LM2642

Two-Phase Synchronous Step-Down Switching

Controller

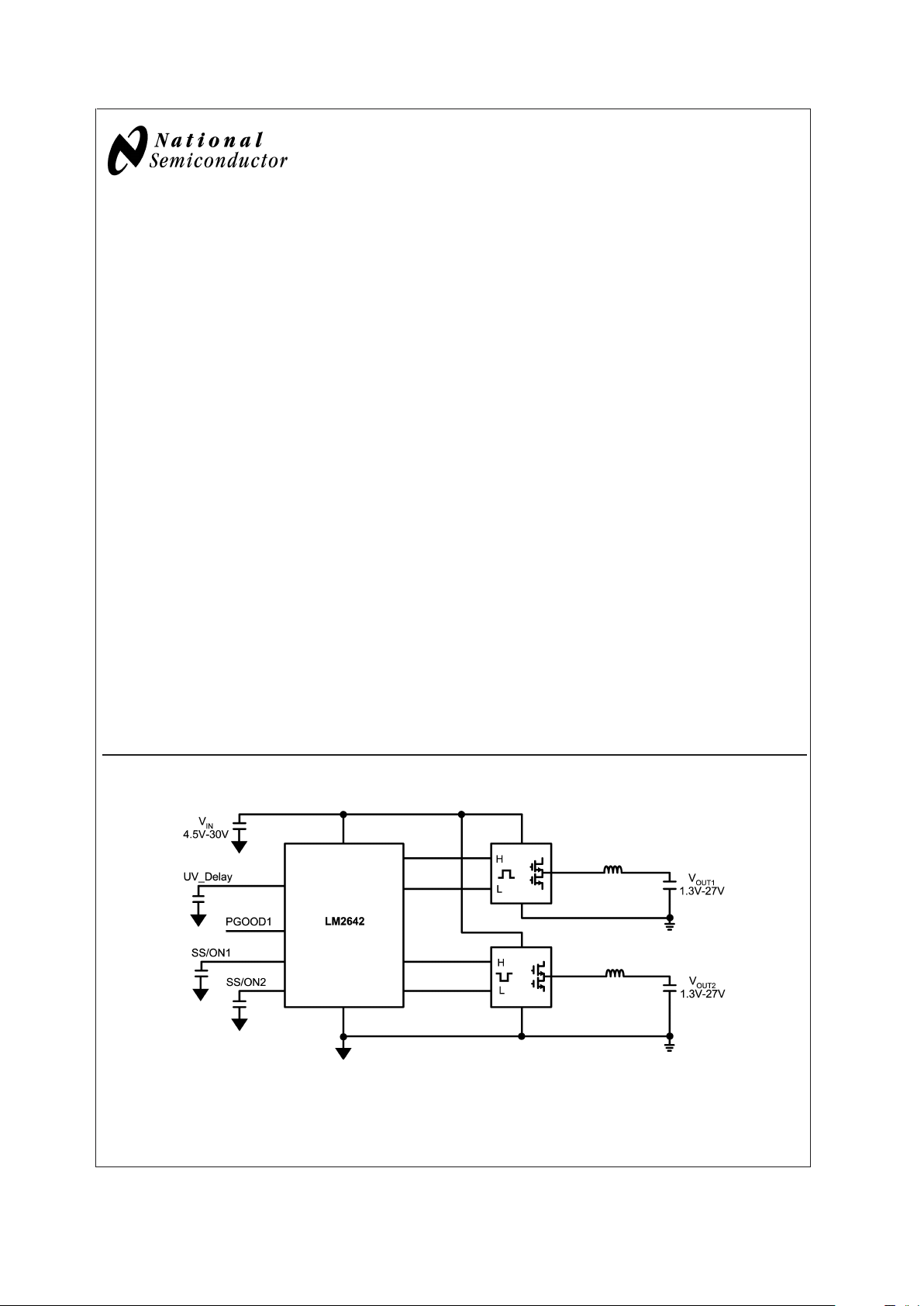

General Description

The LM2642 consists of two current mode synchronous

buck regulator controllers with a switching frequency of

300kHz.

The two switching regulator controllers operate 180˚ out of

phase. This feature reduces the input ripple RMS current,

thereby significantly reducing the required input capacitance.

The two switching regulator outputs can also be paralleled to

operate as a dual-phase single output regulator.

The output of each channel can be independently adjusted

from 1.3 to V

IN

•

maximum duty cycle. An internal 5V rail is

also available externally for driving bootstrap circuitry.

Current-mode feedback control assures excellent line and

load regulation and a wide loop bandwidth for excellent

response to fast load transients. Current is sensed across

either the Vds of the top FET or across an external currentsense resistor connected in series with the drain of the top

FET. Current limit is independently adjustable for each channel.

The LM2642 features analog soft-start circuitry that is independent of the output load and output capacitance. This

makes the soft-start behavior more predictable and controllable than traditional soft-start circuits.

A PGOOD1 pin is provided to monitor the dc output of

channel 1. Over-voltage protection is available for both outputs. A UV-Delay pin is also available to allow delayed shut

off time for the IC during an output under-voltage event.

Features

n Two synchronous buck regulators

n 180˚ out of phase operation

n 4.5V to 30V input range

n Power good function monitors Ch.1

n 37µA Shutdown current

n 0.04% (typical) line and load regulation error

n Current mode control with or without a sense resistor

n Independent enable/soft-start pins allow simple

sequential startup configuration.

n Configurable for single output parallel operation. (See

Figure 2).

n Adjustable cycle-by-cycle current limit

n Input under-voltage lockout

n Output over-voltage latch protection

n Output under-voltage protection with delay

n Thermal shutdown

n Self discharge of output capacitors when the regulator is

OFF

n TSSOP package

Applications

n Embedded computer systems

n High end gaming systems

n Set-top boxes

n WebPAD

Block Diagram

20046201

May 2003

LM2642 Two-Phase Synchronous Step-Down Switching Controller

© 2003 National Semiconductor Corporation DS200462 www.national.com

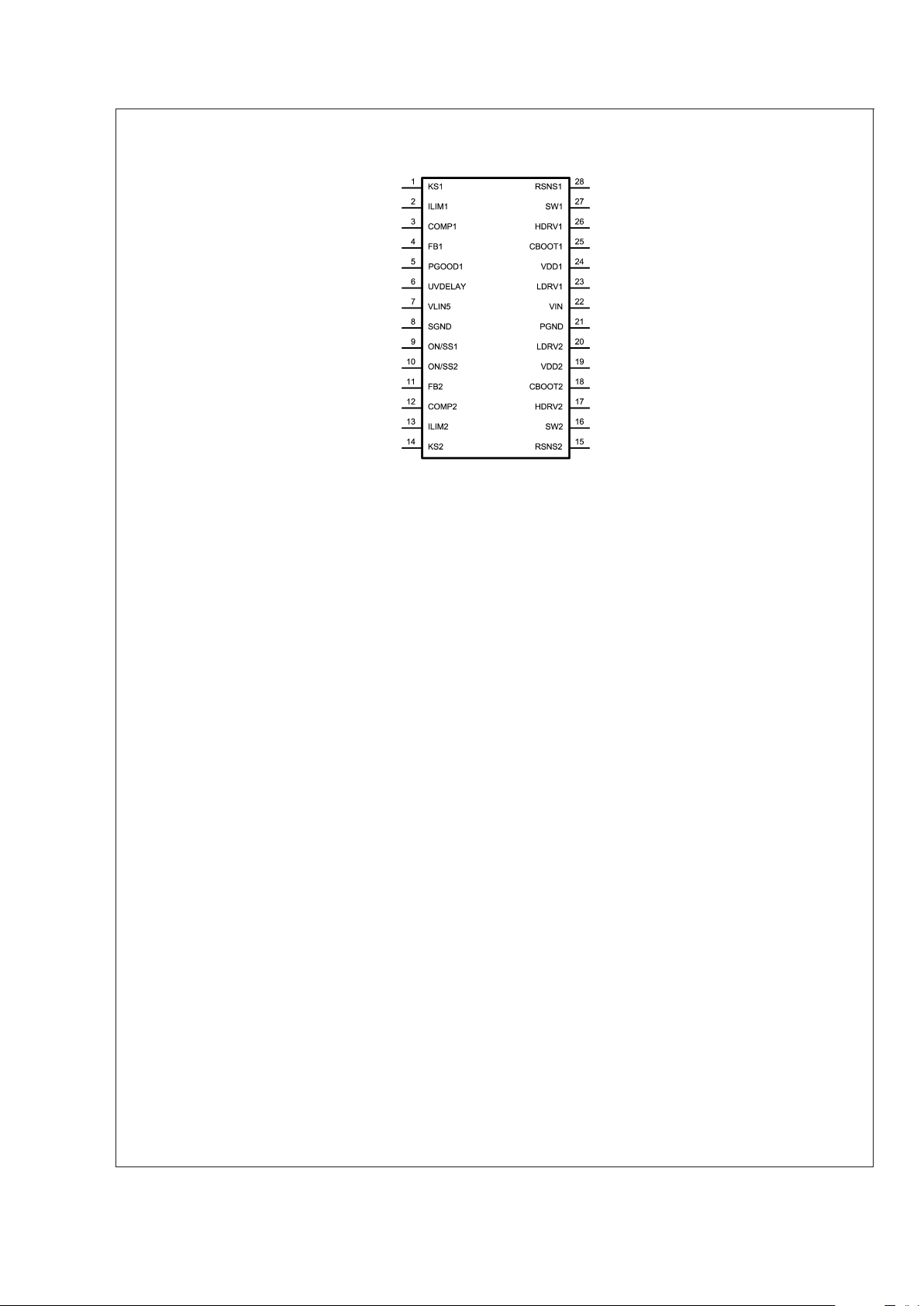

Connection Diagram

TOP VIEW

20046202

28-Lead TSSOP (MTC)

Order Number LM2642MTC

See NS Package Number MTC28

Pin Descriptions

KS1 (Pin 1): The positive (+) Kelvin sense for the internal

current sense amplifier of Channel 1. Use a separate trace to

connect this pin to the current sense point. It should be

connected to VIN as close as possible to the node of the

current sense resistor. When no current-sense resistor is

used, connect as close as possible to the drain node of the

upper MOSFET.

ILIM1 (Pin 2): Current limit threshold setting for Channel 1. It

sinks a constant current of 10 µA, which is converted to a

voltage across a resistor connected from this pin to VIN. The

voltage across the resistor is compared with either the VDS

of the top MOSFET or the voltage across the external current sense resistor to determine if an over-current condition

has occurred in Channel 1.

COMP1 (Pin 3): Compensation pin for Channel 1. This is the

output of the internal transconductance amplifier. The compensation network should be connected between this pin

and the signal ground, SGND (Pin 8).

FB1 (Pin 4): Feedback input for channel 1. Connect to

VOUT through a voltage divider to set the channel 1 output

voltage.

PGOOD1 (Pin 5): An open-drain power-good output for

Channel 1. It is ’LOW’ (low impedance to ground) whenever

the output voltage of Channel 1 falls outside of a +15% to

-9% window. PGOOD1 stays latched in a ’LOW’ state during

OVP or UVP on either channel. It will recover to a ’HIGH’

state (high impedance to ground) after a Channel 1 output

under-voltage event (

<

91%) when the output returns to

within 6% of its nominal value. See Operation Descriptions

for details.

UV_DELAY (Pin 6): A capacitor from this pin to ground sets

the delay time for UVP. The capacitor is charged from a 5µA

current source. When UV_DELAY charges to 2.3V (typical),

the system immediately latches off. Connecting this pin to

ground will disable the output under-voltage protection.

VLIN5 (Pin 7): The output of an internal 5V LDO regulator

derived from VIN. It supplies the internal bias for the chip and

supplies the bootstrap circuitry for gate drive. Bypass this pin

to signal ground with a minimum of 4.7µF capacitor.

SGND (Pin 8): The ground connection for the signal-level

circuitry. It should be connected to the ground rail of the

system.

ON/SS1 (Pin 9): Channel 1 enable pin. This pin is internally

pulled up to one diode drop above VLIN5. Pulling this pin

below 1.2V (open-collector type) turns off Channel 1. If both

ON/SS1 and ON/SS2 pins are pulled below 1.2V, the whole

chip goes into shut down mode. Adding a capacitor to this

pin provides a soft-start feature that minimizes inrush current

and output voltage overshoot.

ON/SS2 (Pin 10): Channel 2 enable pin. See the description

for Pin 9, ON/SS1. May be connected to ON/SS1 for simultaneous startup or for parallel operation.

FB2 (Pin 11): Feedback input for channel 2. Connect to

VOUT through a voltage divider to set the Channel 2 output

voltage.

COMP2 (Pin 12): Compensation pin for Channel 2. This is

the output of the internal transconductance amplifier. The

compensation network should be connected between this

pin and the signal ground SGND (Pin 8).

ILIM2 (Pin 13): Current limit threshold setting for Channel 2.

See ILIM1 (Pin 2).

KS2 (Pin 14): The positive (+) Kelvin sense for the internal

current sense amplifier of Channel 2. See KS1 (Pin 1).

RSNS2 (Pin 15): The negative (-) Kelvin sense for the

internal current sense amplifier of Channel 2. Connect this

pin to the low side of the current sense resistor that is placed

between VIN and the drain of the top MOSFET. When the

Rds of the top MOSFET is used for current sensing, connect

this pin to the source of the top MOSFET. Always use a

separate trace to form a Kelvin connection to this pin.

LM2642

www.national.com 2

Pin Descriptions (Continued)

SW2 (Pin 16): Switch-node connection for Channel 2, which

is connected to the source of the top MOSFET of Channel 2.

It serves as the negative supply rail for the top-side gate

driver, HDRV2.

HDRV2 (Pin 17): Top-side gate-drive output for Channel 2.

HDRV is a floating drive output that rides on the corresponding switching-node voltage.

CBOOT2 (Pin 18): Bootstrap capacitor connection. It serves

as the positive supply rail for the Channel 2 top-side gate

drive. Connect this pin to VDD2 (Pin 19) through a diode,

and connect the low side of the bootstrap capacitor to SW2

(Pin16).

VDD2 (Pin 19): The supply rail for the Channel 2 low-side

gate drive. Connected to VLIN5 (Pin 7) through a 4.7Ω

resistor and bypassed to power ground with a ceramic capacitor of at least 1µF. Tie this pin to VDD1 (Pin 24).

LDRV2 (Pin 20): Low-side gate-drive output for Channel 2.

PGND (Pin 21): The power ground connection for both

channels. Connect to the ground rail of the system.

VIN (Pin 22): The power input pin for the chip. Connect to

the positive (+) input rail of the system. This pin must be

connected to the same voltage rail as the top FET drain (or

the current sense resistor when used).

LDRV1 (Pin 23): Low-side gate-drive output for Channel 1.

VDD1 (Pin 24): The supply rail for Channel 1 low-side gate

drive. Tie this pin to VDD2 (Pin 19).

CBOOT1 (Pin 25): : Bootstrap capacitor connection. It

serves as the positive supply rail for Channel 1 top-side gate

drive. See CBOOT2 (Pin 18).

HDRV1 (Pin 26): Top-side gate-drive output for Channel 1.

See HDRV2 (Pin 17).

SW1 (Pin 27): Switch-node connection for Channel 1. See

SW2 (Pin16).

RSNS1 (Pin 28): The negative (-) Kelvin sense for the

internal current sense amplifier of Channel 1. See RSNS2

(Pin 15).

LM2642

www.national.com3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Voltages from the indicated pins to SGND/PGND:

VIN, ILIM1, ILIM2, KS1, KS2 −0.3V to 32V

SW1, SW2, RSNS1, RSNS2 −0.3 to (V

IN

+

0.3)V

FB1, FB2, VDD1, VDD2 −0.3V to 6V

PGOOD, COMP1, COMP2, UV

Delay

−0.3V to (VLIN5

+0.3)V

ON/SS1, ON/SS2 (Note 2) −0.3V to (VLIN5

+0.6)V

CBOOT1 to SW1, CBOOT2 to SW2 −0.3V to 7V

LDRV1, LDRV2 −0.3V to

(VDD+0.3)V

HDRV1 to SW1, HDRV2 to SW2 −0.3V

HDRV1 to CBOOT1, HDRV2 to

CBOOT2 +0.3V

Power Dissipation (T

A

= 25˚C),

(Note 3) 1.1W

Ambient Storage Temperature

Range −65˚C to +150˚C

Soldering Dwell Time, Temperature

(Note 4)

Wave

Infrared

Vapor Phase

4 sec, 260˚C

10sec, 240˚C

75sec, 219˚C

ESD Rating (Note 5) 2kV

Operating Ratings(Note 1)

VIN (VLIN5 tied to VIN) 4.5V to 5.5V

VIN (VIN and VLIN5 separate) 5.5V to 30V

Junction Temperature −40˚C to +125˚C

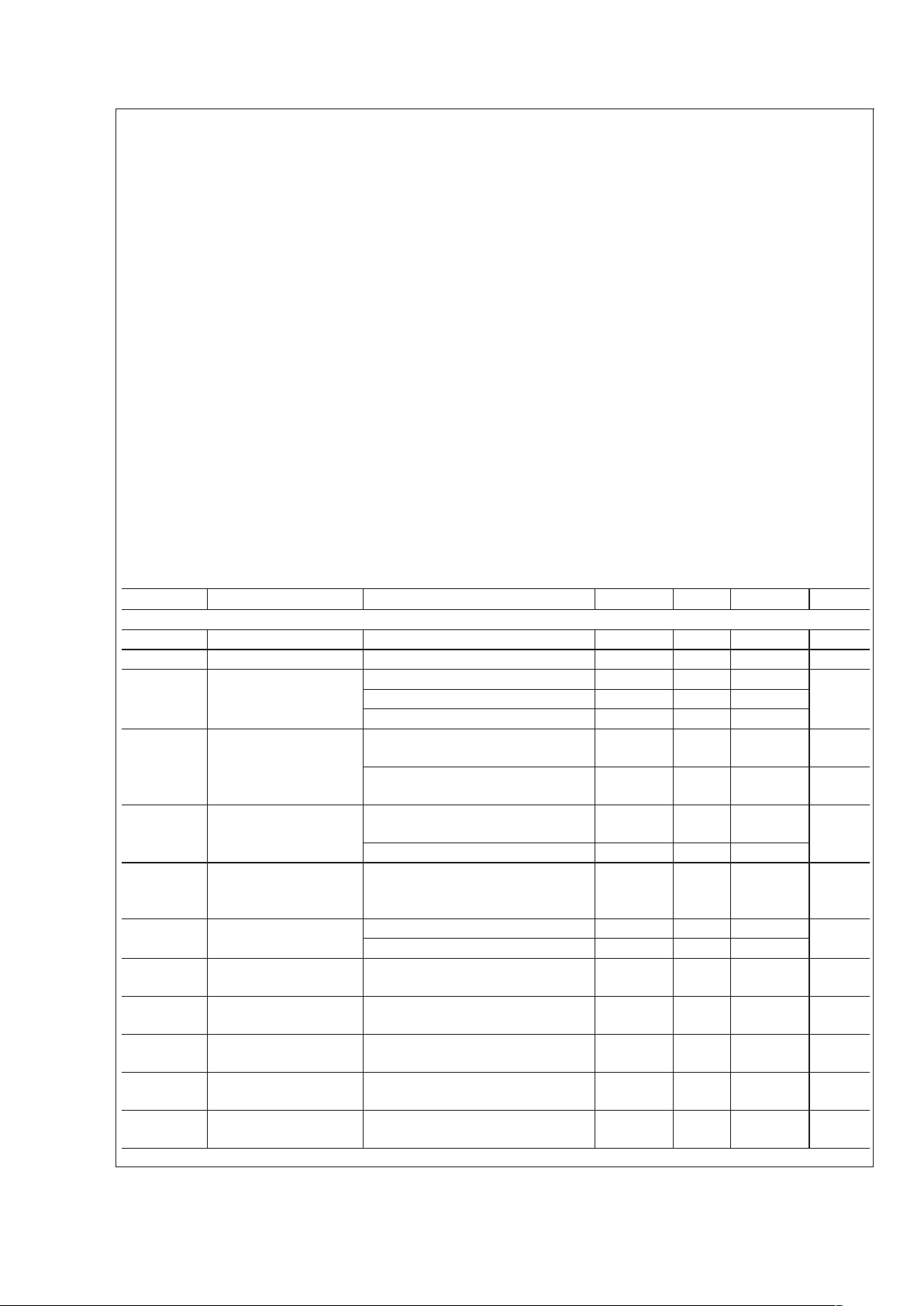

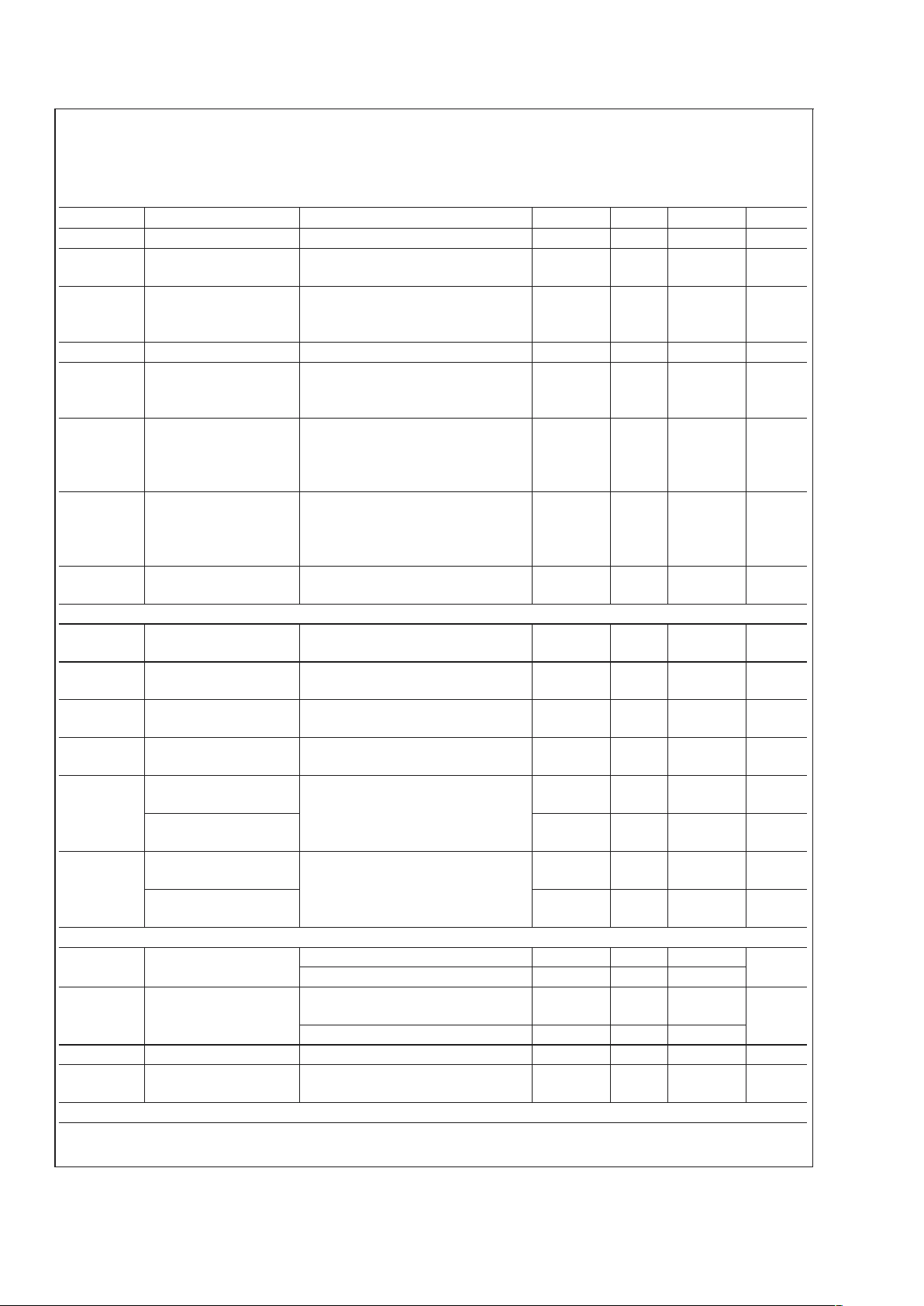

Electrical Characteristics

Unless otherwise specified, VIN= 15V, GND = PGND = 0V, VLIN5 = VDD1 = VDD2. Limits appearing in boldface type apply

over the specified operating junction temperature range, (-20˚C to +125˚C, if not otherwise specified). Specifications appearing

in plain type are measured using low duty cycle pulse testing with T

A

= 25˚C (Note 6), (Note 7). Min/Max limits are guaranteed

by design, test, or statistical analysis.

Symbol Parameter Conditions Min Typ Max Units

System

∆V

OUT/VOUT

Load Regulation VIN = 15V, V

compx

= 0.5V to 1.5V 0.04 %

∆V

OUT/VOUT

Line Regulation 5.5V ≤ VIN ≤ 30V, V

compx

=1.25V 0.04 %

V

FB1_FI2

Feedback Voltage 5.5V ≤ VIN ≤ 30V 1.215 1.238 1.260

V0˚C to 125˚C 1.217 1.259

-40˚C to 125˚C 1.212 1.261

I

VIN

Input Supply Current V

ON_SSx

>

2V

5.5V ≤ VIN ≤ 30V

1.0

2.0

mA

Shutdown (Note 8)

V

ON_SS1

=V

ON_SS2

=0V

37

110

µA

VLIN5 VLIN5 Output Voltage IVLIN5 = 0 to 25mA,

5.5V ≤ VIN ≤ 30V

4.70 5 5.30

V

-40˚C to 125˚C 4.68 5.30

V

CLos

Current Limit

Comparator Offset

(VILIMX −VRSNSX)

±

2

±

7.0 mV

I

CL

Current Limit Sink

Current

9 10 11

µA

-40˚C to 125˚C 8.67 11

I

ss_SC1

,

I

ss_SC2

Soft-Start Source

Current

V

ON_ss1

=V

ON_ss2

= 1.5V (on)

0.5 2 5.0 µA

I

ss_SK1

,

I

ss_SK2

Soft-Start Sink Current V

ON_ss1

=V

ON_ss2

=2V

2 5.2 10 µA

V

ON_SS1

,

V

ON_SS2

Soft-Start On Threshold

0.7 1.12 1.4 V

V

SSTO

Soft-Start Timeout

Threshold

(Note 9)

3.3 V

I

sc_uvdelay

UV_DELAY Source

Current

UV-DELAY = 2V

2 5 9 µA

LM2642

www.national.com 4

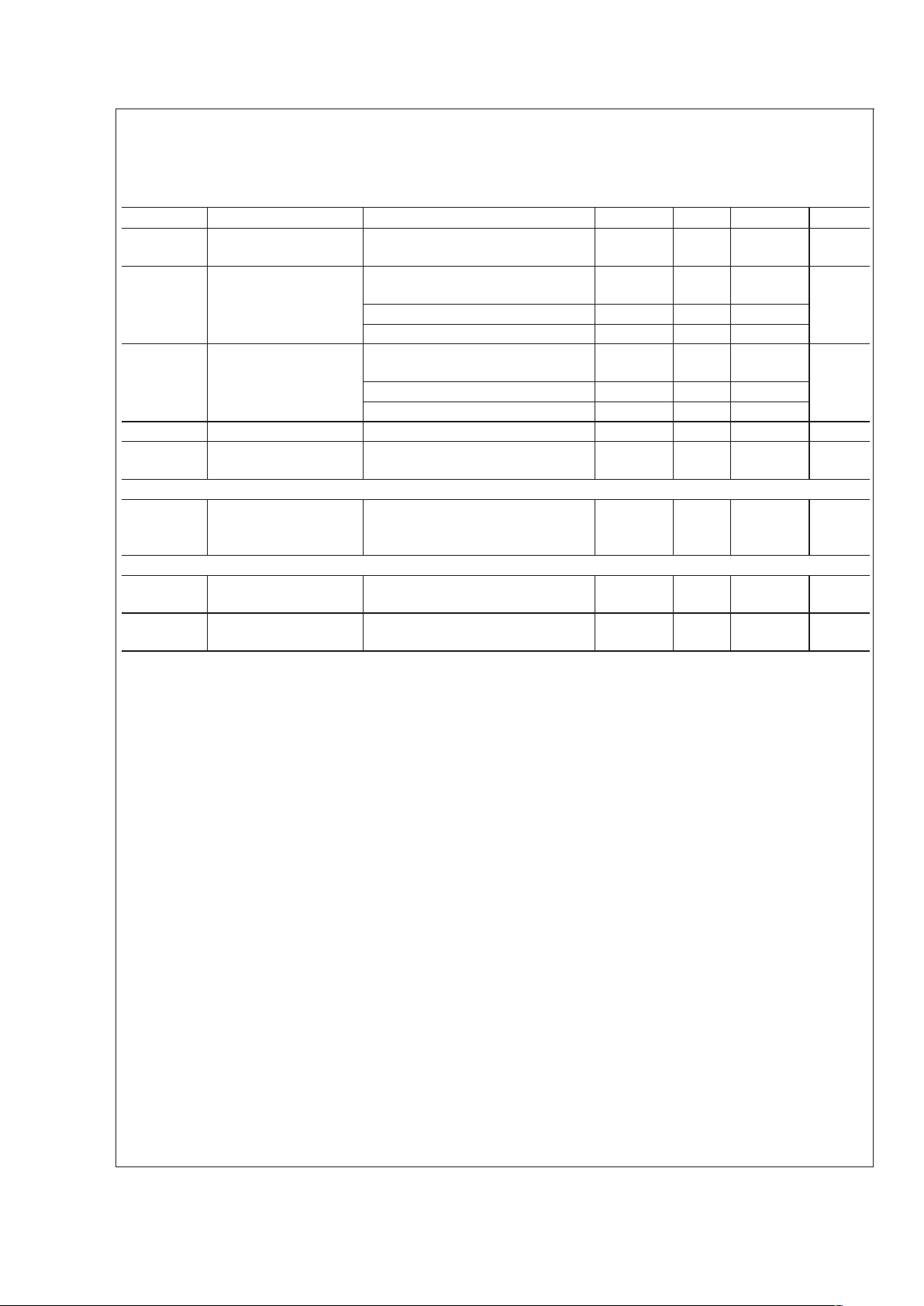

Electrical Characteristics (Continued)

Unless otherwise specified, VIN= 15V, GND = PGND = 0V, VLIN5 = VDD1 = VDD2. Limits appearing in boldface type apply

over the specified operating junction temperature range, (-20˚C to +125˚C, if not otherwise specified). Specifications appearing

in plain type are measured using low duty cycle pulse testing with T

A

= 25˚C (Note 6), (Note 7). Min/Max limits are guaranteed

by design, test, or statistical analysis.

Symbol Parameter Conditions Min Typ Max Units

I

sk_uvdelay

UV_DELAY Sink Current UV-DELAY = 0.4V 0.2 0.48 1.2 mA

V

UVDelay

UV_DELAY Threshold

Voltage

2.3 V

V

UVP

FB1, FB2, Under

Voltage Protection Latch

Threshold

As a percentage of nominal output

voltage (falling edge) 75 80 86 %

Hysteresis 4%

V

OVP

V

OUT

Overvoltage

Shutdown Latch

Threshold

As a percentage measured at V

FB1

,

V

FB2

107 113 122 %

V

pwrbad

Regulator Window

Detector Thresholds

(PGOOD1 from High to

Low)

As a percentage of output voltage

86.5 90.3 94.5 %

V

pwrgd

Regulator Window

Detector Thresholds

(PGOOD1 from Low to

High)

91.5 94 97.0 %

S

wx_R

SW1, SW2

ON-Resistance

V

SW1=VSW2

=2V

420 480 535 Ω

Gate Drive

I

CBOOT

CBOOTx Leakage

Current

V

CBOOT1

=V

CBOOT2

=7V

10 nA

I

SC_DRV

HDRVx and LDRVx

Source Current

V

CBOOT1

=V

CBOOT2

= 5V, VSWx=0V,

HDRVx=LDRVx=2.5V

0.5 A

I

sk_HDRV

HDRVx Sink Current V

CBOOTx

= VDDx = 5V, V

SWx

= 0V,

HDRVX = 2.5V

0.8 A

I

sk_LDRV

LDRVx Sink Current V

CBOOTx

= VDDx = 5V, V

SWx

= 0V,

LDRVX = 2.5V

1.1 A

R

HDRV

HDRV1 & 2 Source

On-Resistance

V

CBOOT1

=V

CBOOT2

= 5V,

V

SW1=VSW2

=0V

3.1 Ω

HDRV1 & 2 Sink

On-Resistance

1.5 Ω

R

LDRV

LDRV1 & 2 Source

On-Resistance

V

CBOOT1

=V

CBOOT2

= 5V,

V

SW1=VSW2

=0V

V

DD1=VDD1

=5V

3.1 Ω

LDRV1 & 2 Sink

On-Resistance

1.1 Ω

Oscillator

F

osc

Oscillator Frequency 260 300 340

kHz

-40˚C to 125˚C 257.5 340

Don_max Maximum On-Duty Cycle V

FB1=VFB2

= 1V, Measured at pins

HDRV1 and HDRV2

96 98

%

-40˚C to 125˚C 95.64

T

on_min

Minimum On-Time 166 ns

SS

OT_delta

HDRV1 and HDRV2

Delta On Time

ON/SS1 = ON/SS2 = 2V

20 150 ns

Error Amplifier

LM2642

www.national.com5

Electrical Characteristics (Continued)

Unless otherwise specified, VIN= 15V, GND = PGND = 0V, VLIN5 = VDD1 = VDD2. Limits appearing in boldface type apply

over the specified operating junction temperature range, (-20˚C to +125˚C, if not otherwise specified). Specifications appearing

in plain type are measured using low duty cycle pulse testing with T

A

= 25˚C (Note 6), (Note 7). Min/Max limits are guaranteed

by design, test, or statistical analysis.

Symbol Parameter Conditions Min Typ Max Units

I

FB1,IFB2

Feedback Input Bias

Current

V

FB1_FIX

= 1.5V, V

FB2_FIX

= 1.5V

65

±

200 nA

I

comp1_SC

,

I

comp2_SC

COMP Output Source

Current

V

FB1_FIX

=V

FB2_FIX

= 1V,

V

COMP1

=V

COMP2

=1V

18 113

µA

0˚C to 125˚C 32

-40˚C to 125˚C 6

I

comp1_SK

,

I

comp2_SK

COMP Output Sink

Current

V

FB1_FIX

=V

FB2_FIX

= 1.5V and

V

COMP1

=V

COMP2

= 0.5V

18 108

µA

0˚C to 125˚C 32

-40˚C to 125˚C 6

gm1, gm2 Transconductance 650 µmho

GI

SNS1

,

GI

SNS2

Current Sense Amplifier

(1&2) Gain

V

COMPx

= 1.25V

4.2 5.2 7.5

Voltage References and Linear Voltage Regulators

UVLO VLIN5 Under-voltage

Lockout

Threshold Rising

ON/SS1, ON/SS2 transition

from low to high 3.6 4.0 4.4 V

Logic Outputs

I

OL

PGOOD Low Sink

Current

V

PGOOD

= 0.4V

0.60 0.95 mA

I

OH

PGOOD High Leakage

Current

V

PGOOD

=5V

5 200 nA

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating Range indicates conditions for which the device is

intended to be functional, but does not guarantee specfic performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

The guaranteed specifications apply only for the test conditions. Some performance characteristics may degrade when the device is not operated under the listed

test conditions.

Note 2: ON/SS1 and ON/SS2 are internally pulled up to one diode drop above VLIN5. Do not apply an external pull-up voltage to these pins. It may cause damage

to the IC.

Note 3: The maximum allowable power dissipation is calculated by using P

DMAX

=(T

JMAX-TA

)/θJA, where T

JMAX

is the maximum junction temperature, TAis the

ambient temperature and θ

JA

is the junction-to-ambient thermal resistance of the specified package. The 1.1W rating results from using 125˚C, 25˚C, and 90.6˚C/W

for T

JMAX,TA

, and θJArespectively. A θJAof 90.6˚C/W represents the worst-case condition of no heat sinking of the 28-pin TSSOP. A thermal shutdown will occur

if the temperature exceeds the maximum junction temperature of the device.

Note 4: For detailed information on soldering plastic small-outline packages, refer to the Packaging Databook available from National Semiconductor Corporation.

Note 5: For testing purposes, ESD was applied using the human-body model, a 100pF capacitor discharged through a 1.5kΩ resistor.

Note 6: A typical is the center of characterization data measured with low duty cycle pulse tsting at T

A

= 25˚C. Typicals are not guaranteed.

Note 7: All limits are guaranteed. All electrical characteristics having room-temperature limits are tested during production with T

A=TJ

= 25˚C. All hot and cold limits

are guaranteed by correlating the electrical characteristics to process and temperature variations and applying statistical process control.

Note 8: Both switching controllers are off. The linear regulator VLIN5 remains on.

Note 9: When SS1 and SS2 pins are charged above this voltage and either of the output voltages at Vout1 or Vout2 is still below the regulation limit, the under

voltage protection feature is initialized.

LM2642

www.national.com 6

20046203

FIGURE 1. Typical 2 Channel Application Circuit

LM2642

www.national.com7

20046204

FIGURE 2. Typical Single Channel Application Circuit

LM2642

www.national.com 8

Block Diagram

20046205

LM2642

www.national.com9

Typical Performance Characteristics

Softstart Waveforms

(I

LOAD1=ILOAD2

= 0A)

Power On and PGOOD1 Waveforms

(I

LOAD1=ILOAD2

= 0A)

20046223 20046221

UVP Startup Waveforms

Over-Current and UVP Shutdown

(I

LOAD2

= 0A)

20046268 20046220

Shutdown Waveforms

(I

LOAD1=ILOAD2

= 0A)

Ch.1 Load Transient Response

5V

OUT

, 12V

IN

20046222

20046265

LM2642

www.national.com 10

Typical Performance Characteristics (Continued)

Ch.2 Load Transient Response

3.3V

OUT

, 12V

IN

Load Transient Response

Parallel Operation 1.8V

OUT

, 12V

IN

20046229 20046228

Input Supply Current vs Temperature

(Shutdown Mode V

IN

= 15V)

Input Supply Current vs V

IN

Shutdown Mode (25˚C)

20046224

20046225

VLIN5 vs Temperature VLIN5 vs VIN(25˚C)

20046226 20046227

LM2642

www.national.com11

Typical Performance Characteristics (Continued)

FB Reference Voltage vs Temperature Operating Frequency vs Temperature

20046266

20046267

Error Amplifier Gain vs Temperature

Efficiency vs Load Current

Ch.1 = 5V, Ch.2 = Off

20046269

20046270

Efficiency vs Load Current

Ch.2 = 2.5V, Ch.1 = Off

Efficiency vs Load Current

Ch.2 = 3.3V, Ch.1 = Off

20046271

20046272

LM2642

www.national.com 12

Operation Descriptions

SOFT START

The ON/SS1 pin has dual functionality as both channel

enable and soft start control. The soft start block diagram is

shown in Figure 3.

The LM2642 will remain in shutdown mode while both soft

start pins are grounded.In a normal application (with a soft

start capacitor connected between the ON/SS1 pin and

SGND) soft start functions as follows. As the input voltage

rises (note: Iss starts to flow when VIN ≥ 2.2V), the internal

5V LDO starts up, and an internal 2µA current charges the

soft start capacitor. During soft start phase, the error amplifier output voltage at the COMPx pin is clamped at 0.55V

and the duty cycle is controlled only by the soft start voltage.

As the SSx pin voltage ramps up, the duty cycle increases

proportional to the soft start ramp, causing the output voltage

to ramp up. The rate at which the duty cycle increases

depends on the capacitance of the soft start capacitor. The

higher the capacitance, the slower the output voltage ramps

up. When the corresponding output voltage exceeds 98%

(typical) of the set target voltage, the regulator switches from

soft start to normal operating mode. At this time, the 0.55V

clamp at the output of the error amplifier releases and peak

current feedback control takes over. Once in peak current

feedback control mode, the output of the error amplifier will

travel within the 0.5V and 2V window to achieve PWM

control. See Figure 4.

During soft start, over-voltage protection and current limit

remain in effect. The under voltage protection feature is

activated when the ON/SS pin exceeds the timeout threshold (3.3V typical). If the ON/SSx capacitor is too small, the

duty cycle may increase too rapidly, causing the device to

latch off due to output voltage overshoot above the OVP

threshold. This becomes more likely in applications requiring

low output voltage, high input voltage and light load. A

capacitance of 10nF is recommended at each soft start pin

to provide a smooth monotonic output ramp.

SEQUENTIAL STARTUP

Sequential startup can be implemented by simply connecting

PGOOD1 to SS/ON2. Once channel 1 has reached 94% of

nominal, PGOOD1 will go high, thus enabling SS/ON2. In

this mode of operation, channel 2 will be controlled by the

state of channel 1. If channel 1 falls out of the PGOOD1

window, channel 2 will be switched off immediately.

OVER VOLTAGE PROTECTION (OVP)

If the output voltage on either channel rises above 113% of

nominal, over voltage protection activates. Both channels

will latch off, and the PGOOD1 pin will go low. When the

OVP latch is set, the high side FET driver, HDRVx, is immediately turned off and the low side FET driver, LDRVx, is

turned on to discharge the output capacitor through the

inductor. To reset the OVP latch, either the input voltage

must be cycled, or both channels must be switched off.

UNDER VOLTAGE PROTECTION (UVP) AND UV DELAY

If the output voltage on either channel falls below 80% of

nominal, under voltage protection activates. As shown in

Figure 5, an under-voltage event will shut off the UV_DELAY

MOSFET, which will allow the UV_DELAY capacitor to

charge at 5uA (typical). At the UV_DELAY threshold (2.3V

20046206

FIGURE 3. Soft Start and ON/OFF

20046207

FIGURE 4. Voltage Clamp at COMPx Pin

20046208

FIGURE 5. PGOOD, OVP and UVP

LM2642

www.national.com13

Operation Descriptions (Continued)

typical) both channels will latch off. Also, UV_DELAY will be

disabled and the UV_DELAY pin will return to 0V. During

UVP, both the high side and low side FET drivers will be

turned off. If no capacitor is connected to the UV_DELAY pin,

the UVP latch will be activated immediately. To reset the

UVP latch, either the input voltage must be cycled, or both

ON/SS pins must be pulled low. The UVP function can be

disabled by connecting the UV_DELAY pin to ground.

POWER GOOD

A power good pin (PGOOD1) is available to monitor the

output status of Channel 1. As shown in Figure 5, the pin

connects to the output of an open drain MOSFET, which will

remain open while Channel 1 is within operating range.

PGOOD1 will go low (low impedance to ground) under the

following four conditions:

1. Channel 1 is turned off

2. Channel 1 output falls below 90.3% of nominal (UVPG1)

3. OVP on either channel

4. UVP on either channel

When on, the PGOOD1 pin is capable of sinking 0.95mA

(typical). If an OVP or UVP condition occurs, both channels

will latch off, and the PGOOD1 pin will be latched low. During

a UVPG1 condition, however, PGOOD1 will not latch off. The

pin will stay low until Channel 1 output voltage returns to

94% (typical) of nominal. See Vpwrgd in the Electrical Characteristics table.

OUTPUT CAPACITOR DISCHARGE

Each channel has an embedded 480Ω MOSFET with the

drain connected to the SWx pin. This MOSFET will discharge the output capacitor of its channel if its channel is off,

or the IC enters a fault state caused by one of the following

conditions:

1. UVP

2. UVLO

3. Thermal shut-down (TSD)

If an output over voltage event occurs, the HDRVx will be

turned off and LDRVx will be turned on immediately to

discharge the output capacitor of both channels through the

inductor.

SWITCHING NOISE REDUCTION

Power MOSFETs are very fast switching devices. In synchronous rectifier converters, the rapid increase of drain

current in the top FET coupled with parasitic inductance will

generate unwanted Ldi/dt noise spikes at the source node of

the FET (SWx node) and also at the VIN node. The magnitude of this noise will increase as the output current increases. This parasitic spike noise may turn into electromagnetic interference (EMI), and can also cause problems in

device performance. Therefore, it must be suppressed using

one of the following methods.

It is strongly recommended to add R-C filters to the current

sense amplifier inputs as shown in Figure 7. This will reduce

the susceptibility to switching noise, especially during heavy

load transients and short on time conditions. The filter components should be connected as close as possible to the IC.

As shown in Figure 6, adding a resistor in series with the

SWx pin will slow down the gate drive (HDRVx), thus slowing

the rise and fall time of the top FET, yielding a longer drain

current transition time.

Usually a 3.3Ω to 4.7Ω resistor is sufficient to suppress the

noise. Top FET switching losses will increase with higher

resistance values.

Small resistors (1-5 ohms) can also be placed in series with

the HDRVx pin or the CBOOTx pin to effectively reduce

switch node ringing. A CBOOT resistor will slow the rise time

of the FET, whereas a resistor at HDRV will reduce both rise

and fall times.

CURRENT SENSING AND LIMITING

As shown in Figure 7, the KSx and RSNSx pins are the

inputs of the current sense amplifier. Current sensing is

accomplished either by sensing the Vds of the top FET or by

sensing the voltage across a current sense resistor connected from VIN to the drain of the top FET. The advantage

of sensing current across the top FET are reduced parts

count, cost and power loss, whereas using a current sense

resistor improves the current sense accuracy. Keeping the

differential current-sense voltage below 200mV ensures linear operation of the current sense amplifier. Therefore, the

Rdson of the top FET or the current sense resistor must be

small enough so that the current sense voltage does not

exceed 200mV when the top FET is on. There is a leading

edge blanking circuit that forces the top FET on for at least

166ns. Beyond this minimum on time, the output of the PWM

comparator is used to turn off the top FET. Additionally, a

minimum voltage of at least 50mV across Rsns is recommended to ensure a high SNR at the current sense amplifier.

Assuming a maximum of 200mV across Rsns, the current

sense resistor can be calculated as follows:

where Imax is the maximum expected load current, including

overload multiplier (ie:120%), and Irip is the inductor ripple

current (See equation 7). The above equation gives the

maximum allowable value for Rsns. Switching losses will

increase with Rsns, thus lowering efficiency.

The peak current limit is set by an external resistor connected between the ILIMx pin and the KSx pin. An internal

10µA current sink on the ILIMx pin produces a voltage

across the resistor to set the current limit threshold which is

compared to the current sense voltage. A 10nF capacitor

across this resistor is required to filter unwanted noise that

could improperly trip the current limit comparator.

20046209

FIGURE 6. SW Series Resistor

LM2642

www.national.com 14

Operation Descriptions (Continued)

Current limit is activated when the inductor current is high

enough to cause the voltage at the RSNSx pin to be lower

than that of the ILIMx pin. This toggles the comparator, thus

turning off the top FET immediately. The comparator is disabled either when the top FET is turned off or during the

leading edge blanking time. The equation for current limit

resistor, R

lim

, is as follows:

Where Ilim is the load current at which the current limit

comparator will be tripped.

When sensing current across the top FET, replace Rsns with

the Rdson of the FET. This calculated Rlim value guarantees

that the minimum current limit will not be less than Imax. It is

recommended that a 1% tolerance resistor be used.

When sensing across the top FET, Rdson will show more

variation than a current sense resistor, largely due to temperature. Rdson will increase proportional to temperature

according to a specific temperature coefficient. Refer to the

manufacturer’s datasheet to determine the range of Rdson

values over operating temperature or see the Component

Selection section (equation 12) for a calculation of maximum

Rdson. This will prevent Rdson variations from prematurely

setting off the current limit comparator as the operating

temperature increases.

To ensure accurate current sensing, special attention in

board layout is required. The KSx and RSNSx pins require

separate traces to form a Kelvin connection to the corresponding current sense nodes.

INPUT UNDER VOLTAGE LOCKOUT (UVLO)

The input under-voltage lock out threshold, which is sensed

via the VLIN5 internal LDO output, is 4.0V (typical). Below

this threshold, both HDRVx and LDRVx will be turned off and

the internal 480Ω MOSFETs will be turned on to discharge

the output capacitors through the SWx pins. During UVLO,

the ON/SS pins will sink 5mA to discharge the soft start

capacitors and turn off both channels. As the input voltage

increases again above 4.0V, UVLO will be de-activated, and

the device will restart again from soft start phase. If the

voltage at VLIN5 remains below 4.5V, but above the 4.0V

UVLO threshold, the device cannot be guaranteed to operate within specification.

If the input voltage is between 4.0V and 5.2V, the VLIN5 pin

will not regulate, but will follow approximately 200mV below

the input voltage.

DUAL-PHASE PARALLEL OPERATION

In applications with high output current demand, the two

switching channels can be configured to operate as a two180˚ out of phase converter to provide a single output voltage with current sharing between the two switching channels. This approach greatly reduces the stress and heat on

the output stage components while lowering input ripple

current. The sum of inductor ripple current is also reduced

which results in lowering output ripple voltage. Figure 2

shows an example of a typical two-phase circuit. Because

precision current sense is the primary design criteria to

ensure accurate current sharing between the two channels,

both channels must use external sense resistors for current

sensing. To minimize the error between the error amplifiers

of the two channels, tie the feedback pins FB1 and FB2

together and connect to a single voltage divider for output

voltage sensing. Also, tie the COMP1 and COMP2 together

and connect to the compensation network. ON/SS1 and

ON/SS2 must be tied together to enable and disable both

channels simultaneously.

Component Selection

OUTPUT VOLTAGE SETTING

The output voltage for each channel is set by the ratio of a

voltage divider as shown in Figure 8. The resistor values can

be determined by the following equation:

(1)

Where Vfb=1.238V. Although increasing the value of R1 and

R2 will increase efficiency, this will also decrease accuracy.

Therefore, a maximum value is recommended for R2 in

order to keep the output within .3% of Vnom. This maximum

R2 value should be calculated first with the following equation:

(2)

Where 200nA is the maximum current drawn by FBx pin.

Example: Vnom=5V, Vfb=1.238V, Ifbmax=200nA.

20046210

FIGURE 7. Current Sense and Current Limit

20046211

FIGURE 8. Output Voltage Setting

LM2642

www.national.com15

Component Selection (Continued)

(3)

Choose 60K

(4)

The output voltage is limited by the maximum duty cycle as

well as the minimum on time. Figure 9 shows the limits for

input and output voltages. The recommended maximum output voltage is approximately 1V less than the nominal input

voltage. At 30V input, the minimum output is approximately

2.3V and the maximum is approximately 27V.

For input voltages below 5.5V, VLIN5 must be connected to

Vin through a small resistor (approximately 4.7 ohm). This

will ensure that VLIN5 does not fall below the UVLO threshold.

Output Capacitor Selection

In applications that exhibit large and fast load current

swings, the slew rate of such a load current transient may be

beyond the response speed of the regulator. Therefore, to

meet voltage transient requirements during worst-case load

transients, special consideration should be given to output

capacitor selection. The total combined ESR of the output

capacitors must be lower than a certain value, while the total

capacitance must be greater than a certain value. Also, in

applications where the specification of output voltage regulation is tight and ripple voltage must be low, starting from the

required output voltage ripple will often result in fewer design

iterations.

ALLOWED TRANSIENT VOLTAGE EXCURSION

The allowed output voltage excursion during a load transient

(∆Vc_s) is:

Where±δ% is the output voltage regulation window and

±

e% is the output voltage initial accuracy.

Example: Vnom = 5V, δ% = 7%, e% = 3.4%, Vrip = 40mV

peak to peak.

Since the ripple voltage is included in the calculation of

∆Vc_s, the inductor ripple current should not be included in

the worst-case load current excursion. That is, the worstcase load current excursion should be simply maximum load

current change specification, ∆Ic_s.

MAXIMUM ESR CALCULATION

Unless the rise and fall times of a load transient are slower

than the response speed of the control loop, if the total

combined ESR (Re) is too high, the load transient requirement will not be met, no matter how large the capacitance.

The maximum allowed total combined ESR is:

Example: ∆Vc_s = 160mV, ∆Ic_s = 3A. Then Re_max =

53.3mΩ.

Maximum ESR criterion can be used when the associated

capacitance is high enough, otherwise more capacitors than

the number determined by this criterion should be used in

parallel.

MINIMUM CAPACITANCE CALCULATION

In a switch mode power supply, the minimum output capacitance is typically dictated by the load transient requirement.

If there is not enough capacitance, the output voltage excursion will exceed the maximum allowed value even if the

maximum ESR requirement is met. The worst-case load

transient is an unloading transient that happens when the

input voltage is the highest and when the present switching

cycle has just finished. The corresponding minimum capacitance is calculated as follows:

Notice it is already assumed the total ESR, Re, is no greater

than Re_max, otherwise the term under the square root will

be a negative value. Also, it is assumed that L has already

been selected, therefore the minimum L value should be

calculated before Cmin and after Re (see Inductor Selection

below). Example: Re = 20mΩ,Vnom=5V,∆Vc_s = 160mV,

∆Ic_s = 3A, L = 8µH

Generally speaking, Cmin decreases with decreasing Re,

∆Ic_s, and L, but with increasing Vnom and ∆Vc_s.

20046213

FIGURE 9. Available Output Voltage Range

LM2642

www.national.com 16

Inductor Selection

The size of the output inductor can be determined from the

desired output ripple voltage, Vrip, and the impedance of the

output capacitors at the switching frequency. The equation to

determine the minimum inductance value is as follows:

In the above equation, Re is used in place of the impedance

of the output capacitors. This is because in most cases, the

impedance of the output capacitors at the switching frequency is very close to Re. In the case of ceramic capacitors, replace Re with the true impedance.

Example: Vin (max)= 30V, Vnom = 5.0V, Vrip = 40mV, Re

=20mΩ, f = 300kHz

Lmin = 7µH

The actual selection process usually involves several itera-

tions of all of the above steps, from ripple voltage selection,

to capacitor selection, to inductance calculations. Both the

highest and the lowest input and output voltages and load

transient requirements should be considered. If an inductance value larger than Lmin is selected, make sure that the

Cmin requirement is not violated.

Priority should be given to parameters that are not flexible or

more costly. For example, if there are very few types of

capacitors to choose from, it may be a good idea to adjust

the inductance value so that a requirement of 3.2 capacitors

can be reduced to 3 capacitors.

Since inductor ripple current is often the criterion for selecting an output inductor, it is a good idea to double-check this

value. The equation is:

Where D is the duty cycle, defined by V

nom/Vin

.

Also important is the ripple content, which is defined by Irip

/Inom. Generally speaking, a ripple content of less than 50%

is ok. Larger ripple content will cause too much loss in the

inductor.

Example: Vin = 12V, Vnom = 5.0V, f = 300kHz, L = 8µH

Given a maximum load current of 3A, the ripple content is

1.2A / 3A = 40%.

When choosing the inductor, the saturation current should

be higher than the maximum peak inductor current and the

RMS current rating should be higher than the maximum load

current.

Input Capacitor Selection

The fact that the two switching channels of the LM2642 are

180˚ out of phase will reduce the RMS value of the ripple

current seen by the input capacitors. This will help extend

input capacitor life span and result in a more efficient system. Input capacitors must be selected that can handle both

the maximum ripple RMS current at highest ambient temperature as well as the maximum input voltage. In applications in which output voltages are less than half of the input

voltage, the corresponding duty cycles will be less than 50%.

This means there will be no overlap between the two channels’ input current pulses. The equation for calculating the

maximum total input ripple RMS current for duty cycles

under 50% is:

where I1 is maximum load current of Channel 1, I2 is the

maximum load current of Channel 2, D1 is the duty cycle of

Channel 1, and D2 is the duty cycle of Channel 2.

Example: Imax_1 = 3.6A, Imax_2 = 3.6A, D1 = 0.42, and D2

= 0.275

Choose input capacitors that can handle 1.66A ripple RMS

current at highest ambient temperature. In applications

where output voltages are greater than half the input voltage,

the corresponding duty cycles will be greater than 50%, and

there will be overlapping input current pulses. Input ripple

current will be highest under these circumstances. The input

RMS current in this case is given by:

Where, again, I1 and I2 are the maximum load currents of

channel 1 and 2, and D1 and D2 are the duty cycles. This

equation should be used when both duty cycles are expected to be higher than 50%.

Input capacitors must meet the minimum requirements of

voltage and ripple current capacity. The size of the capacitor

should then be selected based on hold up time requirements. Bench testing for individual applications is still the

best way to determine a reliable input capacitor value. The

input capacitor should always be placed as close as possible

to the current sense resistor or the drain of the top FET.

MOSFET Selection

BOTTOM FET SELECTION

During normal operation, the bottom FET is switching on and

off at almost zero voltage. Therefore, only conduction losses

are present in the bottom FET. The most important parameter when selecting the bottom FET is the on resistance

(Rdson). The lower the on resistance, the lower the power

loss. The bottom FET power loss peaks at maximum input

voltage and load current. The equation for the maximum

allowed on resistance at room temperature for a given FET

package, is:

LM2642

www.national.com17

MOSFET Selection (Continued)

where Tj_max is the maximum allowed junction temperature

in the FET, Ta_max is the maximum ambient temperature,

R

θja

is the junction-to-ambient thermal resistance of the FET,

and TC is the temperature coefficient of the on resistance

which is typically in the range of 10,000ppm/˚C.

If the calculated Rdson_max is smaller than the lowest value

available, multiple FETs can be used in parallel. This effectively reduces the Imax term in the above equation, thus

reducing Rdson. When using two FETs in parallel, multiply

the calculated Rdson_max by 4 to obtain the Rdson_max for

each FET. In the case of three FETs, multiply by 9.

If the selected FET has an Rds value higher than 35.3Ω,

then two FETs with an Rdson less than 141mΩ (4 x 35.3mΩ)

can be used in parallel. In this case, the temperature rise on

each FET will not go to Tj_max because each FET is now

dissipating only half of the total power.

TOP FET SELECTION

The top FET has two types of losses: switching loss and

conduction loss. The switching losses mainly consist of

crossover loss and bottom diode reverse recovery loss.

Since it is rather difficult to estimate the switching loss, a

general starting point is to allot 60% of the top FET thermal

capacity to switching losses. The best way to precisely determine switching losses is through bench testing. The equation for calculating the on resistance of the top FET is thus:

Example: Tj_max = 100˚C, Ta_max = 60˚C, Rqja = 60˚C/W,

Vin_min = 5.5V, Vnom = 5V, and Iload_max = 3.6A.

When using FETs in parallel, the same guidelines apply to

the top FET as apply to the bottom FET.

Loop Compensation

The general purpose of loop compensation is to meet static

and dynamic performance requirements while maintaining

stability. Loop gain is what is usually checked to determine

small-signal performance. Loop gain is equal to the product

of control-output transfer function and the output-control

transfer function (the compensation network transfer function). Generally speaking it is a good idea to have a loop gain

slope that is -20dB /decade from a very low frequency to well

beyond the crossover frequency. The crossover frequency

should not exceed one-fifth of the switching frequency, i.e.

60kHz in the case of LM2642. The higher the bandwidth is,

the faster the load transient response speed will potentially

be. However, if the duty cycle saturates during a load transient, further increasing the small signal bandwidth will not

help. Since the control-output transfer function usually has

very limited low frequency gain, it is a good idea to place a

pole in the compensation at zero frequency, so that the low

frequency gain will be relatively large. A large DC gain

means high DC regulation accuracy (i.e. DC voltage

changes little with load or line variations). The rest of the

compensation scheme depends highly on the shape of the

control-output plot.

As shown in Figure 10, the control-output transfer function

consists of one pole (fp), one zero (fz), and a double pole at

fn (half the switching frequency). The following can be done

to create a -20dB /decade roll-off of the loop gain: Place the

first pole at 0Hz, the first zero at fp, the second pole at fz,

and the second zero at fn. The resulting output-control transfer function is shown in Figure 11.

20046214

FIGURE 10. Control-Output Transfer Function

LM2642

www.national.com 18

Loop Compensation (Continued)

The control-output corner frequencies, and thus the desired

compensation corner frequencies, can be determined approximately by the following equations:

Since fp is determined by the output network, it will shift with

loading (Ro) and duty cycle. First determine the range of

frequencies (fpmin/max) of the pole across the expected

load range, then place the first compensation zero within that

range.

Example: R

e

= 20mΩ,Co= 100µF, R

omax

= 5V/100mA =

50Ω,R

omin

= 5V/3A = 1.7Ω:

Once the fp range is determined, Rc1should be calculated

using:

Where B is the desired gain in V/V at fp (fz1), gm is the

transconductance of the error amplifier, and R1 and R2 are

the feedback resistors. A gain value around 10dB (3.3v/v) is

generally a good starting point.

Example: B = 3.3 v/v, gm=650 m, R1 = 20 KΩ, R2 = 60.4 KΩ:

Bandwidth will vary proportional to the value of Rc1. Next,

Cc1 can be determined with the following equation:

Example: fpmin = 363 Hz, Rc1=20 KΩ:

The value of Cc1should be within the range determined by

Fpmin/max. A higher value will generally provide a more

stable loop, but too high a value will slow the transient

response time.

The compensation network (Figure 12) will also introduce a

low frequency pole which will be close to 0Hz.

A second pole should also be placed at fz. This pole can be

created with a single capacitor Cc2 and a shorted Rc2 (see

Figure 12). The minimum value for this capacitor can be

calculated by:

Cc2 may not be necessary, however it does create a more

stable control loop. This is especially important with high

load currents and in current sharing mode.

Example: fz = 80 kHz, Rc1 = 20 KΩ:

A second zero can also be added with a resistor in series

with Cc2. If used, this zero should be placed at fn, where the

control to output gain rolls off at -40dB/dec. Generally, fn will

be well below the 0dB level and thus will have little effect on

stability. Rc2 can be calculated with the following equation:

20046212

FIGURE 11. Output-Control Transfer Function

20046274

FIGURE 12. Compensation Network

LM2642

www.national.com19

Physical Dimensions inches (millimeters)

unless otherwise noted

28-Lead TSSOP Package

Order Number LM2642MTC

NS Package Number MTC28

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

LM2642 Two-Phase Synchronous Step-Down Switching Controller

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...