NOVUS N960 User Manual

Controlador N960

CONTROLADOR DE TEMPERATURA - MANUAL DE INSTRUÇÕES – V3.0x E

INSTALLATION

TYPE

CODE

FEATURES

J

0

Range: -50 to 760 °C (-58 to 1400 °F)

K

1

Range: -90 to 1370 °C (-130 to 2498 °F)

T

2

Range: -100 to 400 °C (-148 to 752 °F)

N

3

Range: -90 to 1300 °C (-130 to 2372 °F)

R

4

Range: 0 to 1760 °C (32 to 3200 °F)

S

5

Range: 0 to 1760 °C (32 to 3200 °F)

Pt100 (Resolution 0.1

ºC)

6

Range: -199.9 to 530.0 °C (-199.9 to

986.0 °F)

Pt100 (Resolution 1

ºC)

7

Range: -200 to 530 °C (-328 to 986 °F)

The controller must be installed in panels with square slots. To fix it,

insert the controller in the panel slot through the front side and fix the

clamps on the controller body through the rear end of the panel.

Press the clamps tightly to fix the controller on the panel.

You can withdraw the internal part of the device from its case through

the panel front side, it is not necessary to remove the case, the

clamps or connections. Pull firmly the controller from the front panel

and it will leave the case.

SPECIFICATIONS

Dimensions: 96 x 96 x 90 mm. Panel slot 93 x 93 mm. Weight:

11.64 oz

Power supply: 100 to 240 Vac/dc, 50 / 60 Hz, Optional: 24 Vdc

(15 to 30 Vdc/ac); Consumption max: 9 VA.

Environmental conditions: 5 to 50 °C; Relative humidity

(maximum): 80 % up to 30 °C. For temperatures above 30 ºC,

decrease 3 % per °C. Installation category II. Pollution degree 2.

Altitude <2000 m.

Sensor input Pt100 ( = 0.00385) Three-wire connection

excitation: 170 A

Thermocouple sensor input: Input impedance 10 M .

A/D converter resolution: 15000 levels

Sampling rate: 10 measures/second

Front Panel: IP65, Polycarbonate UL94 V-2; Enclosure: IP30,

ABS + PC UL94 V-0

EMC: EN61326-1:1997 and EN61326-1/A1:1998

Emission: CISPR11/EN55011

Immunity: EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-

4-5, EN61000-4-6, EN61000-4-8 and EN61000-4-11

Safety: EN61010-1:1993 and EN61010-1/A2:1995 (UL file

E300526)

Accuracy: 0.20 % of the maximum range 1 °C for Pt100

0.25 % of the maximum range 1 °C for Thermocouple

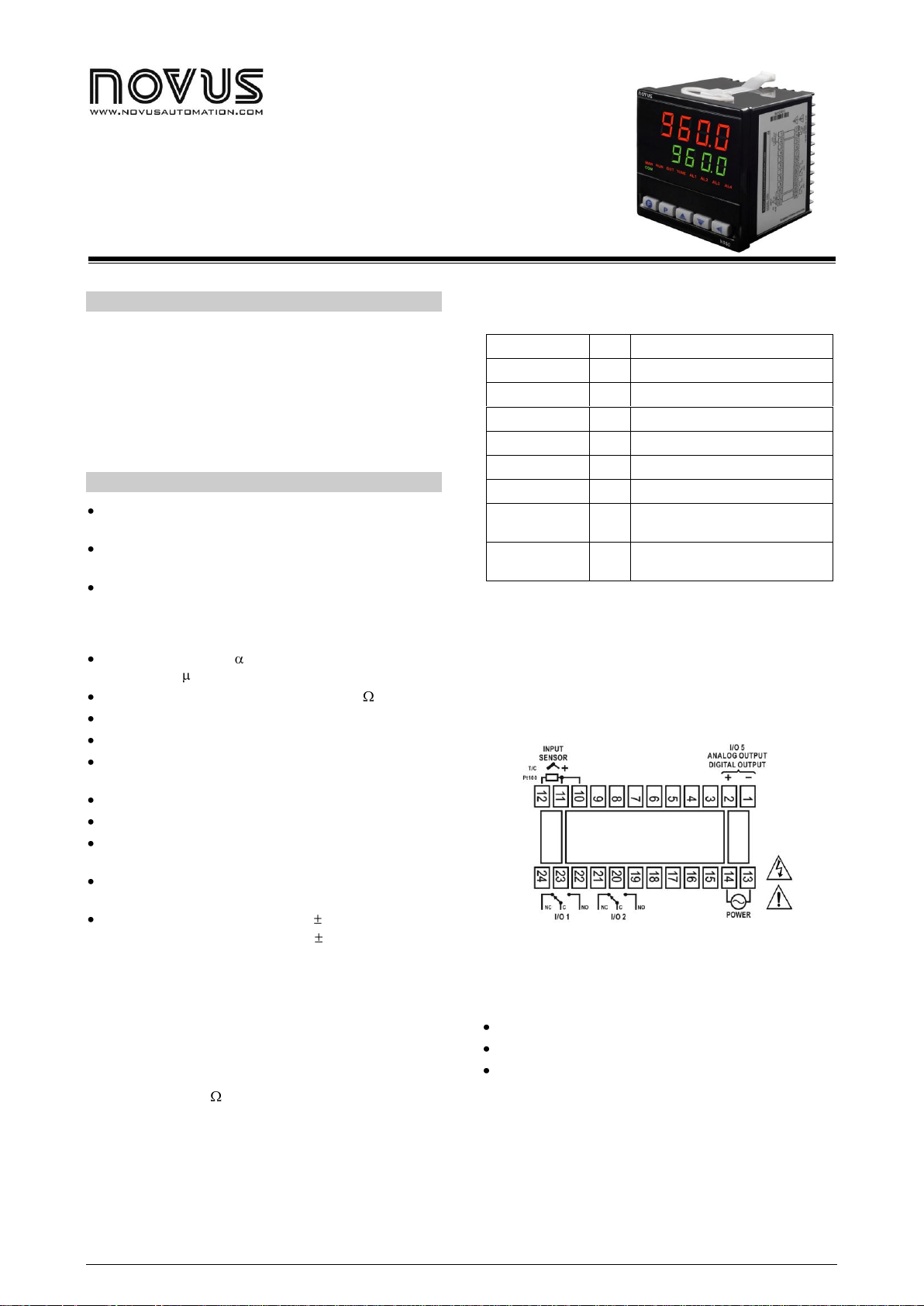

The thermocouples must be connected to the 11 and 12 pins,

observing polarity. A compensation or extension cable is required.

Pt100 sensors must be 3-wire connected to terminals 10, 11 and 12

as Fig. 1 shows. For an adequate cable resistance compensation, all

the conductors must have the same electrical resistance. If the Pt100

is a 4-wire sensor, leave one disconnected by the controller. For 2wire Pt100, use a jumper in the 10 and 11 terminals of the controller

(in this case, there is no auto compensation of the cables length, 1

°C is added to each 0.4 of the total cable resistance).

Table 1 shows the different types of temperature sensor the

controller can accept and the keypad code for their selection.

Table 1 – Sensors the controller is able to accept

POWER SUPPLY

Power is supplied through the terminals 13 and 14. Check the voltage

written on the device box.

ELECTRICAL CONNECTIONS

Fig. 1 shows the controller electrical connections.

Fig. 1 – Controller electrical connections

CONTROL OUTPUTS AND ALARM

There are THREE outputs for process control or alarm.

O/I 1: - Relay output, SPDT 3 A / 250 Vac (3 A / 30 Vdc);

O/I 2: - Relay output, SPDT 3 A / 250 Vac (3 A / 30 Vdc);

O/I 5: - Output current 0-20 mA / 4-20 mA; 500 R max;

- Digital Pulse Output; 12 V / 25 mA;

The output features (control or alarm) are user-defined at the

controller settings. The I/O output is able to provide a current signal

of 0-20 mA or 4-20 mA and a voltage pulse digital signal with no

changes in the controller hardware required.

Different outputs may be set up to perform the same function. The

outputs are automatically turned off whenever the controller

displays the message “ER1”, which accounts for a device fault or

disconnection.

NOVUS AUTOMATION 1/4

SET UP AND OPERATION

TEMPERATURE

AND

SP

Temperature and SP Display: The upper display

shows the current measured temperature. The lower

display indicates the control SP value.

If the measured temperature exceeds the sensor

range limits or the input is open (broken sensor), the

screen will display “- - - -“. In hardware faults, the

screen will display “Er1”

Pr n

Program Execution: Determines the immediate

execution of the ramp and soak program elaborated

at the program level.

no – does not run the program;

yes– runs the program created;

When the control is enabled (run=yes) the selected

program will run immediately.

rVN

Run: In this screen it is possible to enable or disable

the controller action, turning on or off the alarm

control outputs.

0– Does not enable outputs;

1– Disable outputs.

ATVN

Auto-Tune: Enables the auto tune of PID

parameters.

0– Auto-tune disabled;

1– Auto-tune enabled.

pb

Proportional Band: P parameter of the PID

control mode. Expressed as a percentage of the

maximum range of the type of sensor used.

Adjustable from 0 to 500 %.

To use the control mode ON/OFF, set zero (0).

ir

Integral Rate: Value of the integral parameter (I) of

the PID control mode. Expressed as repetitions per

minute. Adjustable from 0.00 to 55.20 repetitions per

minute. It is not displayed when the ON/OFF control

is selected (Pb=0).

dt

Derivative Time: Value of the derivative parameter

(D) of the PID control mode, in seconds. Adjustable

from 0 to 250 s. It is not displayed when the ON/OFF

control is selected (Pb=0).

(t

PWM Cycle Time: Value in seconds of the PWM of

the control output: Adjustable from 0.0 to 99.9

seconds. In processes that use power contactors, this

value must be higher than 10s. In process with solid

state relays, it is possible to use lower values. It is not

displayed if the ON/OFF control is selected (Pb=0).

kyst

Control Hysteresis: It is the ON/OFF control

hysteresis (programmed in a temperature unit). Used

only when the controller is set to ON/OFF control

(pb=0).

Act

Control Action:

rE – Reverse Action usually used for heating.

dir – Direct Action usually used for cooling.

Ai.sp

a2.sp

Alarm 1 and 2 Setpoints: Temperature values that

trigger alarm 1 and 2.

Ptol

Program Tolerance: Maximum deviation between

the program PV and SP. If it is exceeded, the

program is aborted (stops counting the time) until the

deviation falls within the tolerance range. Set zero to

disable this function.

Psp0

Psp7

Program SPs, 0 to 7 Set of 8 SP values that define

the ramp and soak program profile.

Pt1

Pt7

Program Segments Time, 1 to 7 Defines time, in

minutes, of each program segment.

Loop

Program Loop: Option for automatic restart of the

ramp and soak program.

yes – Restart the program automatically.

No – Does not restart the program

automatically.

Fva1

Fva2

Function of Alarm 1 and 2 Selects the function for

Alarms. See Table 2 for a description of functions

and their code, which will be programmed in this

screen.

oFF, iErr, Lo, xi, DiFL, DiFx, DiF

Bla1

bla2

Initial Alarm Blocking Initial alarm blocking function

for alarms 1 to 4.

YES – enables the initial blocking

NO – disables the initial blocking

xya1

xya2

Alarm Hysteresis: Defines the difference between

the temperature value that enables and the one that

disables the alarm.

The controller must be configured before use. The user must assign

each parameter a condition presented as, for example, type of

temperature sensor (“TYPE”), required work temperature (“SP“),

temperature values for alarm triggering (“AISP”), etc.

PARAMETERS ORGANIZATION

The controller parameters are organized in six levels (parameter sets):

Operation / Tuning / Program / Alarm / Output / Calibration

When the controller is turned on, the Operation level is displayed and

remains activated during normal operation. The other levels can be

accessed when changes are required in the controller set up.

To access the other levels, press together the keys P and .

When you reach the required level, which can be identified through

the first parameter shown, use the key P to access the other

parameters in this level. At the end of each level, the controller

returns to the Operation level, showing the process temperature.

When the keyboard is not activated for more than 20 seconds, the

controller returns to the Operation level, showing the process

temperature.

Using and the operator is allowed to change the value of each

parameter shown.

Set up changes are saved in a protected memory and the controller

will use them as soon as the user passes to the next parameter or in

case no key is pressed within 20 seconds. This is not valid for the

RvN parameter, whose setting changes are immediately taken by the

controller.

Controlador N960

PROGRAM LEVEL

OPERATION LEVEL

TUNING LEVEL

CONFIGURATION LEVEL

NOVUS AUTOMATION 2/4

Loading...

Loading...