TEMPERATURE CONTROLLER

N440

OPERANTING MANUAL - V1.1x

The N440 is a digital temperature controller in 1/16 DIN size with 2 ON/OFF outputs

for control and alarm. Its 3½ digit display is used for temperature indication as well as

for parameter configuration. Easy to configure, the N440 is intended for use in

furnaces, ovens, fryers, etc., delivering accurate temperature measurements with

excellent immunity to electromagnetic fields. Three sensor types are available (Pt100

and thermocouples J or K) with sensor offset correction.

SAFETY SUMMARY

The symbols below are used on the equipment and throughout this document to draw

the user’s attention to important operational and safety information.

CAUTION or WARNING:

Read complete instructions prior to

installation and operation of the unit.

All safety related instructions that appear in the manual must be observed to ensure

personal safety and to prevent damage to either the instrument or the system. If the

instrument is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

CAUTION or WARNING:

Electrical Shock Hazard

SPECIFICATIONS

Sensor Input: The sensor type is defined in the production process. Check the

instrument label to find out the input type of your particular model. The available

sensors options are:

Pt100; range: –50 °C to 530 °C (-58 to 986 °F); Accuracy: 1 °C (1.8 °F);

α=385. 3-wire connection. Excitation current: 0.170 mA;

Thermocouple J; 0 to 600 °C (32 to 999 °F); Accuracy: 2 °C (3.6 °F);

Thermocouple K; 0 to 1370 °C (32 to 2498 °F); Accuracy: 3 °C (5.4 °F);

Measurement resolution:

Pt100: 0,1 °C in the range –19.9 to 199.9 °C/°F, 1 °C/°F otherwise

Thermocouples: 1 °C/°F;

Output 1 (OUT1) (check instrument label for installed option)

Relay SPDT: 3 A / 250 Vac (3 A / 30 Vdc);

Output 2 (OUT2) (check instrument label for installed option)

Relay SPST-NO 1.5 A / 240 Vac (1.5 A / 30 Vdc);

Logic pulse: 5 Vdc, 15 mA max;

Power supply:

100 to 240 Vac/dc or 24 Vac/dc ± 10 % (check instrument label for installed option);

Frequency: 50/ 60 Hz; Power consumption: 2 VA

Environmental conditions: Temperature: 5 to 50 °C. Relative humidity (maximum): 80 %

up to 30 ºC. For temperatures above 30 ºC, decrease 3 % per ºC. Installation category II.

Pollution degree 2. Altitude < 2000 m.

EMC: EN 61326-1:1997 and EN 61326-1/A1:1998.

SAFETY: EN61010-1:1993 and EN61010-1/A2:1995

Warm-up time: 15 minutes;

Housing: Front panel: Polycarbonate UL94 V-2; Rear case: ABS+PC UL94 V-0

Dimensions: 48 x 48 x 110 mm. Panel cut-out: 45,5 x 45,5 mm; Weight: 150 g

OVER-TEMPERATURE PROTECTION

When designing any control system it is essential to consider what will happen if any

part of the system should fail. In temperature control applications the primary danger is

one in which the heating remains constantly on. In any application where physical

injury or destruction of equipment might occur, it is recommend to install an

independent protection equipment, with a separate temperature sensor, to disable the

heating circuit in case of overheating. Please note that the alarm relays within the

controller will not give protection under all failure conditions.

INSTALLATION

Panel mounting: Insert the unit into the panel cut-out and slide the mounting clamp

from the rear to a firm grip at the panel.

Electrical connections:

All electrical connections are made to the screw terminals at the rear of the controller.

They accept wire sizes from 0.5 to 1.5 mm2 (16 to 22 AWG). The terminals should be

tightened to a torque of 0.4 Nm (3.5 lb in).

Routing of wires

To minimize the pick-up of electrical noise, the low voltage DC connections and the

sensor input wiring should be routed away from high-current power conductors. If this

is impractical, use shielded cables. In general, keep cable lengths to a minimum.

It is strongly recommended to install RC filters (47 R and 100 nF, serial combination) at

contactor coils and other inductors.

WARNING: System failure should always be taken into account when designing a

control panel to avoid irreversible damage to equipment or people.

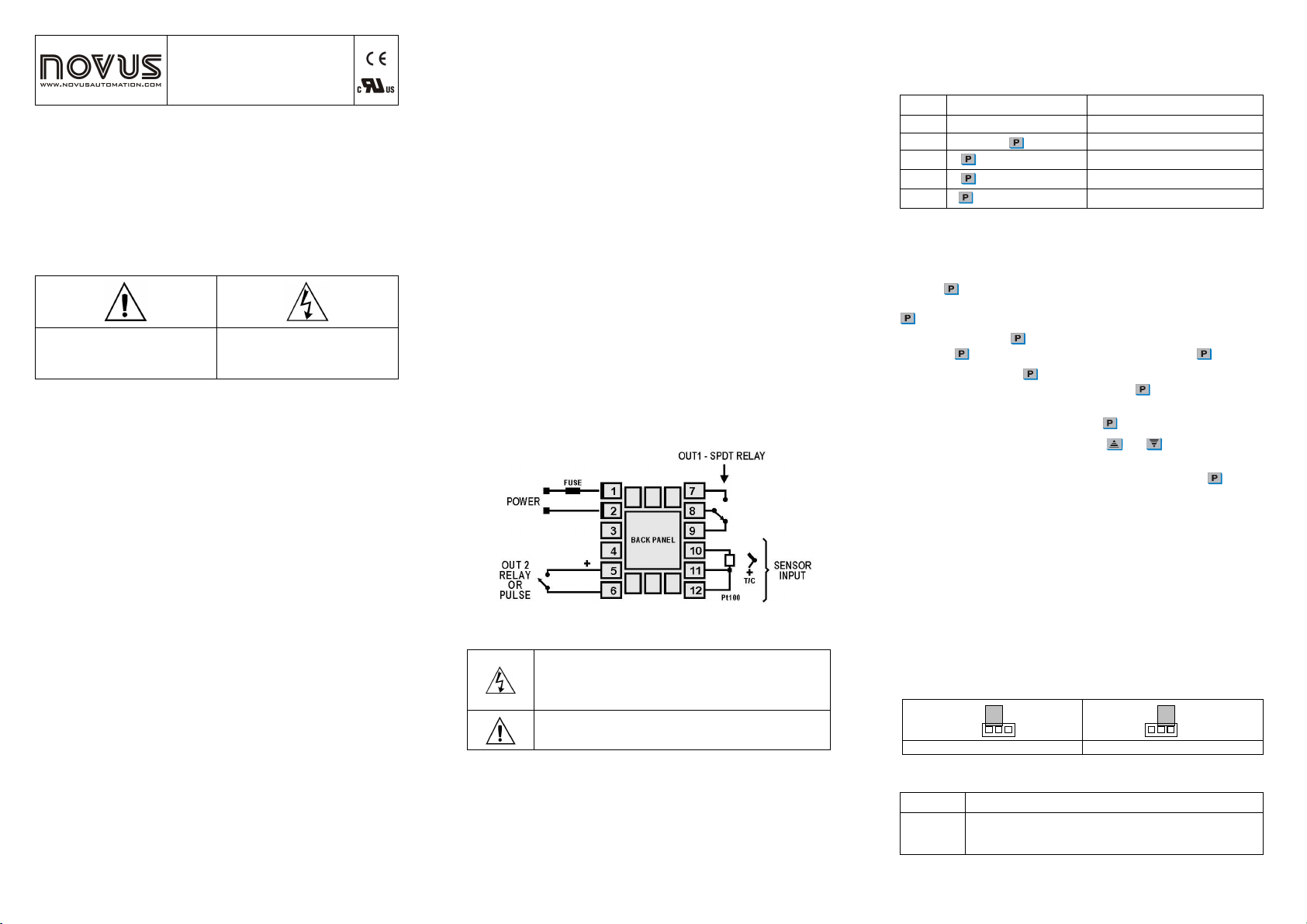

The figure below shows the N440 connections to mains, sensor and outputs.

Figure 1 – N440 back panel terminals

The installation must include a power isolating switch or circuit breaker

that disconnects all current carrying conductors. The device should be

mounted close to the controller, within easy reach of the operator and

marked as the disconnecting device for the instrument.

Wire sensor and outputs according to figure 1.

OPERATION

Before the controller is ready to be used in a given process, it requires some basic

configuration. The parameters are arranged in 4 levels:

Level Access Function

0 - Temperature measurement

1

2

3

4

After power-up, the controller will display the firmware version for 1 second. This

information is important for traceability and when contacting the manufacturer.

The instrument then shows the temperature measured by the sensor. This is the level

0 or temperature measurement level.

Pressing will lead to level 1, causing the display to alternate between the

messages “SP1

again.

To reach level 2, press for 2 seconds until the parameter “ sp2

Release the key to stay in this level. To go back to level 0, press again.

To enter level 3, press the key for 4 seconds and the parameter “Ac1

displayed. Release the key to stay in this level. Press to access other parameters

in this level. At the end of this cycle, the controller will return to level 0.

To enter the calibration level (level 4) press the key for 10 seconds.

To change a parameter setting, press the keys and until the desired value is

reached.

The new configuration value is saved in the controller by pressing the key (when

advancing to the next parameter in the level).

holding for 10 seconds

SP1” (set point 1) and the programmed value. To go back to level 0, press

SP1SP1

holding for 2 seconds

holding for 6 seconds

PROGRAM SECURITY

To avoid tampering, parameter “Prot

access to programming parameters.

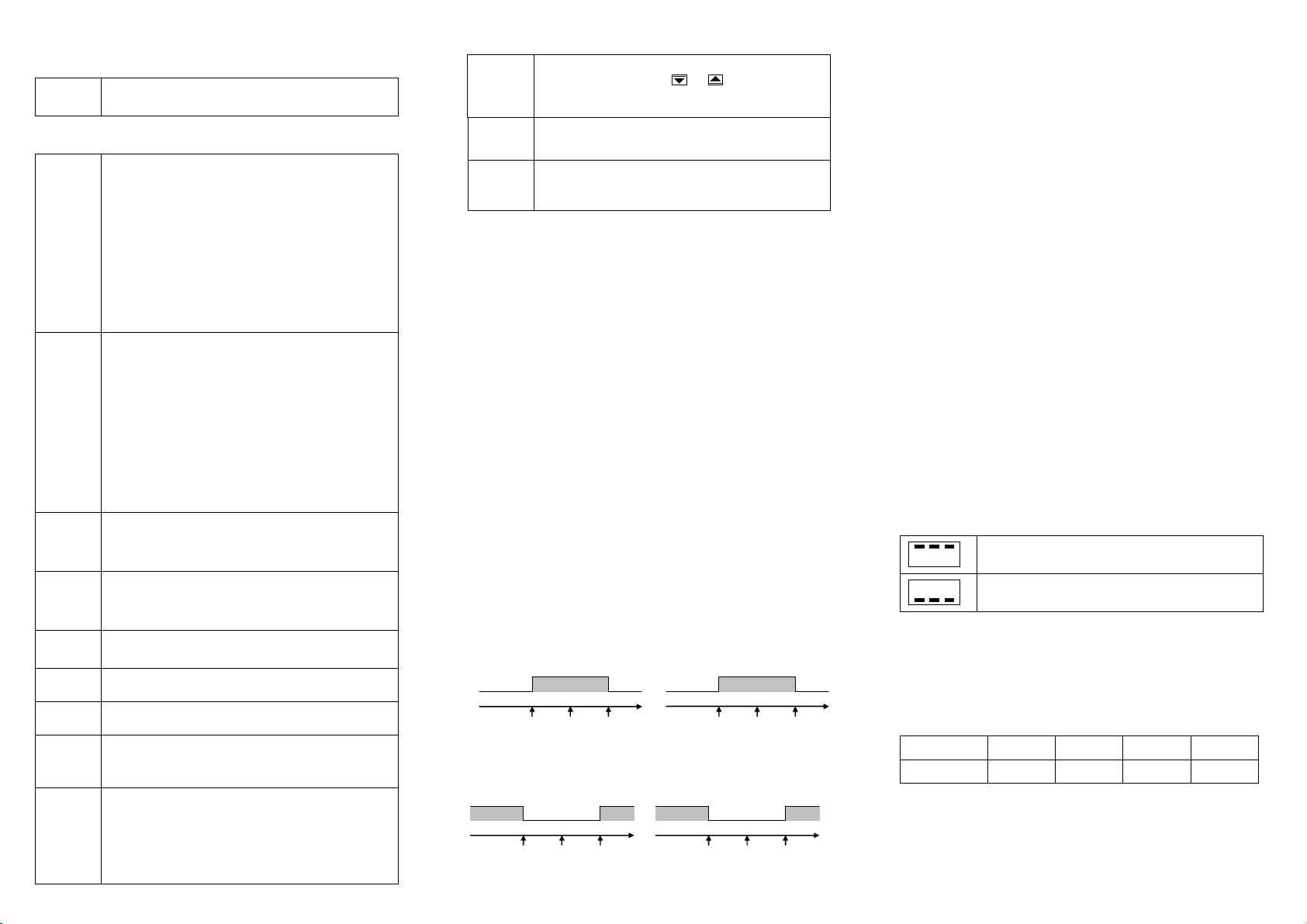

With the jumper in the OFF position, all program levels are unprotected. The “ Pro t

parameter can only be changed with the jumper in the OFF position.

With the jumper in the ON position or removed, the protection level is defined by the

current value of the “Prot

0000 No protection. All parameters can be accessed;

1111 No access to the Calibration level;

2222 No access to Calibration and Configuration levels;

3

3 No access to Calibration, Configuration and SP2 levels;

33

4

4 Full protection.

44

Figure 2 – Protection Disabled Figure 3 – Protection Enabled

Prot” parameter:

ProtProt

OFF

Prot” and a hardware jumper can be used to disable

ProtProt

LEVEL 1 –OUT1 SET POINT

Parameter Description/Parameter function

SP1

SP1

SP1SP1

Set Point 1

Temperature set point associated to the OUT1 output. Possible

values are limited by the parameters SPL

Set point for output OUT1

Set point for output OUT2

Parameter configuration

SPL e S Pk

SPLSPL

Calibration

sp2” is displayed.

sp2sp2

ON

SPk in level 3

SPk SPk

Ac1” will be

Ac1Ac1

Prot”

ProtProt

LEVEL 2 –OUT2 SET POINT

–

OUTPUT ON

TEMPERATURE

-

TEMPERATURE

ON

–

-

(Available only on models with 2 outputs).

SP2

SP2

SP2SP2

Set Point 2

Temperature set point associated to the OUT1 output. Possible

values are limited by the parameters SPL

LEVEL 3 – PARAMETERS CONFIGURATION

Ac1

Ac1

Ac1Ac1

Action 1

OUT1 Functions:

0

0 Reverse action usually used for heating

00

1

1 Direct Action usually used for cooling.

11

2

2 Low temperature alarm

22

3

3 High temperature alarm

33

4

4 Low temperature alarm with initial blocking

44

5

5 High temperature alarm with initial blocking

55

6

6 Out of range alarm (differential).

66

7

7 In range alarm (differential).

77

8

8 Out of range alarm with initial blocking.

88

9

9 In range alarm with initial blocking.

99

See the following section for details.

Ac2

Ac2

Ac2Ac2

Action 2

OUT2 Functions:

0

0 Reverse action usually used for heating

00

1

1 Direct Action usually used for cooling.

11

2

2 Low temperature alarm

22

3

3 High temperature alarm

33

4

4 Low temperature alarm with initial blocking

44

5

5 High temperature alarm with initial blocking

55

6

6 Out of range alarm (differential).

66

7

7 In range alarm (differential).

77

8

8 Out of range alarm with initial blocking.

88

9

9 In range alarm with initial blocking.

99

See the following section for details.

ky1

ky1

ky1ky1

Histeresis 1

OUT1 Hysteresis: Defines the differential range between the

temperature value at which the alarm is turned on and the value at

which it is turned off (in engineering units - °C or °F). Adjustable in

the range 0.1 to 70.

ky2

ky2

ky2ky2

Histeresis 2

OUT2 Hysteresis: Defines the differential range between the

temperature value at which the alarm is turned on and the value at

which it is turned off (in engineering units - °C or °F). Adjustable in

the range 0.1 to 70.

ofs

ofs

ofsofs

Offset

spl

spl

splspl

SP Low Limit

spK

spK

spKspK

SP High Limit

Unt

Unt

UntUnt

Unit

prt

prt

prtprt

Protection

Offset value to be added to the measured temperature to

compensate sensor error. Default value: zero. Range: –15 to +15.

Set point Low Limit: sets the minimum value allowed for the set

points 1 and 2. Spl

Spl< s pK

spK

SplSpl

spKspK

Set point High Limit: sets the maximum value allowed for the set

points 1 and 2. Spx

Spx > spl

spl

Spx Spx

splspl

Selects the display indication to be in ºC or ºF.

0000 Temperature in degrees Celsius.

1111 Temperature in degrees Fahrenheit.

Configuration protection:

0 No protection

1 No access to the Calibration level;

2 No access to Calibration and Configuration levels;

3 No access to Calibration, Configuration and SP2 levels;

4 No access to Calibration, Configuration, SP2 and SP1 levels;

SPL e S Pk

SPk in level 3

SPLSPL

SPk SPk

LEVEL 4 – CALIBRATION

(al

(al

(al(al

CAlibration Low

(Ak

CAlibration High

(jl

Cold Junction Low

Calibration

INPUT LOW CALIBRATION: Sets the Process Variable low calibration

(offset). Several keystrokes at or might be necessary to

increment one digit. The displayed value corresponds to the actual

(calibrated) temperature as seen by the controller.

INPUT HIGH CALIBRATION: Adjusts the Process Variable span

calibration (gain).

COLD JUNCTION OFFSET CALIBRATION: Adjusts the offset of the

cold junction temperature. Valid for thermocouple inputs only.

USING THE CONTROLLER

When in the process, the N440 displays the temperature measured by the sensor

connected in the terminals named SENSOR INPUT.

The sensor is defined at the purchase. The user needs then to configure outputs OUT1

and OUT2 (OUT2 is optional) with the desired functionality. Parameters Ac 1

define the outputs working mode. OUT1 is normally used as the control output,

whereas OUT2 is used as the alarm output. Depending on output requirements (relay

or logic pulse), the outputs may be configured differently.

The OUT1 e OUT2 outputs can perform in the following ways:

0000- Reverse action usually used for heating.

Output turns on when temperature is bellow set point minus hysteresis. Output

turns off when temperature is above set point.

1111- Direct Action usually used for cooling.

Output turns on when temperature is above set point plus hysteresis Output turns

off when temperature is bellow set point.

2222- Low temperature alarm.

Output turns on when temperature is bellow set point. Output turns off when

temperature is above set point plus hysteresis.

3333- High temperature alarm.

Output turns on when temperature is above set point. Output turns off when

temperature is bellow set point minus hysteresis.

4444- Low temperature alarm with initial blocking.

Same as low temperature alarm, but with initial blocking as described next.

5555- Low temperature alarm with initial blocking.

Same as high temperature alarm, but with initial blocking as described next.

6666- In range alarm (differential).

Available only for OUT2. Output turns on when temperature is in the range from

(SP1

SP1 - SP2

SP2) to (S P1

SP1 + S P2

SP1SP1

SP2SP2

OUT

SP2

SP1

OUT1 programmed for in of range alarm OUT2 programmed for in of range alarm

SP1SP1

SP2

SP2).

SP2SP2

SP2 + SP1

SP1

SP2

7777- Out of range alarm (differential).

Available only for OUT2. Output turns on when temperature is out of the range from

(SP1

SP1 - SP2

SP2) to (S P1

SP1 + S P2

SP1 SP1

SP2SP2

OUTPUT ON

OUT

TEMPERATURE

SP2

SP1

OUT1 programmed for out of range alarm OUT2 programmed for out of range alarm

SP1SP1

SP2

SP2).

SP2SP2

SP2 + SP1

OUTPUT ON

OUTPUT ON

OUT

TEMPERATURA

SP1

SP2

OUTPUT ON

SP1

SP1

Ac1 and Ac2

Ac2

Ac1Ac1

Ac2 Ac2

SP1 + SP2

OUTPUT ON

SP1 + SP2

8888- In range alarm with initial blocking.

Same as in range alarm, but with initial blocking as described next.

9999- Out of range alarm with initial blocking.

Same as out of range alarm, but with initial blocking as described next.

Note 1: OUT1 and OUT2 outputs can’t be simultaneously configured for In Range and

Out of Range alarm.

Note 2: The initial blocking feature, when enabled, results in the controller ignoring

alarm conditions which exists when the controller is powered-on or started.

Alarms with initial blocking:

The initial blocking option inhibits the alarm from being recognized if an alarm condition

is present when the controller is first energized. The alarm will actuate only after the

occurrence of a non alarm condition followed by a new occurrence for the alarm.

In the front panel, OUT indicator will light on when OUT1 is active, and AL1 indicator

will light on when OUT2 is active.

Hysteresis parameters ky1

ky1 and ky2

ky1ky1

ky2 are associated to outputs OUT1 and OUT2,

ky2ky2

and defines the differential range between the temperature value at which the alarm is

turned on and the value at which it is turned off

Offset (ofs

ofs) parameter may be adjusted to correct temperature indication due to

ofsofs

sensor error. The adjusted value is added to the temperature read before indication.

Parameters write protection:

Write to parameters may be disabled for each parameter level by means of an internal

protection strap key which when ON will block access to configuration. The instrument

is not protected with the strap key in OFF position. By placing the strap at ON, access

will be limited as defined in the “Prt

The protection parameter “Prt

Prt’’ parameter description.

PrtPrt

Prt” must be defined with the strap key in place otherwise

PrtPrt

it cannot be changed.

PROBLEMS WITH THE CONTROLLER

Connection and configuration errors state for most of the problems in using the

controller. A final revision of parameters will save time and further losses. Error

messages are displayed to help the user to identify possible problems. If one of the

messages bellow is displayed, all outputs are turned off for safety.

• Temperature above high limit.

• Broken sensor. Pt100 badly connected

• Temperature bellow low limit.

• Pt100 short-circuited.

TECHNICAL ASSISTANCE

If you encounter a problem with your controller, review the configuration with regard to

inputs, outputs, alarms, etc. If the problem persists, contact your supplier or Novus at

info@novus.com.br.

ORDERING INFORMATION:

N440 - J R R - 24V

A B C D E

A. Series model: N440;

B. Input sensor: C (Pt100), J (type J thermocouple) or K (type K thermocouple);

C. Output 1: R (Relay);

D. Output 2: R (Relay) or P (Pulse);

E. Voltage rating: blank (100-240 Vac or 24V (24 Vac/dc);

Loading...

Loading...