NC400-6 Counter

ELECTRONIC PROGRAMMABLE COUNTER – INSTRUCTIONS MANUAL – V1.2x A

SAFETY ALARMS

The following symbols appear in the device and throughout this

manual to call the user’s attention as to important information related

to safety and device use.

CAUTION:

Read manual carefully before

installing and operating the device

All safety recommendations must be followed as to warrant the

individual’s safety and prevent damage to the instrument or system. If

the instrument is used in another way other than that specified in this

manual, the equipment safety protections may not work properly.

Over Temperature Protection

When a system is designed, it is fundamental that one considers the

consequence of any failure in any component of such system. In

temperature control application, danger is even higher when heating

remains constantly on. In applications where physical damage or

device destruction may occur, the installation of an independent

protection device is recommended, which has its own temperature

sensor and can turn off the heating circuit in case of over heating. Note

that the counter output relays of NC400-6 do not offer protection to all

failure conditions.

CAUTION OR DANGER:

Risk of electrical shocks

DESCRIPTION

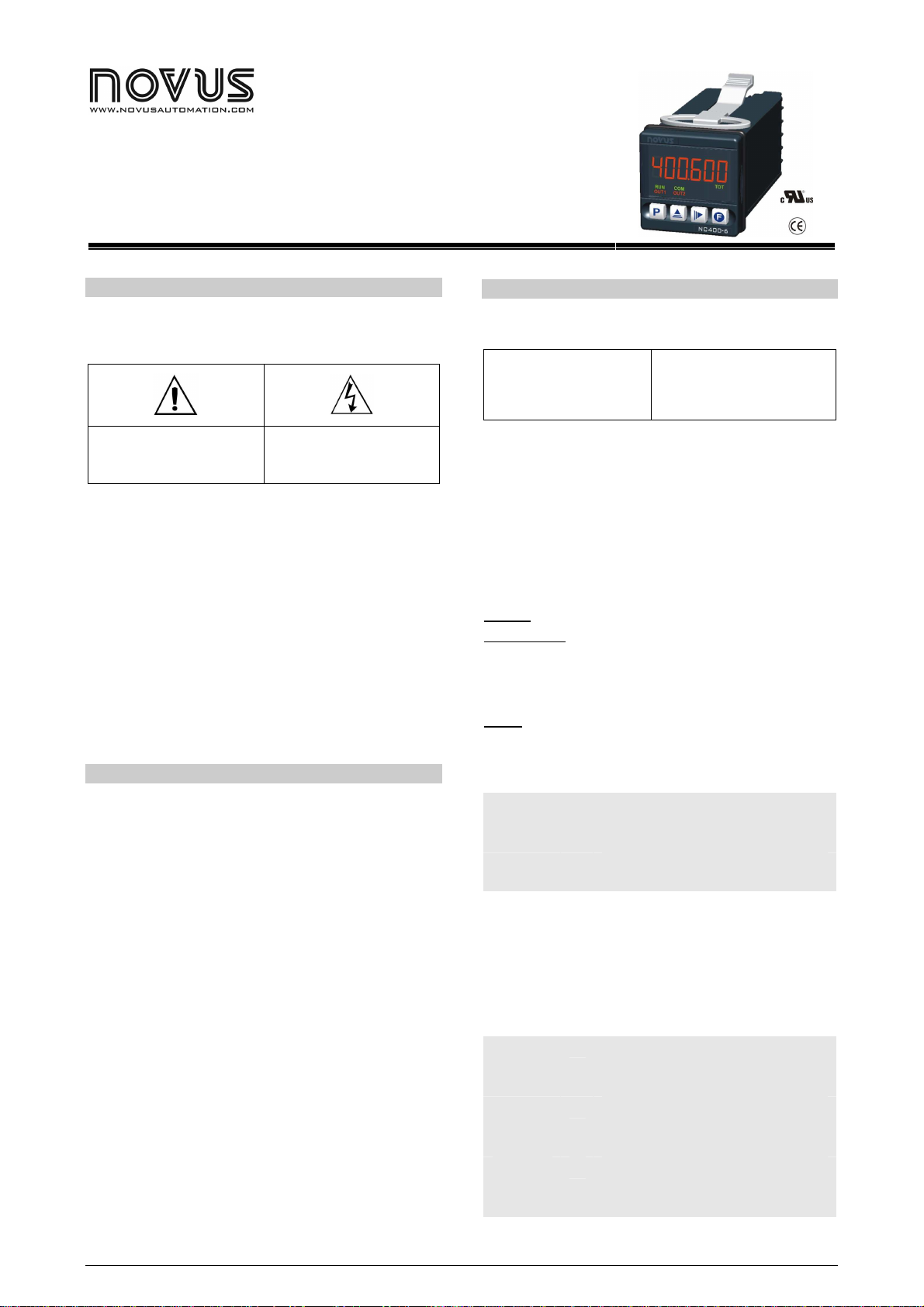

The NC400-6 counter and its configuration parameters are divided in

the following blocks:

• Inputs

• Main counter

• Batch counter

Each of these blocks has its own set of configuration parameters,

which together determine how the device works. A summary of the

operation of each block is presented below as well as their

parameters.

INPUTS

NC400-6 has three inputs that can be configured to read contacts,

NPN sensors, PNP sensors or voltage pulse connections. All inputs

must receive the same type of input signal. Functions of each input

are:

COUNT1: Main counting input

HOLD/COUNT2: Input to hold counting or second counting input. The

RESET: Input for external reset of counters and/or outputs.

Man 5001392

• Totalizador counter

• OUT1

• OUT2

second counting input is required when the NC4006 counter increases or decreases actions are

determined by an external signal (quadrature

signals, for example).

INTRODUCTION

NC400-6 is an advanced 6-digit counter that also performs batch and

totalizer counting operations. It has two outputs with independent and

configurable presets that can be triggered based on counting, batch

or totalization values. Its 2 outputs allow for an independent timed

triggering.

The counting input can be configured to read dry-contact, voltage

pulse, NPN our PNP sensor connections. Sensors may be powered

by an internal power supply.

Counting mode can be configured as progressive, regressive,

quadrature, ADD or SUB. Several reset modes — automatic or

manual — can be configured. Manual reset can be generated by a

digital input or key from the front panel.

The following configuration parameters are directly related to the

operation of inputs:

SEnS.tY

SEnS.tY

SEnS.tYSEnS.tY

Coun.tY

Coun.tY

Coun.tYCoun.tY

Coun.UP

Coun.UP

Coun.UPCoun.UP

MAIN COUNTER

It counts pulses from inputs, showing the value in the display after

multiplying it by a configurable scaling factor. Manual or automatic

reset. Two Set points can be defined (presets); when they are

reached they produce configurable actions (enable output, increment

batch counter, reset counter etc.) The following configuration

parameters are directly related to the main counter operation.

FActor

FActor

FActorFActor

SP1 C

SP1 C

SP1 CSP1 C

SP2 C

SP2 C

SP2 CSP2 C

OPt.SP.C

OPt.SP.C

OPt.SP.COPt.SP.C

OFF.C

OFF.C

OFF.COFF.C

rES.C

rES.C

rES.CrES.C

Selection of type of signal (contact, pulse,

NPN, PNP).

Selection of counting speed (slow or fast).

Progressive or regressive counting choice

and use of COUNT2 input.

Factor that multiplies the number of input

pulses (0.00001

0.00001 to 9.99999

0.000010.00001

Set point 1 for the main counter.

Set point 2 for the main counter.

Condition for Set point 1 reached (main

counter higher or lower than Set point 1).

Initial value (Offset) for main counter.

Reset options in the main counter (input,

key, Set point, output, etc.).

9.99999).

9.999999.99999

NOVUS AUTOMATION 1/8

Contador Eletrônico NC400-6

BATCH COUNTER

Counts the number of times that Set point 2 for the main counter was

reached, with manual or automatic reset. When its Set point is

exceeded (greater than or equals to) results in configurable actions

(enable output or increment totalizer counter). It is always a

progressive counter. The following configuration parameters are

directly related to the batch counter operation.

SP bAt

SP bAt

SP bAtSP bAt

OFF.bAt

OFF.bAt

OFF.bAtOFF.bAt

rES.bAt

rES.bAt

rES.bAtrES.bAt

Batch counter Set point.

Initial value (Offset) for the batch counter.

Reset options for the batch counter (input,

key, Set point, output, etc.).

TOTALIZER COUNTER

Totalizes the main counter or the number of times that the batch

counter Set point was reached, with manual or automatic reset.

When its Set point is reached (greater than or equals to) it can

activate an output. The following configuration parameters are

directly related to the totalizer operation.

Opt.tot

Opt.tot

Opt.totOpt.tot

Totalizer counting option (input pulse or

batch)

SP tot

SP tot

SP totSP tot

OFF.t

OFF.t

OFF.tOFF.t

rES.tot

rES.tot

rES.totrES.tot

Totalizer Set point.

Initial value (Offset) for the totalizer.

Reset options for the totalizer (input, key,

Set point, output, etc.).

OUT1

This output is always associated to the main counter, and it is

activated when Set point 1 is reached, and disabled with time,

reset, Set point 1 or when OUT2 is enabled. The following

configuration parameters are directly related to the OUT1 operation.

Out1.t

Out1.t

Out1.tOut1.t

Time to deactivate OUT1 (0.00

0.00 to 9999.99

9999.99

0.000.00

9999.999999.99

s).

Out1.E

Out1.E

Out1.EOut1.E

Turn-off options of OUT1 (time, OUT2,

reset, Set point 2).

Out1.OP

Out1.OP

Out1.OPOut1.OP

Freeze counting while OUT1 is activated

(yes, no).

Out1.c

Out1.c

Out1.cOut1.c

OUT1 normal state open or closed.

OUT2

This output can be activated by Set point 2 of the main counter, by

the batch counter Set point or by the totalizer Set point. It can be

deactivated by time, reset, activation of OUT1 or Set point that

activated it. The following configuration parameters are directly

related to the OUT2 operation.

Out2.SE

Out2.SE

Out2.SEOut2.SE

OUT2 activation options (Set point 2, batches

or totalizer).

Out2.t

Out2.t

Out2.tOut2.t

Time to deactivate OUT2 (0.00

0.00 to 9999.99

9999.99

0.000.00

9999.999999.99

s).

Out2.E

Out2.E

Out2.EOut2.E

Turn-off options of OUT2 (time, OUT1,

reset).

Out2.OP

Out2.OP

Out2.OPOut2.OP

Freeze counting while OUT2 is activated

(yes, no).

Out2.c

Out2.c

Out2.cOut2.c

OUT2 normal mode open or closed.

BLOCK DIAGRAM

Figure 1 illustrates associations among features and resources of

NC400-6:

Figure 1 – Diagram with features and resoucers of NC400-6

COUNTING MODES

The Coun.tY

Coun.tY parameter selects the counting mode as slow or fast.

Coun.tYCoun.tY

In the slow counting mode, a filter is applied to the counting signals,

limiting the maximum pulse frequency, which is necessary to count

the number of activations of electromechanical contacts. In the fast

counting mode, NC400-6 operates up to the maximum frequency

specified for the input signal. The frequency limits for each mode are

defined in Item 5.

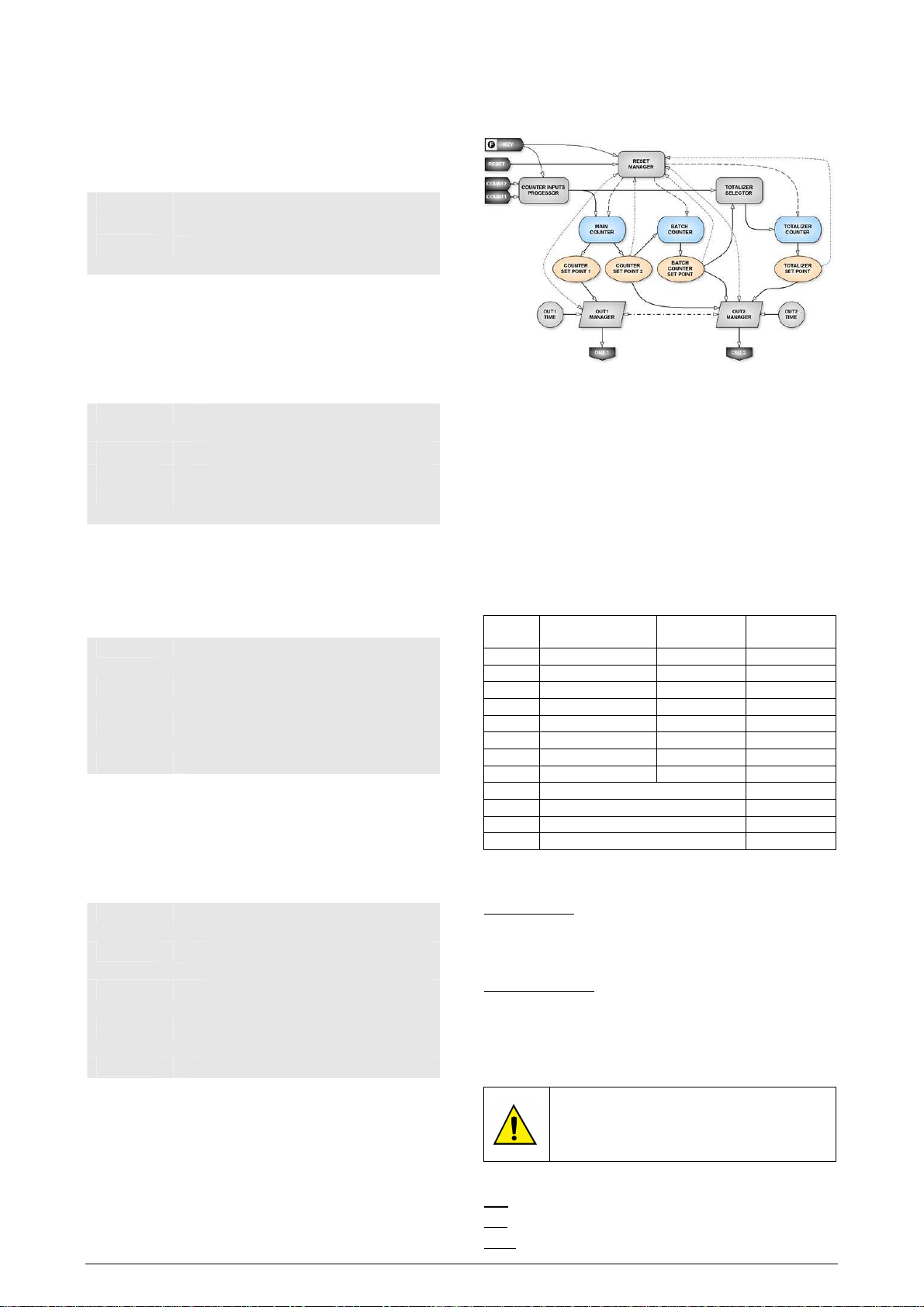

The Coun.UP

Coun.UP parameter defines the main counting direction (UP or

Coun.UPCoun.UP

DOWN) and the function of each input. Table 1 shows options for

this parameter.

Code

0000

1111

4444

5555

6666

7777

8888

9999

12

12

1212

13

13

1313

14

14

1414

15

15

1515

Table 1 – Counting modes that can be selected with the Coun.UP

COUNT2/HOLD

Input

COUNT1 Input Main direction

HOLD SUB DOWN

HOLD ADD UP

SUB SUB DOWN

SUB ADD UP

ADD SUB DOWN

ADD ADD UP

Select ADD SUB or ADD DOWN

Select SUB ADD or SUB UP

QUADRATURE DOWN

QUADRATURE UP

QUADRATURE 2x DOWN

QUADRATURE 2x UP

Coun.UP parameter.

Coun.UPCoun.UP

The main counting direction affects the main counter:

Main direction UP: Main counter count upstream, starting from

the Offset value defined (usually zero).

Actions can be programmed to take place

in Set point 1 and 2 values.

Main direction DOWN: The main counter count downstream,

starting from the Set point 2 value (SP2C

SP2C).

SP2CSP2C

The action programmed for this Set point

will take place when the counter reaches

the programmed Offset value.

The totalizer direction is always up.

You can select functions for COUNT1 and COUNT2/HOLD inputs:

ADD: Progressive counting input.

SUB: Regressive counting input.

Operation descriptions in this manual consider that

the NC400-6 counter is operating in the UP direction.

To operate in DOWN direction, refer to the

explanation above.

HOLD: Stops the counting input for COUNT1.

NOVUS AUTOMATION

2

Contador Eletrônico NC400-6

Select ADD/SUB: COUNT2 input defines if COUNT1 input is

progressive or regressive.

QUADRATURE: Bidirectional counting mode that uses two

counting inputs to determine if counting is

progressive or regressive. In this counting

mode, the Coun.tY

Coun.tY parameter is ignored

Coun.tYCoun.tY

and the counting mode is always fast.

QUADRATURE 2X: The same as the QUADRATURE mode,

but it counts twice as fast, increasing

resolution. In this counting mode, the

Coun.tY

Coun.tY parameter is ignored and the

Coun.tYCoun.tY

counting mode is always fast.

The counter is incremented or decremented whenever the voltage

level in the counting inputs increases (rising edge) except in the fast

counting mode (Coun.tY

Coun.tY = 1111) in COUNT1 input.

Coun.tYCoun.tY

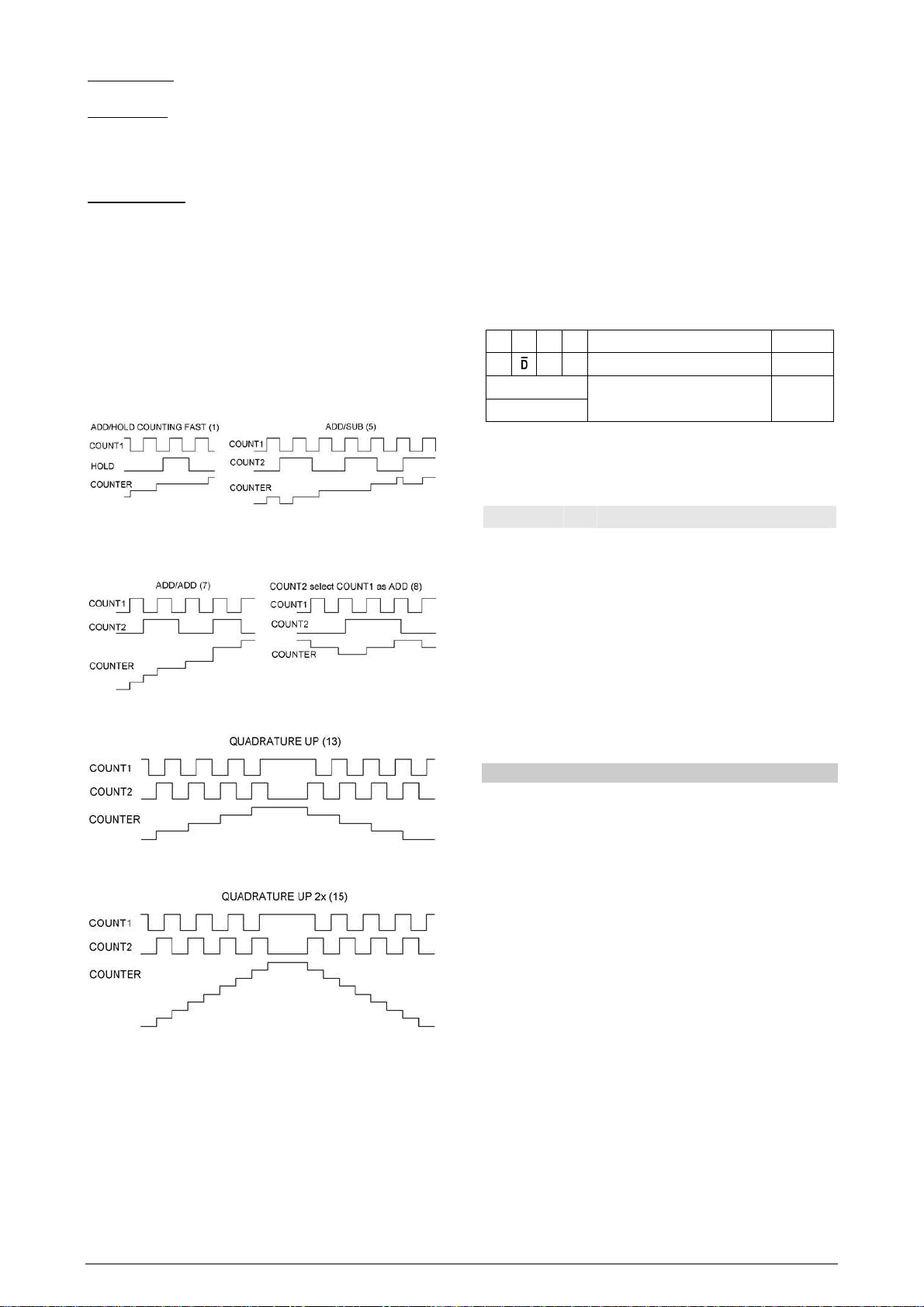

The most representative counting modes are shown in Figures 2 to

5. Low and High levels in the following figures correspond to voltage

levels in these inputs with PNP sensor or Voltage pulse. For the case

of NPN sensors or dry contact, signals will be reversed.

Figure 2 – Counting modes 1 and 5

Figure 3 – Counting modes 7 and 8

FEATURES

• Signals compliant with the RS-485 standard. MODBUS (RTU)

protocol. 2 wire connection between 1 master and up to 31 (able

to address up to 247) instruments in bus topology.

Communication signals are electrically isolated from the rest of

the device;

• Maximum connection distance: 1000 meters;

• NC400-6 disconnection time: Maximum 2 ms after the last byte;

• Fixed communication speed (Baud Rate): 9600 bps;

• Number of data bits: 8, no parity. Number of stop bits: 1;

• Transmission onset and response time: maximum of 100 ms

after command.

RS-485 signals are:

D1 D D + B

D0

D - A

C

GND

CONFIGURATION OF SERIAL COMMUNICATION PARAMATERS

Bidirectional data line. Terminal 16

Reserved bidirectional data line. Terminal 17

Optimal connection that enhances

the communication performance.

Parameter that must be configured when the serial communication

used:

Addres

Addres

AddresAddres

OVERFLOW AND UNDERFLOW

NC400-6 counter communication adress.

If the counter is at 0000 and it receives a pulse to decrement, the

counter will show 999.999

that the counter rolls to 999.999

999.999 and turn the OVFL flag on. This means

999.999999.999

999.999. If it increments beyond this, it will

999.999999.999

roll back to 0000, clearing OVFL flag.

On a similar way, when the counter is at 999.999

999.999 and it is

999.999999.999

increased, it will roll to 0000 and turn the OVFL flag on. When it

decreases again below 0000, it will turn the flag off and roll back to

999.999

999.999.

999.999999.999

Note: The setpoints and output control have no effect while OVFL

flag is on, except those who are cleared by time.

Terminal 18

Figure 4 – Counting mode 13 (quadrature)

Figure 5 – Counting mode 15 (quadrature 2x)

SERIAL COMUNICATION (OPTIONAL)

Optionally, NC400-6 can be deliverd with an assynchronous masterslave serial communication interface RS-485 to communicate with a

supervisor computer (master). The counter is always the slave.

Communication always start with the master, which sends a

command to the slave address with whom it wants to communicate.

The addressed slave undertakes the command and sends the

response to the master. NC400-6 also accepts broadcast

commands.

INSTALATION

PANEL MOUNT

NC400-6 must be installed in a papel. To install, follow the steps

below:

1. Make a panel cutout of 45.5 x 45.5 mm;

2. Remove the clips from NC400-6;

3. Insert NC400-6 in the frontal panel cutout;

4. Replace clips in NC400-6 and press them tightly to clamp the

counter to the panel.

INSTALLATION RECOMMENDATIONS

• Input signal wires must be installed in grounded conduits and

away from power or contactor wires+

• Instruments must be powered only by an exclusive power

supply.

• System failure should always be taken into account when

designing a control panel to avoid irreversible damage to

equipment or people. The output internal relay does not warrant

total protection.

• Installing RC filters (47 Ohms and 100 nF, serial) is strongly

recommended at contactor coils or any other inductors.

NOVUS AUTOMATION

3

Contador Eletrônico NC400-6

ELECTRICAL CONNECTIONS

You can remove the internal part of the device from its case

without removing connections. Signals are distributed in the rear

panel as shown in Figure 6.

Figure 6 – Electrical connections of NC400-6

POWER SUPPLY - POWER

Before making the power supply connection (terminals 1 and 2),

check the power voltage specified in the NC400-6 lateral

identification label. It is recommended to install electrical safety

devices.

Installation must have a switch that is able to turn off

all electrical current leads. This device must be

mounted close to the NC400-6, with easy operator

access and identified as a device that disconnects

the instrument.

Input, output and power connections, according to

Figure 6.

OUTPUTS – OUT1 / OUT2

OUT 2 (terminals 3 and 4) is always a relay. OUT1 (terminals 5 and

6) can be a relay or voltage pulse. See Item 6 – Identification to

determinate the OUT1 type.

Connect outputs respecting the specified capacity for voltage and

current. Check polarity for pulse output.

Counting and command inputs – COUNT1 / COUNT2 / RESET

COUNT1, COUNT2 and RESET inputs accept connections of NPN

or PNP sensors, dry-contact or voltage pulse. The type of signal is

configured through the SEnS.tY

SEnS.tY parameter, and all inputs must be

SEnS.tYSEnS.tY

the same type.

Figures 7a, 7b and 7c illustrates connections of those signals to the

COUNT1 input. The same connection scheme applies to the other

inputs.

NPN or PNP sensors

Figure 7a – Connections to the NC400-6 inputs

Voltage pulse

Figure 7c – Connections to the NC400-6 inputs

AUXILIARY SUPPLY OUTPUT

NC400-6 has an auxiliary power supply output for external sensors

(terminals 7 and 8). Check polarity and current limits before

connecting external devices to the auxiliary supply. Inputs 8 and 9

are internally connected (not isolated)

CONFIGURATION

The proper operation of NC400-6 depends on the proper

configuration of all parameters. Read the manual carefully and

thoroughly before using the equipment.

KEYBOARD AND DISPLAY OPERATION

All configuration operations are performed through the front panel

display and keyboard. The following are the panel elements and how

to operate them.

RUN: It is activated when the display shows

the main counter value.

PM: It is activated when the display shows

the batch counter value.

TOT: It is activated when the display shows

the totalizer value.

OUT1: It is activated whenever OUT1 is on.

OUT2: It is activated whenever OUT2 is on.

HOLD: It is activated whenever the counting

input is on hold (because of Hold input

activation, programmed input for key

or configuration in Out1.OP

Out2.OP

Out2.OP).

Out2.OPOut2.OP

COM: Flashes whenever NC400-6 is exchanging data

through the communication interface (optional).

OVFL: When the display shows the value of one of the 3

counters, it means that the counter displayed is in

overflow (counting over 999999 or below 0).

MIN: When the display shows the value of the main counter

or totalizer, it means that the counter displayed is with

a value below the offset (OFF.C

MAX: When the display shows the value of the main counter,

the batch counter or totalizer, it means that the counter

displayed is with a value above SP2C

SPtot

SPtot, respectively.

SPtotSPtot

Navigation key to access parameters.

Key to increment NC400-6 parameters.

Navigation key to access different digits in NC400-6.

User-programmed key (see parameter F.Fun

OFF.C or OFF.t

OFF.COFF.C

OFF.t).

OFF.tOFF.t

SP2C, SPbAt

SP2CSP2C

Out1.OP or

Out1.OPOut1.OP

SPbAt or

SPbAtSPbAt

F.Funcccc).

F.FunF.Fun

Dry contact

Operation and configuration parameters of NC400-6 are grouped in 4

Cycles:

CYCLE ACCESS

Figure 7b – Connections to the NC400-6 inputs

Count Free

Set points (presets) Timed. Can be password-protected

Configuration Timed. Can be password-protected

Hardware setup Time and password-protected

NOVUS AUTOMATION

4

Contador Eletrônico NC400-6

ffect

When the device is powered, display shows the counting cycle and the

main counter value. Press to switch to the batch counter and

totalizer. Press to select the decimal point position for the main

counter and totalizer (the batch counter does not use decimal points).

To access cycles with timed access, press and hold for 2 seconds,

which will provide access to the following upper cycle. Press and hold

to access the following upper cycles.

In any cycle you can use to go to the next parameter. Press

to change a parameter. Press to increment the flashing digit and

to go to the next digit. In screens with decimal point configuration,

it can be configured after passing through all the other digits. The

parameter changed is saved in nonvolatile memory when is

pressed.

Keys to access, change and save configuration parameters

To change parameters For 2 seconds to change cycle

Blink the most significant

digit

To change the blinking digit

To increment the blinking digit

To save and change parameter

again

PASSWORD

Depending on the protection level defined in Prot

Prot, the PASS

ProtProt

PASS screen

PASSPASS

can be displayed before access to Set points, Configuration or

Hardware setup Cycles. If the wrong password is informed, all

parameters will be protected against changes, and could only be

viewed. Insert the right password to change parameters for a cycle.

Default password is 1111

1111, and can be changed in Pass.C

11111111

Pass.C

Pass.CPass.C

parameter.

In case you enter the wrong password 5 consecutive

times, a new attempt will only be allowed after 10

minutes.

In case you have changed or forgotten the password,

see item “Master Password” to check how to

determine a master password for your device.

MASTER PASSWORD

The master password allows user to define a new password for the

NC400-6. It is the first four digits of the serial number.

Ex.: The master password for device with serial number 87123465 is:

8 7 1 2

How to use the master password:

1- Enter the master password value at PasS

2- Go to PAS.c

PAS.c parameter and enter a new password.

PAS.cPAS.c

PasS.

PasSPasS

3- Now you can use this new password.

COUNTING CYCLE

Indication of MAIN COUNTER value

Press to change the decimal point position

Indication of BATCH COUNTER value

Indication of TOTALIZER COUNTER value

Press to change the decimal point position.

SET POINTS CYCLE

SP1 C

SP1 C

SP1 CSP1 C

Set Point 1 -

Counter

Sp2 c

Sp2 c

Sp2 cSp2 c

Set Point 2 -

Counter

Set point 1 value of the main counter.

Values range from 0.00000

configurable decimal point.

Set point 2 value of the main counter.

Values range from 0.00000

configurable decimal point.

0.00000 to 999999

0.000000.00000

0.00000 to 999999

0.000000.00000

999999 with

999999999999

999999 with

999999999999

SP bat

SP bat

SP batSP bat

Set Point – Batch

SP tot

SP tot

SP totSP tot

Set Point -

Totalizer

Batch counter Set point value.

Values range from 0000 to 999999

Set point 1 value of the totalizer counter.

Values range from 0.00000

configurable decimal point.

CONFIGURATION CYCLE

Duration in seconds of OUT1 pulse. Configurable

from 0.00

0.00 to 9999.99

Out1.t

Out1.t

Out1.tOut1.t

Out1 Time

Out2.t

Out2.t

Out2.tOut2.t

Out2 Time

Off.c

Off.c

Off.cOff.c

Offset - Counter

Off.bat

Off.bat

Off.batOff.bat

Offset - Batch

Off.tot

Off.tot

Off.totOff.tot

Offset - Totalizer

f.func

f.func

f.funcf.func

F Key Function

Opt.tot

Opt.tot

Opt.totOpt.tot

Options - Totalizer

0.000.00

If OUT1 is configured to turn off after a period of time

(Out1.E

Out1.E) parameter) and the programmed time is 0000,

Out1.EOut1.E

OUT1 will not be enabled.

Duration in seconds of OUT2 pulse. Configurable

from 0.00

0.00 to 9999.99

0.000.00

If OUT2 is configured to turn off after a period of time

(Out2.E

Out2.E parameter) and the programmed time is 0000,

Out2.EOut2.E

OUT2 will not be enabled.

Value assigned to the main counter when it is started

(reset).

May vary from 0000 to 999999

Value assigned to the batch counter when it is

started (reset).

May vary from 0000 to 999999

Value assigned to the totalizer counter as soon as it

is started (reset).

May vary from 0000 to 999999

Function programmed to key.

0000: No function associated.

1111: Holds input countings. Press once to hold

the counters. Press the key again to return

counting.

2222: Reset of counters configured to reset with

key. Leaves Hold state.

3333: Output Reset.

4444: Reset of counters configured to reset with

key. Outputs reset. Leaves Hold state.

Define work modes for the totalizer.

1111: Totalizes pulses applied to the main counter

0000: Counts how many times the batch counter

reached SPbAt

Condition for OUT1 to turn off.

out1.e

out1.e

out1.eout1.e

Out1 – End

999999.

999999999999

0.00000 to 999999

0.000000.00000

9999.99s.

9999.999999.99

9999.99s.

9999.999999.99

999999.

999999999999

999999.

999999999999

999999.

999999999999

SPbAt.

SPbAtSPbAt

0000: Set point 1 does not turn off

OUT1.

1111: Turns off when (see parameter

opt.sp.c

opt.sp.c). For example: If OUT1

opt.sp.copt.sp.c

was enabled when the Set point 1

value was reached in a

progressive counting, OUT 1 will

be disabled when the counter

becomes lower than Set point 1.

0000: Set point 2 does not affect OUT1.

1111: Turns off when the counter

reaches Set point 2.

0000: External reset does not a

OUT1.

1111: Turns off at the start of na external

reset pulse.

2222: Turns off at the end of an external

reset pulse.

3333: Turns off at the start of an external

reset pulse.

0000: OUT2 does not affect OUT1.

1111: Turns off when OUT2 is turned on.

2222: Turns off when OUT2 is turned off.

3333: Turns off when OUT2 is turned on

or off.

0000: OUT1 (out1.t

1111: Turns off after the time defined in

out1.t) time does not

out1.tout1.t

affect OUT1.

OUT1 Time parameter (out1.t

has expired.

999999 with

999999999999

out1.t)

out1.tout1.t

NOVUS AUTOMATION

5

Contador Eletrônico NC400-6

out2.e

out2.e

out2.eout2.e

Out2 - End

res.c

res.c

res.cres.c

Reset Counter

rES.bat

rES.bat

rES.batrES.bat

Reset Batch

Condition for OUT2 to turn off.

0000: Set points do not turn off OUT2.

1111: Turns off when the condition that

turned it on is not valid anymore

(see parameter out2.se

0000: External reset does not affect

OUT2.

1111: Turns off at the start of an external

reset pulse.

2222: Turns off at the end of an external

reset pulse.

3333: Turns off at the start of an external

reset pulse.

0000: OUT1 does not affect OUT2.

1111: Turns off when OUT1 is turned on.

2222: Turns off when OUT1 is turned on.

3333: Turns off when OUT1 is turned on

or off.

0000: OUT2 (out2.t

1111: Turns off after the time in OUT2

Effect of reset on the main counter.

0000: OUT2 does not affect the main

1111: Resets when OUT2 is turned on.

2222: Resets when OUT2 is turned off.

3333: Resets when OUT2 is turned on

0000: OUT1 does not affect the main

1111: Resets when OUT1 is turned on.

2222: Resets when OUT1 is turned off.

3333: Resets when OUT1 is turned on

0000: key does not affect the main

1111: key resets the main counter if

0000: Remote reset does not affect the

1111: Remote reset resets the main

0000: Set point 2 does not affect the

1111: Resets the main counter when Set

Effect of reset on the batch counter.

0000: OUT2 does not affect the batch

1111: Resets when OUT2 is turned on.

2222: Resets when OUT2 is turned off.

3333: Resets when OUT2 is turned on

0000: key does not affect the batch

1111: key resets the batch counter if

0000: Remote reset does not affect the

1111: Remote reset resets the batch

0000: Batch Set point does not affect the

1111: Resets batch counter when Batch

out2.t) time does not

out2.tout2.t

affect OUT2.

Time parameter (out2.t

expired.

counter.

or off.

counter.

or off.

counter.

configured as reset.

main counter.

counter.

main counter.

point 2 is triggered.

counter.

or off.

counter.

configured as reset.

batch counter.

counter.

batch counter.

Set point 2 is triggered.

out2.se).

out2.seout2.se

out2.t) has

out2.tout2.t

rES.tot

rES.tot

rES.totrES.tot

Reset Totalizer

Opt.sp.c

Opt.sp.c

Opt.sp.cOpt.sp.c

Option for Counter

Setpoint

Out1.op

Out1.op

Out1.opOut1.op

Out1 Option

Out2.op

Out2.op

Out2.opOut2.op

Out2 Option

Out2.se

Out2.se

Out2.seOut2.se

Out2 Selector

HARDWARE CONFIGURATION CYCLE

Pass

Pass

PassPass

Password

Out1.c

Out1.c

Out1.cOut1.c

Out1 Contact

Out2.c

Out2.c

Out2.cOut2.c

Out2 Contact

Sens.ty

Sens.ty

Sens.tySens.ty

Sensor Type

coun.ty

coun.ty

coun.tycoun.ty

Counter Type

Effect of reset on the totalizer counter.

0000: OUT2 does not affect the totalizer

counter.

1111: Resets when OUT2 is turn on.

2222: Resets when OUT2 is turn off.

3333: Resets when OUT2 is turned on

or off.

0000: key does not affect the

totalizer counter.

1111: key resets totalizer counter if

configured as reset.

0000: Remote reset does not affect the

totalizer counter.

1111: Remote reset resets the totalizer

counter.

0000: Set point 2 does not affect the

totalizer counter.

1111: Resets totalizer counter when

Set point 1 reached.

0000: Actions corresponding to SP1 are performed when

the main counter becomes lower than or equal to

SP1 value.

1111: Actions corresponding to SP1 are performed when

the main counter becomes higher than or equal

to SP1 value.

Option that determines whether counting will be

frozen or not while OUT1 is triggered.

0000: Releases counting while OUT1 is triggered.

1111: Holds counting while OUT1 is triggered.

Option that determines whether counting will be

frozen or not while OUT2 is triggered.

0000: Releases counting while OUT2 is triggered

1111: Holds counting while OUT2 is triggered.

Selects which Set point will enable OUT2.

0000: Main counter Set point 2.

1111: Batch counter set point.

2222: Totalizer set point.

Parameter that requires a password to be inserted in

order to enable changes on next parameters (see item

“Password”).

Accepts values from 0000

Definition of OUT1 normal mode.

0000: Relay (NO - closes contact when triggered).

1111: Relay (NC - opens contact when triggered).

Definition of OUT2 normal mode.

0000: Relay (NO - closes contact when triggered).

1111: Relay (NF - opens contact when triggered).

Signal polarity applied to all inputs of NC400-6, it makes

possible to change hardware input settings according to

signal used.

0000: Sensor with open collector output NPN or dry contact.

1111: Sensor with open collector output PNP or pulse input.

It define the input signal reading mode.

0000: slow reading speed. A filter is applied to inputs and

after a pulse is acknowledged it ignores for 9 ms any

following pulse in that input (it must be used in Dry

Contac signals). In quadrature counting modes

(coUn.UP

coUn.UP ≥12

coUn.UPcoUn.UP

1111: fast reading speed. A filter is not applied to inputs.

Totalizer Set point is triggered.

0000 to 9999

00000000

12) this filter is ignored.

1212

9999.

99999999

NOVUS AUTOMATION

6

Contador Eletrônico NC400-6

coun.up

coun.up

coun.upcoun.up

Counter Up

Erase.0

Erase.0

Erase.0Erase.0

Erase 0

factor

factor

factorfactor

Factor

addres

addres

addresaddres

Addres

Prot

Prot

ProtProt

Protection

Pass.c

Pass.c

Pass.cPass.c

Password

Change

Ser.n.1

Ser.n.1

Ser.n.1Ser.n.1

Serial Number 1

Ser.n.2

Ser.n.2

Ser.n.2Ser.n.2

Serial Number 2

Selections of the NC400-6 counting direction.

Note: See “Counting Modes” for further details.

Regressive (DOWN) starting from Set point 2 down.

Progressive (UP) starting from offset.

For counting modes with two inputs, the COUNT2 input

is used as secondary counting input.

Code

0000: Does not erase zeros on the left.

1111: Erases zeros on the left of the first decimal point digit.

Counter conversion factor is the value by which the

input pulses are multiplied. Configurable from 0.00001

to 9.99999

value (or decrement) applied to main counter at every

counting pulse.

NC400-6 communication address. Configurable from 1

to 247. Only used in equipment with RS-485

communication (optional).

Defines the parameter levels that will be protected,

preventing changes in parameters.

1111: Only the Hardware Configuration level is protected

2222: Configuration and Hardware Configuration levels

3333: Hardware Configuration, Configuration and Set

Parameter that makes possible to change the current

password. Can only be accessed if the right password

was informed in Pass

0000

0000 to 9999

00000000

Shows the four first digits of the NC400-6 serial

number.

Shows the four last digits of the NC400-6 serial

number.

COUNT2/HOLD

Input

0000

1111

4444

5555

6666

7777

8888

9999

12

12

1212

13

13

1313

14

14

1414

15

15

1515

9.99999. Value programmed here is the increment

9.999999.99999

(factory setting)

are protected.

points levels are protected.

HOLD SUB DOWN

HOLD ADD UP

SUB SUB DOWN

SUB ADD UP

ADD SUB DOWN

ADD ADD UP

Select ADD

Select SUB

QUADRATURE DOWN

QUADRATURE UP

QUADRATURE 2x DOWN

QUADRATURE 2x UP

Pass screen. Configurable from

PassPass

9999.

99999999

COUNT1

Input

SUB or

ADD

ADD or

SUB

Main

Direction

DOWN

UP

0.00001

0.000010.00001

SPECIFICATIONS

6-digit red display 12 mm-high.

Three inputs: COUNT1, COUNT2 and Reset.

Can be configured four NPN, PNP, dry-contact or voltage

pulse

Low level: < 2 Vdc, High level: > 3 Vdc

Input Impedance: 4700 Ω.

Maximum input voltage: ± 30 Vdc.

Dry-contact input polarization: 5 V / 4700 Ω.

Maximum counting frequency (square wave):

•

20 kHz in COUNT1 input for Coun.tY

COUNT.UP

COUNT.UP < 12

COUNT.UPCOUNT.UP

•

4 kHz in COUNT2 input for Coun.tY

COUNT.UP

COUNT.UP < 12

COUNT.UPCOUNT.UP

•

55 Hz for Coun.tY

•

4 kHz for both inputs Coun.UP

12.

1212

12.

1212

Coun.tY = 0000 and Coun.UP

Coun.tYCoun.tY

Coun.UP ≥ 12

Coun.UPCoun.UP

Coun.tY = 1111 and

Coun.tY Coun.tY

Coun.tY = 1111 and

Coun.tY Coun.tY

Coun.UP < 12

Coun.UPCoun.UP

12.

1212

12.

1212

Counting modes: Up, down, ADD/ADD, ADD/SUB, SUB/ADD,

SUB/SUB, external selection of UP/DOWN Quadrature, Quadrature

2x..

Response time for output activation, reset and batch count: 0,5 to 5 ms.

Relay outputs: SPST 3 A @ 250 Vca.

Pulse output: 5 Vdc. Output impedance 100 Ω.

Timing accuracy: 3 %.

Supply output: 12 Vdc (± 10 %) / 50 mA.

Power supply: 100 to 240 Vac/dc, 50/60 Hz; opcional 24 Vdc/ac.

Consumption: 9 VA max.

Internal battery: Lithium CR2032 4-year autonomy.

Configuration parameters hold: 10-year minimum in E2PROM memory.

Dimensions: 48 x 48 x 110 mm.

Panel cutout: 45.5 x 45.5 mm.

Material and front panel sealing: Polycarbonate UL94 V-2, IP65.

Material and case sealing: ABS+PC UL94 V-0, IP20.

Operating Temperature: 0 to 50 °C

Relative humidity: Maximum: 80 % up to 30 ºC. For temperatures 30

ºC, decrease 3 % per ºC.

Panel protection: Complies to NEMA 4X internal use; Installation II,

Pollution level 2; altitude < 2000 m.

EMC: EN 61326-1:1997 and EN 61326-1/A1:1998

Safety: EN61010-1:1993 and EN61010-1/A2:1995

IDENTIFICATION

In order to identify your model of NC400-6, check the name in the

device label, as per Table 1.

Example:

NC400-6 - RR - 485 - 24V

A B C D

A: Model

B: Optional

C: Digital

Communication

D: Power Supply

NC400-6

RR (model with OUT1: Relay and OUT2: Relay)

RP (model with OUT1: Pulse and OUT2: Relay)

blank (basic version, without serial

communication)

485 (version with serial RS485, Modbus

protocol)

blank (basic version, with 100 to 240 Vac/dc

power supply)

24V (version with 24 Vdc/ac power supply)

Table 1 – Identification of NC400-6

NOVUS AUTOMATION

7

WARRANTY

The manufacturer products are covered by a 12-month warranty

provided the purchaser presents the sales receipt and the following

conditions are met:

• Products are covered for one year from the original date of

purchase.

• Within this period, warranty against defects in material and

workmanship under normal use is free of charge.

• For repair, send the product and the sales receipt to our address.

• Expenses and transportation risks are under the purchaser’s

responsibility.

• This warranty does not cover any damage due to accident,

misuse, abuse, or negligence.

Contador Eletrônico NC400-6

NOVUS AUTOMATION

8

Loading...

Loading...