NSC 5962-9059301MEA, 5962-9059301M2A Datasheet

TL/F/9535

54F/74F402 Serial Data Polynomial Generator/Checker

January 1995

54F/74F402 Serial Data Polynomial

Generator/Checker

General Description

The ’F402 expandable Serial Data Polynomial generator/

checker is an expandable version of the ’F401. It provides

an advanced tool for the implementation of the most widely

used error detection scheme in serial digital handling systems. A 4-bit control input selects one-of-six generator polynomials. The list of polynomials includes CRC-16, CRCCCITT and Ethernet

É

, as well as three other standard poly-

nomials (56

th

order, 48thorder, 32ndorder). Individual clear

and preset inputs are provided for floppy disk and other

applications. The Error output indicates whether or not a

transmission error has occurred. The CWG Control input

inhibits feedback during check word transmission. The

’F402 is compatible with FAST

É

devices and with all TTL

families.

Features

Y

Guaranteed 30 MHz data rate

Y

Six selectable polynomials

Y

Other polynomials available

Y

Separate preset and clear controls

Y

Expandable

Y

Automatic right justification

Y

Error output open collector

Y

Typical applications:

Floppy and other disk storage systems

Digital cassette and cartridge systems

Data communication systems

Commercial Military

Package

Package Description

Number

74F402PC N16E 16-Lead (0.300×Wide) Molded Dual-In-Line

54F402DM (Note 1) J16A 16-Lead Ceramic Dual-In-Line

54F402FM (Note 1) W16A 16-Lead Cerpack

54F402LM (Note 1) E20A 20-Lead Ceramic Leadless Chip Carrier, Type C

Note 1: Military grade device with environmental and burn-in processing. Use suffixeDMQB, FMQB and LMQB.

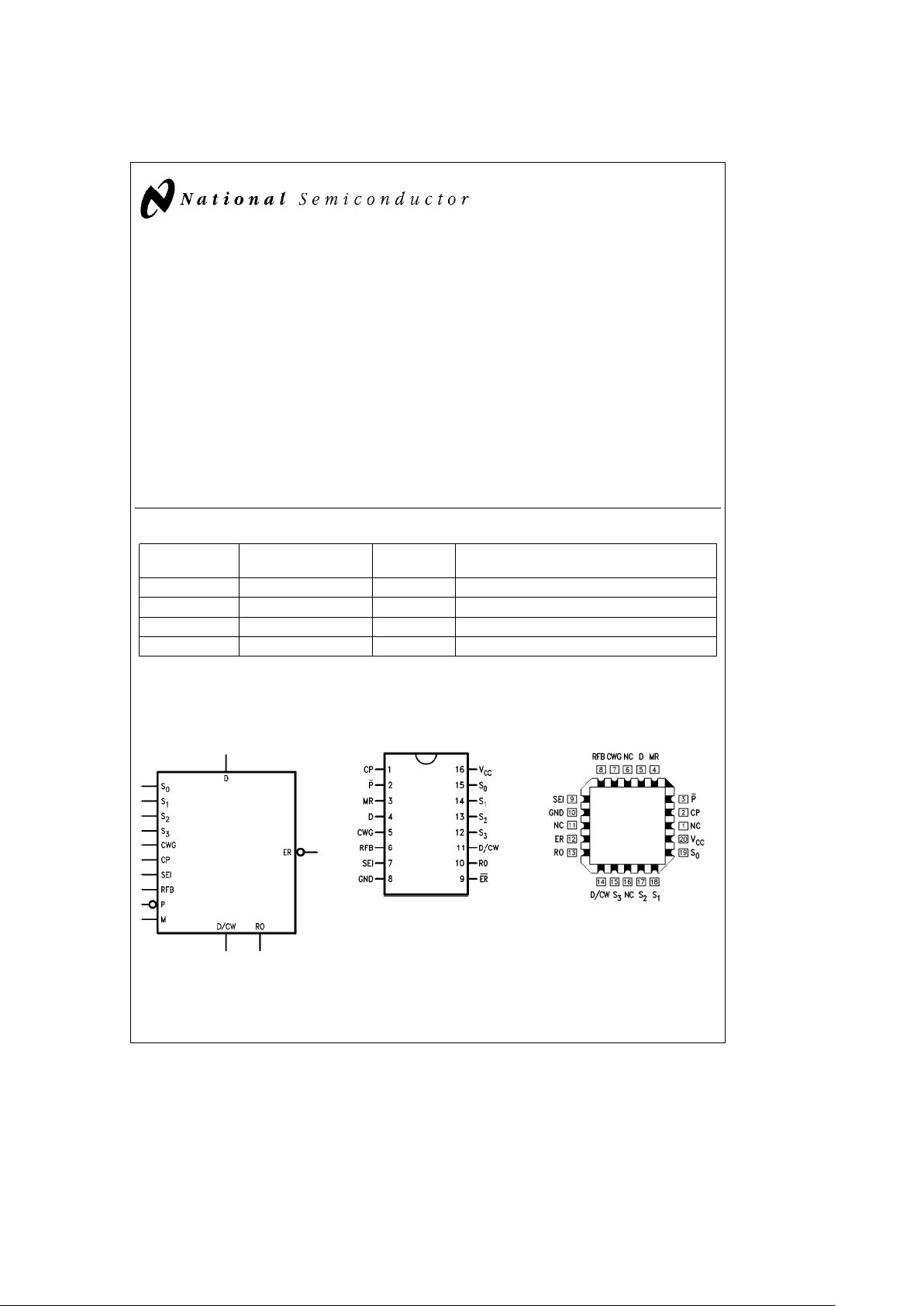

Logic Symbol Connection Diagrams

TL/F/9535– 4

Pin Assignment

for DIP, SOIC and Flatpak

TL/F/9535– 1

Pin Assignment

for LCC

TL/F/9535– 2

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

Ethernet

É

is a registered trademark of Xerox Corporation.

C

1995 National Semiconductor Corporation RRD-B30M105/Printed in U. S. A.

Unit Loading/Fan Out

54F/74F

Pin Names Description

U.L. Input I

IH/IIL

HIGH/LOW Output IOH/I

OL

S0–S

3

Polynomial Select Inputs 1.0/0.67 20 mA/b0.4 mA

CWG Check Word Generate Input 1.0/0.67 20 mA/

b

0.4 mA

D/CW Serial Data/Check Word 285(100)/13.3(6.7)

b

5.7 mA(b2 mA)/8 mA (4 mA)

D Data Input 1.0/0.67 20 mA/b0.4 mA

ER

Error Output */26.7(13.3) */16 mA (8 mA)

RO Register Output 285(100)/13.3(6.7)

b

5.7 mA(b2 mA)/8 mA (4 mA)

CP Clock Pulse 1.0/0.67 20 mA/

b

0.4 mA

SEI Serial Expansion Input 1.0/0.67 20 mA/

b

0.4 mA

RFB Register Feedback 1.0/0.67 20 mA/

b

0.4 mA

MR Master Reset 1.0/0.67 20 mA/

b

0.4 mA

P

Preset 1.0/0.67 20 mA/b0.4 mA

*Open Collector

Functional Description

The ’F402 Serial Data Polynomial Generator/Checker is an

expandable 16-bit programmable device which operates on

serial data streams and provides a means of detecting

transmission errors. Cyclic encoding and decoding schemes

for error detection are based on polynomial manipulation in

modulo arithmetic. For encoding, the data stream (message

polynomial) is divided by a selected polynomial. This division results in a remainder (or residue) which is appended to

the message as check bits. For error checking, the bit

stream containing both data and check bits is divided by the

same selected polynomial. If there are no detectable errors,

this division results in a zero remainder. Although it is possible to choose many generating polynomials of a given degree, standards exist that specify a small number of useful

polynomials. The ’F402 implements the polynomials listed in

Table I by applying the appropriate logic levels to the select

pins S

0,S1,S2

and S3.

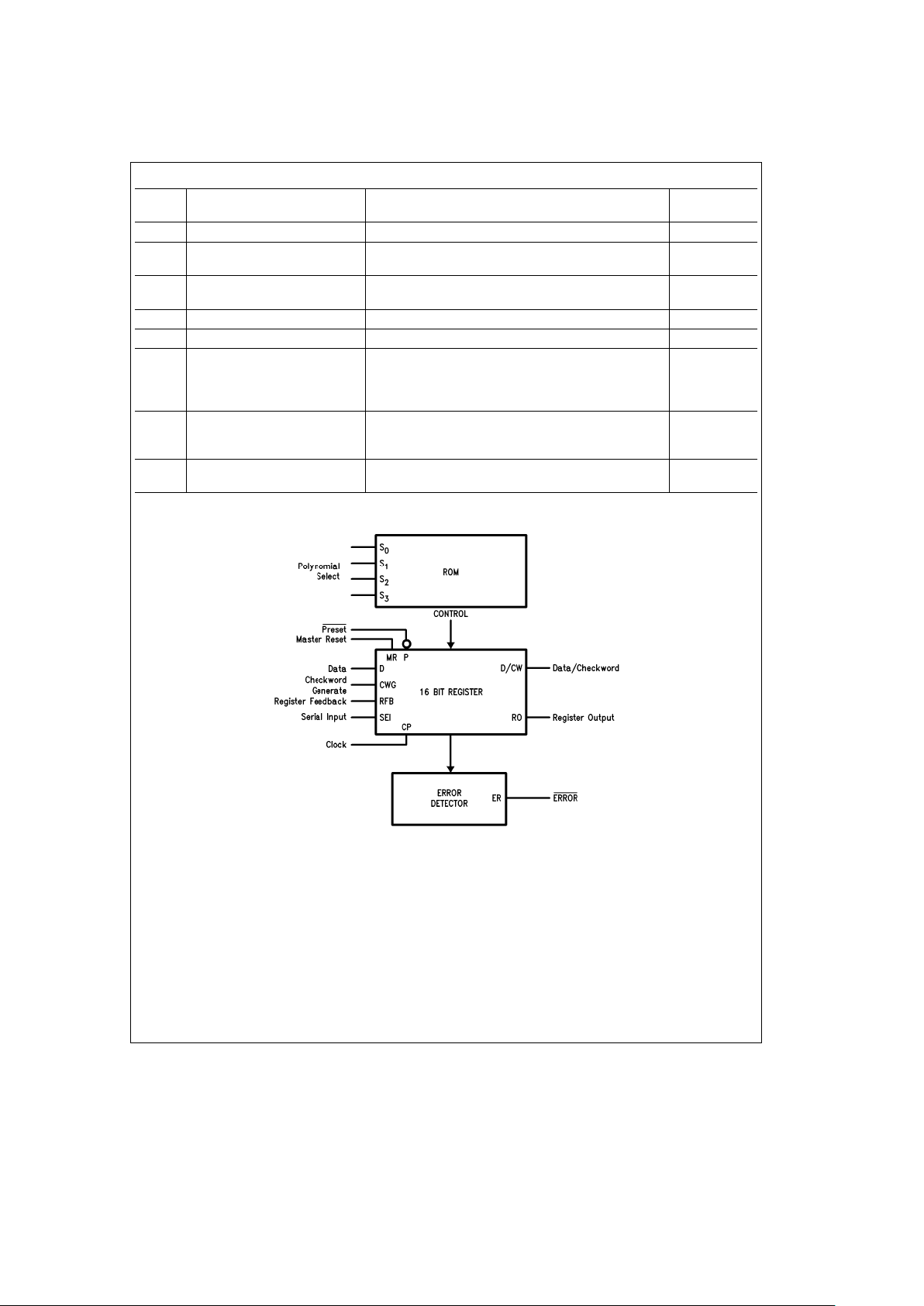

The ’F402 consists of a 16-bit register, a Read Only Memory

(ROM) and associated control circuitry as shown in the

Block Diagram. The polynomial control code presented at

inputs S

0,S1,S2

and S3is decoded by the ROM, selecting

the desired polynomial or part of a polynomial by establishing shift mode operation on the register with Exclusive OR

(XOR) gates at appropriate inputs. To generate the check

bits, the data stream is entered via the Data Inputs (D), using the LOW-to-HIGH transition of the Clock Input (CP). This

data is gated with the most significant Register Output (RO)

via the Register Feedback Input (RFB), and controls the

XOR gates. The Check Word Generate (CWG) must be held

HIGH while the data is being entered. After the last data bit

is entered, the CWG is brought LOW and the check bits are

shifted out of the register(s) and appended to the data bits

(no external gating is needed).

To check an incoming message for errors, both the data

and check bits are entered through the D Input with the

CWG Input held HIGH. The Error Output becomes valid after the last check bit has been entered into the ’F402 by a

LOW-to-HIGH transition of CP, with the exception of the

Ethernet polynomial (see Applications paragraph). If no detectable errors have occurred during the data transmission,

the resultant internal register bits are all LOW and the Error

Output (ER

) is HIGH. If a detectable error has occurred, ER

is LOW. ER remains valid until the next LOW-to-HIGH transition of CP or until the device has been preset or reset.

A HIGH on the Master Reset Input (MR) asynchronously

clears the entire register. A LOW on the Preset Input (P

)

asynchronously sets the entire register with the exception

of:

1 The Ethernet residue selection, in which the registers

containing the non-zero residue are cleared;

2 The 56th order polynomial, in which the 8 least significant

register bits of the least significant device are cleared;

and,

3 Register S

e

0, in which all bits are cleared.

2

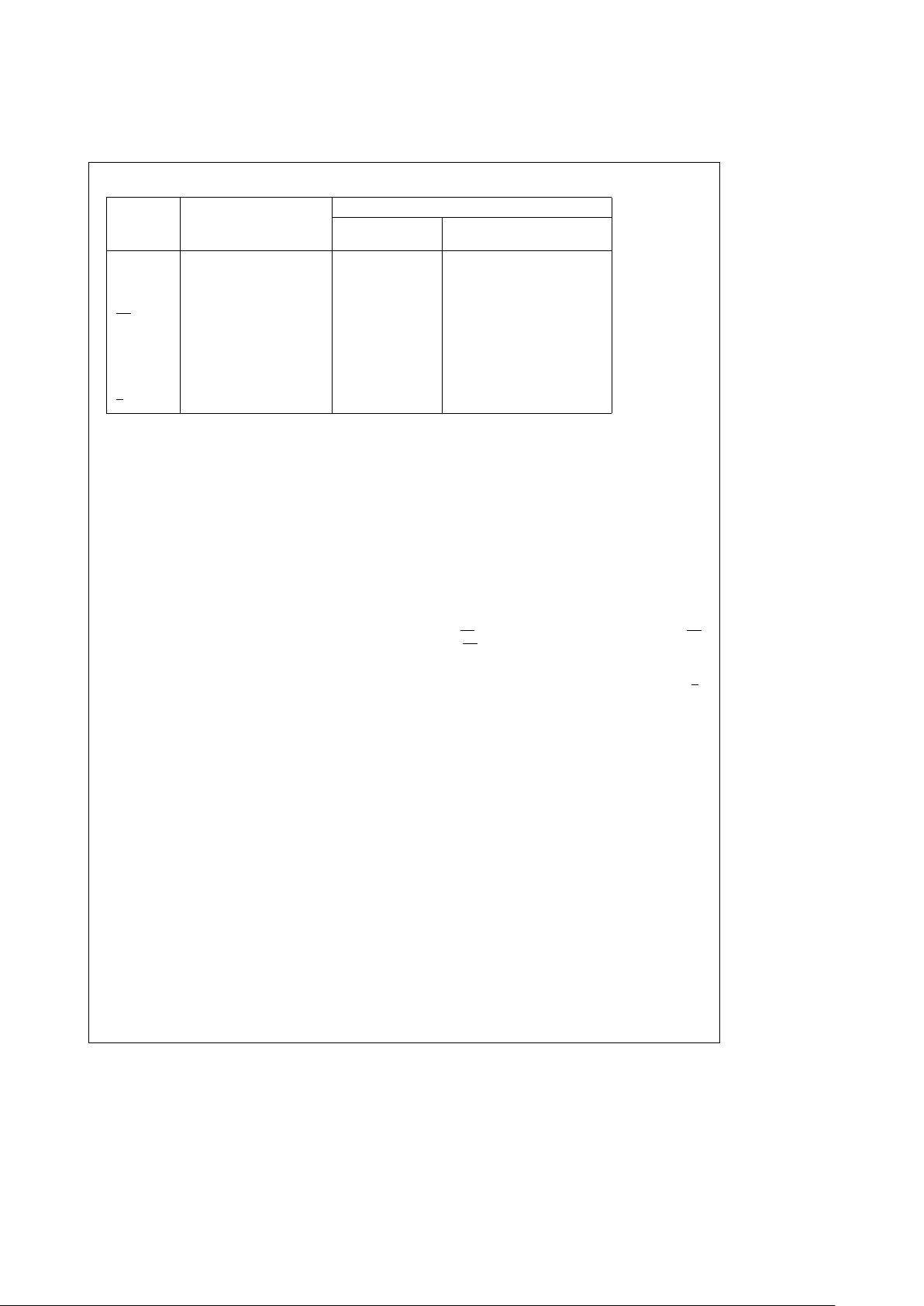

TABLE I

Hex

Select Code

Polynomial Remarks

S

3

S

2

S

1

S

0

0 LLLL0 S

e

0

CHHLLX

32

a

X

26

a

X

23

a

X

22

a

X

16

a

Ethernet

D HHLHX

12

a

X

11

a

X

10

a

X

8

a

X

7

a

X

5

a

X

4

a

X

2

aXa

1 Polynomial

E HHH LX

32

a

X

31

a

X

27

a

X

26

a

X

25

a

X

19

a

X

16

a

Ethernet

F HHHHX

15

a

X

13

a

X

12

a

X

11

a

X

9

a

X

7

a

X

6

a

X

5

a

X

4

a

X

2

aXa

1 Residue

7 L HHHX

16

a

X

15

a

X

2

a

1 CRC-16

B HLHHX

16

a

X

12

a

X

5

a

1 CRC-CCITT

3LLHHX

56

a

X

55

a

X

49

a

X

45

a

X

41

a

2 L LHLX

39

a

X

38

a

X

37

a

X

36

a

X

31

a

56th

4 LHL LX

22

a

X

19

a

X

17

a

X

16

a

X

15

a

X

14

a

X

12

a

X

11

a

X

9

a

Order

8 HLLLX

5

a

X

a

1

5 LHLHX

48

a

X

36

a

X

35

a

9HLLHX

23

a

X

21

a

48th

1 LLLHX

15

a

X

13

a

X

8

a

X

2

a

1

Order

6LHHLX

32

a

X

23

a

X

21

a

32nd

A HLHLX

11

a

X

2

a

1 Order

Block Diagram

TL/F/9535– 5

3

TABLE II

Select Code P

3

P

2

P

1

P

0

C

2

C

1

C

0

Polynomial

0 0000100S

e

0

C 1 1 1 1 1 0 1 Ethernet

D 1 1 1 1 1 0 1 Polynomial

E 0 0 0 0 0 0 0 Ethernet

F 0 0 0 0 0 1 0 Residue

7 1 1 1 1 1 0 0 CRC-16

B 1 1 1 1 1 0 0 CRC-CCITT

3 1111100

2 1 1 1 1 1 0 0 56th

4 1 1 1 1 1 0 0 Order

8 0011100

5 1111100

48th

9 1111100

Order

1 1111100

6 1 1 1 1 1 0 0 32nd

A 1 1 1 1 1 0 0 Order

Applications

In addition to polynomial selection there are four other capabilities provided for in the ’F402 ROM. The first is set or

clear selectability. The sixteen internal registers have the

capability to be either set or cleared when P

is brought

LOW. This set or clear capability is done in four groups of 4

(see Table II, P

0–P3

). The second ROM capability (C0)isin

determining the polarity of the check word. As is the case

with the Ethernet polynomial the check word can be inverted when it is appended to the data stream or as is the case

with the other polynomials, the residue is appended with no

inversion. Thirdly, the ROM contains a bit (C

1

) which is used

to select the RFB input instead of the SEI input to be fed

into the LSB. This is used when the polynomial selected is

actually a residue (least significant) stored in the ROM

which indicates whether the selected location is a polynomial or a residue. If the latter, then it inhibits the RFB input.

As mentioned previously, upon a successful data transmission, the CRC register has a zero residue. There is an exception to this, however, with respect to the Ethernet polynomial. This polynomial, upon a successful data transmission, has a non-zero residue in the CRC register (C7 04 DD

7B)

16

. In order to provide a no-error indication, two ROM

locations have been preloaded with the residue so that by

selecting these locations and clocking the device one additional time, after the last check bit has been entered, will

result in zeroing the CRC register. In this manner a no-error

indication is achieved.

With the present mix of polynomials, the largest is 56

th

or-

der requiring four devices while the smallest is 16

th

order

requiring just one device. In order to accommodate multiplexing between high order polynomials (X 16

th

order) and

lower order polynomials, a location of all zeros is provided.

This allows the user to choose a lower order polynomial

even if the system is configured for a higher order one.

The ’F402 expandable CRC generator checker contains 6

popular CRC polynomials, 2-16

th

Order, 2-32ndOrder, 1-

48

th

Order and 1-56thOrder. The application diagram

shows the ’F402 connected for a 56

th

Order polynomial.

Also shown are the input patterns for other polynomials.

When the ’F402 is used with a gated clock, disabling the

clock in a HIGH state will ensure no erroneous clocking

occurs when the clock is re-enabled. Preset and Master Reset are asynchronous inputs presetting the register to S or

clearing to 1s respectively (note Ethernet residue and 56

th

Order select code 8, LSB, are exceptions to this).

To generate a CRC, the pattern for the selected polynomial

is applied to the S inputs, the register is preset or cleared as

required, clock is enabled, CWG is set HIGH, data is applied

to D input, output data is on D/CW. When the last data bit

has been entered, CWG is set LOW and the register is

clocked for n bits (where n is the order of the polynomial).

The clock may now be stopped if desired (holding CWG

LOW and clocking the register will output zeros from D/CW

after the residue has been shifted out).

To check a CRC, the pattern for the selected polynomial is

applied to the S inputs, the register is preset or cleared as

required, clock is enabled, CWG is set HIGH, the data

stream including the CRC is applied to D input. When the

last bit of the CRC has been entered, the ER

output is

checked: HIGH

e

error free data, LOWecorrupt data. The

clock may now be stopped if desired.

To implement polynomials of lower order than 56

th

, select

the number of packages required for the order of polynomial

and apply the pattern for the selected polynomial to the S

inputs (0000 on S inputs disables the package from the

feedback chain).

4

Loading...

Loading...