Page 1

MODEL 773BNNT

DECORATIVE VENTILATION

FAN WITH LIGHT

READ AND SAVE THESE INSTRUCTIONS

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at

the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must be done by

a qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. DO NOT install in a tub or shower enclosure.

8. This unit must be grounded.

9. This unit is U.L. listed. Type I.C. inherently protected.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. This product is designed for installation in FLAT CEILINGS

ONLY. Do not mount this product in a wall.

3. The light fixture assembly must be mounted to the fan

housing assembly included with this product. Do not

mount the light fixture assembly to a wiring outlet box.

4. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust,

etc. off power unit.

5. Please read specification label on product for further

information and requirements.

!

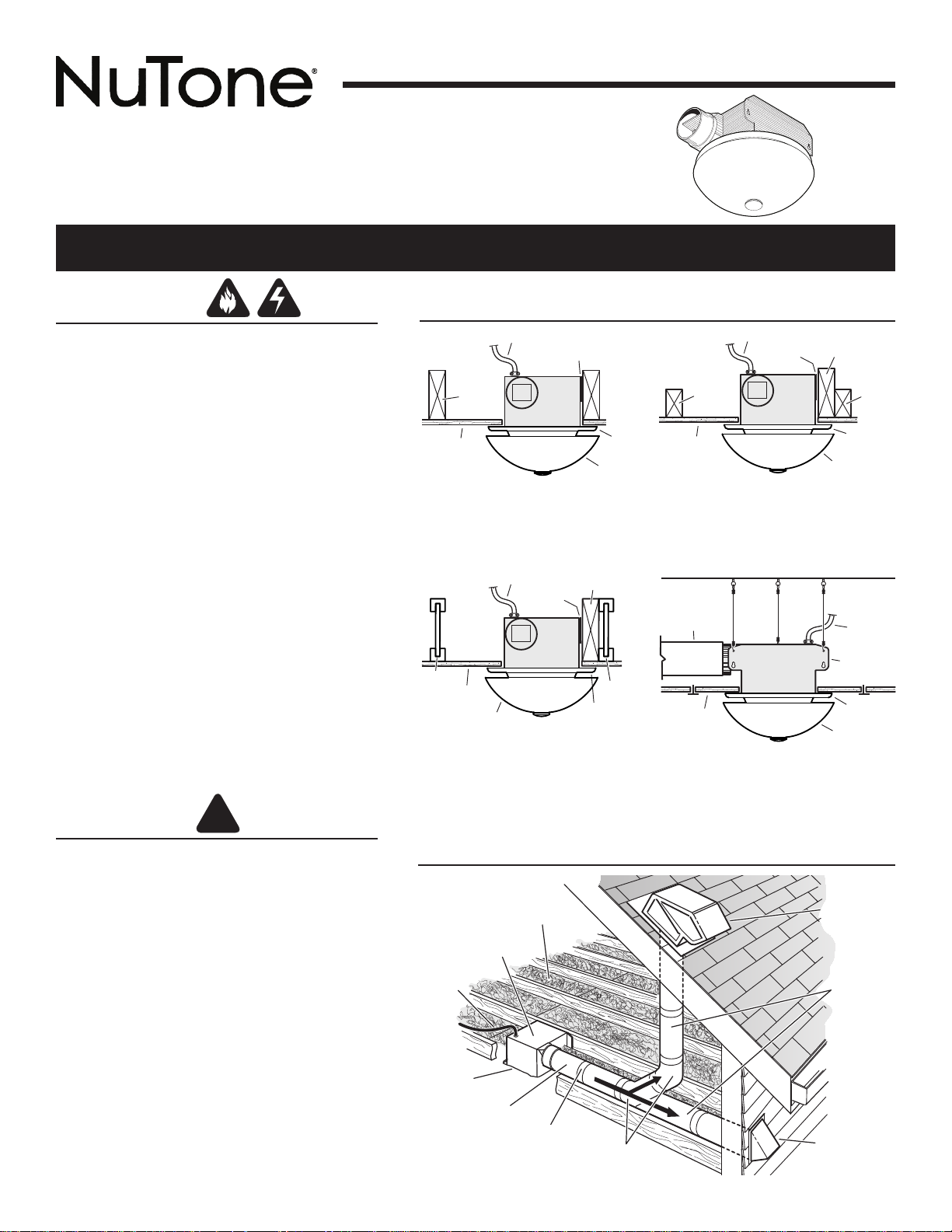

TYPICAL INSTALLATIONS

POWER CABLE

MOUNTING TABS

CEILING

JOIST

CEILING

MATERIAL

HOUSING

HOUSING

GRILLE

PAN

GLASS

LIGHT SHADE

HOUSING MOUNTED

DIRECTLY TO JOIST

2x6 (or larger)

Discharge parallel to joists.

POWER CABLE

"I"

JOIST

CEILING

MATERIAL

GLASS LIGHT SHADE

MOUNTING

TABS

HOUSING

ADDITIONAL

FRAMING

"I"

JOIST

GRILLE

PAN

*

HOUSING MOUNTED TO “I” JOIST

Requires additional framing

for mounting tabs.

Discharge parallel to joists.

Additional framing must be a 2x6 (minimum height).

*

POWER CABLE

2 x 4

CEILING

JOIST or

TRUSS

CEILING

MATERIAL

HOUSING MOUNTED

TO 2x4 TRUSS

Requires additional framing

for mounting tabs.

Discharge parallel to joists.

4" ROUND

DUCT

SUSPENDED

CEILING

MATERIAL

SUSPENDED CEILINGS

Housing hung with wires -

3-point mount.

PLAN THE INSTALLATION

INSULATION

(Place around and

over fan housing.)

FAN

HOUSING

POWER

CABLE*

MOUNTING

TABS

HOUSING

HOUSING

ADDITIONAL

FRAMING

*

2 x 4

CEILING

JOIST or

TRUSS

GRILLE

PAN

GLASS

LIGHT SHADE

POWER

CABLE

MOUNTING

TAB

GRILLE

PAN

GLASS

LIGHT SHADE

ROOF CAP*

(with built-in

damper)

Keep duct

runs short.

Installer:

Leave this manual with the

homeowner.

Homeowner:

Use and Care information on page 4.

Seal gaps

around

housing.

4-IN. ROUND

DUCT*

*Purchase

separately.

Seal duct

joints with

tape.

OR

4-IN. ROUND

ELBOWS*

WALL CAP*

(with built-in

damper)

Page 2

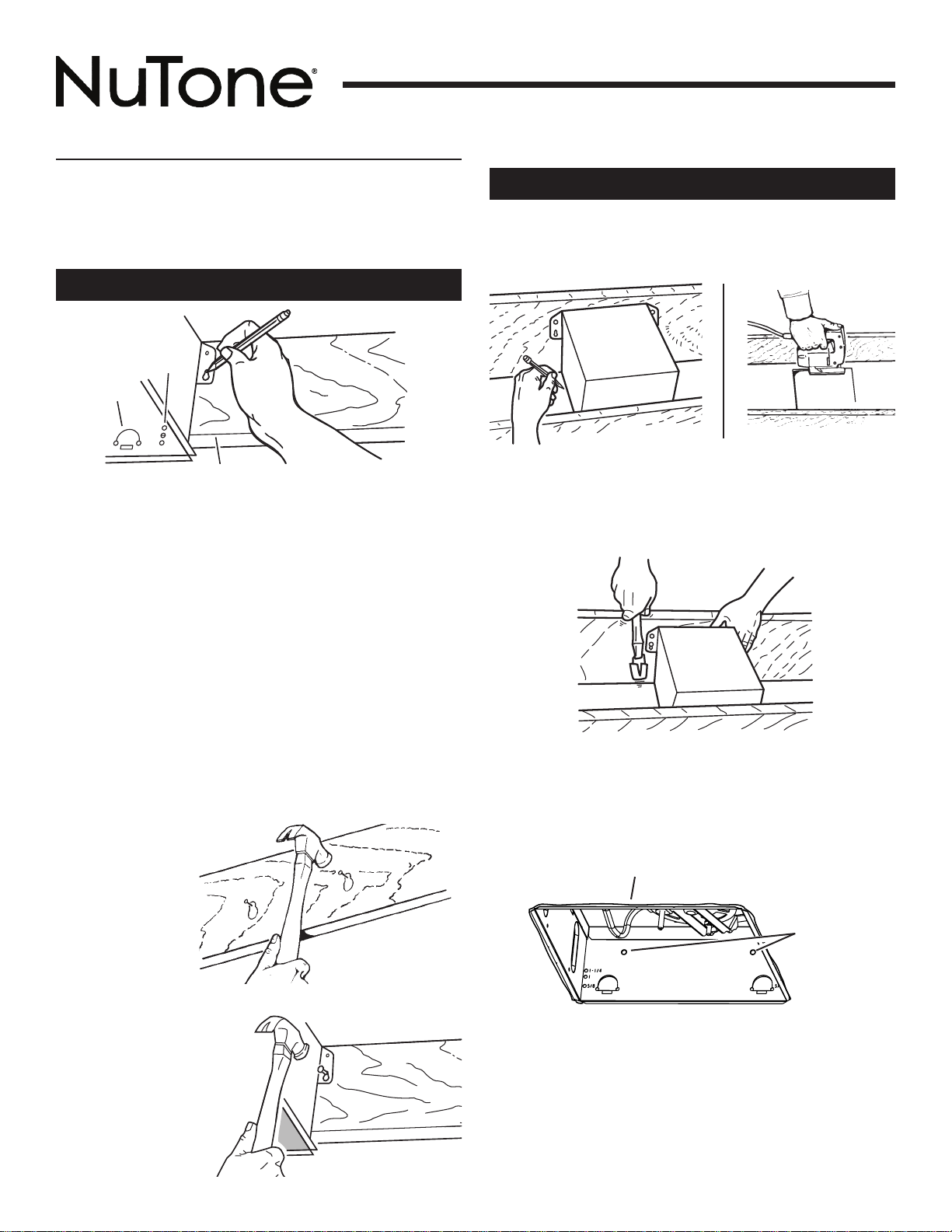

INSTALL THE HOUSING

MODEL 773BNNT

Page 2

THE FOLLOWING INSTALLATION ILLUSTRATIONS SHOW 2 X

6 JOISTS. IF YOU HAVE A TRUSS OR “I”-JOIST INSTALLATION,

MOUNT THE VENTILATOR TO THE ADDITIONAL FRAMING IN

THE SAME MANNER. (Additional framing must be a 2x6 (minimum height).

- PLEASE NOTE -

New Construction

HOLES

TAB

1-1/4

1

5/8

BOTTOM EDGE OF JOIST

1. Choose the location for your fan in the ceiling. For best

possible performance, use the shortest possible duct run

and a minimum number of elbows.

2. Position mounting brackets against joist so that bottom

edge of housing will be flush with finished ceiling.

Additional positioning feature for 5/8”, 1”, &

1-1/4” thick ceiling material:

Holes in corners of housing are labeled with various

ceiling material thicknesses. Position housing so

bottom edge of joist is visible through a matched

set of holes. The housing is now in the proper

position for that ceiling material thickness.

Additional positioning feature for 1/2” thick

ceiling material:

Bend two tabs, on side of housing,

housing until tabs contact underside of joist.

Mark the keyhole slot on both mounting brackets.

900 outward. Lift

Existing Construction

1. Choose the location for your fan/light in the ceiling. For best

possible performance, use the shortest possible duct run

and a minimum number of elbows.

2. In attic, position mounting brackets against joist. Trace

outline of housing on ceiling material.

3. Set housing aside and cut ceiling opening slightly larger

than marked.

4. Place housing in opening so that its bottom edge is flush

with finished ceiling. Nail to joist through keyhole on both

sides. To ensure a noise-free installation, drive another nail

through the top hole of each mounting bracket.

3. Set housing

aside and drive

nails partially

into joist at the

top of both keyhole marks.

4. Hang housing from

nails and pound

nails tight. To ensure a noise-free

mount, pound another nail through

the top hole of each

mounting tab.

RECOMMENDED: SEAL BETWEEN

CEILING MATERIAL & HOUSING (4 SIDES)

ADDITIONAL

MOUNTING

HOLES

5. Additional mounting holes are provided for installations

where access from above is inconvenient or not possible.

Nail or screw housing directly to joists or framing.

Recommended: Seal between ceiling material & housing

on all 4 sides to prevent air leakage.

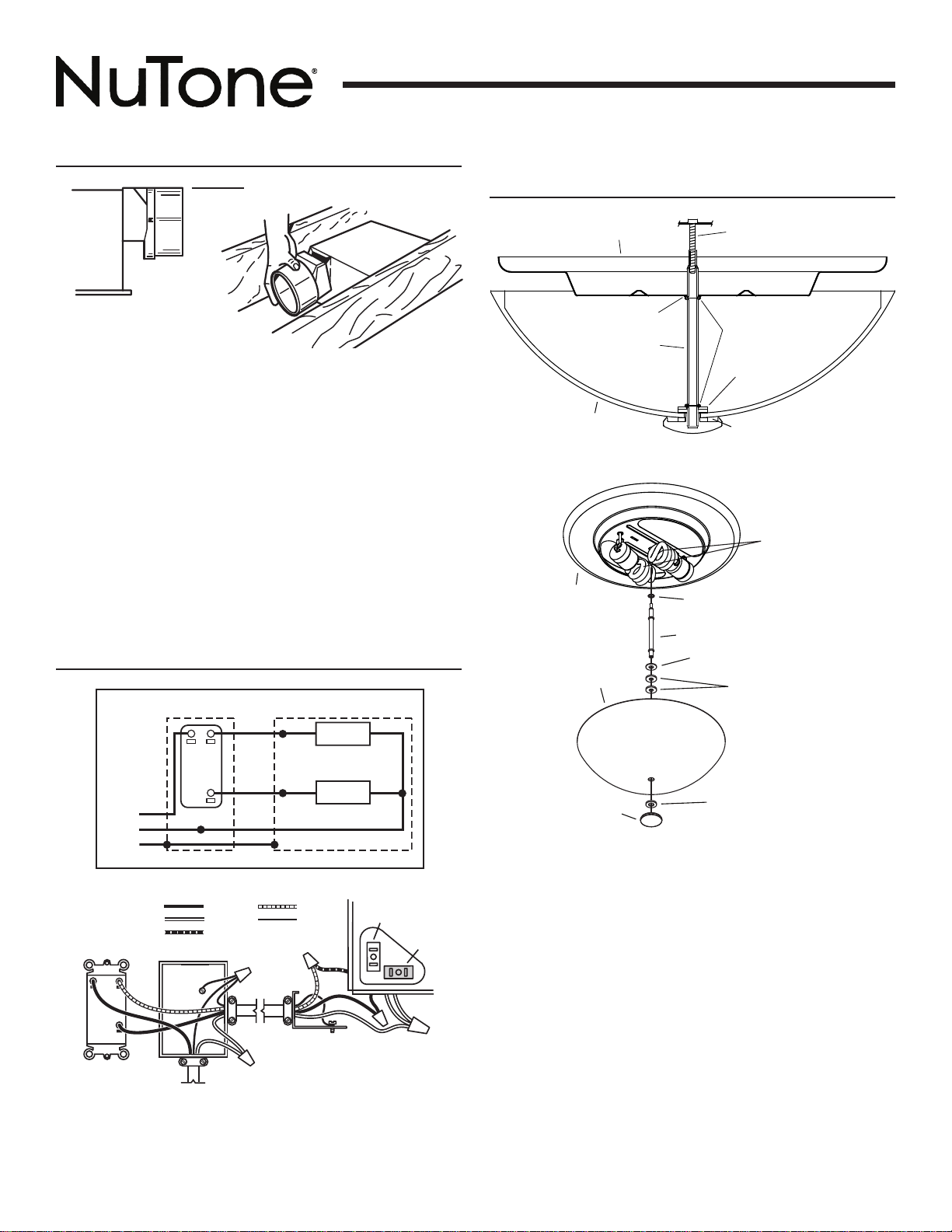

Page 3

MODEL 773BNNT

RECEPTACLE

Page 3

INSTALL THE DUCTWORK

FLUSH

NOTE: The duct connector has a counter-balanced damper

flap. The flap will be “open” approx. 1” when duct connector

is attached to housing. This design permits insulation to be

in direct contact with fan/light housing per UL (Underwriters

Laboratories) standards. The slightest backdraft, however,

will close the damper flap, preventing air from entering unit

or finished space.

1. Snap the damper/duct connector onto housing. Make sure

that tabs on the connector lock into slots in housing. Top of

damper/duct connector should be flush with top of housing.

2. Connect 4” round duct to damper/duct connector and

extend duct to outside through a roof or wall cap. Check

damper to make sure that it opens freely. Tape all duct

connections to make them secure and air tight.

CONNECT THE WIRING

SCHEMATIC WIRING DIAGRAM

LIGHT

SWITCH

VENT

SWITCH

LINE

IN

DUAL CONTROL

(purchase separately)

LIGHT

FAN

BLK

WHT

GRD

SWITCH BOX

SWITCH BOX

120 VAC

LINE IN

BLACK

WHITE

BLUE

RED

BLK

WHT

GRD

BLU

BLK

WIRING

PLATE

LIGHT

(WHITE)

(BLACK)

RED

GROUND

(bare)

VENT

UNIT

WHT

WHT

WHITE

RECEPTACLE

(LIGHT)

BLACK

(FAN)

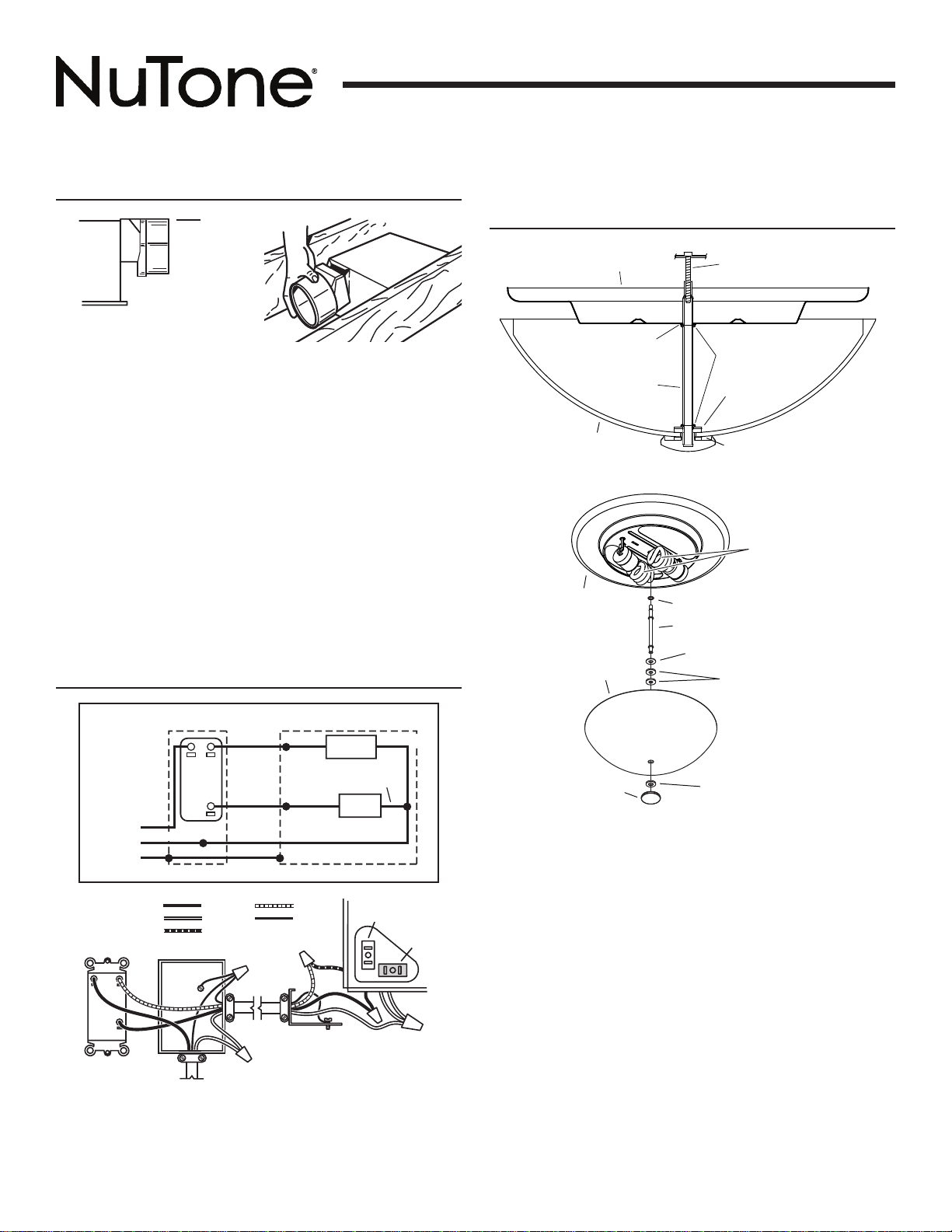

ATTACH THE GRILLE PAN AND

GLASS SHADE

GRILLE PAN

LOCK WASHER

ROD

GLASS SHADE

GRILLE

PAN

WASHER

ROD

GLASS

SHADE

FINIAL

NUT

1. Locate the grille pan over the fan housing and connect the

wiring harness plug into white receptacle in the fan housing.

2. Insert rod through center hole of grille pan. Use lock washer

between collar on rod and pan.

3. Thread rod onto grille screw in housing, until pan is tight

against ceiling. Do not over-tighten mounting rod.

4. Install bulbs. Use 13-watt (maximum), GU24 base, fluorescent

bulbs with a M.O.L. (maximum overall length) of 4.8 inches

or less.

5. Place washers and glass shade over mounting rod and align

shade over grille pan. Secure glass shade to mounting rod

with felt washer and finial nut as shown.

6. Restore electrical power and check operation of the unit.

GRILLE SCREW

COLLAR

WASHERS

FELT WASHER

13 WATT

MAX.

GU24 BASE

FLUORESCENT

BULBS

LOCK

(2 REQ.)

STEEL WASHER

FELT

WASHER

(Add second

washer as

needed to

secure shade

tightly.)

FELT

WASHER

1. Wire unit following diagram above. Run electrical cable as

direct as possible to unit. Do not allow cable to touch sides

or top of unit after installation is complete.

Page 4

USE AND CARE USE AND CARE

MODEL 773BNNT

Page 4

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND

LOCK OUT SERVICE PANEL BEFORE CLEANING OR SERVICING

THIS UNIT.

BULB REPLACEMENT

Remove glass shade. Replace bulbs as required. Replace glass

shade.

Use 13 Watt (maximum), GU24 base, fluorescent bulbs with a M.O.L.

(maximum overall length) of 4.8 inches or less.

MOTOR LUBRICATION

The motor is permanently lubricated. Do not oil or disassemble motor.

SERVICE PARTS

KEY PART NO. DESCRIPTION

1 99527649 Glass Shade

2 97018636 Shade Mounting Hardware

3 99271452 Lamp, 13 W GU24 Type Fluorescent

4 99260425 Motor Nut, Hex Keps

5 97018311 Motor Plate

6 99150583 Grille Screw

7 99080634 Motor

8 99020300 Blower Wheel

9 99270981 Lamp Receptacle, White

10 99270982 Motor Receptacle, Black

11 98009612 Wiring Panel

12 99150471 Ground Screw

13 99170245 Screw, #8-18 X 3/8”

14 98008868 Wiring Plate

15 97014185 Damper / Duct Connector

16 97014922 Housing Assembly

A 97018631 Light Fixture Assembly

(Includes Key Nos. 1, 2 and B)

B 97018734 Grille Pan Assembly

(Includes Key No. 3)

C 97018327 Blower Assembly

(Includes Key Nos. 4 thru 8)

D 97015171 Wire Panel Assembly

(Includes Key Nos. 9, 10, 11)

CLEANING

TO CLEAN GLASS SHADE AND GRILLE PAN:

Remove glass shade. Shade can be wiped clean with a mild detergent solution or glass cleaner and dried with a soft cloth. Remove

2 bulbs. Grille pan may be gently vacuumed and wiped clean with

a soft cloth. Never use abrasive cloth, steel wool pads or scouring

powders on glass shade or grille pan. METAL AND ELECTRICAL

PARTS SHOULD NEVER BE IMMERSED IN WATER.

TO CLEAN FAN ASSEMBLY:

Remove grille pan and unplug fan assembly (black receptacle).

Gently vacuum fan, motor and interior of housing. METAL AND

ELECTRICAL PARTS SHOULD NEVER BE IMMERSED IN WATER.

14

16

13

12

10

8

7

5

4

15

B

3

D

11

9

A

2

1

2

C

6

Order replacement parts by “PART NO.” - not by “KEY NO.”

WARRANTY

WARRANTY PERIOD: NuTone warrants to the original consumer purchaser of its NuTone Ventilation Fan/light (the “Fan”) that your Fan, including lamps/bulbs, will be materially free from defects in materials or workmanship for a period of one (1) years

from the date of original purchase. The warranty on the lamps/bulbs provided with the Fan does not cover lamp/bulb breakage. This warranty does not cover accessories, such as speed controls, that may be purchased separately and installed with the Fan.

The limited warranty period for replacement parts, and for Fans repaired or replaced under this limited warranty, shall continue for the remainder of the original warranty period.

NO OTHER WARRANTIES: THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED. NUTONE DISCLAIMS AND EXCLUDES ALL OTHER EXPRESS WARRANTIES, AND DISCLAIMS AND

EXCLUDES ALL WARRANTIES IMPLIED BY LAW, INCLUDING WITHOUT LIMITATION THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. TO THE EXTENT THAT APPLICABLE LAW PROHIBITS THE EXCLUSION OF IMPLIED

WARRANTIES, THE DURATION OF ANY APPLICABLE IMPLIED WARRANTY IS LIMITED TO THE PERIOD SPECIFIED FOR THE EXPRESS WARRANTY. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation

may not apply to you. Any oral or written description of the Fan is for the sole purpose of identifying it and shall not be construed as an express warranty.

REMEDY: During the applicable limited warranty period, NuTone will, at its option, provide replacement parts for, or repair or replace, without charge, any Fan or part thereof, to the extent NuTone finds it to be covered by and in breach of this limited

warranty. NuTone will ship the repaired or replaced Fan or replacement parts to you at no charge. You are responsible for all costs for removal, reinstallation and shipping, insurance or other freight charges incurred in the shipment of the Fan or part

to NuTone. This warranty does not cover (a) normal maintenance and service, (b) normal wear and tear, (c)any Fans or parts which have been subject to misuse, abuse, abnormal usage, negligence, accident, improper or insufficient maintenance,

storage or repair (other than repair by NuTone), (d)damage caused by faulty installation, or installation or use contrary to recommendations or instructions, (e) any Fan that has been moved from its original point of installation, (f)damage caused by

environmental or natural elements, (g)damage in transit, (h)natural wear of finish, (i)Fans in commercial or nonresidential use, or (j)damage caused by fire, flood or other act of God. This warranty covers only Fans sold in the United States or Canada

or through distributors authorized by NuTone.

EXCLUSION OF DAMAGES: NUTONE’S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT NUTONE’S OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY AND NUTONE’S SOLE

AND EXCLUSIVE OBLIGATION. NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, INDIRECT, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE FAN, ITS USE OR PERFORMANCE. Incidental damages include

but are not limited to such damages as loss of time and loss of use. Consequential damages include but are not limited to the cost of repairing or replacing other property which was damaged if the Fan does not work properly.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from

state to state.

This warranty supersedes all prior warranties and is not transferable from the original consumer purchaser.

NUTONE SHALL NOT BE LIABLE TO YOU, OR TO ANYONE CLAIMING UNDER YOU, FOR ANY OTHER OBLIGATIONS OR LIABILITIES, INCLUDING, BUT NOT LIMITED TO, OBLIGATIONS OR LIABILITIES ARISING OUT OF BREACH OF CONTRACT OR

WARRANTY, NEGLIGENCE OR OTHER TORT OR ANY THEORY OF STRICT LIABILITY, WITH RESPECT TO THE FAN OR NUTONE’S ACTS OR OMISSIONS OR OTHERWISE.

This warranty covers only replacement or repair of defective Fans or parts thereof at NuTone’s main facility and does not include the cost of field service travel and living expenses.

Any assistance NuTone provides to or procures for you outside the terms, limitations or exclusions of this limited warranty will not constitute a waiver of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty.

NuTone will not reimburse you for any expenses incurred by you in repairing or replacing any defective Fan, except for those incurred with NuTone’s prior written permission.

HOW TO OBTAIN WARRANTY SERVICE: To qualify for warranty service, you must (a) notify NuTone at the address or telephone number stated below within seven (7)days of discovering the covered defect, (b) give the model number and part identification and (c)describe the nature of any defect in the Fan or part. At the time of requesting warranty service, you must present evidence of the original purchase date.

Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027 (1-800-637-1453)

If you must send the Fan or part to NuTone, as instructed by NuTone, you must properly pack the Fan or part—NuTone is not responsible for damage in transit.

NuTone Ventilation Fan/Lights - Limited Warranty

99044768D

Page 5

MODELO 773BNNT

VENTILADOR DECORATIVA

CON LA LUZ

LEA Y CONSERVE ESTAS INSTRUCCIONES

Página 5

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA O LESIONES PERSONALES, OBSERVE LO SIGUIENTE:

1. Utilice esta unidad solamente de acuerdo con las instrucciones

del fabricante. Si tiene preguntas comuníquese con el fabricante

a la dirección o al número telefónico que se indica en la garantía.

2. Antes de dar servicio o limpiar la unidad, interrumpa el suministro

de energía en el panel de servicio y bloquee los dispositivos de

desconexión para evitar la reinstalación accidental de la energía.

Cuando no se puedan bloquear los dispositivos de desconexión,

fije seguramente en el panel de servicio un medio de advertencia

que sea visible, como por ejemplo una etiqueta.

3. Una persona o personas calificadas deben realizar el trabajo de

instalación y el cableado eléctrico, de acuerdo con todos los

códigos y normas aplicables, inclusive los códigos y normas

de construcción para evitar incendios.

4. Se necesita suficiente aire para que se realice la combustión

y la descarga de gases adecuadas a través de la chimenea del

equipo para quemar combustible a fin de evitar las corrientes

de inversión. Observe los lineamientos del fabricante del equipo

de calefacción y las normas de seguridad, como por ejemplo

las publicadas por la Asociación Nacional de Protección contra

Incendios (National Fire Protection Association: NFPA), y la

Sociedad Americana de Ingenieros en Calefacción, Refrigeración

y Sistemas de Acondicionamiento de Aire (American Society for

Heating, Refrigeration and Air Conditioning Engineers: ASHRAE),

y los códigos locales.ditioning Engineers (ASHRAE), y las

autoridades de los códigos locales.

5. Cuando corte o perfore la pared o el cielo raso, tenga cuidado de

no dañar el cableado eléctrico ni otras conexiones de servicios

que se encuentren ocultas.

6. Los ventiladores con conductos siempre deben tener salida hacia

el exterior.

7. NO instale el aparato en una caja de bañera o ducha.

8. Esta unidad se debe conectar a tierra.

9. Esta unidad está incluida en la lista de U.L. Tipo I.C. proteger

inherente.

PRECAUCIÓN

1. Esta unidad debe usarse solamente para ventilación general.

No la utilice para la descarga de materiales ni vapores peligrosos

o explosivos.

2. Este producto está diseñado SOLAMENTE PARA INSTALARSE

EN EL CIELO RASO. No monte este producto en la pared.

3. El conjunto de la luz se debe montar al montaje de la cubierta

del ventilador incluido con este producto. No monte el conjunto

de la luz a una caja del enchufe del cableado.

4. Para evitar causar daño a los cojinetes del motor y pistones

impulsores ruidosos y/o no balanceados, mantenga los

aerosoles para pirca, el polvo de construcción, etc. lejos del

motor.

5. Por favor consulte la información y los requerimientos

adicionales contenidos en la etiqueta de especificaciones que

se encuentra en el producto.

A la persona que realiza la instalación:

Deje este manual con el dueño de la casa.

Al dueño de la casa:

Las instrucciones de operación y limpieza se

encuentran en la página 12.

!

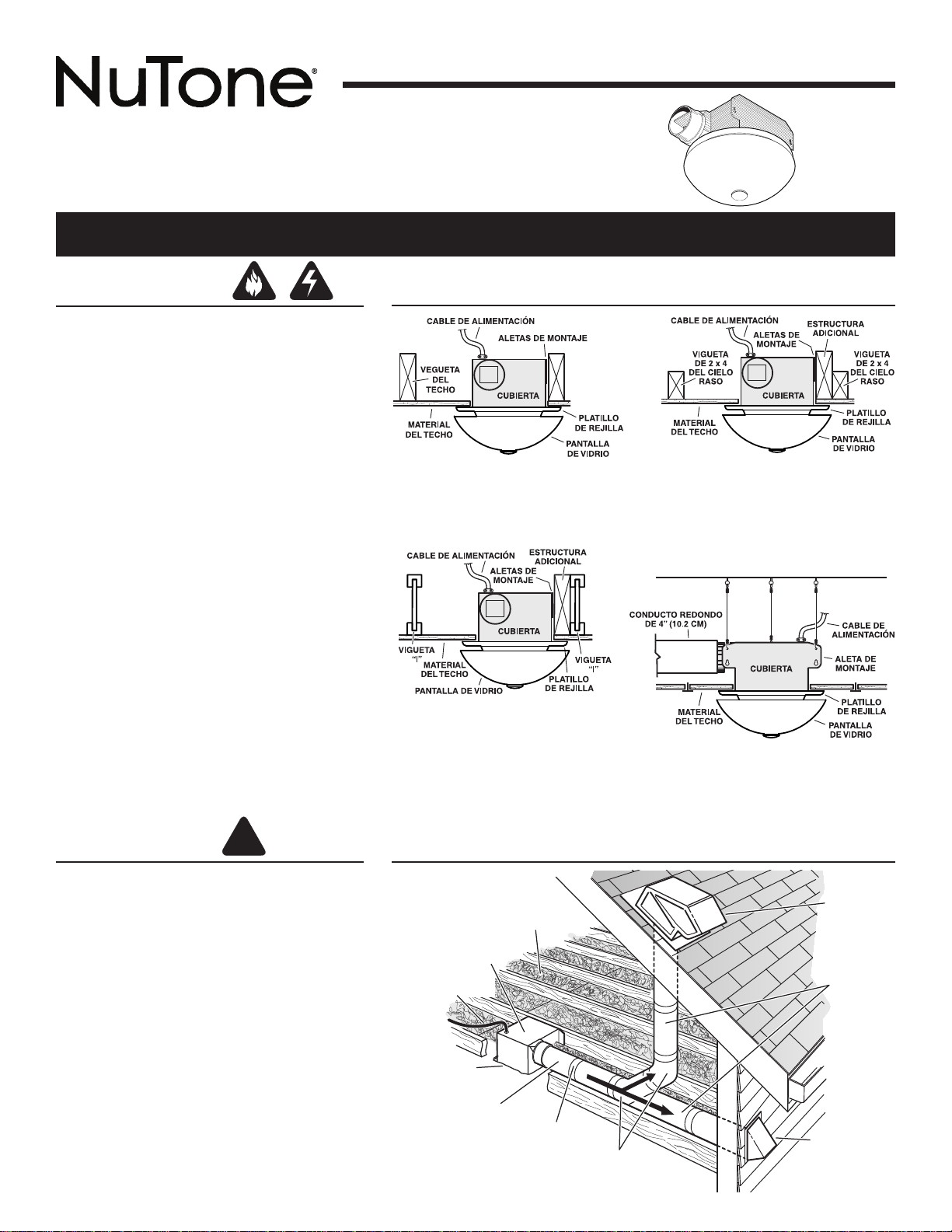

INSTALACIONES TÍPICAS

*

CUBIERTA MONTADA

DIRECTAMENTE EN LA VIGUETA

2x6 (o más grande).

Descarga paralela a las viguetas.

*

CUBIERTA MONTADA

EN UNA VIGUETA “I”

Se requiere una estructura

adicional para las aletas de

montaje. Descarga paralela a

las viguetas.

La estructura adicional debe ser un tramo de 2x6 (altura mínima).

*

CUBIERTA MONTADA

EN UNA VIGA DE 2x4

Se requiere una estructura

adicional para las aletas de

montaje. Descarga paralela a

las viguetas.

TECHOS SUSPENDIDOS

Cubierta montada con cables.

Montaje de tres puntos.

PLANIFICACIÓN DE LA INSTALACIÓN

AISLAMIENTO

(Puede ser colocado

alrededor y sobre de la

cubierta del ventilador.)

CUBIERTA DE

VENTILADOR

CABLE DE

ALIMENTACIÓN*

Selle los

huecos alrededor

de la cubierta.

CONDUCTO REDONDO

DE 4 PULG. *

*Se compran

por separado.

Sellar las juntas

O

con cinta.

CODO REDONDO

DE 4 PULG.*

TAPA DE

TECHO*

(con

amortiguador

integral)

Mantenga

corre

conducto

corto.

TAPA DE

PARED*

(con amortiguador

integral)

Page 6

INSTALACIÓN DE LA CUBIERTA

LAS SIGUIENTES ILUSTRACIONES DE LA INSTALACIÓN MUESTRAN

VIGUETAS DE 2 X 6. SI LA INSTALACIÓN ES EN UNA VIGA O EN

UNA VIGUETA EN “I”, MONTE EL VENTILADOR EN LA ESTRUCTURA

ADICIONAL DE LA MISMA MANERA. (La estructura adicional debe ser

un tramo de 2x6 (altura mínima).

1. Seleccione la ubicación del ventilador con lámpara en el cielo

raso. Para obtener el mejor rendimiento posible, utilice un tramo

de conductos lo más corto posible y un número mínimo de codos.

OROFICIOS

ALETA

1-1/4

- POR FAVOR NOTE -

Construcción nueva

1

5/8

MODELO 773BNNT

Página 6

Construcción existente

1. Seleccione la ubicación del ventilador con lámpara en el cielo

raso. Para obtener el mejor rendimiento posible, utilice un tramo

de conductos lo más corto posible y un número mínimo de codos.

2. En el entretecho, coloque las abrazaderas de montaje contra la

vigueta. Trace el perímetro de la cubierta en el material del techo.

3. Coloque la cubierta a un lado y haga una abertura en el techo

ligeramente más grande que el perímetro marcado.

BORDE INFERIOR DE LA VIGUETA

2. Coloque las abrazaderas de montaje contra la vigueta, de manera

que el borde inferior de la cubierta quede al ras del cielo raso

terminado.

Característica adicional para la colocación en material de

cielo raso de 5/8” (1.6 cm), 1” (2.5 cm) y 1 ¼” (3.2 cm):

Los orificios que se encuentran en las esquinas de la

cubierta están marcados con varios espesores del material

del cielo raso. Coloque la cubierta de manera que el borde

inferior de la vigueta sea visible a través del conjunto de

orificios que coinciden. Ahora la cubierta se encuentra en

la posición adecuada para ese espesor del material del

cielo raso.

Característica adicional para la colocación en material de

cielo raso de ½” (1.3 cm):

Doble a 90° y hacia afuera las dos aletas que se encuentran a

los costados de la cubierta. Levante la cubierta hasta que las

aletas entren en contacto con la cara inferior de la vigueta.

Marque el orificio con forma de cerradura de ambas abrazaderas

de montaje.

3. Coloque la

cubierta a un

lado e introduzca

parcialmente

los clavos en la

vigueta, en la

parte superior de

ambas marcas

de los orificios en

forma de cerradura.

4. Suspenda la cubierta con los clavos e

introduzca los clavos

completamente. Para

asegurar un montaje

sin ruido, coloque

otro clavo en el orificio superior de cada

aleta de montaje.

4. Coloque la cubierta en la abertura de manera que su borde

inferior quede al ras del cielo raso terminado. Clave la cubierta en

la vigueta a través del orificio en forma de cerradura, en ambos

lados. Para asegurar un montaje sin ruido, coloque otro clavo

en el orificio superior de cada aleta de montaje.

RECOMENDADO: SELLO ENTRE EL MATERIAL

DEL TECHO Y LA VIVIENDA (4 LADOS)

ORIFICIOS DE

MONTAJE

ADICIONALES

5. En la cubierta se pueden encontrar orificios de montaje adicionales

para aquellas instalaciones en las que es inconveniente o

imposible el acceso desde arriba. Clave o atornille la cubierta

directamente en las viguetas o el armazón.

Recomendado: Sello entre el material del techo y la vivienda en

los 4 lados para evitar las fugas de aire.

Page 7

MODELO 773BNNT

RECEPTÁCULO

Página 7

INSTALACIÓN DEL SISTEMA

DE CONDUCTOS

AL RAS

NOTA: El conector del conducto

tiene una aleta compensadora

para el regulador de tiro La aleta

estará “abierta” aproximadamente 1” (2.5 cm) cuando el conector

del conducto se sujete a la cubierta. Este diseño permite que el

material de aislamiento esté en contacto directo con la cubierta

del ventilador con lámpara de acuerdo con las normas de UL

(Underwriters Laboratories). Sin embargo, la más ligera corriente

invertida cerrará la aleta del regulador de tiro, evitando así la entrada

de aire a la unidad o al espacio terminado.

1. Conecte a presión el conector del regulador de tiro/conducto en

la cubierta. Asegúrese de que las aletas del conector queden

fijas en las ranuras de la cubierta. La parte superior del conector del regulador de tiro/conducto debe quedar al ras de la parte

superior de la cubierta.

2. Conecte el conducto redondo de 4” (10.2 cm) en el conector del

regulador de tiro/conducto y extienda el conducto hasta el exterior

a través de una tapa de techo o de pared. Revise el regulador

de tiro para asegurarse de que abre libremente. Coloque cinta

en todas las conexiones de los conductos para asegurarlas y

hacerlas herméticas.

CONEXIÓN ELÉCTRICA

DIAGRAMA ELÉCTRICO

COMM.

LAMP.

COMM.

VENT.

NEGRO

LÍNEA

DE ENT.

TIERRA

CAJA DE CONMUTADOR

CONTROL DOBLE

(se vende por separado)

LAMP.

VENT.

BLANCO

NEGRO

BLANCO

AZUL

CAJA DEL CONMUTADOR

LÍNEA DE ENTRADA

DE 120 VCA

ROJO

NEGRO

BLANCO

TIERRA

AZUL

NEGRO

ROJO

TIERRA

(desnudo)

PLACA DE

CONEXIONES

LAMP.

(BLNC.)

UNIDAD

1. Conecte la unidad de acuerdo con este diagrama. Extienda el

cable eléctrico a la unidad tan directamente como sea posible.

No permita que el cable toque los costados ni la parte superior

de la unidad después de que la instalación esté terminada.

BLANCO

BLANCO

VENT.

(NEG.)

RECEPTÁCULO

BLANCO (LAMP.)

NEGRO (VENT.)

ACOPLE EL PLATILLO DE

LA REJILLA Y LA PANTALLA

DEVIDRIO

PLATILLO

DE LA REJILLA

ARANDELA

DE SEGURIDAD

VARILLA

PANTALLA

DE VIDRIO

PLATILLO

DE LA REJILLA

PANTALLA

DE VIDRIO

TUERCA

DE REMATE

1. Coloque el platillo de la rejilla sobre la caja del ventilador y conecte el enchufe del arnés de cables en el receptáculo blanco

de la caja del ventilador.

2. Introduzca la varilla por el orificio central del platillo de larejilla.

Coloque la arandela entre el collar de la varilla y el platillo.

3. Enrosque la varilla en el tornillo de la rejilla de la caja hasta

apretar el platillo contra el techo. No apriete en exceso lavarilla

de montaje.

4. Instale las bombillas.

Utilice bulbos fluorescentes, tipo de GU24,

13 vatios máximo a un M.O.L. (longitud total máxima) de 4,8

pulgadas o menos.

5. Coloque las arandelas y la pantalla de vidrio sobre la varilla de

montaje y alinee la pantalla sobre el platillo de la rejilla. Fije la

pantalla de vidrio sobre la varilla con arandelas de fieltro y la

tuerca remate, como se ilustra.

6. Restablezca la energía eléctrica y compruebe el funcion amiento

de la unidad.

TORNILLO

DE LA REJILLA

COLLARÍN

ARANDELAS

ARANDELA

DE FIELTRO

ARANDELA

VARILLA

ARANDELA

DE ACERO

ARANDELA

DE FIELTRO

(agregue una

segunda arandela

según sea necesario,

para asegurar

la pantalla

firmemente)

ARANDELA

DE FIELTRO

BULBOS

FLUORESCENTES,

TIPO DE GU24,

13 VATIOS MÁXIMO

(SE REQUIEREN 2)

Page 8

USO Y CUIDADO

ADVERTENCIA: DESCONECTE LA CORRIENTE ELECTRICA Y

BLOQUEE EL TABLERO DE SERVICIO ANTES DE LIMPIAR OR

REPARAR LA UNIDAD.

REEMPLAZO DEL FOCO

Quite la pantalla de vidrio. Reemplace los bulbos como necesarios.

Utilice bombillas fluorescentes, tipo de GU24, 13 vatios máximo a

un M.O.L. (longitud total máxima) de 4,8 pulgadas o menos.

LUBICACIÓN DEL MOTOR

El motor lleva lubricación permanente. No lo enaceite o desarme.

MODELO 773BNNT

Página 8

LIMPIEZA

PARA LIMPIAR EL LENTE Y LA REJILLA:

Saque la tuerca de remate y sombrerete y quite la platalla. La

cortinilla puede limpiarse con una ligera solución detergente o

limpiavidrio y secarse con un trapo suave. Saque los 4 focos y

desconecte el enchufe del portalámpara. El tacho de rejilla puede

limpiarse cuedadosamente con la aspiradora de polvo y secarse

con un trapo suave. Nunca unse telas abrasivas o estropajo de

acero o polvos para frejar cuando limpie la cortinilla o el tacho de

rejilla. LAS PIEZAS METALICAS Y ELECTRICAS NUNCA DEBEN

SUMERGIRSE EN AGUA.

PARA LIMPIAR EL VENTILADOR:

Saque la placa de la rejilla y desenchufe el ventilador (receptáculo

NEGRO). Con la aspiradora limpie cuidadosamente el ventilador,

motor, e interior de la caja. LAS PIEZAS METALICAS Y ELECTRICAS

NUNCA DEBEN SUMERGIR EN AGUA.

PIEZAS DE SERVICIO

CLAVE PIEZA N.º DESCRIPCIÓN

1 99527649 Pantalla de vidrio

2 97018636 Herrajes de montaje de la pantalla

3 99271452 Bombilla fluorescente, 13 W tipo GU24

4 99260425 Tuerca para motor, hexagonal Keps

5 97018311 Placa del motor

6 99150583 Tornillo de la rejilla

7 99080634 Motor

8 99020300 Rueda del soplador

9 99270981 Receptáculo de la lámpara, blanco

10 99270982 Receptáculo del motor, negro

11 98009612 Panel de cableado

12 99150471 Tornillo de puesta a tierra

13 99170245 Tornillo, #8-18 x 3/8pulg.

14 98008868 Placa de cableado

15 97014185 Conector del regulador de tiro/conducto

16 97014922 Conjunto de la cubierta

A 97018631 Conjunto del accesorio de la luz

(incluye claves n.° 1, 2 y B)

B 97018734 Conjunto del platillo de la rejilla

(incluye clave n.° 3)

C 97018327 Conjunto del ventilador

(incluye claves n.° 4 a 8)

D 97015171 Conjunto del panel de cableado

(incluye claves n.° 9, 10, 11)

Pida piezas de repuesto dando como referencia

el N°. DE PIEZA, no el N°. DE CLAVE.

14

16

13

12

10

8

15

B

3

D

11

9

A

2

1

2

C

6

7

5

4

GARANTIA

PERIODO DE GARANTÍA: NuTone garantiza al consumidor comprador original del ventilador/lámpara de NuTone (el “Ventilador” que el ventilador, incluso las lámparas/bombillas, estará libre de defectos en materiales o mano de obra durante un período de un (1)

año a partir de la fecha de la compra original. La garantía en las bombillas/lámparas provista con el ventilador no cubre el rompimiento de las bombillas/lámparas. Esta garantía no cubre accesorios, como controles de velocidad, que pueden comprarse por separado

e instalarse con el ventilador.

El periodo de garantía limitada para las piezas de repuesto y para los ventiladores reparados o reemplazados bajo esta garantía limitada continuará durante el resto del periodo de garantía original.

NO HAY OTRAS GARANTÍAS: LAS GARANTÍAS ANTERIORES SON EXCLUSIVAS Y EN LUGAR DE CUALQUIER OTRA GARANTÍA, EXPRESA O IMPLÍCITA. NUTONE NIEGA Y EXCLUYE CUALQUIER OTRA GARANTÍA EXPRESA, Y NIEGA Y EXCLUYE TODAS LAS

GARANTÍAS IMPLÍCITAS POR LEY, INCLUYENDO, SIN LIMITACIONES, LAS DE COMERCIALIZACIÓN Y APTITUD PARA UN PROPÓSITO EN PARTICULAR. HASTA EL GRADO QUE LA LEY APLICABLE PROHÍBA LA EXCLUSIÓN DE GARANTÍAS LIMITADAS, LA

DURACIÓN DE CUALQUIER GARANTÍA IMPLÍCITA APLICABLE ESTÁ LIMITADA AL PERIODO ESPECIFICADO PARA LA GARANTÍA EXPRESA. Algunos estados no permiten limitaciones en la duración de una garantía implícita, así que la limitación anterior tal vez no

aplique en su caso. Cualquier descripción verbal o escrita del ventilador es para el único propósito de identificarlo y no deberá considerarse como una garantía expresa.

RECURSO: Durante el periodo de garantía limitada aplicable, NuTone, a su opción, suministrará piezas de repuesto, o reparará o reemplazará, sin cargo alguno, cualquier ventilador o pieza del mismo, hasta el grado en que NuTone lo encuentre cubierto bajo esta

garantía limitada y en incumplimiento de la misma. NuTone le enviará el ventilador reparado o reemplazado o las piezas de repuesto sin cargo. Usted es responsable de todos los costos de retiro, reinstalación y envío, seguro u otros cargos de flete incurridos en

el envío del ventilador o la pieza a NuTone. Esta garantía no cubre (a) mantenimiento y servicio normal, (b) uso y desgaste normal, (c) ventiladores o piezas sujetos a mal uso, abuso, uso anormal, negligencia, accidente, mantenimiento inadecuado o insuficiente,

almacenamiento o reparación (que no sea reparación por parte de NuTone), (d) daños causados por instalación defectuosa, o bien instalación o uso contrario a las recomendaciones o instrucciones, (e) cualquier ventilador que se haya movido de su punto de

instalación original, (f) daños ocasionados por el medio ambiente o los elementos naturales, (g) daños en tránsito, (h) desgaste natural del acabado, (i) ventiladores en uso comercial o no residencial, o (j) daños ocasionados por incendio, inundación u otro caso

fortuito. Esta garantía cubre únicamente los ventiladores vendidos en Estados Unidos o Canadá o a través de distribuidores autorizados por NuTone.

EXCLUSIÓN DE DAÑOS: LA OBLIGACIÓN DE NUTONE DE SUMINISTRAR PIEZAS DE REPUESTO, O DE REPARAR O REEMPLAZAR, A OPCIÓN DE NUTONE, SERÁ SU ÚNICO Y EXCLUSIVO REMEDIO BAJO ESTA GARANTÍA LIMITADA, Y LA ÚNICA Y EXCLUSIVA

OBLIGACIÓN DE NUTONE. NUTONE NO SERÁ RESPONSABLE POR DAÑOS INCIDENTALES, INDIRECTOS, RESULTANTES O ESPECIALES QUE SURJAN POR EL USO O DESEMPEÑO DEL VENTILADOR, O EN RELACIÓN CON EL MISMO. Los daños incidentales

incluyen, entre otros, daños como la pérdida de tiempo y la pérdida de uso. Los daños resultantes incluyen, entre otros, el costo de reparar o reemplazar otros bienes que fueran dañados si el ventilador no funcionara adecuadamente.

Algunos estados no permiten la exclusión o limitación de daños incidentales o resultantes, por lo que la limitación antes mencionada podría no aplicarse a usted. Esta garantía le otorga derechos legales específicos, y usted podría tener otros derechos que varían

de un estado a otro.

Esta garantía sustituye todas las garantías anteriores y no es transferible del comprador consumidor original.

NUTONE NO SERÁ RESPONSABLE ANTE USTED, O ANTE NADIE QUE RECLAME POR USTED, DE NINGUNA OTRA OBLIGACIÓN O RESPONSABILIDAD QUE INCLUYEN, ENTRE OTRAS, OBLIGACIONES O RESPONSABILIDADES QUE SURJAN POR INCUMPLIMIENTO

DE CONTRATO O GARANTÍA, NEGLIGENCIA U OTRO ACTO ILÍCITO O CUALQUIER TEORÍA DE RESPONSABILIDAD ESTRICTA, CON RESPECTO AL VENTILADOR O A LOS ACTOS U OMISIONES DE NUTONE O DE CUALQUIER OTRA ÍNDOLE.

Esta garantía cubre únicamente el reemplazo o la reparación de ventiladores o piezas de los mismos con defectos en la planta principal de NuTone, y no incluye el costo del viaje para el servicio de campo ni los viáticos.

Cualquier asistencia que proporcione o procure NuTone para usted fuera de los términos, limitaciones o exclusiones de esta garantía limitada no constituirá una renuncia a dichos términos, limitaciones o exclusiones, ni dicha asistencia extenderá o renovará la garantía.

NuTone no le reembolsará ningún gasto en el que usted haya incurrido al reparar o reemplazar cualquier ventilador defectuoso, excepto los incurridos con el permiso previo por escrito de NuTone.

CÓMO OBTENER EL SERVICIO CUBIERTO POR LA GARANTÍA: Para tener derecho al servicio cubierto por la garantía, usted debe (a) notificar a NuTone a la dirección o número de teléfono que aparecen abajo en un plazo de siete (7) días después de descubrir el

defecto cubierto, (b) proporcionar el número de modelo y la identificación de la pieza y (c) describir la naturaleza de cualquier defecto en el ventilador o la pieza. En el momento de solicitar el servicio cubierto por la garantía, debe presentar un comprobante de la

fecha original de compra.

Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027 (1-800-637-1453)

Si debe enviar el ventilador o la pieza a NuTone y tal como lo indique NuTone, debe empaquetar adecuadamente el ventilador o la pieza; NuTone no se hace responsable por los daños en tránsito.

Ventiladores/lámparas de NuTone - Garantía limitada

99044768D

Loading...

Loading...