N1

UNIVERSAL

CODE

Tc j

Tc k

Tc t

Tc n

Tc r

Tc s

Tc b

Tc e

Pt

L0.20

L4.20

L0.50

L0.5

L0.10

Lnj

Ln k

ln t

ln n

ln r

ln s

ln b

ln E

Ln.Pt

off

lo

SPA1

PV

ki

of the Absolute Maximum

SPA1

PV

dif

SPA1

SPA2

ALrF

ALrF

PV

ALrF+SPA1

ALrF–SPA1

ALrF

PV

ALrF – SPA1

ALrF + SPA1

difl

ALrF

PV

ALrF – SPA1

ALrF

PV

ALrF – SPA1

difk

ALrF

PV

ALrF + SPA1

ALrF

PV

ALrF + SPA1

ierr

ierr

540 Process Indicator

INDICATOR – INSTRUCTIONS MANUAL – V1.1x A

PRESENTATION

N1540 is a quite versa tile process indicator. With a wide list of input

types - thermocouples, thermo-resistance, voltage and current – the

N1540 is capable of measuring the majority of the variables and

sensors encountered in industrial processes.

It contains two alarms (six functions), sensor offset, configuration of

parameters protected by password, serial communication, indication in

degrees Celsius (°C) or Fahrenheit (°F), among others.

The configuration ca n be perform ed di rectly o n the indicator or t hroug h

the USB interface. The NConfig software (free) is the configuration

management tool. Connec ted to the USB of a Windows comput er, the

indicator i s recognized as a serial c ommunic ations port (CO M) running

with a Modbus RTU protocol.

Through the USB interface, even if disconnected from the power

supply, the configuration performed in a piece of equipment can be can

be saved in a file and repeated in other pieces of equipment that

require the same configuration.

FEATURES

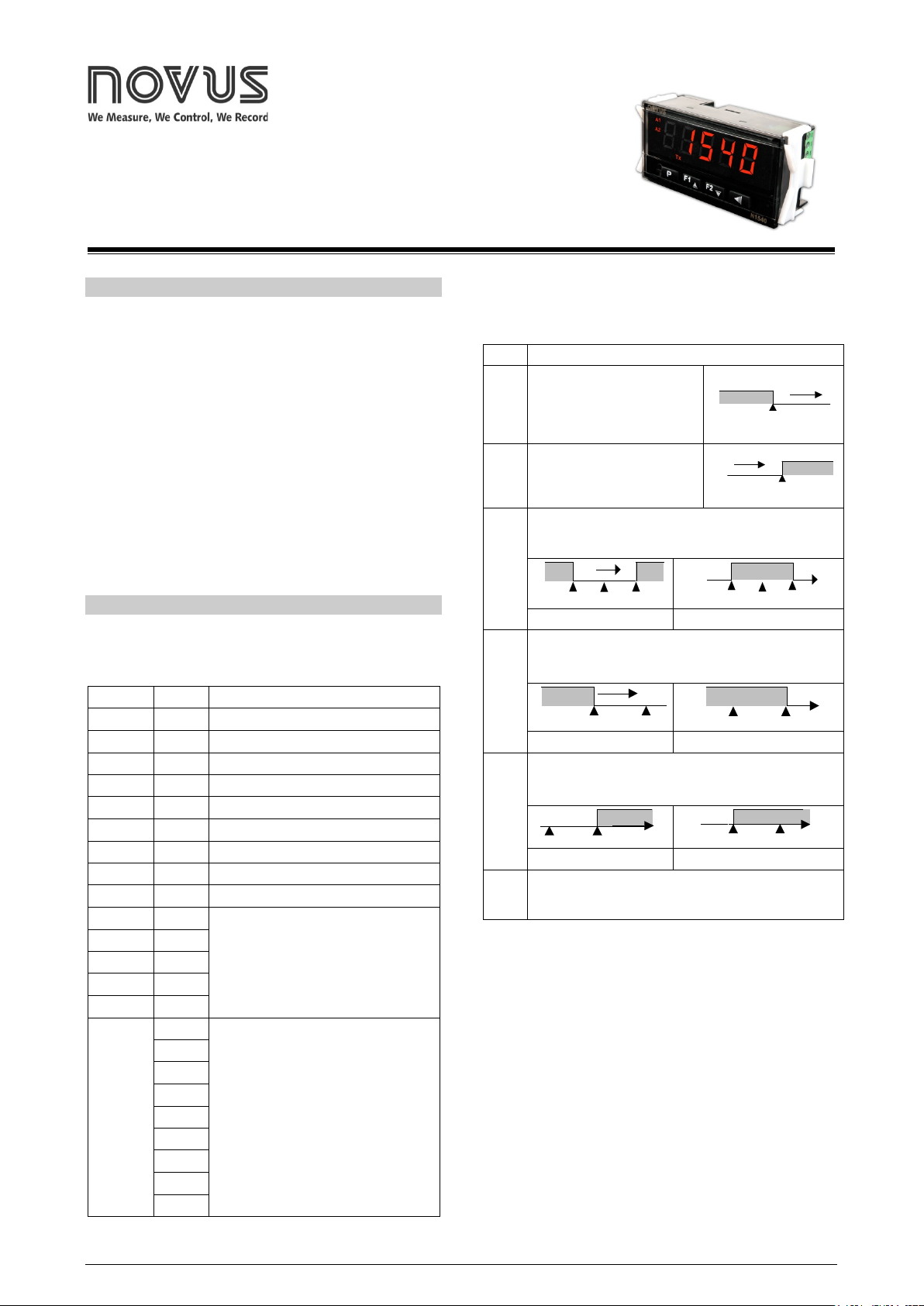

SIGNAL INPUT (TYPE)

The input type to be used by the indicator is defi ned in the equipm ent

configuration. Table 01 pres ents th e input option s available for the user .

TYPE

J

K

T

N

R

S

B

E

Pt100

0-20 mA

4-20 mA

0–50 mV

0-5 V DC

0-10 V DC

4-20 mA

NON

LINEAR

RANGE OF MEASUREMENT

Range: -110 to 950 ºC (-166 to 1742 ºF)

Range: -150 to 1370 ºC (-238 to 2498 ºF)

Range: -160 to 400 ºC (-256 to 752 ºF)

Range: -270 to 1300 ºC (-454 to 2372 ºF)

Range: -50 to 1760 ºC (-58 to 3200 ºF)

Range: -50 to 1760 ºC (-58 to 3200 ºF)

Range: 400 to 1800 ºC (752 to 3272 ºF)

Range: -90 to 730 ºC (-130 to 1346 ºF )

Range: -200 to 850 ºC (-328 to 1562 ºF)

Analog Linear Signal

Indication programmable from -1999 to

9999.

Non Linear Analog Signal

Indication range according to the

associated sensor.

ALARMS

The instrument has two alarm outputs: Alarm-1 and Alarm-2.

The alarms can assume the functions described on Table 02.

Alarm off.

Alarm of the Absolute Minimum

Value. It triggers when the value of

the PV is below the value defined

by the alarm Setpoint (SPA1 or

SPA2).

Alarm

Value. It triggers when the value of

the PV is above the value defined

by the alarm Setpoint.

Alarm of the Differential Value. In this function the parameters

“

” and “

and one reference value

” represent errors (difference) between the PV

.

SPA1 positive SPA1 negative

Alarm of the Minimum Differential Value. It triggers when the

value of the PV is below the point defined by:

ALrF-SPA1 (using alarm 1 as an example).

SPA1 positive SPA1 negative

Alarm of the Maximum Differential Value. It triggers when the

value of the PV is above the point defined by:

ALrF+SPA1 (using alarm 1 as an example).

SPA1 positive SPA1 negative

Alarms of the Sensor Break (Sensor Break Alarm). It is activated

when the Input presents problems such as interrupted sensor, bad

connection, etc.

Table 02 – Alarm Functions

Note: The figures are also valid for Alarm 2 (SPA2).

BLOCKING INITIAL OF THE ALARM

The initial blocking option inhibits the alarm from being recogni zed

if an alarm condition is present in t he process when the indicator is

first energized. The alarm will be enabled only after the oc curre nc e of

no alarm condition.

The initial blocking is useful, for example, when one of the alarms is

set up as a minimum v alue alarm, whic h may cause the activ ation of

the alarm soon upon the process start-up; an occurrence t hat may

undesirable in many cases.

The initial blocking is not valid for the function

(Sensor Break).

Table 01 – Inputs Types

NOVUS AUTOMATION 1/5

N1540 Indicator

OFFSET

Allows fine adjustments to the PV indication, correcting measurement

errors that appear, for example, after the replacement of the

temperature sensor.

MAXIMUM AND MINIMUM

The indicator memorizes the measured maximum and minimum

values (peak and valley). These two values are shown when

pressing the F1 (maximum) and F2 (mi nimum) keys. Pressing both

keys simultaneously will c lear the memory for a new peak and valley

detection.

24 VDC AUXILIARY VOLTAGE SOURCE

The standard version of the N1540 provides an auxiliary power

supply for exciting fiel d transmitters (terminals 11 and 13 on the rear

panel).

SERIAL COMMUNICATION

Follows a description of th e usual communication registers. For full

documentation download the Registers Table N1540 for Serial

Communication on our web site – www.novusautomation.com

.

The USB interface IS NOT SEPARATE from the

signal input (PV) or the indicator’s d igital inputs and

outputs. It is intended for temporary use during

CONFIGURATION and MONITORING periods. For

the safety of people and equipment, it must only be

used when the piece of equipment is completely

disconnected from the input/o utput si gnals . Using the

USB in any other type of connecti on is possible but

requires a careful analy sis by the p erson respons ible

for installing it. When MONITORING for long periods

of time and with connected inputs and outputs, we

recommend using the RS485 interface, which is

available or optional in most of our products.

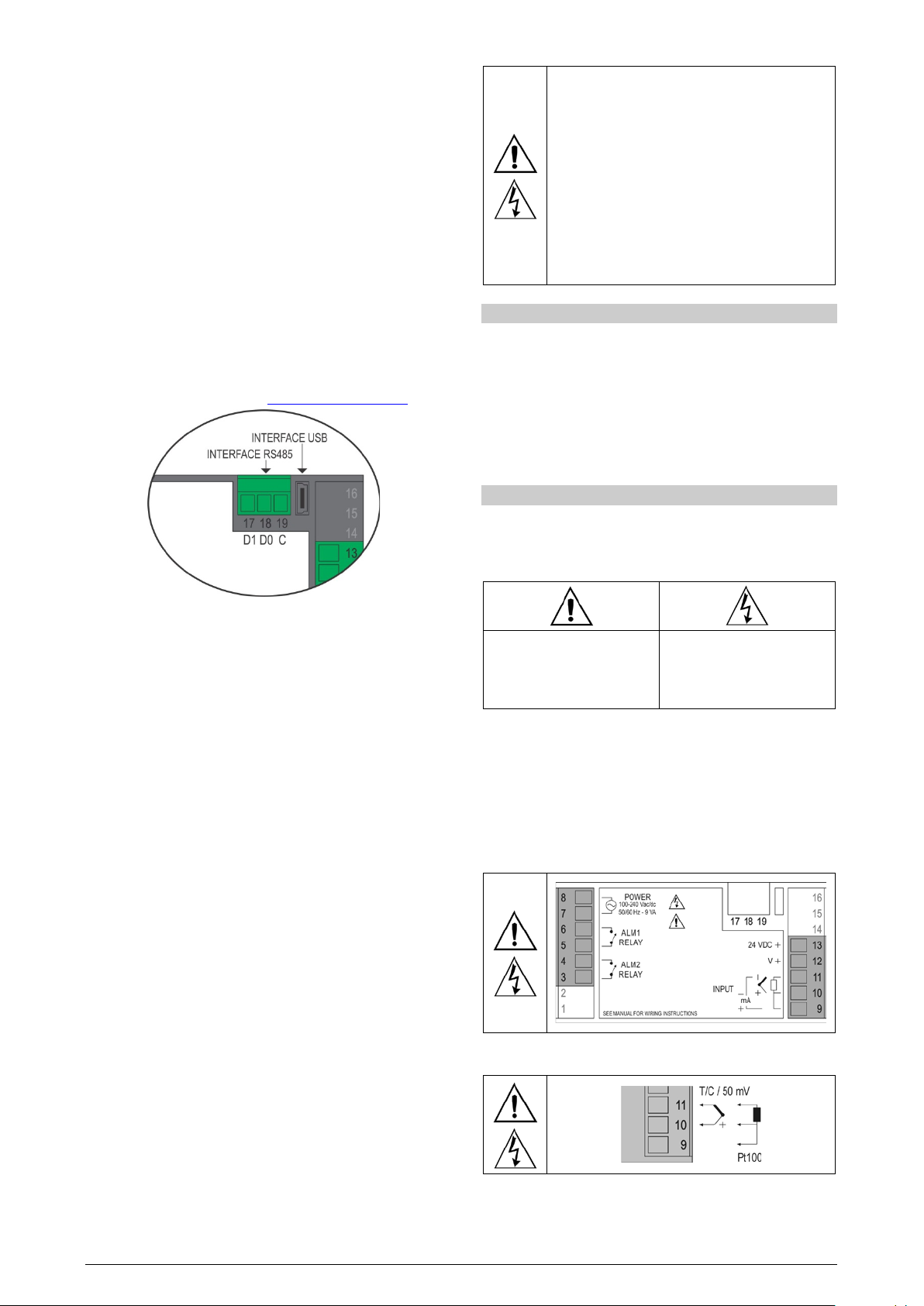

INSTALLATION / CONNECTIONS

The indicator is meant for panel mounting. The sequence of steps is:

• Prepare a cut-out of 93.0 by 45.5 mm on the panel;

• Remove the mounting clamp from the indicator;

• Insert the indicator into the cut-out from the front side of the

panel;

• Place the c lamp on the indicator again, pressing until firm grip to

the panel.

SAFETY ALERTS

The symbols below are used on the equipment and throughout this

manual in orde r to draw the user´s attention to important information

related to the equipment safety and operation.

USB INTERFACE

The USB interface is used for CONFIGURING or MO NITORING the

indicator. The NConfig softw are must be used fo r the configuration.

It makes it possible to create, view, save and open configurations

from the equipment or fil es in your compute r. The t ool fo r saving a nd

opening configurations in files makes it possible to transfer

configurations between pieces of equipment and to make backup

copies. For specific models, the NConfig software also makes it

possible to update the firmware (internal software) of the indicator

through the USB.

For MONITORING purposes you c an use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication on a serial communi cations port. When connec ted to

the USB of a computer, the indicator is rec ognized as a c onvent ional

serial port (COM x). Use the NConfig software or consult the

DEVICE MANAGER in the Wi ndows CONTROL PANEL to identify

the COM port that was assigned to the indicator. Consult the

mapping of the MODBUS memory in the indicator’s communications

manual and the documentation of your supervisory software to

conduct the MONITORING process.

Follow the procedure below to use the USB communic ation of the

equipment:

1. Download th e NConfig software from our website and ins tall i t on

your computer. The USB drivers necessary for operating the

communication will be installed together with the software.

2. Connect the USB cable between the equipment and the

computer. The indicator does not have to be connected to a

power supply. The USB will provide enough power to operate t he

communication (other equipment functions cannot operate).

3. Open the NConfig software, configure the communication and

start recognition of the device.

4. Consult the NConfig help desk for detailed instructions about

how to use it and solve problems.

CAUTION:

Read the manual thoroughly

before installing and operating

the instrument

All safety related instructions that appear in the manual must be

observed to ensure pe rsonal safety and to prevent damag e to either

the instrument o r the syste m. If the in strumen t is used in a manner not

specified by the manufacturer, the protection provided by the

equipment may be impaired.

ELECTRICAL CONNECTIONS

The terminals configurations are shown in Figure 01.

Figure 01 – Input s conn ec ti ons and power supply

Figure 02 – Thermocouple, Pt100 and 50 mV s ignal connec tion

CAUTION OR DANGER:

Electrical shock hazard

NOVUS AUTOMATION 2/5

Loading...

Loading...