TEMPERATURE CONTROLLER N450D

www.novusautomation.com

INSTRUCTION MANUAL

NOVUS AUTOMATION INC.

2315 NW 107th Ave.

Warehouse 1A16 Box 133

info@novusautomation.com / www.novusautomation.com

The N450D is a digital temperature controller in 1/16 DIN size with 2 outputs for control and

alarm. The four digit display is used for temperature indication as well as for parameter

configuration. Easy to configure, the N450D is intended for use in heating or cooling

applications, delivering accurate temperature measurements with excellent immunity to

electromagnetic fields. A large variety of sensor types are available (J, K, T, Pt100, etc).

SAFETY SUMMARY

The symbols below are used on the equipment and throughout this document to draw the

user's attention to important operational and safety information.

Doral FL 33172 USA

Phone: 1-786-235 2674

INSTALLATION

The controller should be installed in a panel cut out as specified. First, remove the mounting

clamp and insert the controller into the panel cut out. Place the unit into the panel cut-out and

slide the mounting clamps from the rear to a firm grip at the panel.

The internal circuitry can be fully removed from the housing without disconnecting any wiring.

Grab firmly the front panel and pull out the circuitry from the housing.

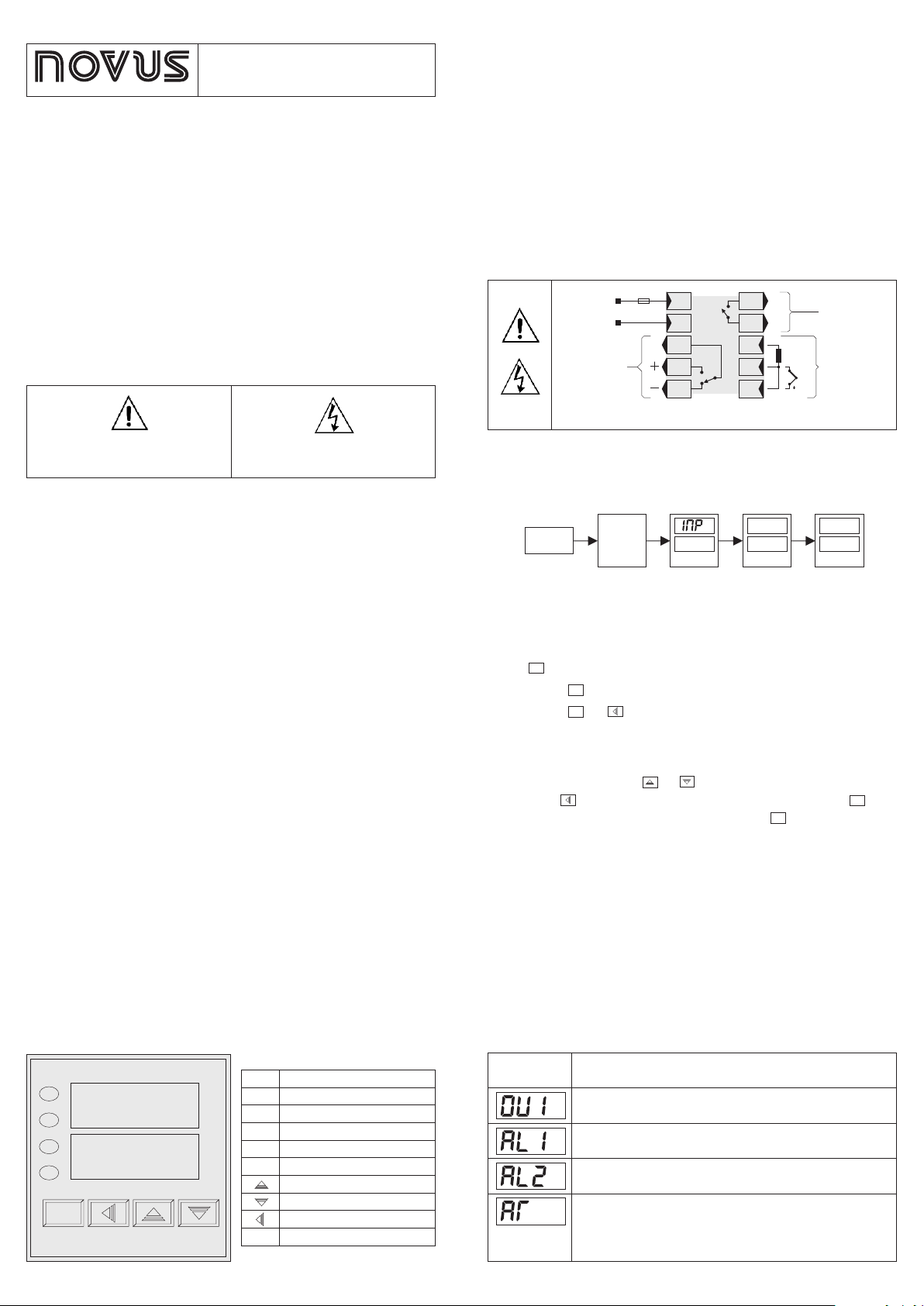

ELECTRICAL CONNECTIONS

All electrical connections are made to the screw terminals at the rear of the controller. They

accept wire sizes from 0.5 to 1.5 mm (16 to 22 AWG). The terminals should be tightened to a

2

torque of 0.4 Nm (3.5 lb in).

The installation must include a power isolating switch or circuit breaker that disconnects all

current carrying conductors. The device should be mounted close to the controller, within easy

reach of the operator and marked as the disconnecting device for the instrument.

Figure 1 shows the electrical terminals of the controller.

FUS E

POWER

OUT 1

(RE LAY OR P ULSE )

1

2

3

4

5

Figure 01 - Back panel terminals

6

7

8

9

10

ALM 1

INPUT

T/CPt1 00

CAUTION or WARNING:

Read complete instructions prior to installation

and operation of the unit.

CAUTION or WARNING:

Electrical Shock Hazard

All safety related instructions that appear in the manual must be observed to ensure personal

safety and to prevent damage to either the instrument or the system. If the instrument is used

in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

SPECIFICATIONS

POWER: ..........................100 to 240 Vac/dc (±10 %), 50/60 Hz. Transient overvoltage: ±2 kV

Optional:................................................................................................... 24 Vac/dc ±10

Max. Consumption:............................................................................................... < 4 VA

INPUT ..........................................................Keyboard selection of input type (refer to table 1)

Internal resolution: .............................................................................................14 bits

Display resolution:....................................................12000 levels (from -1999 to 9999)

Input sample rate:......................................................................................2 per second

Accuracy: .......................................Pt100, V and thermocouples: 0.5 % of span, ±1 ºC

Input impedance: .................................................. Pt100, V and thermocouples: >10 M

Pt100 measurement: .....................................................................standard (=0.00385)

Excitation current:..................0.170 mA. 3-wire circuit, cable resistance compensation

All input types are factory calibrated according to IEC-584 for thermocouples and IEC751 for Pt100.

OUTPUTs: (OUT1-RR):....................................Relays SPDT: 3 A / 250 Vac

(OUT1-PR): ..........Logic pulse for SSR drive :12 V max / 20 mA

(ALM1): ..........................................Relays SPST: 3 A / 250 Vac

ENVIRONMENTAL CONDITIONS:....................................................................-10 to +50 °C

Relative humidity (maximum): 80 % up to 30 ºC. For temperatures above 30 ºC, decrease

3 % per ºC. Installation category II. Pollution degree 2. Altitude < 2000 m.

EMC :..................................................................EN 61326-1:1997 and EN 61326-1/A1:1998

SAFETY: .............................................................EN61010-1:1993 and EN61010-1/A2:1995

DIMENSIONS:..................................48 x 48 x 110 mm (1/16 DIN). Approximate weight: 150 g

PANEL CUT-OUT:.........................................................................45 x 45 mm (+0.5 -0.0 mm)

TERMINAL CONNECTION: ........................................10 screws accepting 6.3 mm fork lugs

PROGRAMMABLE PWM CYCLE FROM 0.0 SEC. TO 100 SEC.;

START UP 7.5 SEC AFTER POWER UP;

Notes:

- Pt100 sensors are connected to terminals 8, 9 and 10. For full compensation of cable resistance, only cables

with equal wire electrical resistance should be used. For 2 wire Pt100, short circuit terminals 9 and 10.

STARTUP PROCEDURE

upper limit PV

startup

all

LEDs

flash

unit / type low limit SP

2.5 s 2.5 s 2.5 s

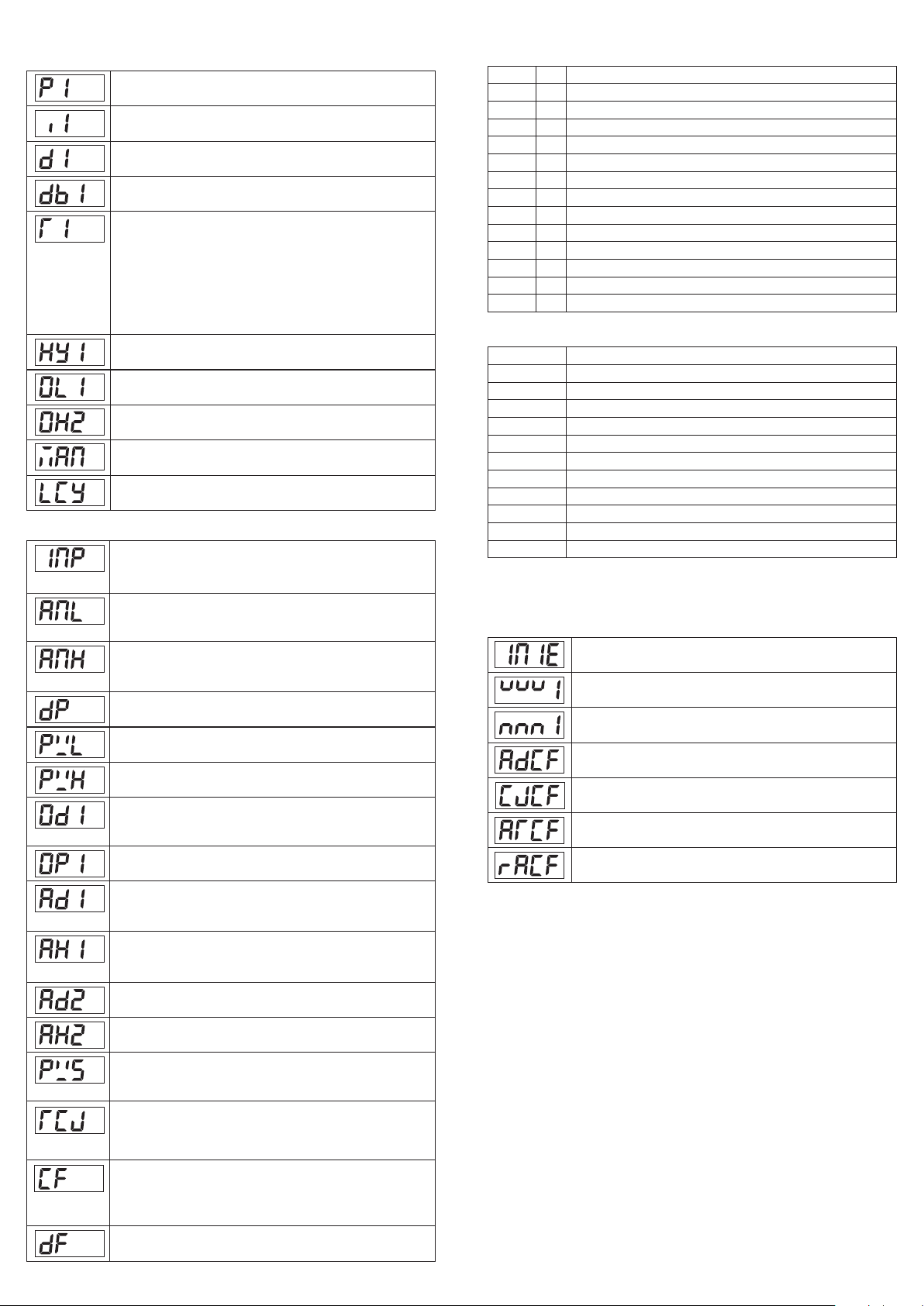

BASIC OPERATION

This instrument has three modes: LEVEL 1, LEVEL 2 & LEVEL 3. LEVEL 2 & LEVEL 3 can

only be changed during system setting and parameter change. The operation of changing

mode is listed below according to the LCK selected in parameter setting.

1. Press key once to enter LEVEL 1 mode;

2. Press and hold key for more than 2.5 s to enter or exit from LEVEL 2 mode;

3. Press and hold and keys for more than 2.5 s to enter or exit from LEVEL 3 mode.

This instrument has a display auto-recovery function. It will automatically change back to main

display mode whenever the display setting is innactive for about 20 seconds.

(Except for LEVEL 3 mode.)

When changing parameter, press or key to change the value while the SV digit is

flashing. Press key to shift the digit being changed. After changing, press key to

validate the new value (the original value will be retained if the key is not pressed after

changing any parameter).

Parameter setting for data lock LCK:

1. When LCK=0000, all parameters in all levels can be accessed and changed.

2. When LCK=0001, parameters in LEVEL 1 & LEVEL 2 can be changed, yet the operator

cannot enter LEVEL 3 mode;

3. When LCK=0002, parameters in LEVEL 1 can be changed, and the operator can enter

LEVEL 2 mode, yet its parameters cannot be changed. The value of LCK can be changed.

Note: 1. Read contents below before using the instrument or during parameter

P

P

P

P

P

carefully

changing .

2. The instrument will not display a certain parameter and value if this respective

function is not available.

FRONT PANEL AND FUNCTIONS

OUT1

AT

ALM1

ALM2

P

PV

SV

Measuring value / Mode display value

PV

Setting value / Mode display value

SV

Output 1 indicator

OUT1

AT

P.I.D. auto-calculating indicator

Alarm 1 indicator

ALM1

ALM2

Alarm 2 indicator

Increase key

Decrease key

Shift key

Setting and mode key

P

LEVEL 1 procedure (main setting):

MAIN

DISPLAY

TEMPERATURE measured by the sensor (INPUT).

Temperature SETPOINT (SP) associated to the OUT1 output. Full

range.

SETPOINT for Alarm 1: Tripping point for alarm 1. Full range. Exfactory setting: 10

SETPOINT for Alarm 2: Tripping point for alarm 2. Full range. Ex-factory

setting: 10 (This alarm is not available in all models)

AUTO-TUNE: Activates the PID auto-tuning parameters

1

0: Auto-tune is off (Ex-factory)

1: SV self-setting

2: 90 % SP self-setting

LEVEL 2 procedure (control parameter setting): Table1: Input mode selection:

0.0 to 400.0 °C / 0 to 1372 °C (0.0 to 752.0 °F / 0 to 2501 °F)

00

01

02

03

04

05

06

07

08

09

10

11

0

0.0 to 400.0 °C / 0 to 1200 °C (0.0 to 752.0 °F / 0 to 2192 °F)

1

0 to 1768 °C ( 0 to 3214 °F)

2

0 to 1768 °C ( 0 to 3214 °F)

3

0 to 1800 °C ( 0 to 3272 °F)

4

0 to 800 °C ( 0 to 1472 °F)

5

0 to 1200 °C ( 0 to 2192 °F)

6

-199.9 to 400.0 °C / -200 to 400 °C (-328.0 to 752.0 °F / 328 to 752 °F)

7

-199.9 to 400.0 °C / -200 to 600 °C (-328.0 to 752.0 °F / 328 to 1112 °F)

8

Not valid for this model.

9

Not valid for this model.

10

-1999 to 9999 (input and display range can be set arbitrarilly by software)

11

Not valid for this model.

12

-1999 to 9999 (input and display range can be set arbitrarilly by software)

13

No alarm.

High deviation alarm.

High deviation alarm. No alarm first time.High deviation alarm. No alarm first time.

Low deviation alarm.

Low deviation alarm. No alarm first time.

High/Low deviation alarm.

High/Low deviation alarm. No alarm first time.

In-range alarm.

High absolute value alarm.

High absolute value alarm, no alarm first time.

Low absolute value alarm.

Low absolute value alarm, no alarm first time.

Proportional band (%). 0.0 to 100.0 (%). Where 0.0 is ON/OFF control.

Ex-factory setting: 3.0 %

Integration time (s). 0 to 3600 s. 0= no integration.

Ex-factory setting: 240 s

Derivative time (s). 0 to 900 s. 0= no derivative.

Ex-factory setting: 60 s

Manual Reset. Offset added the PID control output. Range: 0 to 100 %.

Ex-factory setting: 50 %. When in doubt, leave the present setting.

Cycle time or PWM time. Time proportional period: 0 to100 s.

0: current / voltage (not available)

1: Pulse output for Solid State Relays

2 to 100: Relay output

This setting should be compatible with the type of output available.

The value should not be 0 or 1 for relay output, and should not be 0 for

SSR output. The lower the value the faster will be the output actuation.

For contactors select 10 s or more.

Main control hysteresis width. Setting range: 0 to 1000, unit same as that

of PV. Ex-factory setting: 2 / 2.0

Main control output lower limit.

Setting range: 0 to 100 %. Ex-factory setting: 0

Main control output upper limit.

Setting range: 0 to 100 %. Ex-factory setting: 100

Manual control. 0: manual allowed (Ex-factory setting).

Data lock (refer to BASIC OPERATION paragraph).

Setting range: 0 to 3. Ex-factory setting: 0000

LEVEL 3 procedure (system setting):

INPUT. Selects the input sensor type to be connected to the controller.

T/C K

T/C J

T/C R

T/C S

T/C B

T/C E

T/C N

T/C T

Pt100

Cu50

0-500 R

0-50 mV

0-20 mA

0-5 V

Table 2: Alarm mode selection:

1: manual prohibited

This is the first parameter to be set.

Setting range: 0 to 13. Ex-factory value: as per order.

INPUT LOW LIMIT: Available for input types from 10 to 13.

Input zero adjust.

MALFUNCTION DISPLAY

When the instrument fails, it will automatically display malfunction messages after selfdiagnosis.

Setting range: 0-2200. Ex-factory value: as per order.

INPUT HIGH LIMIT: Available for input types from 10 to 13.

Input full-scale adjust.

Setting range: 0-2200. Ex-factory value: as per order.

Input wire broken, wrong polarity or out of range.

Solution: Check input signal.

Input signal is above the input range. Solution: Check input signal.

DECIMAL POINT adjusment for display value. Setting range: 0-3.

Ex-factory value: as per order.

Input signal is below the input range. Solution: Check input signal.

RANGE LOWER LIMIT.

Setting range: full scale. Ex-factory value: maximum range

A/D conversion fail. Solution: Send to repair.

RANGE UPPER LIMIT.

Setting range: full scale. Ex-factory value: maximum range

CONTROL ACTION.

0: Reverse action. Generally used for heating.

Cold junction compensation fail.

Solution: Check ambient temperature or send to repair.

Self-setting calculation fail. Solution: Change to manual PID setting.

1: Direct action. Generally used for cooling.

CONTROL MODE: Control mode selection for main control.

Memory fail. Solution: Send to repair.

0: PID Control (Ex-factory setting)

ALARM 1 FUNCTION: Refer to Table 2 for function description and

respective codes to set at this prompt.

Setting range: 0 to 11. Ex-factory value: 2.

ALARM 1 HYSTERESIS: Defines the differential range between the PV

value at which the alarm is turned on and the value at which it is turned

off.Setting range 0-1000. Ex-factory value: 2 / 2.0.

ALARM 2 FUNCTION .

Not available in this model

ALARM 2 HYSTERESIS.

Not available in this model

SENSOR OFFSET: Offset value to be added to the PV to compensate

WARRANTY

This product is covered by a 12-month warranty provided the purchaser presents the sales

invoice and the following conditions are met:

- Products are covered for one year from the original date of purchase. Please retain the

dated sales receipt as evidence of the date of purchase. You will need it for any warranty

service

- Within this period, warranty against defects in material and workmanship under normal use

is free of charge.

- For repair, send the product and the sales receipt to our address. Expenses and

transportation risks are under the purchaser's responsibility.

- This warranty does not cover any damage due to accident, misuse, abuse, or negligence.

sensor error. Setting range: -200 to +200 / 20.0 to 120.0. Ex-factory

value: 0 / 0.0

COLD JUNCTION OFFSET CALIBRATION: Sets the cold junction

offset calibration. A good thermometer or a temperature simulator should

be used to properly adjust this parameter. Setting range: 0.0 to 50.0.

PRODUCT IDENTIFICATION

The label attached to the controller case identifies the model and the included options as

described below:

MODEL: N450D – A – B, where:

A: Outputs: RR: (OUT 1 = Relay, ALM1 = Pulse);

TEMPERATURE UNIT: Selects display indication for degrees Celsius or

Fahrenheit.

0: °C (Ex-factory value)

1: °F

FILTER: Filter factor of main input.

Setting range: 0 to 99. Ex-factory value: 1

B. Voltage rating: blank (100-240 Vac/dc) or 24V (24 Vac/dc);

TECHNICAL ASSISTANCE

Should you encounter any problem with your controller, review the configuration with regard to

inputs, outputs, alarms, etc. If the problem persists, contact your supplier or Novus at

info@novusautomation.com.

PR (OUT 1 = Pulse, ALM1= Relay);

2

Loading...

Loading...