NOVUS N1500G User Manual

Alarm SP

PV

PV

AL SP + Deviation

AL SP

PV

AL SP +

Deviation

AL SP

PV

AL SP +

Deviation

Positive

Deviation

AL SP

AL SP -

Deviation

PV

AL SP - Deviation

Negative Deviation

AL SP AL SP + Deviat.

N1500G

UNIVERSAL INDICATOR - OPERATING MANUAL

1. PRESENTATION

N1500G is a universal process indicator which accepts a large

variety of input signals and sensors.

A five-digit LED display shows measured value and all programming

parameters.

Instrument configuration is achieved from the keyboard, without any

hardware change.

The user should read this manual thoroughly before using the

instrument. It is a fine electronic device and should be used

accordingly for best results.

Some of the features of the basic version are:

• Universal input: Pt100, thermocouples, 4-20 mA, 0-50 mV and 0-5

Vdc

• 24Vdc power supply for remote transmitters excitation

• Maximum and minimum memory

• Digital input with Hold Peak Tare and hold function

• Process Variable retransmission in 0-20 mA or 4-20 mA

• RS485 MODBUS RTU serial communication

Display: Shows process variable (PV) and the programming

prompts.

ALM1 and ALM2: show alarm status.

INDEX key - This key is used to access the programming

menu and prompts.

BACK key - This key is used to go back to the previously

reached prompt in the menu cycle.

UP / MAX key and DOWN / MIN - Used to increase

and decrease parameters values, these keys are also used

to display maximum and minimum values stored in memory..

Special FUNCTION key - This special function key is used

for pre-programmed functions as explained in the SPECIAL

FUNCTION KEY section of this manual.

2. PROCESS VARIABLE INPUT - PV

The Process Variable input type should be keyboard programmed by

the user according to the codes shown on table 1 (refer to INPUT

TYPE parameter "in.typ

All input types are factory calibrated and no additional calibration is

required.

Thermocouples are calibrated to NBS standards. RTD’s are

calibrated to DIN 43760 (α=0.00385).

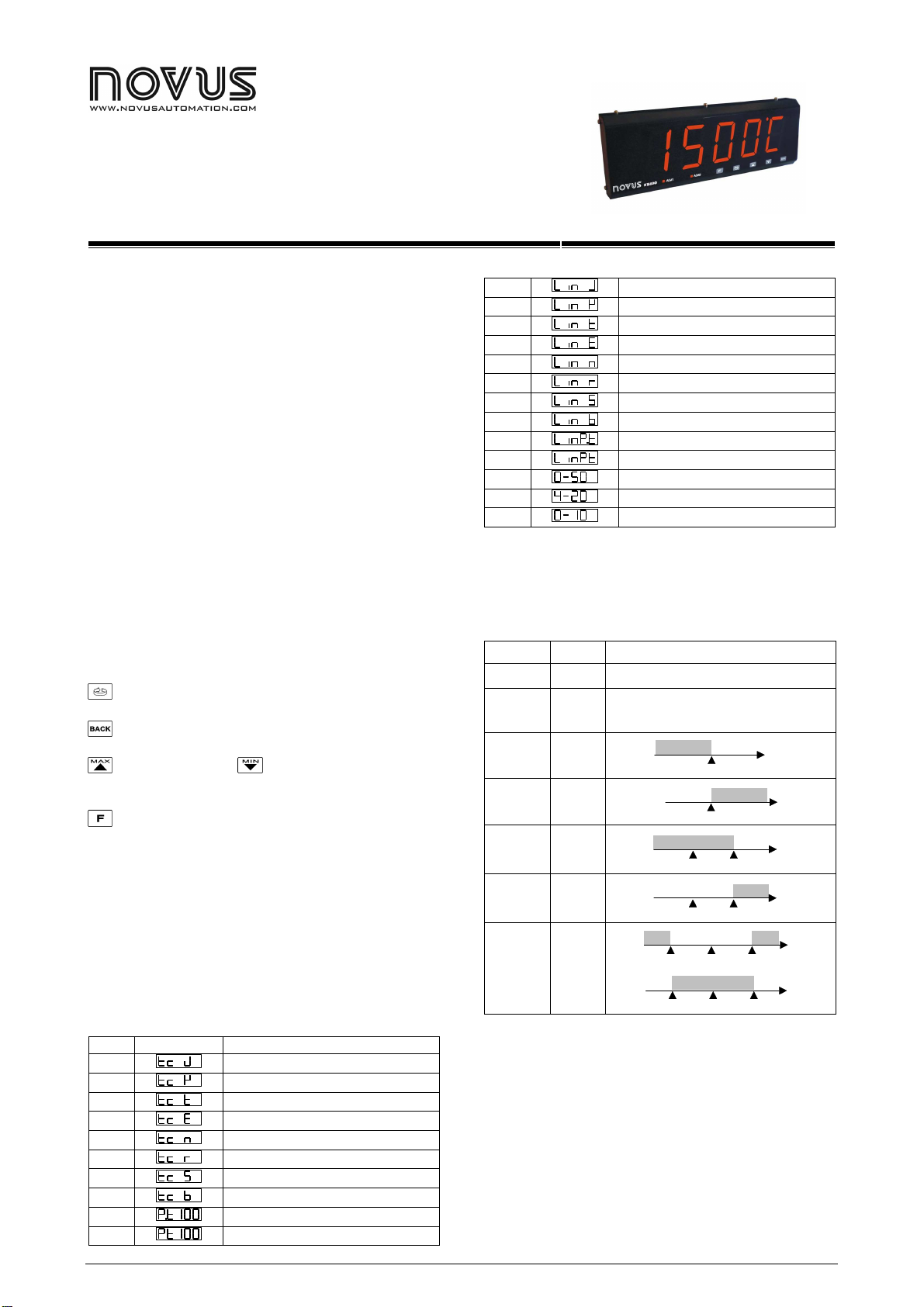

TIPO CODE CARACTERÍSTICAS

J

K

T

E

N

R

S

B

Pt100

Pt100

in.typ").

in.typin.typ

Range: -50 to 760 °C (-58 to 1400 °F)

Range: -90 to 1370 °C (-130 to 2498 °F)

Range: -100 to 400 °C (-148 to 752 °F)

Range: -35 to 720 °C (-31 to 1328 °F)

Range: -90 to 1300 °C (-130 to 2372 °F)

Range: 0 to 1760 °C (-32 to 3200 °F)

Range: 0 to 1760 °C (-32 to 3200 °F)

Range: 150 to 1820 °C (302 to 3308 °F)

Range: -199.9 to 530.0 °C (-327.8 to 986.0 °F)

Range: -200 to 530 °C (-328 to 986 °F)

4-20 mA

4-20 mA

4-20 mA

4-20 mA

4-20 mA

4-20 mA

4-20 mA

4-20 mA

4-20 mA

4-20 mA

0 -50 mV

4-20 mA

0 a 5 V

Linearizes J. Adjustable range: -110 to 760 °C

Linearizes K. Adjustable range.: -150 to 1370 °C

Linearizes T. Adjustable range.: -160 to 400 °C

Linearizes E. Adjustable range.: -90 to 720 °C

Linearizes N. Adjustable range -150 to 1300 °C

Linearizes R. Adjustable range 0 to 1760 °C

Linearizes S. Adjustable range.: 0 to 1760 °C

Linearizes B. Adjustable range.: 100 to 1820 °C

Linearizes Pt100. Adj. range.:-200.0 to 530.0 °C

Linearizes Pt100. Adj. range.: -200 to 530 °C

Linear. Adjustable range.: -1999 to 9999

Linear. Adjustable range.: -1999 to 9999

Linear. Adjustable range.: -1999 to 9999

Table 1 - Input type codes

3. ALARMS

The indicator features 2 alarm outputs in the basic version. Each

alarm has a corresponding LED anunciator in the front panel to show

alarm status.

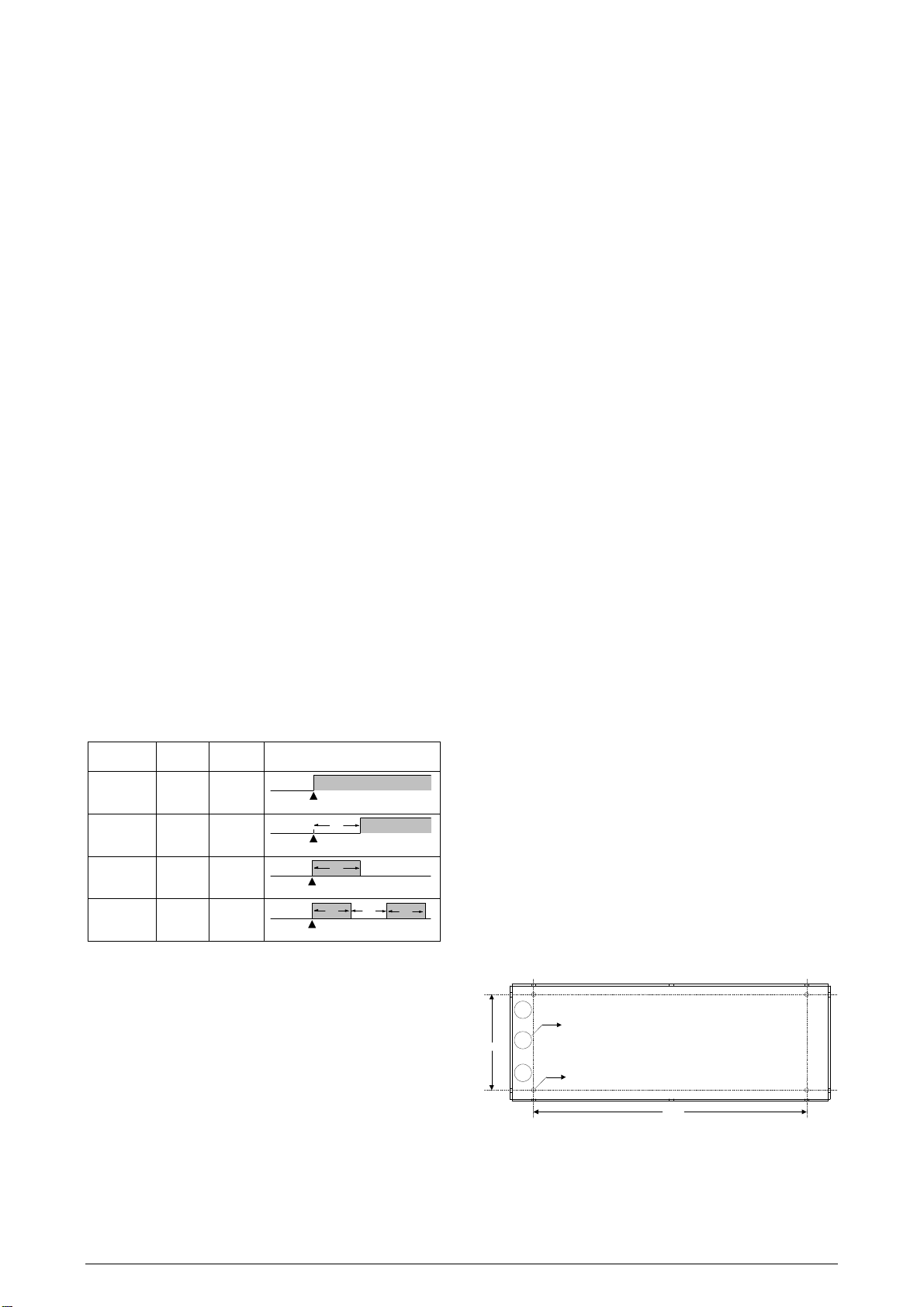

TYPE PROMPT ACTION

Disabled

Sensor Break

(input Error)

Low Alarm

High Alarm

Diferential Low

Diferential High

Diferential

off

ierr

Lo

Ki

Dif.lo

Dif.ki

Dif

signal is out of range or Pt100 is shorted.

Table 2 - Alarm functions

3.1. ALARM FUNCTIONS

The alarms can set to operate in six different functions: Sensor

break, Low Alarm, High Alarm, Differential Low, Differential High or

Differential (Band). These functions are shown in table 2 and

described as follows

3.1.1. Sensor break

The alarm will go ON whenever the sensor breaks or is badly

connected.

3.1.2. Low alarm

The alarm relay will go ON whenever the measured value is below

the alarm set point.

Alarm is inactive

Alarm will go ON if sensor breaks, input

Alarm SP

PV

NOVUS AUTOMATION 1/5

3.1.3. High alarm

The alarm relay will be ON whenever the measured value is above

the alarm set point.

3.1.4. Differential (Band)

For differential alarm 2 parameters must be set: Differential Alarm

Reference value (ALrEF) or alarm setpoint and Alarm Deviation

(Band).

For a positive deviation the alarm will switch on whenever the

measured value is out of the band defined as:

(ALrEF - Deviation) and (ALrEF + Deviation)

For a negative deviation the alarm will be switched on whenever the

measured value is within the band defined above.

3.1.5. Differential Low

The alarm relay will be ON whenever the measured value is below

the band defined as:

(ALrEF - Deviation)

3.1.6. Differential High

Alarm relay will be ON when the measured value is above the band

defined as:

(ALrEF + Deviation)

3.2. ALARM INITIAL BLOCKING

The initial blocking option inhibits the alarm from being recognized if

an alarm condition is present when the controller is first energized.

The alarm will actuate only after the occurrence of a non alarm

condition followed by a new occurrence for the alarm.

The initial blocking is disabled for the sensor break alarm function.

3.3. ALARM TIMER

The alarms can be programmed to have timer functions where the

user can set a delayed alarm action, just one pulse in an alarm

event, or an oscillator function with sequential pulses.

Table 3 shows these advanced functions. Times T1 and T2 can be

programmed from 0 to 6500 seconds (refer to item 8.2). Set 0 (zero)

at the T1 and T2 prompt for a normal non-timer alarm operation.

The LEDs alarm anunciators will go ON whenever there is an alarm

condition regardless of the present alarm status which may be

temporarily off because of timer action.

Advanced

Function

Normal

Operation

Delayed 0 1s to 6500s

Pulse 1s to 6500s 0

Oscillator 1s to 6500s 1s to 6500s

T1 T2 ACTION

0 0

Table 3 - Timer Alarm Functions

Alarm

Output

Alarm

Output

Alarm

Output

Alarm

Output

Alarm Event

T2

Alarm Event

T1

Alarm Event

T1

Alarm Event

T2

T1

4. SPECIAL FUNCTIONS

4.1. MAXIMUM AND MINIMUM

The indicator memorizes the measured maximum and minimum

values (peak and valley). These two values are shown by pressing

either the MAX or MIN key. Pressing both keys simultaneously will

clear the memory for a new peak and valley detection.

Indicator N1500G

4.2.1. Hold

The hold function freezes the measured value in the display. Each

touch at the F key or closing the digital input alternates from hold to

normal mode.

Whenever the indicator is in the hold mode a “HoLd” message is

briefly displayed to show the operator that the displayed value is the

frozen value and not the present reading.

4.2.2. Peak Hold

The indicator turns automatically to Peak Hold mode whenever the F

key or the digital input are programmed for “PHoLd”

This operation mode makes the indicator display only the maximum

reading value from the time the key was pressed of the digital input

was activated.

Each activation of the F key or digital input triggers a new Peak

Hold cycle and the display resets with a new peak value.

4.2.3. Reset (clears maximum and minimum)

This function works the same way as the MAX and MIN keys pressed

simultaneously, as explained in the 5.1 section.

If this “rESEt” function is programmed, for every touch of the F key or

activation of the digital input the memory will be cleared and a new

cycle of maximum and minimum will start.

4.2.4. AL.oFF - Alarm blocking

This function allows the user to block or inhibit the alarm relays by

pressing the F key or by activating the digital input. Each touch of

the key or activation of the digital input will alternate the function from

ON to OFF and vice-versa.

If an alarm situation occurs, the respective alarm status LEDs in the

front panel will light regardless of the relay alarm blocking status.

4.2.5. Tare

This function is used to zero the display. The tare residual values is

subtracted or added to the total measured value. This function is

generally used with load cells and strain gauges and applies to linear

4-20 mA, 0-50 mV and 0-5 V inputs.

4.3. PROCESS VARIABLE RETRANSMISSION

As an option, the indicator can be supplied with an isolated 0-20 mA

or 4-20 mA analog output for Process Variable (PV) retransmission.

The PV values which define the range of the 0-20 mA or 4-20 mA

retransmission can be programmed by the user in the high and low

indication limits.

When available, this current output will be always active.

For a voltage output signal an external shunt (calibrated resistor)

should be installed at the analog output terminals.

5. INSTALLATION

5.1. PANEL ASSEMBLY

The indicator is composed of two parts: the fixing base and the front

part with main circuits. The base must be removed from the front and

fixed onto a wall by means of four designed holes as shown in figure

2.

3X 12mm

90

4X 4mm

4.2. SPECIAL FUNCTION KEY AND DIGITAL INPUT

The F key and the optional digital input can execute special functions

according to the user selection.

These functions can be chosen independently to the F key or to the

digital input. Figure 10 shows how to activate the digital input. A

Figure 2 - Mounting the indicator in the panel cut-out.

The front part is only attached to the fixing base after all electrical

wire connections are done.

266

closed contact or a short circuit at terminals 8 and 9 is recognized as

activating the digital input.

The special functions for the F key and for the digital input are

explained as follows.

NOVUS AUTOMATION 2/5

Loading...

Loading...