LM3100

SIMPLE SWITCHER

®

Synchronous 1MHz 1.5A

Step-Down Voltage Regulator

LM3100 SIMPLE SWITCHER

February 2006

General Description

The LM3100 Synchronously Rectified Buck Converter features all functions needed to implement a highly efficient,

cost effective buck regulator capable of supplying 1.5A to

loads with voltages as low as 0.8V. Dual 40V N-Channel

synchronous MOSFET switches allow for low external component thus reducing complexity and minimizing board

space. The LM3100 is designed to work exceptionally well

with ceramic and other very low ESR output capacitors. The

Constant ON-Time (COT) regulation scheme requires no

loop compensation, results in fast load transient response,

and simplifies circuit implementation. Through the use of a

unique design the regulator does not rely on output capacitor

ESR for stability, as do most other COT regulators. The

operating frequency remains nearly constant with line and

load variations due to the inverse relationship between the

input voltage and the on-time. The oprating frequency can

be externally programmed up to 1MHz. Protection features

include V

gate drive under-voltage lockout. The part is available in a

thermally enhanced eTSSOP-20 package

under-voltage lockout, thermal shutdown and

CC

Features

n Input voltage range 4.5V - 36V

n 1.5A output current

n 0.8V,

n Integrated 40V, dual N-Channel buck synchronous

n Low component count and small solution size

n No loop compensation required

n Ultra-fast transient response

n Stable with ceramic and other low ESR capacitors

n Programmable switching frequency up to 1MHz

n Max. duty cycle limited during start-up

n Valley current limit

n Precision Internal Reference for adjustable output

n Thermal shutdown

n Thermally enhanced eTSSOP-20 package

±

1.5% reference

switches

voltage down to 0.8V

Typical Applications

n 5VDC, 12VDC, 24VDC, 12VAC, and 24VAC systems

n Embedded Systems

n Industrial Controls

n Automotive Telematics and Body Electronics

n Point of Load Regulators

n Storage Systems

n Broadband Infrastructure

n Direct Conversion from 2/3/4 Cell Lithium Batteries

Systems

®

Synchronous 1MHz 1.5A Step-Down Voltage Regulator

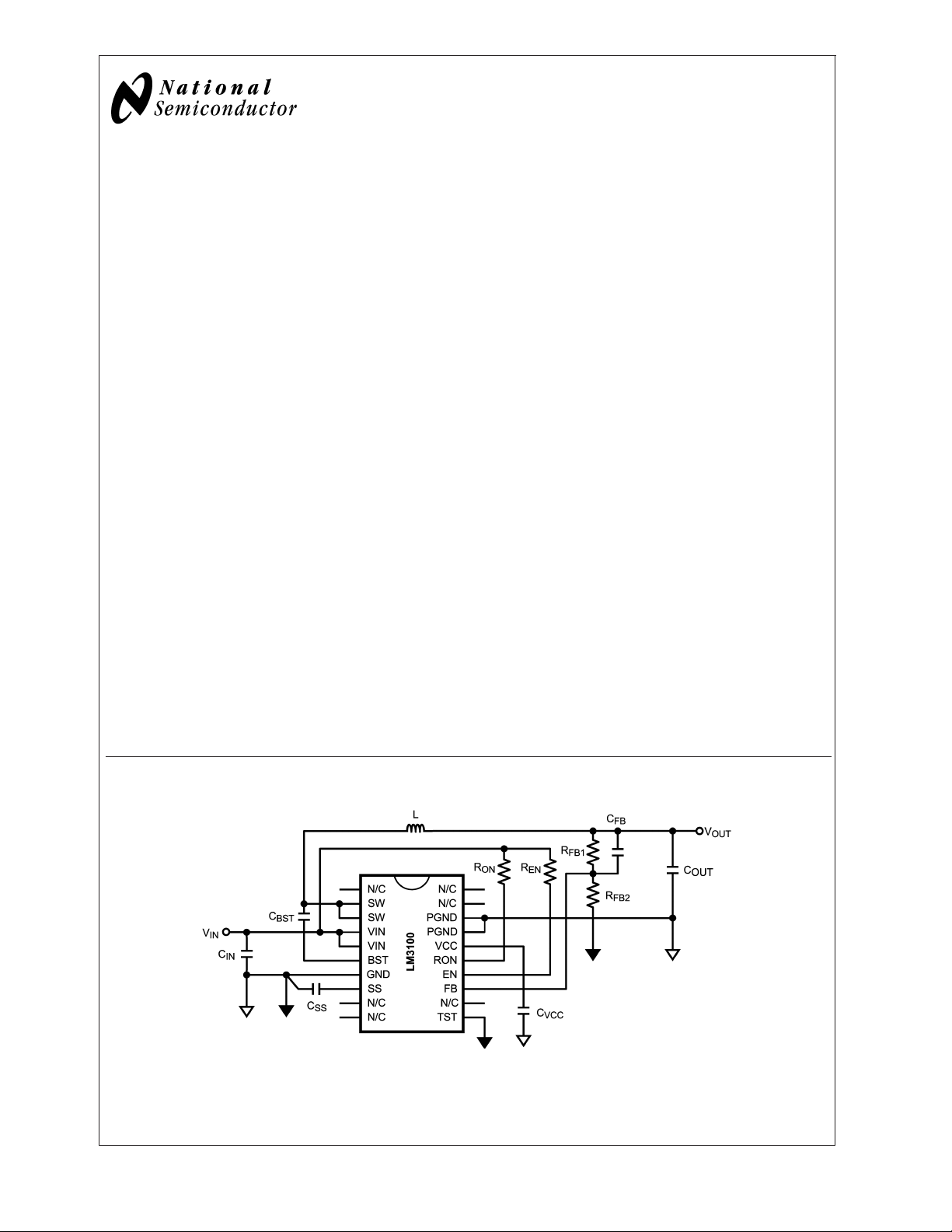

Typical Application

20174702

SIMPLE SWITCHER®is a registered trademark of National Semiconductor Corporation

© 2006 National Semiconductor Corporation DS201747 www.national.com

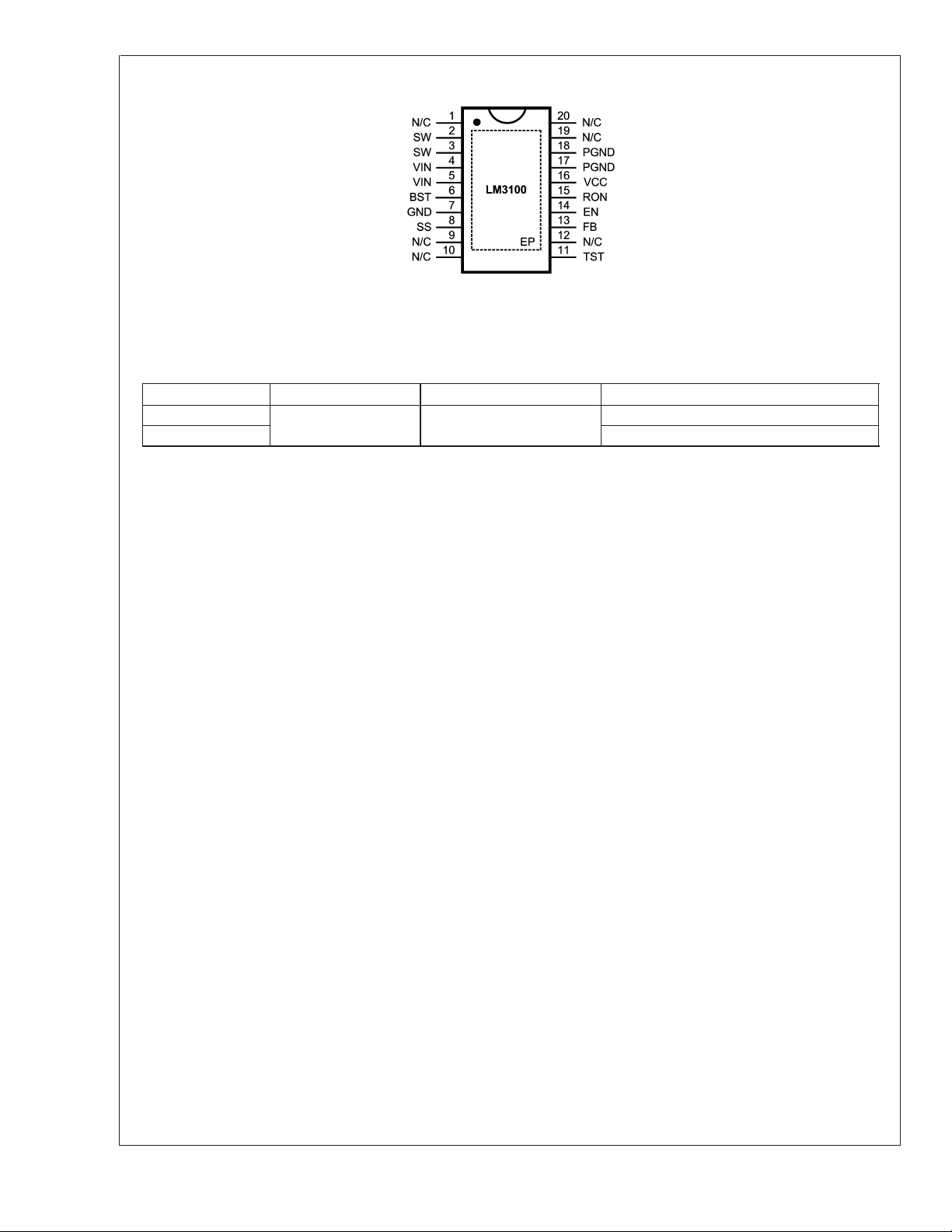

Connection Diagram

LM3100

20-lead Plastic

eTSSOP (MXA20A)

20174703

Ordering Information

Order Number Package Type NSC Package Drawing Supplied As

LM3100MH Exposed Pad

LM3100MHX 2500 Units on Tape and Reel

TSSOP-20

MXA0020 73 units per Anti-Static Tube

www.national.com 2

Pin Descriptions

Pin Name Description Application Information

1,9,10,12,19,20 N/C No Connection These pins must be left unconnected.

2, 3 SW Switching Node Internally connected to the buck switch source.

Connect to output inductor.

4, 5 VIN Input supply voltage Supply pin to the device. Nominal input range is

4.5V to 36V.

6 BST Connection for bootstrap capacitor Connect a 0.033µF capacitor from SW pin to this

pin. An internal diode charges the capacitor during

the high-side switch off-time.

7 GND Analog Ground Ground for all internal circuitry other than the

synchronous switches.

8 SS Soft-start An internal 8µA current source charges an external

capacitor to provide the soft- start function.

11 TST Test mode enable pin Force the device into test mode. Must be connected

to ground for normal operation.

13 FB Feedback Internally connected to the regulation and

over-voltage comparators. The regulation setting is

0.8V at this pin. Connect to feedback divider.

14 EN Enable pin Connect a voltage higher than 1.26V to enable the

regulator.

15 RON On-time Control An external resistor from VIN to this pin sets the

high-side switch on-time.

16 VCC Start-up regulator Output Nominally regulated to 6V. Connect a capacitor of

not less than 680nF between VCC and GND for

stable operation.

17, 18 PGND Power Ground Synchronous rectifier MOSFET source connection.

Tie to power ground plane.

DAP EP Exposed Pad Thermal connection pad, connect to GND.

LM3100

www.national.com3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

LM3100

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN, RON to GND -0.3V to 40V

SW to GND -0.3V to 40V

SW to GND (Transient) -2V (

VIN to SW -0.3V to 40V

BST to SW -0.3V to 7V

All Other Inputs to GND -0.3V to 7V

<

100ns)

ESD Rating (Note 2)

Human Body Model

±

2kV

Storage Temperature Range -65˚C to +150˚C

Junction Temperature (T

) 150˚C

J

Operating Ratings (Note 1)

Supply Voltage Range (VIN) 4.5V to 36V

Junction Temperature Range (T

Thermal Resistance (θ

) (Note 3) 6.5˚C/W

JC

) −40˚C to + 125˚C

J

Electrical Charateristics Specifications with standard type are for T

ply over the full Operating Junction Temperature (T

sign, or statistical correlation. Typical values represent the most likely parametric norm at T

erence purposes only. Unless otherwise stated the following conditions apply: V

) range. Minimum and Maximum limits are guaranteed through test, de-

J

= 25˚C only; limits in boldface type ap-

J

= 25˚C, and are provided for ref-

= 18V, V

IN

J

OUT

= 3.3V.

Symbol Parameter Conditions Min Typ Max Units

Start-Up Regulator, V

V

CC

V

IN-VCC

I

VCCL

V

CC-UVLO

CC

VCCoutput voltage CCC= 680nF, no load 5.0 6.0 7.2 V

VIN-VCCdropout voltage ICC= 2mA 50 140 mV

I

= 20mA 350 570

CC

VCCcurrent limit (Note 4) VCC=0V 40 65 mA

VCCunder-voltage lockout threshold

VINincreasing 3.6 3.75 3.85 V

(UVLO)

V

CC-UVLO-HYS

t

VCC-UVLO-D

I

IN

I

IN-SD

VCCUVLO hysteresis VINdecreasing 130 mV

VCCUVLO filter delay 3 µs

IINoperating current No switching, VFB= 1V 0.7 1 mA

IINoperating current, Device shutdown VEN=0V 17 30 µA

Switching Characteristics

R

DS-UP-ON

R

DS- DN-ON

V

G-UVLO

Main MOSFET Rds(on) 0.18 0.35 Ω

Syn. MOSFET Rds(on) 0.11 0.2 Ω

Gate drive voltage UVLO V

BST-VSW

increasing 3.3 4 V

Soft-start

I

SS

SS pin source current VSS= 0.5V 6 8 9.8 µA

Current Limit

I

CL

Syn. MOSFET current limit threshold 1.9 A

ON/OFF Timer

t

ON

t

ON-MIN

t

OFF

ON timer pulse width VIN= 10V, RON= 100 kΩ 1.38 µs

V

= 30V, RON= 100 kΩ 0.47

IN

ON timer minimum pulse width 200 ns

OFF timer pulse width 260 ns

Enable Input

V

EN-HYS

V

EN

EN Pin input threshold VENrising 1.236 1.26 1.285 V

Enable threshold hysteresis VENfalling 90 mV

Regulation and Over-Voltage Comparator

V

V

FB

FB-OV

I

FB

In-regulation feedback voltage VSS≥ 0.8V

= −40˚C to + 125˚C

T

J

V

≥ 0.8V

SS

= 0˚C to + 125˚C

T

J

Feedback over-voltage threshold 0.894 0.920 0.940 V

0.784 0.8 0.816 V

0.788 0.812

5 100 nA

Thermal Shutdown

T

SD

Thermal shutdown temperature TJrising 165 ˚C

www.national.com 4

LM3100

Electrical Charateristics Specifications with standard type are for T

over the full Operating Junction Temperature (T

statistical correlation. Typical values represent the most likely parametric norm at T

purposes only. Unless otherwise stated the following conditions apply: V

) range. Minimum and Maximum limits are guaranteed through test, design, or

J

= 18V, V

IN

= 25˚C only; limits in boldface type apply

J

= 25˚C, and are provided for reference

J

= 3.3V. (Continued)

OUT

Symbol Parameter Conditions Min Typ Max Units

T

SD-HYS

Thermal shutdown temperature

TJfalling 20 ˚C

hysteresis

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the device

is intended to be functional. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin.

Note 3: θ

@

60˚C.

Note 4: V

measurements are performed in general accordance with Mil-Std 883B, Method 1012.1 and utilizes the copper heat sink technique. Copper Heat Sink

JC

provides self bias for the internal gate drive and control circuits. Device thermal limitations limit external loading.

CC

www.national.com5

Typical Performance Characteristics All curves taken at V

plication circuit for V

LM3100

Quiescent Current, I

= 3.3V shown in this datasheet. TA= 25˚C, unless otherwise specified.

OUT

vs V

IN

IN

20174718 20174719

VCCvs V

IN

= 18V with configuration in typical ap-

IN

VCCvs I

TONvs V

CC

IN

20174720 20174721

Switching Frequency, FSWvs V

IN

20174722

www.national.com 6

VFBvs Temperature

20174723

LM3100

Typical Performance Characteristics All curves taken at V

application circuit for V

R

V

Regulation vs Load Current

OUT

= 3.3V shown in this datasheet. TA= 25˚C, unless otherwise specified. (Continued)

OUT

vs Temperature

DS(ON)

20174724

= 3.3V)

(V

OUT

= 18V with configuration in typical

IN

Efficiency vs Load Current

(V

= 3.3V)

OUT

Efficiency vs Load Current

(V

= 0.8V)

OUT

20174725

V

Regulation vs Load Current

OUT

(V

OUT

= 0.8V)

20174726 20174727

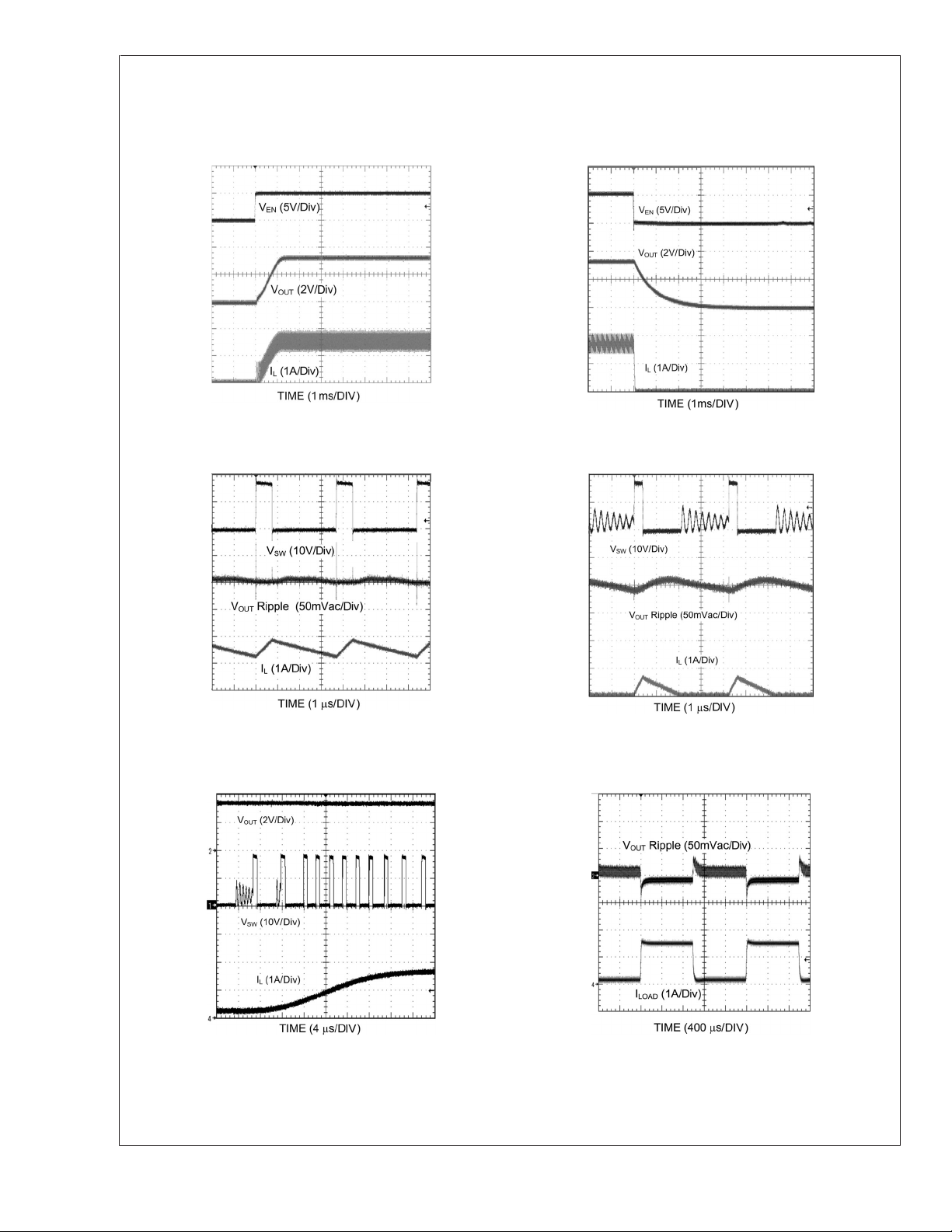

Power Up

(V

= 3.3V, 1.5A Loaded)

OUT

20174729

20174728

www.national.com7

Typical Performance Characteristics All curves taken at V

application circuit for V

LM3100

(V

OUT

= 3.3V shown in this datasheet. TA= 25˚C, unless otherwise specified. (Continued)

OUT

Enable Transient

= 3.3V, 1.5A Loaded)

= 18V with configuration in typical

IN

Shutdown Transient

(V

= 3.3V, 1.5A Loaded)

OUT

Continuous Mode Operation

= 3.3V, 1.5A Loaded)

(V

OUT

CCM to DCM Transition

= 3.3V, 0.15A - 1.5A Load)

(V

OUT

20174730

20174732

Discontinuous Mode Operation

(V

= 3.3V, 1.5A Loaded)

OUT

Load Transient

(V

= 3.3V, 0.15A - 1.5A Load, Current slew-rate:

OUT

2.5A/µs)

20174731

20174733

20174734

www.national.com 8

20174735

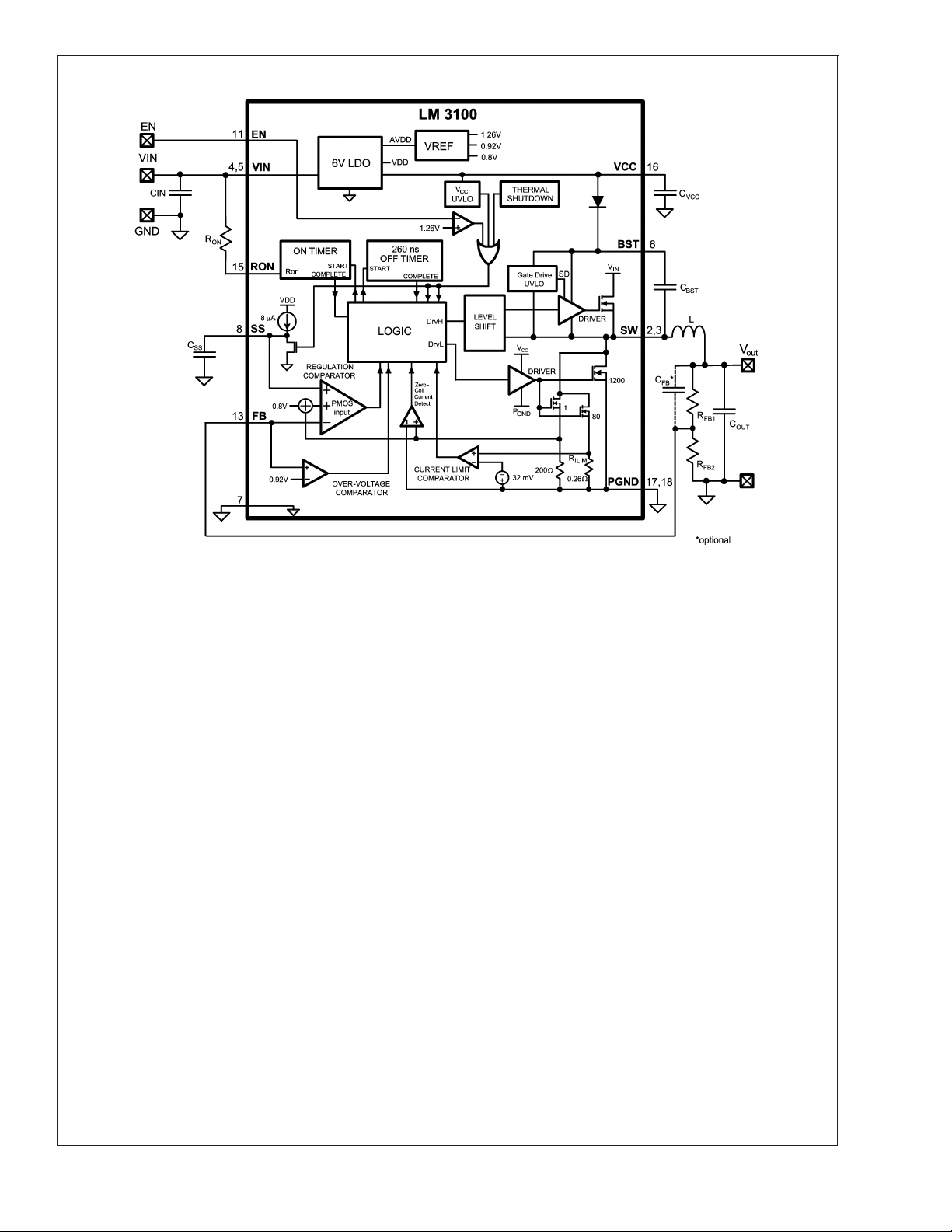

Simplified Functional Block Diagram

LM3100

20174701

www.national.com9

Functional Description

The LM3100 Step Down Switching Regulator features all

LM3100

functions needed to implement a cost effective, efficient buck

power converter capable of supplying 1.5A to a load. This

voltage regulator contains Dual 40V N-Channel buck synchronous switches and is available in a thermally enhanced

eTSSOP-20 package. The Constant ON-Time (COT) regulation scheme requires no loop compensation, results in fast

load transient response, and simplifies circuit implementation. It will work correctly even with an all ceramic output

capacitor network and does not rely on the output capacitor’s

ESR for stability. The operating frequency remains constant

with line and load variations due to the inverse relationship

between the input voltage and the on-time. The valley current limit detection circuit, internally set at 1.9A, inhibits the

high-side switch until the inductor current level subsides.

Please refer to the functional block diagram with a typical

application circuit.

The LM3100 can be applied in numerous applications and

can operate efficiently from inputs as high as 36V. Protection

features include: Thermal shutdown, V

CC

lockout, gate drive under-voltage lockout.

Hysteretic Control Circuit Overview

The LM3100 buck DC-DC regulator employs a control

scheme in which the high-side switch on-time varies inversely with the line voltage (V

comparator and the one-shot on-timer, with the output voltage feedback (FB) compared with an internal reference of

0.8V. If the FB level is below the reference the buck switch is

turned on for a fixed time determined by the input voltage

and a programming resistor (R

the switch remains off for a minimum of 260ns. If FB is below

the reference at that time the switch turns on again for

another on-time period. The switching will continue until

regulation is achieved.

The regulator will operate in discontinuous conduction mode

at light load currents, and continuous conduction mode with

heavy load current. In discontinuous conduction mode

(DCM), current through the output inductor starts at zero and

ramps up to a peak during the on-time, then ramps back to

zero before the end of the off-time. The next on-time period

starts when the voltage at FB falls below the internal reference. Until then the inductor current remains zero and the

load is supplied entirely by the output capacitor. In this mode

the operating frequency is lower than in continuous conduction mode, and varies with load current. Conversion efficiency is maintained since the switching losses are reduced

with the reduction in load and switching frequency. The

discontinuous operating frequency can be calculated approximately as follows:

). Control is based on a

IN

). Following the on-time,

ON

under-voltage

(2)

The output voltage is set by two external resistors (R

). The regulated output voltage is calculated as follows:

R

FB2

V

=0.8Vx(R

OUT

FB1+RFB2

)/R

FB2

FB1

(3)

Start-up Regulator (VCC)

The start-up regulator is integrated within LM3100. The input

pin (VIN) can be connected directly to line voltage up to 36V,

with transient capability to 40V. The V

output regulates at

CC

6V, and is current limited to 65 mA. Upon power up, the

regulator sources current into the external capacitor at V

(C

VCC

). C

must be at least 680nF for stability. When the

VCC

CC

voltage on the VCC pin reaches the under-voltage lockout

threshold of 3.75V, the buck switch is enabled and the

Soft-start pin is released to allow the soft-start capacitor

) to charge.

(C

SS

The minimum input voltage is determined by the dropout

voltage of V

V). If VIN is less than )4.0V, the V

, and the VCCUVLO falling threshold ()3.7

CC

UVLO activates to shut

CC

off the output.

Regulation Comparator

The feedback voltage at FB is compared to the internal

reference voltage of 0.8V. In normal operation (the output

voltage is regulated), an on-time period is initiated when the

voltage at FB falls below 0.8V. The buck switch stays on for

the on-time, causing the FB voltage to rise above 0.8V. After

the on-time period, the buck switch stays off until the FB

voltage falls below 0.8V. Bias current at the FB pin is nominally 100 nA.

Over-Voltage Comparator

The voltage at FB is compared to an internal 0.92V reference. If the voltage at FB rises above 0.92V the on-time

pulse is immediately terminated. This condition can occur if

the input voltage, or the output load, changes suddenly.

Once the OVP is activated, the buck switch remains off until

the voltage at FB pin falls below 0.92V. The low side switch

will stay on to discharge the inductor energy and until the

inductor current decays to zero. The low side switch will be

turned off.

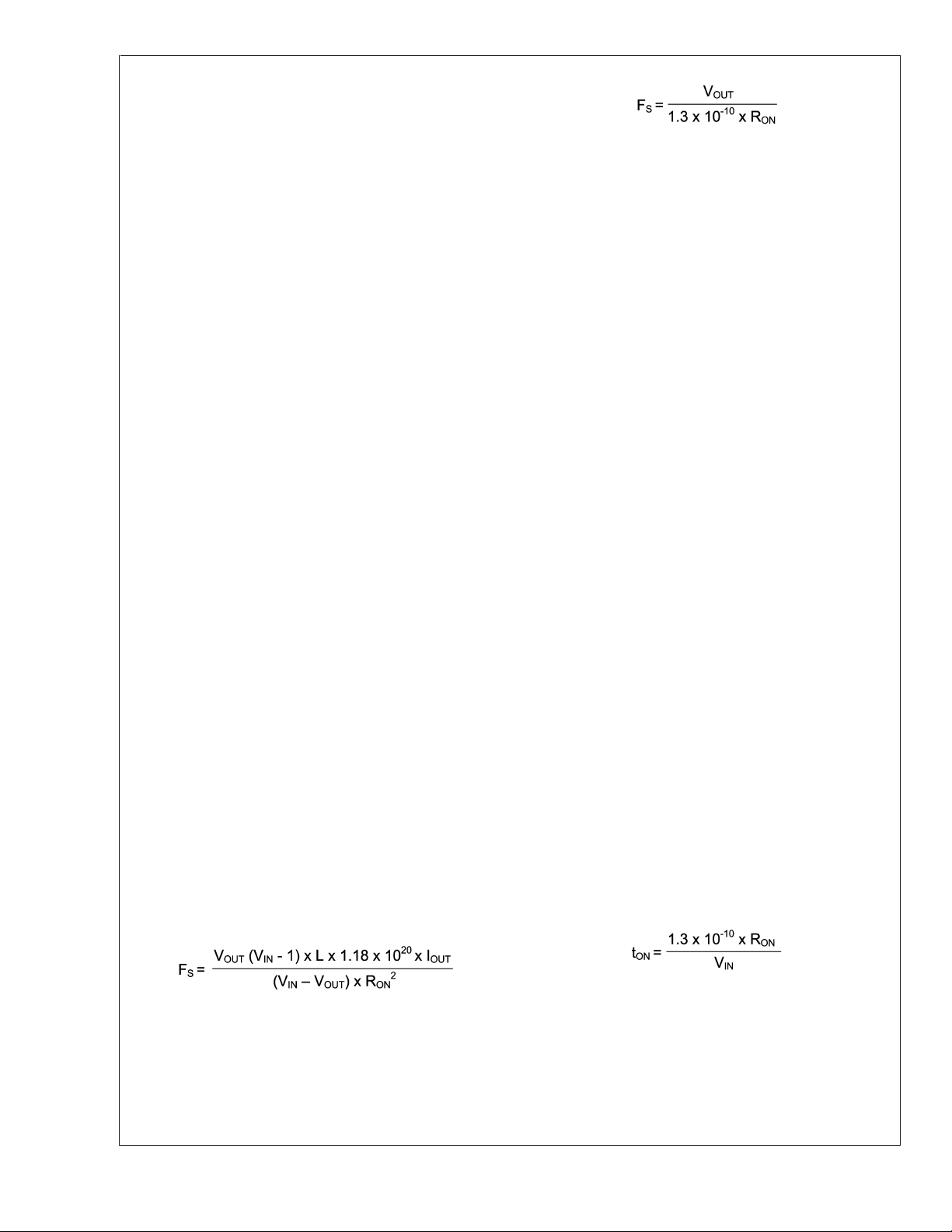

ON-Time Timer, Shutdown

The LM3100 main switch is determined by the RONresistor

and the input voltage (V

), and is calculated from:

IN

,

(1)

where R

= the load resistance

L

In continuous conduction mode (CCM), current always flows

through the inductor and never reaches zero during the

off-time. In this mode, the operating frequency remains relatively constant with load and line variations. The CCM operating frequency can be calculated approximately as follows:

www.national.com 10

(4)

The inverse relationship with VIN results in a nearly constant

frequency as V

minimum on-time (at maximum V

is varied. RONshould be selected for a

IN

) greater than 200 ns for

IN

proper current limit operation. This requirement limits the

maximum frequency for each application, depending on V

and V

, calculated from the following:

OUT

IN

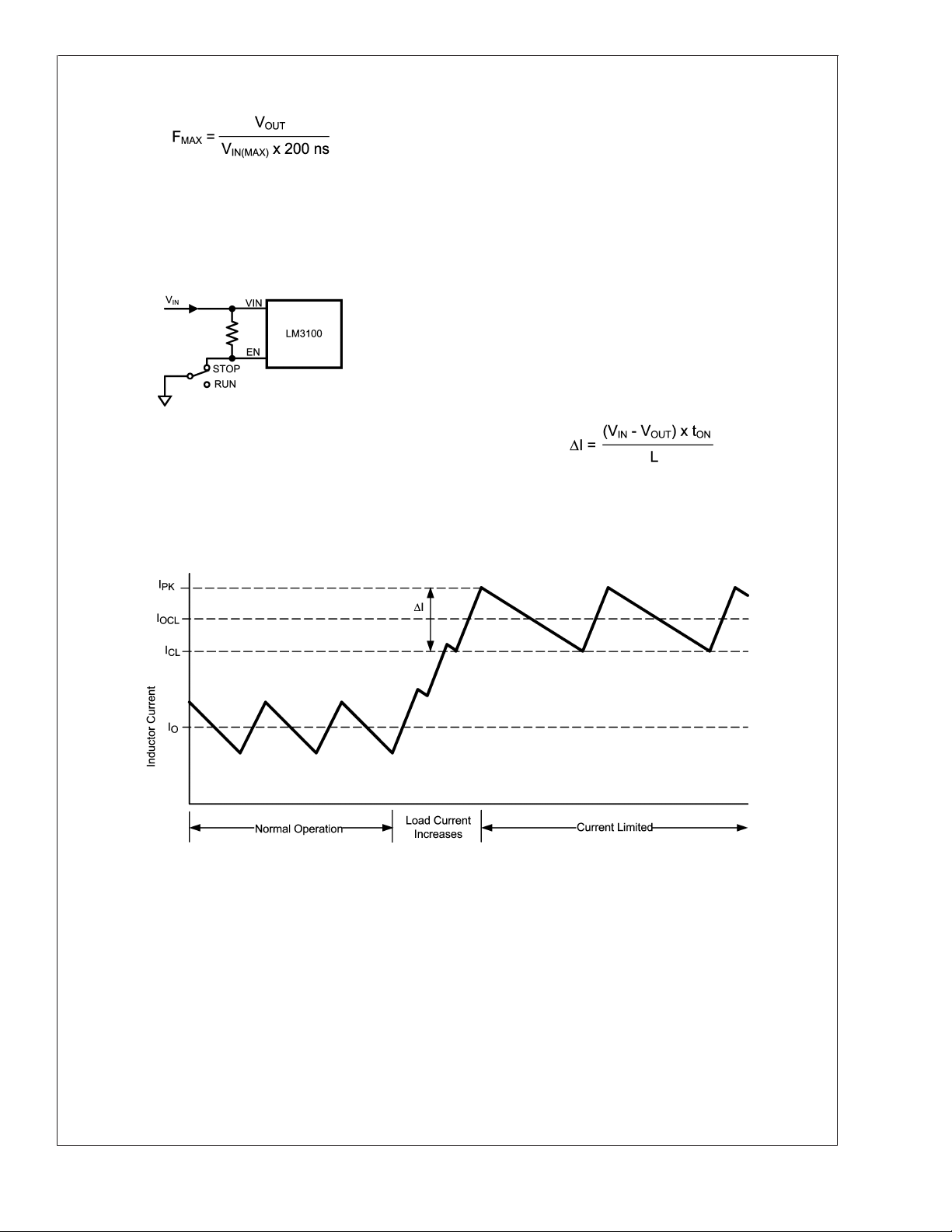

ON-Time Timer, Shutdown (Continued)

(5)

The LM3100 can be remotely shut down by taking the EN pin

below 1.1V. Refer to Figure 1. In this mode the SS pin is

internally grounded, the on-timer is disabled, and bias currents are reduced. Releasing the EN pin allows normal

operation to resume. The voltage at the EN pin is between

1.5V and 3.0V, depending on V

and the pull-up resistor.

IN

20174704

FIGURE 1. Shutdown Implementation

Current Limit

Current limit detection occurs during the off-time by monitoring the re-circulating current through the low-side synchro-

nous switch. Referring to Functional Block Diagram, when

the buck switch is turned off, inductor current flows through

the load, into PGND, and through the internal low-side synchronous switch. If that current exceeds 1.9A the current

limit comparator toggles, forcing a delay to the start of the

next on-time period. The next cycle starts when the recirculating current falls back below 1.9A and the voltage at

FB is below 0.8V. The inductor current is monitored during

the low-side switch on-time. As long as the overload condition persists and the inductor current exceeds 1.9A, the

high-side switch will remain inhibited. The operating frequency is lower during an over-current due to longer than

normal off-times.

Figure 2 illustrates the inductor current waveform. During

normal operation the load current is low, the average of the

ripple waveform. When an overload occurs the current ratchets up until it exceeds 1.9A. During the Current Limited

portion of Figure 2, the current ramps down to 1.9A during

each off-time, initiating the next on-time (assuming the volt-

<

age at FB is

0.8V). During each on-time the current ramps

up an amount equal to:

(6)

During this time the LM3100 is in a constant current mode,

with an average load current (I

) equal to 1.9A +∆I/2.

OCL

LM3100

FIGURE 2. Inductor Current - Current Limit Operation

20174705

www.national.com11

N - Channel Buck Switch and Driver

LM3100

The LM3100 integrates an N-Channel buck (high-side)

switch and associated floating high voltage gate driver. The

gate drive circuit works in conjunction with an external bootstrap capacitor and an internal high voltage diode. A 33 nF

capacitor (C

) connected between BST and SW pins pro-

BST

vides voltage to the high-side driver during the buck switch

on-time. During each off-time, the SW pin falls to approximately -1V and C

charges from the VCCsupply through

BST

the internal diode. The minimum off-time of 260ns ensures

adequate time each cycle to recharge the bootstrap capacitor.

Softstart

The soft-start feature allows the converter to gradually reach

a steady state operating point, thereby reducing start-up

stresses and current surges. Upon turn-on, after V

reaches the under-voltage threshold, an internal 8µA current

source charges up the external capacitor at the SS pin. The

ramping voltage at SS (and the non-inverting input of the

regulation comparator) ramps up the output voltage in a

controlled manner.

An internal switch grounds the SS pin if V

under-voltage lockout threshold, if a thermal shutdown occurs, or if the EN pin is grounded. Using an externally

controlled switch, the output voltage can be shut off by taking

the SS pin to ground. Releasing the switch allows the SS pin

to ramp up, and the output voltage to return to normal. The

shut-down configuration is shown in Figure 3.

CC

CC

is below the

R

FB1/RFB2

and R

R

FB1

should be chosen from standard value resis-

FB2

=(V

OUT

/0.8V) - 1

tors in the range of 1.0 kΩ -10kΩ which satisfy the above

ratio.

For V

= 0.8V, the FB pin can be connected to the output

OUT

directly. However, the converter operation needs a minimum

inductor current ripple to maintain good regulation when no

load is connected. This minimum load is about 10 µA and

can be implemented by adding a pre-load resistor to the

output.

: The minimum value for RON is calculated from:

R

ON

Equation 1 can be used to select RONif a specific frequency

is desired as long as the above limitation is met.

L: The main parameter effected by the inductor is the output

current ripple amplitude (I

). The maximum allowable (I

OR

OR

must be determined at both the minimum and maximum

nominal load currents. At minimum load current, the lower

peak must not reach 0 mA. At maximum load current, the

upper peak must not exceed the current limit threshold

(1.9A). The allowable ripple current is calculated from the

following equations:

I

OR(MAX1)

=2xI

O(min)

or

I

OR(MAX2)

= 2 x (1.9A - I

O(max)

)

20174706

FIGURE 3. Alternate Shutdown Implementation

Thermal Protection

The LM3100 should be operated so the junction temperature

does not exceed the maximum limit. An internal Thermal

Shutdown circuit, which activates (typically) at 165˚C, takes

the controller to a low power reset state by disabling the buck

switch and the on-timer, and grounding the Softstart pin. This

feature helps prevent catastrophic failures from accidental

device overheating. When the junction temperature falls

back below 145˚C (typical hysteresis = 20˚C), the Softstart

pin is released and normal operation resumes.

Applications Information

EXTERNAL COMPONENTS

The following guidelines can be used to select the external

components.

R

FB1

from:

and R

: The ratio of these resistors is calculated

FB2

The lesser of the two ripple amplitudes calculated above is

then used in the following equation:

(7)

where V

is the maximum input voltage and Fs is deter-

IN

mined from equation 1. This provides a value for L. The next

larger standard value should be used. L should be rated for

current level shown in Figure 2.

the I

PK

Inductor Selector for V

OUT

= 3.3V

20174736

www.national.com 12

Applications Information (Continued)

Inductor Selector for V

OUT

= 0.8V

C

: The recommended value for CBST is 33 nF. A high

BST

quality ceramic capacitor with low ESR is recommended as

supplies a surge current to charge the buck switch gate

C

BST

at turn-on. A low ESR also helps ensure a complete recharge

during each off-time.

: The capacitor at the SS pin determines the soft-start

C

SS

time, i.e. the time for the reference voltage at the regulation

comparator, and the output voltage, to reach their final value.

The time is determined from the following:

CFB: If output voltage is higher than 1.6V, this feedback cap

is needed for Discontinuous Conduction Mode to improve

the output ripple performance, the recommended value for

is 10 nF.

C

FB

LM3100

20174737

C

: The capacitor on the VCCoutput provides not only

VCC

noise filtering and stability, but also prevents false triggering

of the V

this reason, C

UVLO at the buck switch on/off transitions. For

CC

should be no smaller than 680 nF for

VCC

stability, and should be a good quality, low ESR, ceramic

capacitor.

and CO3: COshould generally be no smaller than 10 µF.

C

O

Experimentation is usually necessary to determine the minimum value for C

, as the nature of the load may require a

O

larger value. A load which creates significant transients requires a larger value for C

is a small value ceramic capacitor to further suppress

C

O3

high frequency noise at V

than a fixed load.

O

. A 47nF is recommended,

OUT

located close to the LM3100.

and C

C

IN

current during the on-time, and limit the voltage ripple at V

on the assumption that the voltage source feeding V

: CIN’s purpose is to supply most of the switch

IN3

IN

has

IN

an output impedance greater than zero. If the source’s dynamic impedance is high (effectively a current source), it

supplies the average input current, but not the ripple current.

At maximum load current, when the buck switch turns on, the

current into V

suddenly increases to the lower peak of the

IN

inductor’s ripple current, ramps up to the peak value, then

drop to zero at turn-off. The average current during the

on-time is the load current. For a worst case calculation, C

must supply this average load current during the maximum

on-time. C

is calculated from:

IN

(8)

where I

and ∆V is the allowable ripple voltage at V

C

IN3

long lead inductance at V

is the load current, tONis the maximum on-time,

O

.

IN

’s purpose is to help avoid transients and ringing due to

. A low ESR, 0.1µF ceramic chip

IN

capacitor is recommended, located close to the LM3100.

PC BOARD LAYOUT

The LM3100 regulation, over-voltage, and current limit comparators are very fast, and will respond to short duration

noise pulses. Layout considerations are therefore critical for

optimum performance. The layout must be as neat and

compact as possible, and all of the components must be as

close as possible to their associated pins. Refer to the

functional block diagram, the loop formed by C

, the high

IN

and low-side switches internal to the IC, and the PGND pin

should be as small as possible. The PGND connection to Cin

should be as short and direct as possible. There should be

several vias connecting the Cin ground terminal to the

ground plane placed as close to the capacitor as possible.

The boost capacitor should be connected as close to the SW

and BST pins as possible. The feedback divider resistors

and the C

capacitor should be located close to the FB pin.

FB

A long trace run from the top of the divider to the output is

,

generally acceptable since this is a low impedance node.

Ground the bottom of the divider directly to the GND (pin 7).

The output capacitor, C

, should be connected close to

OUT

the load and tied directly into the ground plane. The inductor

should connect close to the SW pin with as short a trace as

possible to help reduce the potential for EMI (electromagnetic interference) generation.

If it is expected that the internal dissipation of the LM3100

will produce excessive junction temperatures during normal

IN

operation, good use of the PC board’s ground plane can help

considerably to dissipate heat. The exposed pad on the

bottom of the IC package can be soldered to a ground plane

and that plane should extend out from beneath the IC to help

dissipate the heat. The exposed pad is internally connected

to the IC substrate. Additionally the use of wide PC board

traces, where possible, can help conduct heat away from the

IC. Using numerous vias to connect the die attach pad to an

internal ground plane is a good practice. Judicious positioning of the PC board within the end product, along with the

use of any available air flow (forced or natural convection)

can help reduce the junction temperature.

www.national.com13

Applications Information (Continued)

LM3100

Typical Application Schematic for V

Typical Application Schematic for V

OUT

OUT

= 3.3V

20174716

20174717

= 0.8V

www.national.com 14

Physical Dimensions inches (millimeters) unless otherwise noted

LM3100 SIMPLE SWITCHER

®

Synchronous 1MHz 1.5A Step-Down Voltage Regulator

20-Lead Plastic eTSSOP Package

NS Package Number MXA20A

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor follows the provisions of the Product Stewardship Guide for Customers (CSP-9-111C2) and Banned Substances

and Materials of Interest Specification (CSP-9-111S2) for regulatory environmental compliance. Details may be found at:

www.national.com/quality/green.

Lead free products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...