1 SAFETY SUMMARY........................................................................................1

2 TECHNICAL ASSISTANCE..............................................................................1

3 PRESENTATION.............................................................................................2

4 PROCESS VARIABLE INPUT - PV...................................................................3

5 ALARMS..........................................................................................................3

5.1

ALARM FUNCTIONS ................................................................................................3

5.2

ALARM TIMER..........................................................................................................4

5.3

6 SPECIAL FUNCTIONS ....................................................................................5

7 INSTALLATION ...............................................................................................6

8 OPERATION....................................................................................................7

9 PROGRAMMING THE INDICATOR..................................................................8

10 SERIAL COMMUNICATION...........................................................................12

11 PROBLEMS WITH THE INDICATOR..............................................................13

12 SPECIFICATIONS.........................................................................................13

13 WARRANTY..................................................................................................14

ALARM INITIAL BLOCKING .....................................................................................4

6.1

SPECIAL FUNCTION KEY AND DIGITAL INPUT ....................................................5

6.2

6.3

6.4

6.5

7.1

7.2

8.1

9.1

9.2

9.3

9.4

9.5

9.6

9.7

10.1 RS485 INTERFACE: ELECTRICAL CONNECTION...............................................12

12.1 ORDERING INFORMATION:..................................................................................14

AND KEYS..........................................................................................5

POWER SUPPLY FOR LOAD CELLS (10 VDC)......................................................5

PROCESS VARIABLE RETRANSMISSION .............................................................6

CUSTOMIZED LINEARIZATION...............................................................................6

RECOMMENDATIONS FOR INSTALLATION ..........................................................6

ELECTRICAL CONNECTIONS.................................................................................6

CONFIGURATION PROTECTION............................................................................8

WORK CYCLE ..........................................................................................................8

ALARM CYCLE.........................................................................................................9

FUNCTION CYCLE...................................................................................................9

CONFIGURATION CYCLE .....................................................................................10

CUSTOMIZED LINEARIZATION CYCLE................................................................10

CALIBRATION CYCLE ...........................................................................................11

AUTOMATIC CALIBRATION CYCLE .....................................................................11

INDEX

1 SAFETY SUMMARY

The symbols below are used on the equipment and throughout this document to draw the user’s

attention to important operational and safety information.

All safety related instructions that appear in the manual must be observed to ensure personal safety

and to prevent damage to either the instrument or the system. If the instrument is used in a manner

not specified by the manufacturer, the protection provided by the equipment may be impaired.

2 TECHNICAL ASSISTANCE

CAUTION or WARNING:

Read complete instructions prior to

installation and operation of the unit.

CAUTION or WARNING:

Electrical Shock Hazard

If you encounter a problem with your controller, review the configuration with regard to inputs, outputs,

alarms, etc. If the problem persists, contact your supplier.

SPECIAL RECOMMENDATIONS

Should the indicator be repaired, some special handling care should be taken. The device must be

withdrawn from the case and immediately placed in an anti-static wrap; protected from heat and

humidity.

3 PRESENTATION

N1500LC is a universal process indicator which accepts a large variety of input signals and sensors.

A six-digit LED display shows measured value and all programming parameters.

Instrument configuration is achieved from the keypad, without any hardware change. Thus, the

selection of input type and alarms modes, besides other special functions, are accessed and defined

from the frontal keypad.

The user should read this manual thoroughly before using the instrument. It must be handled with

care and should be used accordingly for best results.

Some of the features of the basic version are:

Input:: 4 to 20 mA, 0 to 20 mA, 0 to 20 mV, -20 to +20 mV and 0 to 50 mV

2 alarm relays

10 Vdc (or 5 Vdc) power supply for load cells;

Memory for maximum and minimum values.

Hold, peak hold, tare, zero tare and automatic zero functions;

Process Variable (PV) retransmission in 0-20 mA or 4-20 mA.

RS485 MODBUS RTU serial communication.

3rd and 4th alarm relays.

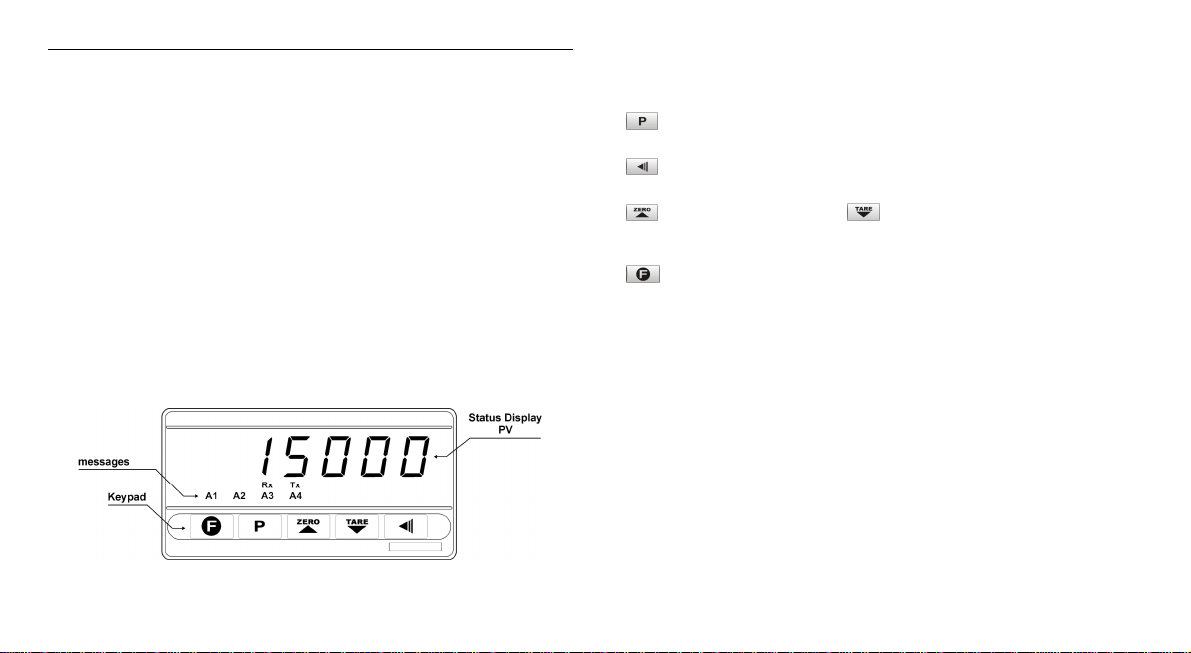

The front panel is shown below.

Figure 1 - Front panel identification

Status Display: Shows the process variable (PV) and the programming prompts.

Indicators A1, A2, A3 and A4: show active alarms.

Indicators Rx and Tx: indicate RS485 communication line is active.

PROGRAM key - This key is used to access different displays with the programmable

parameters of the device.

BACK key - This key is used to go back to the previous parameter displayed in the menu

cycle.

INCREMENTS/ZERO key and DECREMENTS/ZERO key – They make possible

the change the parameter values. They are also used to display maximum and minimum

values stored in memory.

FUNCTION key - This special function key is used for pre-programmed functions as

explained in the SPECIAL FUNCTION KEY section of this manual.

2

4 PROCESS VARIABLE INPUT - PV

5 ALARMS

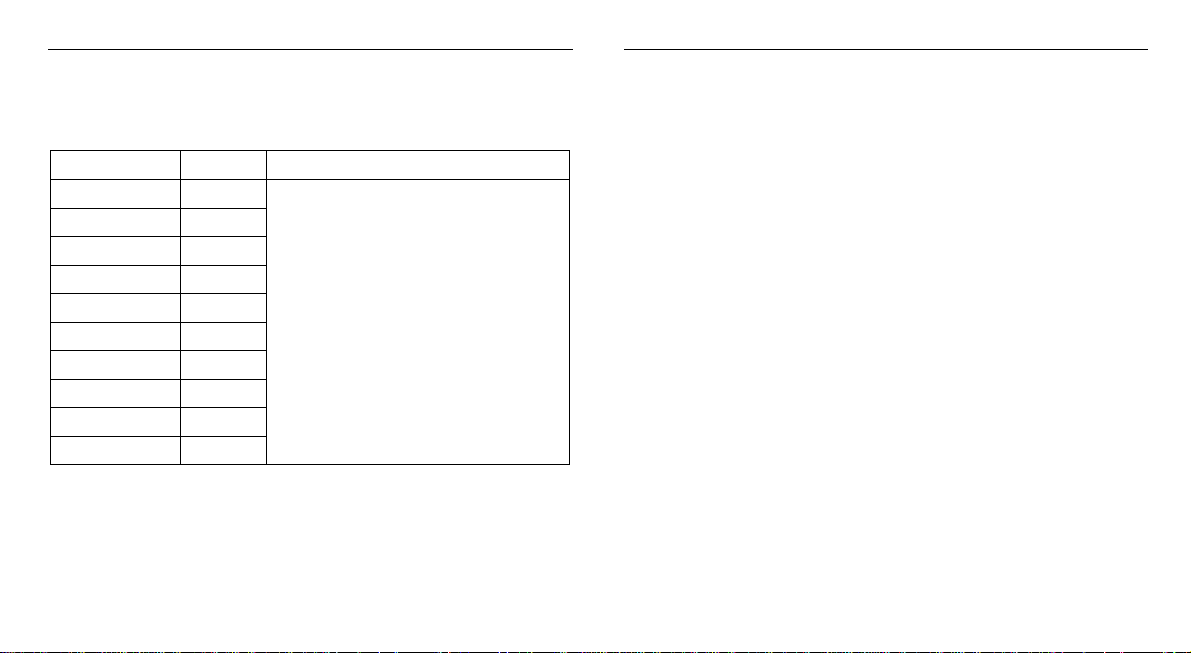

The process variable (PV) input type is configured through the frontal keypad according to the codes

shown in Table 1 (refer to INPUT TYPE parameter "in.typ"). All input types are factory calibrated

and no additional calibration is required.

Type Code Measurement Range

Non-linear 4-20 mA

Non-linear 0-20 mA

Linear 4-20 mA

Linear 0-20 mA

Linear 0 – 50 mV

Non-linear -20 a 20 mV

Non-linear 0 – 20 mV

Linear 0 – 50 mV

Linear -20 a 20 mV

Linear 0 –20 mV

c.4-20

c.0-20

4-20 a

0-20 a

c.50

c.-20

C.20

50

-20 . 20

20

Programmable indication range.

Three maximum range options:

-32000 to +32000

0 to 120000 (only even values are shown)

Non linear signals will be linearized according to the

Table 1 - Input type codes

0 to 60000

programmed custom linearization.

The indicator has 2 alarm outputs in the basic version and up to 4 alarms outputs optionally.

Each alarm has a corresponding LED message in the front panel to show alarm status.

5.1 ALARM FUNCTIONS

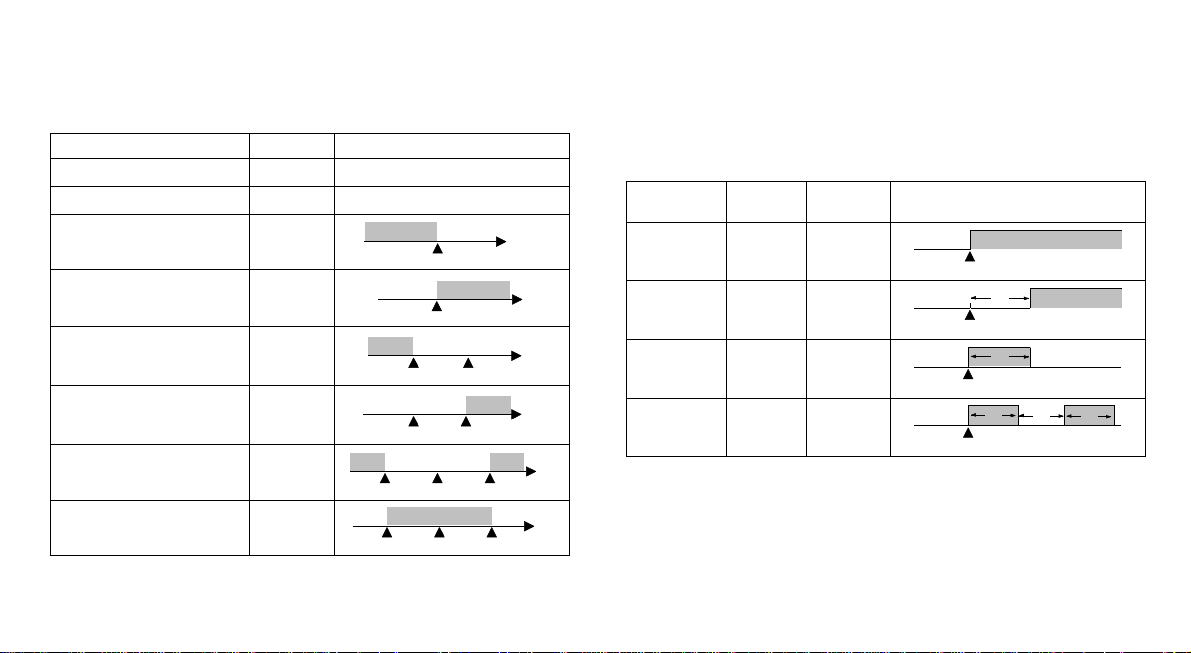

The alarms can be set to operate in seven different modes. These modes are shown in Table 2 and

described below. The alarm can also be set as ‘disabled’.

5.1.1 Sensor break - Ierr

The alarm is triggered whenever the sensor breaks or is badly connected.

5.1.2 Low alarm - Lo

The alarm relay is triggered whenever the measured value is below the alarm set point.

5.1.3 High alarm - Ki

The alarm relay is triggered whenever the measured value is above the alarm set point.

Differential low – Dif.lo

Deviation alarm. Alarm relay is triggered whenever the difference (deviation) between the Process

Variable and the reference value (AlrEF) is lower than the values defined in SP.AL. For this function,

the triggering point is defined as:

(ALrEF – SP.AL)

Differential High – Dif.ki

Deviation alarm. Alarm relay is triggered when the difference (deviation) between the Process

Variable value and the reference value (AlrEF) is greater than the value defined in SPAL. For this

function, the triggering point is defined as:

(ALrEF + SP.AL)

4.1.6 Differential (or Band) out of range – Dif.ov

Deviation alarm. Alarm relay is triggered when the difference (deviation) between the Process

Variable value and the reference value (AlrEF) has its modulus greater than the value configured in

SPAL. For this function, the triggering point is defined as:

(ALrEF – SP.AL) and (ALrEF + SP.AL)

3

4.1.7 Differential (or Band) within range – Dif.In

Alarm SP

PV

PV

AL SP +

Deviation

AL SP

PV

AL SP +

Deviation

AL SP

PV

AL SP +

Deviation

Positive

Deviation

AL SP

AL SP -

Deviation

PV

AL SP +

Deviation

Negative

Deviation

AL SP

AL SP -

Deviat.

Deviation alarm. Alarm relay is triggered when the difference (deviation) between the Process

Variable value and the reference value (AlrEF) has its modulus lower than the value defined in

SPAL. For this function, the triggering points are defined as:

(ALrEF – SP.AL) and (ALrEF + SP.AL)

TYPE PROMPT ACTION

Disabled

Sensor Break (input Error)

Low Alarm

(Low)

High Alarm

(High)

Off

Ierr

Lo

Ki

Alarm is inactive

Alarm will go ON if sensor breaks

Alarm SP

PV

Differential Low

(differential Low)

Dif.lo

Differential High

(differential High)

Dif.ki

Differential out of range

(differential out)

Differential within range

(differential Within)

Dif.ov

Dif.In

Table 2 - Alarm functions

5.2 ALARM TIMER

The alarms can be configured to perform timing functions. The configuration allows the alarm output

to be delayed, or to deliver a single pulse or a train of pulses. The delay, the pulse width and the

period are defined by the user.

Table 3 shows these advanced functions. Times T1 and T2 can be programmed from 0 to 6500

seconds. Programming 0 (zero) in the timer parameters T1 and T2 disables the timer function.

The display alarm indicators (A1, A2, A3 or A4) remain ON while their respective alarm conditions are

present, regardless of the current output status, which may be temporarily off due to the timer action.

Advanced

Function

Normal

Operation

Delayed 0

Pulse

Oscillator

T1 T2 ACTION

0 0

1 s to 6500

s

1 s to 6500

s

0

1 s to 6500 s 1 s to 6500

s

Table 3 - Timer Alarm Functions

Alarm

Output

Alarm

Output

Alarm

Output

Alarm

Output

Alarm Event

Alarm Event

Alarm Event

Alarm Event

T2

T1

T1

T2

T1

5.3 ALARM INITIAL BLOCKING

The initial blocking option inhibits the alarm from being recognized if an alarm condition is present

when the controller is first energized. The alarm will be triggered only after the occurrence of a non

alarm condition followed by a new occurrence for the alarm.

The initial blocking is disabled for the sensor break alarm function.

4

6 SPECIAL FUNCTIONS

6.1 SPECIAL FUNCTION KEY AND DIGITAL INPUT

The key (special function key) in the frontal panel of the controller as well as the Digital Input

may be assigned different functions that will be chosen by the user during the setup: These functions

can be chosen independently, both for the key and the Digital Input. The key and Digital

Input functions are explained below.

6.1.1 kold – Freeze measured value

The hold function freezes the measured value showed in the display. Each time the key or the

Digital Input is selected, there is a change from hold to normal mode.

Whenever the indicator is in the hold mode, the message “koLd” will be displayed so that the

operator will be aware that the value displayed is the frozen value and not the current reading.

6.1.2 Pkold – Maximum value

The indicator will automatically work in the Peak Hold mode whenever the key or the Digital

Input are programmed as “PkoLd”.

While in this operation mode the indicator always shows the maximum value measured, since the last

time the key or the Digital Input were pressed.

Each activation of the key or digital input triggers a new Peak Hold cycle and the display resets

with a new peak value.

6.1.3 xi – Displays Maximum

Displays the maximum (High) value the indicator measured since the last reset.

6.1.4 Lo – Displays Minimum

Displays the minimum (Low) value the indicator measured since the last reset.

6.1.5 rESEt - Clears Maximum and Minimum

If this “rESEt” function is programmed, every touch of the key or Digital Input activation clears

the memory and a new cycle of maximum and minimum values memorization will start.

6.1.6 zero – Zero Function

Available only for the key. It resets the scale. This function is used to eliminate the influence of

interference or small deviations in the zero of a scale. Reset is only accomplished if the value shown

in the scale is within 2% of the end of scale. Zero is not lost if the scale is turned off.

6.1.7 tarE – Tare function

It is available only in the Digital Input configuration or through the key. It changes indication to

zero (0000.0), regardless of the value applied to the input. It is used to eliminate indications of defined

values. In order to eliminate the tare, the user must press the key.

6.2 AND KEYS

The same Tare function available for the Digital Input can be quickly applied by using the key,

which does not need to be set up. The key is used to eliminate the tare applied.

The indicator accepts successive tares provided that the input signal (gross weight) does not exceed

the equipment end of scale.

6.3 POWER SUPPLY FOR LOAD CELLS (10 VDC)

N1500LC provides a 10 Vdc (or 5 Vdc) output to excite load cells. This power supply capacity is 50

mA.

5

Loading...

Loading...