TEMPERATURE CONTROLLER

N321

OPERATING MANUAL - V1.8x

The N321 is a temperature controller for heating and cooling applications. It is

Level

Function

0

Temperature measurement

1

Setpoint Adjustment

2

Configuration

3

Calibration

SP

Set Point

Temperature adjustment for control OUTPUT 1. SP value is limited

to the values programmed in SPL and SPk in the programming

level (Parameter configuration, level 2).

Unt

Temperature Unit - Selects display indication for degrees Celsius

or Fahrenheit.

0 - Temperature in degrees Celsius

1 - Temperature in degrees Fahrenheit

typ

Input Type - Selects the input sensor type to be connected to the

controller. Available only for thermocouple models, allowing

selection of types J, K and T.

0 - Thermocouple type J

1 - Thermocouple type K

2 - Thermocouple type T

ofs

Sensor Offset - Offset value to be added to the measured

temperature to compensate sensor error.

spl

SP Low Limit - Lower range for SP. SPL must be programmed

with a lower value than spK.

spK

SP High Limit - Upper range for SP. SPx must be greater than

spl.

ky1

OUTPUT 1 Hysteresis: defines the differential range between the

temperature value at which the OUTPUT 1 is turned on and the

value at which it is turned off. In degrees.

Act

Control action for OUTPUT 1 :

0 Reverse: For heating applications. Outputs turn on when

temperature is lower than SP.

1 Direct: For cooling applications. Output turns on when

temperature is above SP.

oft

Off time

Off time - Defines the minimum off time for control OUTPUT 1.

Once OUTPUT 1 is turned off, it remains so for at least the time

programmed in oft. For thermocouple inputs this parameter is not

available. This parameter is intended for refrigeration systems

where longer compressor life is desired. For heating systems,

program oft to zero. Value in seconds, 0 to 999 s.

ont

on time

On time - Defines the minimum on time for control OUTPUT 1.

Once turned on, OUTPUT 1 remains so for at least the time

programmed in ont. For thermocouple inputs this parameter is not

available. This parameter is intended for refrigeration systems

where increased compressor life is desired. For heating systems,

program ont to zero. Value in seconds, 0 to 999 s.

dly

Delay1

Delay time to start control. Upon power-on, control OUTPUT 1 is kept

off until the time programmed in dly is elapsed. Its usage is

intended to prevent multiple compressors to start simultaneouly

after the turn-on of a system with several controllers. Value in

seconds, 0 to 250 s.

Add

Address

Adress - Controllers with the optional RS485 Modbus RTU

communication interface have the Add parameter at the

Configuration level. Set a unique Modbus address for each

equipment connected to the network. Address range is from 1 to 247.

available with NTC thermistor input sensor, Pt100, Pt1000 or J/K/T type

thermocouple. Sensor offset correction is provided. The output can be used as

control or alarm.

The features of a particular model (input sensor type, sensor range, mains supply,

etc) are identified by the label placed on the controller body.

SPECIFICATIONS

INPUT SENSOR: The input sensor type can be chosen form the 4 options below

(specified when placing the order):

NTC Thermistor, 10 k @ 25 ºC; range: –50 to 120 ºC (-58 to 248 ºF);

Accuracy: 1.0 ºC (1.1 °F), with original sensor;

Sensor interchangeability: 1 ºC (1.35 ºF). This error can be compensated by the

offset parameter in the controller.

Pt100 (= 385); Range: –50 to 300 ºC (-58 to 572 ºF);

Accuracy: 0.7 ºC (1.3 ºF); IEC-751.

Pt1000 (= 385); Range: –200 to 530 ºC (-328 to 986 ºF); Accuracy: 0,7 ºC (1.3 ºF);

J, K or T thermocouple (IEC-584):

Type J: Range: 0 to 600 ºC (32 to 1112 ºF); Accuracy: 3 ºC (5.4 ºF);

Type K: Range: -50 to 1000 ºC (-58 to 1832 ºF); Accuracy: 3 ºC (5.4 ºF);

Type T: Range: -50 to 400 ºC (-58 to 752 ºF); Accuracy: 3 ºC (5.4 ºF);

Note: In the controller with NTC input, a 3 m-sensor cable is bundled with the

instrument. The cable can be extended up to 200 m.

WARM-UP: ............................................................................................ 15 minutes

MEASUREMENT RESOLUTION:

from –19.9º to 199.9º display units with NTC, Pt100 and Pt1000: ...................... 0.1

elsewhere: ......................................................................................................... 1

OUTPUT1: ........... Relay SPDT; 1 HP 250 Vac / 1/3 HP 125 Vac (16 A Resistive)

POWER SUPPLY: .............. 100~240 Vac (± 10 %) or 24 Vdc/ac (12~30 Vdc/ac)

......................................... Mains frequency: 50~60 Hz. Power consumption: 5 VA

Caution: check the power supply specification before energizing the controller.

DIMENSIONS: ....................................... Width x Height x Depth: 74 x 32 x 75 mm

.............................................................. Panel cut-out: 70 x 29 mm; Weight: 100 g

ENVIRONMENT: ....................... Operating temperature: 0 to 40 ºC (32 to 122 ºF)

.................................................... Storage temperature: -20 to 60 ºC (-4 to 140 ºF)

....................................................... Relative humidity: 20 to 85 % non condensing

CASE: ............ Polycarbonate UL94 V-2; Protection: Front panel: IP65, Box: IP42

................................................................................ Suitable wiring: Up to 4.0 mm²

RS-485 digital communication; RTU MODBUS protocol (optional)

Serial interface not isolated from input circuitry.

Serial interface isolated from input circuitry, except in 24 V powered model.

Man 5001222

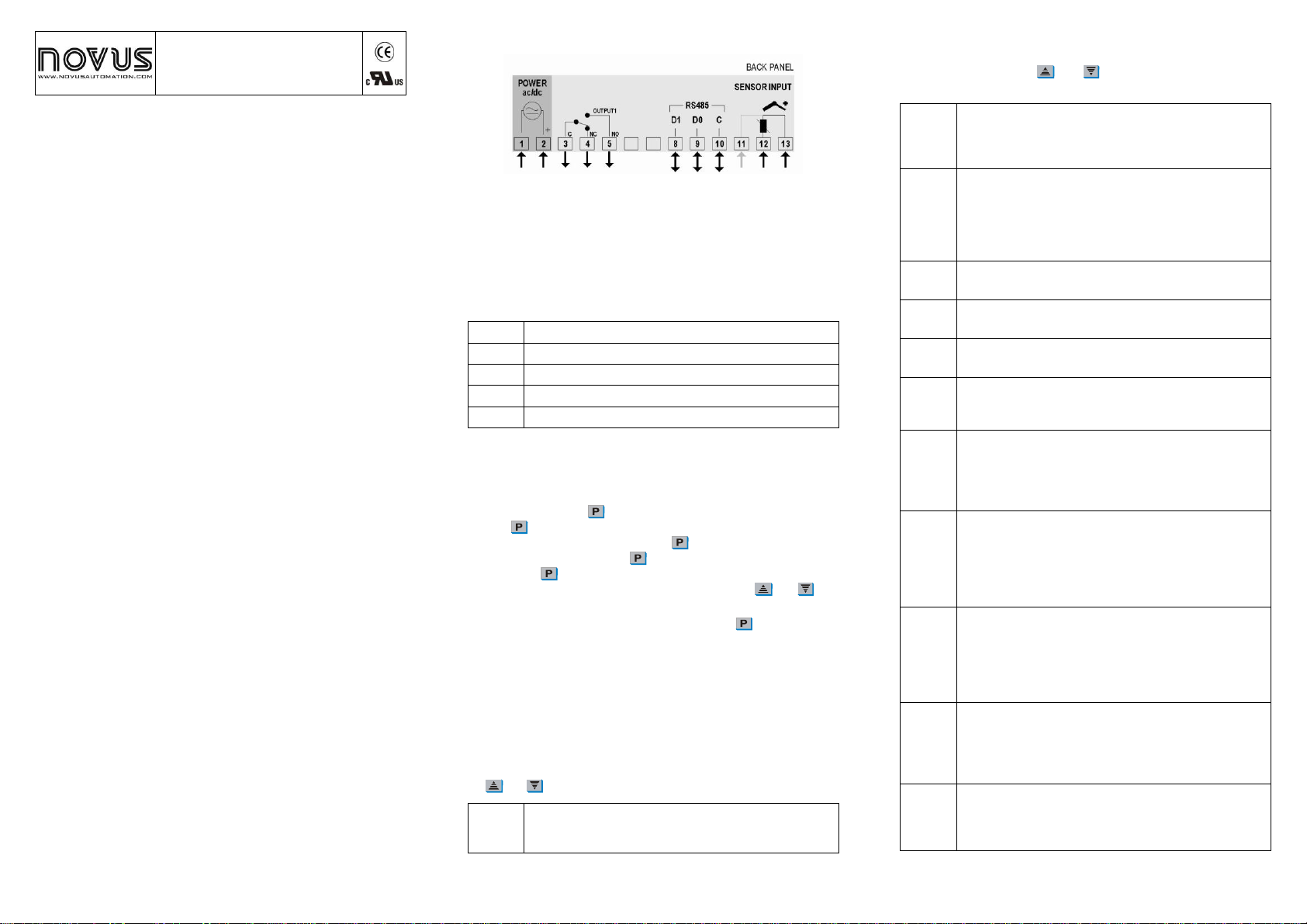

Fig. 1 below shows the controller connections to sensor, mains and outputs.

Fig. 1 – N321 terminals

Pt100 with 3 conductors: Terminals 11, 12 and 13 must have the same wire

resistance for proper cable length compensation. For 2 wire Pt100, short circuit

terminals 11 and 13.

OPERATION

The controller requires the internal parameters to be configured according to the

intended use for the instrument. The parameters are organized in 4 groups or levels:

Upon power-up, the N321 display shows for 1 second its firmware version. This

information is useful when consulting the factory.

Then, the temperature measured by the sensor is shown on the display. This is

the parameter level 0 (temperature measurement level).

To access level 1, press for 1 second until the “SP1” message shows up.

Pressing again to go back to level 0.

To access level 2 of paramenters, press for 2 seconds until the “uNT”

message is shown. Release the key to remain in this level. Each new

pressing on the key will advance to the next parameter in the level. At the end

of the level, the controller returns to the first level (0). Use the and keys

to alter a parameter value.

Notes: 1 A parameter configuration is saved when the key is pressed to

advance to the next parameter in the cycle. The configuration is

stored in a non-volatile memory, retaining its value when the controller

is de-energized.

2 If no keyboard activity is detected for over 20 seconds, the controller

saves the current parameter value and returns to the measurement

level.

Level 1 – Setpoint Adjustment

In this level only the Setpoint (SP) parameter is available, alternating the name

with its respective value. Adjust the desired temperature for setpoint by clicking on

the and keys.

Level 2 – Configuration - Parameters configuration Level

Contains the configuration parameters to be defined by the user, according to the

system’s requirements. Use and keys to set the value. The display

alternates the parameter name and respective value.

Level 3 – Calibration level

pas

Password - Enter the correct password to unlock write

operations for the parameters in the following levels.

[Al

Calibration low - Offset value of the input. It adjusts the lower

measurement range of the sensor.

[Ak

Calibration High - Gain calibration. It adjusts the upper

measurement range of the sensor.

[JL

Cold Junction Offset calibration - This parameter is available

only for thermocouple.

FA(

Factory Calibration - Restores factory calibration

parameters. Change from 0 to 1 to restore the calibration

parameters with factory values.

Prt

Protection - Defines the levels of parameters that will be

password protected. See "Configuration Protection" for details.

Pa(

Password Change - Allows changing the current password to a

new one. Values from 1 to 999 are allowed.

Sn2

Serial number - First part of the controller electronic serial number.

sn1

Serial number - Second part of the controller electronic serial

number.

sn0

Serial number - Third part of the controller electronic serial number.

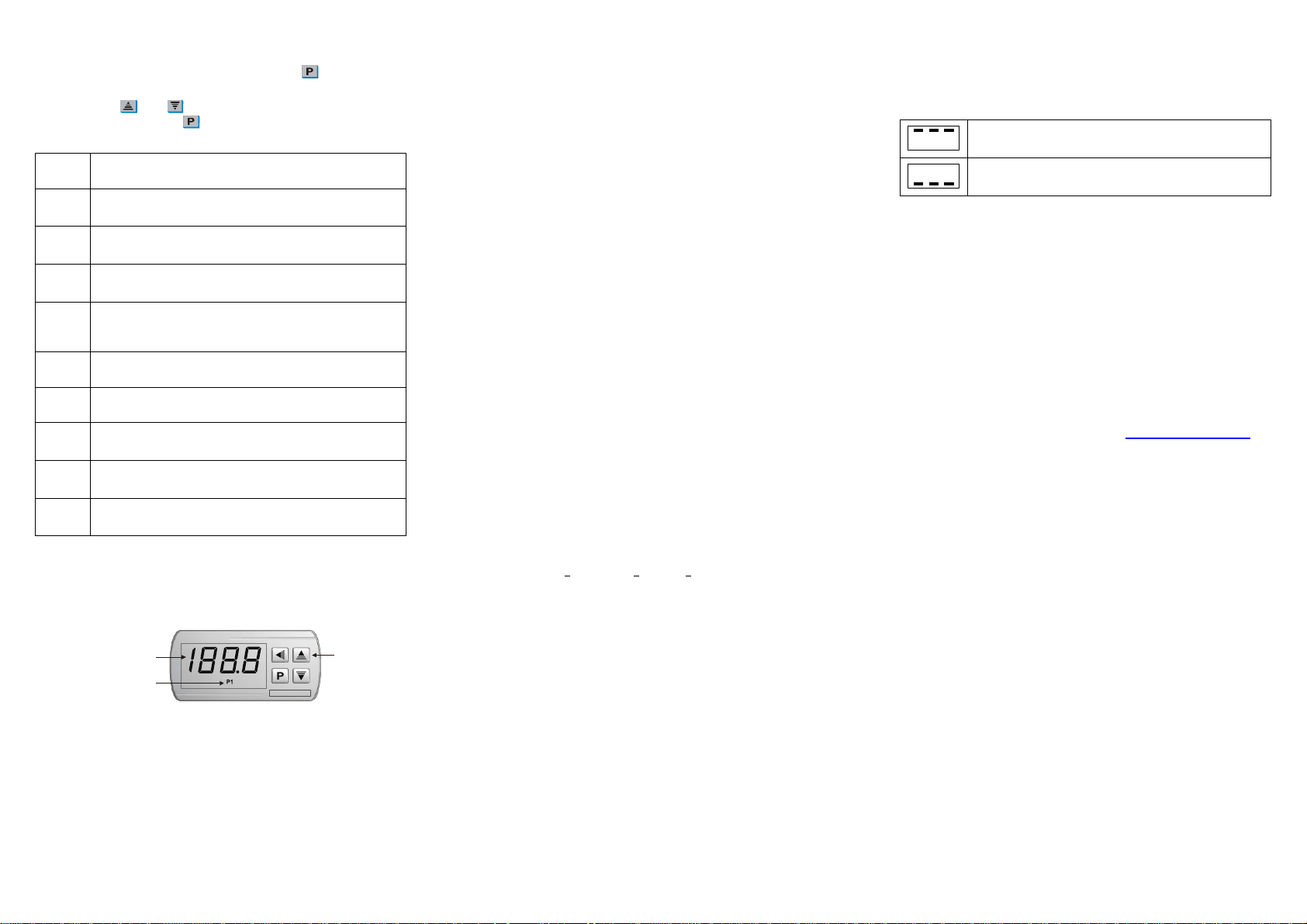

DISPLAY

OUTPUT STATUS LED

KEYBOARD

Measured temperature exceeded maximum allowed range for

the sensor. Broken Pt1000 or T/C. Short circuited NTC sensor.

Measured temperature is below minimum measurement range of

the sensor. Short circuited Pt1000 or T/C. Broken NTC.

The controller is factory calibrated. The following parameters should be accessed

only by experienced personnel. To enter this cycle, the key must be kept

pressed for 4 seconds.

Don’t press the and keys if you are not sure of the calibration

procedures. Just press the key a few times until the temperature

measurement level is reached again.

WORKING WITH THE CONTROLLER

The N321 energizes the output relay such as to maintain the process temperature

on the setpoint value defined by the user. The output status led P1 signals when

the control output is on.

CONFIGURATION PROTECTION

A protection system to avoid unwanted changes to the controller parameters

is implemented. The level of protection can be selected from partial to full. The

following parameters are part of the protection system:

Pas When this parameter is presented, the correct password should be entered

to allow changes of parameters in the following levels.

Prt Defines the level of parameters that will be password protected:

1 - Only calibration level is protected (factory configuration);

2 - Calibration and Configuration levels are protected;

3 - All levels are protected - calibration, Configuration and setpoints.

PA( Parameter for definition of a new password. Since it is located in the

calibration level, can only be changed by a user that knows the current

password. Valid passwords are in the range 1 to 999.

Configuration protection usage

PAS parameter is displayed before entering a protected level. If the correct

password is entered, parameters in all following levels can be changed. If wrong

or no password is entered, parameters in the following levels will be read only.

Important notes:

1- After five consecutive attempts to enter a wrong password, new tentative will be

blocked for the next 10 minutes. If the current valid password is unknown, the

master password can be used only to define a new password for the controller.

2 - The password for a brand new device is 111.

MASTER PASSWORD

The master password allows user to define a new password for the controller,

even if the current password is unknown. The master password is based in the

serial number of the controller, and calculated as following:

[ 1 ] + [ higher digit of SN2 ] + [ higher digit of SN1 ] + [ higher digit of SN0 ]

for example the master password for the device with serial number 987123465 is:

1 9 3 6

as follows: 1 + sn2= 987; sn1= 123; sn0= 465 = 1 + 9 + 3 + 6

How to use the master password:

1- Enter the master password value at PaSprompt.

2- Go to PA( parameter and enter the new password, which must not be zero (0).

3- Now you can use this new password to access all controller parameters with

modify rights.

ERROR MESSAGES

Sensor measurement errors force the controller outputs to be turned off. The

cause for these errors may have origin in a bad connection, sensor defect (cable

or element) or system temperature outside the sensor working range. The display

signs related to measurement errors are shown below:

ELECTRICAL WIRING

It is important to follow the recommendations below:

Signal wires should be installed in grounded conduits and away from power or

contactor wires.

The instrument should have its own power supply wires that should not be

shared with electrical motors, coils, contactors, etc.

Installing RC filters (47 R and 100 nF, series combination) is strongly

recommended at contactor coils or any other inductors.

System failure should always be taken into account when designing a control

panel to avoid irreversible damage to equipment or people.

WARRANTY

Warranty conditions are available on our web site www.novusautomation.com.

Fig. 2 – Frontal Panel

Loading...

Loading...