NOVUS N480 User Manual

Controller N480

TEMPE RAT URE CONTROLLER – OPERATION MANUAL – V2.6x

1. ASSEMBLY

The control ler should be inst alled in a panel cut out as speci fied in

item 2. 1. First rem ove the mounting clam p and insert the c ontroller

into the panel c ut out . P lace t he unit into t he panel c ut-out and sl ide

the mounting clamp from the rear to a fi rm grip at the panel.

The internal circ uitry can be f ully remov ed from t he housing without

disconnect ing any wiring. By us ing the thumb just press the tab in

the lower part of the f ront panel, grab firm ly the f ront panel and pull

out the circuitry from the housing.

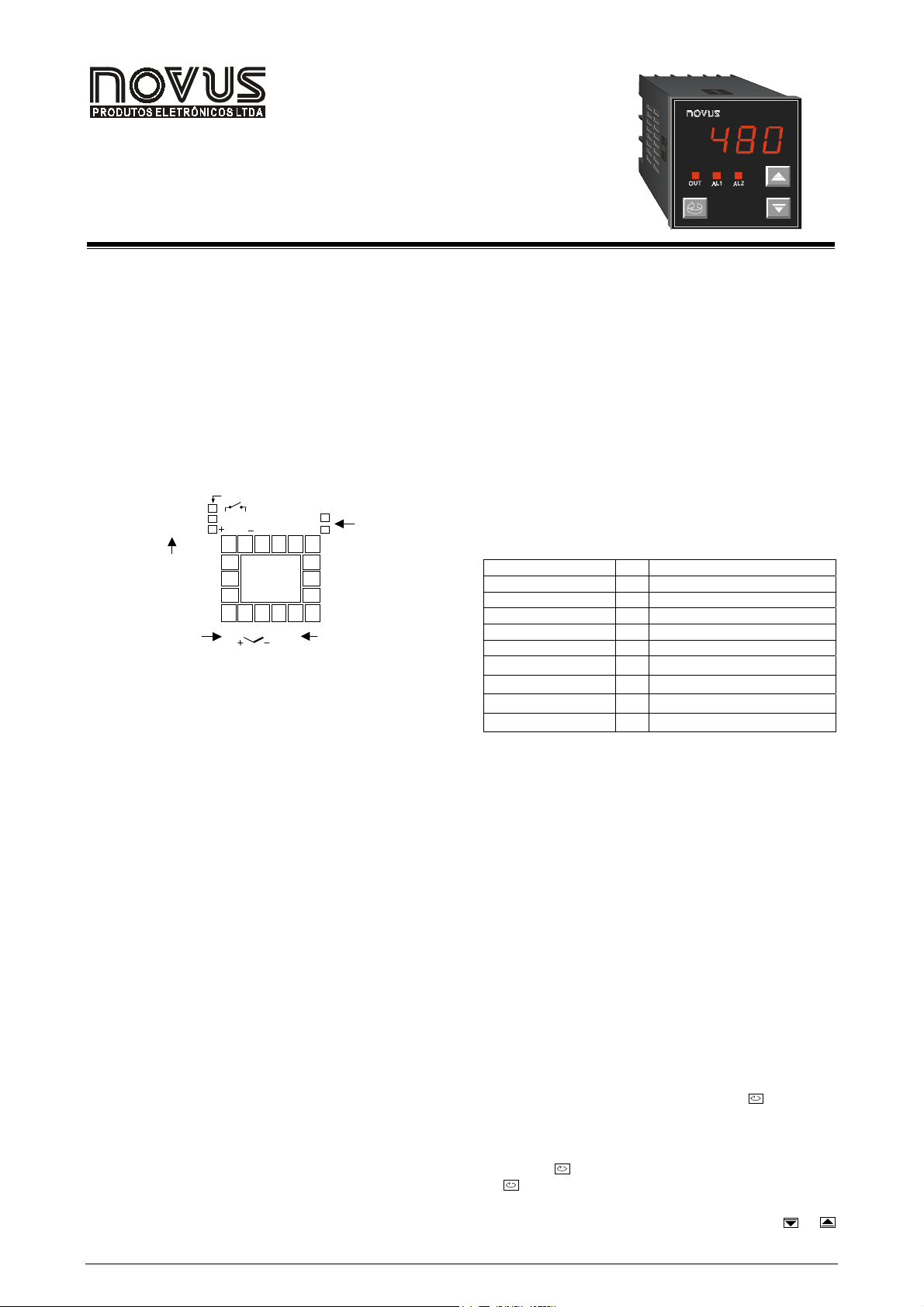

1.1. ELECTRICAL CONNECTIONS

Figure 1 shows the electrical te rm i nal s of the cont rol ler.

RELAY OUTPUT

4-20m A O UTPUT

PULSE OUTPUT

CONTROL

OUTPUT

OR ALARME 1

SENSOR INPUT

2. SPECIFICATIONS

2.1. GENERAL

• Dimensions : 48x48x106mm (1/ 16 DIN).

• Panel cut-out : 45,5x45,5mm

• Weight: 140g (1 relay), 160g (3 relays)

• Power: 85 to 264Vdc/ac, 50/60Hz, 3VA max . Optional: 15

to 30Vdc/ac

• Operation: 0 to 55°C, hum i d i ty 20 to 85%

OUT-A

OUT-B

4-20mA

PULSE

1 2 3 4 5

13

14

15

7 8 9 10 11 12

Figure 1 - Electr ic al connections

AL2

POWER

AC/DC

85-264V

15-30V

6

16

17

18

ALARM 2

POWER

N480

2.5. TEMPERATURE SENSOR INPUT

• Pt100: 3-wire connection. E xcitation current: 170µA

• Thermocouple input i m pedance: 10MΩ

• A/D conv erter resolution: 15000 steps

• Sampling rate: 10 measurements per second

• Accuracy: 0.2% of full scale for Pt100 and 0.25% of full

scale ±1°C for T/C

Thermocouples are connec ted to term inals 8 and 9 with pos itive in

terminal 8.

Pt100 sensors are c onnect ed to t erminal s 7, 8 and 9, as indicated in

figure 1. For full c ompensation of cable resist ance only c ables with

equal wire electri cal resistance should be used.

Table 1 shows the sensor types accepted and their respective

codes. v i a keyboard.

TYPE CODE RANGE

J

K

S

Pt100 (Resolution 0,1°C)

Pt100 (Resolution 1°C)

T

E

N

R

Table 1 - Sensor types, codes and ranges

-50 to 760°C (-58 to 1400°F)

0000

-90 to 1370°C (-130 to 2498°F)

1111

0 to 1760°C (32 to 3200°F)

2222

-199.9 to 530.0°C (-199.9 to 986.0°F)

3333

-200 to 530°C (-328 to 986°F)

4444

5555

-100 to 400 °C (-148 to 752°F)

6666

-30 to 720°C (-22 to 1328°F)

7777

-90 to 1300°C (-130 to 2372°F)

8888

0 to 1760°C (32 to 3200°F)

3. CONFIGURATION AND OPERATION

Prior to firs t operation the c ontroller should be f ully conf igured. The

user mus t set bas ic parameters as temperature t ype (“TYPE

desired c ontrol s et poi nt (“ SP

“SPA2

SPA2”), etc.

SPA2SPA2

SP “), the alarm s s et poi nts (“ SPA1

SPSP

TYPE”), the

TYPETYPE

SPA1” and

SPA1SPA1

2.2. CONTROL OUTPUT

• Relay output: SPST (U type) relay. Maximum current

3A/250Vac.

• Voltage pulse output: 5Vdc/20m A

Both outputs are available in the basic model and the desired

main control output is user selected via keyboard (refer to “

Cntr

Cntr “ prompt ). The remaining output can then be us ed as an

CntrCntr

alarm output.

In case of sensor break or failure an error "Erro

Erro" message is

ErroErro

displayed and t he control output i s turned off.

2.3. ALARM OUTPUTS

• Alarm Output 1: SPST relay 3A/250Vac or 5Vdc/20mA

pulse

• Alarm Output 2: SPST relay 3A/250Vca (optional)

2.4. POWER

Mains power is connected to terminals 5 and 6. Chec k the upper

side of the housing for proper power indicati on.

3.1. PARAMETERS FLOW CHART

The programming parameters are organized in 4 different sets or

levels:

• Operation level

• Alarms and tuning level

• Configuration level

• Calibration level

At power up the c ontroller di splays a prompt at t he Operation Lev el

and remains in this level whil e under normal operation.

The other lev els are only acc ess ed when a c hange of parameters is

necessary (except for Set Point change). To reach these other

parameters the us er must keep the INDEX Key (

) pressed for

about three sec onds. Af ter this time t he control ler will show the first

parameter of the nex t level. By keeping the INDEX key pressed for

another 3 seconds the next level w ill be accessed.

Release the

to go to the next prom pt in the same level.

the

key when t he desi red lev el is reached. Pres s onc e

When a parameter is shown the displ ay will alternate its name and

value. The v alue can then be changed by pressing the

or

key.

Novus Produtos Elet rônic os Lt da. / T el: +55-51-3323-3600 / www.novus.com.br 1/3

Controller N480

After the l ast paramet er in one lev el is reac hed the control ler returns

to operation level and the display will indicate the measured

temperature.

The display will also go back to the measured temperature whenever

the display is inacti ve for 20 seconds or m ore.

When a paramet er val ue is c hanged via key board the control ler will

only ac cept the new value af ter the us er presses the INDEX key t o

go to next prompt or if the keyboard is left inac tive for 20 seconds.

For disabl ing the keyboard, move the internal strap to the posit ion

KEY DISABLE. All parameters will be protected, accept the SP

parameter.

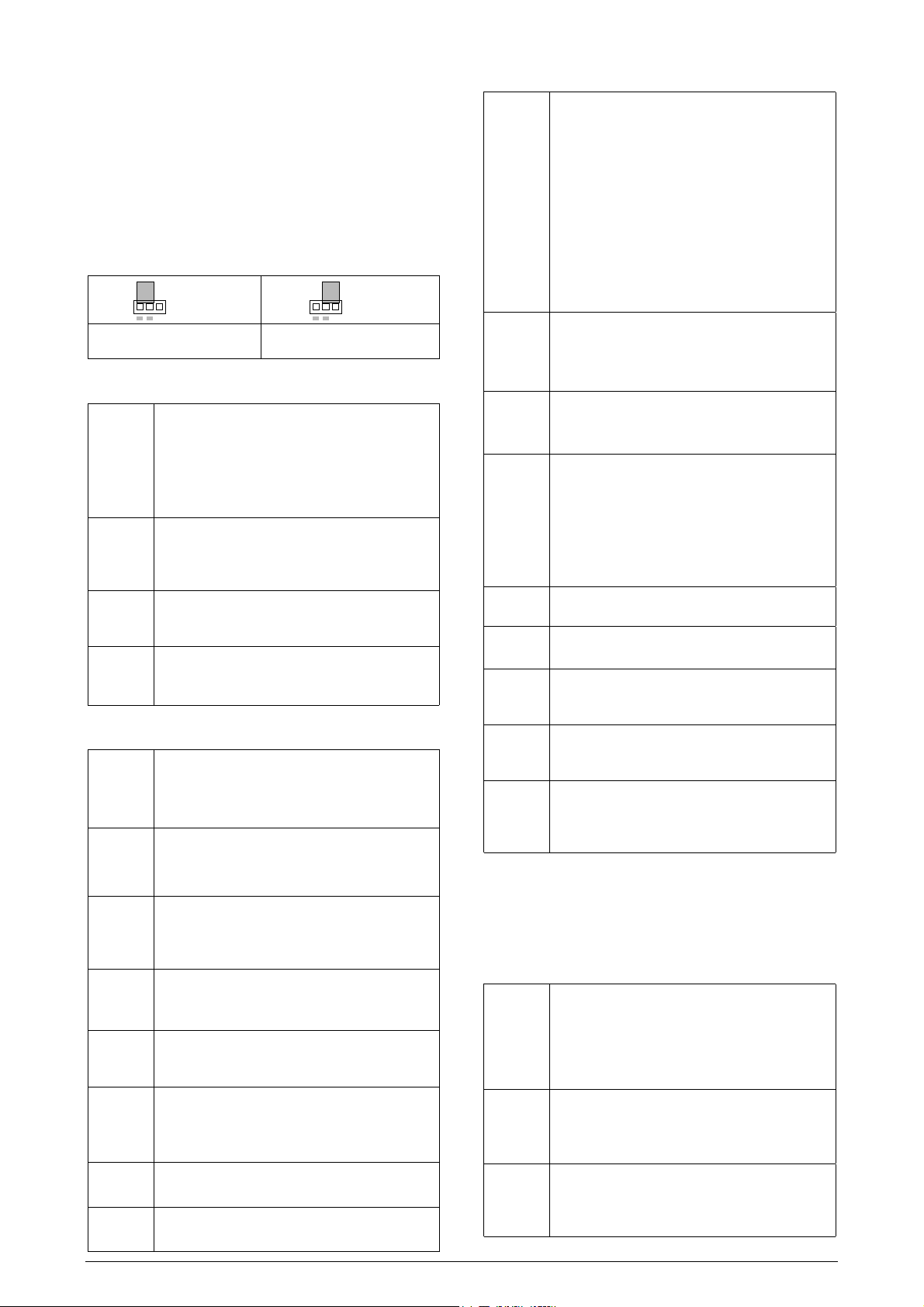

KEY

DISABLE

Figure 2 – St r ap in nor m al operating

position (enabled)

3.2. OPERATION LEVEL

TEMPERATURE

INDICATION

END

SP

Set Point

rAte

rAtE

T Sp

time for soak

Rvn

run

3.3. TUNING AND ALARMS LEVEL

Atvn

Auto tune

Pb

Proportional

band

Ir

integral rate

Dt

derivative

time

(t

Cycle time

KySt

HYSterisis

A1SP

SP Alarm 1

A2SP

SP Alarm 2

TEMPERATURE measured by the sensor.

At power up, the upper di splay shows the process

temperature value. It also shows the messages

described in c hapter 5 of this m anual .

The lower di splay s s hows the s et point v alue which

is the tem perature value desired f or the process.

TEMPE RATURE RATE OF RIS E: The us er defines

the rate of temperature rise from the starting

temperature to t he value set in “ SP

Rate is defi ned i n °C / minute.

TIME FOR SOAK: Time in minutes which the

temperature will remain at the selected “ SP

Refer to item 4.

RUN: At thi s prompt the user sets the c ontrol output

and alarms to ac tive or to inac tive.

0

0 - inactive outputs; 1111 - active outputs;

00

AUTO-TUNE: Activates the auto-tuning of PID

parameters.

0000 - Auto-tune is off;

1111 - Auto-tune is on;

PROPORTI ONAL BAND: percentage of maxim um

input span.

When set ot z ero (0), control acti on is ON/OFF.

INTEGRAL RATE: Integral time constant in

repetitions per minute (Res et). This const ant is not

used when controller is set to ON/OFF action

(Pb=0).

DERIVATIVE TIME: Derivative time constant in

seconds. This c onstant i s not used when controller

is set to ON/OFF action (Pb=0).

CYCLE TIME: Pulse Width Modulation (PWM)

period in seconds. This term is not used when

controller is set to ON/OFF action (Pb=0).

CONTROL HYSTERESIS: Is the hysteresis for

ON/OFF cont rol (set in temperat ure uni ts).

This param eter is only us ed when the controll er is

in ON/OFF mode (Pb=0).

SETPOINT for Alarm 1: Triping point for alarm 1

SETPOINT for Alarm 2: Triping point for alarm 2

Figura 3 – St r ap pos it ion for inhibiting the

KEY

DISABLE

keyboard

SP ”.

SPSP

SP “.

SPSP

3.4. CONFIGURATION LEVEL

INPUT TYPE: Selects the input sensor type t o be

Type

tYPE

Vnit

unit

A(t

ACtion

(ntr

Control

spll

SP Low Limit

spKl

SP High Limit

A1fv

Alarm 1 Function

A2fv

Alarm 2 Function

Aiky

A2ky

Alarm HYsteresis

3.5. CALIBRATION LEVEL

These parameters are used to calibrate the temperature

measurement and s hould only be dealt with by experienc ed and well

equipped personnel.

Inl(

Input Low

Calibration

InK(

Input High

Calibration

(j L

Cold Junction Low

Calibration

connected to the controller. This is the first

parameter to be set.

0

0 - Thermocouple type J;

00

1

1 - Thermocouple type K;

11

2

2 - Thermocouple type S;

22

3

3 - Pt100 with 0,1° resolution;

33

4

4 - Pt100 with 1° resolution;

44

5

5 - Thermocouple type T;

55

6

6 - Thermocouple type E;

66

7

7 - Termopar tipo N;

77

8

8 - Termopar tipo R;

88

TEMPERATURE UNIT: Selects display indication

for degrees Celsius or F arenhei t.

0

0 - degrees Celsius ( °C );

00

1

1 - degrees Farenheit ( °F );

11

CONTROL ACTIO N:

0

0 - reverse action. Generally used for heating.

00

1

1 - direct ac tion. Generally used for cooling.

11

CONTROL OUTP UT :

0

0 - Sets c ontrol output to terminals OUT A.

00

1

1 - Sets c ontrol output to terminals OUT B.

11

As control output is defined to terminals OUT A,

alarm output is automatic al l y set to OUT B.

If cont rol output is defined to OUT B alarm 1 will

then be automati cally set to OUT A.

SET POINT LOW LIMIT: sets t he lower range for

SV

SET POINT HIGH LIMIT

FUNCTION OF ALARM 1: Refer to table 2 for

function des cription and res pective codes to set at

this prompt.

FUNCTION OF ALARM 2: Refer to table 2 for

function des cription and res pective codes to set at

this prompt.

ALARM 1 AND ALARM 2 HYSTERESIS: Defines

the differential range between the PV value at

which t he alarm is turned on and the value at which

it is t urned off (in engineering units).

A T E N T I O N

SENSOR OFFSET CALIBRATION. Sets the

temperature sensor low calibration (offset). The

display shows only the correc ted temperature and

not the offset added. A signal simulat or should be

used to injec t a low value signal to properly adjust

the offset.

INPUT HI GH CALI BRATI ON. S ets the s ensor input

circuit gain or high cal i bration.

A signal simul ator should be used to inject a high

value signal to properl y adjust the offset.

COLD JUNCTION OFFSET CALIBRATION: Sets

the cold junction offset calibration. A good

thermometer or a temperature sim ulator should be

used to properly adj ust this param eter.

: Sets the upper range for SV.

Novus Produtos Elet rônic os Lt da.

Tel.:+55-51-3323-3600

2/3

Loading...

Loading...