured into a wall stud or other suitable support.

3. Hang power unit securely on bracket.

WIRING See Figure 27.

Grounding Instructions – This appliance must be grounded. If it

should malfunction or break down, grounding provides a path of least

resistance for electric current, to reduce the risk of electric shock. This

appliance is equipped with a cord having an equipment-grounding

conductor and grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Danger –

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as to whether the outlet

is properly grounded. Do not modify the plug provided with the

appliance – if it will not fit the outlet, have a proper outlet installed by a

qualified electrician.

This appliance is for use on a nominal 120 volt circuit and has a

grounding plug. Make sure that the appliance is connected to an outlet

having the same configuration as the plug. No adapter should be used

with this appliance.

1. Connect low voltage wire (18 gauge, 2-conductor, Model 376-UL or

376) to crimp connectors located on outside of the power unit.

2. The power unit is equipped with a six foot grounded cord.

Plug cord into 120 volt grounded receptacle.

CONVENIENCE

OUTLET

MOUNTING

BRACKET

INLET INLET INLET

TO

OTHER

INLETS

POWER

UNIT

DIMENSIONAL CHART

DIMENSION CV554 CV556 CV570

A11

3

⁄4"11

3

⁄4"15

1

⁄8"

B40

3

⁄8"41

1

⁄4" 39"

C4

3

⁄4"6"4

3

⁄8"

D2

3

⁄8"2

1

⁄2"5"

E17

7

⁄8"18

1

⁄2"20

1

⁄2"

F15

1

⁄2"15

1

⁄2"15

1

⁄2"

FIGURE 25

MINIMUM WALL CLEARANCE DIMENSIONS

18"

18"

BACK VIEW

C

D

F

INTAKE

EXHAUST

CONVENIENCE

OUTLET

12" MINIMUM TO CEILING

FRONT VIEW

C

E

B

OVERALL

HEIGHT

INTAKE

18" MINIMUM ABOVE FLOOR

(MORE IS RECOMMENDED)

A

TOP VIEW

WIRING

MODEL

376-UL

OR

376

(181⁄2) WIRE

POWER

CORD

120 VAC

ELECTRICAL

OUTLET

PUSH-ON

CONNECTORS

®

NOTE: INLET

LEADS CONNECT

TO POWER UNIT

USING PUSH-ON

CONNECTORS

SUPPLIED ON

POWER UNIT

Page 9

9

Use the following procedures for installation in existing construction.

Starting from farthest wall inlet location, install each inlet as described

below. Working back toward power unit, connect each inlet line and

branch line into main trunk line. See page 5. Complete low voltage wiring

as main trunk line is continued back to power unit. Mount power unit and

complete wiring. See page 8.

1. See Figure 29. A small ‘pilot’ or ‘locating’ hole can be drilled behind

baseboard toe strip to determine proper location of 2

1

⁄2" diameter tubing

hole in sole plate.

2. Measure the total thickness of the wall, including baseboard. One half of

this wall thickness measured from the pilot hole (dimension ‘X’) will

determine the proper location of the 2

1

⁄2" tubing hole in the sole plate.

3. Once desired inlet locations have been determined, cut a 2

1

⁄2" hole in

sole plate directly in line with proposed inlet location. Check through

tubing hole to be sure no obstruction exists.

4. Be sure tubing hole is centered in sole plate and directly in line with

proposed wall inlet cutout.

BASEBOARD

TOE STRIP

PILOT HOLE

“X”

SOLE PLATE

FIGURE 28

NOTE: If 330 Wall Inlet is being used refer to Model 330 Wall Inlet

Installation on next page.

5. If area is clear, cut an inlet opening in the wall approximately 18" above the floor.

Make sure wall opening and 2

1

⁄2" tube hole line up (Figure 29).

6. Cut a length of tubing that will extend from inlet opening to a point below floor level

(or above ceiling level in attic installation). Tape low voltage wire to tube and insert tube

through predrilled hole to a level opposite the wall opening.

7. Apply cement to tube and install flanged wall fitting. Make sure fitting is well seated

and sealed (Figure 30).

8. Remove plaster frame from mounting bracket. Pull low voltage wire through hole in

bracket and insert bracket into cutout. Secure bracket to flanged fitting with four screws

provided. Be sure seal is secure between flange fitting and

mounting bracket (Figure 31).

9. Attach the low voltage wires to terminal screws on back of wall

inlet (Figure 32).

10. Insert wall inlet into bracket and secure with the two screws

provided (Figure 33).

FIGURE 29

FIGURE 31

FIGURE 32 FIGURE 33

LOW

VOLTAGE

WIRING

FLANGED

FITTING

FIGURE 30

INSTALLATION IN EXISTING CONSTRUCTION

NOTE: If the wall for mounting the Model 360 inlet is less

than

1

⁄2", a spacer must be used. See Figure 20 on page 6 as

a guide.

WALL INLET INSTALLATION

MODEL 360 SERIES INLETS (361 Rough-In)

31/16 "

29/16 "

21/2"

18"

Page 10

10

INSTALLATION IN EXISTING CONSTRUCTION

(continued)

MOUNTING

PLATE

MOUNTING

HOLE (2)

ELBOW

FIGURE 36

FIGURE 37

1. Make cutout according to dimensions in Figure 34.

2. Refer to Figure 35. Break off nail plate at scored line.

3. Refer to Figure 36. Glue elbow to mounting plate, place

assembly into cutout, and attach elbow to tubing inside

the wall.

4. Make sure mounting holes are exactly at top and bottom.

FIGURE 34 FIGURE 35

MODEL 330N WALL INLET INSTALLATION (329 Rough-in)

5. Connect 2-conductor low voltage wire to terminal screws on

back of wall inlet.

6. Refer to Figure 37. Align inlet mounting holes with mounting

plate holes, place inlet into mounting plate, and secure with

provided screws. NOTE: If 382-S shorter radius elbow is

used, it may be necessary to use the short mounting screw to

avoid interference with elbow.

FLOOR INLET INSTALLATION IN NEW & EXISTING CONSTRUCTION

1. Refer to Figures 38 and 39. After floor inlet location has been

selected, cut a 31⁄16" x 29⁄16" square hole in floor. Center line of

inlet must be located at least 21⁄2" from wall to allow cover to

be opened when hose is inserted.

2. Determine direction of tubing and attach appropriate flanged

fitting to mounting bracket with four (4) screws supplied. Be

sure mounting bracket flange does not interfere with

tubing and seal is securely in place.

3. Refer to Figure 40. Position bracket with frame and flanged

fitting assembly into cutout from below and secure to sub

floor.

4. Refer to Figure 41. Large end of Model 399 extension sleeve

should be cut to length to allow proper seating of inlet against

floor or carpet.

5. Refer to Figure 42. Pull low-voltage 2-conductor wire through

mounting bracket and attach to terminal screws on back of

floor inlet. Cement extension sleeve to model 360 inlet. Insert

extension sleeve through vinyl gasket in mounting bracket

and firmly seat into flanged fitting.

6. For convenience of operation, floor inlet should be installed to

open back toward wall.

7. Refer to Figure 40. Secure floor inlet in place with two screws.

FIGURE 38

FIGURE 39

MODEL 360 SERIES INLETS (361 Rough-in)

1

/4"

7

/8"

3

1

/4"

13/8"

3

2

/4"

3

/8" DIA.

3

/8" DIA.

INLET

MOUNTING

PLATE

1

3

/16"

TOP VIEW

9

2

/16"

MOLDING

WALL

21/2" MIN.

APPROX.

SIDE VIEW

MOUNTING BRACKET

FLANGE

Page 11

11

FLOOR INLET INSTALLATION

FLOOR

SUB-FLOOR

2

9

/16"

3

1

/16"

INLET

EXTENSION

FLOOR

INLET

FRAME

MOUNTING

BRACKET

SEAL

FLANGED

FITTING

FIGURE 40

FIGURE 41

WALL

INLET

EXTENSION SLEEVE

BRACKETFLANGED FITTING

TUBING

FIGURE 42

FINAL SYSTEM CHECK

Be sure all inlets are closed and lower cannister is in place.

Check switch on power unit for manual on/off operation.

Check each wall inlet to be sure contacts activate power unit

when hose is inserted and switched on, if applicable. If Central

Cleaning hose is not available at the time, a short piece of wire

can be used to short contacts in wall inlet to activate power unit.

Check each wall inlet and tubing connection for air leaks. Check

power unit for leaks around inlet tube and dirt cannister.

Make sure the permanent cloth filter is properly installed in the

power unit according to directions in the homeowner’s operating

instructions.

Now it’s time to enjoy the benefits of a NuTone Central Cleaning

System.

INLET

CUT TO

LENGTH

EXTENSION

FLANGED

FITTING

SLEEVE

MOUNTING

BRACKET

FLANGE

Page 12

Systè

me

Central

PLANIFICATION ET DISPOSITION DU SYSTEME . . . . . . . . . . .2

Exemples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Emplacement du Groupe d’Aspiration . . . . . . . . . . . . . . . . . . . . . .3

Tuyauterie et Emplacement des Prises Murales . . . . . . . . . . . . . .3

Emplacement des Points d’Accès dans une

Construction Existante . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION DANS UNE NOUVELLE CONSTRUCTION . . .4-8

Encastrement de Prise Murale . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation de la Tuyauterie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation des Prises Murales

Modèle 360 Prise d’Aspiration Murale . . . . . . . . . . . . . . . . . . . .6

Modèle 330 Prise Murale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Modèle CI390 Prise Murale (Electrifiée) . . . . . . . . . . . . . . . . . .7

INSTALLATION DU GROUPE D’ASPIRATION . . . . . . . . . . . . . .8

Tableau des Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Raccords de la Tuyauterie au niveau du Groupe d’Aspiration . . .8

Câblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

INSTALLATION DANS UNE CONSTRUCTION EXISTANTE .9-10

Installation des Prises Murales

Modèles 360 Prise Murale . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Modèle 330 Prise Murale . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

INSTALLATION DES PRISES AU SOL . . . . . . . . . . . . . . . . .10-11

VERIFICATION FINALE DU SYSTEME . . . . . . . . . . . . . . . . . . . .11

GUARANTIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

INSTRUCTIONS

D’INSTALLATION

Page 13

2

PLANIFICATION ET DISPOSITION DU SYSTEME

Le système central d'aspiration intégré de NuTone comprend un groupe

d'aspiration, une tuyauterie et des raccords en PVC, des prises

d'aspiration murales, un tuyau souple et de différents accessoires de

nettoyage.

Le Groupe d'Aspiration est conçu pour un montage mural éloigné de la

zone d'habitation de la maison mais connecté à celle-ci grâce à une

tuyauterie, des raccords et des prises installés de façon permanente

dansles murs.

Généralement une installation requiert de 3 à 4 prises avec 5 à 6

mètres de tuyauterie par prise d'aspiration. Il est suggéré qu'un plan soit

utilisé pour mieux déterminer la quantité du matériel qui sera nécessaire.

Comme une aide dans la planification d'une installation dans une

construction nouvelle ou déjà existante, voyez les exemples suivants.

Vous devriez pouvoir adapter les exemples montrés à la disposition

spécifique de votre maison.

Dans cet exemple, le groupe

d'aspiration est monté dans le garage.

Les tuyaux d'admission et d'évacuation, les

seuls exposés de l'installation, montent le

long du mur du garage jusqu’au grenier.

La ligne principale parcourt

horizontallement le grenier en partant du

groupe d'aspiration jusqu'à l'emplacement

de la prise d'aspiration la plus éloignée.

Les lignes secondaires s'étendent à travers

le grenier, pour raccorder la ligne

principale aux tuyaux d’admission.

Chaque tube d'aspiration est installé

verticallemen

t dans un mur intérieur. Situées dans les couloirs, et dans de

grandes pièces, les prises d'aspiration sont placées de façon à vous procurer un

accès maximum aux zones à nettoyer. Voyez la figure 1.

EXHAUST

TRUNK LINE

BRANCH LINE

INLETS

POWER

UNIT

INTAKE

INLET LINE

VERTICAL

BRANCH

LINE

ATTIC

TRUNK

LINE

INLET

LINE

INLET

EXHAUST

INTAKE

POWER

UNIT

BASEMENT

TRUNK LINE

FIGURE 2

FIGURE 1

Tout comme la maison à un étage, l'installation dans une maison

à plusieurs niveaux, nécessite communément une ligne principale

à deux niveaux. Dans cet exemple, le groupe d'aspiration est

monté dans le garage. La tuyauterie d'admission exposée

monte le long du mur du garage jusqu'au grenier

du rez-de-chaussé. Deux lignes secondaires

raccordent cette partie de la ligne

principale aux lignes de prise qui

descendent à l'intérieur des murs

intérieurs. Une ligne secondaire

verticale passe dans le grenier du

premier étage, où la ligne principale

adopte la forme d'un "T". Cette

ligne principale se raccorde à

deux lignes de prise du

premier étage et a une ligne qui

descend à travers le mur jusqu'à la

buanderie pour desservir entièrement

ce niveau. Voyez la figure 3.

EXHAUST

POWER

UNIT

INTAKE

TRUNK

LINE

VERTICAL

BRANCH

LINE

BRANCH

LINES

INLET

LINE

INLET

INLET

BRANCH

LINE

LA MAISON DU STYLE "RANCH"

LA MAISON A UN ETAGE

LA MAISON A PLUSIEURS NIVEAUX

Un système de double ligne principale est communément utilisé pour les maisons

à un étage. Dans l'installation montrée à gauche,

le groupe d'aspiration est installé dans le sous-sol. Le tuyau d'admission

remonte le long d'un mur du sous-sol et se raccorde à la ligne principale qui

est installée au plafond non fini du sous-sol.

Deux prises au rez-de-chaussée sont connectées à la ligne principale du sous-sol

grâce à des lignes verticales d'admission installées dans des murs intérieurs. Dans le

centre de la maison, une ligne secondaire verticale parcourt de la ligne principale du

sous-sol à travers les placards superposés jusqu'au grenier. Une seconde ligne

principale traverse le grenier et deux lignes secondaires se raccordent à deux lignes

de prise qui descendent à travers les murs intérieurs du premier étage.

Voyez la figure 2.

FIGURE 3

EVACUATION

GROUPE

D’ASPIRATION

ADMISSION

LIGNE

SECONDAIRE

LIGNE

PRINCIPALE

PRISES

LIGNE DE

PRISE

PRISE

EVACUATION

ADMISSION

LIGNE

PRINCIPALE

DU SOUS-SOL

LIGNE

PRINCIPALE

DU GRENIER

GROUPE

D’ASPIRATION

LIGNE

SECONDAIRE

VERTICALE

LIGNE DE

PRISE

LIGNE DE

PRISE

EVACUATION

GROUPE

D’ASPIRATION

ADMISSION

LIGNE

SECONDAIRE

VERTICALE

LIGNES

SECONDAIRES

LIGNE

SECONDAIRE

PRISE

LIGNE

PRINCIPALE

PRISE

Page 14

3

• Installez le groupe d’aspiration à l’écart de la zone habitée, à un

endroit facile d’accès pour le nettoyage du filtre et la vidange du bac

à saleté.

• Lors de votre planification, rappelez-vous que le groupe d'aspiration

est équipé d'une prise pour vous servir dans le garage, le sous-sol, la

buanderie, etc., où qu'il soit localisé.

• Installez le groupe d’aspiration à moins de 6 pi. d’une prise

électrique mise à la terre. Ce groupe exige une source de courant

de 120 V c.a.

• Ne placez pas le groupe d'aspiration à proximité d'une source de

chaleur (par exemple, un chauffe-eau) ou dans un lieu avec une

température ambiante élevée (par exemple, le grenier, la pièce où se

trouve la chaudiere).

• Si vous installez le groupe d'aspiration dans un placard ou une petite

buanderie, faites en sorte que la pièce soit bien aérée (par exemple,

dotée d'une porte à persiennes).

• L'évacuation extérieure du groupe d'aspiration est recommandée en

vue d'une performance optimale mais elle n'est pas requise.

L'évacuation ne doit pas se faire dans le mur, un plafond ou un

espace clos de la maison. Pour une évacuation extérieure, un

chaperon mural modèle 393 ou un ventilateur de toit est

recommandé.

ATTENTION: Le groupe d'aspiration ne doit pas être monté dans

un lieu où la température est élevée tel que le grenier ou la pièce

dans laquelle se trouve la chaudière, etc.

TUYAUTERIE ET EMPLACEMENT DES

PRISES MURALES

1. Placez les prises d'aspiration murales aux murs intérieurs, en

choisissant des emplacements centraux qui permettront d'aspirer

plusieurs pièces à partir d'une seule prise et en utilisant un boyau de

9,14 m de long.

2. L'installation de la tuyauterie devrait consister en une ligne

principale partant de la prise murale la plus éloignée jusqu'à

l'emplacement du groupe d'aspiration, avec des lignes secondaires

raccordant chaque prise additionelle. En commençant par la zone la

plus éloignée du groupe d'aspiration, choisissez un emplacement

provisoire de la prise. Mesurez 9,14 m de l'emplacement provisoire

de la prise au coin le plus éloigné des pièces qui seront aspirées de

cette prise pour determiner si son emplacement est correct.

3. Si vous travailler à partir d'un plan (ou des plans de construction à

une échelle de 0,64 cm = 30,48 cm), utilisez une chaîne de 19,05

cm comme guide pour déterminer l'emplacement des prises.

4.

Changez l'emplacement provisoire des prises si nécessaire. Utilisez

la même procédure pour déterminer l'emplacement des prises

supplémentaires, en vous dirigeant toujours vers le groupe

d'aspiration.

5. Soyez certain que la tuyauterie n'interfère pas avec des installations

électriques, de plomberie ou d'autres installations mécaniques.

6. Placez les prises à une distance maximum de 1,8 m de la prise pour

permettre l'utilisation d'un boyau à courant électrique fourni en

option.

7. Soyez sûr que les prises ne seront pas bloquées par une porte ou

un meuble.

EMPLACEMENT DU GROUPE D’ASPIRATION

Equipement de cuisine intégré. Vous

trouverez souvent un espace vide derrière

votre équipement de cuisine intégré. Si cet

espace s'aligne avec un mur intérieur

sans obstruction de l'étage supérieur ou

avec un placard, cela pourrait être le point

clé de votre installation. Voyez la figure 5.

Vous pourriez également envisager

d'installer la tuyauterie non intégrée à

travers les armoires ou les cabinets de

cuisine.

Le conduit de reprise d'air froid.

Un conduit de reprise d'air froid

fournit souvent un parcours direct du

sous-sol aux autres niveaux de la

maison. Voyez la figure 6. Il est facile

de découper les conduits pour y faire

passer les tuyaux. Il suffit de sceller

l'extérieur du tuyau en terminant

l'installation.

FIGURE 5

FIGURE 6

EMPLACEMENT DES POINTS D'ACCES

DANS UNE CONTRUCTION EXISTANTE

Disons, par exemple, que vous avez une maison à un étage et que

vous voulez installer le groupe d'aspiration au sous-sol. Si vous ne

pouvez pas trouver de murs intérieurs au rez-de-chaussée ou au

premier étage qui s'alignent et sont sans obstacles, comment passezvous du sous-sol au grenier?

A moins que votre maison ne soit du style "Ranch", au quel cas une seule

ligne principale peut être installée directement dans le sous-sol ou le

grenier, vous devez d'abord inspecter votre résidence pour déceler les

points d'accès d'un étage à l'autre pour les tuyaux. Vous devez rechercher

une zone libre de tout obstacle où vous pourrez faire passer un tuyau de

2". Si vous comprenez comment votre maison existante est construite,

cela peut être relativement facile de trouver les points d'accès pour

installer la tuyauterie. Consultez encore une fois l'illustration de la page 2

en considérant la construction de votre maison.

Certains des points d’accès que vous pourriez trouver dans votre maison

sont illustrés ci-dessous.

FIGURE 4

Placards superposés et conduit

de chute à linge. Dans certaines

résidences, un placard est situé

directement au-dessus d’un

placard au rez-de-chaussée. Il est

alors facile de faire passer le tuyau

d'un étage à l'autre en passant par

ces placards superposés. Dans de

tels cas, le tuyau passe souvent

directement dans le placard, sans

être intégré au mur. Voyez la

figure 4. Un conduit de chute à

linge peut également procurer un

accès du sous-sol aux autres

niveaux de la maison.

Tuyau

Page 15

4

INSTALLATION DANS UNE NOUVELLE CONSTRUCTION

Une fois l'emplacement des prises murales déterminé, mettez en

place tous les supports de prise.

1. Choisissez les supports de fixation appropriés pour la prise à

installer. (Voyez le tableau).

2. Pour positionner le support sur le montant, mesurez

approximativement 45,7 cm au-dessus du niveau du sol fini.

(La hauteur peut varier suivant vos préférences).

MODELE 361 (CONVIENT AUX PRISE 360)

3. Voyez la figure 7. Clouez le support sur le côté du montant de façon

à ce que l'avant du support soit dans l'alignement avec l'avant du

montant. (Le support peut également être cloué sur l'avant du

montant. Voyez l'illustration du montage de face. Pour le montage de

face, utilisez les pattes d'alignement des supports pour un

alignement correct.)

4. Voyez la figure 8. Enlevez le carton du cadre protecteur. Utilisez les

quatres (4) vis qui vous sont fournies, pour attacher le raccord à

bride approprié ainsi que le joint à l'arrière de la prise.

5. Replacez le carton dans le cadre protecteur.

MODELE 329 (CONVIENT AUX PRISES 330)

6. Lors de l'utilisation du Modèle 329, collez le coude à la plaque de

montage. Attachez-le au montant comme il est indiqué à la figure 9.

SIDE

MOUNTING

FACE

MOUNTING

MODEL 361

23/8"

1

13

/16"

FIGURE 7

FIGURE 8

ENCASTREMENT DE PRISE MURALE

SIDE

MOUNTING

M

TH

2

3

/8"

M

FIGURE 9

Prises NuTone Encastrement

Série 330 329

Série 360 361

Série CI390 Prise Electrifiée CI390RK

INSTALLATION

DE CÔTÉ

INSTALLATION

DE FACE

6,03 cm

4,60 cm

Page 16

5

INSTALLATION DANS UNE NOUVELLE CONSTRUCTION

(suite)

Suivez les lignes directrices ci-dessous lors de la mise en place de la

tuyauterie.

1. Commencez l'installation de la tuyauterie par la prise la plus éloignée

et avancez vers le groupe d'aspiration.

2. La tuyauterie qui rejoint le groupe d'aspiration devrait être la plus

droite possibe.

3. Lors de l'assemblage des sections avec les coudes et les raccords

en "T", soyez sûr que la courbe du raccord est alignée de façon à ce

que l'air se dirige vers le groupe d'aspiration.

4. Les lignes secondaires devraient toujours se raccorder à la ligne

principale par le dessus ou au même niveau que celle-ci. Ne

connectez jamais une ligne secondaire avec un angle inférieur à la

ligne principale.

5. Voyez la figure 28 de la page 8. Faites passer le câblage de basse

tension (Modèle 376-UL) et fixez-le à la tuyauterie à mesure que

vous installez celle-ci. Le modèle CF-380 de support de tuyau peut

être utilisé pour soutenir de longues sections de tuyau (placez-le à

côté des solives) et pour tenir le câblage le long de la tuyauterie.

Fixez la tuyauterie aux solives ou montants. Prévoyez

approximativement 15,24 cm de câblage pour le raccordement à

chaque prise.

6. Découpez un trou de 6,35 cm de diamètre dans la plaque d'assise,

collecteur ou le montant directement en ligne avec l'ouverture du

raccord du support de prise. Voyez la figure 6 pour les dimensions

de la ligne centrale.

7. Voyez la figure 11. Mesurez la longueur du tuyau nécessaire pour

raccorder la prise à la ligne principale. Accordez approximativement

1,905 cm de tuyauterie pour insertion dans les raccords.

8. Voyez la figure 12. Coupez le tuyau, en faisant une découpe droite.

9. Voyez la figure 13. Enlevez la barbure à l'intérieur et l'extérieur du

tuyau.

10. Avant de coller, pré-assemblez la section jusqu'au raccord de la prise

pour vérifier que la longueur soit correcte.

11. Voyez la figure 14. Appliquez la colle PCV (Modèle 379) à l'extérieur

du tuyau. Couvrez le tube à 2,54 cm du bout du tuyau. Faites

attention de ne pas mettre de colle à l'intérieur du tuyau

12. Voyez la figure 15. Insérez le tuyau dans le raccord en le faisant

tourner pour étaler uniformément la colle. Soyez sûr que le tuyau soit

solidement en place.

13. Si les raccords ont été attachés au tuyau au bout opposé du support

de prise, soyez sûr que l'alignement est correct avant la prise de la

colle.

14. Voyez la figure 16. Attachez le câblage avec du scotch pour le

maintenir en place et faites-le passer par le trou du support de prise.

15. Raccordez toutes les lignes de prise et lignes secondaires à la ligne

principale. Complétez le câblage de basse tension à mesure que

vous avancez vers le groupe d'aspiration.

INSTALLATION DE LA TUYAUTERIE

SIDE

MOUNTING

FACE

MOUNTING

MODEL 361 MOUNTING

2

1

/2" DIA. HOLE

THROUGH SOLE PLATE

2

3

/8"

1

13

/16"

MODEL 329 MOUNTING

2"

FACE

MOUNTING

1

13

/16"

1

13

/16"

2

1

/2" DIA. HOLE

THROUGH SOLE PLATE

1

13

/16"

FIGURE 10

FIGURE 11

FIGURE 12 FIGURE 13

FIGURE 14 FIGURE 15

FIGURE 16

5,08 cm- 382S

6,67 cm - 382

Attention: Lorsqu’un tuyau passe à

travers un montant, une plaque

d'assise, des collecteurs ou à tout

autre endroit où vous pourriez fixer

des matériaux - installez une plaque

protectrice (Modèle 378) à cet endroit

(des deux côtés au besoin) pour

empêcher les clous de percer le

tuyau.

INSTALLATION

DE CÔTÉ

INSTALLATION

DE FACE

INSTALLATION MODÈLE 361

ORIFICE DE 6,35 cm DE DIAMÈTRE

À TRAVERS LA PLAQUE D’ASSISE

INSTALLATION

DE FACE

ORIFICE DE 6,36 cm DE

DIAMÈTRE À TRAVERS LA

PLAQUE D’ASSISE

INSTALLATION MODÈLE 329

TUYAU DE PVC

RACCORD

RACCORD

TENIR COMPTE DES

RACCORDS DANS

LES MESURES

MESURE DU TUYAU

1,905 cm

1,905 cm

5,08

cm

6,03 cm

4,6 cm

4,6 cm

4,6 cm

INCLUDE FITTING

RECESS IN

MEASUREMENT

TUBING MEASUREMENT

PVC TUBING

FITTING

3

/4"

FITTING

3

/4"

Page 17

6

INSTALLATION DANS UNE NOUVELLE CONSTRUCTION (suite)

FIGURE 19

FIGURE 21

FIGURE 17

MODELE 360 PRISE MURALE (ENCASTREMENT 361)

1. Enlevez le carton du cadre protecteur.

2. Voyez la figure 17. Pour certaines cloisons sèches ou constructions à

panneaux, le cadre va s'etendre au-delà du mur fini. Dans ce cas-là,

retirez le cadre du support de montage en enlevant les vis de montage.

NOTA: Quand le modèle 361 de support de prise est utilisé pour des murs

d’une épaisseur inférieure à 1,27 cm, utilisez une entretoise de 0,64 cm

(non fournie) entre le mur et le support de prise. Voyez la figure 20.

L'entretoise peut être faite de bois contreplaqué, Masonite™, etc. De

l'adhésif de contact peut être utilisé pour maintenir l'entretoise en place

pendant l'assemblage. La configuration de l'entretoise peut varier suivant

l'installation.

3. Voyez la figure 18. Connectez le fil à rayures rouges du câble de

basse tension à deux âmes à la vis de borne non utilisée de la prise.

Connectez le fil qui reste à la queue de cochon noire. Couvrez les deux

fils en utilisant un capuchon isolant (fourni).

4. Faites passer l'excédent de câble en arrière à travers le trou du support

de la prise et le raccord à bride.

5. Voyez la figure 19. Placez la prise dans le support de montage et fixez-la.

NOTA: Lorsque les prises murales sont installées dans les murs

d’une épaisseur inférieure à 1,27 cm ou lorsque les prises sont

installées dos-à-dos dans un mur, le tube de la prise pourrait se

mettre en contact avec le coude du raccord à bride et causer des

blocages. Raccourcissez le tube de la prise murale pour éviter ceci.

Voyez la figure 21.

Pour des murs très épais, utilisez des manchons-allonge modèle 399 pour

connecter les prises au raccord à bride.

MODELE 330 DE PRISE MURALE (ENCASTREMENT 329)

Voyez la figure 22

1. Connectez le câble de basse tension à deux âmes aux vis de borne à

l'arrière de la prise murale.

2. Alignez les orifices de montage avec les orifices de la plaque de

montage.

3. Insérez la prise dans la plaque de montage et fixez-la à l'aide des deux

vis qui vous sont procurées.

MOUNTING

PLATE

INLET

FIGURE 22

INSTALLATION DES PRISES MURALES

FIGURE 20

FIGURE 18

VIS DE BORNE

FIL À

RAYURES

ROUGES

QUEUE DE

COCHON NOIRE

CAPUCHON

ISOLANT

SUPPORT DE MONTAGE

DE LA PRISE

ENTRETOISE

MUR D’EPAISSEUR

INFERIEURE À 1,27 CM

ORIFICE DU

CADRE

PROTECTEUR

MODÈLE 365

T À DOUBLE BRIDES

MUR

PARTIE

ENLEVÉE

SUPPORT DE

MONTAGE

PRISE

PLAQUE DE

MONTAGE

PRISE

MURALE

5,72

cm

0,64

cm

8,26 cm

INLET MOUNTING

BRACKET

21/4"

DOUBLE FLANGED

SPACER

1

/4"

31/4"

MODEL 365

TEE

PLASTER

GUARD

HOLE

WALL

INLET

WALL LESS THAN

1

/2" THICK.

WALL

SHORTEN

MOUNTING

BRACKET

Page 18

7

INSTALLATION DANS UNE NOUVELLE CONSTRUCTION (suite)

1. Voyez la figure 23. Attachez la plaque de montage à un montant à

une distance maximum de trois montants (1,22 m) d'un coffret de

sortie électrique. Mesurez et marquez le câble à 25,4 cm de la

prise (A). Avancez le câble à travers le trou du haut de la plaque

de montage juste au-dessus de l'ouverture circulaire. Enclenchez

la prise moulée dans la plaque de montage comme illustré (B).

Ceci le fixera en place et en sûreté durant le montage des

cloisons et les finitions. Alignez le câble sur la marque de 25,4 cm

auparavant mesurée avec le réducteur de tension situé à l'arrière

de la plaque de montage. Fixez-le avec le lien fourni (C).

2. Faites passer le câble de la prise jusqu'au coffret électrique

adjacent. Si vous devez faire passer le câble à travers le montant,

percez un trou directement à travers le centre du montant (D).

3. Voyez la figure 24. Placez les bouts exposés des deux câbles

dans le coffret électrique à travers le réducteur de tension(E).

Serrez le réducteur de tension (ne le serrez pas trop) sur la gaine

blanche laissant 1,27 cm de cette gaine exposé à l'intérieur du

coffret.

Incorporez le câble de 15,24 cm noir et blanc dans la boîte de sortie.

Laissez les câbles être connectés par un électricien lors de

l'installation des récepteurs de prises. (Attention: l'utilisation d'outils

motorisés tels que la guimbarde n'est pas recommandée pour

l'installation de la prise, vu que le retrait des cloisons avec ces

appareils pourrait causer des dommages à la plaque de montage

et/ou la prise).

4. Une fois que le montage des cloisons et les dernières étapes de

finition ont été complétés, retirez la prise moulée de la plaque de

montage (à l'aide d'un tournevis à tête plate) et enclenchez-la

dans la fente à l'arrière de la prise (F). (Notez s'il vous plaît: la

prise moulée ne s'emboîte que d'une seule façon, avec

l'ouverture étroite en haut). Insérez la prise dans la plaque de

montage et fixez-la à la plaque de montage avec les vis qui vous

sont procurées.

NOTA: Tous les appareils électriques tels que les prises électrifiées

devraient être signalés à l'électricien de construction pour les lister

sur le rapport d'inspection dans le but d'une inspection de

construction.

NOTA: Mettez la prise en ligne avec la tuyauterie en utilisant le

raccord de coude Modèle 382-S 90° de NuTone.

INSTALLATION DE LA PRISE ELECTRIFIEE ELECTRAVALVE™ CI--390

( ENCASTREMENT CI-390RK)

(NON DISPONIBLE AU CANADA)

D

E

FIGURE 23

FIGURE 24

Vue de

derrier

Page 19

8

1. Utilisez des raccords de caoutchouc noir et des brides pour connecter les

conduites d'arrivée et d'évacuation.

2. Raccordez la conduite d'arrivée à l'entrée du groupe d'aspiration.

3. Raccordez la conduite d'évacuation à l'échappement supérieur du groupe

d'aspiration.

4. Assurez-vous que tous les raccords sont bien solides.

5. Un silencieux facultatif (modèle 392) peut être installé pour réduire le bruit du

moteur.

6. L'évacuation ne doit pas se faire dans un mur, un plafond ou un espace clos

de la maison. Si l'évacuation se fait à l'extérieur, la conduite doit être dotée

d'un capuchon mural (modèle 393) ou d'une sortie murale à registre

appropriée.

INSTALLATION DU GROUPE D'ASPIRATION

RACCORD DES CONDUITES AU GROUPE D'ASPIRATION

MONTAGE Consultez la Figure 25 ainsi que la page 3.

1. Installez le groupe d'aspiration à moins de 6 pi. d'une prise de courant mise à

la terre.

2. Retirez le support de montage du groupe, puis fixez-le au mur en tenant

compte des données de dégagement minimums de la Figure 25. Les vis

doivent être placées dans un montant mural ou dans une autre structure

solide appropriée.

3. Suspendez le groupe d'aspiration sur le support de montage.

CABLAGE Voyez la figure 27.

Mise à la terre - Cet appareil doit être mis à la terre. En cas de bris ou de

défaillance, la mise à la terre constitue une voie de moindre résistance pour

évacuation du courant, ce qui réduit les risques de chocs électriques. Cet

appareil est doté d'un cordon électrique comportant un fil de mise à la terre et

une fiche avec une troisième broche pour mise à la terre. Cette fiche doit être

branchée dans une prise de courant mise à la terre et installée conformément

aux codes et aux règlements locaux en vigueur.

Danger - Le raccordement non approprié du cordon de l'appareil entraîne

des risques de chocs électriques. Demandez à un électricien ou à une

personne qui s'y connaît de vérifier la prise si vous n'êtes pas certain qu'elle est

bien mise à la terre. Ne modifiez pas la fiche du cordon de l'appareil. Si elle ne

peut se brancher dans la prise, faites installer une nouvelle prise par un

électricien.

Cet appareil est conçu pour une prise de 120 V nominale et est doté d'une

fiche avec mise à la terre. Assurez-vous que l'appareil est branché dans une

prise électrique convenant à la fiche. Aucun adaptateur ne doit être utilisé avec

cet appareil.

1. Raccordez le fil basse tension (calibre 18, 2 conducteurs, modèle 376-UL ou

376) aux connecteurs à sertir sur le boîtier du groupe d'aspiration.

2. Le groupe d'aspiration est doté d'un cordon électrique mis à la terre de six

pieds. Branchez la fiche de ce cordon dans une prise électrique 120 V mise

à la terre.

FIGURE 26

FIGURE 27

PRISE

D’ASPIRATION

DE L’APPAREIL

SUPPORT

DE

MONTAGE

PRISE PRISE PRISE

VERS

LES

AUTRES

PRISES

UNITÉ

D’ASPIR-

ATION

FIGURE 25

DÉGAGEMENT MINIMUM AU MUR

18"

18"

VIE ARRIÈRE

C

D

F

ENTRÉE

ÉVACUATION

PRISE

D’ASPIRATION

DE L’APPAREIL

12po MINIMUM DU PLAFOND

VUE DE FACE

C

E

B

HAUTER

GLOBALE

ENTRÉE

18 po MINIMUM DU PLANCHER

(PLUS SI POSSIBLE)

A

VUE EN PLONGÉE

CÂBLAGE

MODÈLE

376-UL OU

378 AVEC

FIL (18 1/2)

CORDON

ÉLECTRIQUE

PRISE 120 V

C.A.

CONNECTEURS

À PRESSION

®

NOTE: LES FILS

DES PRISES

SONT BRANCHÉS

AU GROUPE

D’ASPIRATION

AU MOYEN DE

CONNECTEURS

À PRESSION

TABLEAU DES DIMENSIONS

DIMENSION CV554 CV556 CV570

A 29,85 cm 29,85 cm 38,42 cm

B 1,02 m 1,05 m 99 cm

C 12,07 cm 15,24 cm 11,11 cm

D 6,03 cm 6,35 cm 12,70 cm

E 45,40 cm 46,99 cm 52,07 cm

F 39,37 cm 39,37 cm 39,37 cm

Page 20

9

Utilisez les procédures suivantes pour une installation dans une construction

existante. En commençant par la prise murale la plus éloignée, installez chaque

prise tel qu' il vous est décrit ci-dessous. Travaillez vers le groupe d'aspiration;

connectez chaque ligne de prise et ligne secondaire à la ligne principale. Voyez

la page 5. Complétez le câblage de basse tension en avançant vers le groupe

d'aspiration. Montez le groupe d'aspiration et complétez le câblage. Voyez la

page 8.

1. Voyez la figure 29. Un petit trou "de guidage" ou "de repérage" peut être

percé derrière le bord inférieur de la plinthe pour determiner l'emplacement

du trou de la tuyauterie de diamètre dans la plaque d'assise.

2. Mesurez la totalité de l'épaisseur du mur, y compris la plinthe. Une moitié de

l'épaisseur de ce mur mesuré depuis le trou de guidage (dimension 'X') va

déterminer l'emplacement du trou de la tuyauterie de 6,35 cm de diametre

dans la plaque d'assise.

3. Une fois que l'emplacement des prises est déterminé, pratiquez un trou de

6,35 cm dans la plaque d'assise directement en ligne avec l'emplacement de

la prise envisagé. Regardez à travers le trou pour vous assurer qu'il n'y a

aucune obstruction.

4. Assurez-vous que le trou est centré dans la plaque d'assise et directement en

ligne avec la découpe de la prise murale envisagée.

BASEBOARD

TOE STRIP

PILOT HOLE

“X”

SOLE PLATE

FIGURE 28

NOTA: Si vous utilisez une prise murale 330, voyez "Installation de la prise murale modèle 330N" à la page

suivante.

5. S'il n'y a aucune obstruction, découpez une ouverture pour la prise dans le mur à approximativement 45 cm

du sol. Assurez-vous que l'ouverture du mur et le trou de la tuyauterie de 6,35 cm de diamètre sont alignés

(Figure 29).

6. Coupez une longueur de tube qui pourra s'étendre de l'ouverture de la prise à un point au-dessous du

plancher ( ou au-dessus du plafond pour une installation au grenier). Attachez le câble de basse tension au

tube avec du scotch et insérez le tube à travers le trou pré-percé jusqu'à un niveau opposant l'ouverture du

mur.

7. Appliquez de l'adhésif de contact au tube et installez le raccord à brides. Soyez sûr que le raccord est bien

en place et scellé (Figure 30).

8. Retirez le cadre du support de montage. Tirez le câble de basse tension à travers le trou du support et

insérez le support dans la découpe. Fixez le support au raccord à bride avec les quatre vis fournies.

Assurez-vous que la soudure est sûre entre le raccord à bride et le

support de montage (Figure 31).

9. Attachez les câbles de basse tension aux vis de borne à l'arrière de la

prise murale (Figure 32).

10. Insérez la prise murale dans le support et fixez-la avec les deux vis

fournies (Figure 33).

21/2"

29/16 "

31/16 "

18"

FIGURE 29

FIGURE 31

FIGURE 32 FIGURE 33

LOW

VOLTAGE

WIRING

FLANGED

FITTING

FIGURE 30

INSTALLATION DANS UNE CONSTRUCTION EXISTANTE

NOTA: Si le mur envisagé pour le montage de la prise modèle 360

fait moins de 1,27 cm d’épaisseur, il faut utiliser une entretoise.

Voir la figure 20 à la page 6 comme référence.

INSTALLATION DES PRISES MURALE

MODELE CI370 OU SERIE 360 DE PRISES (ENCASTREMENT 361)

PLINTHE

BORDE INFÉRIEUR

DE LA PLINTHE

PLAQUE

D’ASSISE

TROU DE GUIDAGE

RACCORD À

BRIDE

FIL BASSE

TENSION

6,3 cm

45 cm

5,8 cm

7,7

cm

Page 21

10

INSTALLATION DANS UNE CONSTRUCTION EXISTANTE (suite)

MOUNTING

PLATE

MOUNTING

HOLE (2)

ELBOW

FIGURE 36

FIGURE 37

1. Faites la découpe en accord avec les dimensions de la Figure 35.

2. Voyez la Figure 36. Détachez la plaque suivant les pointillés.

3. Voyez la Figure 37. Collez le coude à la plaque de montage, placez

l'ensemble dans la découpe, et attachez le coude à la tuyauterie à

l'interieur du mur.

4. Assurez-vous que les orifices de montage sont bien en haut et en bas.

5. Connectez le fil de basse tension à 2 âmes aux vis de borne à

FIGURE 34 FIGURE 35

INSTALLATION DE PRISE MURALE MODELE 330N (ENCASTREMENT 329)

l'arrière de la prise murale.

6. Voyez la Figure 38. Alignez les orifices de montage de la prise avec

les trous de la plaque de montage, placez la prise dans la plaque de

montage, et fixez-la avec les vis fournies. NOTA: Si un coude de

rayon court 382-S est utilisé, il peut être nécessaire d'utiliser des vis

de montage courtes pour qu’elle ne rentre pas en contact avec le

coude.

INSTALLATION DES PRISES AU SOL DANS UNE CONSTRUCTION NOUVELLE

OU EXISTANTE.

1. Voyez les figures 38 et 39. Après avoir déterminé l'emplacement de

la prise au sol, découpez un orifice rectangulaire de 7,78 cm X

6,51cm. Le point central de la prise doit être situé à au moins 6,35

cm du mur pour permettre l'ouverture du couvercle au moment de

l'insertion du boyau.

2. Déterminez la direction de la tuyauterie et attachez le raccord à bride

approprié au support de montage avec les quatre (4) vis fournies.

Assurez-vous que la bride du support de montage ne rentre pas

en contact avec la tuyauterie et que la soudure est bien en

place.

3. Voyez la figure 40. Positionnez le support avec le cadre et le raccord

à bride dans la découpe d’en dessous et fixez-le au sous-plancher.

4. Voyez la figure 41. Le grand bout du manchon-allonge modèle 399

devrait être découpé à la longueur désirée afin de permettre une

assise propre de la prise contre le sol ou la moquette.

5. Voyez la figure 42. Tirez les câbles de basse tension à 2 âmes à

travers le support de montage et attachez-les aux vis de borne à

l'arrière de la prise de sol. Collez le manchon-allonge au modèle 360

de prise. Insérez le manchon-allonge à travers la garniture en vinyl

dans le support de montage et placez-le fermement dans le raccord à

bride.

6. En vue de commodité, les prises de sol devraient être installées de

façon à ce qu'elles s'ouvrent vers le mur.

7. Voyez la figure 40. Fixez la prise de sol en place avec deux vis.

FIGURE 38

FIGURE 39

MODELE SERIE 360 DE PRISE (ENCASTREMENT 361)

PLAQUE DE

MONTAGE

ORIFICE DE

MONTAGE (2)

COUDE

PLAQUE DE

MONTAGE

PRISE

MURMOULURE

VUE DE DESSUS

VUE LATÉRALE

BRIDE DE SUPPORT

DE MONTAGE

0,95 cm

DIA.

0,95 cm

DIA.

9,84

cm

0,64

cm

0,64

cm

3,49

cm

7,78 cm

6,51

cm

6,35 cm MIN.

APPROX.

6,99 cm

1

/4"

7

/8"

3

1

/4"

13/8"

3

2

/4"

3

/8" DIA.

3

/8" DIA.

INLET

MOUNTING

PLATE

SIDE VIEW

TOP VIEW

9

2

1

3

/16"

MOLDING

/16"

WALL

21/2" MIN.

APPROX.

MOUNTING BRACKET

FLANGE

Page 22

11

INSTALLATION DES PRISES AU SOL

FLOOR

SUB-FLOOR

2

9

/16"

3

1

/16"

INLET

EXTENSION

FLOOR

INLET

FRAME

MOUNTING

BRACKET

SEAL

FLANGED

FITTING

FIGURE 40

FIGURE 41

WALL

INLET

EXTENSION SLEEVE

BRACKETFLANGED FITTING

TUBING

FIGURE 42

VERIFICATION FINALE DU SYSTEME

Assurez-vous que toutes les prises sont fermées et que le sac à

poussière est en place. Vérifiez le bon fonctionement marche/arrêt de

l'interrupteur situé sur le groupe d'aspiration.

Vérifiez chaque prise murale pour vous assurer que le groupe

d’aspiration démarre lorsqu’on enfonce le boyau et qu’on active

l’interrupteur, s’il y a lieu. si vous n’avez pas de boyau sous la main, un

bout de fil peut suffire à relier les deux contacts électriques de la prise.

Vérifiez chaque prise murale ainsi que tous les raccords des conduites à

la recherche de fuites. Assurez-vous également qu’il n’y a pas de fuite

au niveau de l’entrée du groupe d’aspiration et autour du joint du bac à

saleté.

Asurez-vous que le filtre de tissu permanent est bien en place dans

l’appareil, conformément aux directives du guide de l’utilisateur.

Il est maintenant temps de profiter des bénéfices du Système Central

d'Aspiration de NuTone.

PRISE

PRISE DE

PLANCHER

EXTENSION DE

PRISE

PLANCHER

SOUS-PLANCHER

CADRE

GARNITURE

SUPPORT DE

MONTAGE

RACCORD À

BRIDE

TUYAUTERIE

RACCORD À BRIDE

BRIDE

MANCHON-ALLONGE

COUPEZ À LA LONGUEUR

APPROPRIEE

MANCHON-ALLONGE

RACCORD À

BRIDE

BRIDE DE

SUPPORT DE

MONTAGE

6,51 cm

7,78 cm

CUT TO

LENGTH

EXTENSION

SLEEVE

FLANGED

FITTING

MOUNTING

BRACKET

FLANGE

Page 23

4820 Red Bank Road, Cincinnati, Ohio 45227

1140 Tristar Drive, Mississauga, Ontario, Canada L5T 1H9

www.nutone.com

Two Year Limited Warranty

WARRANTY OWNER: NuTone warrants to the original consumer purchaser of its products that such products will be free from defects in materials or workmanship for a period

of two (2) years from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this two year period, NuTone will, at its option, repair or replace, without charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS OR TUBES, FILTERS, DUCT, ROOF CAPS, WALL CAPS AND OTHER ACCESSORIES

FOR DUCTING. This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident,

improper maintenance or repair (other than by NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one year period as specified for the express warranty. Some states do not allow limitation on how long an implied warranty

lasts, so the above limitation may not apply to you.

NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT NUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS

WARRANTY. NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH

PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty supersedes all prior warranties.

WARRANTY SERVICE: To qualify for warranty service, you must (a) notify NuTone at the address stated below or telephone 1/800-543-8687, (b) give the model

number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you must present

evidence of the original purchase date.

Date of Installation Builder or Installer

Model No. and Product Description

IF YOU NEED ASSISTANCE OR SERVICE:

For the location of your nearest NuTone Independent Authorized Service Center:

Residents of the contiguous United States Dial Free 1-800-543-8687

Please be prepared to provide:

Product model number • Date and Proof of purchase • The nature of the difficulty

Residents of Alaska or Hawaii should write to: NuTone Inc. Attn: Department of National Field Service, 4820 Red Bank Road, Cincinnati Ohio 45227-1599.

Residents of Canada should write to: Broan-NuTone Canada, 1140 Tristar Drive, Mississauga, Ontario, Canada L5T 1H9.

Rev. 03/2001

Tout autre article du système central d’aspiration est guaranti pour un an à partir du moment d’achat.

Les caractéristiques peuvent être modifiées sans préavis. Imprimé aux E.-U.

All other Central Cleaning products are warranted for one year from date of purchase.

Product specifications subject to change without notice. Printed in U.S.A., Rev. 3/02, Part No. 99962

Garantie limitée de deux ans

GARANTIE DU PROPRIÉTAIRE: NuTone garantie à l'acheteur original de ses produits que ces derniers seront exempts de tout défaut de matériaux et de fabrication pour une période

de deux (2) ans à compter de la date d'achat. AUCUNE AUTRE GARANTIE, IMPLICITE OU EXPRESSE, N'EST DONNÉE, Y COMPRIS, MAIS SANS S'Y LIMITER, GARANTIE DE

MARCHANDIBILITÉ OU D'ADAPTATION À UN USAGE PARTICULIER.

Pendant cette période de deux ans, NuTone procédera au remplacement ou à la réparation sans aucuns frais, mais à sa propre discrétion, de tout produit ou pièce jugé défectueux

dans le cadre d'une utilisation normale. CETTE GARANTIE NE VISE PAS LES DISPOSITIFS D'AMORÇAGE NI LES TUBES DES LUMINAIRES FLUORESCENTS. Cette garantie ne

couvre pas (a) l'entretien et le service courants ni (b) les produits et les pièces ayant fait l'objet d'un usage abusif, de négligence, d'un accident, d'un entretien ou d'une réparation non

appropriée (par du personnel non autorisé par NuTone), d'une mauvaise installation ou d'une installation non conforme aux directives d'installation fournies.

La durée de toute garantie implicite est limitée à la période de deux ans précisée pour la garantie expresse. Certains états ne reconnaissent pas les restrictions relatives à la durée des

garanties implicites; il se pourrait donc que cette restriction ne s'applique pas dans votre cas.

LE REMPLACEMENT OU LA RÉPARATION PAR NUTONE, À SA PROPRE DISCRÉTION, DE TOUT PRODUIT OU PIÈCE DÉFECTUEUX CONSTITUE LE SEUL REMÈDE DE

L'ACHETEUR EN VERTU DE CETTE GARANTIE. NUTONE NE PEUT ÊTRE TENUE RESPONSABLE DES DOMMAGES INDIRECTS, CONSÉCUTIFS OU SPÉCIAUX

ATTRIBUABLES À L'UTILISATION OU AU RENDEMENT DU PRODUIT. Certains états ne reconnaissent pas les restrictions ni les exclusions relatives aux dommages indirects,

consécutifs ou spéciaux; il se pourrait donc que cette restriction ne s'applique pas dans votre cas. La présente garantie vous accorde des droits spécifiques, mais vous pourriez aussi

avoir d'autres droits en fonction de l'état dans lequel vous résidez. Cette garantie remplace toute autre garantie donnée précédemment.

SERVICE SOUS GARANTIE Pour être admissible au service sous garantie, vous devez (a) aviser NuTone, à l'adresse fournie ci-dessous ou par téléphone au 1 800 5433687, (b) fournir le numéro du modèle et la description de la pièce et (c) décrire la nature du défaut de la pièce ou du produit. Au moment de la demande de service sous

garantie, vous devez fournir une preuve de la date d'achat originale.

Date d’installation Entrepreneur ou installateur

N° de modèle et description du produit

POUR OBTENIR DE L’ASSISTANCE OU DU SERVICE:

Pour connaître le Centre de service NuTone autorisé indépendant le plus proche:

Résidents des États-Unis continentaux, composez le numéro sans frais: 1 800 543 8687

Garder à protée de la main le numéro du modèle, la date et la preuve d’achat, le type de problème.

Résidents de l’Alaska et d’Hawaii: Écrivez à NuTone Inc. Attn: Department of National Field Service, 4820 Red Bank Road, Cincinnati Ohio USA 45227-1599.

Résidents du Canada: Écrivez à Broan-NuTone Canada, 1140 Tristar Drive, Mississauga, Ontario Canada L5T 1H9.

Rev. 03/2001

Loading...

Loading...