Controller N20

UNIVERS

tYPE

Tc j

Tc k

Tc t

Tc n

Tc r

Tc s

Tc b

Tc e

Pt

L.0.50

L.4.20

L0.5

L0.10

Sqrt

ln j

Ln k

ln t

ln n

ln r

ln s

ln b

ln E

Ln.Pt

00

AL PROCESS CONTROLLER – INSTRUCTIONS MANUAL – V3.0x A

SAFETY ALERTS

The symbols below are used on the equipment and throughout this

document to draw the user’s attention to important operational and

safety information.

CAUTION or WARNING:

Read complete instr uct i ons pr ior t o

installation and oper ati on of t he uni t.

All safety related instructions that appear in the manual must be

observed to ensure personal safety and to prevent damage to either

the instrument or the system. If the instrument is used in a manner

not specified by the manufacturer, the protection provided by the

equipment may be impaired.

PRESENTATION

The N2000 is an extraordinarily versatil e process controll er. It holds in

one single instrument al l the main features needed for the vast maj ority

of industrial processes. It acc epts in a single model virtually all the

sensors and signals used in the industry and provides the main

output types required for the operation of diverse processes.

The configuration can be performed directly on the controller or through

the USB interface. The NConfig software (free) is the configuration

management tool. Connected to the USB of a Windows computer, the

controller is recognized as a serial communicati ons port (COM) running

with a Modbus RTU protocol.

Through the USB interface, even if disconnected from the power supply,

the configuration performed in a piece of equipment can be can be

saved in a file and repeated in other pieces of equi pment that require

the same configuration.

It is important that the users read carefully thi s manual before using

the controller. Verify if the release of this manual matches the

instrument version (the firmware versi on is shown when the c ontroll er

is energized).

• Multi-sensor universal input (sensors and standard signals);

• Relay, 4-20 mA and logic pulse control outputs al l avai lable in the

standard model;

• Self-tuning of PID parameters;

• Automatic / Manual function with “bumpless” transfer;

• Four modes of independents alarms, with functions of minimum,

maximum, differential (deviation), open sensor and event;

• Timer functions that can be associated to the alarms;

• Retransmission of PV or SP in 0-20 mA or 4-20 mA;

• Input for remote setpoint;

• Digital input with 5 functions;

• Programmable soft-start;

• 7 setpoint profile programs with 7 segments each, with the ability

to be linked together for a total of 49 segments;

• Comunicação serial RS-485, protocolo MODBUS RTU;

• Password for parameters protection;

• Universal power supply.

NOVUS AUTOMATION 1/11

CAUTION or WARNING:

Electrical S hock Hazard

CONFIGURATION

INPUT TYPE SELECTION

Select the input type (in parameter “

TYPE CODE CHARACTERISTICS

J

K

T

N

R

S

B

E

Pt100

0–50 mV

4-20 mA

0-5 Vdc

0-10 Vdc

4-20 mA

4-20 mA

NO

LINEAR

Range: -110 a 950 ºC (-166 a 1742 ºF)

Range: -150 a 1370 ºC (-238 a 2498 ºF)

Range: -160 a 400 ºC (-256 a 752 ºF)

Range: -270 a 1300 ºC (-454 a 2372 ºF)

Range: -50 a 1760 ºC (-58 a 3200 ºF)

Range: -50 a 1760 ºC (-58 a 3200 ºF)

Range: 400 a 1800 ºC (752 a 3272 ºF)

Range: -90 a 730 ºC (-130 a 1346 ºF)

Range: -200 a 850 ºC (-328 a 1562 ºF)

Linear Signals

Programmable indication from-1999 to 9999

4-20 mA input with Square Root extraction.

Programmable indication from-1999 to 9999

Non Linear Analog Signals

Indication range depends on the selected sensor

Table 1 - Input Types

Note: All input types are factory calibrated.

OUTPUTS, ALARMS AND DIGITAL INPUTS CONFIGURATION

The controller input/output c hannels can assume multiple functions,

depending on configuration: control output, alarm output, digital

output, digital input, and PV or SV analog retransmission. These

channels are identified as I/O1, I/O2, I/O3, I/O4, I/O 5 and I/O6.

The basic controller model comes loaded with:

I/O1 and I/O2 - SPDT relay output;

I/O3 and I/O4 - SPST relay output;

I/O5 - analog output (0-20 or 4-20 mA), pulse 10 V max, digital I/O;

I/O6 - Digital Input.

Note: When a function is selected to operate through digital

input, the controller does not respond to the equivalent function

command given in the frontal keypad.

”) from Table 1 below.

Controller N2000

OFF

A1

A2

A3

A4

Lbd

CTRL

mAN

RVN

RSP

KPRG

PR 1

(.0.20

(.4.20

P.0.20

P.4.20

S.0.20

S.4.20

OFF

A1, A2, A3, A4

Lbd

CTRL

mAN

RVN

rvn

RSP

KPRG

PR 1

(.0.20

(.4.20

P.0.20

P.4.20

S.0.20

s.4.20

off

off

ierr

dif

SPA1

SPA2

SPA3

SPA4

difl

difk

The function to be used in each c hannel of I/O i s defined by the user

in accordance with the options shown in the Table 2.

I/O FUNCTION I/O TYPE CODE

No function Alarm 1 Output Output

Alarm 2 Output Output

Alarm 3 Output Output

Alarm 4 Output Output

LDB Output - Loop break detection Output

Control Output (Rel ay or Digital Pulse) Output

Automatic/Man mode c hange Digital Input

Run/Stop mode change Digital Input

Selected Remote SP Digital Input

Freezes program execution Digital Input

Program 1 selecti on Digital Input

0 to 20 mA analog control out put Analog Output

4 to 20 mA analog control out put Analog Output

0 to 20 mA PV retransmission Analog Output

4 to 20 mA PV retransmission Analog Output

0 to 20 mA SP retransmission Analog Output

4 to 20 mA SP retransmission Analog Output

Table 2 - I/O channel f unctions

The description for the functions follows:

•

- No function.

The I/O channel programmed with code 0 will not be used by the

controller. It is available to be us ed by s erial communication as digital

output.

•

- Alarm output.

Available for all I/O channels . The selected channel c an be used as

output to Alarms 1 to 4.

•

– Loop Break Detector function.

Assigns the output of the Loop Break Detector alarm to an I/O

channel. Available to all I/O channels.

•

- PWM control output.

Defines the channel to be used as control output (relay or digital

pulse). Available for all the channels. The digital pulse is available on

(when available) I/O5 and I/O6.

•

- Digital input with Auto/Manual function.

Defines the channel as Digital Input with the funct ion of swit ching the

control mode between Automatic and Manual. Available for I/O5,

I/O6 and key

.

Closed: Manual control /no

Opened: Automatic control /YES

•

- Digit al input - Standard for I/O5, I/O6 and key. Start/Stop

input (“

”: YES / no).

Closed: outputs enabled/ YES

Opened: outputs disabled/ no

•

- Digital input - Standard for I/O5, I/O6 and key.

Closed: remote SP (4-20 mA in remote SP input)

Opened: main SP (internal programmed SV)

•

- Digital input - Standard for I/O5, I/O6 and key.

Opened: enables R&S program

Closed: holds R&S program (the program resumes when the contact

is opened again)

Closed Contact: Enables execution of the program

Opened Contact : Interrupts execution of the program

Note: Even when the execution of the program is interrupted,

the control output remains active and controlling the process at

the point (Setpoint) of interruption. The program will resume its

normal execution starting from this same point when the digital

input is closed.

•

- Di gital input - St andard for I/O5, I/O6 and key. Selects

R&S program 1. Used to alternate between the main Setpoint and

a second Setpoint defined by the R&S program 1.

Closed: selects program 1

Opened: uses main Setpoint

•

/

- 0-20 mA and 4-20 mA Control Output.

Available for I/O 5 only, defines the channel as a 0-20 mA and 4-20 mA

control output.

•

/

- 0-20 mA and 4-20 mA PV retransmissions.

Available for I/O 5 only, configures t he channel to retransmit the PV

measurement in 0-20 mA and 4-20 mA.

•

/

- 0-20 mA and 4-20 mA SP (Setpoint)

retransmissions.

Available for I/O 5 only, configures the channel to retransmit the

values of SP in 0-20 mA and 4-20 mA.

ALARMS FUNCTIONS

The controller has 4 independent alarms. They can be programmed

to operate with eight different functions, represented in Table 3.

•

•

– Alarms turned

– Sensor break alarm

.

It is activated whenever the input sensor is broken or disconnected.

• rs – Ramp & soak program event alarm

This alarm is activated by the Ramp & Soak program (refer to the

PROGRAMS OF RAMP AND SOAK section on how to set the event

alarm).

• lo – Alarm of Absolute Minimum Value

It is activated when the measured value is below the value defined in

the alarm Setpoint.

• ki – Alarm of Absolute Maximum Value

It is activated when the measured value is above the value defined in

the alarm Setpoint.

•

– Alarm of Differential Value

In this function, the parameters “

”, “

”,”

” and “

represent the PV deviation as compared to the main SP.

Using the Alarm 1 as example: for Positive SPA1 values, the

differential alarm will be triggered when the PV val ue is out of the

range defined in:

(SP –SPA1) to (SP + SPA1)

For a negative SPA1 value, the differential alarm will be triggered

when the PV value is within the range defined above

•

– Alarm of Minimum Differential Value

It is activated when the PV value is below the value defined in:

(SP –SPA1)

Using the Alarm 1 as example.

•

– Alarm of Maximum Differential Value

It is activated when the PV value is above the value defined in:

(SP + SPA1)

Using the Alarm 1 as example.

”

NOVUS AUTOMATION 2/11

Controller N2000

off

ierr

Alarm will be ON if P V sensor breaks, i nput signal

rs

lo

SPAn

PV

ki

SPAn

PV

difl

SV

PV

SV - SPAn

SV

PV

SV - SPAn

difk

dif

SV

PV

SV + SPAn

SV - SPAn

SV

PV

SV - SPAn

SV + SPAn

A1t1, A2t1, A3t1, A4t1, A1t2, A2t2

A3t2, A4t2

Alarm Event

Alarm

Output

1 s to 6500

Alarm Event

Alarm

Output

T2

1 s to 6500

Alarm Event

Alarm

Output

T1

1 s to 6500

1 s to 6500

Alarm Event

Alarm

Output

T1

T2

T1

SPLL

SPkL

rsp

E.rsp

lbd.t

LDB

LDB

lbd.t

LDB

LDB

RVN , RSP, kPRG, PR1

fFvn

mAN

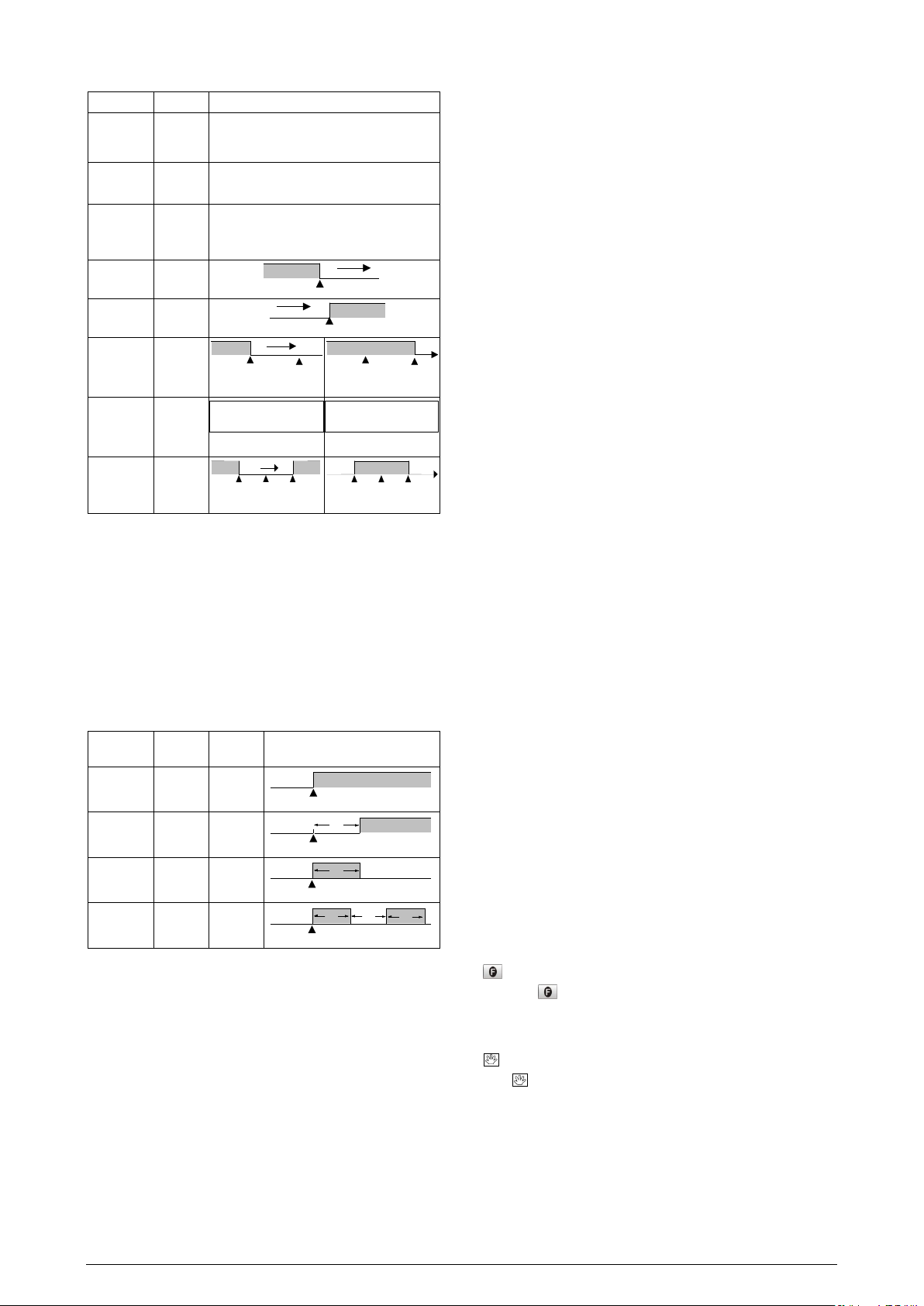

The alarm functions are described in Table 3.

TYPE PROMPT ACTION

Disabled

Sensor Break

(input Error)

Event Alarm

(ramp and

Soak)

Low Alarm

High Alarm

LOW

Differential

HIGH

Differential

Differential

No active alarm. This output can be used as a

digital output to be set by the serial

communication.

is out of range or Pt100 is shorted.

Can be activated at a specific segment of ramp

and soak program.

positive SPAn

positive SPAn

positive SPAn

Table 3 - Alarm functions

negative SPAn

negative SPAn

negative SPAn

ANALOG RETRANSMISSION OF PV AND SP

The analog output, when not used for control purposes, is available

for retransmitting the SV and SP values in 0-20 or 4-20 mA. This

analog output is elec trically isolated from other inputs and outputs.

The analog output signal is scaleable, with the output range

determined by the values programmed in the parameters “

”. To obtain a voltage output, connect a resistor shunt to the

“

” and

current output terminals.

It is possible to obtain a voltage out put by installing a resistor shunt

(550 Ω max.) to the current output terminals (terminals 7 and 8). T he

actual resistor value depends on the desired output voltage span.

SOFT START

The soft-start feature avoids abrupt variations i n the power delivered

to the load regardless of the system power demand.

This is accomplished by defi ning a limiting ramp for the control output.

The output is allowed to reach maximum value (100 %) only after the

time programmed in the soft-start parameter has elapsed.

The Soft-start function is generally used i n processes that require slow

start-up, where the instantaneous appl ication of 100 % of the available

power to the load may cause damages to parts of the system.

In order to disable this function, the soft-start parameter must be

configured with 0 (zero).

Note:

1- This feature is available only with PID (Proportional Band greater

than zero).

2- This feature is disabed if the parameter is set to 0 (zero)

ALARM TIMER FUNCTIONS

The controller alarms can be configured to perform 4 timer modes:

• Continuous (normal mode).

• One pulse with defined duration;

• Delayed activation;

The illustrations in Tab le 4 show the behavior of the alarm output for

various combinations of times T1 and T2. T he timer functi ons can be

configured in parameters

ALARM

FUNCTION

Normal 0 0

Delayed 0

Pulse

Oscillator

.

T1 T2 ACTION

s

s

s

0

s

Table 4 - Advanced Timer A larm.

The LEDs associated to the alarms will light when the alarm condition

is recognized, not following the actual stat e of the output, which may

be temporarily OFF because of the temporization.

REMOTE SETPOINT

The controller can have its Setpoint value defined by an analog,

remotely generated signal. This feature is enabled through the

channels I/O3, I/O4 or I/O5 when configured as digital inputs and

configured with the function

the parameter

. The remote Setpoint input accept s the signals

(Remote SP selection) or through

0-20 mA, 4-20 mA, 0-5 V and 0-10 V.

,

For the signals of 0-20 and 4-20 mA, a shunt resi stor of 100 Ω is

required between terminals, as shown in Figure 4d.

LBD - LOOP BREAK DETECTION ALARM

The parameter defines a t ime interval, in minutes, within which the

PV is expect to react to a control output signal . If the PV does not

react properly within the time interval configured in

, the

controller interprets this as a control loop break and signals this

occurrence in the display.

A LBD event may be sent to any I/O channel. Simply c onfigure the

function to the desired I/O channel: the selected output will be

activated when a

parameter is programmed with 0 (zero), the

The

is useful in system supervisi on and troubleshooting, allowing

condition is detected. When the

function is disabled.

early detection of problems in the actuator, power source or load.

KEY FUNCTIONS

Both the key digital input can be programmed to execute

functions

function is configured in parameter (

shown in Table 2. The key

).

ALARM INITIAL BLOCKING

The initial blocking opti on inhibits the alarm from being recognized if

an alarm condition is present when the controll er is first energized.

The alarm will actuate only after the occurrence of a non alarm

condition followed by a new occurrence for the alarm.

The initial blocking is disabled for the sensor break alarm function.

SQUARE ROOT EXTRACTION

Available when input type 19 is selected. The indicator displays the

square root of the current signal input applied to terminals 22 and 24.

NOVUS AUTOMATION 3/11

KEY

The

key in front panel executes function 6 of Table 2:

Auto/Manual mode change. Operation of this key is enabled in

parameter

. The MAN indic ator lights when the manual control

mode is selected.

EXTRA 24 VDC POWER SUPPLY – AUXILIAR P.S.

The controller provides a voltage power suppl y of 24 Vdc to excite

field transmitters with 25 mA current capac ity. Available at the back

panel terminals 17 and 18.

Controller N2000

r temporary use during

USB INTERFACE

The USB interface is us ed for CONFIGURING or MONITORING the

controller. The NConfig software must be used for the configuration.

It makes it possible to create, view, save and open configurations

from the equipment or files in your computer. The tool for saving and

opening configurations in files makes it possible to transfer

configurations between pieces of equipment and to make backup

copies. For specific models, the NConfig software also makes it

possible to update the firmware (internal software) of the controller

through the USB.

For MONITORING purposes you can use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication on a serial communicati ons port. When connected to

the USB of a computer, the controller is recognized as a conventional

serial port (COM x). Use the NConfig software or consult the

DEVICE MANAGER in the Windows CONTROL PANEL to identify

the COM port that was assigned to the controller. Consult the

mapping of the MODBUS memory in the c ontroller’ s communic ations

manual and the documentation of your supervisory software to

conduct the MONITORING process.

Follow the procedure below to use the USB c ommunication of the

equipment:

1. Downl oad the NConfig software from our website and install it on

your computer. The USB drivers necessary for operating the

communication will be installed together with the software.

2. Connect the USB cable between the equipment and the

computer. The controller does not have to be connected to a

power supply. The USB will provide enough power to operate the

communication (other equipment functions cannot operate).

3. Open the NConfig software, configure the communication and

start recognition of the device.

4. Cons ult t he NConfig help desk for detailed instructions about how

to use it and solve problems.

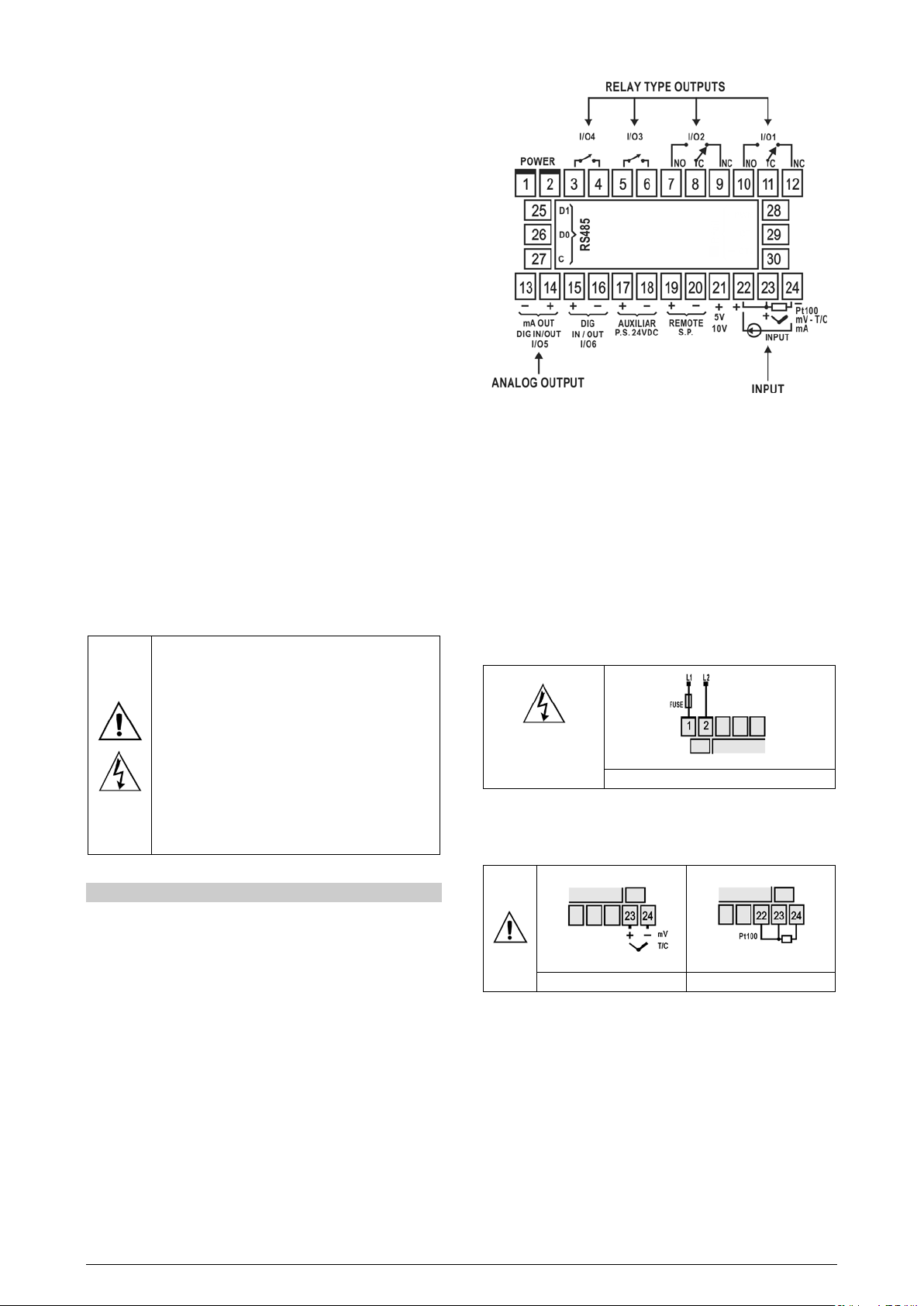

Fig. 1 - Backpanel terminals

RECOMMENDATIONS FOR INSTALLATION

• Input signal wires should be lai d out away from power lines and

preferably inside grounded conduits.

• Instrument mains (line) supply should be sui table for this purpose

and should not be shared.

• In controlling and monitoring applications, possible consequences of

any system failure must be considered in advance. The internal

alarm relay does not warrant total protection.

• Use of RC filters (47 R and 100 nF, serial) are highly recommended

when driving solenoids, contactor coils or other inductive loads.

The USB interface IS NOT SEPARATE from the

signal input (PV) or the controller’s digital inputs and

outputs. It is intended fo

CONFIGURATION and MONITORING periods. For

the safety of people and equipment, it must only be

used when the piece of equipment is completely

disconnected from the input/output signals. Using the

USB in any other type of connecti on is possible but

requires a careful analysis by the person responsibl e

for installing it. When MONITORING for long periods

of time and with connected inputs and outputs, we

recommend using the RS485 interface, which is

available or optional in most of our products.

INSTALLATION/ CONNECTIONS

The controller must be fastened on a panel, following the sequence

of steps described below:

• Prepare a panel cut-out of 45 x 93 mm;

• Remove the mounting clamps from the controller;

• Insert the controller into the panel cut-out;

• Slide the mounting clamp from the rear to a firm grip at the panel.

The controller's internal circui ts can be removed without undoing the

connections on the back panel.

The controller complete set of features is drawn in Figure 1. The

features loaded in a particular unit are shown on its label

ELECTRICAL CONNECTIONS

If high voltage is applied to

a low voltage input,

irreversible damage will

occur

Fig. 2 – High and Low Voltage AC power wiring

INPUT CONNECTIONS

It is important that they are very well connected; the sensor wires

must be well fixed in the terminals of the rear panel.

Fig. 3a – T/C and Voltage wiring Fig. 3b - RTD input wiring

• Thermocouple (T/C) and 0-50 mV

The Figure 3a indicates the wiri ng for the thermocoupl e and 0-50 mV

signals. If the thermocouple wires need to be extended, use

appropriate compensation cables.

• RTD (Pt100):

Figure 3b shows the Pt100 wiring, for 3 conductors. For proper cable

length compensation, use conductors of same gauge and length). For

4-wires Pt100, leave one conductor disconnected at the controller.

For 2-wire Pt100, short-circuit terminals 22 and 23.

NOVUS AUTOMATION 4/11

Loading...

Loading...