NorthStar ProShot Owner's Manual

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

M157565D

ITEM NUMBER: 157565

SERIAL NUMBER: _________________________

OWNER’S MANUAL

Instructions for Set-up, Operation, Maintenance, & Storage

TRAILER MOUNTED DUAL GUN HOT WATER/STEAM PRESSURE WASHER

3000 PSI/8 GPM

(Hereafter referred to as hot water pressure washer.)

PORTABLE OUTDOOR – USE ONLY

This pressure washer produces both cold and hot water high-pressure spray. Cleaning chemicals may be incorporated into the spray if desired.

The pressure pump for this equipment is powered by a gasoline engine and the water is heated by a diesel/kerosene/fuel-oil fired, open flame

burner.

WARNING – READ THIS MANUAL

READ and UNDERSTAND this Owner's Manual and the Engine Owner's Manual completely before attempting to set up and use the

pressure washer! Failure to properly set up, operate, and maintain this pressure washer could result in serious injury or death to operator or

bystanders.

WARNING – SPECIAL HAZARDS

CO Poisoning

• Exhaust from both the engine and burner contains carbon monoxide, a poisonous gas that can cause carbon monoxide

poisoning and death if inhaled. Operate OUTDOORS and at least 20 feet from the home, away from windows, vents, and

air intakes, to allow proper ventilation. If you start to feel sick, dizzy, or weak while using the pressure washer, shut off the

engine and get to fresh air RIGHT AWAY.

Skin/Eye Injury

• High-pressure spray can cause serious skin or eye injury, including injection injury if fluid pierces the skin. Injection injury

can result in blood poisoning and/or severe tissue damage.

Burns

• Hot spray can scald and burn skin.

• Hot surfaces of wand, engine, and burner, as well as hot exhaust from both the engine and burner can cause burns.

Slips/Falls

• Spray discharge can cause puddles and slippery surfaces.

• Spray-gun kickback can cause operator loss of balance and fall.

Flying Debris

• High-pressure spray can cause surface damage and flying debris.

Fire/ Explosion

• Engine and burner sparking can ignite fuel or other flammable liquids or vapors in the vicinity.

• Hot exhaust from engine and burner can ignite combustible materials.

Chemical

Exposure

• Cleaning chemical vapors or contact with skin may be hazardous.

Electric Shock

• Spray contact with electrical sources can cause electric shock.

Trailer Tipover

• Sudden stopping or turning while towing the pressure washer with a filled water tank can result in driving

instability and/or trailer tipover.

A summary of important safety information is provided at the end of the manual.

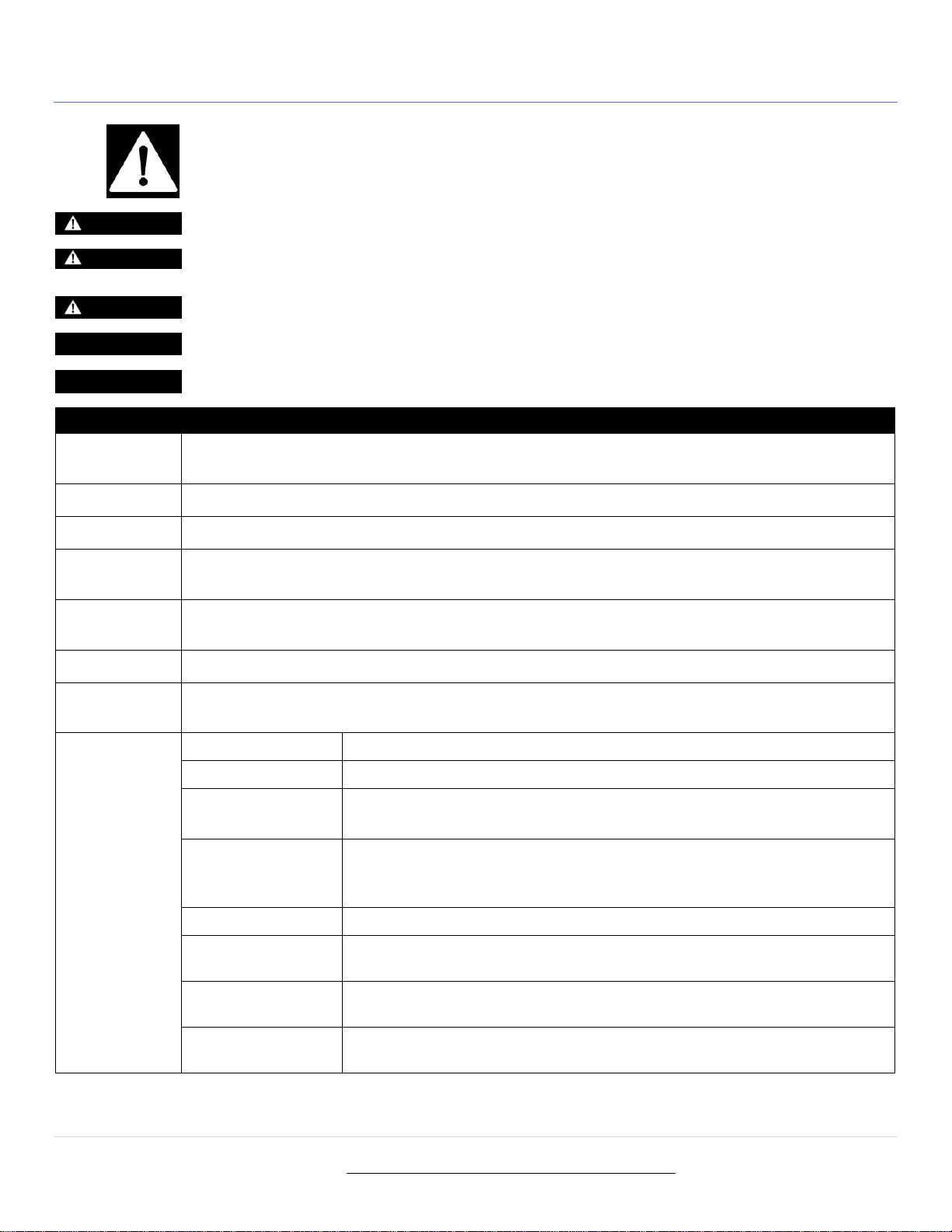

Hazard Signal Word Definitions

2 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that

follow this symbol to avoid injury or death.

DANGER

DANGER indicates a hazardous situation, which if not avoided, will result in death or severe injury.

WARNING

WARNING indicates a hazardous situation, which if not avoided, could result in death or severe injury.

CAUTION used with the safety alert symbol, indicates a hazardous situation, which if not avoided, could result in minor or

moderate injury.

CAUTION

CAUTION

CAUTION without the safety alert symbol, is used to address practices not related to personal injury.

NOTICE

NOTICE is used to address practices not related to personal injury.

EQUIPMENT PROTECTION QUICK FACTS

Inspect Upon

Delivery

STOP! Thoroughly inspect to make sure no components are missing or damaged. See the "Assembly and Initial Set-Up"

section for instructions on whom to contact to report missing or damaged parts.

Check Engine Oil

Engine is shipped with oil. Check the engine oil level before starting the pressure washer.

Check Pump Oil

Pump is shipped with oil. Check the pumps oil level before starting.

Battery Required

A battery is included, but not connected. The engine will not run unless the battery is connected. If replacing, purchase a

12 Volt, minimum 24 Amp/Hr. standard top post mount automotive (Group 75/86).

Water Flow

Requirements

Make sure your supply water flow rate is 20% higher than the pressure washer's flow rate (see "Specifications" section for

detail), and that your water is clean and particle free.

Storage

Do not allow water to freeze in the pump, hose, coil, or spray gun(s).

Chemical

Spraying

Use only NorthStar brand or equivalent pressure washer chemicals designed for high-pressure washer use. Use soap

adjustment knob to regulate cleaning power if applicable.

Maintenance

Schedule

Engine:

• See engine’s owner's manual.

Pump:

• Change oil after first 40 hours, then every 3 months or 500 hours.

Burner Fuel Filter/Water

Separator:

• Drain water as needed.

• Change filter after every 500 hours of use.

Coil:

• Descale coil annually or more frequently as conditions/performance

require.

• Inspect coil for soot build-up annually and desoot if needed.

Electrodes:

• Inspect electrodes annually and clean/adjust as needed.

Belts:

• Check belt tension after the first 24 hours of use, then routinely with each oil

change. Tighten or change belts as needed.

Brakes and Breakaway

Switch:

• Check before each use.

Tires:

• Check before each use. Maintain proper tire pressure, check for signs of wear and

check lug nuts to be certain they are at proper torque.

Table of Contents

3 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Important Safety Information

4

Specifications

5

Component Identification

6-7

Safety Labeling

8-10

Special Equipment Safety Features

11

Assembly & Initial Set-Up Instructions

12-15

Moving & Towing the Pressure Washer

16-18

Before Each Use

19-22

Operating the Pressure Washer

23-30

Storing the Pressure Washer

31-32

Maintenance & Repair

33-43

Major Components

44-45

Parts Explosion (Ladder Rack & Chem. Tank)

46

Parts Explosion (Fenders)

47

Parts Explosion (Heat Exchanger/Blower)

48-51

Parts Explosion (Pump, Engine, & Generator Head)

52-57

Parts Explosion (Skid) (Roll Cage)

58-67

Parts Explosion (Trailer Tongue, Frame & Bumper)

69-71

Parts Explosion (Trailer Water Tank)

72-73

Parts Explosion (Trailer Hose Reel)

74-77

Parts Explosion (Torsion Axle)

78

Parts Explosion (Generator Head)

79

Parts Explosion (Pump)

80-81

Branding Decal Locations

82

Schematic Drawing

83-87

Summary of Important Safety Information

88-91

Limited Warranty

92-93

Important Safety Information

4 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Thank you for purchasing a NorthStar ProSHOT Brand Hot Water Pressure Washer. Your machine is designed for long life, dependability, and

the top performance you demand. This pressure washer is designed to:

1) Produce a high-pressure spray of heated or unheated water (up to 8 gallons per minute at 3000 psi).

2) Cleaning chemicals can be incorporated using a low-pressure water spray.

Water is supplied to the pressure washer via an external water tank. The water tank is supplied to the customer on all trailer models. The water

supply will have a flow rate of at least 9.6 gallons per minute. Any cleaning chemicals that are used must be specifically approved for use in

pressure washers.

The pump is powered by a gasoline engine. The spray water is heated (when desired) by a kerosene/diesel/fuel-oiled, spark-ignited, open

flame burner. Normal operation of this equipment will require you to supply:

• Gasoline for the engine

• Water

• Fuel for the burner (kerosene, diesel, or fuel oil)

• Chemical (if desired)

See the Specifications section of this manual for more detail.

Engine powered pressure washers are for OUTDOOR USE ONLY. Be sure to read about site selection for running this pressure washer in

the Before Each Use section of this manual.

The operator should acquire and wear safety apparel during operation of this pressure washer. Safety apparel includes waterproof insulated

gloves, safety goggles, non-slip protective footwear, and ear protection. Some cleaning chemicals may require the use of a respirator mask (as

instructed on chemical label).

Before using this pressure washer, the operator shall determine the suitability of this product for its intended use and assumes liability therein.

READ THIS MANUAL

DANGER

Carefully read and follow all instructions and safety information for using this pressure washer. Improper use or maintenance of the

pressure washer can result in serious injury or death to the operator or bystanders from:

• Carbon monoxide poisoning

• Fire/explosion

• Chemical exposure

• Skin/eye injury from high pressure spray

• Burns

• Slips/falls

• Electric shock

• Flying objects/debris

Keep this manual for reference and review. A summary of important safety information can be found at the end of the manual.

Proper preparation, operation, and maintenance of this pressure washer will result in optimal performance and a long life for this equipment.

For detailed engine operation and maintenance information, always refer to the engine Owner's Manual furnished with the pressure washer.

ATTENTION:

Rental companies and private owners who loan this equipment to others, please read this manual!

All persons to whom you rent/loan this pressure washer must have access to and read this manual. Always keep this owner’s manual with the

pressure washer and advise all persons who will operate the machine to read it. You must also provide personal instruction on how to safely setup and operate the pressure washer and remain available to answer any questions a renter/borrower might have.

Specifications

5 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

MODEL

Model #

157565

FLOW OUTPUT

Pressure Rating

3000 psi

Flow Rate

8 gallons per minute

Maximum Temperature

250 F

DIMENSIONS / COMPONENTS

Length

202"

Width

85"

Height

84"

Trailer Weight – Wet

Trailer Weight – Dry

8,716 lbs.

3,350 lbs.

Tongue Weight – Wet

Tongue Weight – Dry

580 lbs.

341 lbs.

Pump Model

General Pump TSF2219

Engine Model

Kohler ECH730

Engine Displacement

747cc

High Pressure Discharge Hose

(2) 3/8" x 150'

Chemical Injector

Maximum dilution ratio 18:1

Trailer GVWR

9,800 lbs.

Hitch Size

2-5/16"

Input Water Supply (Tank Feed)

600-gallon tank. Flow rate must be maintained at 9.6 gpm

Tire Size

16'" 8 Lug on 6.5

Battery

12 Volt, minimum 24 Amp/Hr. Standard top post mount automotive (Group 75/86)

The inside dimensions of the battery compartment are 11-1/8"L x 7-3/4"W x 10-1/8"H.

SUPPLIES REQUIRED

Engine Fuel

Regular, Unleaded Gasoline (Capacity: 16 Gal.)

Engine Oil

See Engine’s Owner's Manual

Burner Fuel

#1 or #2 Diesel, B5 or lower Biodiesel, Kerosene, or Fuel Oil (Capacity: 16 Gal.)

Pump Oil (shipped with oil, but refills required)

33.8 ounces SAE Non-detergent 30wt. capacity

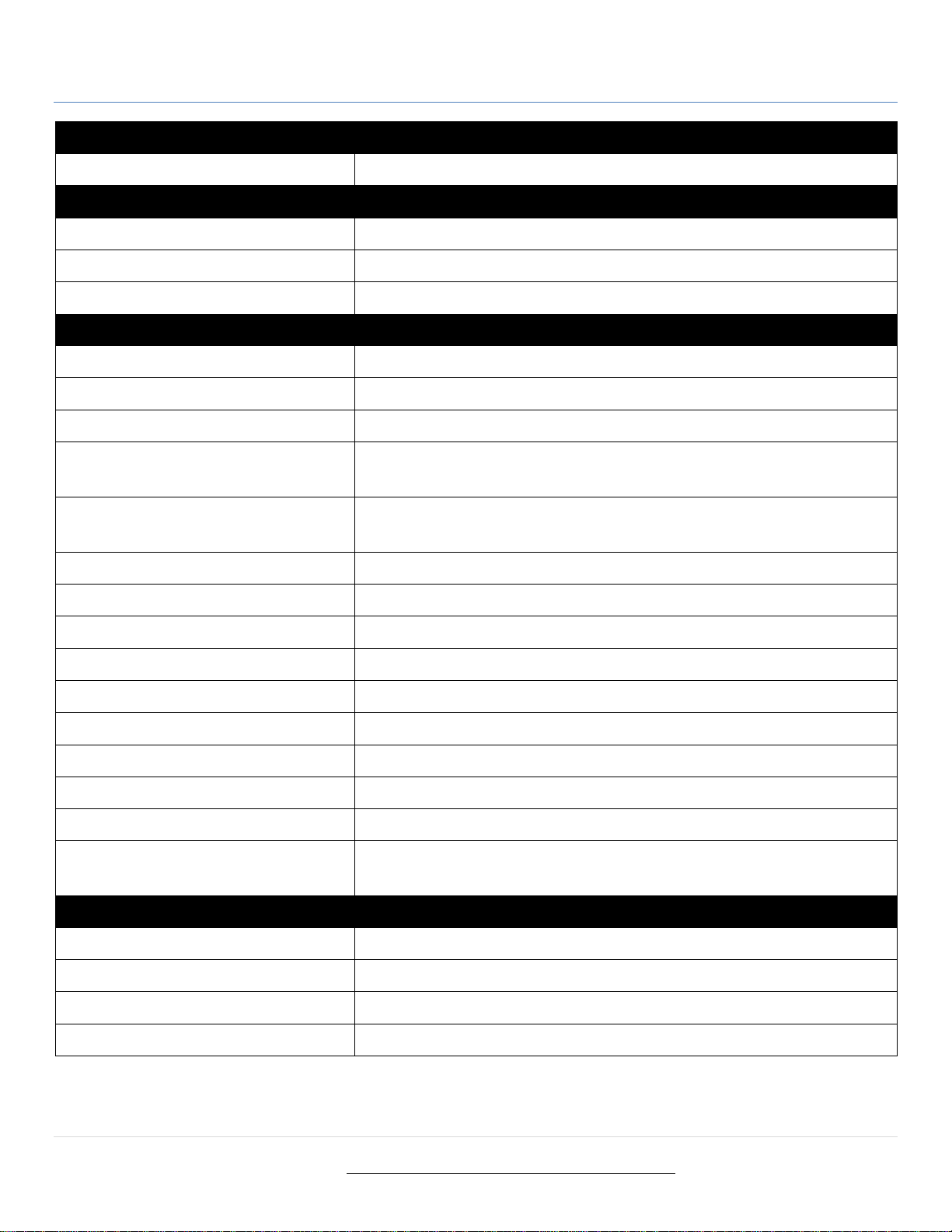

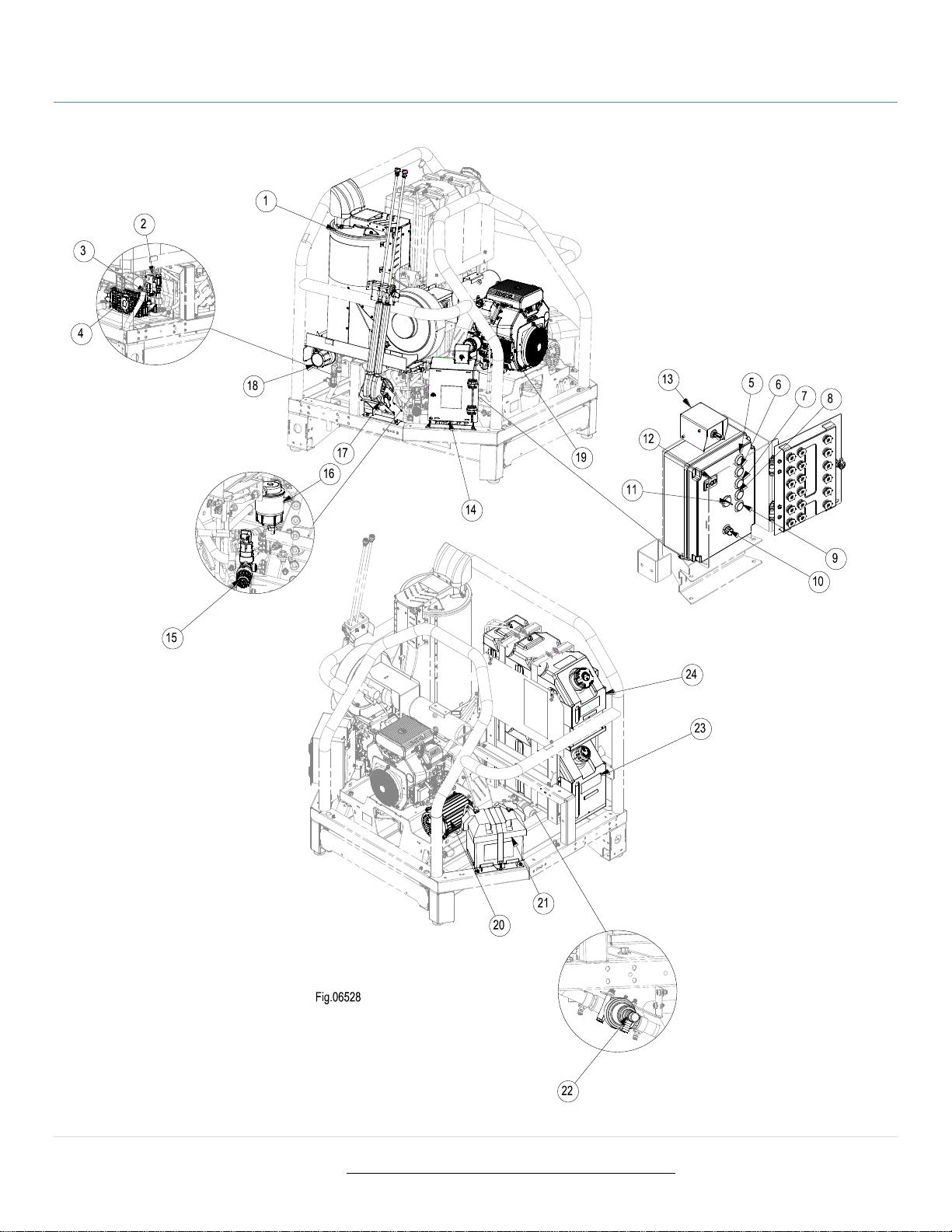

Component Identification – REV. D

6 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Component Identification – REV. D

7 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

COMPONENT REFERENCE GUIDE

REF#

NAME

DESCRIPTION

1

Heat Exchanger

Device that heats the water by forcing a flame across steel pipe.

2

Hi-PSI Switch

This is a backup safety feature. If the system pressure exceeds the set pressure limit this device will

stop the burner from firing.

3

Water Outlet

Connection point for the high-pressure hose.

4

Pump

The device that moves fluid through a combination of suction and displacement.

5

Indicator Light (Heat)

Instrument used to monitor unit operation. Will illuminate when the burner has power when heat switch

is in the ON position.

6

Indicator Light (Spraying)

Instrument used to monitor unit operation. Will illuminate when the gun trigger is being squeezed and

water is flowing though the spray gun.

7

Indicator Light

(Thermostat)

Instrument used to monitor unit operation. Will illuminate when the gun trigger is being squeezed and

water is heating.

8

Indicator Light

(Burner Motor)

Instrument used to monitor unit operation. Will illuminate when the blower is operating properly.

9

Indicator Light (Ignition)

Instrument used to monitor unit operation. Will illuminate when burner is firing.

10

Thermostat Knob

Turn to adjust water temperature.

11

Heat Switch

On/Off device for power to burner components.

12

Hour Meter

Indicates the number of hour’s the pressure washer has been used.

13

Engine Key Switch

Start the engine by turning clockwise. (Refer to the engine manual for details.)

14

Control Box

Mounted housing that holds electrical controls for the burner. Storage location for nozzles.

15

Unloader

Valve that regulates pressure and directs flow into bypass when trigger is released.

16

Burner Fuel Filter/

Water Separator

Used to remove contaminant water from burner fuel to prevent water in the fuel from reaching the

burner.

17

Gun Mount

Location to secure up to 3 spray guns.

18

Manual Tube

Storage location for Owner’s Manual.

19

Engine (see engine’s

owner’s manual)

The air-cooled engine powers the pump and generator.

20

Generator

Powers burner components with 120V AC electricity.

21

Battery Box

Storage compartment to house the battery.

22

Water Inlet

Used to connect water from the feed tank to the inlet plumping.

23

Engine Fuel Tank

Engine fuel storage container.

24

Diesel/Kerosene/Fuel Oil

Burner fuel storage container.

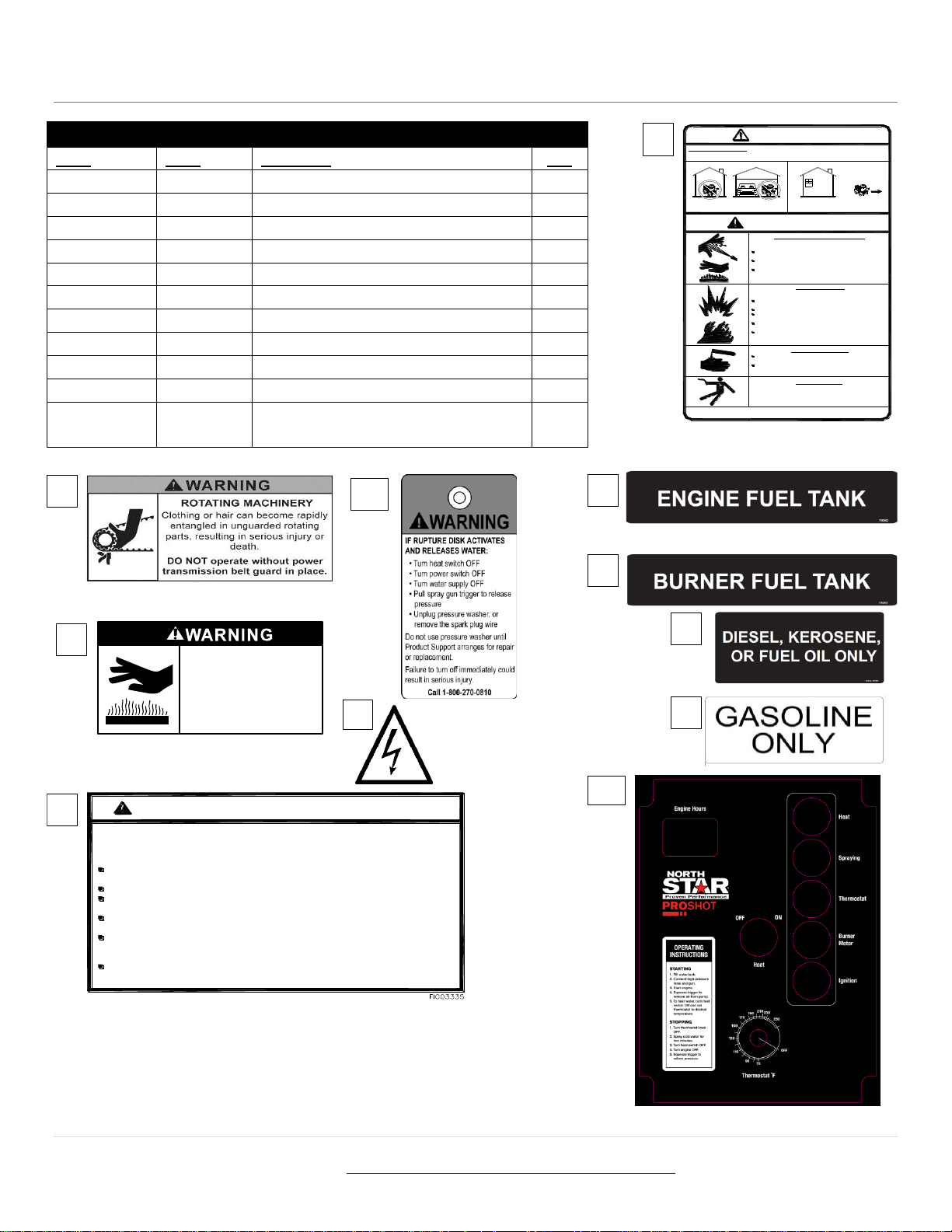

Safety Labeling – REV. D

8 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Safety Labeling – REV. D

9 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

2

10

11

8

5

4

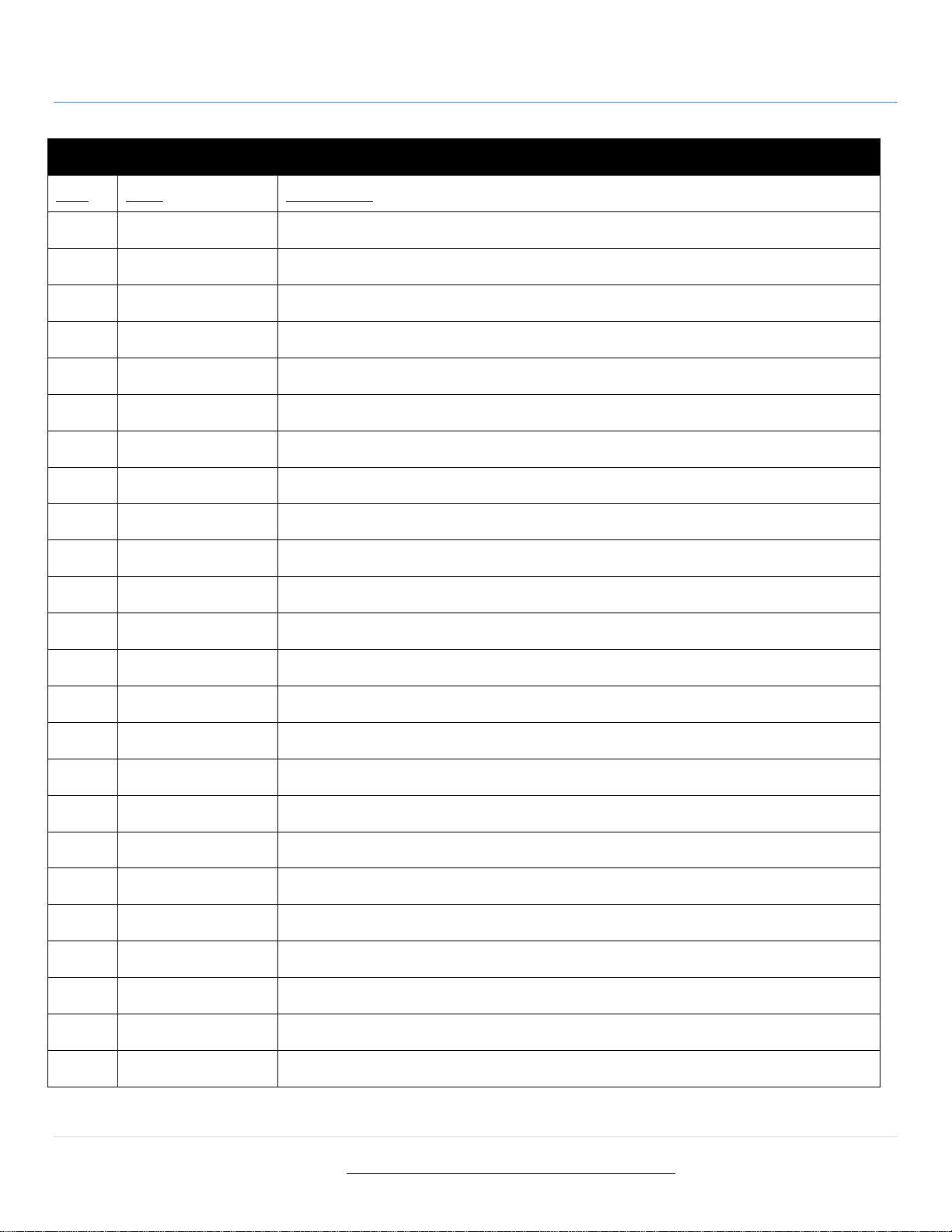

ON-PRODUCT WARNING LABELS

Ref. #

Part #

Description

Qty.

1

782325

Decal, Danger and Warning

1 2 786632

Decal, Rotating Equipment Warning

2 3 797513

Decal, Burn Hazard

3

4

777666

Decal, Gasoline Only

1 5 796496

Decal, ISO Electric Shock Warning Triangle

1

6

782397

Decal, Battery Warning

1 7 796862

Decal, Engine Fuel Tank

1 8 796861

Decal, Burner Fuel Tank

1 9 787827

Decal, Diesel, Kerosene or Fuel Oil Only

1

10

797448

Decal, Control Box, Operating Instructions

1

11

798057

Hantag, Rupture Disc Warning

1

11.1

32821

Lanyard, Hangtag Warning (not shown)

1

Always make sure safety labels are in place and in good

condition. If a safety label is missing or not legible, order new labels

or unsafe operation could result.

To order replacement safety labels, call NorthStar ProSHOT Product

Support at 1-800-969-7073.

1

NEVER use inside any building, structure or

garage, EVEN IF doors and windows are open.

DANGER

WARNING

FOR OUTDOOR USE ONLY! Using this pressure washer indoors CAN KILL YOU IN MINUTES.

Engine exhaust and burner exhaust contain carbon monoxide. This is a poison you cannot

see or smell.

High pressure spray can cause injection injury, eye injury, and

loss of balance. Hot discharge fluid and hot surfaces can burn.

NEVER direct discharge stream at or near any person. Do not

allow any part of the body to come in contact with the fluid stream.

Gun kicks back - hold with two hands. Keep good footing and

balance at all times.

Surfaces of engine, burner, and wand can become very hot. Use

only designated gripping area of wand. Avoid contact with hot

engine and burner.

Spraying flammables can cause explosion. Fuel is flammable

and explosive. Exhaust can ignite combustible materials.

NEVER spray flammable liquids. Operate only where open flame

or torch is permitted.

NEVER fuel a running or hot engine or oil burner.

Ensure there are no fuel leaks before starting. Keep sources of

sparks and flames away.

Use approved container only for transferring fuel. Clean up fuel

spills immediately.

Keep engine and burner exhaust at least 7 feet from all

combustible objects. Situate on heat-resistant flooring when

using burner.

Understand all safety hazards and first aid measures for chemicals

being used.

Follow chemical manufacturer's directions when handling and

cleaning with chemicals. Wear safety gear as directed.

Keep spray away from electrical wiring, or electric shock /

electrocution could occur.

CAUTION: To Reduce Risk of Injury, Read Operating Instructions Carefully Before Using.

782325

Chemical Exposure Hazard

Electric Shock Hazard

Only use OUTSIDE and far away from

windows, doors, and vents.

Fire / Explosion Hazard

High Pressure Fluid Forces / Burn Hazards

7

ALWAYS use eye protection. Caustic acid and explosive

gases can cause blindness or severe burns.

NO smoking, sparks, or flames.

NEVER touch both battery terminals at the same time with your

hand or any non-insulated tools.

FLUSH immediately with water if battery acid contacts eyes,

skin, or clothing.

CONNECT cables in correct sequence: FIRST RED to POSITIVE

terminal, then BLACK to NEGATIVE terminal. When disconnecting,

DISCONNECT BLACK cable first, then RED.

NEVER charge a visibly damaged or frozen battery. ALWAYS

read and follow charger instructions.

BATTERIES:

1) contain caustic acid, 2) emit explosive gases,

3) can cause electric shock

WARNING - BATTERY HAZARDS

782397

6

2”

BURN HAZARD

Do not touch hot surface.

3

9

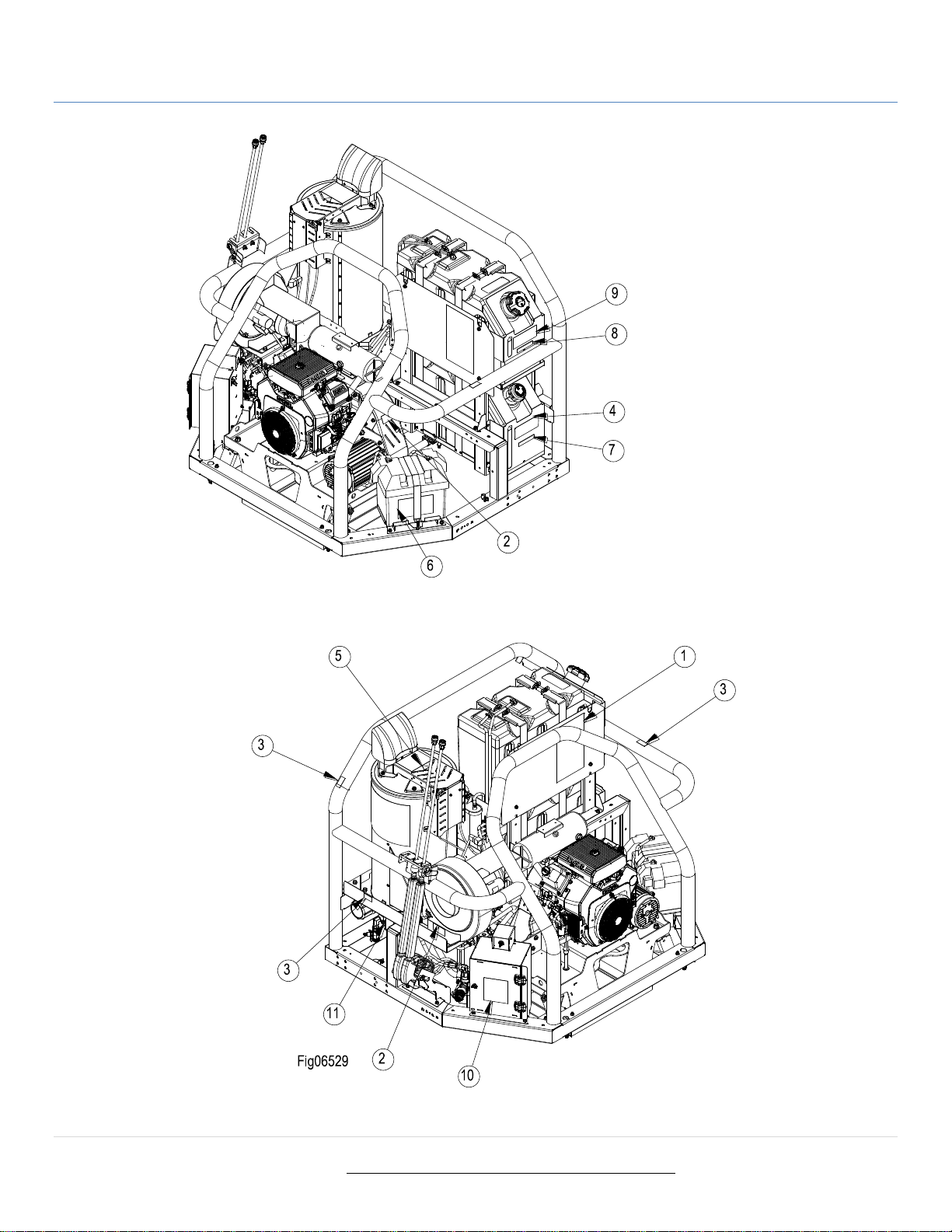

Safety Labeling – REV. D

10 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

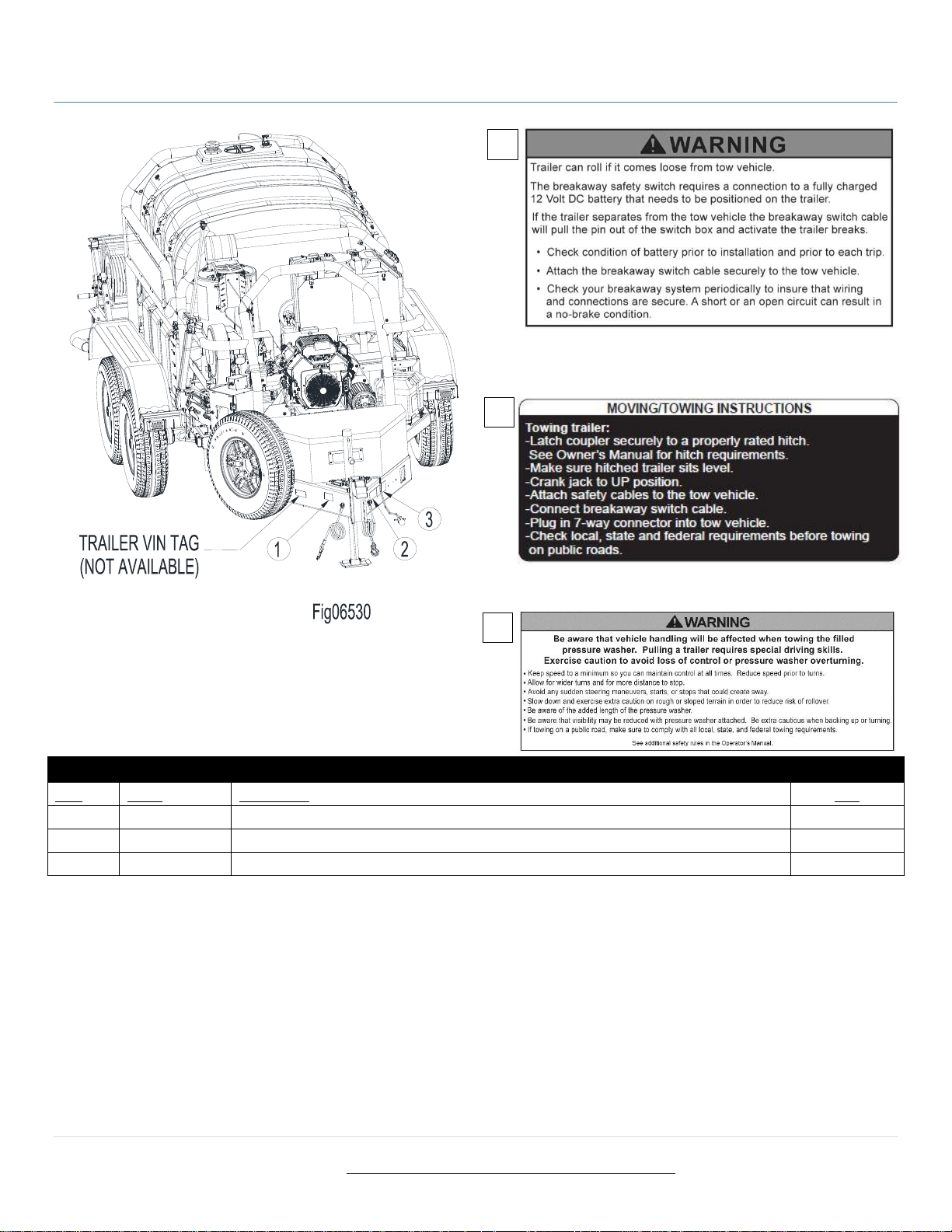

1

ON-PRODUCT WARNING LABELS

Ref#

Part #

Description

Qty.

1

792538

Decal, Breakaway Switch

1

2

797512

Decal, Towing/Moving

1

3

786633

Decal, Moving Warning

1

3

2

Special Equipment Safety Features

11 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

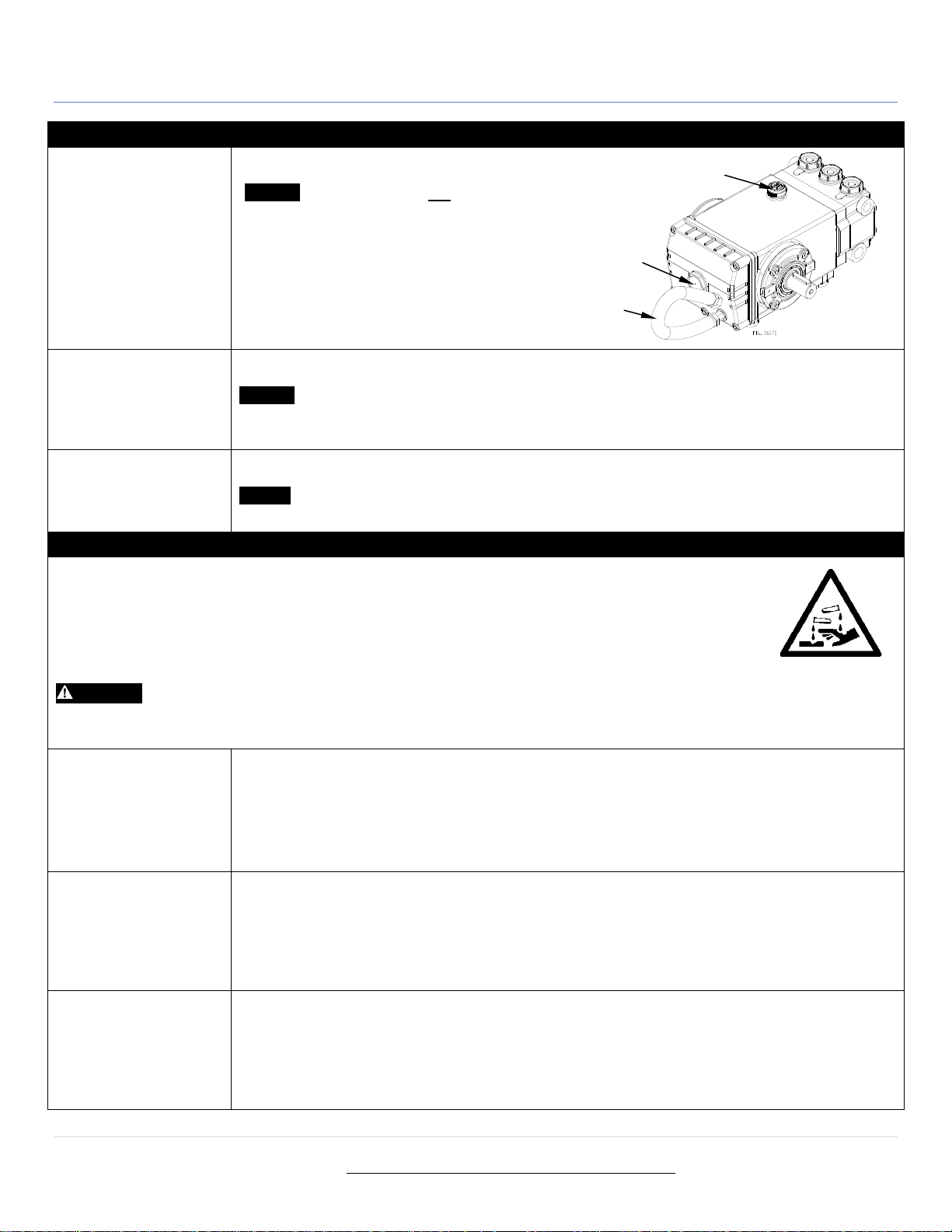

High Pressure Safety

Device (Rupture Disc)

WARNING: If the high-pressure safety device ever discharges water, turn the engine off and do

not use the machine. The device will no

longer function properly. See a dealer or call

Product Support at 1-800-969-7073.

This unit is equipped with a high-pressure safety

device, which acts as a safety feature. If the

unloader malfunctions, the high-pressure safety

device will open and relieve excess system

pressure.

Temperature Sensor

(Thermistor)

This unit is equipped with a temperature sensor that

measures discharge spray temperature and automatically

turns the burner off when the temperature setting is

reached or is at maximum preset limit. When the

discharge spray temperature drops, the burner

automatically reignites.

Spray Gun Safety Latch

The spray gun is equipped with a built-in trigger safety latch to

guard against accidental trigger actuation.

High Pressure Limit Switch

This unit is equiped with a high-pressure limit

switch, which acts as a primary safety feature. If the

system pressure exceeds the set pressure limit this

device will stop the burner from firing.

00417

Safety Latch

Assembly & Initial Set-Up Instructions – REV. D

12 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

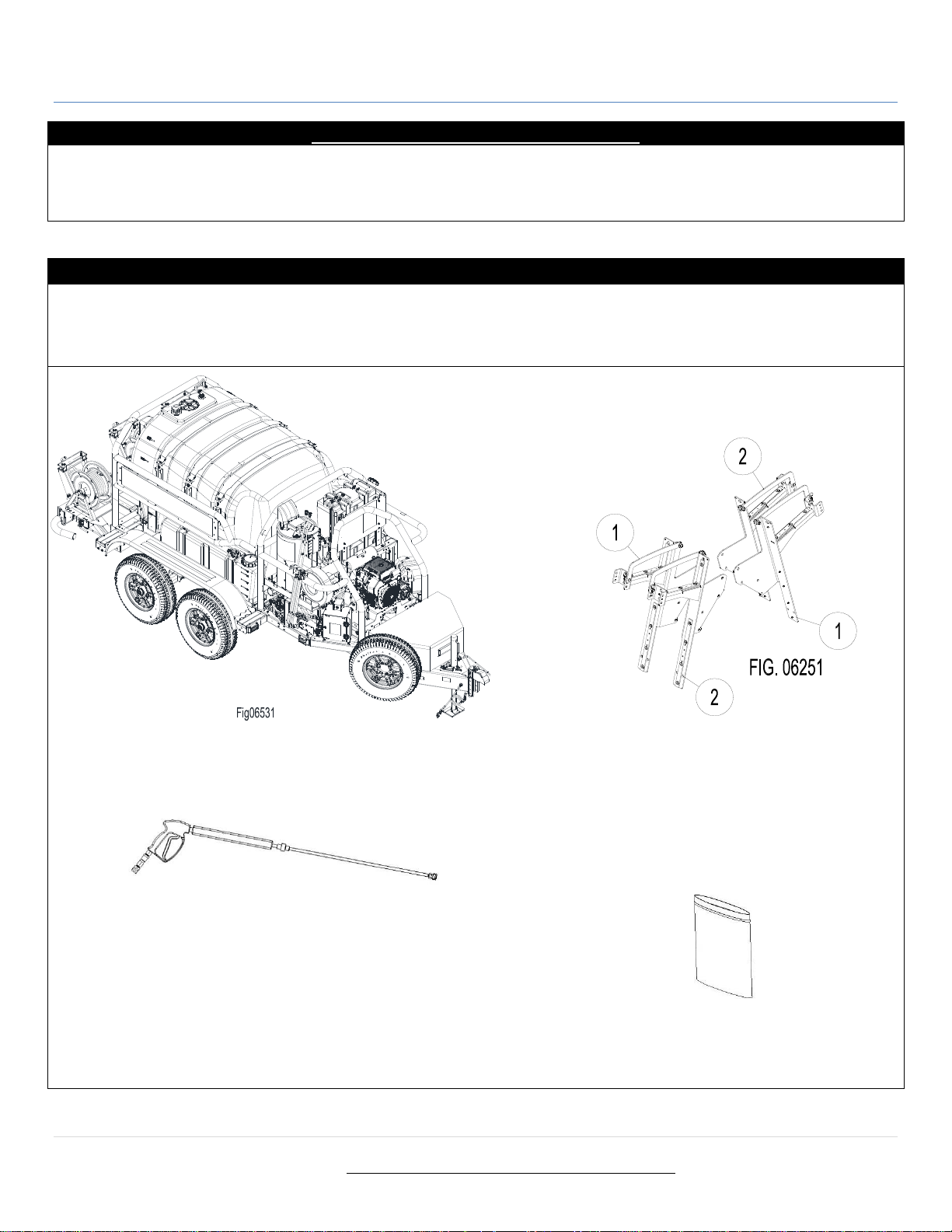

STEPS FOR ASSEMBLY / INITIAL SET-UP

• Unpacking & Delivery Inspection

• Connecting Battery

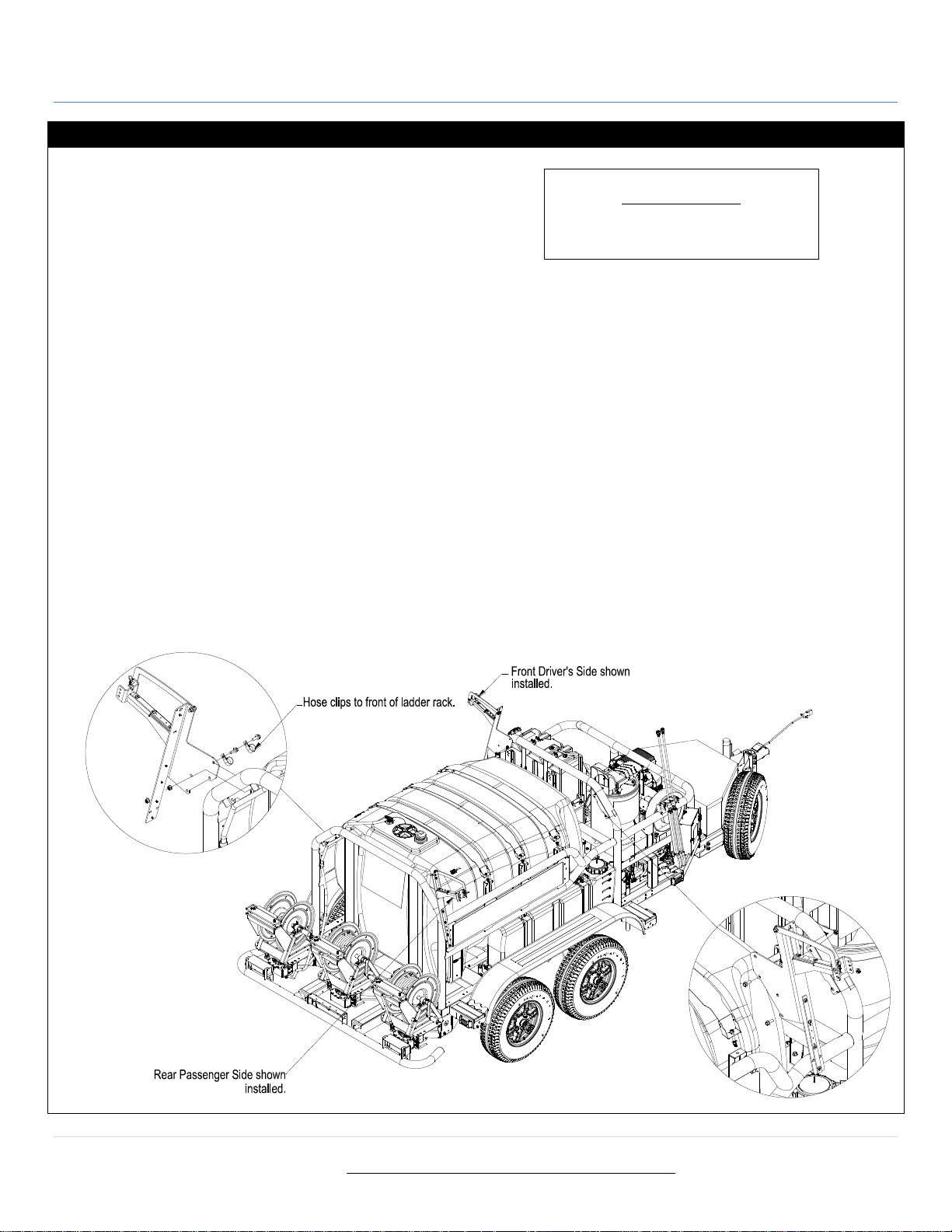

• Ladder Rack to Trailer Assembly Instruction

• Initial Pump & Engine Preparation

Each of these steps will be discussed in detail below:

STEP 1. UNPACKING & DELIVERY INSPECTION

Find and separate the components identified in Fig. 06251 and Fig.06546 – Hardware Bag. Inspect the pressure washer immediately after you

receive delivery for missing parts and damage.

If you have missing or damaged components, contact Product Support at 1-800-969-7073.

Pressure Washer Trailer

Ladder Racks

Ref.#1

(1) Drivers Side Front, (1) Passenger Side Rear

Ref.#2

(1) Drivers Side Rear, (1) Passenger Side Front

(Located inside large cardboard box)

Pressure Washer Spray Gun – Qty. 2

Spray Gun – Part #796731

Lance – Part #791279

(Located strapped to the back of the Roll Cage)

Hardware Bag

(Located inside the small cardboard box on top of

the battery compartment)

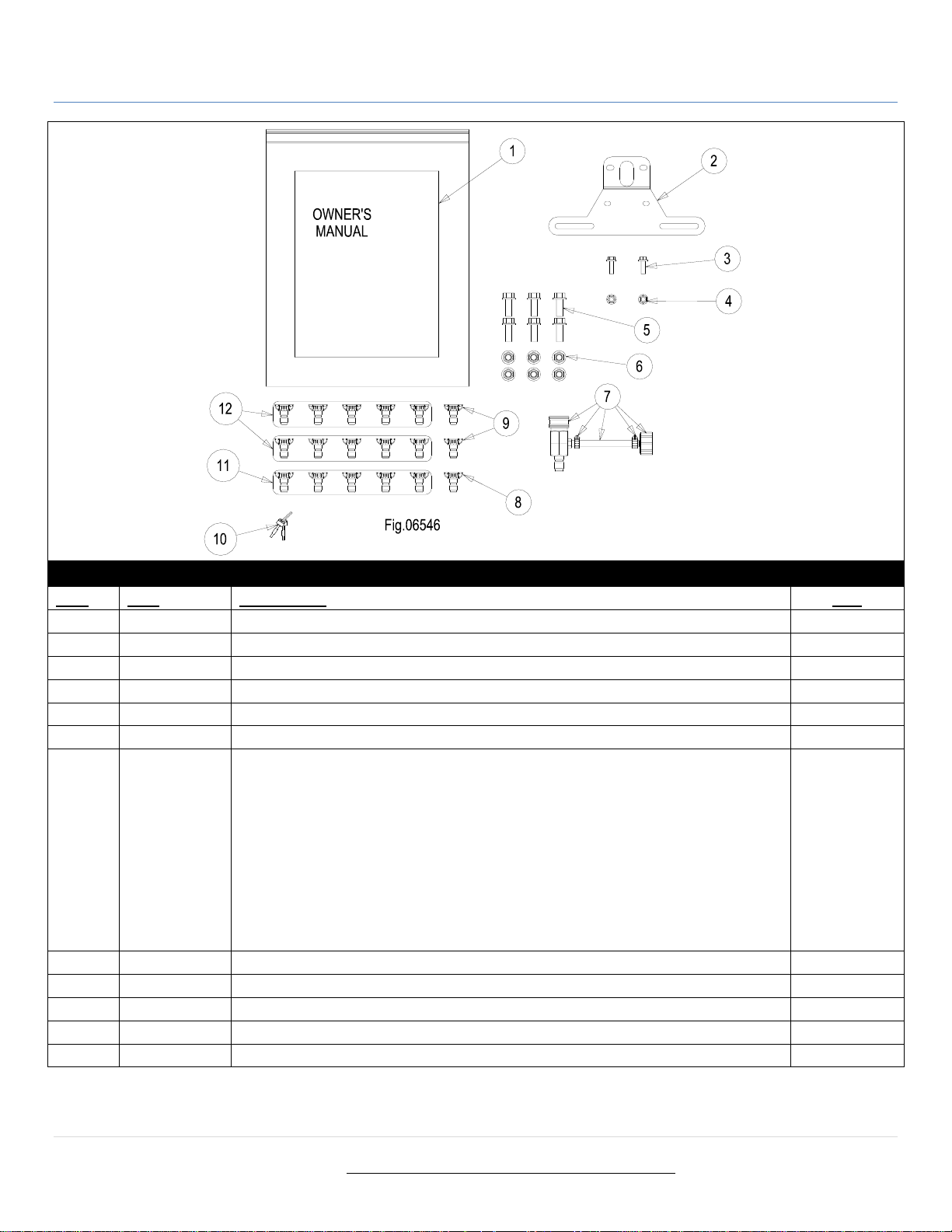

Assembly & Initial Set-Up Instructions – REV. D

13 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

HARDWARE BAG CONTENTS

REF#

Part#

DESCRIPTION

QTY.

1

N/A

Manual, 157565

1

2

N/A

Bracket, License Plate

1

3

82009

Bolt, 1/4-20 x 3/4" hex head serrated flange

2

4

82013

Nut, 1/4-20 Serrated flange

2

5

82624

Bolt, 3/8-16 x 1" hex head flange, Gr. 5

6

6

82631

Nut, 3/8-16 hex flange nylon

6

7

N/A

Chemical Injector, 2.3 high draw assembly

1

7.1

799571

Chemical Injector, 2.3, 3/8” high draw

1

7.2

777165

Hose, 1/4" braided

.5’

7.3

777834

Clamp, Hose

2

7.4

797557

Fitting, 1/4" Flat seat HB

1

7.5

777850

Nut, Swivel, Female Garden Hose

1

7.6

5232

Washer, Rubber, Garden Hose

1

7.7

777914

Coupling, QC 3/8” FNPT

1

7.8

777915

Nipple, QC 3/8” x 3/8” FNPT

1

8

799395

Nozzle, #7.0 Yellow, (Steam)

1

9

799396

Nozzle, #3.0 Yellow, (Steam)

2

10

KO2434003

Kohler Engine Keys

1

11

796627

Nozzle, 5 Pack #9.0

1

12

796216

Nozzle, 5 Pack #4.5

2

Assembly & Initial Set-Up Instructions – REV. D

14 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

TOOLS REQUIRED:

9/16” SOCKET AND WRENCH

Torque: 27.2 – 34 ft./lbs.

STEP 2. LADDER RACK TO TRAILER ASSEMBLY INSTRUCTIONS

1) Remove ladder racks from box. Be sure there are 4. There will be (2) front

racks and (2) rear racks.

2) Locate (6) bolts and (6) nuts in the hardware bag.

3) Using bolts and nuts form the hardware bag install front driver’s side and

passenger side ladder racks using bottom mount holes as shown in figure below.

4) Using remaining (2) bolts form the hardware bag install rear passenger side ladder rack using upper mount holes as shown in

figure below.

5) Install rear driver’s side ladder rack using upper mount holes as shown in figure below. Note you will need to remove and reuse

existing nuts and bolts in place for mounting hose clips.

Note: If proper mounting holes were used for the front and rear ladder racks, ladders should

be close to parallel with the ground when hung.

Assembly & Initial Set-Up Instructions – REV. D

15 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

STEP 3. INITIAL PUMP & ENGINE PREPARATION

Prepare Water Pump

Verify pump oil level.

NOTICE: The pump is shipped with oil.

1. Verify that oil level is half way up the sight

glass (or at the indicator line on the dip stick).

2. If oil level is low, fill with SAE Non-detergent

30wt. oil.

3. Replace oil fill dipstick.

Check Engine Oil

Check the engine oil before starting the pressure washer.

NOTICE: The engine is shipped with oil. You must check oil before use.

Refer to the engine manual to locate oil-fill port and for instructions on filling. Use the oil grade and quantity specified

in the engine manual.

Prepare High PSI Hose on

Hose Reel

Completely unwrap / unwind the high-pressure hose from the hose reel.

NOTICE: New hose will “grow” when charged for the first time and should always be charged one time before being

wrapped on the reel.

STEP 4. CONNECTING THE BATTERY

Unit is supplied with a battery, but not connected for shipping. The engine will not run unless a battery is connected.

Follow the steps below for connecting and disconnecting the battery.

If replacing the existing battery, a 12-volt standard, top-post mount, automotive battery (Group 75/86) with a minimum 24

amp-hour rating should be used. The battery should be installed in the protective battery box located near the engine. The

inside dimensions of the battery compartment are 11-1/8" L x 7-3/4" W x 10-1/8" H.

WARNING: Batteries are hazardous because they contain caustic acid, can emit explosive gases, and can cause electric shock. Caution must

be exercised when making connections to a battery to avoid shock and contact with the acid, and to prevent any sparking that could lead to an

explosion. ALWAYS follow the general battery safety rules and instructions listed below.

General Battery Safety

Rules

• ALWAYS use eye protection and protective clothing when handling batteries.

• NEVER smoke or work near sparks or other sources of ignition.

• NEVER touch both battery terminals at the same time with your hand or any other non-insulated tools.

• If battery acid contacts skin or clothing, flush immediately with water and neutralize with baking soda.

Connecting the Battery

Always connect the cables in the following sequence to avoid shock:

1) Find the battery cables located inside the battery compartment.

2) Connect the red cable to the positive (+) terminal of the battery.

3) Then connect the black cable to the negative (-) terminal of the battery.

Disconnecting the Battery

Always disconnect cables in the following sequence to avoid shock:

1) First, disconnect the black cable from the negative (-) terminal of the battery.

2) Next, disconnect the red cable from the positive (+) terminal of the battery.

3) Remove the battery from the battery compartment.

Oil fill dipstick

Sight glass

Oil drain hose

Moving & Towing the Pressure Washer

16 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

FIG02017

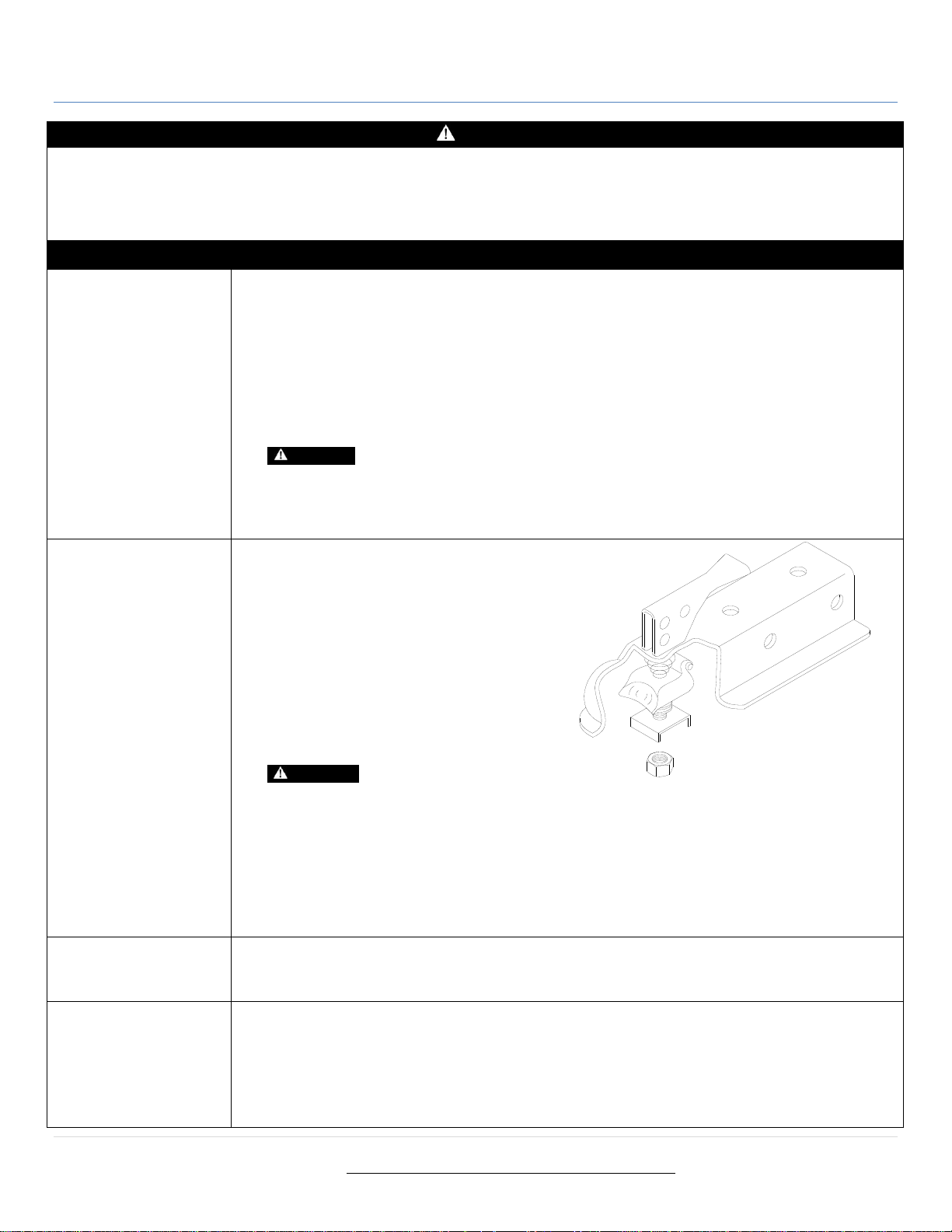

DANGER

The filled pressure washer is heavy. It can crush and cause serious injury if it rolls out of control or tips over.

• Always keep the jack cranked down to help balance the trailer when it is not connected to a vehicle hitch.

• Follow all the instructions below for safely connecting and towing the pressure washer.

CONNECTING TRAILER AND TOWING

Inspect Trailer

Always inspect the trailer before hitching it to your vehicle.

1) Check and be sure tires are fully inflated and in good repair. See tire sidewall for recommended pressure.

2) Check to make sure that trailer is in safe working condition. Make sure all nuts, bolts, and connections are

tight. If a part needs replacement, only use parts that meet the manufacturer's specifications.

3) Check coupler and latch be sure it is working properly.

4) Check to make sure coupler and ball size are the same.

5) Check wheel lug nuts to be certain they are tight.

6) Check all trailer lighting to insure they are in proper working order.

WARNING:

• Do not over-inflate tires. Severe injury can occur if tire explodes.

• Damaged or missing components, or replacement parts that do not meet specifications, may result in a

safety hazard or poor operation of the trailer.

Attach Trailer to Hitch

Attach trailer to vehicle hitch.

Trailer and tongue weights listed in the specification

section of the manual. Ensure the towing vehicle is

properly equipped to handle the load.

1) Attach trailer coupler to the vehicle’s class 4 or

higher hitch with 2-5/16" ball (only).

2) Ensure trailer is level, with A-frame tow bar parallel

to the ground. You may need to adjust your coupler

height or purchase the proper hitch to achieve the

correct tongue height, so trailer is level.

WARNING: Vehicle handling may be

adversely affected while towing if the trailer is not

level.

3) Adjust coupler to ball by raising locking lever and turning lock nut with fingers. Proper adjustment is obtained

when coupler is as tight as possible on ball and locking lever can still be opened and closed.

4) Lock lever closed to secure the attachment.

An optional locking pin or padlock may be inserted in the locking lever hole for extra security.

Attach Safety Cables

Two safety cables must be used while towing.

Cross safety cables under the coupler, allowing only enough slack for vehicle turns.

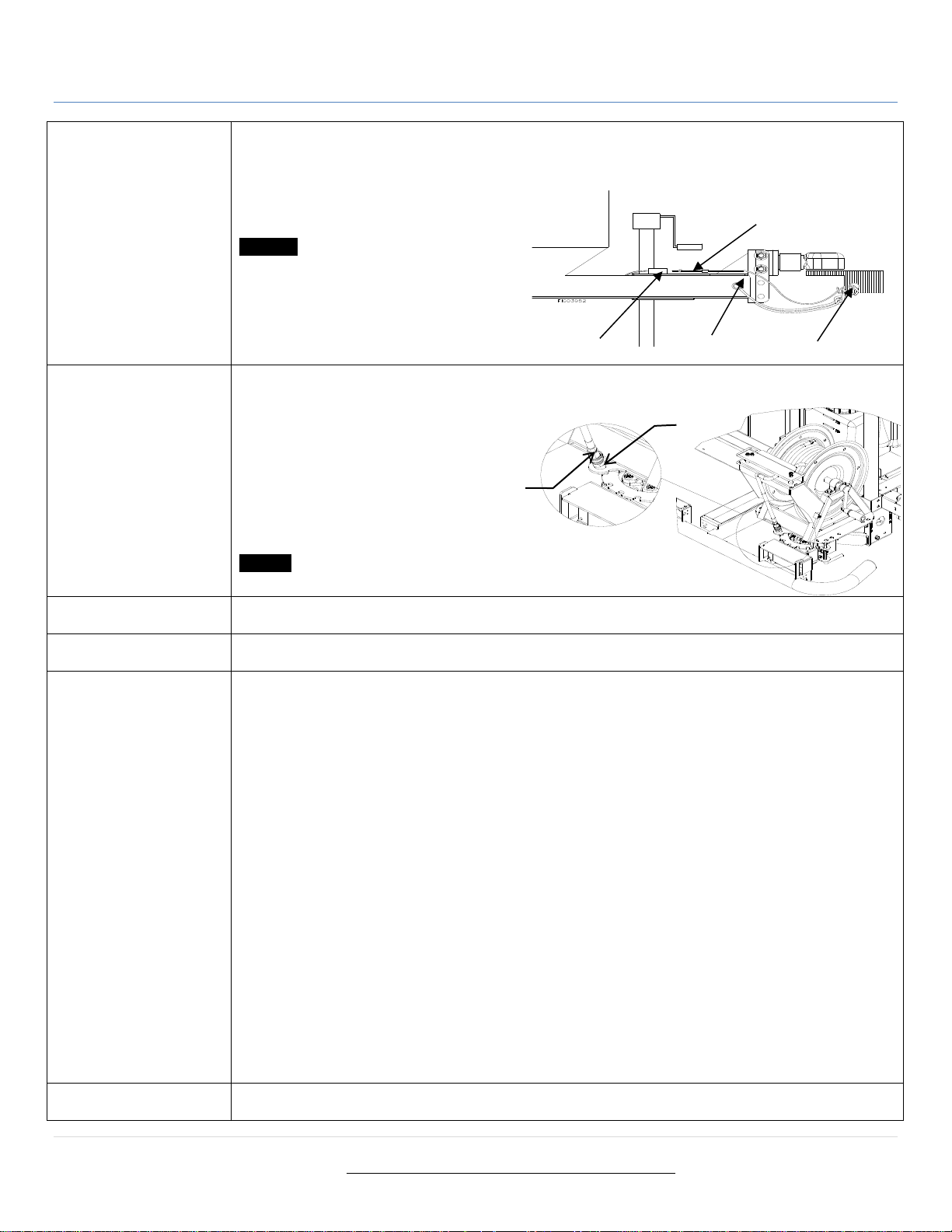

Route Breakaway Switch

Cable

Route breakaway switch cable.

The breakaway switch is a device that will activate the trailer brakes should the trailer become disconnected from

the tow vehicle. A cable is connected to a pin inserted into the breakaway switch. You must route this cable so that

it will pull the pin out of the breakaway switch if the trailer begins to separate from the tow vehicle, which in turn will

activate the trailer brakes.

Moving & Towing the Pressure Washer

17 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Breakaway

switch

Lanyard

Safety cable

1) Pull the pin with its attached cable out of the breakaway switch. Note: The other end of the cable is a terminal

loop.

2) Route the pin and its attached cable through the safety cable latch-point on the tow vehicle, and then back

through its own terminal loop.

3) Reinsert the pin into the breakaway switch.

CAUTION Always keep the pin inserted in the

breakaway switch, even when not towing.

Failure to have the pin inserted will drain your

pressure washer's battery. Never use the

breakaway switch as a parking brake.

Note: An extra pin is attached to the lanyard.

Secure Hoses

Each high-pressure hose reel is equipped with a quick coupler to secure hoses to hose reel mounts. The

low-pressure hose reel mount is

equipped with a 3/4” garden hose thread.

Quick connect hose nipple into the collar on

the hose reel mount. See Figure 06277.

NOTICE: Be sure to secure hose(s)

before towing.

Plug in Lights/Brakes

Plug 7-way electrical pin connector into vehicle.

Raise the Jack

Always crank the jack into the UP position before towing.

Tow

Tow the pressure washer to your desired work location.

When towing, always adhere to the following safety rules.

• Read vehicle instructions. Review towing safety instructions in your towing vehicle manual.

• Driving skills. Special attention and driving skills are necessary for towing any type of trailer.

• Vehicle handling. Be aware that vehicle handling will be affected when towing the filled pressure washer.

Exercise caution to avoid loss of control or pressure washer overturning:

o Keep speed to a minimum so you can always maintain control. Reduce speed prior to turns.

o Allow for wider turns and for more distance to stop.

o Avoid any sudden steering maneuvers, starts, or stops that could create sway.

• Rough or sloped terrain. Slow down and exercise extra caution on rough or sloped terrain to reduce risk of

rollover. Pick the most level route possible when transporting across fields. Drive up and down slopes that

cannot be avoided, rather than across. Use a vehicle equipped with a Roll Over Protection System (ROPS) if

you will be operating on non-level terrain.

• Added length. Be aware of the added length of the pressure washer.

• Reduced visibility. Be aware that visibility may be reduced with pressure washer attached. Be extra cautious

when backing up or turning.

• Ride / transport. Never ride or transport cargo on the pressure washer.

• On public roads. If towing on a public road, make sure to comply with all local, state, and federal towing

requirements. It is the sole responsibility of the purchaser to obtain licensing, trailer lights, safety chains, or

signage as needed to comply.

• Under the influence. Never tow or operate this pressure washer while under the influence of alcohol, drugs, or

medication.

If Leaving Unattended

Turn off the vehicle and block the trailer wheels if leaving the pressure washer unattended.

Fig. 06277

Collar

Hose Nipple

Moving & Towing the Pressure Washer

18 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

FIG.06311

FIG.06623

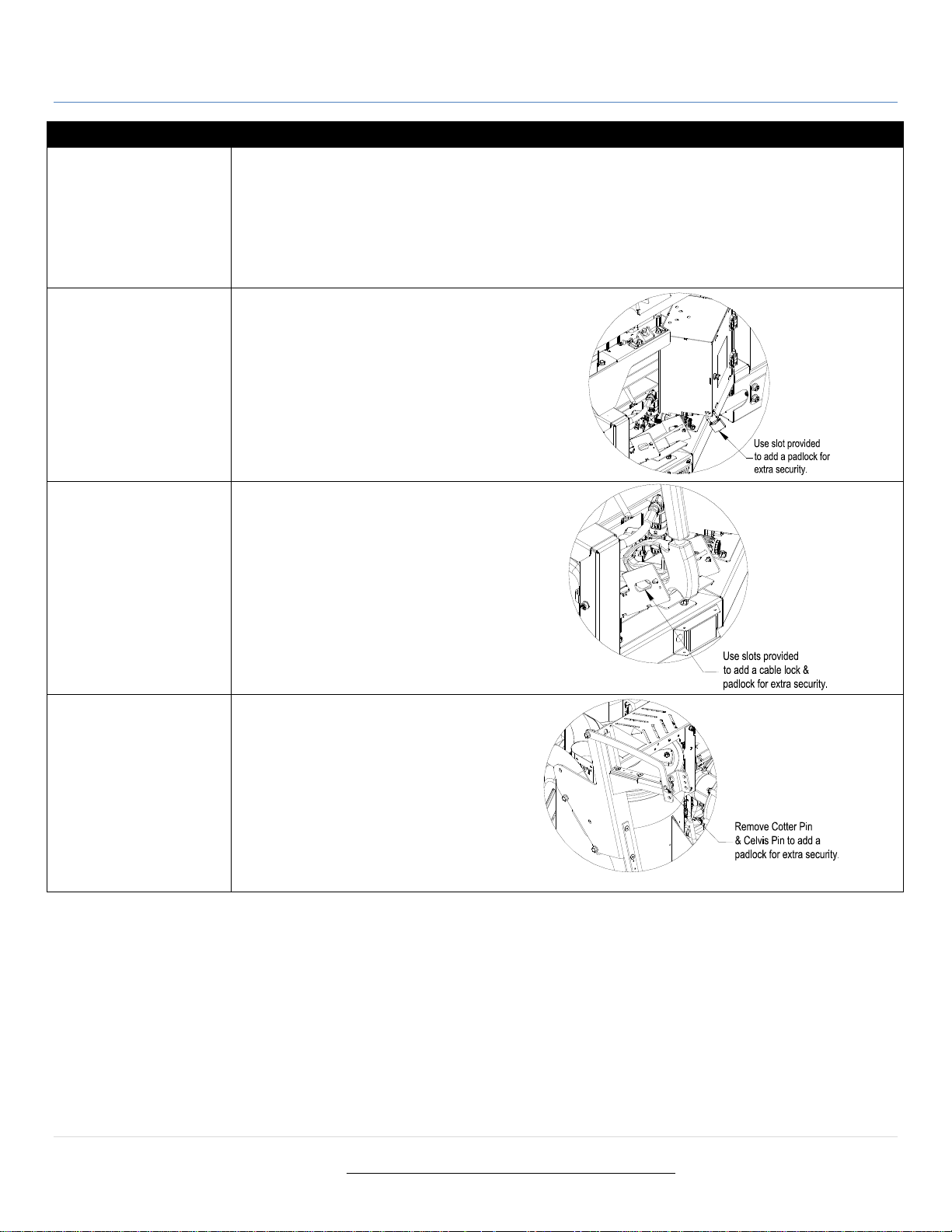

SECURITY FEATURES

Anti-Theft Features

This skid is designed for easy use of cable locks and/or padlocks to secure your items.

• Lockable hitch coupler. Using an optional locking pin or a padlock.

• Lockable spare tire mount. Using an optional lockable lug or use a cable lock.

• Lockable control box/nozzle holder. Features are added for the use of a padlock.

• Lockable spray gun mount. Features are added for the use of a cable lock.

• Lockable ladder rack. Features are added for the use of a padlock.

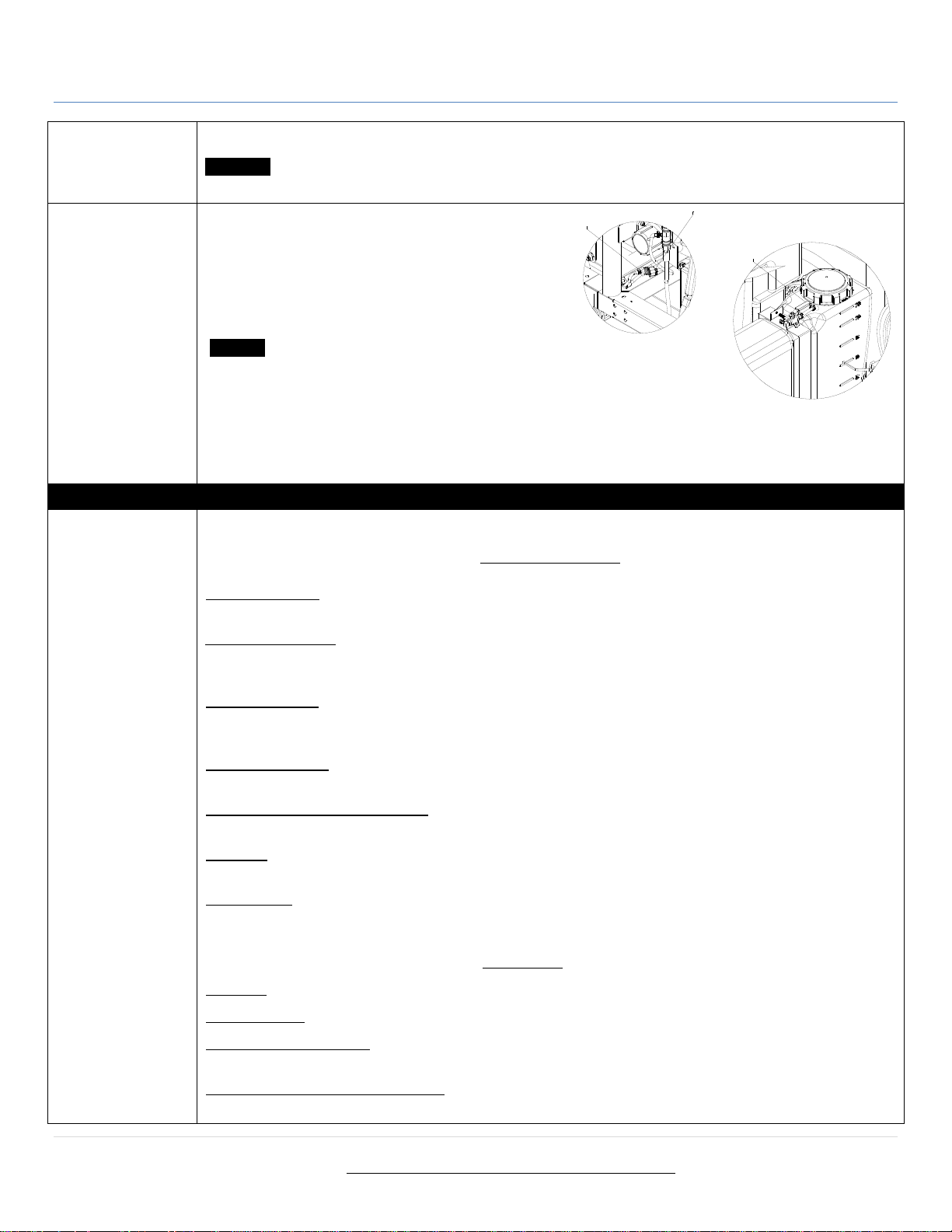

Secure Control Box

The control box housing has been designed with slots

for the use of a padlock.

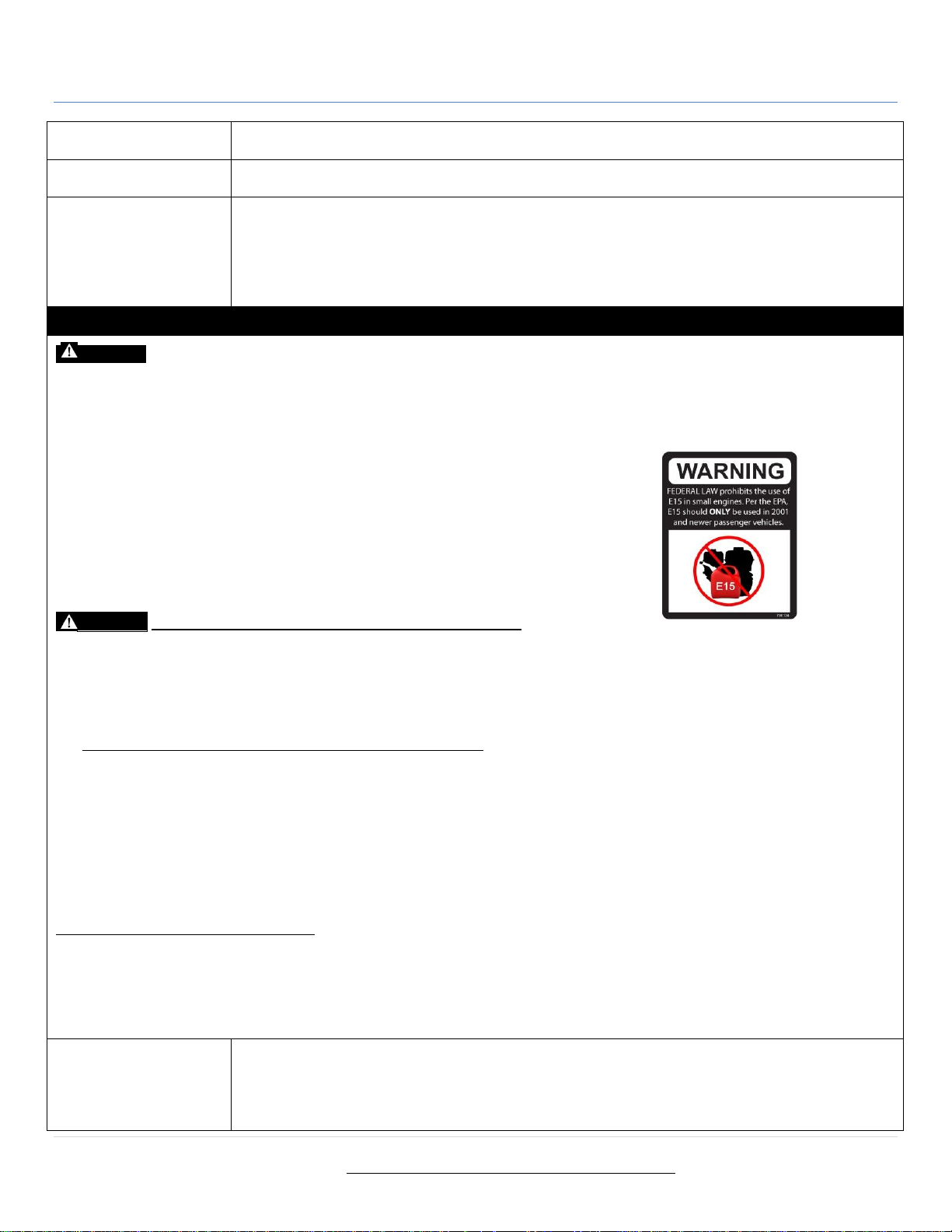

Secure Spray Gun

Secure spray gun in gun mount using the (2)

detent pins before towing. The gun mount has

been designed with added slots to allow the use of

a cable lock.

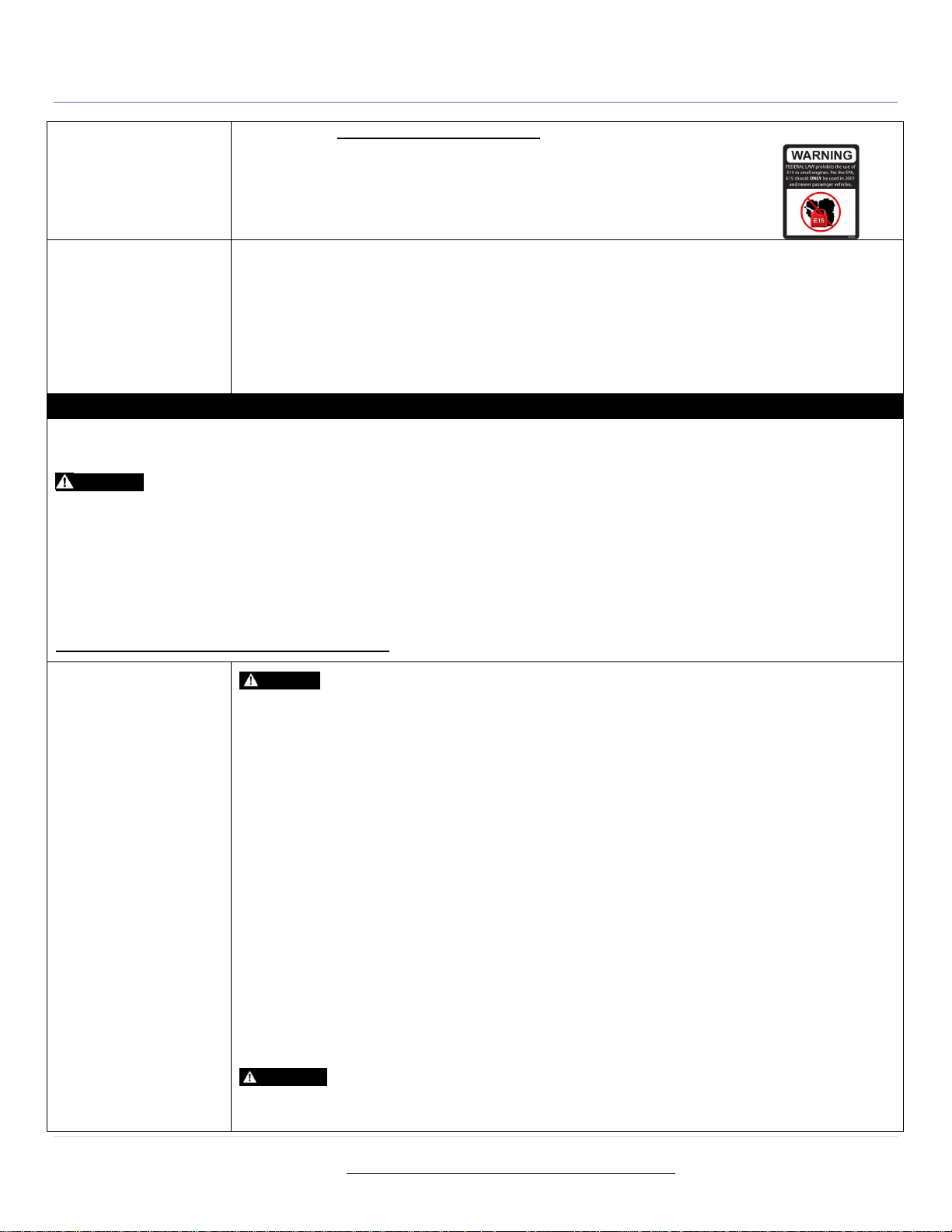

Ladder Rack

If you are going to install a ladder on the

ladder racks, pull cotter pin and clevis pin to

open ladder lock. (See Parts Explosion Ladder

Rack to locate the ladder lock.) Replace clevis

pin and cotter pin or you can use a paddle

lock for theft prevention. A rubber strap or

other strap is recommended to prevent ladder

from moving around during transport.

Before Each Use

19 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Follow the steps below prior to each use of the pressure washer.

STEPS TO FOLLOW BEFORE EACH USE

• Check Equipment

• Add fuel (s)

• Select a Suitable Worksite

STEP 1. CHECK EQUIPMENT

Check/Add Pump Oil

Check/add pump oil.

CAUTION: Never run the pump without enough lubrication!

1) Check oil level. Verify that oil level is half way up the sight glass (or at the indicator line on the oil fill dipstick).

2) If oil level is low, fill using SAE Non-detergent 30wt. oil.

3) Replace oil fill dipstick.

Check/Add Engine Oil

Check the engine oil level and add oil as needed.

Use the recommended oil type for your engine and expected ambient conditions.

(See engine owner's manual for oil type and capacity, and more detailed oil check/fill instructions.)

WARNING: Burn hazard

Never open oil port while engine is running. Hot oil can spray over face and body.

NOTICE:

• Low oil shutdown feature prevents the engine from starting without enough oil.

• Engine is shipped with oil. You must check oil before first use.

Inspect Spray System

Always inspect spray system for damage and leaks before each use.

DO NOT START PRESSURE WASHER UNTIL ALL NEEDED REPAIRS HAVE BEEN COMPLETED.

WARNING: High pressure fluid injection hazard

High-pressure fluid discharge from leaks (even pin-sized) or ruptured components can pierce skin and

inject fluid into the body. Injection injury can result in blood poisoning and/or severe tissue damage

leading to infection, gangrene, and loss of limb.

• Never use a finger or skin to check for leaks.

• Never operate machine with damaged or missing hoses/parts.

• Never attempt to repair a high-pressure hose or component – Always replace it with a part that is rated at or

above the pressure rating of this machine.

1) Check hoses, fittings, wand, trigger gun, and connections for signs of wear, cracks, looseness, or leaks.

Replace as required.

2) Check and clean the nozzle orifice.

3) Clean inlet filter (see Maintenance & Repair).

Inspect Fuel System

Always inspect (engine and burner) fuel systems and check for leaks BEFORE starting pressure washer.

DO NOT START PRESSURE WASHER UNTIL ALL NEEDED REPAIRS HAVE BEEN COMPLETED.

WARNING: Fuel leak hazard

Gasoline fuel and burner fuels are highly explosive and fuel leaks can result in fire or explosions. You can

be burned and seriously injured if the fuel system is not properly hooked up or there is a fuel leak when

you start the engine.

Inspect the entire fuel system. Look for:

• signs of leaks or deterioration

• chafed or spongy fuel hose

• loose connections

Before Each Use

20 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

• loose or missing fuel hose clamps

• damaged fuel tank, or a defective fuel shut-off valve

Clean Inlet Filter

Clean the water inlet filter before each use. For instructions see section Maintenance & Repair.

Perform Other Scheduled

Maintenances as Needed

Make sure that any other regular maintenance has been performed as prescribed in this manual in the

Maintenance & Repair section.

1) Refer to the engine’s owner's manual for engine maintenance instructions.

2) Make sure battery is charged. Charge as needed according to your battery manufacturer's instructions.

STEP 2. ADD FUEL(S)

WARNING: Fuel fire/explosion hazard

Gasoline is highly flammable and explosive. Burner fuels are combustible at warm temperatures. Heat, sparks, and flames can ignite fu el

vapors, which can become widespread during fueling. A flash fire and/or explosion could result and cause serious injury or death. Always use

extreme care when handling fuels. Carefully follow all instructions to avoid the following conditions which could result in fuel ignition:

• gas vapor collection inside enclosures

• static electric sparks

• sparks from electric wiring, batteries, or running engines

• sources of heat (such as a hot engine, burner, or exhaust)

• open flames, including pilot lights

Always follow these general safety rules when fueling:

1) Turn pressure washer off and allow it to cool for at least two minutes before removing any fuel cap.

WARNING: A running, or still-hot engine or burner is hot enough to ignite fuel.

2) Fill fuel tank OUTDOORS – never indoors. Fuel vapors can ignite if they collect inside and enclosure and explosion can result.

3) Stay away from all sources of heat, sparks, and flames. Do not smoke.

4) Never pump fuel directly into the gas tank or burner at a gas station – it could cause a static electric spark.

Follow these steps to avoid static electric sparking during fueling:

• Use an approved portable container to transfer fuel to the pressure washer's tank. (A portable container made of metal or conductive plastic

is preferred because it dissipates charge to ground more readily.)

• Always place container on the ground to be filled. Never fill the portable gas container while it is sitting inside a vehicle, trailer, trunk, or pick-

up truck bed.

• Dissipate static charge from your body before beginning the fueling process by touching a grounded metal object at a safe distance from fuel

sources.

• Keep nozzle in contact with container while filling. Do not use a nozzle lock-open device.

Clean up fuel spills /splashes immediately.

• If possible, move the pressure washer away from spilled fuel on the ground.

• Wipe up spilled fuel and wait 5 minutes for excess fuel to evaporate before starting engine.

• Fuel soaked rags are flammable and should be disposed of properly.

If fuel is spilled on your skin or clothes, change clothes and wash skin immediately.

Fill Fuel Tank

Check the fuel tank level. If needed, fill tank with fresh fuel from a portable container:

1) Remove engine gas cap.

2) Add fuel through the fill opening:

Before Each Use

21 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

- Use only a UL-approved portable fuel container to transfer the fuel to engine's tank.

- Do NOT overfill the fuel tank. Allow at least 1/2" of empty space below the fill neck to

allow for fuel expansion.

3) Replace fuel cap securely before starting engine.

4) Store extra fuel in a cool, dry place in a UL-approved, tightly sealed container.

Fill Burner Fuel Tank (if

planning to use heated

water)

If you are planning to use heated water, fill burner fuel tank with #1 or #2 diesel, B5 or lower biodiesel,

kerosene, or fuel oil.

1) Remove fuel cap.

2) Add fuel through the fill opening. Do not overfill. Allow at least 1/2" of empty space below fill neck to allow for

fuel expansion.

3) Replace fuel cap securely before starting engine.

4) Wipe any excess fuel from unit before starting.

STEP 3. SELECT A SUITABLE OUTDOOR WORKSITE

Before using the pressure washer, you must understand the criteria for selecting a suitable location for operation. Note that this pressure washer is

for OUTDOOR USE only.

WARNING: You must choose a suitable site for operating your pressure washer to avoid equipment damage and/or injury and death

from carbon monoxide poisoning, fire/explosion, uncontrolled equipment movement/tip over, or slips and falls. Choose a site that meets all

the following five criteria:

1) OUTDOORS only, and away from all building windows and air intakes.

2) Where no flammable vapors, dusts, and gases are present.

3) Where there is adequate, unobstructed ventilation airflow.

4) With adequate clearance from combustible materials.

5) On a firm, level, heat-resistant surface with good drainage.

Details regarding each of these criteria are provided below.

Outdoor Use Only

DANGER: Carbon monoxide poisoning hazard

Exhaust fumes from both the engine and the burner contain carbon monoxide (CO), a poisonous gas you

cannot see, smell, or taste. The CO generated by the pressure washer can rapidly accumulate, even in areas

that appear to be well-ventilated, resulting in dangerous and fatal concentrations within minutes. Follow the

directions below for choosing a location to operate your pressure washer to avoid carbon monoxide poisoning.

The location you choose to operate the pressure washer must be OUTDOORS and away from all building

air intakes.

• Never run the pressure washer in an enclosed or partially enclosed location such as a building, garage, barn,

shed, or house. These spaces can trap poisonous gases. Running a fan or opening windows will not

provide adequate ventilation to prevent dangerous CO build-up.

• Only use the pressure washer outdoors and far away from open windows, doors, and building or vehicle

vents.

• Place the pressure washer so that the exhaust fumes will not be directed towards people or building air

intakes.

• Ensure that working, battery-operated or battery back-up carbon monoxide alarms are used in any

dwelling/structure that is near the running pressure washer.

• Note that this pressure washer is NOT designed or approved for use in vehicles or marine applications.

Never run the pressure washer inside RVs or other vehicles, on boats, or on pick-up truck beds.

WARNING: Never attempt to attach ductwork to the engine muffler or burner exhaust to allow for installation

inside an enclosure. This could cause hot air deflection, heat build-up, and increased exhaust back-pressure,

resulting in exhaust leakage or overheating and damage to the pressure washer.

Before Each Use

22 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Stay Away from

Combustible Dust, Liquids

or Vapors

Do not locate and use the pressure washer in the presence of flammable vapors, dust, gases, or other

potentially combustible materials.

The burner is an open flame, which can ignite airborne dusts and flammable vapors. Operate only where open

flames and torches are permitted.

Be Sure to Have Adequate

Airflow

The pressure washer needs adequate, unobstructed flow of air to allow for proper combustion and

adequate cooling.

Proper combustion can only be obtained when there is enough supply of oxygen available for fuel being burned.

Cooling ventilation is required to prevent overheating of the pressure washer and fire.

• Situate so there is adequate clearance around pressure washer to allow for airflow – at least 7 feet from any

non-combustible wall or obstruction.

• Never place any objects against or on top of the pressure washer.

• Do not operate with a tarp, blanket, or cover surrounding the pressure washer.

Have Clearance for Hot

Exhaust

The exhaust gas from your pressure washer is extremely hot and can cause combustible materials to catch

on fire.

• Make sure both the engine exhaust and burner exhaust are at least 7 feet from all combustible materials and

buildings/structures during operation.

• Equip the engine with a spark arrestor if the pressure washer will be used near any ignitable forest, brush, or

grassy land. (See the engine manual provided with this equipment to determine if the engine is already

equipped.) Make sure you comply with applicable local, state, and federal codes.

• Keep a fire extinguisher rated "ABC" nearby. Keep it properly charged and be familiar with its use.

Have a Firm, Level Heat-

Resistant Surface

The pressure washer should be positioned on a firm, level (less that 3-degree slope), heat-resistant surface

with good drainage.

Ensure that the pressure washer sites level and will not slide or shift during operation. If applicable, block the

pressure washer’s wheel to prevent movement. Surface should be heat-resistant if you will be using the burner for

heated spray.

Operating the Pressure Washer

23 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

After you have checked and fueled the equipment and positioned it in a suitable worksite, it is time to start your pressure washer. The

following are the procedures necessary for safe, successful operation of your pressure washer.

WARNING

Carefully read and follow all instructions and safety information for using this pressure washer. Improper use or maintenance of the pressure

washer can result in serious injury or death to the operator or bystanders from:

• Carbon monoxide poisoning

• Fire/explosion

• Chemical exposure

• Skin/eye injury from high pressure

spray

• Burns

• Slips/falls

• Electric shock

• Flying objects/debris

OPERATING INSTRUCTIONS

• Connect hoses, water supply, and spray nozzle

• Set up for chemical spray (if desired)

• Spraying

• Stopping

Each of these procedures will be discussed in detail below.

STEP 1. CONNECT HOSES, WATER SUPPLY, AND SPRAY NOZZLE

Position Pressure

Washer for Use

Place pressure washer in a suitable location for use, as directed in the “Before Each Use, Step 3: Select Suitable

Outdoor Worksite” section of this manual. A suitable location is:

• OUTDOORS only, away from all building air intakes.

• Where no flammable vapors, dusts, and gases are present.

• Where there is adequate, unobstructed ventilation airflow.

• With adequate clearance from combustible materials.

• On a firm, level, heat-resistant surface with good drainage.

DANGER: Carbon monoxide poisoning hazard.

Exhaust fumes from both the engine and the burner contain carbon monoxide (CO), a poisonous gas you cannot see,

smell, or taste. The CO generated by the pressure washer can rapidly accumulate, even in areas that appear to be

well-ventilated, resulting in dangerous and fatal concentrations within minutes. ONLY run pressure washer

OUTDOORS and at least 20 feet from the home, away from windows, vents, and air intakes, to allow proper ventilation.

If you start to feel sick, dizzy, or weak while using the pressure washer, shut off the engine and get to fresh air RIGHT

AWAY. NEVER run pressure washer inside any enclosed or semi-enclosed spaces, including homes, garages,

basements, sheds, boxes, pick-up truck beds, RVs, or boats. These spaces can trap poisonous gases, EVEN if you run

a fan or open windows.

Fill Water Tank

Ensure the water in your tank is clean. Debris can cause excess pump wear and reduce performance.

1) Use low pressure hose with garden hose to fill tank.

2) Fill from the drain tank.

3) Fill from top of tank.

Attach Gun to the

High-Pressure Hose

Attach the high-pressure hose to the pressure washer's water outlet.

WARNING: NEVER operate this pump with components (such as hose, connections, and spray gun) rated for

lower pressure and/or temperature limits than the machine's maximum rated pressure and temperature, or component

could rupture and cause serious personal injury from escaping high pressure fluids.

1) See Component Identification section of this manual for location of the pressure washer's water outlet.

2) Your pressure washer hose is equipped with quick couplers. Simply pull the collar back and push the coupler onto

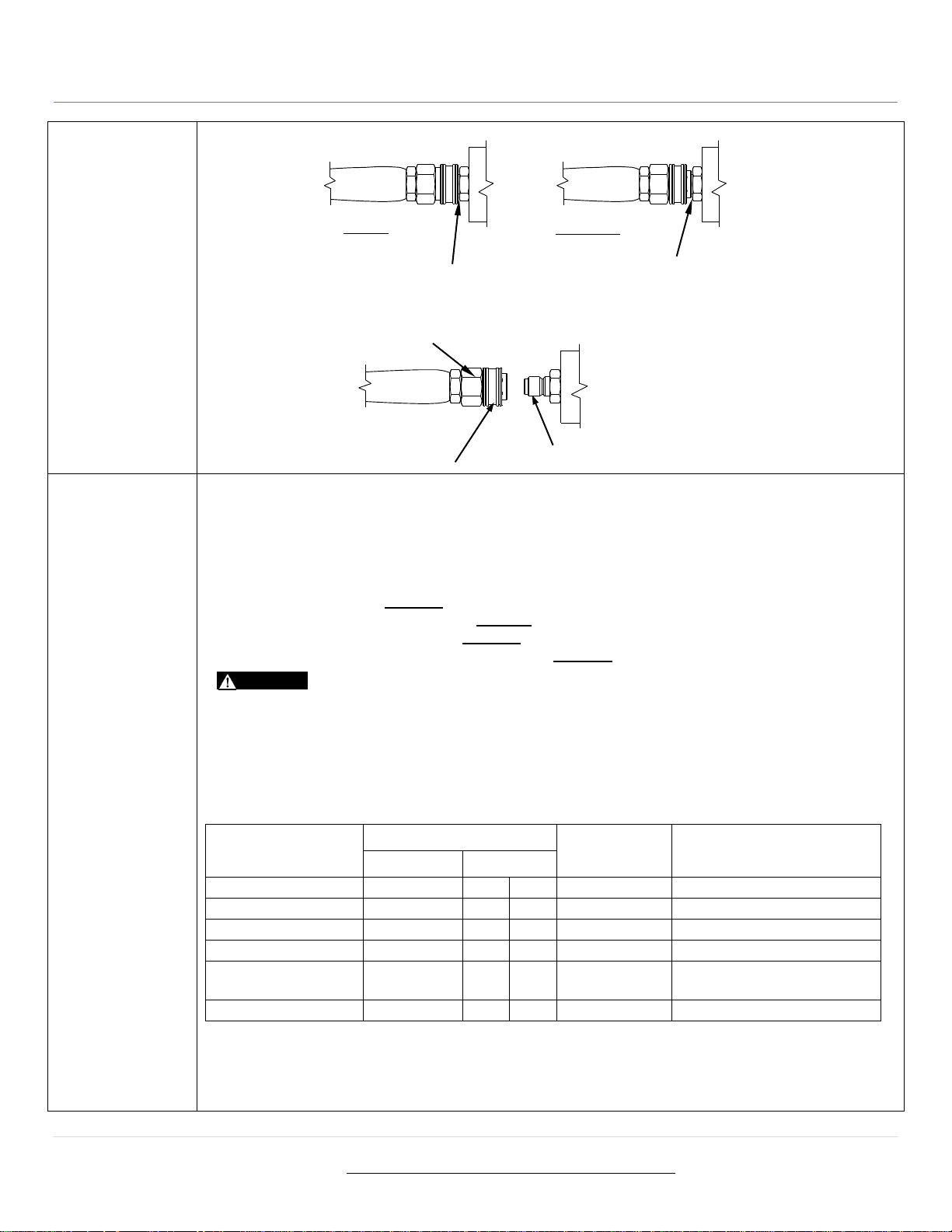

the water outlet nipple (Figure 2a).

The collar should slide over the ball bearings.

Operating the Pressure Washer

24 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Figure 2a

3) Release the collar, making sure it springs back and re-seats to its original (non-retracted) position (Figure 2b).

Check the connection by pulling on the hose to ensure a positive connection.

Figure 2b

Select the Spray

Nozzle

Your pressure washer is equipped with 15 high-pressure nozzles and 3 low-pressure nozzles (1 #7.0 Steam and 2

#3.0 Steam nozzles). Generally, the wider the spray angle of the nozzle, the lower the spray pressure produced. Select

nozzles based on the type of job you are doing (color of nozzle) and whether you are using two guns or one (size of

nozzle).

1. One gun vs. two-gun use:

a) Use a #9.0 nozzle for single gun operation. This will ensure the rated flow and psi are achieved.

b) Use two #4.5 nozzles when operating dual guns.

c) Use a #7.0 yellow steam nozzle for single gun operation.

d) Use two #3.0 yellow steam nozzles when operating dual guns.

WARNING: NEVER use #9.0 nozzles when operating both guns. If two operators use #9.0 nozzles and one

operator releases the trigger on their gun, the flow through the second operator’s gun will suddenly increase from 4.5 to

8 GPM. This will cause the second operator’s gun to kick without warning, which could result in loss of balance and/or

spraying control.

2. Type of cleaning job:

Select the appropriate color nozzle for the job based on the following table. Generally, the wider the spray angle of

the nozzle, the lower the spray pressure produced.

COLOR OF NOZZLE

SIZE

SPRAY ANGLE

USED FOR

1 GUN USE

2 GUN USE

RED

9.0

4.5

4.5 0 HIGHEST IMPACT

YELLOW

9.0

4.5

4.5

15

TOUGH STAINS/STRIPPING

GREEN

9.0

4.5

4.5

25

GENERAL

WHITE

9.0

4.5

4.5

40

LIGHT CLEANING

BLACK-LOW

PRESSURE

40.0

40.0

40.0

65

CHEMICALS

YELLOW

7.0

3.0

3.0

15

STEAM

NOTE:

You must use the low-pressure black nozzle for spraying chemicals. For dual gun use with chemicals, you will

need a black, #40.0 nozzle on each gun; you will not be able to spray chemicals out of one gun and plain water

out of the other gun at the same time.

Correct Insertion

Incorrectly Inserted

Collar Seated

Collar NOT Seated

Collar

Coupler

High-Pressure Output

Operating the Pressure Washer

25 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

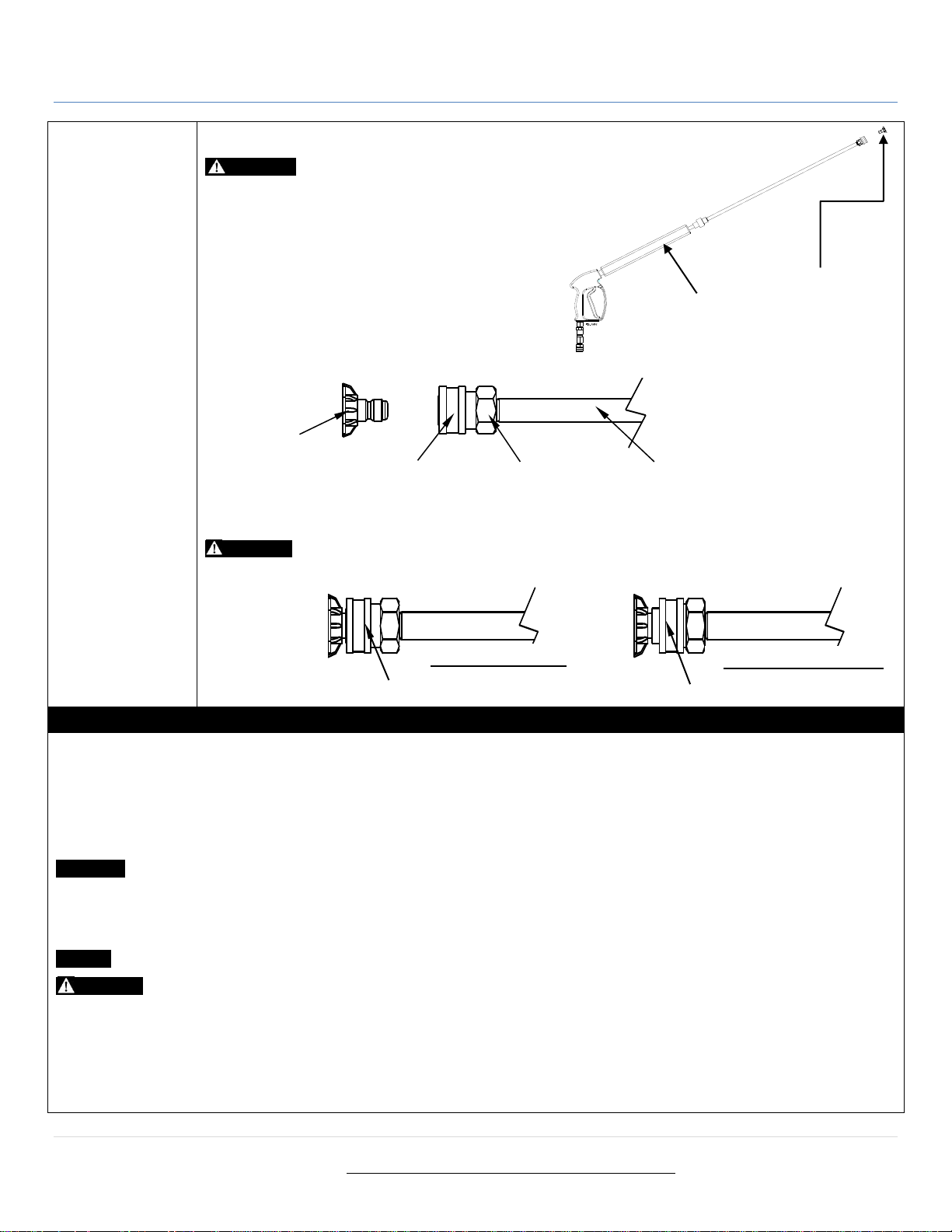

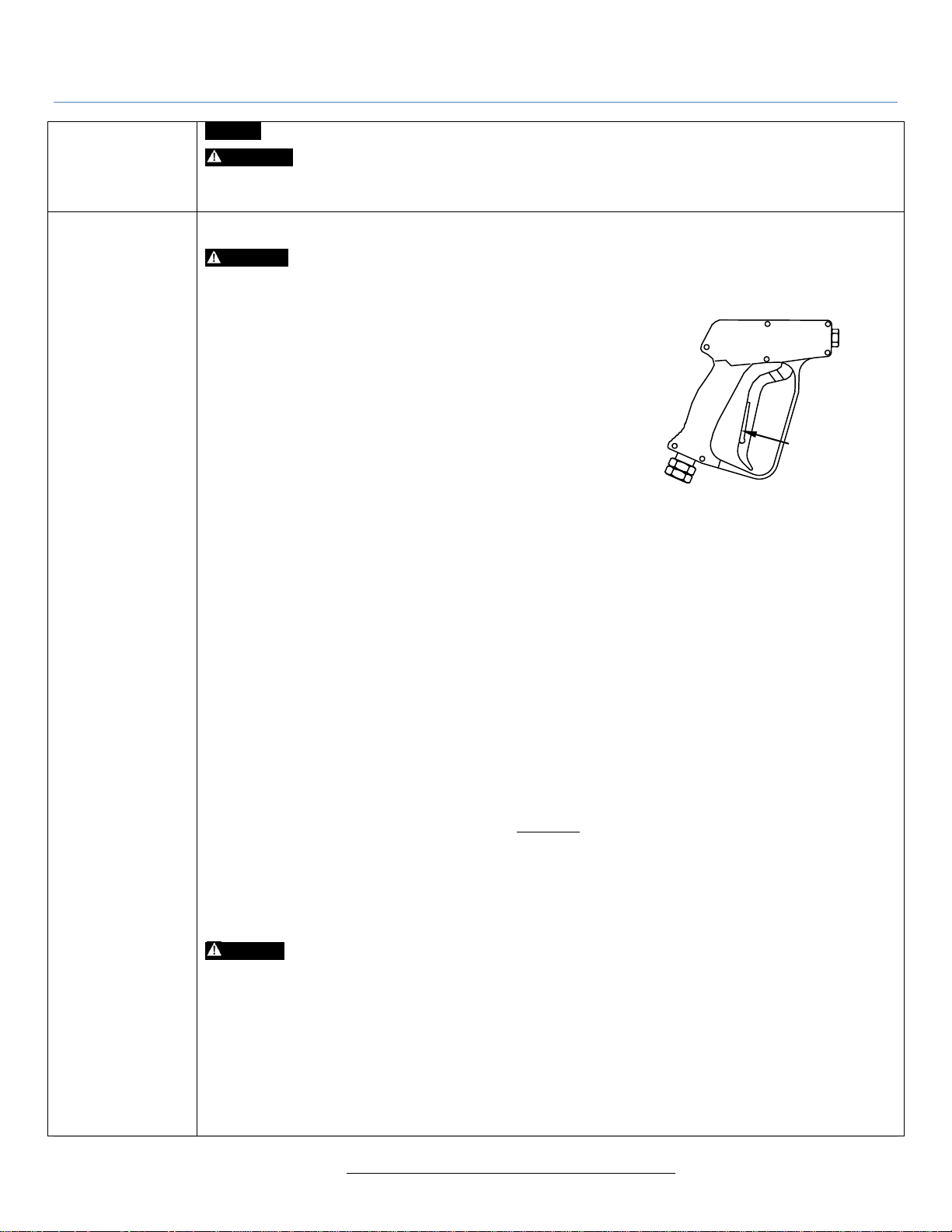

Attach the Nozzle

Attach nozzle to the spray gun.

WARNING: DEPRESSURIZE FIRST

Any time you remove/install/change a nozzle, you must

depressurize hose line by squeezing the spray gun trigger

while the engine is off. Even if the engine has been off for a

long period of time, the hose may remain dangerously

pressurized.

1) Make sure the engine is off and the hose line

depressurized.

2) To install the nozzle, pull the collar back and twist the

nozzle firmly into the coupler on the end of the wand

(Figure 3a).

Figure 3a

3) Release the collar, making sure it springs back and re-seats to its original (non-retracted) position (Figure 3b).

Check the connection by pulling on the nozzle to ensure a tight connection -- if correctly inserted, nozzle will rotate

but not pull out.

WARNING: Make sure the nozzle is correctly inserted. Sprayer nozzle can become a projectile and cause serious

personal injury or property damage if not properly connected to the spray gun. Do not attempt to use different types of

nozzles that may not fit the coupler.

Figure 3b

STEP 2. SET UP FOR CHEMICAL SPRAY (IF DESIRED)

Using the proper cleaning chemical for the application can speed up cleaning jobs tremendously.

Your pressure washer is equipped with a chemical tank and chemical injector, which siphons cleaning chemicals into a low-pressure washer

spray downstream of the pump. Adequate suction pressure is created only when the low pressure (black) spray nozzle is used.

The introduction of cleaning chemicals via the chemical injector affords the following advantages:

• It protects the pump from damage because no chemical passes through the pump.

CAUTION: Certain chemicals, such as bleach or those containing muriatic acid, will cause pump damage if introduced upstream through the

pump's water inlet.

• It mixes the cleaning chemical into a low-pressure spray. Cleaning chemicals applied under low pressure adhere better to the surface

being cleaned, allowing the formula time to react and remove dirt more effectively.

NOTICE: An external chemical injector pump is not recommended for use with this pressure washer.

WARNING: Chemical Spraying

• Never spray acids, corrosives, or abrasive or flammable liquids. Breathing hazards, surface burns/corrosion, or fire/explosion

could result.

Follow the chemical manufacturer's label instructions for proper use and handling of the chemical. Understand all safety hazards and first aid

for all chemicals being used. Always wear protective gloves when handling and cleaning with chemicals, and wear other protective gear as

directed by chemical manufacturer. Always dispose of hazardous fluids per local, state, and national guidelines.

Nozzle

Spray Gun

Nozzle

Coupler

Lance

Collar

CORRECT INSERTION

INCORRECTLY INSERTED

Collar seated

Collar NOT seated

Operating the Pressure Washer

26 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Ball Valve

Fig.06255

To Chemical Injector

To Chemical Tank

Acquire Cleaning

Chemicals

Use only NorthStar pressure washer chemicals or chemicals specifically formulated for use with pressure washers.

CAUTION: Non-approved chemicals can damage pressure washer components (seals, wand, hoses, pump, etc.) and be

harmful to the environment. It could also void the warranty.

Prepare for Chemical

Spray (if you plan to

use)

Prepare the pressure washer for chemical spraying

using the following steps:

1) Prepare the chemical cleaning solution as

recommended by the chemical label required for

the job. This chemical injector is an 18:1 ratio. Place

into both chemical tanks located on sides of the trailer.

NOTICE: The chemical injector is not adjustable and will mix the

chemical solution into the spray. It is designed to be removable for

added pressure.

2) Connect garden hose coupler to coupler on chemical injector.

3) Turn ball valve to open position on chemical tank.

4) Use chemical nozzle and spray.

STEP 3. SPRAYING

Safety Rules for

Operation

Before starting the pressure washer, review the following general safety rules for operation:

CONDITIONS FOR USE

Know how to stop. Be thoroughly familiar with proper use of the equipment and all controls and connections. Know how

to stop the pressure washer and depressurize system quickly if needed (see "Step 4. Stopping").

Instruct all operators. The pressure washer's owner must instruct all operators and potential renters in safe set-up and

operation. Do not allow anyone to operate the pressure washer who has not read the owner's manual and been instructed

on its safe use.

Adult control only. Only trained adults should set up and operate the pressure washer. Do not let children operate.

Pressure washers can generate forces greater-than children can control and require judgment beyond what can be

expected of children.

Under the influence. Never operate, or let anyone else operate, the pressure washer while fatigued or under the

influence of alcohol, drugs, or medication.

Safety equipment / controls in place. Do not operate the pressure washer unless all safety covers, guards, and barriers

are in place and in good working order, and all controls are properly adjusted for safe operation.

Damaged. Do not operate the pressure washer with damaged, missing, or broken parts. Never attempt to repair a highpressure hose or component. Always replace it with a part that is rated at or above the pressure rating of the machine.

Modifications. Do not modify the pressure washer in any way or deactivate any safety device. Do not change or add to

fuel tank, fuel lines, or exhaust system. Modifications can result in hazards related to carbon monoxide poisoning, fuel

leaks, fire, explosion, or other serious safety hazards, and will also void the warranty.

DURING USE

Stay alert. Watch what you are always doing.

Clear work area. Clear the work area of all bystanders. Keep children and pets away.

Dual gun use (if equipped). During dual gun use, always stay aware of the other operator’s location and keep spray

directed away from them.

Keep spray away from electrical wiring. Spray contact with electrical wiring will result in severe electrical shock or

electrocution.

Operating the Pressure Washer

27 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Hot exhaust/parts. Stay clear of the engine and burner exhausts. Never touch a hot engine muffler, burner/heating coil,

or other hot surfaces. All are extremely hot and will burn you.

Do not direct spray at this machine. Do not attempt to clean this machine with its own spray. Engine damage will

result. Cleaning should be done with a damp sponge with the engine OFF.

Let engine cool. At least two minutes before refueling.

Avoid inhalation of exhaust. This product emits CO and chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

Never pull by hose. Do not move this machine by pulling on the hose. Hose or connections could fail and result in

catastrophic high-pressure release of fluid as well as hose whipping.

Avoid sharp objects. Keep hose away from sharp objects. Bursting hoses may cause injury.

No load bearing. Do not use the pump to support other items of equipment that impose unacceptable loads on the pump.

Do not attempt to use this machine as a prop.

Lock trigger safety latch when not spraying. Spray gun is equipped with a built-in trigger safety latch to guard against

accidental trigger release. Rotate safety latch to the locked position when not spraying.

Never leaving unattended. Always turn off the pressure washer and relieve system pressure before leaving the sprayer

unattended.

PROMPT EMERGENCY RESPONSE

Seek medical aid for suspected injection injury. If injured by high-pressure fluid, no matter how small the wound is,

see a doctor at once. A typical injection injury may be a small puncture wound that does not look serious. However,

severe infection or reaction can result if proper medical treatment is not administered immediately by a doctor who is

familiar with injection injuries.

Seek medical aid for suspected carbon monoxide poisoning. The running engine gives off carbon monoxide, a

poisonous gas that can kill you. If you start to feel sick, dizzy, or weak while using the pressure washer, shut off the

engine and get to fresh air RIGHT AWAY. See a doctor. You may have carbon monoxide poisoning.

Put on Personal

Protective Gear

WARNING: Use personal protective gear to prevent:

• Eye and skin injection injury from high pressure spray

• Hearing loss

• Burns from hot water or steam

• Eye injury from flying debris

• Wear waterproof, thermally insulated gloves, safety goggles, face protection, and protective clothing when operating

the machine. If spraying pressure washer specific chemicals, wear a respirator mask to avoid inhalation of vapors if

directed on the chemical label.

• Wear non-slip, protective footwear. Use of pressure washer can create puddles and slippery surfaces. Wear

footwear capable of maintaining a good grip on wet surfaces.

Water Supply

Always have a constant water supply.

CAUTION: Never run the pump without the water in the tank. Operating the pressure

washer without enough incoming flow of water will damage the pump.

1) Make sure the water feed tank contains adequate water.

2) Turn ball valve on hose reel to the open position when spraying.

Operating the Pressure Washer

28 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

Start Engine

Start the engine to power the pump.

CAUTION: Running the pump dry will cause damage and void the warranty.

1) To prevent accidental spraying, engage the safety latch on spray gun trigger by rotating it to the locked position.

2) Follow the instructions in the engine manual for starting the engine.

If the engine does not start on the first try, pressure may build up in the pump. Relieve pressure by squeezing the spray

gun trigger before attempting to start engine again. This will make starting easier.

DANGER: Do not inhale engine exhaust. It contains dangerous carbon monoxide that can kill you.

Apply Cleaning

Chemical (if desired)

If desired, spray cleaning chemical at low pressure (with or without heated water).

1) Make sure the chemical injector is properly set up according to the instructions in Step 2, Set Up for Chemical

Spraying.

2) Make sure the low-pressure BLACK nozzle is attached before beginning to spray chemicals -- Only the low-pressure

black nozzle will allow chemicals to be drawn through the chemical injector into the water stream.

3) You can apply chemicals with either warm or cold water. Check chemical label. If warm water is specified, start

burner according to instructions provided below.

4) Apply chemicals by squeezing the spray gun trigger. The chemical injector will draw the chemical into the water

stream.

5) Apply chemicals evenly to the cleaning surface. Never use more chemical than is necessary to clean the surface.

6) Allow the chemicals time to react with the dirt before rinsing.

7) Prepare to rinse by changing to a high-pressure nozzle. Changing the nozzle from the low-pressure black nozzle to

a high-pressure nozzle will stop the flow of chemicals into the water stream.

Refer to instructions for selecting and changing the nozzle in Step 1, Connect Hoses, Water Supply, and Nozzle.

8) Rinse with high-pressure spray, either hot or cold, as instructed below.

Turn on Burner (if hot

spray or steam is

desired)

If HOT spray or steam is desired, turn on the burner:

1) First make sure vicinity is free of flammable vapors, dust, gases, or other potentially combustible materials. Operate

only where open flame or torch is permitted.

2) Make sure there is fuel in the burner fuel tank.

CAUTION: Do not run the machine in hot mode without fuel in the burner's fuel tank, or damage can occur.

3) Turn the heat switch ON and adjust the thermostat to the desired temperature.

4) If steam is desired set the thermostat to 212°F or higher and use the yellow steam nozzle.

WARNING:

• NEVER attempt to immediately run or re-light the burner if it does not ignite the first time. Unburned oil or gas

may have accumulated, causing potential explosion or fire hazard.

• Do not attempt to set temperature limit above the preset limit.

• NEVER touch hot burner surfaces and stay clear of burner exhaust. All are extremely hot and will burn you.

• Do not inhale burner exhaust. It contains dangerous carbon monoxide that can kill you.

5) The burner will fire when the trigger is squeezed – follow instructions for spraying.

NOTICE: If burner exhaust is white, adjust burner for peak performance. See the Maintenance & Repair section of this

manual.

6) When the trigger is released, a flow switch automatically turns the burner off. Also, when the temperature setting is

reached, the thermostat automatically turns the burner off.

Operating the Pressure Washer

29 | P a g e

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar ProSHOT Product Support 1-800-969-7073

00417

Safety Latch

NOTICE: The blower fan will continue to run for approximately 90 seconds after thermostat is turned off.

WARNING: It is important that the burner stops firing when the trigger is released. If the burner remains firing,

discontinue use until the pressure washer is serviced. Extremely high temperatures can result in serious injury and

equipment damage.

Begin High Pressure

Spray

High Pressure Spray Procedure

WARNING: High pressure spraying safety

• Keep spray away from people. Never direct discharge stream at or near any person. Do not allow any part of the

body to meet the fluid stream. High-pressure spray can cause serious

skin, eye, or falling injuries, and hot water can burn. Injection injury will

occur if high-pressure spray pierces the skin, injecting liquid under the

skin. Injection injury can result in blood poisoning and/or severe tissue

damage leading to infection, gangrene, and amputation. Seek medical

attention.

• Do not secure trigger open. To reduce risk of injury, do not attempt to

secure the spray gun open by blocking or tying the spray gun in the

open position.

• Prevent slips / loss of balance. High-pressure spray could cause you

to lose balance from kickback forces, and wet surfaces can be slippery.

- Always keep good footing and balance. Do not overreach.

- Do not stand on unstable support when spraying.

- If spraying from an elevated surface, use fall protection because spray gun kickback can propel you off the

elevated surface. When spraying from a ladder or scaffolding, ensure it is firmly anchored from sway or tip-over.

• Be aware of puddles and slippery surfaces. Ensure there is adequate drainage to prevent pooling of water.

• Prevent surface damage & flying debris. Surfaces being sprayed must be strong enough to withstand high-

pressure spray or damage may result. In addition, high-pressure spray will dislodge unsecured objects as well as

surface chips and debris, resulting in hazardous flying objects that can cause personal injury or property damage. Do

not spray brittle surfaces or breakable, fragile, or unsecured objects such as:

• stucco or laminar flagstone

• some painted surfaces

• windows or glass doors (because they may break)

• light fixtures, flowerbeds, mailboxes

• unsecured, lightweight objects

Procedure:

1) Put on one of the high-pressure spray nozzles (always relieve system pressure first and follow instructions for

attaching a nozzle).

2) Clear the cleaning area of all persons. Keep children and pets away.

3) Hold the spray gun firmly with two hands and a sturdy stance: (gun kicks back when triggered).

CAUTION: Spray gun metal gets extremely hot when using the burner and can burn you on contact. Never touch the

metal screw or any metal parts of the spray gun when the heater is being used. Use only designated grip areas.

4) Wash from the bottom to the top, using side-to-side motions. This washes away heavy dirt and allows the detergent

to soak as you work toward the top.

5) Use the width of the spray pattern to wash a wide path. Overlap the spray path for complete coverage.

6) The nozzle should be 12" to 24" from the work, closer for tough areas.

7) Small parts should be washed in a basket, so the pressure does not push them away. Larger, lightweight parts

should be clamped down.

Loading...

Loading...