NOVUS N1200 User Manual

Controller N1200

UNIVERSAL CONTRO

tYPE

TYPE

CODE

RANGE OF MEASUREME NT

J

Tc j

Range: -110 to 950 ºC (-166 to 1742 ºF)

K

Tc k

Range: -150 to 1370 ºC (-238 to 2498 ºF)

T

Tc t

Range: -160 to 400 ºC (-256 to 752 ºF)

N

Tc n

Range: -270 to 1300 ºC (-454 to 2372 ºF)

R

Tc r

Range: -50 to 1760 ºC (-58 to 3200 ºF)

Tc s

B

Tc b

Range: 400 to 1800 ºC (752 to 3272 ºF)

Tc e

Pt100

Pt

Range: -200 to 850 ºC (-328 to 1562 ºF)

0-20 mA

L0.20

4-20 mA

L4.20

0–50 mV

L0.50

L0.5

0-10 Vdc

L0.10

ln j

Ln k

ln t

ln n

ln r

ln s

ln b

ln E

Ln.Pt

SAFETY ALERTS

The symbols below are used on th e equipment and throughout this

document to draw the user’s att ention to important operational and

safety information.

CAUTION:

Read the manual thoroughly

before installing and operating the

equipment.

All safety related instructions that appear in the manual must be

observed to ensure personal safet y and to prevent damage to either

the instrument or the s ystem. If the instrument is used i n a manner

not specified by the manufacturer, the protection provided by the

equipment may be impaired.

INTRODUCTION

The N1200 is an extraordinarily versatile process controller. It holds

in one single instrument all the main features needed for the vast

majority of indust rial processes . It accepts in a singl e model virtually

all the sensors and signals used in the industry and provides the

main output types required for the operation of diverse processes.

The configuration can be performed directly on the controller or

through the USB interface. The NConfig software (free) is the

configuration management tool. Con nected to the USB of a Wi ndows

computer, the controller is recognized as a serial communications

port (COM) running with a Modbus RTU protocol.

Through the USB interface, even if disconnected from the power

supply, the configuration p erformed in a piece of equipment can be

can be saved in a file and repeated in other piec es of eq uipment th at

require the same configuration.

It is important that the users read carefull y this manual before us ing

the controller. Verify if the release of this manual matches the

instrument version (the firmware version is shown when the controller

is energized). The N1200 main characteristics are:

• Multi-sensor universal input;

• Protection for open sensor in any condition;

• Relay, 4-20 mA an d logic pulse control outputs all avail able in

the standard model;

• Self-tuning of PID parameters;

• Automatic / Manual function with “bumpless” transfer;

• Four modes of independents alarms, with functions of mini mum,

maximum, differential (deviation), open sensor and event;

• Timer functions that can be associated to the alarms;

• Retransmission of PV or SP in 0-20 mA or 4-20 mA;

• Input for remote setpoint;

• Digital input with 5 functions;

• Programmable soft-start;

• 20 setpoint profile programs with 9 segments each, with the

ability to be linked together for a total of 180 segments;

• Password for parameters protection;

• Universal power supply.

NOVUS AUTOMATION 1 / 13

LLER - INSTRUCTIONS MANUAL – V2.0x

CONFIGURATION / FEATURES

INPUT TYPE SELECTION

Select the input type (in parameter “

CAUTION OR DAN GER:

Electrical Shock Hazard

0-5 Vdc

4-20 mA

LINEAR

Note: All input types are factory calibrated. CONFIGURATION OF OUTPUTS, ALARMS AND DIGITAL INPUTS

The controller input and output chan nels (I / O) can assume multi ple

functions: control output, digital input, digital output, alarm output,

retransmission of PV and SP. These channel s are identified as I / O

1, I / O 2, I / O 3, I / O 4 and I / O 5.

The basic controller model comes loaded with the following features:

I / O 1- output to Relay SPST-NA;

I / O 2- output to Relay SPST-NA;

Optionally, other features can be a dded, as shown under the item

“Identification” in this manual:

The function to be used in eac h cha nnel of I/ O is de fined by t he us er

in accordance with the options shown in the Table 2.

”) from Table 1 below.

S

E

NON

Range: -50 to 1760 ºC (-58 to 3 200 ºF)

Range: -90 to 730 ºC (-130 to 1346 ºF)

Linear Signals

Programmable indicati on from -1999 to 9999.

Non Linear An alog Signals

Indication range depends on the selected sensor

Table 1 - Input types

I / O 5- current output, digital output, digital input;

- 3R: I / O3 with output to SPDT relay;

- DIO: I / O3 and I / O4 as digital input and output channels;

- HBD: Heater break detect;

- 485: Serial Communication;

Controller N1200

Without Function

OFF

Output

Output of Alarm 1

A1

Output

Output of Alarm 2

A2

Output

Output of Alarm 3

A3

Output

A4

LBD - Loop break detection

Lbd

Output

Control Output (Relay or Digital Pulse)

CTRL

Output

Automatic / Manual mode selection

mAN

Digital Input

Run / Stop mode selection

RVN

Digital Input

Remote SP selection

RSP

Digital Input

program execution)

KPRG

Setpoint Profi le Pr o gram 1 selection

PR 1

Digital Input

0 to 20 mA control output selection

(.0.20

Analogical Output

(.4.20

Retransmiss i on of PV in 0 to 20 mA

P.0.20

Analogical Output

Retransmiss i on of PV in 4 to 20 mA

P.4.20

Analogical Output

Retransmiss i on of Sp in 0 to 20 mA

S.0.20

Analogical Output

Retransmiss i on of SP in 4 to 20 mA

S.4.20

Analogical Output

off

off

Lbd

(trL

mAn

rvn

RvN

rsp

kprg

Pr 1

(.0.20

(.4.20 -

P.0.20

P.4.20

s.0.20

s.4.20

off

off

ierr

Rfai1

dif

SPA1

SPA2

SPA3

SPA4

difl

FUNCTION OF I/O CODE TYPE OF I/O

Output of Alarm 4

Setpoint profil e pr ogr am HO LD ( Freezes

4 to 20 mA control out put sel ec ti on

Table 2 - Types of functions for the I/O channels

During the configuration of the I/O channels, only the valid options for

each channel will be shown on the display. These functions are

described below:

•

- Without function

The I/O channel programmed with code

controller. Although without func ti on, thi s c hannel i s avai labl e through

the serial communication as digital I/O (command 5 MODBUS).

• a1, a2, a3, a4 – Alarm Outputs

The selected channel can be used as output to Alarms 1 to 4.

Defines that the programmed I/O channel acts as alarm outputs.

Available for all the I/O channels.

•

–Loop Break Detector function.

Assigns the output of the Loop Break Detector alarm to an I/O

channel. Available to all I/O channels.

•

– PWM Control Output

Defines the I/O channel to be used as the PWM control out put (relay

or digital pulse). Availabl e for all th e I/O channels. The digital pul s e is

available on I/O5 (standard) or on I/O3 and I/O4 (when the DIO

optional is installed). Check the specifications of each channel.

•

- Digital Input with Auto/Manual function

Defines the I/O chann el as Digi tal In put with t he func tion of switching

the control mode between Automatic an d Man ual . Av ailable on I/O5

(standard) or on I/O3 and I/O4 (when the DIO optional is installed).

Closed = Manual control;

Open = Automatic control

•

- Digital Input with RUN function

Defines channel as Digital Input with the function of

enabling/disabling the control an d alarm outputs (“

Available for I/O5 or I/O3 and I/O4, when installed.

Closed = outputs enabled

Open = control and alarms output shut off

•

- Digital Input with Remote SP function

Defines channel as Digital Input with the function of selecting the

remote SP as the control setpoint. Available for I/O5 or I/O3 and

I/O4, when available.

Closed = remote SP

Open = uses main SP

•

- Digital Input with Hold Program function

Defines channel as Digi tal Input with the funct ion of comman ding th e

execution of the selected setpoint profi le program. Available for I/O5

or I/O3 and I/O4, when available.

Closed = Enables execution of the program

Open = Interrupts (freezes) execution of the program

NOVUS AUTOMATION 2 / 13

Output

Digital Input

Analogical Output

will not be used by t he

”: YES / no).

Note: Even when the execution of the program is interrupted, the

control outp ut remains active a nd controlling the proces s at the point

(Setpoint) of inter rupti o n. T he pr og ram wil l resu me i ts n ormal execution

starting from this same point when the digital input is closed.

•

- Digital Input with function to Execute Program 1

Defines the IO channel as Digital Input with the function of

commanding the execution of the setpoing profile program 1.

Available for I/O5 or I/O3 and I/O4, when available.

Useful function for switching between the main setpoint and a

secondary one defined by the program 1.

Closed = selects program 1;

Open = selects main setpoint

•

–0-20 mA Control Output

Available for I/O 5 only, defines the channel as a 0-20 mA control

output.

•

4-20 mA Control Output

Defines the channel as a 4-20 mA control output.

•

– 0-20 mA PV retransmission

Available for I/O 5 only, configures the channel to retransmit the

values of PV in 0-20 mA.

•

- 4-20 mA PV retransmission

Available for I/O 5 only, configures the channel to retransmit the

values of PV in 4-20 mA.

•

– 0-20 mA SP (Setpoint) retransmission

Available for I/O 5 only, configures the channel to retransmit the values of SP in 0-20 mA.

•

– 4-20 mA SP (Setpoint) retransmission

Available for I/O 5 only, configures the channel to retransmit the

values of SP in 0-20 mA.

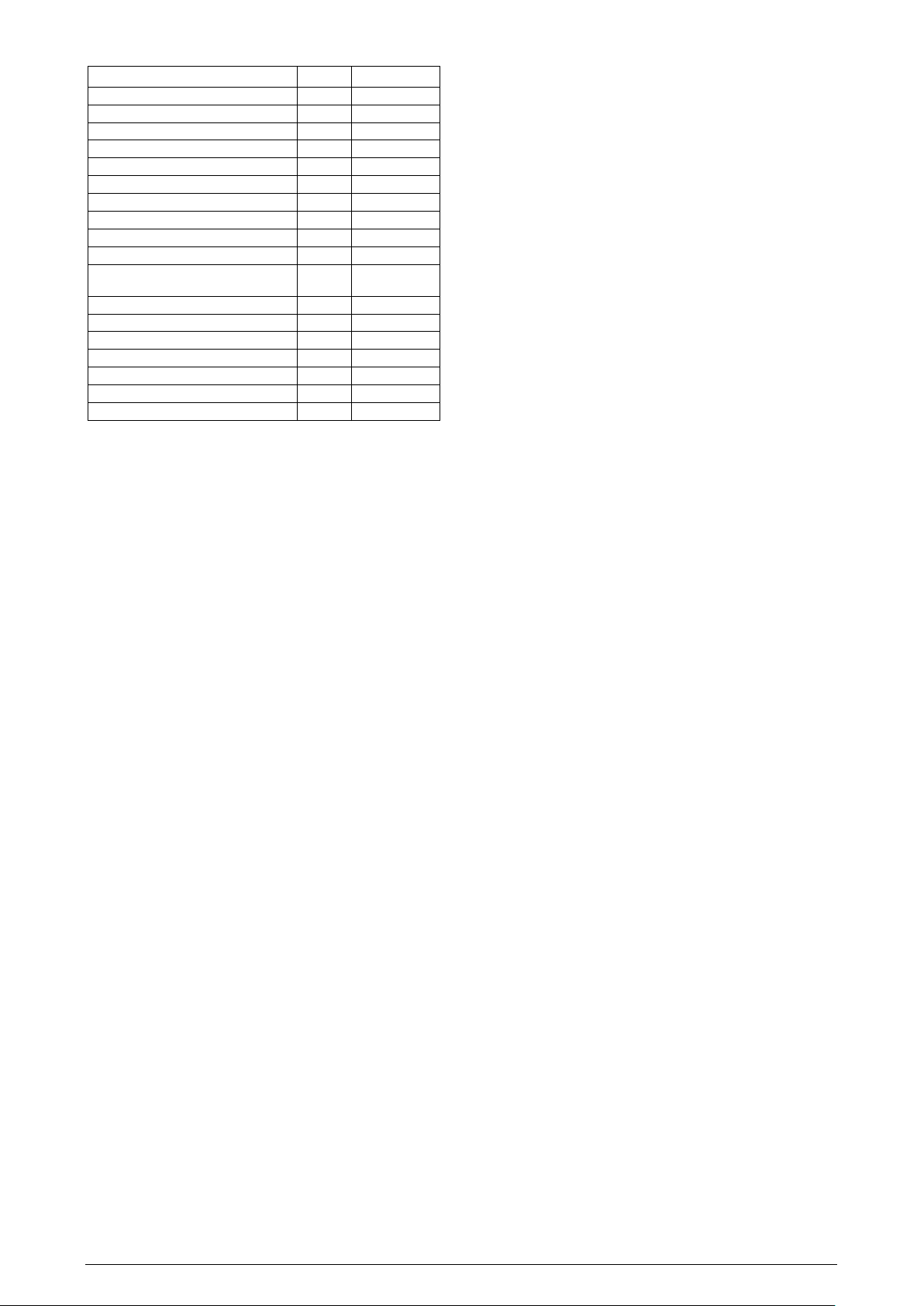

CONFIGURATION OF ALARMS

The controller has 4 independent alarms. These alarms can be

configured to operate with nine different functions, as shown in Table 3.

•

•

– Alarms turned

– Open Sensor alarms - (Loop Break)

.

The open sensor alarm acts whenever the i nput sensor is broken or

badly connected.

• rs – Program Event Alarm

Configures the alarm to act in (a) specific segment(s) of the

programs of ramps and baselines to be created by the user.

•

– Burnt-out Resistance Alarm - (Heat Break)

Signals that the heating element has broken up. This alarm func tion

requires the accessory Cur rent tr ansform er CT1. Details for us e of the

option “burnt-out resistance ” are found in the sp ecific documentation

that accompanies the product whenever this option is requested.

• lo – Alarm of Absolute Minimum Value

Triggers when the value of measure d PV is below the value defined

for alarm Setpoint.

• ki – alarm of Absolute Maximum Value

Triggers when the value of meas ured PV is above the value define d

for alarm Setpoint.

•

– Alarm of Differential Value

In this function the parameters “

”, “

”,”

” and “

represent the Deviation of PV in relation to the SP.

Using the Alarm 1 as example: for Positive SPA1 values, the

Differential alarm t riggers when the value of PV is out of the range

defined for:

(SP – SPA1) to (SP + SPA1)

For a negative SPA1 value, the Differenti al alarm triggers when the

value of PV is within the range defined above:

•

– Alarm of Minimum Differential Value

It triggers when the value of PV is below the defined point by:

(SP – SPA1)

”

Controller N1200

difk

Off

Ierr

Activated when the input signal of PV is

Rs

Event (ramp and

rfail

Resist. burnt out

)

Lo

Minimum val ue

SPAn

PV

Ki

Maximum value

SPAn

PV

Dif

SV

PV

SV + SPAn

SV - SPAn

SV

PV

SV - SPAn

SV + SPAn

Difl

SV

PV

SV - SPAn

SV

PV

SV - SPAn

Difk

SV

PV

SV + SPAn

SV

PV

SV + SPAn

SPA1

SPA2

SPA3

SPA4

A1t1, A1t2, A2t1, A2t2, A3t1, A3t2

A4t1

A4t2

Alarm Event

Alarm

Output

a defined time

Alarm Event

Alarm

Output

T1

Activation wi th

Alarm Event

Alarm

Output

T2

Alarm Event

Alarm

Output

T1

T2

T1

rtLL

rtkL

rsp

E.rsp

(trl

Using the Alarm 1 as example.

•

– Alarm of Maximum Differential Value

Triggers when the value of PV is above the defined point by:

Using the Alarm 1 as example.

SCREEN TYPE ACTUATION

Inoperative Output is not used as alar m .

Open sensor

(input Error)

Soak)

(resistance fail

(Low)

(High)

Differential

(diFerential)

Minimum

Differential

(diFerential

Low)

Maximum

differential

(diFerential

High)

Where SPAn refers to Setpoints of Alarm “

“

” and “

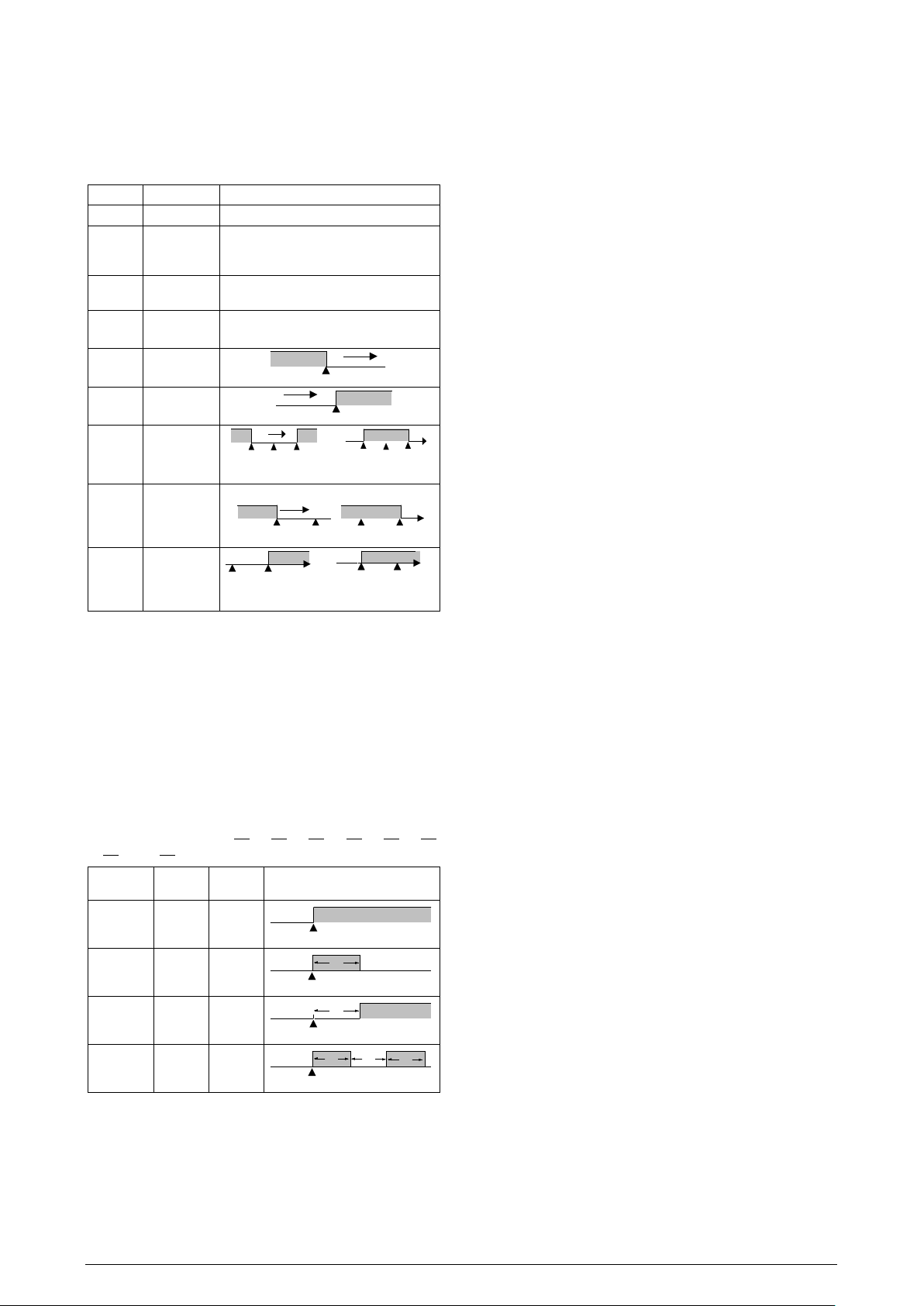

ALARM TIMER MODES

The controller alarms can be configured to perform 3 timer modes:

• One pulse with defined duration;

• Delayed activation;

• Repetitive pulses;

The illustrations in Table 4 show the behavior of the alarm output for

various combinations of times t1 an d t2. The timer functions can be

configured in parameters

and

.

OPERATION T 1 T 2 ACTION

Normal

Operation

Activation for

delay

Intermittent

Activation

0 0

1 to 6500 s 0

0 1 to 6500 s

1 to 6500 s 1 to 6500 s

Table 4 – Temporization Functions for th e Alarms

The LEDs associated to the alarms will light when the alarm

condition is recognized, not foll owing the actual state of the output,

which may be temporarily OFF because of the temporization.

NOVUS AUTOMATION 3 / 13

(SP + SPA1)

interrupted, out of the range lim its or Pt100

in short-circuit.

Activated in a specific s egment of program.

Signals a failure in the he ating element.

Positive SPAn Negative SP A n

Positive SPAn Negative SPAn

Positive SPAn Negative SPAn

Table 3 – Alarm F unctions

”, “

”.

INITIAL BLOCKING OF ALARM

The initial blocking opti on inhibits t he alarm from being recognized if

an alarm condition is present when the controller is first ene rgi zed ( or

after a transition from run YES NO). The alarm will be enabled

only after the occurrence of a non-alarm condition followed by a new

occurrence for the alarm.

The initial blocking is useful, for instance, when one of the alarms is

configured as a minimum val ue alarm, causing the activ ation of the

alarm soon upon the process start -up, an occurrence that may be

undesirable.

The initial blocking is disabled for the sensor break alarm function.

EXTRACTION OF THE SQUARE ROOT

With this feature enabled the control ler uses for di splay and c ontrol a

value that corresponds to the square root of the applied input signal.

Available only for the inputs belonging to the group of l inear analogic

signals: 0-20 mA, 4-20 mA, 0-50 mV, 0-5 V and 0-10 V.

ANALOG RETRANSMISSION OF PV AND SP

The analog output, when not use d for control purposes, i s available

for retransmitting the PV and SP values in 0-20 or 4-20 mA. This

analog output is electrically isolated from other inputs and outputs.

The anal og output signal is scalable, with the output rang e defined by

” and “

the values programmed in the parameters “

”.

To obtain a voltage output, the user must i nstall a resistor shunt (550

Ω max.) to the current output terminals (terminals 7 and 8). The

actual resistor value depends on the desired output voltage span.

SOFT-START

The soft-start feature avoids abrupt variations in the powe r delivered

to the load regardless of the system power demand. .

This is accomplished by d efining a li miting ramp fo r the control outpu t.

”,

The output is all owed to reach m aximum value (100 %) only after the

time programmed in t he soft-start parameter has elapse d. The Softstart function is gene rally used in p rocesses tha t require slo w start-up,

where the instant an eous ap pl ic ati o n o f 10 0 % of the available powe r to

the load may cause damages to parts of the system.

In order to disable this function, the soft-start parameter must be

configured with 0 (zero).

REMOTE SETPOINT

The controller can have its Setpoint value defined by an analog,

remotely generated signal. This feature is enabled through the

,

channels I/O3, I/O4 or I/O5 when configured as digital inputs and

configured with the function

the parameter

. The remote setpoint input accepts the signals

(Remote SP selection) or through

0-20 mA, 4-20 mA, 0-5 V and 0-10 V.

For the signals of 0-20 and 4-20 m A, a shunt resistor of 100 Ω is

required between terminals 9 and 10, as shown in Figure 4c.

CONTROL MODE

The controller can operate in two di fferent manners: Autom atic mode

or Manual mode. In automatic mode the c ontroller defines the amount

of power to be applied on the proc ess, based on defined paramete rs

(SP, PID, etc.).

In the manual mode the user himse lf defines this amount of powe r.

The parameter “

” defines the control mode to be adopted.

PID AUTOMATIC MODE

For the Automatic mode, there a re two differ ent strategies of control:

PID control and ON/OFF control.

PID control has its acti on b as ed on a c ontrol al gorit h m tha t tak es into

account the deviati on of P V with res pect to SP, the rate o f change of

PV and the steady state error.

On the other hand, the ON/OFF control (obtained when Pb=0)

operates with 0 % or 100 % of power, when PV deviates from SP.

The determination of the PID parameters (Pb, Ir and Dt ) i s described

in the item DETERMINATION OF PID PARAMETERS of this manual.

Controller N1200

lbd.t

LDB

LDB

lbd.t

LDB

LDB

1E.ov

1E.ov

nd MONITORING

completely disconnected from the input/output

signals. Using the USB in any other type of

LBD - LOOP BREAK DETECTION ALARM

The parameter defines a time interval, in mi nutes, within which the

PV is expect to react to a control output signal. If the PV does not

react properly within the time interval configured in

, the

controller interprets this as a control loop break and signals this

occurrence in the display.

A LBD event may be sent to any I/O channel. Simply confi gure the

function to the desired I/O channel: the selected out put will be

activated when a

parameter is programmed with 0 (zer o), the

The

is useful in system supervi sion and troubleshooting, allowing

condition is detected. When the

function is disabled.

early detection of problems in the actuator, power source or load.

HBD - HEATER BREAK DETECTION

Available in the products i dentified wi th the suffix HBD. Visit our w eb

site for further information www.novusautomation.com.

SAFE OUTPUT VALUE WITH SENSOR FAILURE

This function defines an output val ue (user defined) to be as si gned to

the control output in the event of a sensor failure.

When the input senso r is identified as broken, the con troller forcing

MV to assume the user configured value in the

When the parameter

is configured with 0.0 (zero ) value, this

parameter.

function is disabled and the control output is s imply turned off upon

input sensor error.

USB INTERFACE

The USB interface is used for CONFIGURING or MO NITORING the

controller. The NConfig software must be used for the co nfiguration.

It makes it possible to create, view, save and open configurations

from the equipment or fil es in your compute r. The t ool fo r savi ng and

opening configurations in files makes it possible to transfer

configurations between pieces of equipment and to make backup

copies. For specific models, the NConfig software also makes it

possible to update the firmware (internal s oftware) of the controller

through the USB.

For MONITORING purposes you c an use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication on a serial communi cations port. When connec ted to

the USB of a computer, the controller is recognized as a conventional

serial port (COM x). Use the NConfig software or consult the

DEVICE MANAGER in the Wi ndows CONTROL PANEL to identify

the COM port that was assigned to the controller. Consult the

mapping of the MODBUS memory in the c ontroller’s communications

manual and the documentation of your supervisory software to

conduct the MONITORING process.

Follow the procedure below to use the USB communic ation of the

equipment:

• Download the NConfig s oftware fro m our website and ins tall i t on

your computer. The USB drivers necessary for operating the

communication will be installed together with the software.

• Connect the USB cable between the equipment and the

computer. The controller does not have to be connected to a

power supply. The USB will provide enough power to operate t he

communication (other equipment functions cannot operate).

• Open the NConfig software, configure the communication and

start recognition of the device.

• Consult the NConfig help desk for detailed instructions about

how to use it and solve problems.

The USB interface IS NOT SEPARATE from the

signal input (PV) or the controller’s /indicator’s digital

inputs and outputs. It is intended for tempora ry use

during CONFIGURATION a

periods. For the safety o f people and equipment, it

must only be used when the piece of equipment is

connection is possible but r equires a careful analysis

by the person responsible for installing it. When

MONITORING for long periods of time and with

connected inputs and outputs, we re commend using

the RS485 interface, which is avail able or optional in

most of our products.

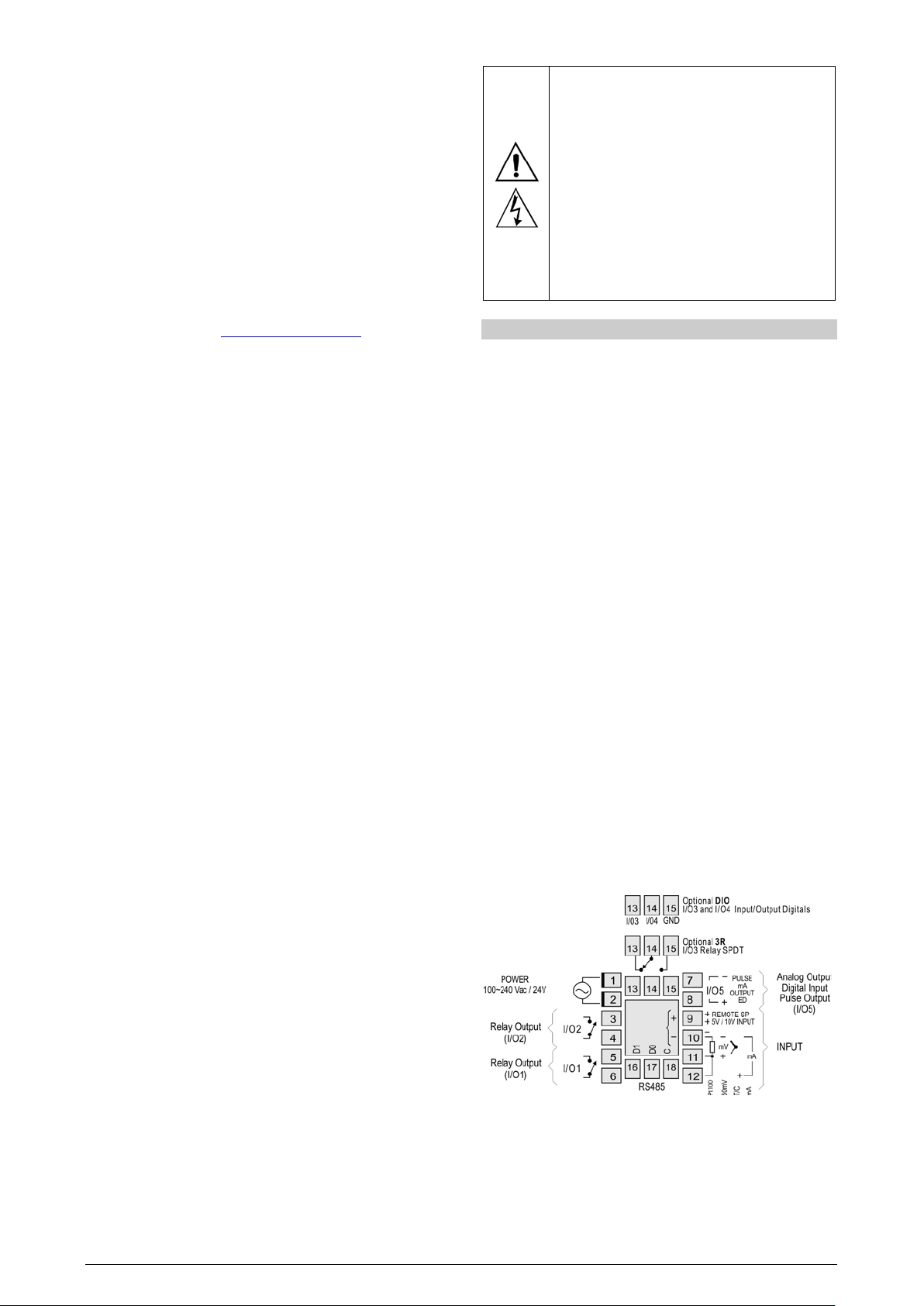

INSTALLATION / CONNECTIONS

The controller must be fastened on a panel, following the seq uence

of steps described below:

• Prepare a panel cut-out of 45.5 x 45.5 mm;

• Remove the mounting clamps from the controller;

• Insert the controller into the panel cut-out;

• Slide the mounting clamp from the rear to a firm grip at the

panel.

RECOMMENDATIONS FOR THE INSTALLATION

• All electrical connections are made to the s crew terminals at the

rear of the controller. They accept wi r e si zes from 0.5 to 1.5 mm

(16 to 22 AWG). The terminals should be ti ghtened to a torque

of 0.4 Nm (3.5 lb in)

• To minimize the pick-up of elect rical noise, the low voltage DC

connections and the sensor input wiring should be routed away

from high-current power conductors. If this is impractical, use

shielded cables. In general, keep cable lengths to a minimum.

• All electronic instruments must be powered by a clean mains

supply, proper for instrumentation.

• It is strongly recommended to apply RC'S FILTERS (noise

suppressor) to contactor coils, solenoids, etc.

• In any application it is essential to consider what can happen when

any part of the system f ails. The co ntroller f eatures by themselv es

can not assure total protection.

ELECTRICAL CONNECTIONS

The controller's internal ci rcuits can be removed without und oing the

connections on the back panel.

The controller complete set of features is drawn in Figure 1. The

features loaded in a particular unit are shown on its label

Figure 1 - Con nections of the back panel

2

NOVUS AUTOMATION 4 / 13

Loading...

Loading...