Controller

UNIVERS

installation and operation of the

tYPE

TYPE

CODE

CHARACTERISTICS

J 0 range: -50 to 760 °C (-58 to 1400 º F )

K 1 range: -90 to 1370 °C (-130 to 2498 ºF)

T 2 range: -100 to 400 °C (-148 to 752 º F )

N 3 range: -90 a 1300 °C (-130 a 2372 ºF)

R 4 range: 0 a 1760 °C (32 a 3200 ºF)

S 5 range: 0 to 1760 °C (32 to 3200 ºF)

Pt100 6 range: -199.9 to 530.0 °C ( -328.0 to 986.0 ºF)

7

4-20 mA

8

J linearization. Programmable range: -110 to 760 °C

4-20 mA

9

K linearization. P rogrammable range: -150 to 1370 °C

4-20 mA

10

T linearization. Programmable range: -160 to 400 °C

4-20 mA

11

N Linearization. Programmable range: -90 a 1370 °C

4-20 mA

12

R Linearization. Programmable range: 0 a 1760 °C

4-20 mA

13

S linearization. P rogrammable range: 0 to 1760 °C

4-20 mA

14

Pt100 linearization. Prog. Range:-200.0 to 530.0 °C

4-20 mA

15

Pt100 linearization Prog. Range:-200 to 530 °C

0 to 50 mV

16

Linear. Programmable i ndication -1999 to 9999

4-20 mA

17

Linear. Programmable i ndication -1999 to 9999

0 to 5 Vdc

18

Linear. Programmable i ndication -1999 to 9999

4 to 20 mA

19

Square Root Extraction

N3000

AL PROCESS CONTROLLER – INSTRUCTIONS MANUAL – V2.1x C

SAFETY SUMMARY

The symbols below are used on the equipment and throughout this

document to draw the user’s attention to important operational and

safety information.

CAUTION OR WARNING:

Read complete instructions prior to

unit.

CAUTION OR WARNING:

Electrical S hock Hazard

All safety related instructions that appear in the manual must be

observed to ensure personal safety and to prevent damage to either

the instrument or the system. If the i nstrument is used in a manner

not specified by the manufacturer, the protection provided by the

equipment may be impaired.

INTRODUCTION

The N3000 is a proc ess controller incorporating a P ID algorithm and

universal inputs (sensor and standard si gnals) and outputs (logical,

relay and analog outputs). It holds in one single instrument all de

main features that are needed for the vast majority of industrial

processes.

CONFIGURATION

INPUT TYPE SELECTION

Select the input type (in parameter “

Pt100

range: -200 to 530 °C (-328 to 986 ºF)

”) from Table 1 below.

OVER-TEMPERATURE PROTECTION

When designing any control system it is essential to consider what

will happen if any part of the system should fail. In temperature

control applications the primary danger is one in which the heating

remains constantly on. In any application where physical injury or

destruction of equipment might occur, it is recommend to install an

independent protection equipment, with a separate temperature

sensor, to disable the heating c ircuit in case of overheating. Please

note that the alarm relays within the controller wil l not give protection

under all failure conditions.

NOVUS AUTOMATION 1/9

Table 1 - Input Types

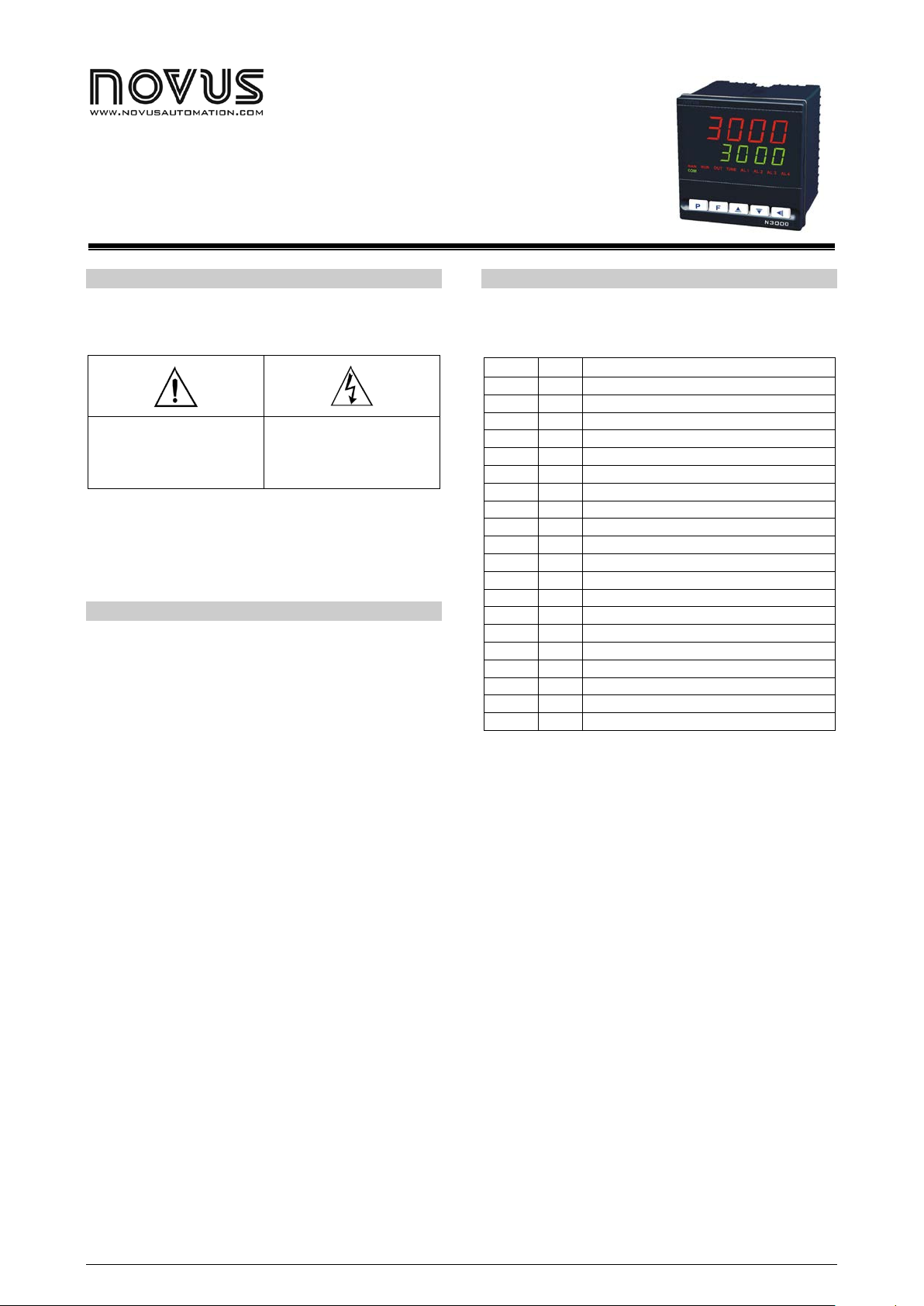

OUTPUTS, ALARMS AND DIGITAL INPUTS CONFIGURATION

The controller input/output c hannels can assume multiple functions,

depending on configuration: control output, alarm output, digital

output, digital input, and PV or SV analog retransmission. These

channels are identified as I/O1, I/O2, I/O3, I/O4, I/O 5 and I/O6.

The basic controller model comes loaded with:

• I/O1 and I/O2 - SPDT relay output;

• I/O3 and I/O4 – SPST relay output;

• I/O5 - analog output (0-20 or 4-20 mA), pulse 10 V max, digital I/O;

• I/O6 – Digital Input;

The function code of each I/O can be selec ted among the options on

Table 2. Only valid function codes are displayed for each I/O (for

example, I/O1, which is a relay , can be confi gured with functi ons 0 to

5 only; on the other hand, I/05 can perform all 16 functions).

The description for the functions follows:

• CODE 0 - No function. The I/O channel programmed with code 0

will not be used by the controller. It is available to be used by serial

communication as digital output.

• CODES 1 to 4 - Alarm output - Available for all I/O channels

(except I/O6). The selected channel can be used as output to

Alarms 1 to 4.

• CODE 6 - Digital input - Standard for I/O5 and I/O6.

Closed: Manual control

Opened: Automatic control

Controller N3000

rvn

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

off

No active alarm. This output can be used as a digital

output to be set by t he serial communication.

(input Error)

ierr

Alarm will be ON if P V sensor breaks, input signal is

Event Alarm

Soak)

rs

Can be activated at a specific segment of ramp and

resistance f ail

rfail

lo

SPAn

PV

ki

SPAn

PV

difl

SV

PV

SV - SPAn

SV

PV

SV - SPAn

difk

SV

PV

SV + SPAn

SV

PV

SV + SPAn

dif

SV

PV

SV + SPAn

SV - SPAn

SV

PV

SV - SPAn

SV + SPAn

SPA1

SPA2

A1t1

A1t2

A2t1

A2t2

• CODE 7 - Digital input - Standard for I/O5, I/O6 and key.

Start/Stop input (“

”: YES / no).

Closed: outputs enabled

Opened: outputs disabled

• CODE 8 - Digital input - Standard for I/O5, I/O6 and

key.

Closed: remote SP (4-20 mA in remote SP input)

Opened: main SP (internal programmed SV)

• CODE 9 - Digital input - Standard for I/O5, I/O6 and key.

Opened: enables R&S program

Closed: holds R&S program (the program resumes when the

contact is opened again)

CODE I/O TYPE I/O FUNCTION

Digital Output Digital Output to be set by the serial comm.

Digital Output Alarm 1 Output

Digital Output Alarm 2 Output

Digital Output Alarm 3 Output

Digital Output Alarm 4 Output

Digital Output PWM Control Output

Digital Input Automatic/Manual mode change

Digital Input Run/Stop mode change

Digital Input Select Remote Set Point Input

Digital Input Executes/Holds selected ramp and soak profile

Digital Input Enable/Disable R&S profile 1 selection

Analog Output 0 to 20mA Analog control out put

Analog Output 4 to 20mA Analog control output

Analog Output 0 to 20mA PV retransmission

Analog Output 4 to 20mA PV retransmission

Analog Output 0 to 20mA SP retransmission

Analog Output 4 to 20mA SP retransmission

Table 2 - I/O channel f unctions

• CODE 10 - Digital input - Standard for I/O5, I/O6 and key.

Selects R&S program 1. Used to alternate between the main

Setpoint and a second Setpoint defined by the R&S program 1.

Closed: selects program 1

Opened: uses main Setpoint

• CODE 11 - Analog control output - I/O5 only. 0-20 mA control

output.

• CODE 12 - Analog control output - I/O5 only. 4-20 mA control

output.

• CODES 13 to 16 - Analog retransmission. I/O5 only. Configures

I/O5 to output a 0-20 mA or 4-20 mA analog signal proportional to

PV or SP.

REMOTE SETPOINT

The remote Setpoint (SP) is enabled by an external digi tal signal in

either I/O5 or I/O6, when programmed with the code 8 (Select remote

SP input).

An external resistor shunt of 100 Ω is required between the terminals

7 and 8.

ALARMS FUNCTION

The controller has 4 alarms. The alarms can the configured to

operate in any of the nine functions listed on Table 3.

• Open sensor

It is activated whenever the input sensor is broken or disconnected.

• Event alarm

It activates alarm(s) in specifi c segments of the program. See item

7.2 in this manual.

• Event alarm

Detects a heater broken condition, by monitoring the load current

when the control output is ac tivated. This alarm functi on requires an

optional device (option 3). Details of the "resis tance fail" option can

be found in a specific documentation that is sent with the product

when the option is purchased.

TYPE PROMPT

Disabled

Sensor Break

(ramp and

Detection

Low Alarm

High Alarm

LOW

Differential

HIGH

Differential

Differential

out of range or Pt100 is shorted.

Detects a heater br oken condition

positive SPAn

positive SPAn

positive SPAn

Table 3 - Alarm functions

ACTION

soak program.

negative SPAn

negative SPAn

negative SPAn

Where SPAn means “SPA1”, “SPA2”, “SPA2” and “SPA4”.

• Minimum value

It is activated when the measured value i s below the v alue defined i n

the alarm Setpoint.

• Maximum value

It is activated when the meas ured val ue is above t he val ue defi ned in

the alarm Setpoint.

• Differential (or Band)

In this function, the parameters “

”, “

” represent the PV

deviation as compared to the main SP.

In a positive deviation, the di fferential alarm will be triggered when

the measured value is out of the range defined in:

( SP – Deviation) and (SP + Deviation)

In a negative deviation, the differenti al alarm will be triggered when

the measured value is within the range defined above.

• Minimum differential

It is activated when the measured value is below the value defined in.

(SP - Deviation)

• Maximum differential

It is activated when the measured value is above the value defined in:

(SP + Deviation)

ALARM TIMER FUNCTIONS

Alarms 1 and 2 can be programmed to have timer functions. The 3

modes of operation are:

1- Pulse 2- delayed actuation 3- Oscillator

The desired function can be achieved programming the parameters

”, “

”, “

” and “

“

” (see Table 4).

The LEDs associated to the alarms will light when the alarm condition

is recognized, not following the actual state of the output, which may

be temporarily OFF because of the temporization.

NOVUS AUTOMATION 2/9

Alarm Function

T1 T2 ACTION

Alarm Event

Alarm

Output

Alarm Event

Alarm

Output

T2

Alarm Event

Alarm

Output

T1

Alarm Event

Alarm

Output

T1

T2

T1

SPLL

SPkL

SfSt

ovLL

ovkL

irreversible damage

will occur

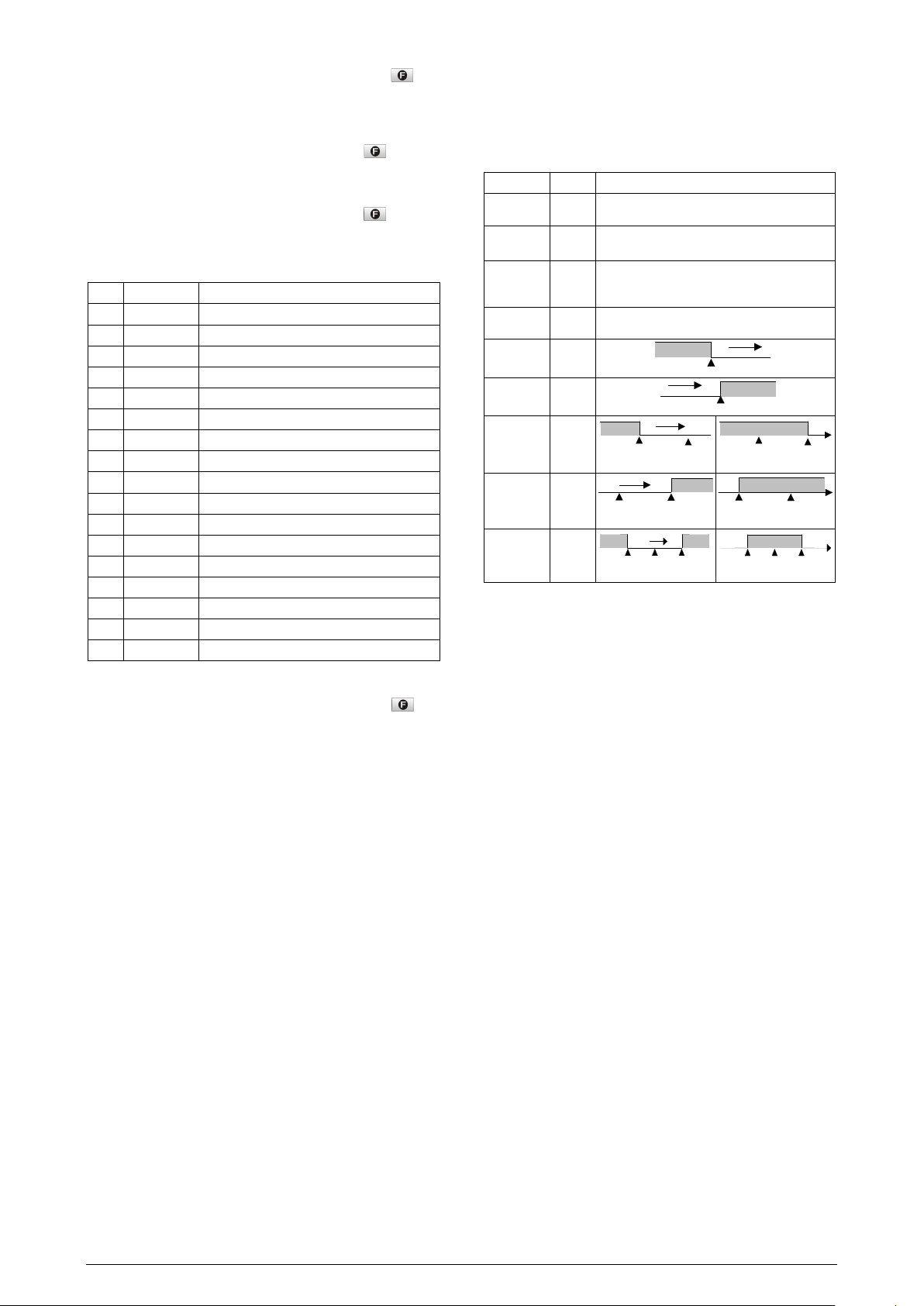

Figure 2 – High and Low Voltage AC power w iring

wiring

three conductors

Figura 5 – connection of 4-20 mA

Figura 6 – Connection of 5 Vdc

Normal 0 0

Delayed 0 1s to 6500s

Controller N3000

Pulse 1s to

6500s

Oscillator 1s to

6500s

Table 4 - Advanced Timer A larm (for alarms 1 or 2)

0

1s to 6500s

ALARM INITIAL BLOCKING

The initial blocking opti on inhibits the alarm from being recognized if

an alarm condition is present when the controll er is first energized.

The alarm will actuate only after the occurrence of a non alarm

condition followed by a new occurrence for the alarm.

The initial blocking is disabled for the sensor break alarm function.

SQUARE ROOT EXTRACTION

Available when input type 19 is sel ected. The indicator displays the

square root of the current signal input applied to terminals 22 and 24.

ANALOG RETRANSMISSION OF PV AND SP

The analog output, when not used for control purposes, is available

for retransmitting the SV and SP values in 0-20 or 4-20 mA. Thi s

analog output is electrically isolated from other inputs and outputs.

The analog output signal is scaleable, with the output range

determined by the values programmed in the parameters “

”. To obtain a voltage output, connect a resistor shunt to the

“

” and

current output terminals (terminal 1 and 2).

Figure 1 – Back panel terminals

POWER WIRING

If high voltage is

applied to a low

voltage input,

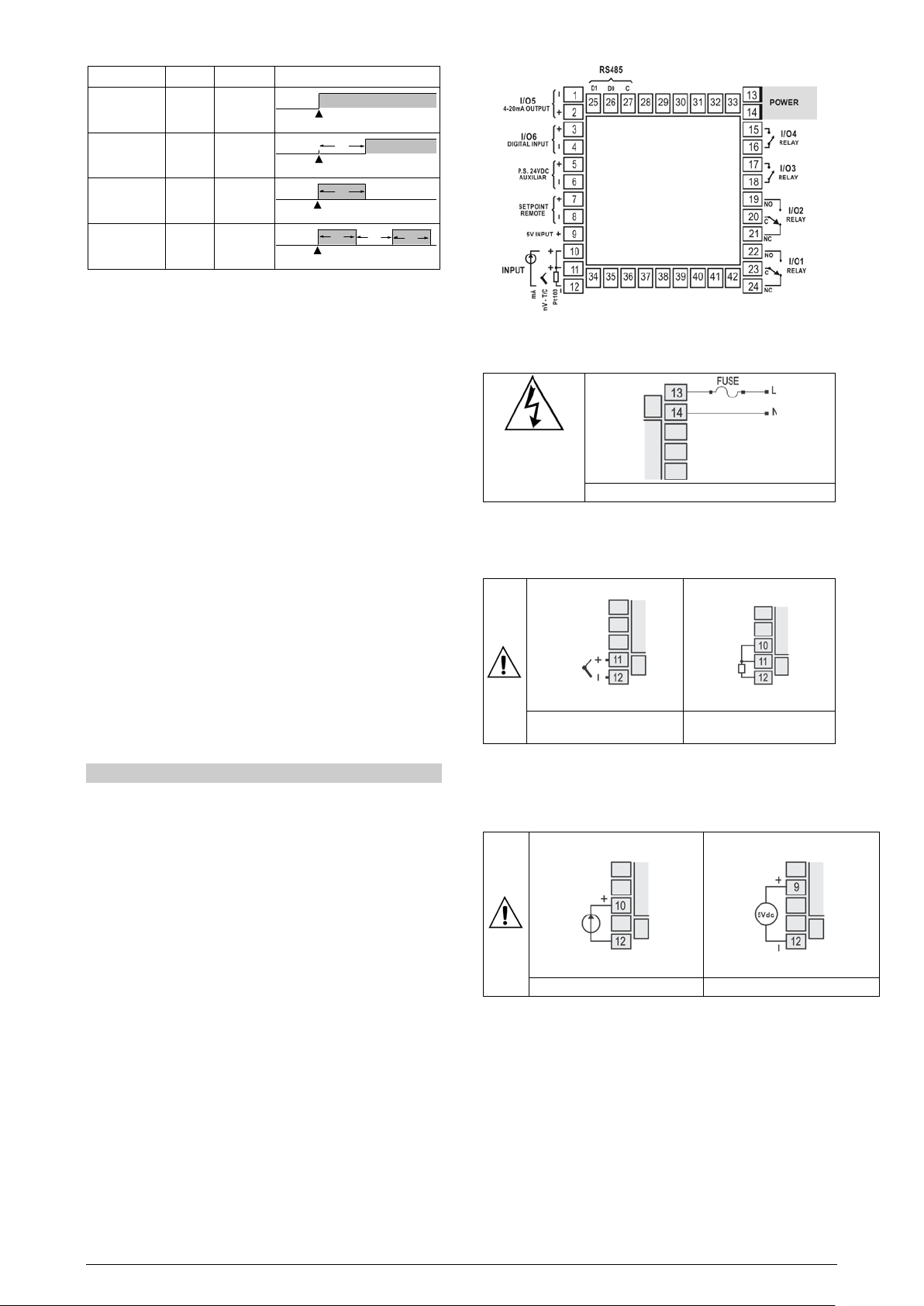

INPUT CONNECTIONS

• Thermocouple and Voltage (Volts and mV) input connect as i n

Figure 3.

SOFT START

Defines the time i nterval for the output to reach its maximum value

(100 %). The soft start value is programmed in “

parameters “

” and “

INSTALLATION / CONNECTION

Insert the unit into the panel cut-out and slide the mounting clamp

from the rear to a firm grip at the panel.

All electrical connecti ons are made to the screw terminals at t he rear

of the controller. They accept wire siz es from 0.5 to 1.5 mm2 (16 to

22 AWG). The terminals should be tightened to a torque of 0.4 Nm

(3.5 lb in).

To minimize the pick-up of electrical noise, the low voltage DC

connections and the sensor input wiring s hould be routed away from

high-current power conductors. If this is impractical, use shielded

cables. In general, keep cable lengths to a minimum.

RECOMMENDATIONS FOR INSTALLATION

• Input signal wires s hould be laid out away from power lines and

preferably inside grounded conduits.

• Instrument mains (line) supply should be suitabl e for this purpose

and should not be shared.

• In controlling and monitoring applicati ons, possible consequences

of any system failure mus t be considered in advanc e. The internal

alarm relay does not warrant total protection.

• Use of RC filters (47 R and 100 nF, serial) are highly

recommended when driving solenoids, contactor coils or other

inductive loads.

NOVUS AUTOMATION 3/9

”. See also

Figure 3 – T/C and Voltage

Figura 4 – Pt100 wiring wi th

”.

• RTD (Pt100)

Figure 4 shows the Pt100 wiring, for 3 conductors. Terminals 10, 11 and 12

must have the same wire resistance for proper cable length compensation.

For 2 wire Pt100, shor t circuit t erminals 10 and 11.

• 4-20 mA:

Refer to Figure 5. (The controller provides an internal electronic

shunt for the input current. No changes in the circuit are necessary).

• Alarm and output connection

When I/O channels are set up as output channels, they must have

their capacity respected, according do specifications.

• Remote setpoint:

The remote Setpoint (SP) is enabled by an external digi tal signal in

either I/O5 or I/O6, when programmed with the code 8 (Select remote

SP input).An external resistor shunt of 100 is required between the

terminals 7 and 8.

DIGITAL INPUT

Controller N3000

fFvn

f.fvnc

tYPE

I/O5 and I/O6 can be used as digital inputs, accepting either dry contact

or NPN open collector signals. Figure 7 shows a switch driving the I/O6

digital input. The digital input at I/O5 is driven only by dry contact

signals. Figure 8 shows a typical digital input wiring for I/O5.

Figure 7 – Digital input at I/O6 Figure 8 – Di git al i nput at I/ O5

DIGITAL OUTPUT

I/O5 can also be configured as digital out put. An example of usage is

shown in Figure 9. I/O5 is electrically isolated from the sensor input.

Figure 9 – I/O5 digit al output wiring.

KEY AND DIGITAL INPUT (I/O6) FUNCTIONS

Both the key and the I/O6 digital input can be programmed to execute

functions 7, 8, 9 and 10 shown in Table 2. The key function is

configured in parameter “

”. The digital input function is

configured in parameter IO6.

The digital input can also be configured for function 6: Auto/Manual

mode change.

Programmable FUNCTION Key: Can be assigned to the

-

special functions described for the

parameter.

When the controller is turned on, its firmware version i s display ed for

3 seconds, after which the controller starts normal operation. The

values of PV and SV are displayed and the outputs are enabled.

Before the controller is ready to be used in a given process, it

requires some basic configuration, such as:

• Input type (T/C, Pt100, 4-20 mA,...) at the “

” prompt,

according to Table 1;

• Output type at “I/O 1”, “I/O 2”,... “I/O 6” prompts (see Table 2);

• Setpoint variable SV. Set the remaining parameters.

• PID parameters (or hysteresis for ON/OFF control)

Other functions, including alarms, ramp and s oak, timer, digital input,

etc., may be useful for a better system performanc e. The parameters

are grouped in 7 cycles.

CYCLE ACCESS

1- Operation Free access parameters *

2- Tuning

3- R&S Program

4- Alarms Reserved access parameters **

5- Input Configuration

6- I/Os

7- Calibration

*These parameters can be viewed but not changed if the cycle is

protected.

**Requires a key combination to access the cycle.

OPERATION

The front panel is shown in Figure 10.

Press

the next one.

and simultaneously to move from one cycle to

Press to advance and to go back in the menu cycle.

Keep pressing the or key to move fast forward or backward.

At the end of each cycle the controller returns to the operation cycle.

PROGRAM SECURITY

Each menu cycle can be locked (protected) by pressing

and

simultaneously for 3 seconds. Press and for 3

seconds to unlock. A short blink of the display confirms the

lock/unlock change.

Figure 10 - Front panel part s

Status display / PV: shows the value of PV (Process Variable).

When in programming mode, shows the parameter name.

Parameter display / SV: shows the SV (Setpoi nt Vari abl e) value and

the value of other parameters of the controller.

COM Indicator: Flashes when communication messages are sent by

the controller.

TUNE Indicator: Lights during the execution of PID automatic

tunning.

MAN Indicator: Lights when the controller is in manual.

RUN Indicator: Lights when the control ler is active, wi th control and

alarm outputs enabled.

OUT Indicator: For relay or pul se control output, reflects the actual

state of the output. If an analog output is assigned for control, lights

continuously.

A1, A2, A3 and A4 Indicators: Status of the alarms.

- PROG key: used to walk through the menu cycles

- BACK key: go back to the previous displayed parameter

For further protection, the unlock operation through the keypad may

be disabled by c hanging the position of an internal strap insi de the

controller:

When PROT is OFF, the user is allowed to lock and unlock the

cycles using the keypad as explained above. If PROT is ON, the

cycles lock/unlock operation is disable.

- INCREASE and - DECREASE keys: Used to change

parameter values

NOVUS AUTOMATION 4/9

Controller N3000

PV Indication

(Red)

SV Indication

(Green)

Ern

avto

PV Indication

(Red)

MV Indication

(Green)

display shows PV value and the lower display shows

the percentage of MV applied to the control output.

When in manual control the MV value can be manually

changed. When in auto mode the MV value can only be

Pr n

programs possible). Refer to chapter 7 for R&S

rvn

atvn

enables the auto tuning of the PID

Pb

PROPORTIONAL BAND: Percentage of maximum

xyst

CONTROL HYSTERESIS (in engIneering. units): This

‘ ir‘

INTEGRAL RATE: Integral time constant in repetitions

dt

DERIVATIVE TIME: Derivative time constant, in

(t

CYCLE TIME: PWM period in seconds. Can only be

act

rE

dir

bias

ovll

ovxl

sfst

Sp.a1

Sp.a2

Sp.a3

Sp.a4

tbas

: Selects the time base for the ramp and

0

Pr n

ptol

Psp0

Psp7

values which define the ramp and soak profile

Pt1

Pt7

Pe1

Pe7

rS

lp

Fva1

Fva2

Fva3

Fva4

bla1

bla2

bla3

bla4

xya1

ALARM 1 HYSTERESIS: Defines the differential

xya2

xya3

xya4

A1t1

A1t2

alarm 1 output, after being ON during the time

A2t1

A2t2

features that can be achieved with these time

CONFIGURATION PARAMETERS

OPERATION CYCLE

PV AND SV INDICATION: The status display shows

the present value of PV (Process Variable). The

parameter display shows SV (Set Variable).

The status display shows “- - - -“ whenever PV exceeds

the maximum range or there is no signal at the input. In

case of hardware error the status display will show

where n is the error c ode.

CONTROL MODE: YES indicates automatic control

mode (closed loop, PID or ON/OFF). NO indicates

manual control mode (open loop). Bumpless transfer

from auto ↔ to manual mode is available. If in doubt

program YES.

MANIPULATED VARIABLE VALUE (MV): The upper

viewed.

To distinguish the MV display from the SV display, the

MV is shown flashing intermittently.

RAMP AND SOAK PROGRAM SELECTION: Selects

the ramp and soak program to be executed (7

description.

CONTROL ENABLE: YES means that the control

output and alarms are enabled and NO means they

are disabled.

AUTO TUNING CYCLE

AUTO-TUNE: YES

parameters and NO dis ables it.

input span. 0 to 500 %. Selec t zero for ON/OFF control.

parameter is only shown for ON/OFF control (Pb=0).

per minute (Reset) .

RAMP AND SOAK PROFILE PROGRAMMING CYCLE

TIME BASE

soak. Valid for all profile programs.

- PT1 to PT7 values are in seconds;

1 - PT1 to PT7 values are in minutes;

PROGRAM TO BE VIEWED: Selects the ramp and

soak profile program to be edited/viewed in the

following cyc le prompts (7 programs available).

,

RAMP AND SOAK TOLERANCE: maximum deviation

between PV and SV. Whenever this deviation is

exceeded the time counter is halted until deviation

lowers to within the tolerance. Set zero to disable this

function.

RAMP AND SOAK SET POINTS (0 to 7): Set of 8 SV

segments. See also PT1 to 7 and PE1 to 7 below.

RAMP AND SOAK SEGMENTS TIME (1 to 7): Set of

7 time intervals in minutes or seconds (9999 max.) for

the 7 segments of the r am p and soak program.

RAMP AND SOAK EVENT (1 to 7): Set of 7 values

that define which alarms must be activated during a

ramp and soak program segment. Alarm function

depends on “

LINK TO PROGRAM: Number of the next profile

program to be linked to follow the current profile.

Profiles can be linked to make larger programs of up

to 49 segments.

” setting (Table 3).

ALARM CYCLE

ALARM 1 FUNCTION: Select options from Table 3.

ALARM 2 FUNCTION: Select options from Table 3.

ALARM 3 FUNCTION: Select options from Table 3.

ALARM 4 FUNCTION: Select options from Table 3.

ALARM BLOCK 1 TO 4: This func tion blocks the alarm

at power-up when the units is first energized.

YES enables and NO inhibits this blocking function.

When enabled the alarm will not be active at power-up

waiting for PV (Process Variable) to reach a non-alarm

situation. From this point on the alarm will be free to

actuate should a new alar m situation occur.

seconds.

viewed if proportional band is other than z ero.

CONTROL ACTION: For Auto Mode onl y.

•

Reverse Action usually used for heating.

•

Direct Acti on usually used for cooling.

Offset for MV (manual reset). Range: -100 % to +100

%. Default value: 0.

OUTPUT LOW LIMIT: minimum percentage value for

MV (Manipulated Variable) when in automatic control

and PID. Default val ue: 0.0 %

OUTPUT HIGH LIMIT: Maximum percentage value for

MV when in automatic control and PID. Default value:

100.0 %

SOFT START: Time in seconds during which the

controller limits the MV value progressively from 0 to

100%. It is enabled at power up or when the control

output is activated. If in doubt set zero.

ALARM PRESET: Tripping point for alarm 1, 2, 3

and 4.

NOVUS AUTOMATION 5/9

range between the PV value at which the alarm is

turned on and the value at which it is turned off (in

engineering units).

ALARM 2 HYSTERESIS: Same as above.

ALARM 3 HYSTERESIS: Same as above.

ALARM 4 HYSTERESIS: Same as above.

ALARM 1 TIME 1: Defines the time (6500 sec. max.)

during which the alarm 1 output will be ON when

alarm 1 is acti ve. Program zero to disable this function.

ALARM 1 TIME 2: Defines the OFF state time for the

selected on ALARM 1 TIME 1. Program zero to

disable this function.

ALARM 2 TIME 1: Defines the time (6500 sec. max.)

during which the alarm 1 output will be ON when

alarm 1 is acti ve. Program zero to disable this function

ALARM 2 TIME 2: Defines the time during which the

alarm 2 output will be, after being ON during the time

selected on ALARM 2 TIME 1. Program zero to

disable this function. Table 4 shows the advanced

functions.

Controller N3000

type

connected to the process variable input. Refer to

dppo

vnIt

offs

spll

Linear inputs: Sets the lower range for SV and PV

spxl

d PV

rsll

rsxl

bavd

addr

Io 1

Io 2

Io 3

Io 4

Io 5

I o 6

f.fvnc

0

7

8

9

10

Programming

atvn

Tbas

fva1 -

fva4

type

io1

avto

pb

pr n

bla1 -

bla4

dppo

io2

hyst

Ptol

kya1 -

kya4

vnit

io3

pr n

ir

psp0 -

psp7

A1t1

offs

Io4

rvn

dt

pt1 -

pt7

a1t2

spll

Io5 (t

pe1 -

pe7

a2t1

spkl

Io6

a(t

Lp

a2t2

rsll

f.fvnc

bias

Rskl

Inl(

INPUT LOW CALIBRATION: Sets the Process

Inx(

INPUT HIGH CALIBRATION: Sets the Process

ovll

OUTPUT LOW CALIBRATION: Sets the analog

Ovx(

(j l

xtyp

HARDWARE TYPE: Configures the controller to

onal hardware

(accessories). The parameters menu will show the

Rsl(

Remote Set Point low calibration (offset). Several

Rsx(

CONFIGURATION CYCLE

INPUT TYPE: Selects the input signal type to be

Table 1.

This is the first p arameter to be set.

DECIMAL POINT POSITION: For input types 16, 17,

18 or 19 only. Selects the decimal point position to be

viewed in both PV and SV.

TEMPERATURE INDICATION IN ºC OR ºF: Selects

the display indication to be in ºC or ºF. Only available

if input type is other than 16, 17, 18 or 19.

SENSOR OFFSET: Offset value to be added to the

PV to compensate sens or error. Default value: zero.

SET POINT LOW LIMIT:

indication.

- T/C and Pt100 inputs: sets the lower range for SV.

SET POINT HIGH LIMIT:

- Linear inputs: Sets the upper range for SV an

indication.

- T/C and Pt100 inputs: sets the upper range for SV.

REMOTE SET POINT LOW LIMIT: Selects the lower

range for indication of the Remote Setpoint.

REMOTE SET POINT HIGH LIMIT: Selects the upper

range for indication of the Remote Setpoint.

DIGITAL COMMUNICATON BAUD RATE

SELECTION:

0: 1200bps; 1: 2400bps; 2: 4800bps; 3: 9600bps; 4:

19200bps.

SLAVE ADDRESS SELECTION: Identifies a slave in

the network. The possible address numbers are from 1

to 247.

I/O CYCLE (INPUTS AND OUTPUTS)

I/O 1 FUNCTION: Selects the I/O function to be used

at I/O 1 (relay 1). Options 0 to 5 are possible for this

output. It is normally used as option 5, PWM main

control output. Refer to Table 2 for func tions.

I/O 2 FUNCTION: Selects the I/O function to be used

at I/O 2 (relay 2). Options 0 to 5 are available. This

output is normally used as alarm output. See Table 2

for functions.

I/O 3 FUNCTION: Selects the I/O function to be used

at I/O 3 (option 1). I/O 3 can be a relay output or a

digital input/output. Functions 0 to 10 are available.

Refer to Table 2 for functions. The presence of this I/O

option is detected by the controller and the prompt

menu will only be shown if the expansion option is

available.

I/O 4 FUNCTION: Selects the I/O function to be used

at I/O 4 (option 2). I/O 4 can be a digital input/output.

Functions 0 to 10 are available. Refer to Table 2 for

functions. The prompt menu will only be shown if the

expansion option is present.

I/O 5 FUNCTION: S elects the I/O function to be used

at I/O 5 (Analog Output). Functions 0 to 15 are

available (See Table 2). This option is normally used

for main control output or PV analog retransmission.

I/O 6 FUNCTION: Selects the I/O function to be used

at I/O 6 (Digital Input). Options 0, 6, 7, 8, 9 and 10 are

possible for this input. Refer t o Table 2 for functions.

F KEY FUNCTION: Selects the I/O function assigned

to the front panel

NOVUS AUTOMATION 6/9

- Key not used;

- Start/Stop the controller (RUN function);

- Select remote setpoint;

- Execute/Hold ramp and soak profile;

- Enable/Disable ramp and soak profile 1;

Details on these f unctions are described in section 5. 2.

key. Available functions are:

Figure 7 shows the sequence of cycles and parameters presented in

the indicator display. There are parameters that must be defined for

each alarm available.

Operation

Cycle

Auto

Tuning

Cycle

Cycle

Alarm

Cycle

Configuration

Cycle

I/Os

Cycle

PV e SP

PV e MV

Figure 10 - Sequence of cy cl es and paramet ers pr esent ed in the c ontroll er display

CALIBRATION CYCLE

All input and output types are factory calibrated. This cycle shoul d

only be accessed by experienced personnel. I f in doubt do not press

or keys in this cycle.

the

Variable low calibration (offset). Several keystrokes at

or

might be necessary to increment one

digit.

Variable span calibration (gain).

current output low calibration (offset).

OUTPUT HIGH CALIBRATION: Sets the analog

current output s pan calibration (gain).

COLD JUNCTION OFFSET CALIBRATION: Sets the

cold junction offset calibrat ion.

recognize the actual installed opti

parameters relative to the optional har dware:

0 - no optionals or c/ RS485 only;

1 - relay 3 (I/O 3);

2 - Digital I/O (2 inputs/outputs : I/O3 and I/O4);

3 - Heater break prot ection (option);

REMOTE SET POINT LOW CALIBRATION: Sets the

keystrokes at or

increment one digit.

REMOTE SET POINT HIGH CALIBRATION: Sets the

Remote Set Point span calibration (gain) .

might be necessary to

Controller N3000

SP

time

T1

T2

T3

T4

T5

SP0

SP1

SP2

SP3

SP4

SP5

SP6

SP7

T6

T7

SV

time

T1

T2

T3

SP0

SP1

SP2

SP3

T4=0

Ptol

SV

time

T1

T2

T3

T4

T5

T1

T2

T3

T4

SP0

SP1

SP2

SP3

SP4

SP5 / SP0

SP1

SP2

SP3

SP4

Program 1

Program 2

rS

PE 0

PE 5

CODE

ALARM 1

ALARM 2

ALARM 3

ALARM 4 0

1 X

2 X

3

4

X

5 X X

6 X X

7 X X X

8

9

X

X

10

X

X

11

X X

X

12

X

X

13

14

X X

X

15

X X X

X

Prn

rvn

PtoL

rvn

Avto

Atvn

rvn

Large Oscillat ion

Increase

Slow Response

Incre ase

Large Oscillat ion

Decrease

Slow Response or Instability

Decrease

inL(

ink(

RAMP AND SOAK PROFILE PROGRAM

Seven ramp and soak profiles with up to 7 segments each can be

programmed. Longer profiles of up to 49 segments can be created by

linking 2 or more profiles.

Figure 11 - Example of a complete ramp

and soak profile

To execute a profile with fewer segments just program 0 (zero) for the

time intervals that follow the last segment to be executed.

The program tolerance “

between PV and SV for the execution of the profile. If this devi ati on is

exceeded, the program will be interrupted until the deviation falls to

within the tolerance band.

Programming 0 (zero) at this prompt disables the tolerance and the

profile execution will not t o be halted even if PV does not follow SV

(time priority as opposed to SV priority).

The ramp and soak event function is used to acti vate alarms at any

segment of program 1. This applies only to program 1.

LINK OF PROGRAMS

It is possible to create a more complex program, with up to 49

segments, joining the seven programs. This way, at the end of a

program execution the controller immediately starts to run another one.

When a program is created, it must be defined in the “LP" screen

whether there will be or not another program.

To make the controller run a given program or many programs

continuously, it is only necessary to l ink a program to i tself or the last

program to the first.

Figure 12 - Example of a pr of ile

with fewer segments. ( T4 i s set 0)

” defines the maximum deviation

To configure and execute a ramp and soak program:

• Program the tolerance value, SV, time and event.

• If any event alarm is required program the ramp and soak event

function.

• Set the control mode to automatic.

• Select ramp and soak program to be executed at prompt

• Start control at the

prompt by selecting YES.

(0 to 7)

Before executing the program the controller waits for PV to reach the

first set point SP0 if

is different than zero.

Should any power failure occur the controller resumes at the

beginning of the segment it currently is.

AUTO TUNE

During auto tune the process is controlled in ON/OFF mode at the

programmed SetPoint (SV). Depending on the process

characteristics large oscil lations above and bel ow SV may occur and

auto tuning may take several minutes to be concluded.

The recommended procedure is as follows:

• Disable the control output at the

• Select auto mode operation at the

• Disable the ramp and soak function (select NO) and program a new

SV value other than the present PV (close to the desired set point).

• Enable auto tuning at the

• Enable the control output at the

During the auto tune procedure the soft-start function will not operate

and large oscillati ons will be induc ed around the setpoint. Make sure

the process can accept these oscillations and fast control output

changes.

If auto tuning results are not satisfactory refer to T able 6 for manual

fine tuning procedure.

PARAMETER RESPONSE SOLUTION

Proportional Band S low Response Decrease

prompt by selecting NO.

prompt by selecting YES.

prompt by selecting YES.

prompt by selecting YES.

EVENT ALARM

To enable this event function the alarms to be activated must be

selected for

prompts. The number to be programmed at the prompt defines the

alarms to be activated (Table 5).

NOVUS AUTOMATION 7/9

Figure 13 - Example of two linked programs

function and are programmed at the

X X

X

X X X

Table 5 - Event codes for ramp and soak

to

Integral Rate

Derivative Ti me

Large Oscillat ion Increase

Table 6 - Suggestions for manual tuning of PID param eters

CALIBRATION

INPUT CALIBRATION

All inputs are fac tory c al ibrated and recal i bration s houl d only be done

by qualified personnel. If you are not fami liar with these procedures

do not attempt to calibrate this instrument. The calibration steps are:

a) Select the input type to be calibrated.

b) Set the desired upper and lower display limits.

c) At the input terminals inject an electric al signal corresponding to

a known indication value a little higher than the lower display

limit.

d) Select the

PV so that it matches the injected signal.

e) Inject a signal that corresponds to a v alue a little lower than the

upper limit of the display.

f) Select the

PV so that it matches the injected signal.

g) Repeat steps c) to f) to improve calibration.

Note: When verifications are proceded, note if the Pt100

excitation/activation current the calibrator requires i s compliant to the

Pt100 excitation current used in this instrument: 0.750 mA.

prompt. Through the and keys adjust

prompt. Through the and keys adjust

Controller N3000

ovLL

ovkL

avto

rvn

ovLC

ovkC

MESSAGE

POSSIBLE PROBLEM

-----

Open input. No sensor is connected or the sensor is

broken.

Err1

Err6

spxl

spll

D1 D D + B Bidirectional data line

Terminal 25

D0

D:

D - A Inverted bidir ectional data line

Terminal 26

Optional connection to improve

GND

ANALOG OUTPUT CALIBRATION

1. Select type 11 or 12 at the I/O5 prompt.

2. Connect a current meter at the analog output.

3. Disable the auto-tune and soft-start functions.

4. Set the output low limit

to 100.0 %.

5. Select the manual mode at the

6. Enable the output at the

7. At the operation cycle, set the MV to 0.0 %.

8. At the output low cal ibration

key until the mA meter reads zero mA. Approach this value

from above.

9. Set 100.0 % for the manipulated variable (MV).

10. At the output high calibration

key unti l the mA meter reads 20 mA. Approach this value

from below.

11. Repeat steps 7. to 10. as necessary.

PROBLEMS WITH THE CONTROLLER

Connection errors or improper configuration will result in malfuncti oning

of the controller. Carefully revise all cable connections and programming

parameters before operating the unit.

Some error messages will help the user identify possible problems.

Pt100 cable resistance is too high or the sensor is badly

connected.

Different messages other than the ones above should be reported to

the manufacturer. Please inform the serial number if this should

occur. The serial number can be viewed at the display by pressing

key for about 3 seconds.

the

The software version of the instrument can be viewed at the time the

unit is powered.

When not properly configured, the instrument may show false error

messages, particularly those related to the type of input selected.

The controller also has a vis ual alarm (the display fl ashes) when the

PV value is out of the range set by

SERIAL COMMUNICATION

The indicator can be supplied with an asynchronous RS-485 digital

communication interface for master-slave connection to a host

computer (master).

The indicator works as a slave only and al l commands are started by

the computer which sends a request to the slave address. The

addressed unit sends back the requested reply.

Broadcast commands (addressed to all indi cator units in a multidrop

network) are accepted but no reply is sent back in this case.

CHARACTERISTICS

• RS-485 compatibility with two-wire connection f rom the host to up

to 31 slaves i n a multidrop network topology. Up to 247 units can

be addressed by the MODBUS RTU protocol. Maximum network

distance: 4,000 feet. T ime of indicator dis connection: Maximum of

2 ms after the last byte.

• Te communication signals are elec trically isolated from the rest of

the instrument, and can be 1200, 2400, 4800, 9600, 19200, 38400,

and 57600 bps.

• Number of data bits: 8, without parity or pair parity

• Number of stop bits: 1

• Time to start response transmission: up to 100 ms after

acknowledging the command.

• Protocol: MODBUS (RTU)

NOVUS AUTOMATION 8/9

to 0.0 % and the output high li mit

prompt.

prompt.

prompt, press the and

prompt, press the and

and

.

RS485 INTERFACE: ELECTRICAL CONNECTION

The RS-485 signals are:

C

communication performance

Terminal 27

SPECIFICATIONS

DIMENSIONS: ................. 96 x 96 x 92 mm. Peso Aproximado: 350 g

TERMINAL CONECCTION: ..... 24 screws acceping 6.3 mm fork lugs

PANEL CUT-OUT: ................................... 93 x 93 mm (+0.5 -0.0 mm)

POWER: ..................................... 100 a 240 Vac/dc (±10 %), 50/60 Hz

Optional: ............................................................ 24 Vac/dc ±10 %

Max. Consumption: ................................................................ 9 VA

ENVIRONMENTAL CONDITIONS:....................................... 5 a 50 ºC

Relative humidity (maximum): .............................80 % up to 30 ºC

.................... For temperatures above 30 ºC, decrease 3 % per ºC

....... Installation category II. Pollution degree 2. Altitude < 2000 m

INPUT .................... Keyboard selection of input type (refer to Table 1)

Internal resolution: .................................................. 19500 levels

Display resolution: ................. 12000 levels (from -1999 to 9999)

Input sample rate: .................................................... 5 per second

Accuracy: .......... Thermocouples J, K e T: 0.25 % of span ±1 ºC

............................. Thermocouples N, R, S: 0.25 % do span ±3 ºC

...................................................................... Pt100: 0.2 % of span

.................................... 4-20 mA, 0-50 mV, 0-5 Vdc: 0.2 % of span

Input impedance: . 0-50 mV, Pt100 and thermocouples: >10 MΩ

................................................................................. 0-5 V: >1 MΩ

................................................. 4-20 mA: 15 Ω (+2 Vdc @ 20 mA)

Pt100 measurement: ................................... standard (=0.00385)

Excitation current: ................................. 0,170 mA. 3-wire circuit,

cable resistance compensation.

All input types are factory calibrated according to IEC-584 for

thermocouples and IEC-751 for Pt100.

DIGITAL INPUT (I/O6): .................. Dry contact or NPN open collector

ANALOG OUTPUT (I/O5): .............. 0-20 mA or 4-20 mA, 550 Ω max.

1500 levels, Isolated, para controle ou retransmissão de PV e SP

.....................................Control output or PV or SP retransmission

CONTROL OUTPUT: 2 Relays SPDT (I/O1 and I/O2): 3 A / 240 Vac

2 Relays SPST-NA (I/O3 and I/O4): 1,5 A / 250 Vac

Logic pulse for SSR drive (I/O5): 10 V max / 20 mA

SECOND ANALOG INPUT: 4-20 mA remote set point (standard).

EMC: ................................ EN 61326-1:1997 and EN 61326-1/A1:1998

SAFETY: ........................... EN61010-1:1993 and EN61010-1/A2:1995

Back panel: IP65, Polycarb onate UL94 V-2; Box: IP30, ABS+PC

UL94 V-0

Programmable PWM cycle from 0.5 seconds and 100 seconds;

Start up 3 seconds after power up.

ORDERING INFORMATION:

N3000 - 485 - 24V

A B C

A: Series model: N3000;

B: Digital communication: blank

485 (RS485, Modbus protocol)

C: Voltage rating: blank (100 to 240 Vac);

24V (24 Vac/dc);

SAFETY INFORMATION

Any control system design should take into account that any part of

the system has the potenti al to fai l . Thi s product i s not a protec ti on or

safety device and its alarms are not intended to protect against

product failures. Independent safety devices should be always

provided if personnel or property are at risk.

Product performance and specifications may be affected by its

environment and installation. It’s user’s responsibility to assure

proper grounding, shielding, cable routing and electrical noise

filtering, in accordance with local regulations, EMC standards and

good installation practices.

SUPPORT AND MAINTENANCE

This product contains no serviceabl e parts inside. Contact our local

distributor in case you need authorized servi ce. For troubleshooting,

visit our FAQ at www.novusautomation.com

.

LIMITED WARRANTY AND LIMITATION OF LIABILITY

NOVUS warrants to the original purchaser that this product is free

from defects in material and workmanship under normal use and

service within one (1) year from the date of shipment from factory or

from its official sales channel to the original purchaser.

NOVUS liability under this warranty shal l not in any case exceed the

cost of correcting defects in the product or of suppl ying replacement

product as herein provided and upon the expiration of the warranty

period all such liability shall terminate.

For complete information on warranty and liability limitations , check

appropriate section in our web site: www.novusautomation.com

.

Controller N3000

NOVUS AUTOMATION 9/9

Loading...

Loading...