Page 1

1 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

The

SIL O

2

Oxygen Analyser

User Operation Manual

Rev. 1.1

30/11/2018

Page 2

2 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

Page 3

3 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

Contents

1. Introduction .................................................................................................................................................... 6

1.1 The purpose of this User and Operation Manual................................................................................... 6

2. Installation and Operation ............................................................................................................................... 7

2.1 Notes for a safe installation ................................................................................................................... 7

2.2 Installation ........................................................................................................................................... 10

2.2.1 Mounting the SIL O2 Analyser....................................................................................................... 10

2.3 Electrical and Interface Connections ................................................................................................... 11

2.3.1 Sensor Input and Customer Interface Wiring.................................................................................. 11

2.3.2 Operational Settings and Wiring Configuration ............................................................................. 12

2.3.3 Typical Relay Configuration........................................................................................................... 13

2.3.4 Sensor Process Connection options ................................................................................................ 15

2.4 Operation ............................................................................................................................................. 16

2.4.1 Calibration Procedures .................................................................................................................... 16

2.4.2 Setting the Zero point. .................................................................................................................... 17

2.4.3 SPAN Calibration ........................................................................................................................... 18

.......................................................................................................................................................................... 18

3. Operational safety and maintenance instructions.......................................................................................... 19

3.1 Fault conditions ................................................................................................................................... 19

3.2 Wire break ........................................................................................................................................... 19

3.3 System faults ....................................................................................................................................... 19

3.4 Troubleshooting .................................................................................................................................. 20

Possible Faults and their solutions ........................................................................................................................ 20

3.4.1 Possible Sensor Faults .................................................................................................................... 21

3.5 General Maintenance .......................................................................................................................... 22

4. Specifications................................................................................................................................................ 23

5. Appendices ................................................................................................................................................... 26

5.1 SIL O2 Analyser and Sensor Connection Diagrams ........................................................................... 27

5.2 SIL O2 Analyser CE and ATEX Certificates ...................................................................................... 28

5.3 Sensor CE and ATEX Certificates ...................................................................................................... 29

Page 4

4 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

Revision History

Revision No.

Change Description

Date

0

First Issue

19-10-2018

1

Note added for Non-ATEX Sensor usage

22-10-2018

1.1

Reference to 15% O2 in trouble shooting section removed.

30-11-2018

Calibration Span instruction amended and note added

Page 5

5 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

Page 6

6 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

1. Introduction

The Ntron SIL O2 Analyser is a ATEX approved SIL 2 rated Oxygen measuring instrument. It contains three

programmable alarm settings, industry standard Analogue Output(active source) and a non-programmable safety

trip relay. The range of operation is 0 to 25% Oxygen. The Reasolution is to 0.01%.

Together with one of the range of Ntron ATEX approved Oxygen Sensors, it forms a SIL2 rated measurement

unit which can operate on its own or as part of a larger installation.

Note. Non-Atex (Ex) Sensors variants of the models listed in the manual may also be used with the SIL O2

Analyser as long as they are installed in a Non-ATEX (Ex) or ‚Safe‘ area or zone.

The Alarm settings are typically factory set according to the end user’s requirements. Interface software and

hardware is available for the user to perform such functions themselves. Contact Ntron for further details.

1.1 The purpose of this User and Operation Manual

This Manual is limited to providing the user with necessary details on installation, interface wiring, operation

and maintenance of the SIL O2 Analyser and Oxygen Sensor, to ensure safe and reliable operation of this

Analyser and Sensor unit.

Note: This manual does not cover the design or application of a safety Instrumented System (SIS) into

which the SIL O2 Analyser unit may be incorporated. Further details of this can be obtained in the Ntron

SILO2 Technical and Safety Manual.

Increase (UP) and

Decrease (Down)

Pushbuttons. Pressing

simultaneously enables

entry into the

calibration mode.

Power, Error/Fault and

Alarm Level indicators

RS232

Communications

connection

The main user interface features

4-Digit LCD

Display/Readout

Page 7

7 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

2. Installation and Operation

Note: For system application information, consult the SIL O2 Analyzer

Technical User Manual

2.1 Notes for a safe installation

Please do not short-circuit the + and -ve sensor cables while connecting to the SIL O2 Analyzer. This

could damage the sensor.

This system can also be used in a non-Ex area application. In all applications, the SIL O2 Analyzer Din

rail module is always located in the non-Ex area!

Assignment of the mounting rail housing terminals with intrinsically safe circuits and non-intrinsically

safe circuits is indicated on the nameplate and is clearly indicated. In addition, the 4-pin terminals of

intrinsically safe circuits follow the standard color protocol for intrinsically safe terminal connections and

are coloured Blue. Connections for intrinsically safe external circuits are arranged in such a way that, in

accordance with EN 60079-11, the exposed parts are at least 50 mm from the exposed connections and

parts of the non-intrinsically safe circuits.

For safe operation, a protective ground/earth connection to terminal 13 or 15 should be made.

Assembly / disassembly, installation, operation and maintenance may only be performed by qualified

personnel in accordance with regulatory requirements and the SIL O2 Oxygen Analysis Manual.

During installation, the technical data and the electrical values of the connected circuits must be

respected.

Electrical supply. The SILO2 Analyser operates with an Extra low Voltage (ELV) supply. (See

specification section in this manual)No special precautions are necessary but the ELV supply to the SIL

O2, if generated from a Mains power source, that mains power source and associated wiring must be in

accordance with IEC/EN standards and is the responsibilty of the user to provide and to ensure correct

and safe installation of such.

When the SIL O2 analyzer is integrated into another system, also refer to the system manual for

additional operational information.

The Ntron SILO2 Analyser is designed for use with a range of Ntron ATEX certified Oxygen Sensors to

form a measurement system.These Sensor options are detailed in the Specification section of this manual.

If the SIL O2 Analyser has been supplied with a Sensor, the two units will have been calibrated at the

Ntron factory prior to delivery. Otherwise, if a Sensor is supplied separately from the SIL O2 Analyser, a

calibration will be required prior to putting the system into operational service.

Page 8

8 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

The Ntron Sensors suitable for use with the SIL O2 analyser are listed in the Installationn section which

follows.

Page 9

9 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

The SIL O2 oxygen analyzer is an associated explosion-proof [Ex ia] IIC or [Ex ib] IIC electrical device

and should always be used outside potentially explosive areas (in a safe area). Only electrical circuits,

certified as intrinsically safe, can be connected to other intrinsically safe circuits in the Ex zone.

Before operation, the intrinsic safety must be verified for the SIL O2 oxygen analyzer circuit connected

to the circuit of other equipment, including the interconnecting cabling.

The data contained in the EC test certificate and the regulations of EN 60079-14: 2011-10 must be

observed.

The Sensors are ATEX rated devices and have certain conditions of use assigned.

Note. Non-Atex (Ex) Sensors variants of the models listed in the manual may also be used with the

SIL O2 Analyser as long as they are installed in a Non-ATEX (Ex) or ‚Safe‘ area or zone.

For Acetal-bodies Sensors, the following instructions apply;

The Sensor should be installed in such a way that it is not subject to impact by other objects and should

not be located close to additional heat sources. Note the ambient temperature range as it appears on the

Sensor labelling.

Care must be taken when installing equipment with plastic enclosures or plastic parts of enclosures to

ensure that the equipment is protected from any situations that could cause a build up of static charge. The

equipment must not be installed into locations in which it could come into contact with, through normal

or abnormal circumstances, fast moving dust laden air/gas or non-conductive fluids. The equipment must

be cleaned only with a damp cloth.

Page 10

10 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

2.2 Installation

The installation must be in accordance with the local electrical codes and taking into account the details

in the Specification section of this manual.

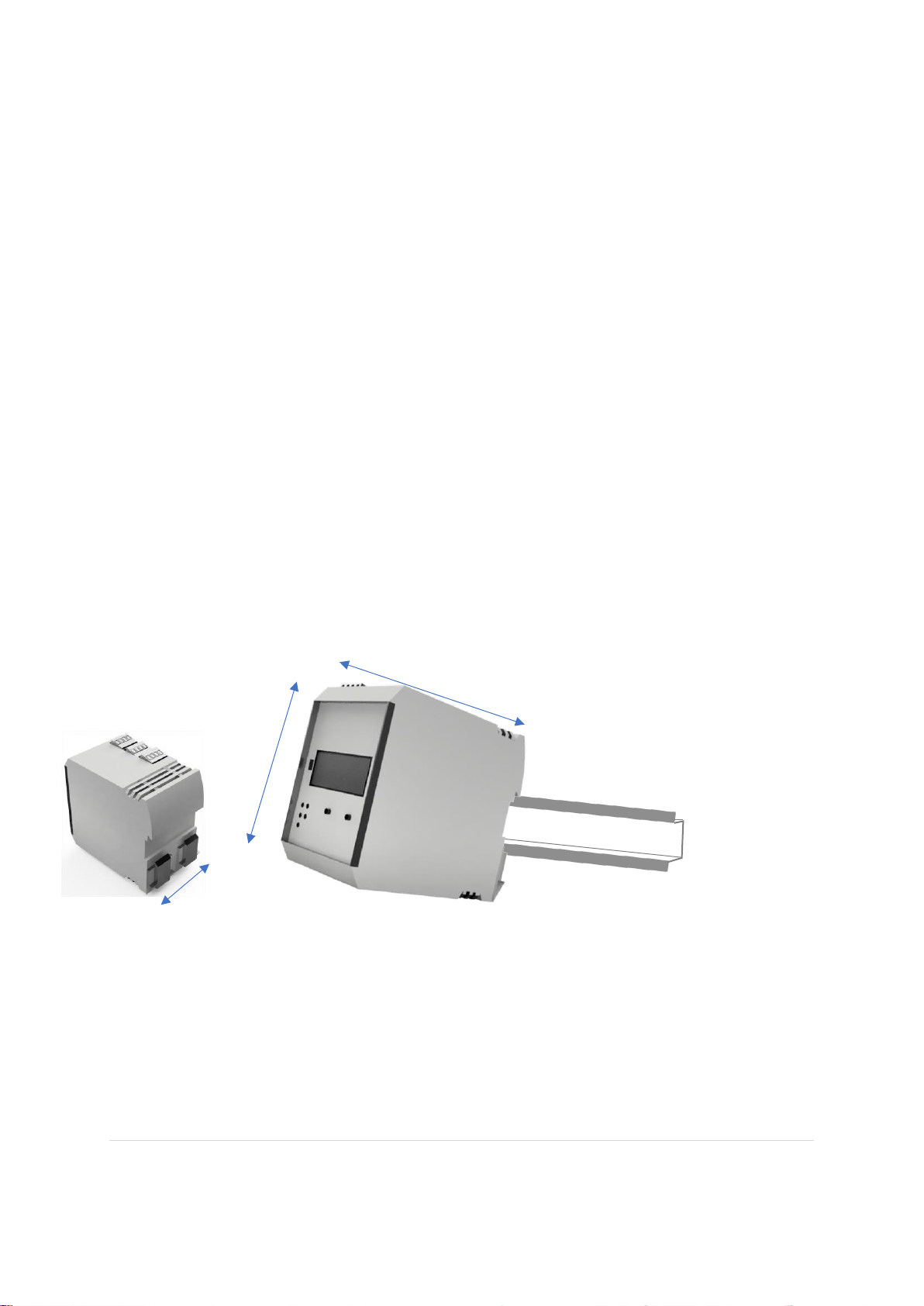

The SIL O2 analyzer is designed for DIN rail mounting and can be supplied mounted in an additional

enclosure or provided without an additional enclosure for customer mounting in a system enclosure or

control panel.

The Sensor option chosen will determine the process connection/installation for that Sensor type. The

Sensor types and related process connections are given below.

Sensor Type: Process Connection:

Model OC-25 Ntron Sensor base, Flow Through or Tri-Clamp

Model OC-26 KF40 Flange

Model OC-200’Oxyprobe‘ series Bushing insert or Extract* Probe Holder

The Sensor is typically supplied with a correcponding connection cable of either standard length or to a

customer specified length.

*The Ntron OxyExtract Manual or Automatic probe insertion mechanism.

2.2.1 Mounting the SIL O2 Analyser

Mount the SIL O2 Analyser onto 35mm DIN rail as shown. Any Trunking/wireways above and below

the Analyer when in situ, must be positioned so that there is a minimum of 30mm clearance between

such trunking and the Analyser connection terminals.

115mm

100mm

67mm

Page 11

11 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

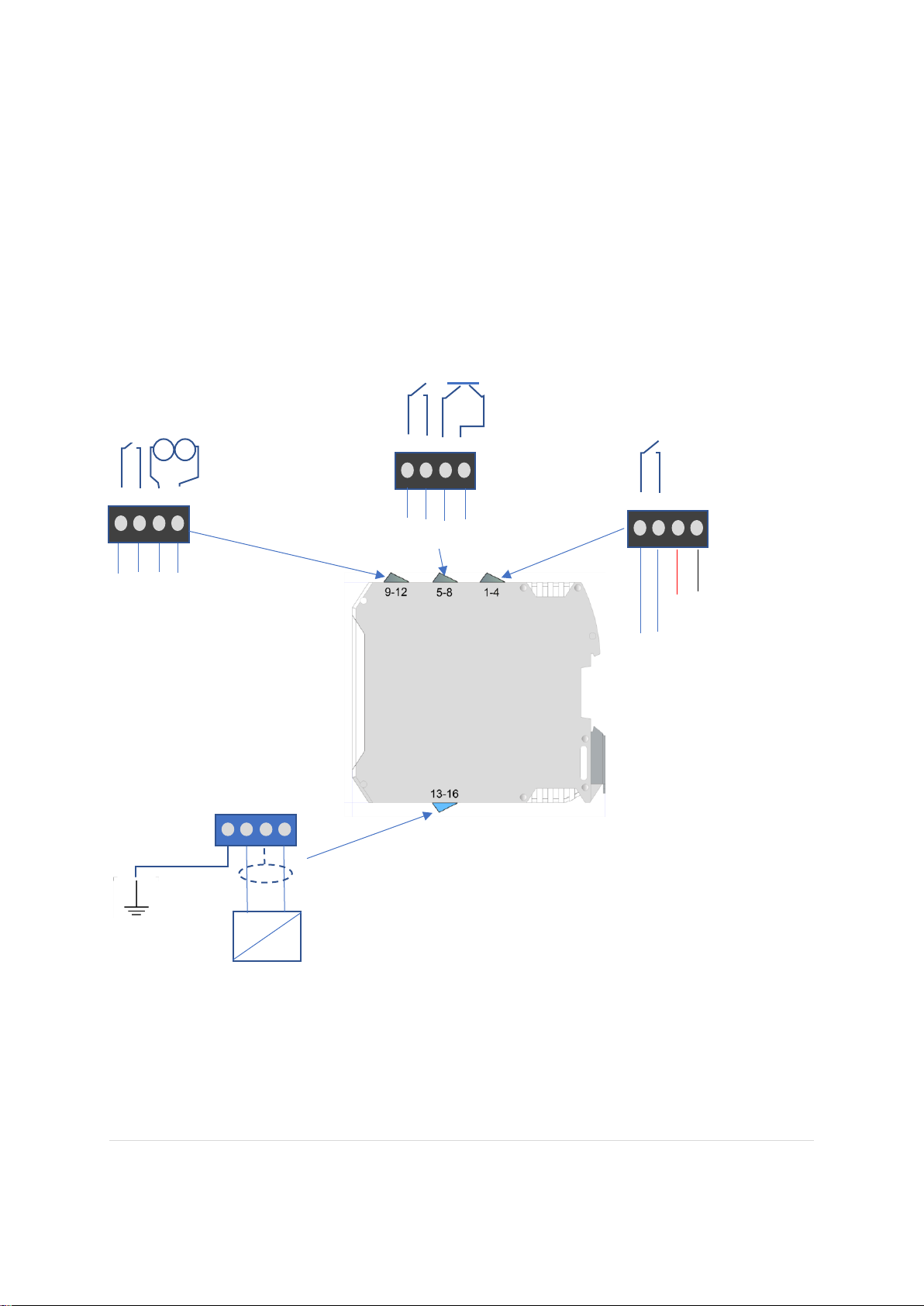

2.3 Electrical and Interface Connections

2.3.1 Sensor Input and Customer Interface Wiring

The Ntron ATEX Sensor selected for use with the SIL O2 Analyser as listed in the Installation section

previously, has intrinisically safe parameter values which match the Isolation Barrier output which is built into

the SIL O2 Analyser. The Sensor connects to the Blue terminals as shown below.

The dark Grey terminals are for safe (Non-Ex area) customer interface connections. See the configuration

section on the following page.

13 14 15 16

+ve -ve

Customer Clean

Earth

O2 Sensor

1 2 3 4

+ - 24 VDC

Relay 1

To customer Circuit

5 6 7 8

Relay 2 Transistor(DO)

To customer Circuit

9 10 11 12

Relay 3 4-20mA (AO)

To customer Circuits

Page 12

12 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

2.3.2 Operational Settings and Wiring Configuration

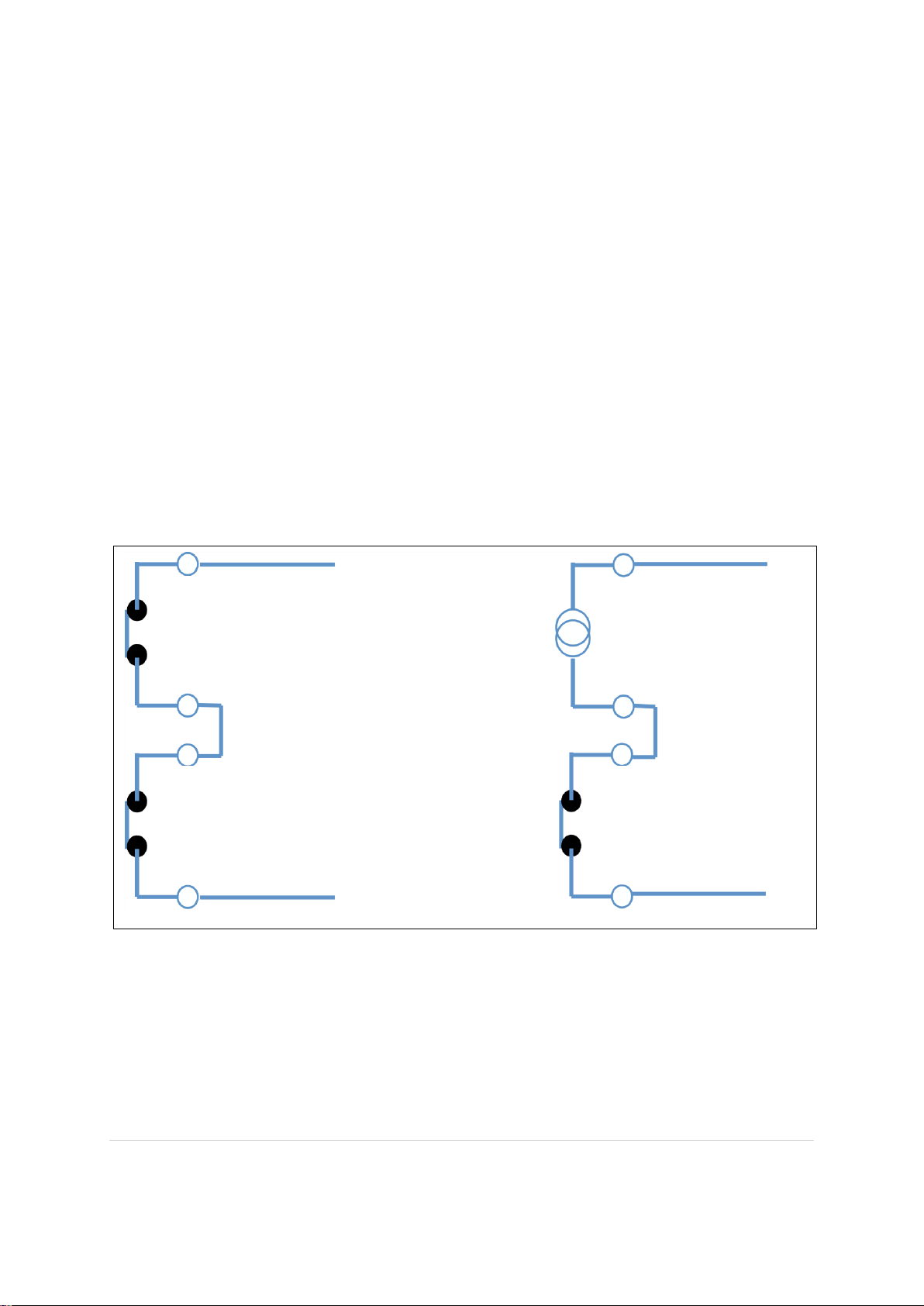

The SIL O2 Analyser has two presettable alarm levels and associated Relays, referred to as RL1 and RL2. It

also has a third presettable alarm level with an associate Transistor Digital Output (DO) The programmed

setting of these outputs can vary depending on application. The Inspection and Calibration certificate supplied

with each SIL O2 Analyser and Sensor unit will detail these settings. See the Ntron SIL O2 Technical and

Safety manual for further details.

The SIL O2 Analyser has a main trip Relay referred to as RL3. This is not programmable and is normally

open(contacts)/de-energised when the Analyser is not under power. The Relay energises and its associate

contacts close when power is applied and the Analyser and Sensor are healthy and ready to operate.

The Analogue output is an industry standard 4-20mA active source output. The connected circuit should be of

maximum resistance 420 ohm.

To meet the SIL 2 operational requirements as an Analyser and Sensor unit, the main trip Relay is required to be

connected in series with other elements within the Analyser as shown in the diagrams below. For any other

configurations, See the Ntron SIL O2 Technical and Safety manual for further details.

*Special case for use of the 4-20 mA analogue output within a safety system

When using the 4-20 mA analogue output from the SILO2 Oxygen Analyser within the safety

system, this signal would typically be required to be processed by a safety PLC which would then

activate the Final Trip Element. See the Ntron SIL O2 Technical and Safety manual for further

details.

Relay 3 Main Trip

Relay 1 or 2

Relay 3 Main Trip

Analogue Output

1/5

2/6

9

10 9 10

11

12

Page 13

13 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

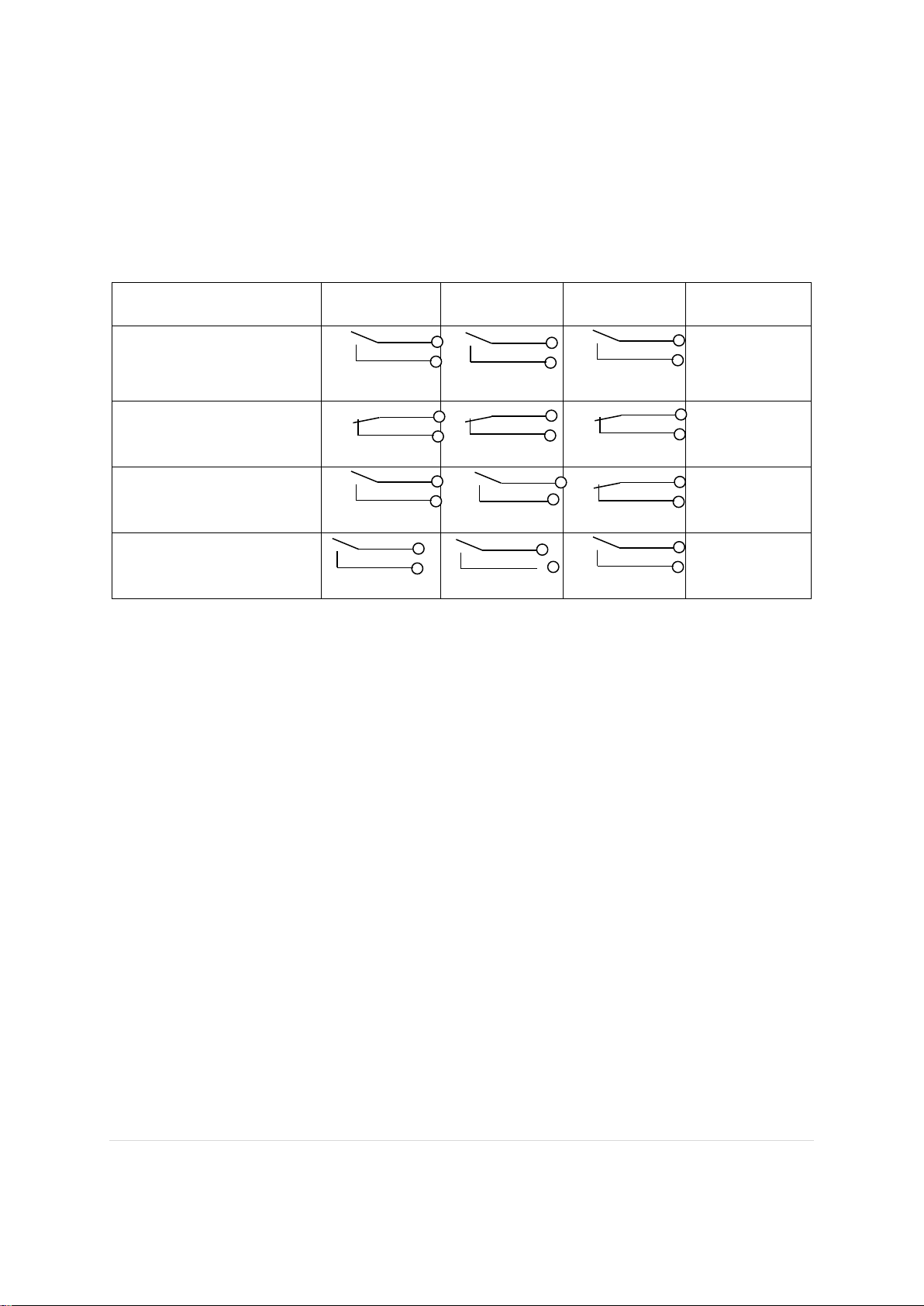

2.3.3 Typical Relay Configuration

Power to the Analyser

Relay

Contact 1

Relay Contact

2

Relay Contact

3

Comments

Power Off

(All relay contacts in Fail

Open condition)

Relays

De-energised

Power on and system

good/healthy

**

** All Relays

Energised

Power on and O2 alarm

level(s) reached

* *

Relays 1 & 2

De-energised

Power on and System fault

**

** All Relays

De-energised

These relays are programmed to respond to the measured Oxygen level setpoints (Alarms), rising or falling in

the range 0-25% Oxygen. These are pre-set to the customer’s requirements.

They operate in ‘Fail Safe’ mode which means that they are energized (under current), presenting a closed

contact to the customer/user when the SIL O2 module is under power and the status is healthy/good.

When at a level setpoint (Alarm) or when the SIL O2 module is not-powered, the relays are de-energised (not

under current), presenting an open contact to the customer/user. This is also known as ‘Fail Open’ (FO)

condition.

Transisitor (DO)

This is an NPN device that can switch 24VDC and can be configured to be normally open or normally closed.

Analogue 4-20mA

This is an active output and requires connection to a passive external circuit suitable for proper operation.

It is set to the range 0-25% Oxygen / 4-20mA (0% Oxygen = 4mA, 25% Oxygen = 20mA.)

This range can not be adjusted.

If the 4-20 mA output is not used, the SIL O2 terminals T11 and T12 must be wired by the user. This output is

internally connected in series with the SIL O2 Analyzer digital display, which will not work if the

aforementioned terminals are in open circuit!

Page 14

14 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

Page 15

15 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

2.3.4 Sensor Process Connection options

The Sensors are suitable for mounting directly onto process

Lines via a selection of process fittings. The electrical signal connectors

are rated to IP67.

Tri-Clamp Sensor Base

Flow Through Sensor Base

OC-25 Sensor

OC-26 Sensor KF40 Process fitting

KF40 Process fitting onto pipeline

OC-200 Sensor with Screwed Bush Process

fitting

Page 16

16 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

2.4 Operation

Before turning on the SIL O2 analyzer for the first time or after disconnecting the sensor for maintenance /

replacement, make sure that a working sensor is connected. Otherwise, the SIL O2 analyzer will go into failure

mode, with the red error indicator on and the RL3 relay disabled. As the fault circuit performs a cyclic check

every 30 seconds or so. When the sensor is connected, resetting the red indicator and relay 3 occurs

automatically, but it is advisable to power off the system to allow the sensor to be disconnected / reconnected

under normal circumstances, if possible.

Turn on/apply power to the SIL O2 Analyser.

When operating under normal process/system conditions, the SIL O2 Analyser will give a digital readout of the

measured Oxygen level (from the Sensor in the process).

This measurement is converted into a 4-20mA output signal proportional to the Oxygen being measured.

If an Alarm level even occurs, the relevant programmed output device will operate (Relay or Transistor) and the

ineterface circuit to the user equipment will be interrupted. For further alarm or fault events and their conditions,

please see the troubleshooting section at the end of this Manual.

2.4.1 Calibration Procedures

The SIL O2 Analyser and Sensor unit requires periodic calibrations performing, the timing between such

calibrations being determined by the application and process requirements.

Typically, a periodic calibration check would reveal if any calibration adjustment is necessary. The SPAN

calibration point of 20.9% O2 (Air) is the important setting and typically, if calibration adjustment is required,

this is the value that would be adjusted. This adjustment can be made ussing ambient air as the calibration

standard or, for greater accuracy, certified cylinder gas at 20.9% O2.

It is possible to also adjust the Zero point of the SIL O2 Analyser. Typically this would only be required when

fitting a new/replacement Sensor. A Complete calibration procedure is given below.

Note: Calibration Adjustment procedure.

The displayed number change starts with the digit to the far right of the decimal point. Press and hold the

Up or Down buttons to change the reading. This gives an accelerated adjustment. More accurate

adjustment is achieved by pressing the Up or Down button at one press (press release, release of press,

etc.). When the display reads 20.9%, the calibration of the range is complete

19.05

19.05

1, 2, 3….

6

6

1-

Page 17

17 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

2.4.2 Setting the Zero point.

This must be done each time a new sensor is installed before a span calibration is performed.

Subsequently, a zeroing can be performed periodically as needed.

A zeroing operation requires the application of a zero oxygen gas to the sensor, typically nitrogen (minimum

quality <100 ppm). Note: Accessing the Zero function when the sensor is in ambient air (20.9% O2) will result

in an error / fault condition.

Depending on the type of sensor installed, zero gas must be applied through a process fitting or calibration

adapter, and be sure to leave a free exhaust at a suitable location so that the sensor does not become pressurized.

The sensors to be used with the SIL O2 unit will generally give a small output at zero oxygen levels. The zero

adjustment function allows the user to adjust this small signal so that the SIL 2 analyzer displays 0.0 when no

oxygen is present in the measured gas.

• ZERO mode is activated after pressing the UP and DOWN button simultaneously for more than one

second. As an acknowledgment of receipt, the A3 LED flashes. An adjustment of the indicated value is

made by pressing the UP or DOWN buttons individually as required.

• The change starts with the digit to the right of the decimal point. (00.0) Press and hold the Up or Down

buttons to change the displayed reading. This allows an accelerated adjustment. Accurate adjustment is

achieved by pressing the Up or Down button at one press (press release, release of press, etc.). When

the display reads 0.0% O2, the setting is complete. By simultaneously pressing the two buttons or a

delay of 20 seconds, the ZERO operating mode ends.

0.00

Page 18

18 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

2.4.3 SPAN Calibration

This can be done periodically or as needed in accordance with the requirements of the calibration protocol.

Calibration can be performed by applying either clean ambient air or a 20.9% certified oxygen rate to the sensor.

Note:

• The SIL 2 analyzer should only be calibrated at approximately 20.9% oxygen.

• If an ambient air calibration is performed, it is recommended to confirm the oxygen level with a

certified portable oxygen analyzer prior to calibration.

• If a zero setting is made first, then after the end of the zero operation mode, the Span mode is

automatically activated after a delay of 20 seconds.

• If A Span only calibration is required, then just press the UP or DOWN buttons individually to

increase or decrease the displayed value of oxygen to read 20.9. Note: Ensure the Sensor is in

20.9% oxygen when you do this!

• Calibration complete.

20.90

Page 19

19 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

3. Operational safety and maintenance instructions.

If it is assumed that safe operation is no longer possible, the device must be taken out of service and protected

against accidental use. The reasons can be:

visible damage to the device

failure of the electrical function

long shelf life at temperatures above 85 ° C

Transport damage

Before the device can be put back into service, a professional routine check must be carried out in accordance

with DIN EN 61010, part. 1. This examination must be carried out by the manufacturer. Repair work on Ex devices

may only be carried out in accordance with § 9 of Ex. (Elex V).

3.1 Fault conditions

The SIL O2 Analyzer failure operation is not locked out by a fault. When a fault condition is repaired, the trip

relay RL3 and the red fault indicator will return to their "healthy" or "operational" state after a few seconds

following an automatic internal cyclic check.

3.2 Wire break

When manually disconnecting the sensor (for example for maintenance) or following a break in the sensor

connection cable, the SIL O2 Analyzer RL3 fault relay switches off and interrupts the safety circuit.

The red fault indicator will illuminate on the SIL O2 analyzer and the 4-20 mA analog output will reach a constant

high value of 22.0 mA. At the same time, the setpoint relays RL1 and RL2 will be deactivated.

When the sensor is reconnected or the cable fault is corrected, the RL3 relay automatically resets after about 30

seconds and the red LED goes out. At the same time, RL1 and RL2 are reset according to their setpoints and the

measured gas level. See also note on page 13 of this manual for reset requirements under specific conditions.

3.3 System faults

A number of internal faults in the SIL O2 analyzer generate a fault output and interrupt the safety circuit. In some

cases, cycling the power supply of the SIL O2 analyzer may be sufficient to remedy the problem. Otherwise,

please contact Ntron for assistance.

Page 20

20 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

3.4 Troubleshooting

Possible Faults and their solutions

The following possible conditions are applicable to a system (Sil Analyser and Sensor) already installed

and commissioned. Some conditions below may also be applied to new systems not yet commissioned.

• Action: Performing a Zero calibration when the Oxygen Sensor is in ambient air.

Problem: An incorrect Zero level input to the Analyser will result in an overrange fault. This can

occur if a Zero calibration is performed when the Sensor is in ambient air. If this occurs, the Red fault

LED will illuminate and the Analyser display and Analogue output will read an over-range value. The

Alarm level LED’s may also illuminate. This may also occur if a genuine overrange event takes place,

with gas containing more than 25% O2 being applied. (25%O2 displayed)

Solution: re-calibrate with Nitrogen gas (Zero) and then re-calibrate at the Span point of 20.9%.

• Action: Powering on the Analyser with no sensor connected or a wire break to the sensor.

Problem: If the sensor is disconnected, this would ordinarily cause relays R1, R2 and R3 to de-

energise. Analyser display and Analogue output will read a fault value. (28% O2 displayed and 22mA

output)

Solution: Check Sensor wiring and connect the sensor to the Analyser. After approximately 30

seconds, the Analyser will reset and the Red LED should extinguish.

• Action: Unable to perform a Span calibration.

Problem: The Analyser cannot be adjusted to display 20.9% O2 during Span calibration.

Solution: The Sensor may be approaching end of life or has been damaged and cannot generate

sufficient output. Replace the sensor

Alarm level LED’s may or may not be illuminated depending on configuration.

• Action: Alarm Level LED’s (Yellow) illuminated.

Problem: Alarm level LED’s illuminated.

Solution: Genuine Oxygen level alarm event.

Incorrect sample gas levels being applied to the Sensor or incorrect alarm level settings are configured

within the Analyser. If this is not expected then check sample gas with independent instrument

gas/and/or re-configure Analyser Alarm setpoints. This will require interface with PC based software.

Page 21

21 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

• Action: Red Fault LED illuminated when none of the above conditions are present.

Problem: Analyser in fault condition. Analyser display and Analogue output will read a fault value.

(28% O2 displayed and 22mA)

Solution: Internal Analyser electronics or programming fault. Try Power On/Off cycle to reset.

If fault does not clear then seek further assistance.

Problem: No Analyser display (Blank)

Solution: Analogue output circuit is broken or interrupted. Investigate and repair.

3.4.1 Possible Sensor Faults

Applicable to all sensor types (OC-25, OC-26, OC-200)

Problem:. SIL O2 Analyser will not calibrate (Cannot be set to 20.9%)

Solution: Sensor is at end of life. Sensor has been wetted or contaminated. The Sensor output signal can be

checked at the SIL O2 Analyser terminals 14 and 16. See specification section for details of a healthy

output signal.

Problem:. SIL O2 Analyser reads Zero (0.00)

Solution: Actual low Oxygen measurement. Sensor wires have been shorted together, damaging the Sensor.

Verify the Oxygen level by other means. Check the Sensor output signal. Replace Sensor as necessary.

Page 22

22 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

3.5 General Maintenance

Establish a periodic checking and maintenance routine in line with the requirements for Safety Instrumented

Systems. See the Ntron SIL O2 Analyser Technical and Safety manual for further details.

The SIL O2 Analyser requires little physical maintenance. The user Enclosure into which it is housed

should provide protection against a build up of dust or other contaminants on the surface of the SIL O2

Analyser housing. If such contaminants are seen during regular inspection, such can be removed by gentle

suction device or by wiping with a damp but not wet, cloth. The ingress of such contaminants should be

investigated.

Ensure all wiring to the SIL O2 Analyser is secure and in good condition, paying particular attention to the

security of the connection terminals if the user enclosure is subject to vibrations.

There are no user serviceable parts within the SIL O2 Analyser. If any malfunction is detected, mechanical

or electrical, the SIL O2 Analyser should be immediately removed from service following the correct

protocols.

The Sensor used has a finite life span. The Performance of the Sensor is verified by calibration check and

this should be performed according to the protocols required by the safety system. Replacement of the

Sensor is necessary when it does not meet the required performance levels.

During operation life, the Sensor should be kept clean of contaminants. It can be wiped with a soft damp

cloth. Observe the restrictions regarding potential static charges as detailed on the Sensor Installation

Instruction Documents found in the appendix to this manual.

When removing Sensors from their process installation for replacement or other service requirements,

observe the following points.

• Ensure any and all system shut down protocols are followed as applicable.

• Do not disconnect the Sensor from the connecting cables whilst the system is operating or is

‘Live’.

• Ensure the process being measured is shut down or the Sensor connection is isolated by any

intermediate valve mechanism if fitted.

• Always remove the Sensor connector before unscrewing the OC-25/OC-200 Sensors or

unclamping the OC-26 Sensors from their process fittings

• Block off the exposed process connection if required during the period the Sensor is disconnected.

• Protect the disconnected Sensor cable from damage during the period the Sensor is disconnected.

Page 23

23 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

4. Specifications

SIL O2 Analyser

Specifications-Electrical

Supply Voltage

24VDC +/- 10%

Supply Power

1.5 Watt

Analogue Output

4-20mA active source. 22mA Max output . Load 390 Ohm@22mA, Max

420 Ohm@20mA constant current.

Communications

RS232/Com 9600bps

Relay Contact outputs

RL1/RL2/RL3

Um 125VAC/110VDC (Typically 30VDC)@ 1Amp. Min Current 10uA

DC. Min. Voltage 10mVDC. Type According to IEC 947-5-1 resp. EN

60947)

Transistor Output (Do)

Switching parameters: <28V @<50mA

Intrinsically Safe

Connection

voltage Uo DC 6 V

current intensity Io 0,2 mA

power Po 0,3 mW

max. outer inductivity Lo 1000 mH

max. outer capacity Co 10 μF

Specifications-Mechanical

Terminal /Wire Size

Pluggable/Quick Releas terminals, capacity 2.5mm

2.

Mounting

35mm Din rail

Housing Material

PBT

Protection Class

IP20

Combustibility Class

VO according to UL

Weight

300g

Enviromental

Temperature: -20 to +60°C, 10-95% Humidity, no condensation.

Dimensions

67 mm x 114.5 mm x 99 mm

Indications

4 Digit LCD Display, Green OK led, Red Fault LED, Amber Alarm LED.

Page 24

24 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

Certification/Standards

CE, ATEX 2014/34/EU/ EN 60079-0:2012 + A11:2013, EN 60079-

11: 2012, EN 60079-26: 2015 0158 II (1) G II (1) D ; [Ex ia

Ga] IIC; [Ex ia Da] IIIC

Functional safety: SIL2 according to IEC 61508/61511

EMC 2014/30/EU

EN 61326-3-2:2008; EN 61000-6-3: 2007 + A1: 2011

EN 61000-4-2:2009; EN 61000-4-3: 2006 + A1: 2008 + A2: 2010

EN 61000-4-4:2012

2006 + A1: 2008 + A2: 2010

EN 61000-4-5:2014

EN 61000-4-6:2014

Oxygen Sensor

Specifications-Electrical

Models

OC-25, OC-26, OC-200 series

Range

0-25% Oxygen

Signal Output

300-375mV in Air OC25, OC-26. 135-160mV in Air OC-200

Technology/Lifespan

Electrochemical Solid State Long Life / 3-5+ Years application

dependant. Storage Life 1 Year.

Connections

Circular Pluggable IP67 Connector with cable to specified length.

Intrinsically Safe Sensor

Input Connection

Parameters.

voltage Uo DC 12 V

current intensity Io 120 mA

power Po 0.55 W

max. outer inductivity Lo 0 mH

max. outer capacity Co 1.2 μF

Specifications-Mechanical

Dimensions OC-25

100mm High x 50mm Diameter

Dimensions OC-26

75mm High x 55 Diameter (KF40)

Dimensions OC-200

Variable length to order, typically 200mm long x 12mm Diameter probe.

Max. Diameter is 30mm.

Page 25

25 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

Protection Class

IP67 When inserted into process fitting with Connector fitted.

Process Connection

OC-25 =Ntron Sensor base; OC-26 = KF40 Flange, OC-200 = Probe

Holder mechanism or Bushing

Weight

OC-25= 250g; OC-26=150g, OC-200=180g

Environmental

Temperature: -20 to +45-50°C, 10-95% Humidity, no condensation.

Certification/Standards

CE, ATEX 2014/34/EU/ 1180 II 1 GD

EN60079-0:2012 + A11:2013

EN60079-11:2012

ATEX II 1 GD; Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Page 26

26 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

5. Appendices

• SIL O2 Analyser and Sensor Connection Diagrams

• SIL O2 Analyser CE and ATEX Certificates

• Sensor CE and ATEX Certificates

Page 27

27 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

5.1 SIL O2 Analyser and Sensor Connection Diagrams

• E364 SIL O2 with OC-25 Sensor

• E511 SIL O2 with OC-26 Sensor

• E395 SIL O2 with OC-200 ‘Oxyprobe’

Page 28

Gas Measurement

Page 29

Gas Measurement

Page 30

Gas Measurement

Page 31

Gas Measurement

Page 32

Gas Measurement

Page 33

28 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

5.2 SIL O2 Analyser CE and ATEX Certificates

• CE Certificate CETX003

• ATEX Certificate Dekra BVS 13 ATEX E 010

Page 34

Rev. 1.5

25/02/2019 Page 1 of 2

CETX003

En: We declare, under our full responsibility, that we believe the products identified in this declaration,

and to which this declaration relates are in conformity with the requirements of Council Directives:

D: Wir erklären unter unserer vollen Verantwortung, dass wir glauben, dass die Produkte in dieser Erklärung identifiziert, auf die sich diese

Erklärung bezieht, in Übereinstimmung mit den Anforderungen der Richtlinien:

Fr: Nous déclarons, sous notre entière responsabilité, que nous croyons que les produits identifiés dans la présente Déclaration, et à

laquelle se réfère cette déclaration sont conformes aux exigences des directives du Conseil:

Es: Declaramos, bajo nuestra responsabilidad exclusiva, que creemos que los productos identificados en esta declaración, y al cual se

refiere esta declaración son conformes con los requisitos de las Directivas del Consejo:

It: Dichiariamo, sotto la nostra piena responsabilità, che crediamo i prodotti identificati in questa dichiarazione, e al quale questa

dichiarazione si riferisce sono conformi alle prescrizioni delle direttive del Consiglio:

This product meets the specifications according to the following European directives:

Dieses Produkt erfüllt die Spezifikationen nach den folgenden Europäischen Richtlinien:

Ce produit est conforme aux spécifications selon les directives Européennes suivantes:

Este producto cumple con las especificaciones de acuerdo a las siguientes directivas Europeas:

Questo prodotto soddisfa le specifiche in base alle seguenti direttive Europee:

Directive/ Richtlinie/ directive/ directiva/ direttiva 2014/34/EU- Equipment and protective systems intended

for use in potentially explosive atmospheres./Richtlinie 2014/34 / EU Geräte und Schutzsysteme zur bestimmungsgemäßen

Verwendung in explosionsgefährdeten Bereichen/ Directive 2014/34 / EU équipements et systèmes de protection destinés à être utilisés

dans des atmosphères explosibles./ Directiva 2014/34 / UE equipos y sistemas de protección destinados a ser utilizados en atmósferas

potencialmente explosivas./ apparecchiature e sistemi di protezione destinati all'uso in atmosfere potenzialmente esplosive.

Directive/ Richtlinie/ directive/ directiva/ direttiva 2014/30/EU–Electromagnetic

Compatibility/Elektromagnetische Verträglichkeit/Compatibilité électromagnétique/ Compatibilidad

Electromagnética/Compatibilità Elettromagnetica

Directive/ Richtlinie/ directive/ directiva/ direttiva 2011/65/EU and of Council of 8th June 2011 on the

restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS2)(*)

*OJ L 174, 1.7.2011, p.88 & P106 Annex IV 1b exemption./ und vom Rat vom 8. Juni 2011 zur Beschränkung der Verwendung

bestimmter gefährlicher Stoffe in Elektro- und Elektronikgeräten (RoHS2) (*)

ABl. L 174 vom 1.7.2011, S. 88 und P106 Anhang IV 1b Befreiung./ et du Conseil du 8 juin 2011 sur la limitation de l'utilisation de

certaines substances dangereuses dans les équipements électriques et électroniques (RoHS2) (*)

* JO L 174 du 1.7.2011, p.88 et P106 Annexe IV 1b./ y del Consejo de 8 de junio de 2011 sobre la restricción del uso de determinadas

sustancias peligrosas en equipos eléctricos y electrónicos (RoHS2) (*)

* DO L 174 de 1.7.2011, p.88 y P106 Anexo IV 1b exención./ e del Consiglio, dell'8 giugno 2011, sulla restrizione dell'uso di talune

sostanze pericolose nelle apparecchiature elettriche ed elettroniche (RoHS2) (*)

* GU L 174 dell'1.7.2011, pag.88 & P106 Allegato IV, punto 1b.

Description of Equipment/Beschreibung des Gerätes/Description de l'équipement/Descripción de

Equipo/Descrizione delle attrezzature:

SilO2 Oxygen Analyser.

SilO2 Sauerstoff Analyser.

SilO2 Analyseur d'oxygène.

SilO2 Analizador de Oxígeno.

SilO2 analizzatore di ossigeno.

EU Declaration of Conformity/ EG-Konformitätserklärung/ Déclaration de

conformité CE/ Declaración de conformidad CE/ Dichiarazione di conformità

CE.

Page 35

Rev. 1.5

25/02/2019 Page 2 of 2

CETX003

Standards and marking/ Standards und Kennzeichnung/ Normes et marquage/ Normas y marcado/ Norme e

marcatura:

ATEX:

EMC:

EN 60079-0: 2012 + A11: 2013

Explosive atmospheres - Part 0: Equipment - General requirements.

EN 60079-11:2012 Explosive atmospheres - Part 11: Equipment protection by intrinsic

safety “i”.

EN61326-3-2:2008 Electromagnetic compatibility – immunity requirements for safety

related systems and for equipment intended to perform safety related functions in

industrial applications with specified electromagnetic environment.

EN 61000-6-3: 2007 + A1: 2011, Emissions Light Industrial

EN61000-4-2:2009, Electrostatic Discharge

EN61000-4-3: 2006 + A1: 2008 + A2: 2010, Immunity Heavy Industrial

EN61000-4-4:2012, Burst Immunity

EN61000-4-5:2014, Surge Immunity

EN61000-4-6:2014, Conducted Immunity

II (1)G (Ex ia Ga) IIC

II (1)D (Ex ia Da) IIIC

Notified body:

Benannte Stelle:

Organisme notifié:

Organismo notificado:

Organismo notificato:

DEKRA Exam GmbH.

Dinnendahlstrasse 9

44809 Bochum

Germany.

BVS 13 ATEX E 010

The Authorised Signatory to this declaration, on behalf of the manufacturer, is identified below:

Der Prokurist dieser Erklärung im Namen des Herstellers, ist unten angegeben:

Le Signataire autorisé à cette déclaration, le nom du fabricant, est identifié ci-dessous:

El Signatario autorizado a esta declaración, en nombre del fabricante, se identifica a continuación:

Il Firmatario autorizzato a tale dichiarazione, per conto del produttore, viene identificata di seguito:

Name/ Nom/Nombre/Nome:

David Beirne

Title/Position; Titel / Position; Titre / Position; Título / Puesto; Titolo / Ruolo :

Managing Director/Geschäftsführer /Directeur Général/ Director Gerente/Amministratore Delegato

Address/Anschrift/ adresse/ dirección/indirizzo

Ntron Ltd, Mullaghboy Industrial Park, Navan, Co. Meath, Ireland.

Signature Date: 25/02/2019

Standards applied:

Normen:

Normes appliquées:

De normas vigentes:

Norme di riferimento:

Equipment marking:

Kennzeichnung der Anlagen:

Matériel de marquage:

Equipo de marcado

Contrassegno degli impianti:

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

29 | P a g e R e v . 1 .1

I s s u e 3 0 - 11- 2018

5.3 Sensor CE and ATEX Certificates

• CE Certificate SUII01, SUII02

• ATEX Certificate BAS02ATEX1230X-11

Page 47

Document: SUII01 Rev. 15

Description of Equipment:

Beschreibung des Gerätes:

Description du matériel:

Descripción de la máquina:

OC-Type Oxygen Sensors For Use in Hazardous Areas.

Standards applied:

Normes appliquées:

Normas aplicadas:

EN60079-0:2012 + A11:2013

EN60079-11:2012

Marking:

Kennzeichnung:

Marquage:

Marcado:

II II 1 GD Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

Certificate No: BAS02ATEX1230X

(Other markings: IECEx BAS 09.0148X)

Notified Body:

Benannte Stelle:

Organisme notifié:

Organismo notificado:

SGS Baseefa

Rockhead Business Park

Staden Lane, Buxton, Derbyshire,

SK17 9RZ, UK.

Notified Body Number: 1180

The Authorised Signatory to this declaration, on behalf of the manufacturer, is identified below:

Name: David Beirne Title/Titel/ Titre/ título: Managing Director/Geschäftsführer/Directeur-Général/director Gerente

Address/Adresse/ dirección: Ntron Ltd Ph: 00353469071333

Mullaghboy Industrial Estate Fx: 00353469071331

Navan email: info@ntron.com

Co. Meath Web: www.ntron.com

Ireland, C15 XD61

Signature: Date: 12/02/2019

EU Declaration of Conformity

EG-Konformitätserklärung / Déclaration de conformité CE /

Declaración de conformidad CE:

We declare, under our sole responsibility, that we believe the products identified in this declaration, and to which

this declaration relates are in conformity with the requirements of the EU Council Directives as stated below;

Directive 2014/34/EU equipment and protective systems intended for use in potentially explosive atmospheres.

Directive 2011/65/EU and of Council of 8th June 2011 on the restriction of the use of certain hazardous substances

in electrical and electronic equipment (RoHS2)(*)

*OJ L 174, 1.7.2011, p.88 & P106 Annex IV 1b exemption.

Wir erklären in alleiniger Verantwortung, dass wir der Ansicht sind, dass die in dieser Erklärung genannten Produkte, auf die sich diese

Erklärung bezieht, den Anforderungen der unten aufgeführten Richtlinien des EU-Rats entsprechen; Richtlinie 2014/34 / EU Geräte und

Schutzsysteme zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen.Richtlinie 2011/65 / EU und des Rates vom 8. Juni

2011 zur Beschränkung der Verwendung bestimmter gefährlicher Stoffe in Elektro- und Elektronikgeräten (RoHS2) (*)* ABl. L 174 vom

1.7.2011, S. 88 & S. 106 Anhang IV 1b Befreiung.

Nous déclarons, sous notre seule responsabilité, que nous croyons que les produits identifiés dans cette déclaration, et auxquels cette déclaration

se rapporte, sont conformes aux exigences des directives du Conseil de l'UE comme indiqué ci-dessous;Directive 2014/34 / EU équipements et

systèmes de protection destinés à être utilisés dans des atmosphères explosibles.Directive 2011/65 / UE et du Conseil du 8 juin 2011 relative à la

limitation de l'utilisation de certaines substances dangereuses dans les équipements électriques et électroniques (RoHS2) (*) * JO L 174 du

1.7.2011, p.88 et P106 Annexe IV 1b.

Declaramos, bajo nuestra exclusiva responsabilidad, que creemos que los productos identificados en esta declaración, y a los que se refiere esta

declaración, están en conformidad con los requisitos de las Directivas del Consejo de la UE como se establece a continuación; Directiva 2014/34

/ UE equipos y sistemas de protección destinados a ser utilizados en atmósferas potencialmente explosivas. Directiva 2011/65 / UE y del Consejo,

de 8 de junio de 2011, sobre la restricción del uso de determinadas sustancias peligrosas en aparatos eléctricos y electrónicos (RoHS2) (*) * DO

L 174 de 1.7.2011, p.88 y P106 Anexo IV 1b exención.

Page 48

Ntron Ltd, Mullaghboy Ind Est, Navan, Co. Meath, Ireland. Ph: ++353 46 9071333 Fx: ++353 46 9071331 Doc No: SUII01 Rev.15

ENGLISH SENSOR USE/INSTALLATION INSTRUCTIONS To ensure security of personnel, goods and plant it is important that the

national standards laid down for the installation of electrical equipment

are followed, that instructions on the nameplate are achieved, and that

the work is carried out by trained personnel. Furthermore, it is necessary

to use the oxygen sensor in accordance with the advice and data given in

this text.

Oxygen sensors for hazardous areas are especially designed to conform

to national and international standards governing risks of explosion and

certificates for each type are issued by an approved organisation or

notified body. Be careful ! A certification number followed with “X” or a

“U” requires specific conditions for use.

1. Care must be taken when installing equipment with plastic enclosures or

plastic parts of enclosures to ensure that the equipment is protected from

any situations that could cause a build up of static charge. The equipment

must not be installed into locations in which it could come into contact with,

through normal or abnormal circumstances, fast moving dust laden air/gas

or non-conductive fluids. The equipment must be cleaned only with a damp

cloth.

2. When installing equipment with Metal enclosures, earthing of the metal

enclosure must be ensured to avoid the potential of electrostatic discharge. STORAGE

The sensor should be stored in a cool dry place.

HANDLING WARNINGS

Do not expose open end of sensor housing to liquids, particulates,

grease, or oil.

Do not touch top of sensor within open end of sensor housing.

Do not allow vacuum grease to coat open end of sensor.

Do not expose sensor to sudden mechanical shocks.

INSTALLATION & CALIBRATION

Remove the sensor connector plug from the old sensor.

Remove the old sensor by uscrewing counterclock wise or by removing

from housing.

Remove and dispose of the old sealing O-Ring where fitted.

Fit the new sealing O-Ring if required.

Install the replacement sensor threading on clockwise or replacing in

housing.

Fully hand tighten the sensor housing to ensure O-Ring compression.

Re-connect the sensor plug.

Calibrate the analyser to the new sensor.

Note: The system must not be put back on-line until the analyser has

been calibrated to the new sensor. ELECTRICAL CERTIFICATION

Sensor Type’s OC-2, OC-7, OC-16, OC-17, OC-18, OC-19, OC-20,

OC-21, OC-22, OC-23, OC-24, OC-28, OC-28M & OC-47 carry the

following markings. BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:30v, Ii:120mA, Pi: 0.55W, Ci:0, Li:0 Sensor types OC-19, OC-20, OC-25, OC-25M, OC-26, OC-26M carry

the following markings. BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0 Application Note For All Sensor Types:

The Oxygen Sensors may only be used within a -20 to +55 Deg. C

temperature range and will withstand a 500V isolation test between the

input connection and frame of the apparatus. Application Note for OC-25M, OC-26M and OC-28M Sensors.

See Sensor use/Installation Instructions note 2 above. MAINTENANCE

At the end of the sensor’s life, the output of the oxygen cell will fall to zero

in less than a day. If the sensor will no longer re-calibrate, it should be

replaced.

FRENCH INSTALLATION ET UTILISATION DU CAPTEUR Pour assurer la sécurité du personnel, des biens et de l’usine, il est

important de respecter les normes nationales en vigueur pour l’installation

des équipements électriques, de se conformer aux consignes figurant sur

la plaque du constructeur et de confier la réalisation des travaux à un

personnel qualifié. De plus, le capteur d’oxygène doit être utilisé dans le

respect des indications et des données fournies par la présente notice.

Les capteurs d’oxygène pour zones dangereuses sont spécifiquement

conçus pour respecter les normes nationales et internationales

réglementant les risques d’explosion. En outre, des certificats sont

délivrés pour chaque type de capteur par un organisme agréé ou un

organisme notifié. Attention : un numéro de certificat suivi d’un « X » ou

d’un « U » signale que des conditions d’utilisation particulières sont

requises.

1. Des précautions doivent être prises lors de l'installation d'équipements

avec boîtiers en plastique ou les pièces en plastique des boîtiers pour assurer

que le matériel est protégé contre toutes les situations qui pourraient causer

une accumulation de charge statique. L'équipement ne doit pas être installé

dans des endroits où il pourrait entrer en contact avec, dans des

circonstances normales ou anormales, se déplaçant rapidement la poussière

chargée air / gaz ou fluides non-conductrices. L'équipement doit être nettoyé

seulement avec un chiffon humide.

2. Lors de l'installation de l'équipement avec des boîtiers métalliques, la mise

à la terre du boîtier métallique doit être assurée pour éviter le risque de

décharge électrostatique.

STOCKAGE

Stocker le capteur dans un endroit sec et frais.

MISES EN GARDE DE MANIPULATION

Ne pas exposer l’extrémité ouverte du boîtier du capteur aux liquides, aux

particules, à la graisse ou à l’huile.

Ne pas toucher la tête du capteur à travers l’extrémité ouverte du boîtier

du capteur.

Ne pas laisser de graisse à vide recouvrir l’extrémité ouverte du capteur.

Ne pas exposer le capteur à des chocs violents.

INSTALLATION MECANIQUE

Retirez le connecteur du capteur de l'ancien capteur.

Retirer l'ancien capteur en dévissant sens anti-horaire ou par démontage

du carter.

Retirer et jeter le joint torique vieille quand elle existe.

Monter le nouveau joint torique si nécessaire.

Installez le capteur de rechange filetage sur aiguilles d'une montre ou le

remplacement dans le logement.

Entièrement serrer à la main le boîtier du capteur pour assurer joint

torique de compression.

Rebranchez le connecteur du capteur.

Calibrer l'analyseur pour le nouveau capteur CERTIFICATION EN ELECTRICITE

Les capteurs de type OC-2, OC-7, OC-16, OC-17, OC-18, OC-19, OC-

20, OC-21, OC-22, OC-23, OC-24, OC-28, OC-28M & OC-47 portent les

inscriptions suivantes : BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:30v, Ii:120mA, Pi: 0.55W, Ci:0, Li:0 OC-19, OC-20, OC-25, OC-25M, OC-26, OC-26M type de capteur a sur

elle le marquage suivant BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0 Note concernant l’utilisation de tous les types de capteurs :

Les capteurs d’oxygène ne doivent être utilisés que dans un intervalle de

température compris entre –20 et +55 ° C et ils résisteront à un test

d’isolation de 500 V entre la connexion d’entrée et le châssis de

l’appareil.

Note d'application pour les capteurs OC-25M, OC-26M et OC-28M.

Voir la section Utilisation du capteur / Instructions d'installation note 2 ci-

dessus. ENTRETIEN

À la fin de la vie du capteur, le signal de sortie de la cellule à oxygène

tombera à zéro en moins d'une journée. Si le capteur ne se ré-étalonne

plus, il doit être remplacé.

GERMAN BEDIENUNGS- UND INSTALLATIONSANLEITUNG DES SENSORS Um die Sicherheit von Personal, Gütern und Anlage gewährleisten zu

können, ist es wichtig, dass die nationalen Normen für die Installation

elektrischer Geräte befolgt werden, dass die Anweisungen auf dem

Typenschild ausgeführt werden und dass die Arbeit von Fachpersonal

erledigt wird. Des Weiteren ist es erforderlich, den Sauerstoffsensor

gemäß den Hinweisen und Angaben in diesem Text zu verwenden.

Sauerstoffsensoren für Gefahrenbereiche werden so konstruiert, dass sie

nationalen und internationalen Normen entsprechen, um so einer

Explosionsgefahr vorzubeugen, und für jeden Typ werden von einer

anerkannten Organisation oder benannten Stelle Zertifizierungen

ausgestellt. Vorsicht! Bei einer Zertifizierungsnummer mit einem „X“ oder

einem „U“ am Ende sind spezielle Bedingungen für den Gebrauch

erforderlich.

1. Es muss bei der Installation von Geräten mit Kunststoffgehäusen oder

Kunststoffteile von Gehäusen, um sicherzustellen, dass die Anlage von allen

Situationen, die einen Aufbau statischer Ladung verursachen können

geschützt sind. Das Gerät darf nicht in die Orte, an denen könnte es in

Kontakt mit durch normale oder abnormale Umstände zu kommen, sich

schnell bewegende Staub beladene Luft / Gas oder nichtleitende

Flüssigkeiten installiert betragen. Das Gerät darf nur mit einem feuchten

Tuch gereinigt werden.

2. Bei der Installation von Geräten mit Metallgehäusen muss die Erdung des

Metallgehäuses gewährleistet sein, um elektrostatische Entladungen zu

vermeiden. LAGERUNG

Der Sensor sollte kühl und trocken gelagert werden.

WARNHINWEISE

Setzen Sie das offene Ende des Sensorgehäuses nicht Flüssigkeiten,

Schwebstoffen, Fett oder Öl aus.

Berühren Sie nicht die Spitze des Sensors im offenen Ende des

Sensorgehäuses.

Achten Sie darauf, dass kein Vakuumfett das offene Ende des Sensors

überzieht.

Setzen Sie den Sensor keinen plötzlichen mechanischen

Erschütterungen aus.

MECHANISCHE INSTALLATION

Entfernen Sie den Sensor Stecker aus der alten Sensor.

Entfernen Sie den alten Sensor durch Abschrauben Gegenuhrzeigersinn

weise oder durch Entfernen aus dem Gehäuse.

Entfernen und entsorgen Sie die alte Dichtungs-O-Ring, wo angebracht.

Den neuen Dichtungs-O-Ring, falls erforderlich.

Installieren Sie die Ersatz-Sensor Einfädeln im Uhrzeigersinn oder

Austausch im Gehäuse.

Vollständig von Hand anziehen Sensorgehäuse O-Ring Kompression zu

gewährleisten.

Re-connect den Sensor ziehen.

Kalibrieren Sie den Analysator mit dem neuen Sensor. ELEKTRISCHE ZERTIFIZIERUNG

Sensoren des Typs OC-2, OC-7, OC-16, OC-17, OC-18, OC-19, OC-20,

OC-21, OC-22, OC-23, OC-24, OC-28, OC-28M & OC-47 Extract

weisen folgende Beschriftung auf. BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:30v, Ii:120mA, Pi: 0.55W, Ci:0, Li:0 Sensortyp OC-19, OC-20, OC-25, OC-25M, OC-26, OC-26M drauf hat,

die folgenden Kennzeichnungen BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0 Hinweis für alle Sensortypen:

Die Sauerstoffsensoren dürfen nur in einem Temperaturbereich von -20

bis +55 °C verwendet werden und halten einer 500 V-Isolationsprüfung

zwischen Eingangsanschluss und Geräterahmen stand.

Anwendungshinweis für OC-25M, OC-26M und OC-28M Sensoren.

Siehe oben unter Sensorgebrauch / Installationsanleitung, Hinweis 2. WARTUNG

Am Ende der typischen Lebensdauer des Sensors, fällt die Leistung der

Sauerstoffzelle in weniger als einem Tag auf Null ab. Wenn der Sensor

nicht mehr neu kalibriert werden kann, sollte er ausgetauscht werden

SPANISH MANUAL DE USO E INSTALACIÓN DEL SENSOR Con el fin de garantizar la seguridad del personal, de los productos y de

las instalaciones, es importante que se cumplan los estándares

nacionales establecidos para la instalación de equipos eléctricos, que se

sigan las instrucciones que indica la placa y que el trabajo sea llevado a

cabo por personal cualificado. Además, se requiere el uso del sensor de

oxígeno de acuerdo con las instrucciones y la información que aporta

este documento.

Los sensores de oxígeno para áreas peligrosas están especialmente

diseñados para ajustarse a los estándares nacionales e internacionales

que regulan los riesgos de explosión, y los certificados de cada tipo han

sido expedidos por una organización autorizada o un organismo

notificado. Advertencia: Un número de certificación seguido de “X” o “U”

necesita unas condiciones específicas para su uso.

1. Se debe tener cuidado al instalar el equipo con cajas de plástico o las

piezas de plástico de recintos para asegurarse de que el equipo está

protegido de las situaciones que podrían causar una acumulación de carga

estática. El equipo no debe ser instalado en lugares en los que podría entrar

en contacto con, por circunstancias normales o anormales, rápido

movimiento cargado de polvo de aire / gas o fluidos no conductores. El

equipo se debe limpiar con un paño húmedo.

2. Al instalar equipos con gabinetes de metal, la conexión a tierra del

gabinete de metal debe estar asegurada para evitar el potencial de descarga

electrostática. ALMACENAJE

El sensor debe guardarse en un lugar fresco y seco.

ADVERTENCIAS SOBRE EL MANEJO

No exponga el extremo abierto de la caja del sensor a líquidos,

partículas, grasa o aceite.

No toque la parte superior dentro del extremo abierto de la caja del

sensor.

Evite que la grasa de vacío cubra el extremo abierto del sensor.

No exponga el sensor a choques mecánicos bruscos.

INSTALACIÓN MECÁNICA

Retire el tapón del sensor del sensor viejo.

Retire el sensor viejo aflojando en sentido contrario al sabio o eliminando

de la vivienda.

Retire y deseche la junta tórica vieja si las hay.

Coloque la nueva junta tórica si es necesario.

Instale el sensor de repuesto enhebrar las agujas del reloj o en

sustitución de la vivienda.

Totalmente apriete a mano la carcasa del sensor para asegurar la junta

tórica de compresión.

Vuelva a conectar el conector del sensor.

Calibrar el analizador para el nuevo sensor

CERTIFICACIÓN ELÉCTRICA

Los tipos de sensor OC-2, OC-7, OC-16, OC-17, OC-18, OC-19, OC-

20, OC-21, OC-22, OC-23, OC-24, OC-28, OC-28M & OC-47 Extract

presentan las siguientes marcas.

BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:30v, Ii:120mA, Pi: 0.55W, Ci:0, Li:0 Tipo de sensor OC-19, OC-20, OC-25, OC-25M, OC-26, OC-26M tiene

sobre ella las siguientes marcas BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0 Nota de aplicación para todos los tipos de sensor:

Los sensores de oxígeno sólo deben emplearse en un intervalo de

temperaturas entre -20 y +55 ° C y resisten una prueba de aislamiento de

500 V entre la conexión de entrada y el marco del aparato.

Nota de aplicación para los sensores OC-25M, OC-26M y OC-28M.

Vea las instrucciones de uso / instalación del sensor nota 2 arriba. MANTENIMIENTO

Al final de la vida del sensor, la salida de la celda de oxígeno caerá a

cero en menos de un día. Si el sensor ya no volverá a calibrar, se debe

reemplazar.

II 1GD

II 1GD

II 1GD

II 1GD

II 1GD

II 1GD

II 1GD

II 1GD

Page 49

Page 50

Ntron Ltd, Mullaghboy Ind Est, Navan, Co. Meath, Ireland. Ph: ++353 46 9071333 Fx: ++353 46 9071331 Doc No: SUII02 Rev.7

ENGLISH SENSOR USE/INSTALLATION INSTRUCTIONS PRELIMINARY ADVICE

To ensure security of personnel, goods and plant it is important that the

national standards laid down for the installation of electrical equipment

are followed, that instructions on the nameplate are achieved, and that

the work is carried out by trained personnel. Furthermore, it is necessary

to use the oxygen sensor in accordance with the advice and data given in

this text.

Oxygen sensors for hazardous areas are especially designed to conform

to national and international standards governing risks of explosion and

certificates for each type are issued by an approved organisation or

notified body. Be careful ! A certification number followed with “X” or a

“U” requires specific conditions for use.

The Specific Condition of Use for the sensor types listed below is;

Possible Electrostatic Risk-Do not charge by Rubbing and do not

clean with Solvent

STORAGE

The sensor should be stored in a cool dry place. HANDLING WARNINGS

Do not expose open end of sensor housing to liquids, particulates,

grease, or oil.

Do not touch top of sensor within open end of sensor housing.

Do not allow vacuum grease to coat open end of sensor.

Do not expose sensor to sudden mechanical shocks. INSTALLATION & CALIBRATION

Remove the sensor plug from the old sensor.

Remove the old sensor by unscrewing counter clock wise.

Install the replacement sensor threading on clockwise.

Fully tighten the sensor housing.

Re-connect the sensor plug.

Calibrate the analyser to the new sensor. Note: The system must not be put back on-line until the analyser has

been calibrated to the new sensor. ELECTRICAL CERTIFICATION Sensor Type’s OxyProbe

200

Sensor Probe carry the following markings.

OXYGEN SENSOR

BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0

Application Note For All Sensor Types:

The Oxygen Sensors must only be used within the temperature range

quoted in the certification details, and will withstand a 500V isolation test

between the input connection and frame of the apparatus.

MAINTENANCE

If the sensor will no longer re-calibrate, it should be replaced. It is

recommended that sensors be replaced after 36 months.

FRENCH INSTALLATION ET UTILISATION DU CAPTEUR INDICATIONS PRELIMINAIRES

Pour assurer la sécurité du personnel, des biens et de l’usine, il est

important de respecter les normes nationales en vigueur pour l’installation

des équipements électriques, de se conformer aux consignes figurant sur

la plaque du constructeur et de confier la réalisation des travaux à un

personnel qualifié. De plus, le capteur d’oxygène doit être utilisé dans le

respect des indications et des données fournies par la présente notice.

Les capteurs d’oxygène pour zones dangereuses sont spécifiquement

conçus pour respecter les normes nationales et internationales

réglementant les risques d’explosion. En outre, des certificats sont

délivrés pour chaque type de capteur par un organisme agréé ou un

organisme notifié. Attention : un numéro de certificat suivi d’un « X » ou

d’un « U » signale que des conditions d’utilisation particulières sont

requises.

Les conditions spécifiques d'utilisation pour les types de capteurs sont

énumérés ci-dessous;

Possibles risques électrostatiques Ne pas charger par frottement et

ne pas nettoyer avec des solvants.

STOCKAGE

Stocker le capteur dans un endroit sec et frais. MISES EN GARDE DE MANIPULATION

Ne pas exposer l’extrémité ouverte du boîtier du capteur aux liquides, aux

particules, à la graisse ou à l’huile.

Ne pas toucher la tête du capteur à travers l’extrémité ouverte du boîtier

du capteur.

Ne pas laisser de graisse à vide recouvrir l’extrémité ouverte du capteur.

Ne pas exposer le capteur à des chocs violents. INSTALLATION MECANIQUE

Débrancher la prise du capteur de l’ancien capteur.

Retirer l’ancien capteur en dévissant dans le sens inverse des aiguilles

d’une montre.

Poser le capteur de remplacement en vissant dans le sens des aiguilles

d’une montre.

Serrer Complètement à fond le boîtier du capteur.

Rebrancher la prise du capteur. CERTIFICATION EN ELECTRICITE

Les capteurs de type OxyProbe

200

Sensor Probeportent les inscriptions

suivantes :

OXYGEN SENSOR

BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0 Note concernant l’utilisation de tous les types de capteurs :

Les capteurs d'oxygène doivent être utilisés uniquement dans la plage de

température indiquée dans les détails de la certification, et ils résisteront

à un test d’isolation de 500 V entre la connexion d’entrée et le châssis de

l’appareil. ENTRETIEN

Si le capteur ne sera plus recalibrer, il doit être remplacé. Il est

recommandé que les capteurs être remplacés après 36 mois..

GERMAN BEDIENUNGS- UND INSTALLATIONSANLEITUNG DES SENSORS VORABHINWEIS

Um die Sicherheit von Personal, Gütern und Anlage gewährleisten zu

können, ist es wichtig, dass die nationalen Normen für die Installation

elektrischer Geräte befolgt werden, dass die Anweisungen auf dem

Typenschild ausgeführt werden und dass die Arbeit von Fachpersonal

erledigt wird. Des Weiteren ist es erforderlich, den Sauerstoffsensor

gemäß den Hinweisen und Angaben in diesem Text zu verwenden.

Sauerstoffsensoren für Gefahrenbereiche werden so konstruiert, dass sie

nationalen und internationalen Normen entsprechen, um so einer

Explosionsgefahr vorzubeugen, und für jeden Typ werden von einer

anerkannten Organisation oder benannten Stelle Zertifizierungen

ausgestellt. Vorsicht! Bei einer Zertifizierungsnummer mit einem „X“ oder

einem „U“ am Ende sind spezielle Bedingungen für den Gebrauch

erforderlich.

Die spezifische Voraussetzung für die Nutzung der Sensor unten

angegebenen Typen ist: möglicher elektrostatischer Risk-Laden Sie

nicht durch Reiben und nicht mit Lösungsmittel reinigen. LAGERUNG

Der Sensor sollte kühl und trocken gelagert werden. WARNHINWEISE

Setzen Sie das offene Ende des Sensorgehäuses nicht Flüssigkeiten,

Schwebstoffen, Fett oder Öl aus.

Berühren Sie nicht die Spitze des Sensors im offenen Ende des

Sensorgehäuses.

Achten Sie darauf, dass kein Vakuumfett das offene Ende des Sensors

überzieht.

Setzen Sie den Sensor keinen plötzlichen mechanischen

Erschütterungen aus. MECHANISCHE INSTALLATION

Ziehen Sie den Stecker vom alten Sensor aus.

Entfernen Sie den alten Sensor, indem Sie ihn entgegen dem

Uhrzeigersinn losschrauben.

Installieren Sie den Austauschsensor, indem Sie ihn im Uhrzeigersinn

eindrehen.

Ziehen Sie den Sensor Fall in vollem Umfang.

Schließen Sie den Stecker des Sensors wieder an. ELEKTRISCHE ZERTIFIZIERUNG

Sensoren des Typs OxyProbe

200

Sensor Probe weisen folgende

Beschriftung auf.

OXYGEN SENSOR

BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0

Hinweis für alle Sensortypen:

Die Sauerstoffsensoren dürfen nur im Temperaturbereich in den

Zertifizierungsangaben zitiert eingesetzt werden, und halten einer 500 V-

Isolationsprüfung zwischen Eingangsanschluss und Geräterahmen stand. WARTUNG

Wenn der Sensor nicht mehr neu zu kalibrieren, sollte sie ausgewechselt

werden. Es wird empfohlen, Sensoren nach 36 Monaten ausgetauscht

werden..

SPANISH

MANUAL DE USO E INSTALACIÓN DEL SENSOR INSTRUCCIONES PRELIMINARES

Con el fin de garantizar la seguridad del personal, de los productos y de

las instalaciones, es importante que se cumplan los estándares

nacionales establecidos para la instalación de equipos eléctricos, que se

sigan las instrucciones que indica la placa y que el trabajo sea llevado a

cabo por personal cualificado. Además, se requiere el uso del sensor de

oxígeno de acuerdo con las instrucciones y la información que aporta

este documento.

Los sensores de oxígeno para áreas peligrosas están especialmente

diseñados para ajustarse a los estándares nacionales e internacionales

que regulan los riesgos de explosión, y los certificados de cada tipo han

sido expedidos por una organización autorizada o un organismo

notificado. Advertencia: Un número de certificación seguido de “X” o “U”

necesita unas condiciones específicas para su uso.

Las condiciones específicas de uso de los tipos de sensores se

enumeran a continuación: Posible riesgo electrostático-No cobran

por frotamiento y no limpiar con solvente. ALMACENAJE

El sensor debe guardarse en un lugar fresco y seco. ADVERTENCIAS SOBRE EL MANEJO

No exponga el extremo abierto de la caja del sensor a líquidos,

partículas, grasa o aceite.

No toque la parte superior dentro del extremo abierto de la caja del

sensor.

Evite que la grasa de vacío cubra el extremo abierto del sensor.

No exponga el sensor a choques mecánicos bruscos. INSTALACIÓN MECÁNICA

Retire el enchufe del sensor antiguo.

Reitre el sensor antiguo destornillando en sentido contrario al de las

agujas del reloj.

Instale el sensor sustituto enroscándolo en el sentido de las agujas del

reloj.

Apriete por completo, thesensor caja.

Vuelva a conectar el enchufe del sensor. CERTIFICACIÓN ELÉCTRICA

Los tipos de sensor OxyProbe

200

Sensor Probe presentan las siguientes

marcas.

OXYGEN SENSOR

BAS02ATEX1230X

Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Ui:12v, Ii:120mA, Pi: 0.55W, Ci:1.2uf, Li:0

Nota de aplicación para todos los tipos de sensor:

Los sensores de oxígeno sólo deben utilizarse dentro del rango de

temperatura citado en los detalles de certificación, y resisten una prueba

de aislamiento de 500 V entre la conexión de entrada y el marco del

aparato. MANTENIMIENTO

Si el sensor ya no se volverá a calibrar, debe ser reemplazado. Se

recomienda que los sensores pueden reemplazar después

de 36 meses

II 1GD

II 1GD

II 1GD

II 1GD

Page 51

Document: SUII02 Rev.7

Description of Equipment:

Beschreibung des Gerätes:

Description du matériel:

Descripción de la máquina:

OxyProbe200 - Oxygen Sensors For Use in Hazardous Areas.

OxyProbe200 - Sauerstoff-Sensoren für den Einsatz in

explosionsgefährdeten Bereichen/OxyProbe200 - capteurs d'oxygène pour

une utilisation dans des zones dangereuses/ OxyProbe200 - Los sensores de

oxígeno para su uso en áreas peligrosas.

Standards applied:

Normes appliquées:

Normas aplicadas:

EN60079-0:2012 + A11:2013

EN60079-11:2012

Marking:

Kennzeichnung:

Marquage:

Marcado:

II II 1 GD Ex ia IIC T6 Ga(-20°C≤Ta≤+55°C)

Ex ia IIIC T90°C Da( -20°C≤Ta≤+55°C)

IECEx BAS 09.0148X

Certificate No: BAS02ATEX1230X

Notified Body:

Benannte Stelle:

Organisme notifié:

Organismo notificado:

SGS Baseefa

Rockhead Business Park

Staden Lane, Buxton, Derbyshire,

SK17 9RZ, UK.

Number/Anzahl/nombre/número: 1180

The Authorised Signatory to this declaration, on behalf of the manufacturer, is identified below:

Der Prokurist dieser Erklärung im Namen des Herstellers, ist unten angegeben:

Le signataire autorisé à cette déclaration, le nom du fabricant, est identifié ci-dessous:

El signatario autorizado a esta declaración, en nombre del fabricante, se identifica a continuación:

Name: David Beirne Title/Titel/ Titre/ título: Managing Director/Geschäftsführer/ Directeur-

Général/ director Gerente

Address/Adresse/ dirección: Ntron Limited

Mullaghboy Industrial Estate

Navan

Co. Meath

Ireland, C15 XD61

Signature: Date: 25/02/2019

EU Declaration of Conformity

EG-Konformitätserklärung / Déclaration de conformité CE /

Declaración de conformidad CE:

We declare, under our sole responsibility, that we believe the products identified in this declaration, and to which this

declaration relates are in conformity with the requirements of the EU Council Directives as stated below;

Directive 2014/34/EU equipment and protective systems intended for use in potentially explosive atmospheres.

Directive 2011/65/EU and of Council of 8th June 2011 on the restriction of the use of certain hazardous substances in

electrical and electronic equipment (RoHS2)(*)

*OJ L 174, 1.7.2011, p.88 & P106 Annex IV 1b exemption.

Wir erklären in alleiniger Verantwortung, dass wir der Ansicht sind, dass die in dieser Erklärung genannten Produkte, auf die sich diese Erklärung

bezieht, den Anforderungen der unten aufgeführten Richtlinien des EU-Rats entsprechen; Richtlinie 2014/34 / EU Geräte und Schutzsysteme zur

bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen.Richtlinie 2011/65 / EU und des Rates vom 8. Juni 2011 zur Beschränkung

der Verwendung bestimmter gefährlicher Stoffe in Elektro- und Elektronikgeräten (RoHS2) (*)* ABl. L 174 vom 1.7.2011, S. 88 & S. 106 Anhang

IV 1b Befreiung.

Nous déclarons, sous notre seule responsabilité, que nous croyons que les produits identifiés dans cette déclaration, et auxquels cette déclaration se

rapporte, sont conformes aux exigences des directives du Conseil de l'UE comme indiqué ci-dessous;Directive 2014/34 / EU équipements et

systèmes de protection destinés à être utilisés dans des atmosphères explosibles.Directive 2011/65 / UE et du Conseil du 8 juin 2011 relative à la

limitation de l'utilisation de certaines substances dangereuses dans les équipements électriques et électroniques (RoHS2) (*) * JO L 174 du 1.7.2011,

p.88 et P106 Annexe IV 1b.

Declaramos, bajo nuestra exclusiva responsabilidad, que creemos que los productos identificados en esta declaración, y a los que se refiere esta