LM2622

600kHz/1.3MHz Step-up PWM DC/DC Converter

General Description

The LM2622 is a step-up DC/DC converter with a 1.6A, 0.2Ω

internal switch and pin selectable operating frequency. With

the ability to convert 3.3V to multiple outputs of 8V, -8V, and

23V, the LM2622 is an ideal part for biasing TFT displays.

The LM2622 can be operated at switching frequencies of

600kHz and 1.3MHz allowingforeasyfilteringandlownoise.

An external compensation pin gives the user flexibility in

setting frequency compensation, which makes possible the

use of small, low ESR ceramic capacitors at the output. The

LM2622 is available in a low profile 8-lead MSOP package.

Features

n 1.6A, 0.2Ω, internal switch

n Operating voltage as low as 2.0V

n 600kHz/1.3MHz pin selectable frequency operation

n Over temperature protection

n 8-Lead MSOP package

Applications

n TFT Bias Supplies

n Handheld Devices

n Portable Applications

n GSM/CDMA Phones

n Digital Cameras

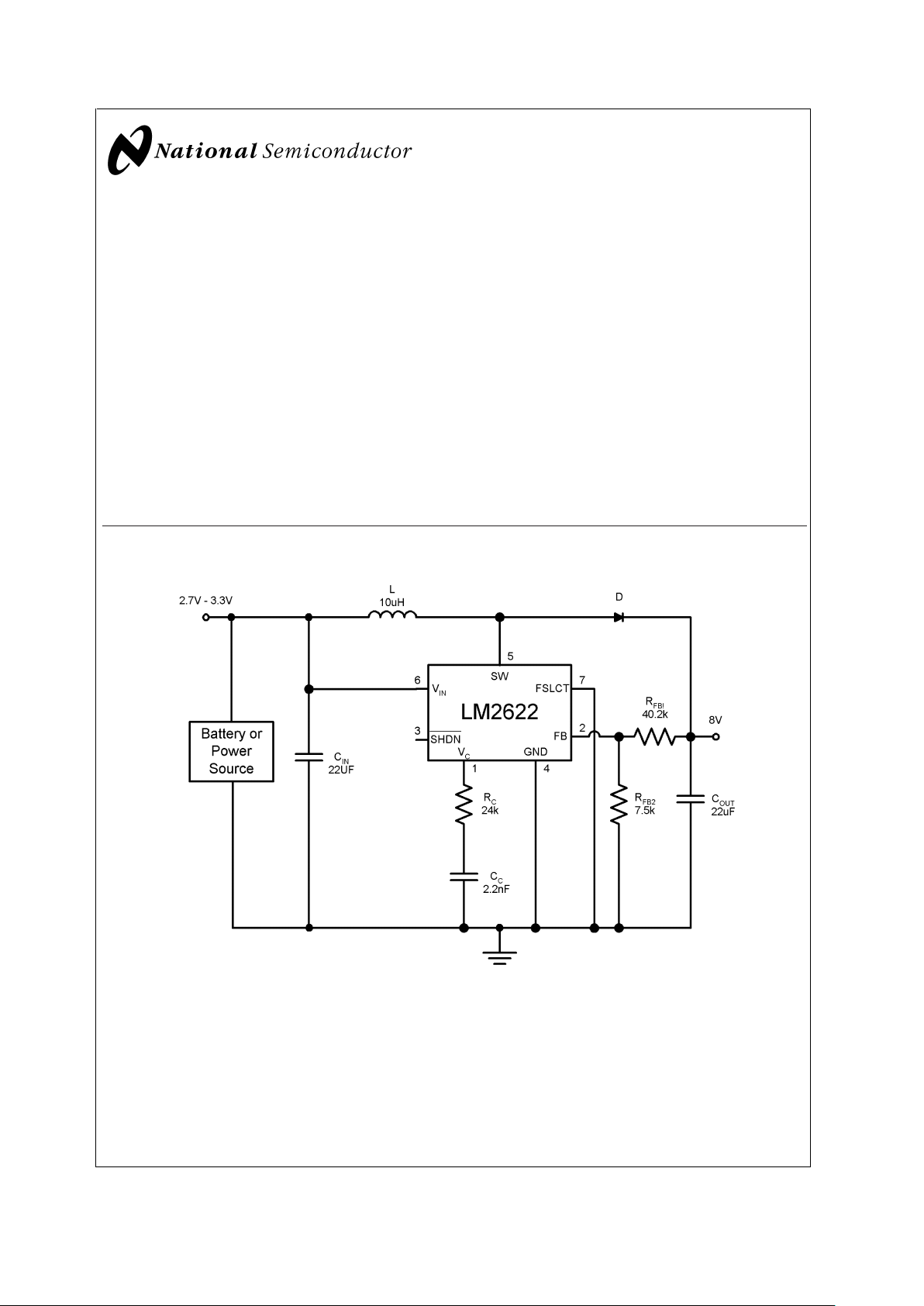

Typical Application Circuit

10127331

600 kHz Operation

October 2001

LM2622 600kHz/1.3MHz Step-up PWM DC/DC Converter

© 2001 National Semiconductor Corporation DS101273 www.national.com

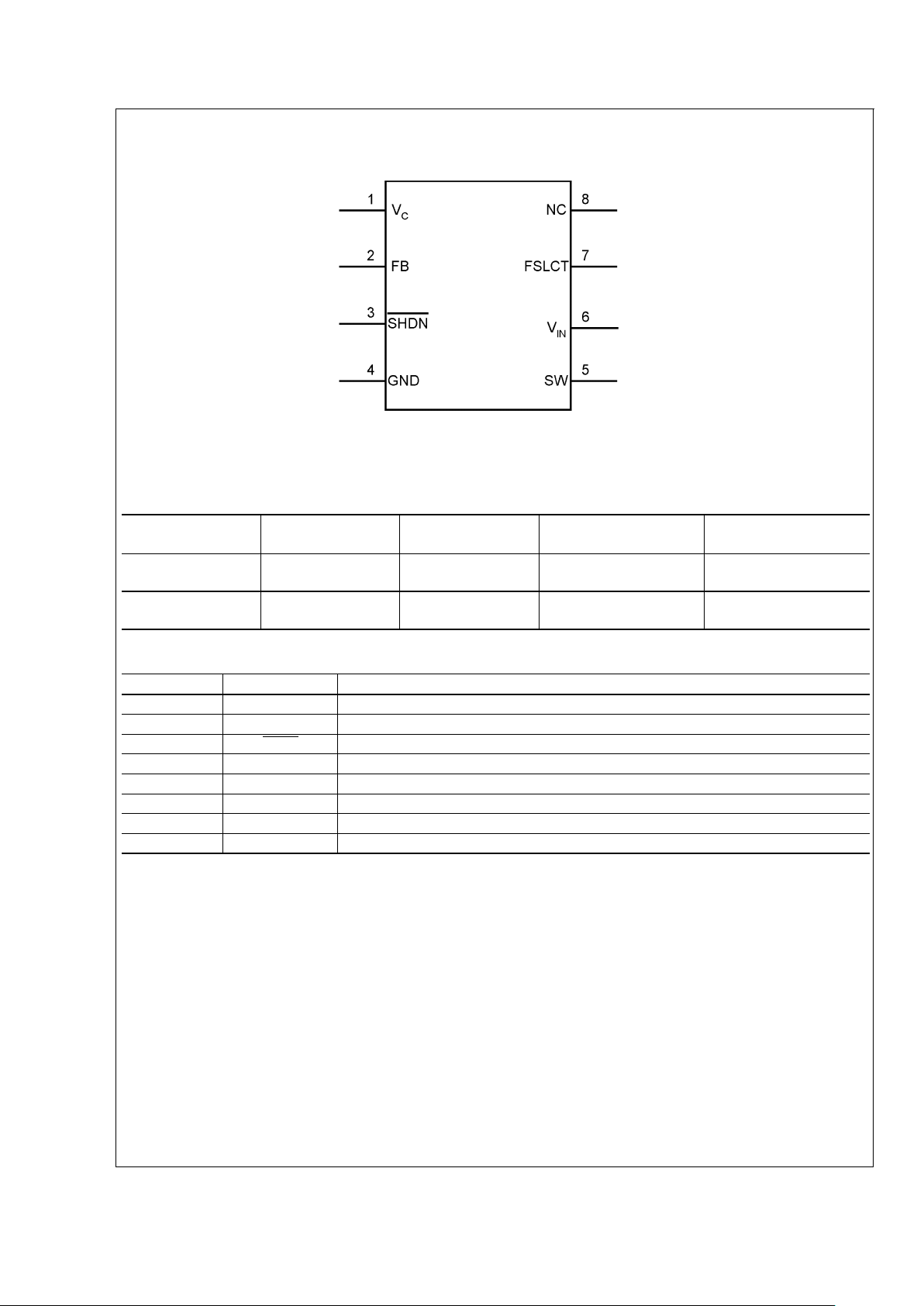

Connection Diagram

Top View

10127304

8-Lead Plastic MSOP

NS Package Number MUA08A

Ordering Information

Order Number Package Type NSC Package

Drawing

Supplied As Package ID

LM2622MM-ADJ MSOP-8 MUA08A 1000 Units, Tape and

Reel

S18B

LM2622MMX-ADJ MSOP-8 MUA08A 3500 Units, Tape and

Reel

S18B

Pin Description

Pin Name Function

1V

C

Compensation network connection. Connected to the output of the voltage error amplifier.

2 FB Output voltage feedback input.

3 SHDN

Shutdown control input, active low.

4 GND Analog and power ground.

5 SW Power switch input. Switch connected between SW pin and GND pin.

6V

IN

Analog power input.

7 FSLCT Switching frequency select input. V

IN

= 1.3MHz. Ground = 600kHz.

8 NC Connect to ground.

LM2622

www.national.com 2

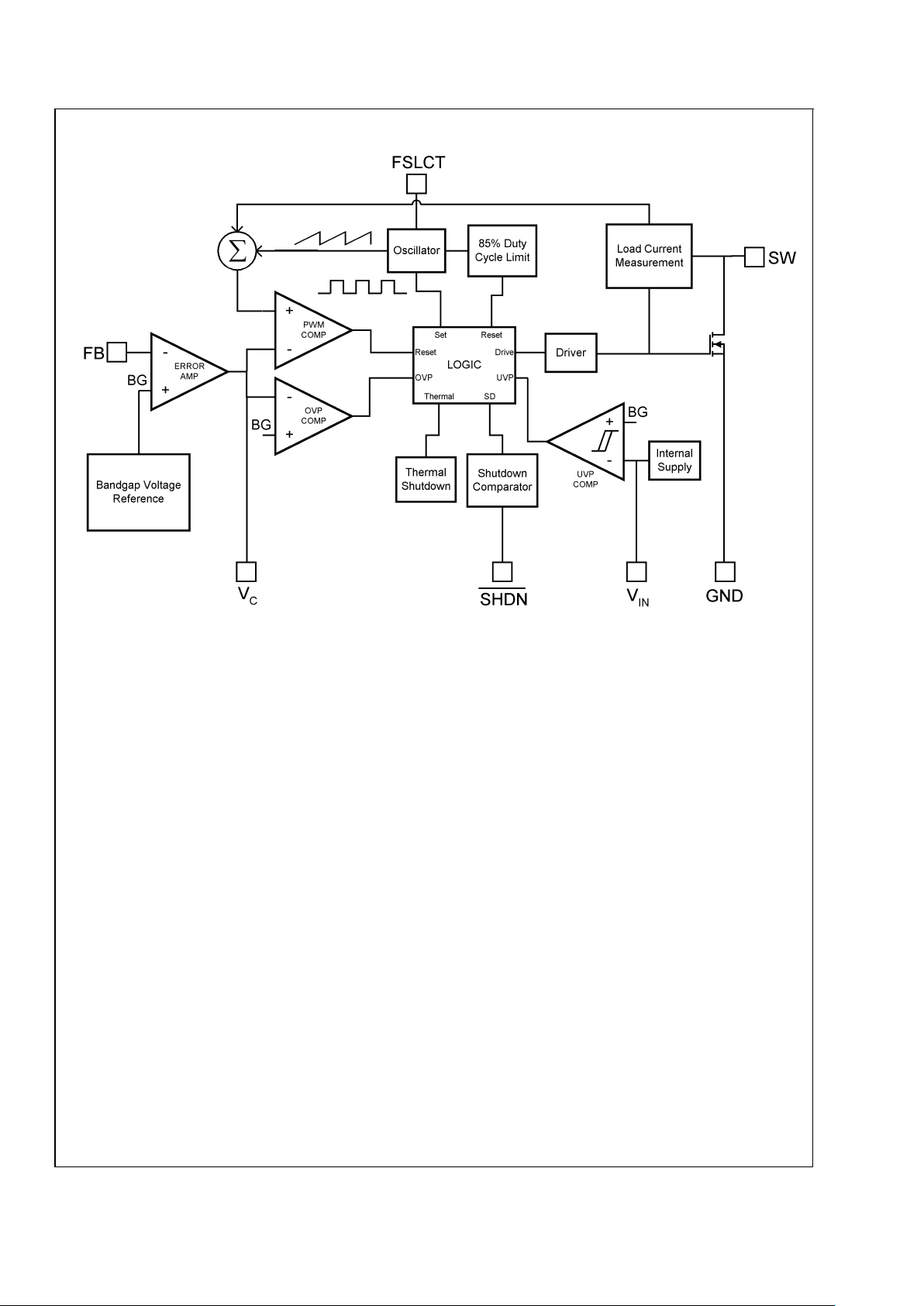

Block Diagram

10127303

LM2622

www.national.com3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

12V

SW Voltage 18V

FB Voltage 7V

V

C

Voltage 7V

SHDN Voltage

7V

FSLCT 12V

Maximum Junction

Temperature

150˚C

Power Dissipation(Note 2) Internally Limited

Lead Temperature 300˚C

Vapor Phase (60 sec.) 215˚C

Infrared (15 sec.) 220˚C

ESD Susceptibility

(Note 3)

Human Body Model 2kV

Machine Model 200V

Operating Conditions

Operating Junction

Temperature Range (Note 4) −40˚C to +125˚C

Storage Temperature −65˚C to +150˚C

Supply Voltage 2V to 12V

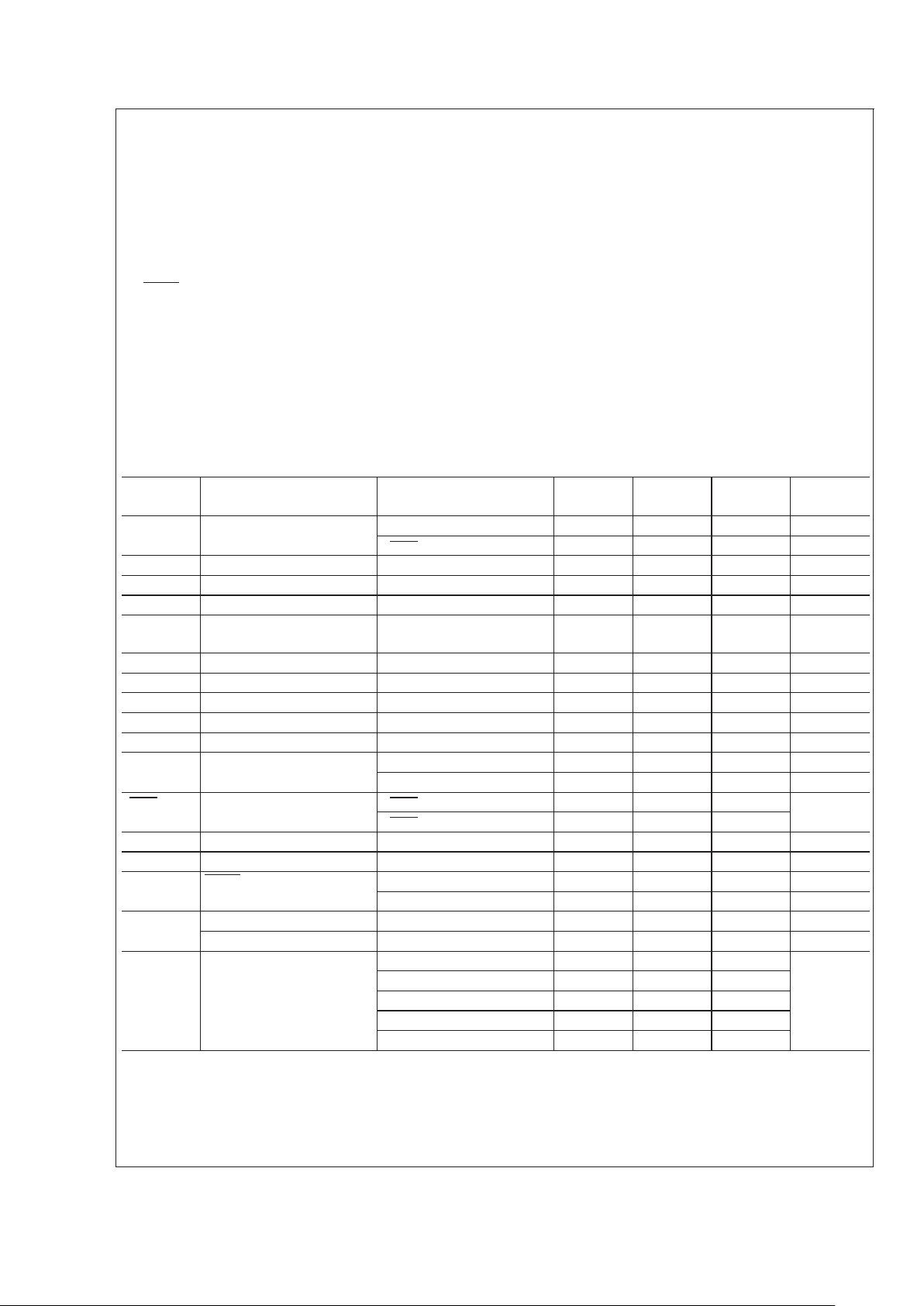

Electrical Characteristics

Specifications in standard type face are for TJ= 25˚C and those with boldface type apply over the full Operating Temperature Range (T

J

= −40˚C to +125˚C)Unless otherwise specified. VIN=2.0V and IL= 0A, unless otherwise specified.

Symbol Parameter Conditions

Min

(Note 4)

Typ

(Note 5)

Max

(Note 4)

Units

I

Q

Quiescent Current FB = 0V (Not Switching) 1.3 2.0 mA

V

SHDN

=0V 5 10 µA

V

FB

Feedback Voltage 1.2285 1.26 1.2915 V

I

CL

(Note 6) Switch Current Limit VIN= 2.7V (Note 7) 1.0 1.65 2.3 A

∆V

O

/∆I

LOAD

Load Regulation VIN= 3.3V 6.7 mV/A

%V

FB

/∆VINFeedback Voltage Line

Regulation

2.0V ≤ VIN≤ 12.0V 0.013 0.1 %/V

I

B

FB Pin Bias Current (Note 8) 0.5 20 nA

V

IN

Input Voltage Range 212V

g

m

Error Amp Transconductance ∆I = 5µA 40 135 290 µmho

A

V

Error Amp Voltage Gain 135 V/V

D

MAX

Maximum Duty Cycle 78 85 %

f

S

Switching Frequency FSLCT = Ground 480 600 720 kHz

FSLCT = V

IN

1 1.25 1.5 MHz

I

SHDN

Shutdown Pin Current V

SHDN=VIN

0.01 0.1 µA

V

SHDN

=0V −0.5 -1

I

L

Switch Leakage Current VSW= 18V 0.01 3 µA

R

DSON

Switch R

DSON

VIN= 2.7V, ISW= 1A 0.2 0.4 Ω

Th

SHDN

SHDN Threshold Output High 0.9 0.6 V

Output Low 0.6 0.3 V

UVP On Threshold 1.8 1.92 2.0 V

Off Threshold 1.7 1.82 1.9 V

θ

JA

Thermal Resistance Junction to Ambient(Note 9) 235 ˚C/W

Junction to Ambient(Note 10) 225

Junction to Ambient(Note 11) 220

Junction to Ambient(Note 12) 200

Junction to Ambient(Note 13) 195

Note 1: Absolute maximum ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is intended to

be functional, but device parameter specifications may not be guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The maximum allowable power dissipation is a function of the maximum junction temperature, T

J

(MAX), the junction-to-ambient thermal resistance, θJA,

and the ambient temperature, T

A

. See the Electrical Characteristics table for the thermal resistance of various layouts. The maximum allowable power dissipation

at any ambient temperature is calculated using: P

D

(MAX) = (T

J(MAX)−TA

)/θJA. Exceeding the maximum allowable power dissipation will cause excessive die

temperature, and the regulator will go into thermal shutdown.

LM2622

www.national.com 4

Electrical Characteristics (Continued)

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5kΩ resistor into each pin. The machine model is a 200pF capacitor discharged

directly into each pin.

Note 4: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are 100%

production tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used to

calculate Average Outgoing Quality Level (AOQL).

Note 5: Typical numbers are at 25˚C and represent the most likely norm.

Note 6: Duty cycle affects current limit due to ramp generator.

Note 7: Current limit at 0% duty cycle. See TYPICAL PERFORMANCE section for Switch Current Limit vs. V

IN

Note 8: Bias current flows into FB pin.

Note 9: Junction to ambient thermal resistance (no external heat sink) for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit.

See ’Scenario ’A’’ in the Power Dissipation section.

Note 10: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.0191 sq. in. of copper heat sinking. See ’Scenario ’B’’ in the Power Dissipation section.

Note 11: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.0465 sq. in. of copper heat sinking. See ’Scenario ’C’’ in the Power Dissipation section.

Note 12: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.2523 sq. in. of copper heat sinking. See ’Scenario ’D’’ in the Power Dissipation section.

Note 13: Junction to ambient thermal resistance for the MSO8 package with minimal trace widths (0.010 inches) from the pins to the circuit and approximately

0.0098 sq. in. of copper heat sinking on the top layer and 0.0760 sq. in. of copper heat sinking on the bottom layer, with three 0.020 in. vias connecting the planes.

See ’Scenario ’E’’ in the Power Dissipation section.

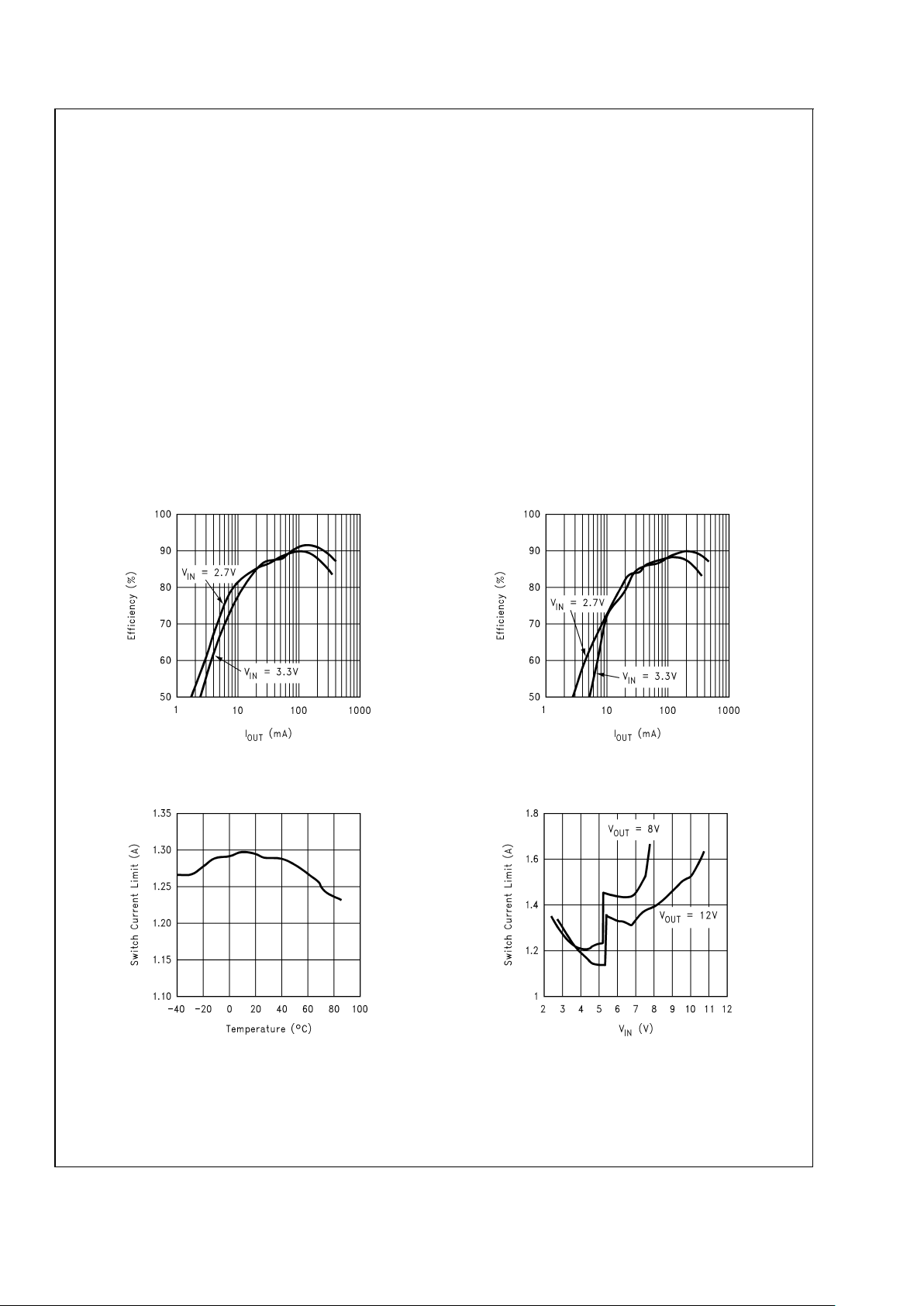

Typical Performance Characteristics

Efficiency vs. Load Current

(V

OUT

= 8V, fS= 600 kHz)

Efficiency vs. Load Current

(V

OUT

= 8V, fS= 1.3 MHz)

10127326 10127325

Switch Current Limit vs. Temperature

(V

IN

= 3.3V, V

OUT

= 8V) Switch Current Limit vs. V

IN

10127320

10127322

LM2622

www.national.com5

Typical Performance Characteristics (Continued)

R

DSON

vs. V

IN

(ISW= 1A)

I

Q

vs. V

IN

(600 kHz, not switching)

10127327 10127328

IQvs. V

IN

(600 kHz, switching)

I

Q

vs. V

IN

(1.3 MHz, not switching)

10127329 10127321

IQvs. V

IN

(1.3 MHz, switching)

I

Q

vs. V

IN

(In shutdown)

10127319

10127318

LM2622

www.national.com 6

Typical Performance Characteristics (Continued)

Frequency vs. V

IN

(600 kHz)

Frequency vs. V

IN

(1.3 MHz)

10127323

10127324

Load Transient Response

(600 kHz operation)

Load Transient Response

(1.3 MHz operation)

10127316

Test circuit is shown in

Figure 4

.

10127317

Test circuit is shown in

Figure 5

LM2622

www.national.com7

Operation

Continuous Conduction Mode

The LM2622 is a current-mode, PWM boost regulator. A

boost regulator steps the input voltage up to a higher output

voltage. In continuous conduction mode (when the inductor

current never reaches zero at steady state), the boost regulator operates in two cycles.

In the first cycle of operation, shown in

Figure 1

(a), the

transistor is closed and the diode is reverse biased. Energy

is collected in the inductor and the load current is supplied by

C

OUT

.

The second cycle isshown in

Figure 1

(b). During this cycle,

the transistor is open and the diode is forward biased. The

energy stored in the inductor is transferred to the load and

output capacitor.

The ratio of these two cycles determines the output voltage.

The output voltage is defined approximately as:

where D is the duty cycle of the switch, D and D' will be

required for design calculations.

Setting the Output Voltage

The output voltage is set using the feedback pin and a

resistor divider connected to the output as shown in the

typical operating circuit. The feedback pin voltage is 1.26V,

so the ratio of the feedback resistors sets the output voltage

according to the following equation:

Introduction to Compensation

10127302

FIGURE 1. Simplified Boost Converter Diagram

(a) First Cycle of Operation (b) Second Cycle Of Operation

10127305

FIGURE 2. (a) Inductor current. (b) Diode current.

LM2622

www.national.com 8

Operation (Continued)

The LM2622 is a current mode PWM boost converter. The

signal flow of this control scheme has two feedback loops,

one that senses switch current and one that senses output

voltage.

To keep a current programmed control converter stable

above duty cycles of 50%, the inductor must meet certain

criteria. The inductor, along with input and output voltage,

will determine the slope of the current through the inductor

(see

Figure 2

(a)). If the slope of the inductor current is too

great, the circuit will be unstable above duty cycles of 50%.

A 10µH inductor is recommended for most 600 kHz applications, while a 4.7µH inductor may be used for most 1.25 MHz

applications. If the duty cycle is approaching the maximum of

85%, it may be necessary to increase the inductance by as

much as 2X. See

Inductor and Diode Selection

for more

detailed inductor sizing.

The LM2622 provides a compensation pin(V

C

) to customize

the voltage loop feedback. It is recommended that a series

combination of R

C

and CCbe used for the compensation

network, as shown in the typical application circuit. For any

given application, there exists a unique combination of R

C

and CCthat will optimize the performance of the LM2622

circuit in terms of its transient response. The series combination of R

C

and CCintroduces a pole-zero pair according to

the following equations:

where ROis the output impedance of the error amplifier,

approximately 1MegΩ. For most applications, performance

can be optimized bychoosing valueswithin the range 5kΩ≤

R

C

≤20kΩ (RCcan be up to 200kΩ if CC2is used, see

High

Output Capacitor ESR Compensation

) and 680pF ≤ CC≤

4.7nF. Refer to the

Applications Information

section for recommended values for specific circuits and conditions. Refer

to the

Compensation

section for other design requirement.

Compensation

This section will present a general design procedure to help

insure a stable and operational circuit. The designs in this

datasheet are optimized for particular requirements. If different conversions are required, some of the components may

need to be changed to ensure stability. Below is a set of

general guidelines in designing a stable circuit for continuous conduction operation (loads greater than approximately

75mA), in most all cases this will provide for stability during

discontinuous operation as well. The power components and

their effects will be determined first, then the compensation

components will be chosen to produce stability.

Inductor and Diode Selection

Although the inductor sizes mentioned earlier are fine for

most applications, a more exact value can be calculated. To

ensure stability at duty cycles above 50%, the inductor must

have some minimum value determined by the minimum

input voltage and the maximum output voltage. This equation is:

where fs is the switching frequency, D is the duty cycle, and

R

DSON

is the ON resistance ofthe internal switchtaken from

the graph ’R

DSON

vs. VIN’ in the

Typical Performance Char-

acteristics

section. This equation is only good for dutycycles

greater than 50% (D

>

0.5), for duty cycles less than50% the

recommended values may be used. The corresponding inductor current ripple as shown in

Figure 2

(a) is given by:

The inductor ripple current is important for a few reasons.

One reason is because the peak switch current will be the

average inductor current (input current or I

LOAD

/D’) plus ∆iL.

As a side note, discontinuous operation occurs when the

inductor current falls to zero during a switching cycle, or ∆i

L

is greater than the average inductor current. Therefore, continuous conduction mode occurs when ∆i

L

is less than the

average inductor current. Care must be taken to make sure

that the switch will not reach its current limit during normal

operation. The inductor must also be sized accordingly. It

should have a saturation current rating higher than the peak

inductor current expected. The output voltage ripple is also

affected by the total ripple current.

The output diode for a boost regulator must be chosen

correctly depending on the output voltage and the output

current. The typical current waveform for the diode in continuous conduction mode is shown in

Figure 2

(b). The diode

must be rated for a reverse voltage equal to or greater than

the output voltage used. The average current rating must be

greater than the maximum load current expected, and the

peak current rating must be greater than the peak inductor

current. During short circuit testing, or if short circuit conditions are possible in the application, the diode current rating

must exceed the switch current limit. Using Schottky diodes

with lower forward voltage drop will decrease power dissipation and increase efficiency.

DC Gain and Open-loop Gain

Since the control stage of the converter forms a complete

feedback loop with the power components, it forms a closedloop system that must be stabilized to avoid positive feedback and instability. A value for open-loop DC gain will be

required, from which you can calculate, or place, poles and

zeros to determine the crossover frequency and the phase

margin.A high phase margin (greater than 45˚)is desired for

the best stability and transient response. For the purpose of

stabilizing the LM2622, choosing a crossover point well below where the right half plane zero is located will ensure

sufficient phase margin. A discussion of the right half plane

zero and checking the crossover using the DC gain will

follow.

Input and Output Capacitor Selection

The switching action of a boost regulator causes a triangular

voltage waveform at the input. A capacitor is required to

reduce the input ripple and noise for proper operation of the

regulator.The size used is dependanton the applicationand

board layout. If the regulator will be loaded uniformly, with

LM2622

www.national.com9

Operation (Continued)

very little load changes, and at lower current outputs, the

input capacitor size can often be reduced. The size can also

be reduced if the input of the regulator is very close to the

source output. The size will generally need to be larger for

applications where the regulator is supplying nearly the

maximum rated output or if large load steps are expected.A

minimum value of 10µF should be used for the less stressful

condtions while a 22µF to 47µF capacitor may be required

for higher power and dynamic loads. Larger values and/or

lower ESR may be needed if the application requires very

low ripple on the input source voltage.

The choice of output capacitors is also somewhat arbitrary

and depends on the design requirements for output voltage

ripple. It is recommended that low ESR (Equivalent Series

Resistance, denoted R

ESR

) capacitors be used such as

ceramic, polymer electrolytic, or low ESR tantalum. Higher

ESR capacitors may be used but will require more compensation which will be explained later on in the section. The

ESR is also important because it determines the peak to

peak output voltage ripple according to the approximate

equation:

∆V

OUT

) 2∆iLR

ESR

(in Volts)

A minimum value of 10µF is recommended and may be

increased to a larger value. After choosing the output capacitor you can determine a pole-zero pair introduced into the

control loop by the following equations:

Where RLis the minimum load resistance corresponding to

the maximum load current. The zero created by the ESR of

the output capacitor is generally very high frequency if the

ESR is small. If low ESR capacitors are used it can be

neglected. If higher ESR capacitors are used see the

High

Output Capacitor ESR Compensation

section.

Right Half Plane Zero

A current mode control boost regulator has an inherent right

half plane zero (RHP zero). This zero hasthe effect of a zero

in the gain plot, causing an imposed +20dB/decade on the

rolloff, but has the effect of a pole in the phase, subtracting

another 90˚ in the phase plot. This can cause undesirable

effects if the control loop is influenced by this zero. To ensure

the RHP zero does not cause instability issues, the control

loop should be designed tohave a bandwidthof less than

1

⁄

2

the frequency of the RHP zero. This zero occurs at a frequency of:

where I

LOAD

is the maximum load current.

Selecting the Compensation Components

The first step in selecting the compensation components R

C

and CCis to set a dominant low frequency polein the control

loop. Simply choose values for R

C

and CCwithin the ranges

given in the

Introduction to Compensation

section to set this

pole in the area of 10Hz to500Hz. The frequency of thepole

created is determined by the equation:

where ROis the output impedance of the error amplifier,

approximately 1MegΩ. Since R

C

is generally much less than

R

O

, it does not have much effect on the above equation and

can be neglected until a value is chosen to set the zero f

ZC

.

f

ZC

is created to cancel out the pole created by the output

capacitor, f

P1

. The output capacitor pole will shift with different load currents as shown by the equation, so setting the

zero is not exact. Determine the range of f

P1

over the ex-

pected loads and then set the zero f

ZC

to a point approximately in the middle. The frequency of this zero is determined by:

Now RCcan be chosen with the selected value for CC.

Check to make sure that the pole f

PC

is still in the 10Hz to

500Hz range, change each value slightly if needed to ensure

both component values are in the recommended range.After

checking the design at the end of this section, these values

can be changed a little more to optimize performance if

desired. This is best done in the lab on a bench, checking the

load step response with different values until the ringing and

overshoot on the output voltage at the edge of the load steps

is minimal. This should produce a stable, high performance

circuit. For improved transient response, higher values of R

C

should be chosen. This will improve the overall bandwidth

which makes the regulator respond more quickly to transients. If more detail is required, or the most optimal performance is desired, refer to a more in depth discussion of

compensating current mode DC/DC switching regulators.

High Output Capacitor ESR Compensation

When using an output capacitor with a high ESR value, or

just to improve the overall phase margin of the control loop,

another pole may be introduced to cancel the zero created

by the ESR. This is accomplishedby adding another capacitor, C

C2

, directly from the compensation pin VCto ground, in

parallel with the series combination of R

C

and CC. The pole

should be placed at the same frequency as f

Z1

, the ESR

zero. The equation for this pole follows:

To ensure this equation is valid, and that CC2can be used

without negatively impacting the effects of R

C

and CC,f

PC2

must be greater than 10fZC.

Checking the Design

The final step is to check the design. This is to ensure a

bandwidth of

1

⁄2or less of the frequency of the RHP zero.

This is done by calculating the open-loop DC gain, A

DC

.After

this value is known, you can calculate the crossover visually

by placing a −20dB/decade slope at each pole, and a

+20dB/decade slope for each zero. The point at which the

gain plot crosses unity gain, or 0dB, is the crossover frequency. If the crossover frequency is less than

1

⁄2the RHP

zero, the phase margin should be high enough for stability.

LM2622

www.national.com 10

Operation (Continued)

The phase margin can also be improved by adding C

C2

as

discussed earlier in the section. The equation for A

DC

is

given below with additional equations required for the calculation:

mc ) 0.072fs (in V/s)

where RLis the minimum load resistance, VINis the maximum input voltage, g

m

is the error amplifier transconduc-

tance found in the

Electrical Characteristics

table, and R

D

-

SON

is the value chosen from the graph ’R

DSON

vs. VIN’in

the

Typical Performance Characteristics

section.

Layout Considerations

The input bypass capacitor C

IN

, as shown in the typical

operating circuit, must be placed close to the IC. This will

reduce copper trace resistance which effects input voltage

ripple of the IC. For additional input voltage filtering,a 100nF

bypass capacitor can be placed in parallel with C

IN

, close to

the V

IN

pin, to shunt any high frequency noise to ground. The

output capacitor, C

OUT

, should also be placed close to the

IC. Any copper trace connections for the C

OUT

capacitor can

increase the series resistance, which directly effects output

voltage ripple. The feedback network, resistors R

FB1

and

R

FB2

, should be kept close to the FB pin, and away from the

inductor, to minimize copper trace connections that can inject noise into the system. Trace connections made to the

inductor and schottky diode should be minimized to reduce

power dissipation and increase overall efficiency. For more

detail on switching power supply layout considerations see

Application Note AN-1149:

Layout Guidelines for Switching

Power Supplies

.

LM2622

www.national.com11

Application Information

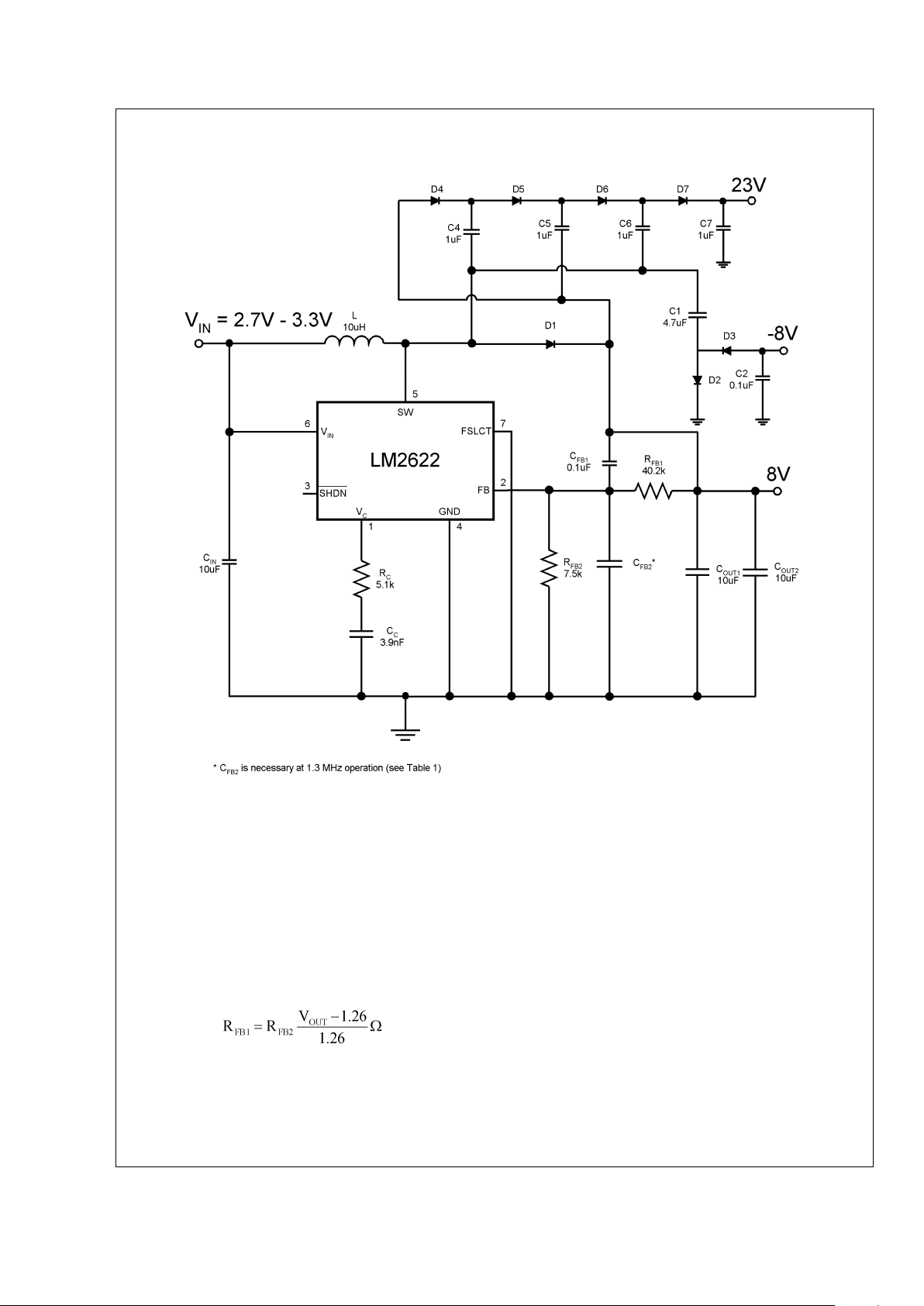

Triple Output TFT Bias

The circuit in

Figure 3

shows how the LM2622 can be

configured to provide outputs of 8V, −8V, and 23V, convenient for biasing TFT displays. The 8V output is regulated,

while the −8V and 23V outputs are unregulated.

The 8V output is generated by a typical boost topology. The

basic operation of the boost converter is described in the

OPERATION section. The output voltage is set with R

FB1

and R

FB2

by:

CFBis placed across R

FB1

to act as a pseudo soft-start. The

compensation network of R

C

and CCare chosen to optimally

stabilize the converter. The inductor also affects the stability.

When operating at 600 kHz, a 10uH inductor is recom-

mended to insure the converter is stable at duty cycles

greater than 50%. Refer tothe COMPENSATION section for

more information.

The -8V output is derived from a diode inverter. During the

second cycle, when the transistor is open, D2 conducts and

C1 charges to 8V minus a diode drop ()0.4V if using a

Schottky). When the transistor opens in the first cycle, D3

conducts and C1’s polarity is reversed with respect to the

output at C2, producing -8V.

The 23V output is realized with a series of capacitor charge

pumps. It consists of fourstages: the firststage includes C4,

D4, and the LM2622 switch; the second stage uses C5, D5,

and D1; the third stage includes C6, D6, and the LM2622

switch; the final stage is C7 and D7. In the first stage, C4

charges to 8V when the LM2622 switch is closed, which

causes D5 to conduct when the switch is open. In the second

stage, the voltage across C5 is VC4 + VD1 - VD5 = VC4 )

8V when the switch is open. However, because C5 is referenced to the 8V output, the voltage at C5 is 16V when

referenced to ground. In the third stage, the 16V at C5

10127308

FIGURE 3. Triple Output TFT Bias (600 kHz operation)

LM2622

www.national.com 12

Application Information (Continued)

appears across C6 when the switch is closed. When the

switch opens, C6 is referenced to the 8V output minus a

diode drop, which raises the voltage at C6 with respect to

ground to about 24V. Hence, in the fourth stage, C7 is

charged to 24V when the switch is open. From the first stage

to the last, there are three diode drops that make the output

voltage closer to 24 - 3xVDIODE (about 22.8V if a 0.4V

forward drop is assumed).

TABLE 1. Components For Circuits in

Figure 3

Component 600 kHz 1.3 MHz

L 10µH 4.7µH

COUT1 10µF 22µF

COUT2 10µF NOT USED

CC 3.9nF 1.5nF

CFB1 0.1µF 15nF

CFB2 NOT USED 560pF

CIN 10µF 22µF

C1 4.7µF 4.7µF

Component 600 kHz 1.3 MHz

C2 0.1µF 0.1µF

C4 1µF 1µF

C5 1µF 1µF

C6 1µF 1µF

C7 1µF 1µF

RFB1 40.2kΩ 91kΩ

RFB2 7.5kΩ 18kΩ

RC 5.1kΩ 10kΩ

D1 MBRM140T3 MBRM140T3

D2

BAT54S BAT54S

D3

D4

BAT54S BAT54S

D5

D6

BAT54S BAT54S

D7

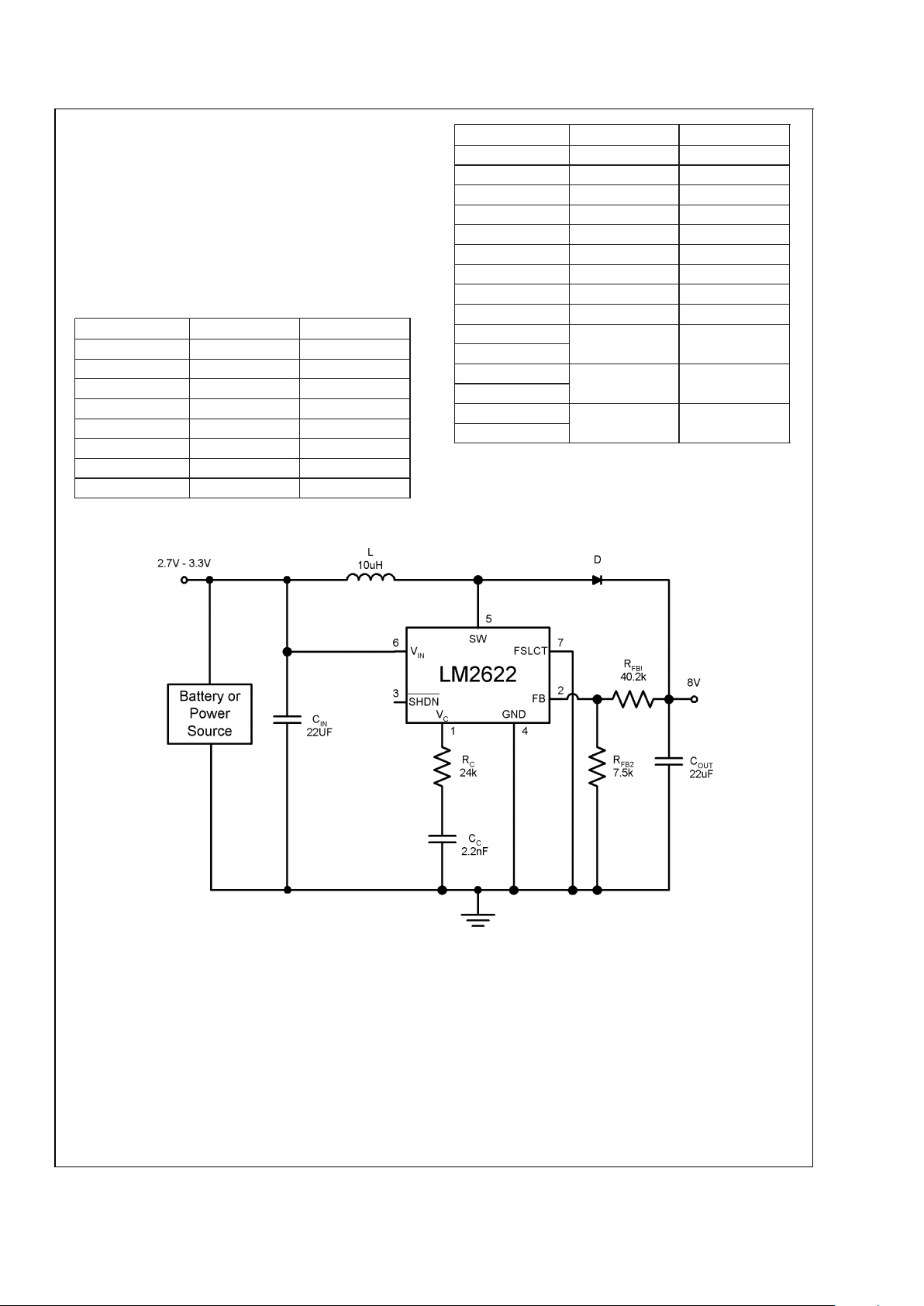

600 kHz Operation

10127331

FIGURE 4. 600 kHz operation

LM2622

www.national.com13

Application Information (Continued)

1.3 MHz Operation

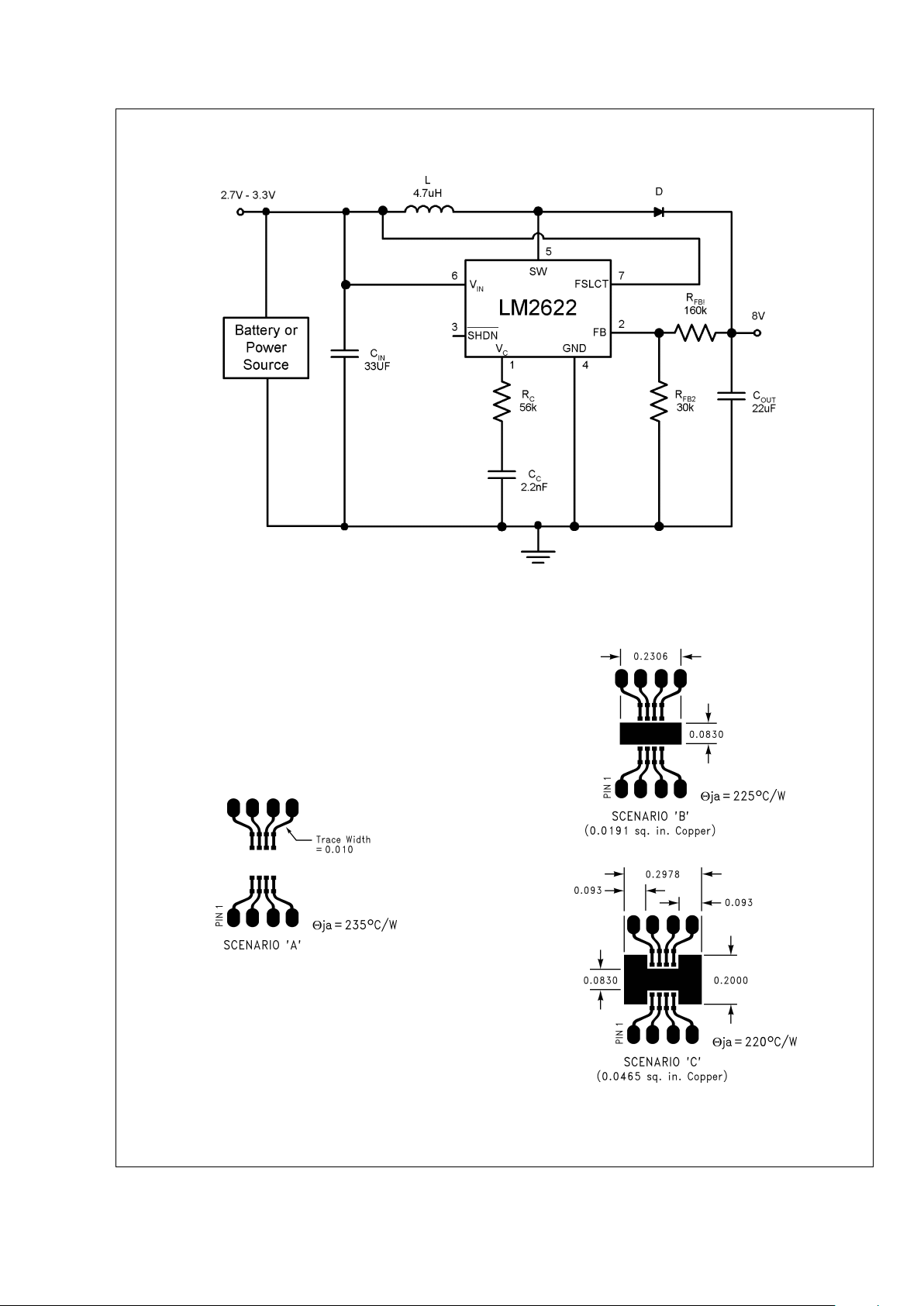

Power Dissipation

The output power of the LM2622 is limited by its maximum

power dissipation. The maximum power dissipation is determined by the formula

P

D

=(T

jmax-TA

)/θ

JA

where T

jmax

is the maximum specidfied junction temperature

(125˚C), T

A

is the ambient temperature, and θJAis the ther-

mal resistance of the package. θ

JA

is dependant on the

layout of the board as shown below.

10127311

10127312

10127313

10127330

FIGURE 5. 1.3 MHz operation

LM2622

www.national.com 14

Application Information (Continued)

10127314

10127315

LM2622

www.national.com15

Physical Dimensions inches (millimeters)

unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

LM2622 600kHz/1.3MHz Step-up PWM DC/DC Converter

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...