North Star PA101, PA071, PA131, PA191, PA321 User Manual

...

P/N: 7243683

(Rev. A1 5/24/10)

If you have questions when i n stalling, programming, operating or maintaining this system

CALL TOLL FREE in Canada call

1---800 --- 627 ---3497 1---800 --- 752 ---3273

1

SHIPMENT INSPECTION

Thoroughly check the commercial system for possible shipping damage and/or parts loss. Also inspect and

note any damage to shipping cartons, crating, etc. If damage is present, notify the transportation company.

The manufacturer is not responsible for damage or parts loss in shippment.

Note: Do not mistakenly discard small parts bags when unpacking the system.

All models are shipped in 3 cartons; (1) resin tank, (2) brine tank, and (3) controller. The mineral bed

consists of 1 cubic foot bags of water softening resin, and 17 or 50 pound bags of various grades of

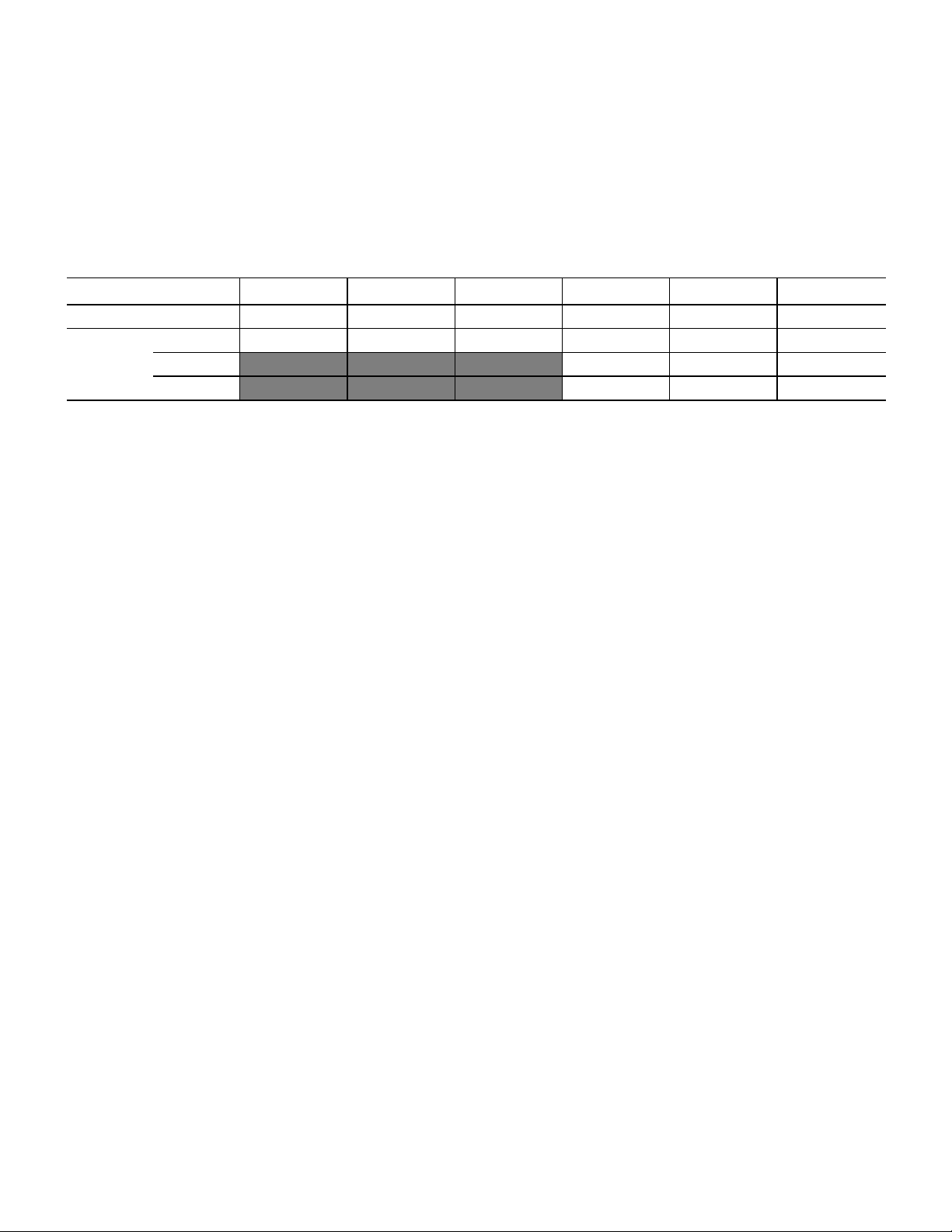

gravel. Refer to the following chart.

MODEL ''

1CU.FT.BAGSOFRESIN 2 3 4 6 8 10

BAGS OF

GRAVEL

(LBS)

fine 1 (17) 2 (17) 2 (17) 1 (50) 1 (50) 1 (50)

medium 1 (50) 1 (50) 1 (50)

coarse 1 (50) 1 (50) 1 (50)

PA071 PA101 PA131 PA191 PA251 PA321

TABLE OF CONTENTS

Page No.

Specifications .......................................................................................... 4--5

Dimensions ............................................................................................ 6

Resin Loading and Assembly ............................................................................ 7-- 8

Planning Installation

InstallationSteps...................................................................................... 8-- 9

Inlet--OutletPlumbingDrawing ......................................................................... 9

NotesandCautions ................................................................................... 10

Connecting Brine Tank ................................................................................. 10

Connect Valve Drain Hose ............................................................................. 11

PressureTesting ...................................................................................... 12

Filling Brine Tank with Water and Salt .................................................................... 12

ProgrammingtheController ............................................................................ 12--15

Sanitizing Procedures ................................................................................ 14--15

Water Softener Controller Setup Information ............................................................. 16

ResettingTime...................................................................................... 17

ControllerFeaturesandOptions ....................................................................... 17--20

FCCInformation..................................................................................... 19

Operation

DemandControllerandWaterMeter ..................................................................... 20

Water Flow Through the Conditioner ..................................................................... 21-- 23

Service Information

Salt, Recommended Type and Refilling .................................................................. 23

Removing a Salt ‘‘Bridge’’ .............................................................................. 23

Cleaning the Nozzle / Venturi ........................................................................... 24

Controller

WiringSchematic ..................................................................................... 25

ErrorCodeTable...................................................................................... 26

Troubleshooting ...................................................................................... 25--28

Repair Parts

BrineTanksandBrineValves ........................................................................... 29--31

ResinTanks/Distributor/Controller ..................................................................... 32--33

ValveAssembly....................................................................................... 34--35

2

SAFETY GUIDES

Follow the installation instructions carefully. Failure to install the commercial system properly voids the

warranty.

Before you begin installation, read this entire manual. Then, obtain all the materials and tools you will need

to make the installation.

Check local plumbing and electrical codes. The installation must conform to them.

Use only lead--free solder and flux for all sweat--solder connections, as required by state and federal codes.

Do not locate this system where freezing temperatures occur. Do not attempt to treat water over 120F. Freez-

ing, or hot water damage voids the warranty.

Avoid installing in direct sunlight. Excessive sun heat may cause distortion or other damage to non--metal-

lic parts.

This system requires a minimum water pressure of 30 psi at the inlet. MAXIMUM ALLOWABLE Inlet water

pressure is 125 psi. If daytime pressure is over 80 psi, nighttime pressure may exceed the maximum. Use

a pressure reducing valve if necessary. (Adding a pressure reducing valve may reduce the flow.)

The system works on 24 volt--60 Hz electrical power only. Be sure to use the included transformer.

This system is not intended to be used for treating water that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

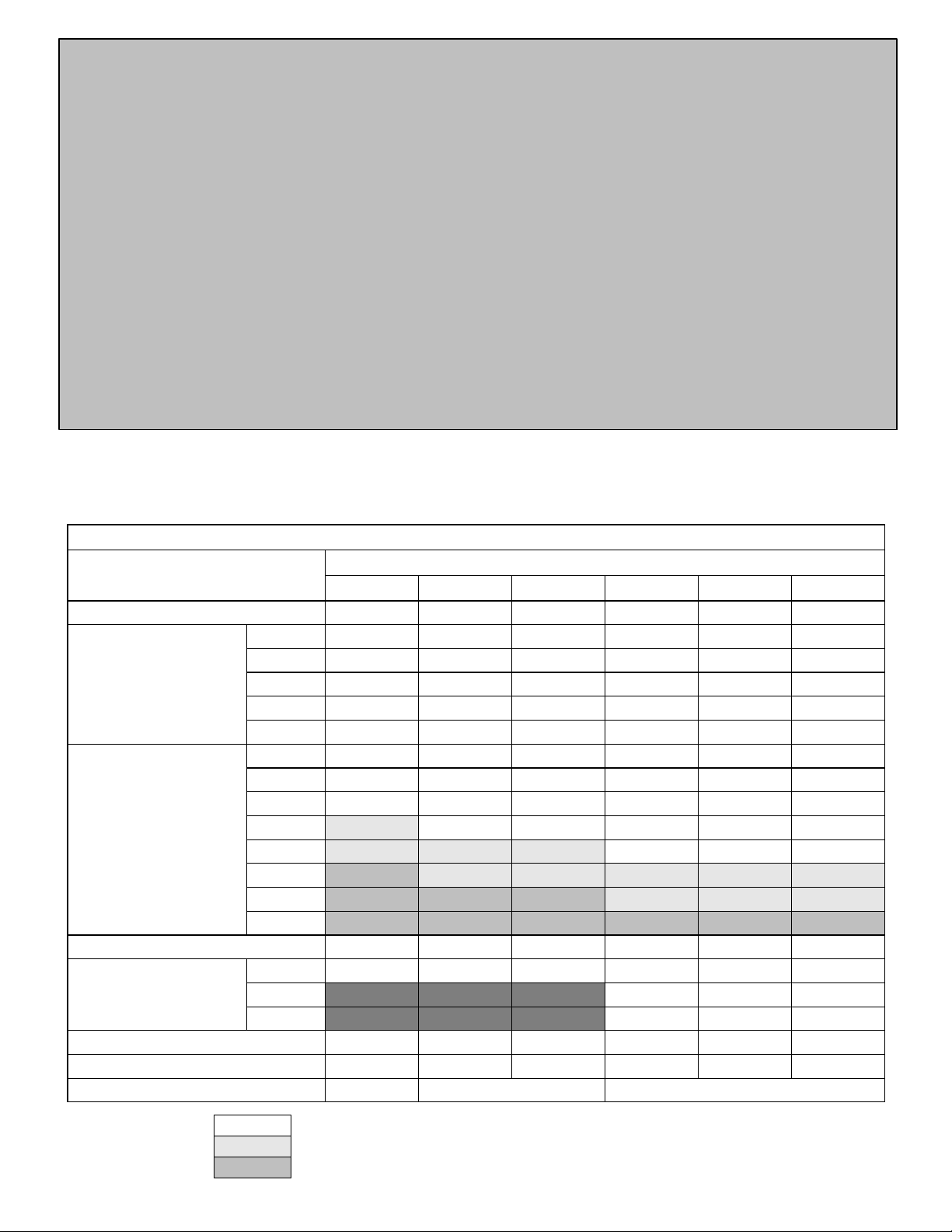

SPECIFICATIONS

EQUIPMENT SPECIFICATIONS

SOFTENERS

MODEL

TANK SIZE (IN) 12” x 54” 17” x 58“ 17” x 58“ 24” x 71” 24” x 71” 24” x 71”

4 LBS. 37,000 54,000 72,000 108,000 144,000 180,000

CAPACITY (GRAINS) @

SALT USAGE PER CU.

FT. RESIN

RECOMMENDED FLOW

RATES ¡

RESIN (CU. FT.) 2 3 4 6 8 10

BAGS OF GRAVEL (LBS)

SALT CAPACITY 340# 1000# 1000# 1500# 1500# 1500#

PIPE SIZE (IN) 1” 1” 1” 1” 1” 1”

BACKWASH/FST. RNS. FLOW RATES 3.0 7.0 10.0

6 LBS. 50,000 72,000 96,000 144,000 192,000 240,000

8 LBS. 61,000 84,000 112,000 168,000 224,000 280,000

10 LBS. 67,000 93,000 124,000 186,000 248,000 310,000

12 LBS. 71,000 99,000 132,000 198,000 264,000 330,000

5GPM 2.9 nP 1.4 nP 1.5 nP 1.3 nP 1.3 nP 1.3 nP

10 GPM 7.3 nP 4.2 nP 4.4 nP 3.4 nP 3.6 nP 3.8 nP

15 GPM 13.0 nP 8.0 nP 8.6 nP 6.9 nP 7.3 nP 7.6 nP

20 GPM 20.0 nP 13.0 nP 14.0 nP 11.6 nP 12.0 nP 12.4 nP

25 GPM 28.6 nP 19.1 nP 20.5 nP 17.9 nP 18.4 nP 19.0 nP

30 GPM 38.3 nP 26.5 nP 28.3 nP 24.0 nP 24.9 nP 25.6 nP

35 GPM N/A 35.0 nP 37.0 nP 32.0 nP 33.0 nP 34.0 nP

40 GPM N/A N/A N/A 41.0 nP 42.2 nP 43.4 nP

FINE 1 (17#) 2 (17#) 2 (17#) 1 (50#) 1 (50#) 1 (50#)

MEDIUM 1 (50#) 1 (50#) 1 (50#)

COURSE 1 (50#) 1 (50#) 1 (50#)

PA071 PA101 PA131 PA191 PA251 PA321

¡ psi pressure loss @

continuous flow rates

intermittent or peak flow rates

flow rates not recommended (hardness leakage, reduced efficiency, etc.)

3

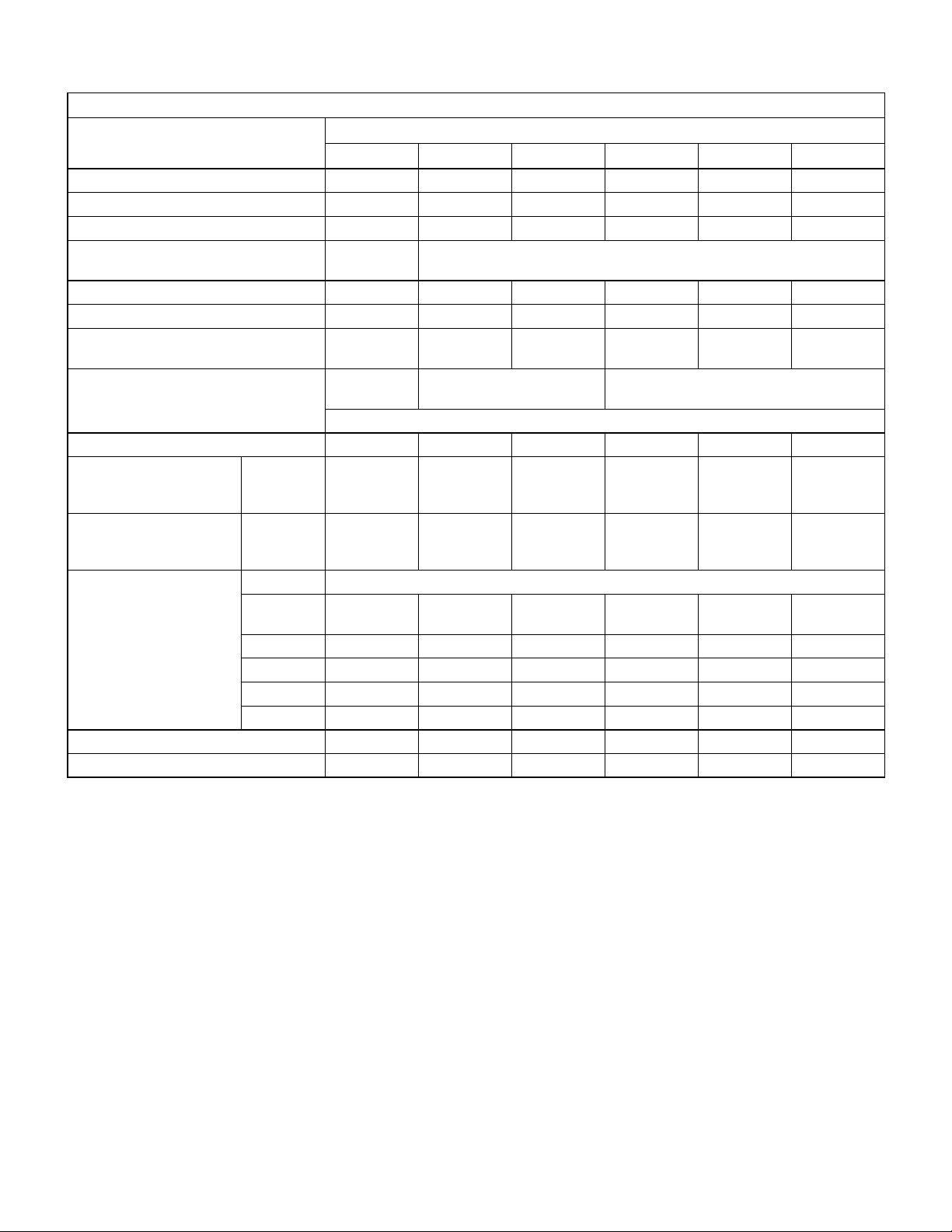

SPECIFICATIONS

PROGRAMMING INFORMATION

MODEL

RESIN QUANTITY (CU. FT.) © 2 3 4 6 8 10

REFILL RATE (GPM) 0.3 0.5 0.5 0.5 0.5 0.5

TURBINE SIZE (IN) 1” 1” 1” 1” 1” 1”

FILL FLOW PLUG LOCATION

BRINE CYCLE FLOW RATE (GPM) .33 .58 .57 1.1 1.1 1.1

BR. RNS. CYCLE FLOW RATE (GPM) .22 .48 .47 .89 .89 .89

BKW. CYCLE & FAST RINSE CYCLE

FLOW RATE (GPM)

BKW. FAST RINSE FLOW PLUG

IDENTIFICATION & LOCATION

FREEBOARD (INCHES) ¢ 19 30 22 36 27 18

LOW

FILL CYCLE TIME (MIN.)

HIGH

BRINING / BR. RINSE

CYCLE TIME (MIN.)

BRINE TIME (MIN) @

SALT DOSE (LBS)

BACKWASH TIME (MIN) 13 15 15 15 15 15

FAST RINSE TIME (MIN) 4 5 5 5 5 5

LOW SALT

HIGH SALT

LBS MINUTES

4, Auto Adj.

or Salt Eff.

6 137 110 150 145 150 175

8 140 105 145 135 145 170

10 135 100 135 130 135 160

12 129 95 130 125 130 150

PA071 PA101 PA131 PA191 PA251 PA321

See key no.

33, page 34

3 7 7 10 10 10

Black --

tan dot (.5)

4.7

31.0

142

112

141 115 160 150 160 180

Brown (.7) Orange (.10)

BEHIND DRAIN ELBOW OF 1” VALVE (SEE PAGE 34)

13.4

50.2

115

95

SOFTENERS

See key no. 16, page 31

17.9

67.0

160

130

16.1

60.3

150

125

21.4

80.4

160

130

26.8

100.5

180

150

© Synthetic high capacity resin

¢ Nominal distance from top of resin bed to top of the tank. This dimension can varyseveral inches, depending on resin moist ure content,

degree of bed expansion or packing, resin tank diameter tolerances, etc.

If you have questions when installing, programming, operating or maintaini ng this system

CALL TOLL FREE in Canada call

1---800 --- 627 ---3497 1---800 --- 752 ---3273

4

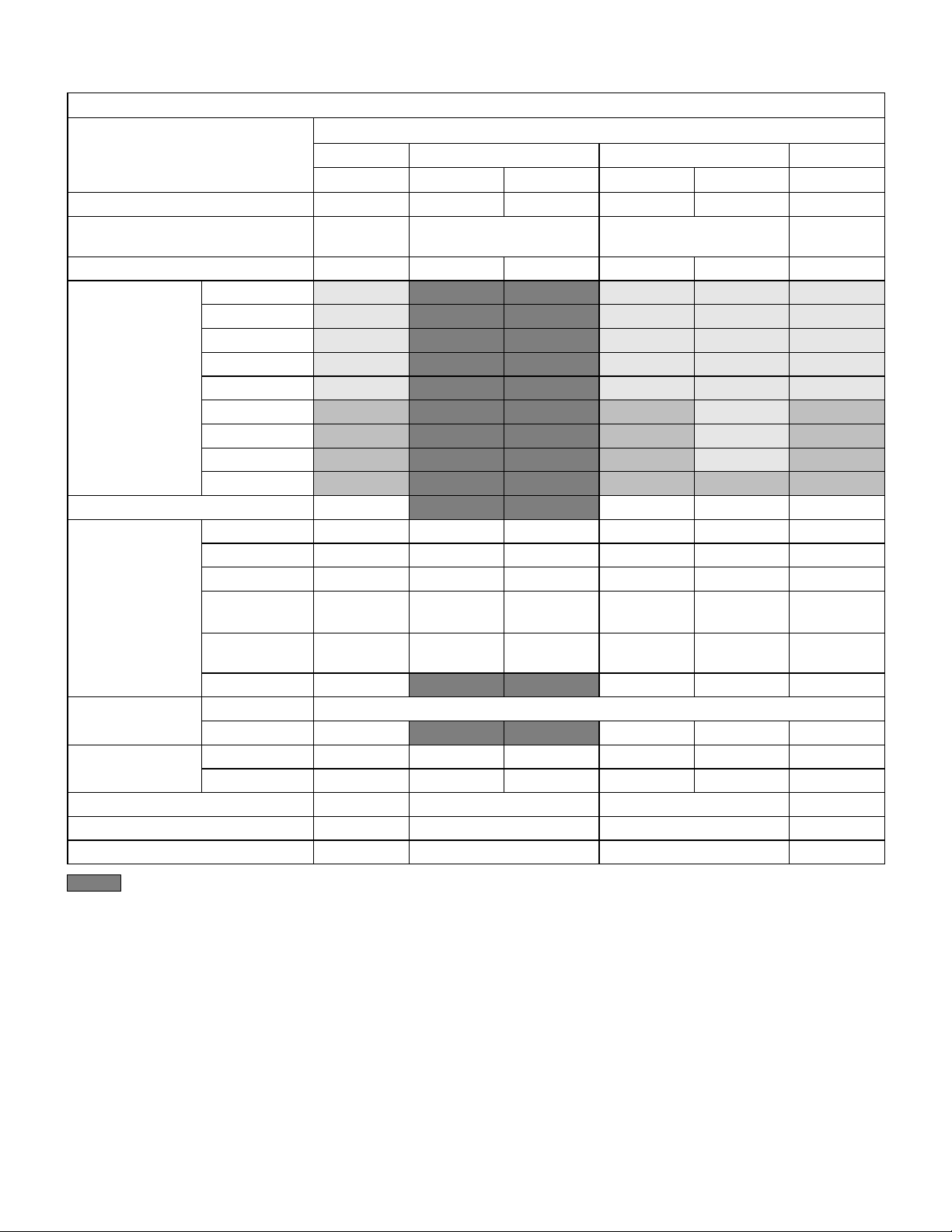

SPECIFICATIONS

EQUIPMENT SPECIFICATIONS

FILTERS

MODEL

TANK SIZE (IN) 12” x 54” 12” x 54” 17” x 58” 12” x 54” 17” x 58” 12” x 54”

CONTAMINANT REMOVAL

SERVICE WATER FLOW RATE (GPM) 4--8 4--8 8--16 4--8 8--16 4--8

2GPM 1.0 nP 1.0 nP 0.6 nP 1.0 nP

4GPM 2.3 nP 2.3 nP 1.1 nP 2.3 nP

6GPM 3.9 nP 3.9 nP 2.2 nP 3.9 nP

RECOMMENDED

FLOW RATES

(GPM @ PSI)

MINERAL (CU. FT.) 2 2 4 2

BAGS OF

MINERAL (LBS)

*Use only partial

bags of supplied

mineral

BKW/FR FLOW

RATES

PIPE SIZE (IN)

WATER PRESSURE LIMITS (PSI) 30 -- 125 30 -- 125 30 -- 125 30 -- 125

MAXIMUM WATER TEMPERATURE 35 -- 100 35 -- 100 35 -- 100 35 -- 100

ELECTRICAL RATING 24v 60Hz 24v 60Hz 24v 60Hz 24v 60Hz

8GPM 5.7 nP 5.7 nP 3.3 nP 5.7 nP

10 GPM 7.9 nP 7.9 nP 4.6 nP 7.9 nP

12 GPM N/A N/A 5.9 nP N/A

14 GPM N/A N/A 7.4 nP N/A

16 GPM N/A N/A 9.7 nP N/A

18 GPM N/A N/A 13.7 N/A

ANTHRACITE 2 (65#)* -- -- -- -- 2 (61#)*

FILTER SAND 1 (52#) -- -- -- -- --

GARNET 1 (33#)* -- -- -- -- 1 (33#)*

ACTIVATED

CARBON

MANGANESE

GREENSAND

GRAVEL 2 (17#) 2 (17#) 1 (50#) 1 (17#) 2 (34#) 1 (17#)

LOCATION Key #10, page 34

(GAL/MIN) 12 12 15 5 5 12

FA 1” 1” 1” 1” 1” 1”

FB 1--1/2” 1--1/2” 1--1/2” 1--1/2” 1--1/2” 1--1/2”

MULTI-MEDIA ALL PURPOSE CARBON GREENSAND

PA121 P A121 P A171 P A121 P A171 P A121

based on

water analysis

-- -- -- 2 (58#) 4 (116#) --

-- -- -- -- -- 2 (170#)

based on water analysis based on water analysis

maximum

iron 20 ppm

dependant on media

5

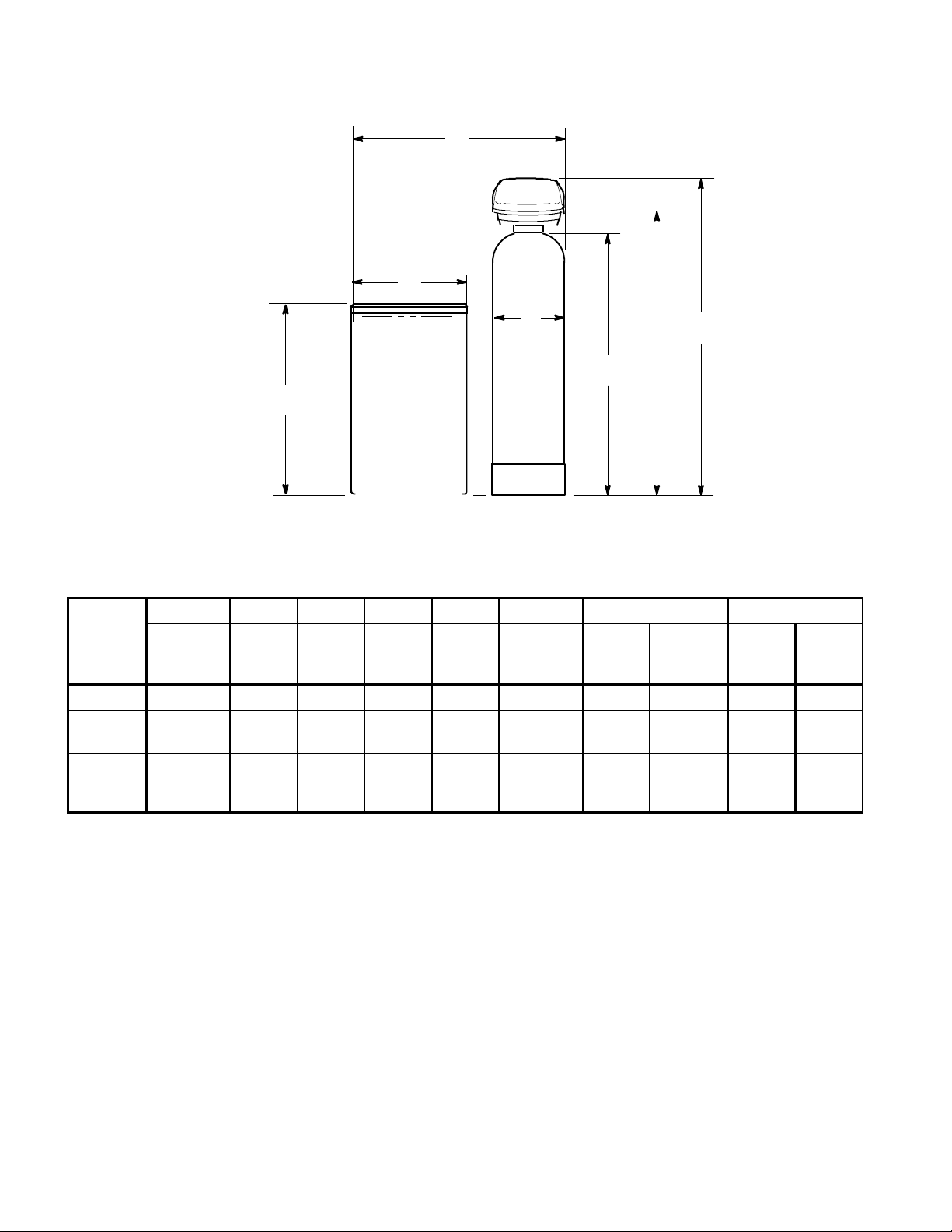

DIMENSIONS

minimum floor space required

G

F

A

B

E

ROUND

BRINE TANK

A B C D E F G INLET--OUTLET

MODEL

PA071 12.3” 55” 58” 63.75” 39” 17” 35.3” 70” 1” 3.8”

PA101

PA131

PA191

PA251

PA321

Resin

Ta n k

Diameter

17.6” 59.5” 62.5” 68.25” 50” 24” 48” 102” 1” 3.8”

24” 76” 79.8” 85.5” 51” 30” 60” 90” 1” 3.8”

Resin

Ta n k

Height

Inlet-Outlet

Height

Overall

Height

Brine

Ta n k

Height

Brine

Ta n k

Diameter

Single

D

C

Multiple¡Pipe

Size ©

Pipe

Center

lines

¡ Includes 6” between tanks.

© Sweat copper (1”) fittings supplied. Optional 1–1/2” fittings available, part no. 7129211, package of 2.

6

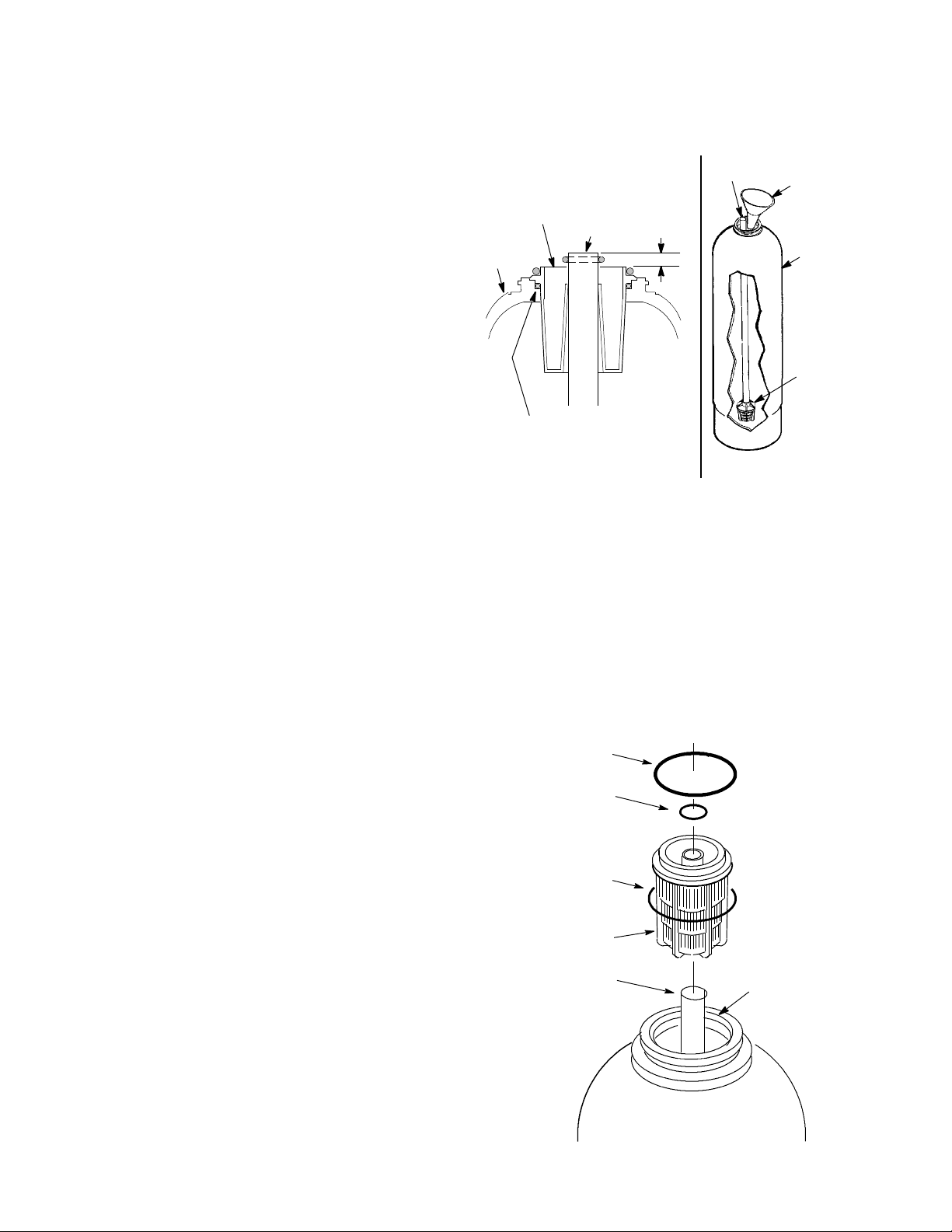

RESIN LOADING AND ASSEMBLY

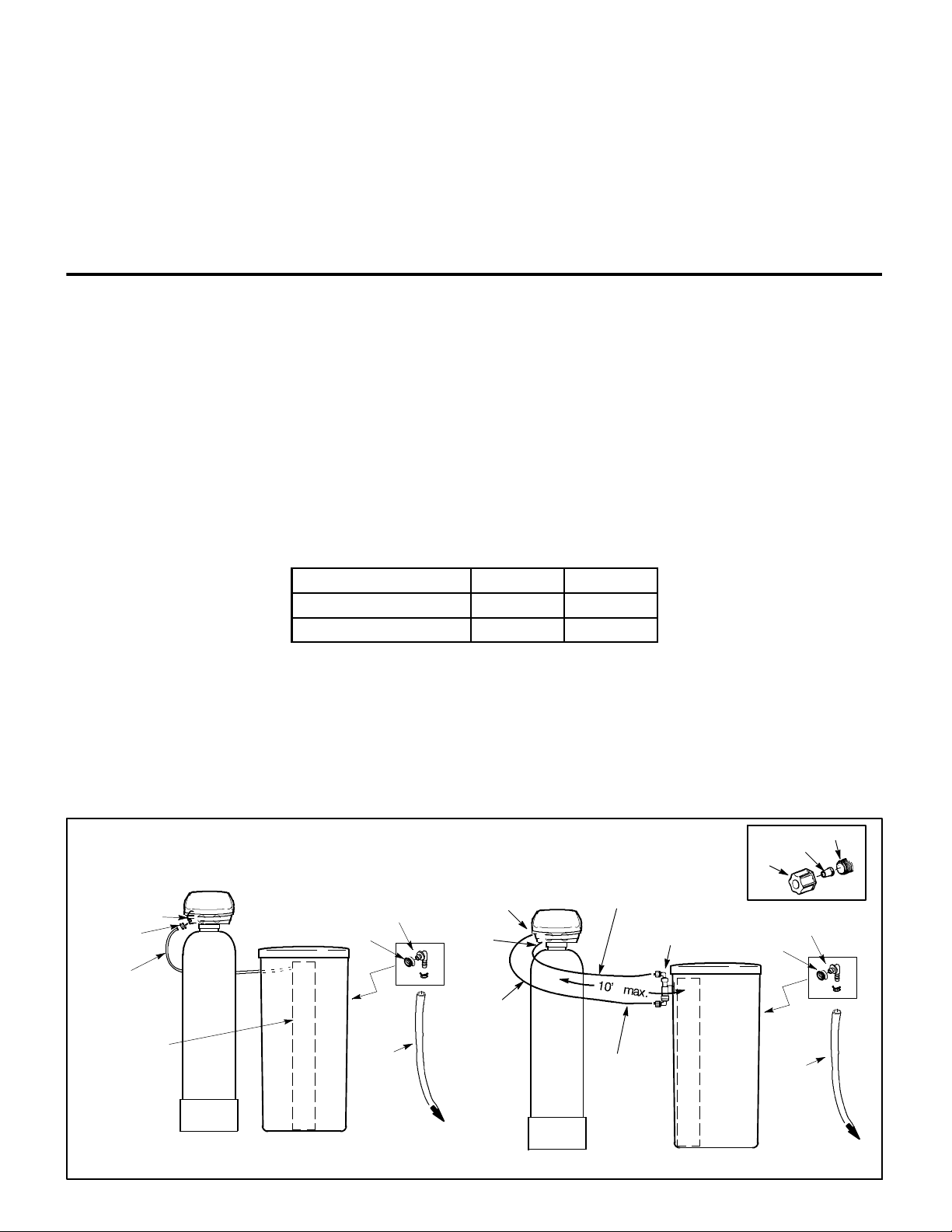

1. Move the resin tank into installation location (see

page 8). Set it on a flat, level surface. If a twin installation, keep tanks separated for ease of service.

2. Remove the shipping cap, top distributor and o--rings. On all models,placethebottom distributor into

the resin tank. Check the distributor length as shown

in Figure 1 and adjust if needed. Center the distributor

in the tank.

3. With a pail or hose, fill the tank with 1 to 2 feet of

water. The water acts as a cushion to protect the bottom distributor while filling the tank with gravel and

resin.

4. Plug the end of the distributor tube with a clean

rag, to keep gravel and resin out.

5. Using a larger neck funnel, add the specified (see

pages 2 and 4) amount of gravel. Be sure the dis-

tributor remains centered.

Note: When coarse, mediumand finegravels are spe-

cified, add in that order.

6. Add the specified amount of resin, using water

sparingly to speed flow through the funnel.

7. Flush the tank opening with water to clean resin

beads from the top of the tank. Then, remove the rag

from the distributor tube.

8. Finish filling the tank withwater, up to the top of the

tank.

Important: Be sure to fill with water. This will eliminate air space and prevent excessive air ---head pressure when the water conditioner is pressurized.

9. Install the o ---ring seals and top distributor exactly

as shown in Figure 2. If the o--- rings need lubrication,

use a high quality silicone grease.

continued

Figure 1

clean

rag

top edge of

top distributor

resin

tank

distributor tube

0” to 1/2”

P l a c e t h e 2 --- 3/ 4 ” x 3” o --ring under the top distributorandslidetopdistributor assembly over distributor tube.

Note: Resin tank height can vary somewhat

within manufacturing tolerance. So the bot-

tom distributor riser pipe has proper clearance with inside valve porting, check for

the correct length as shown above. Cut the

riser if needed to adjust the length. Be sure to

remove burrs and sharp edges.

Figure 2

o --- r i n g s e a l

2---7/8” x 3- --1/4”

o---ring seal

13/16” x 1---1/16”

o---ring seal

2---3/4” x 3”

top distributor

bottom distributor

Be sure o---ring

sealing surfaces

are clean.

funnel

resin tank

bottom

distributor

(centered)

7

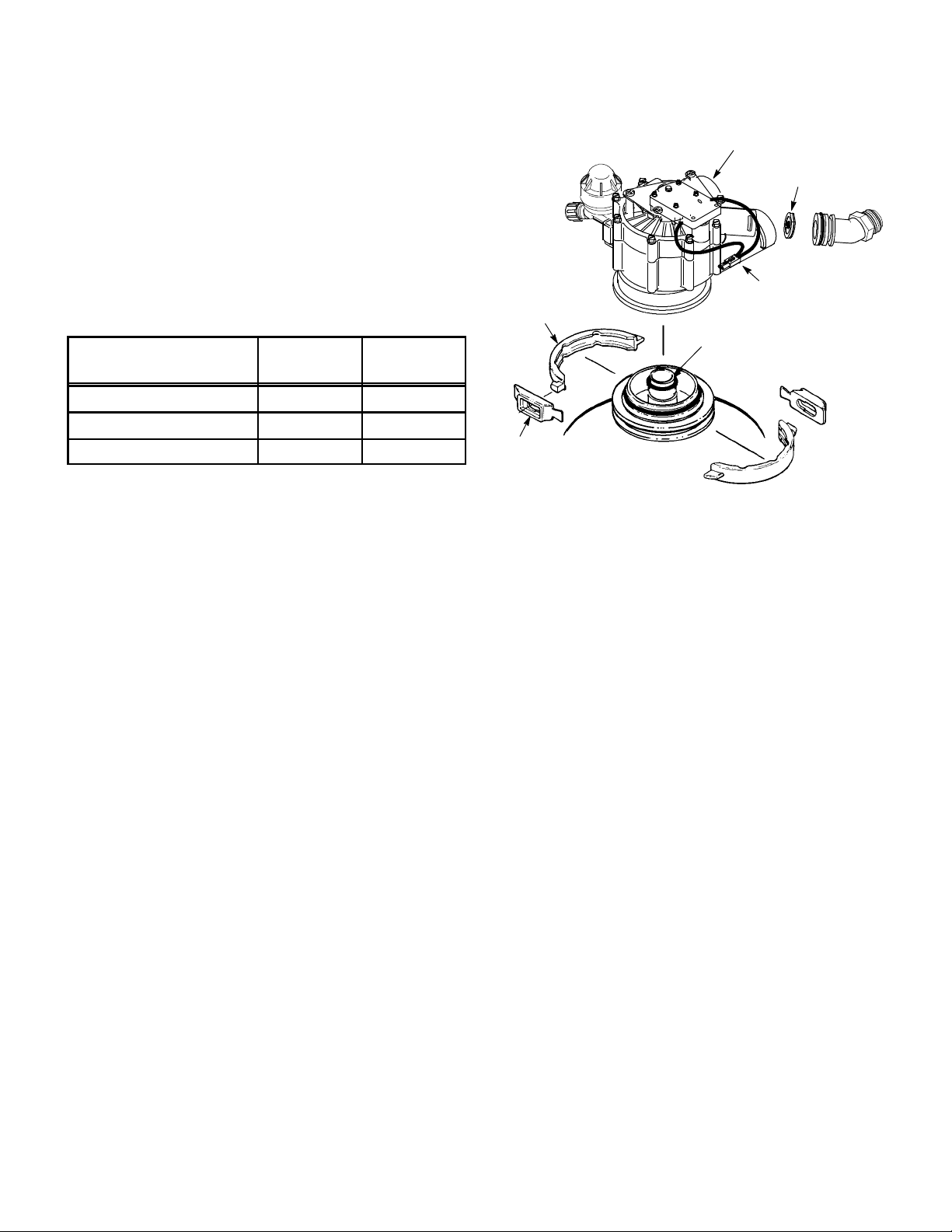

RESIN LOADING AND ASSEMBLY

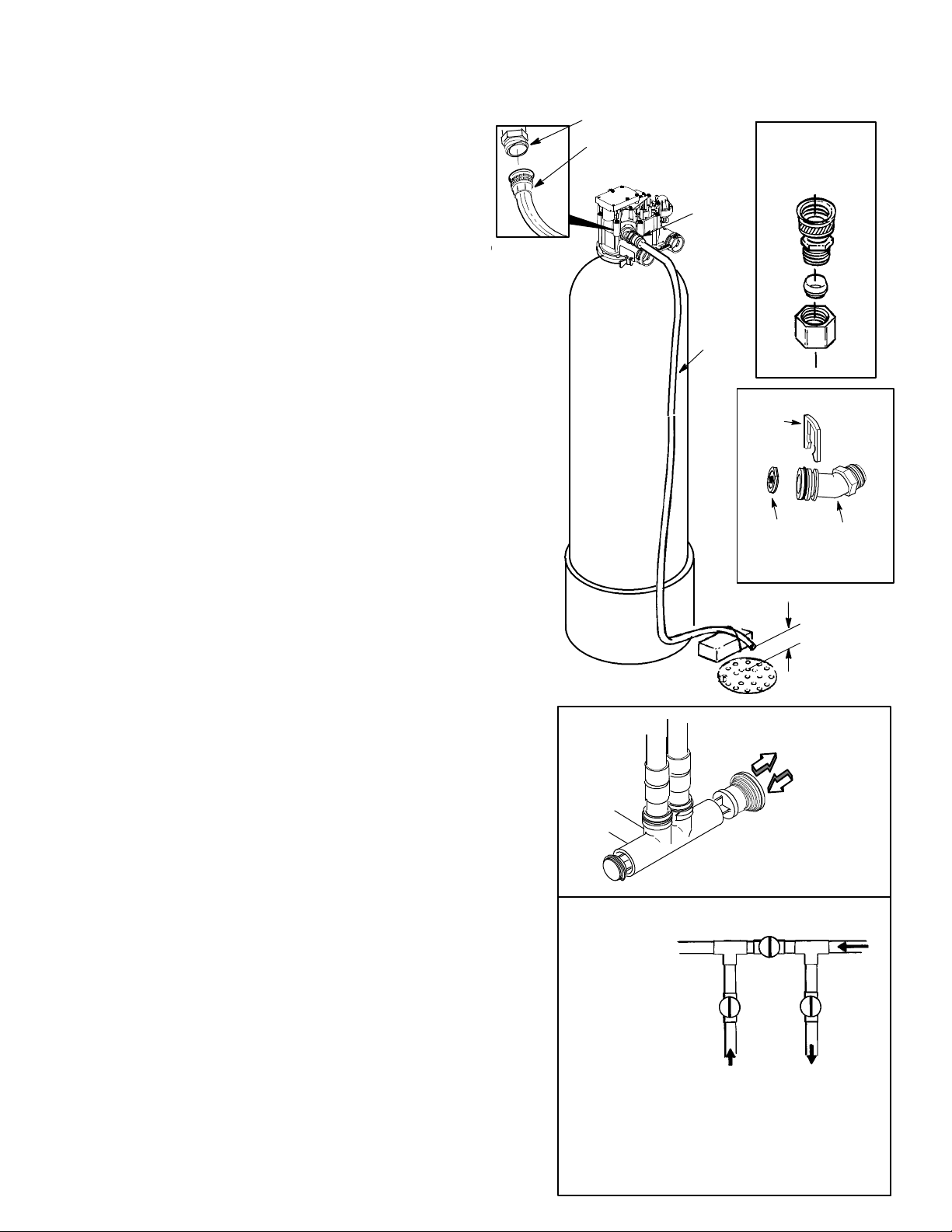

10. Lower the valve assembly onto the resin tank,

centering over the bottom distributor tube. Push

downward, against the o---ring, and install the clamp

sections, securing with the retainers.

Important: Check the valve outlet to be sure the turbine and turbine support are securely in place.

11. Verify that the proper backwash flow washer is

installed. If not, replace with correct flow washer from

parts bag.

Model

BW Flow

Washer

ID Mark

PA071 3gpm tan dot

PA 101 & PA131 7gpm brown

PA 191, P A251 & PA321 10 gpm orange

clamp

section (2)

clamp

retainer (2)

valve

outlet

Valve Assembly

bottom

distributor tube

Figure 3

BW flow

waxher

PLANS FOR LOCATION AND INSTALLATION OF SYSTEM

WATER SUPPLY: The system requires a potable water supply that will provide a continuous flow to meet regeneration flow specifications. A minimum pressure of 30 psi is required at the conditioner inlet.

‘‘FULL LINE’’ (both hot and cold water) WATER CONDITIONING: Connect the system, to the water supply

pipe, immediately after (downstream) the municipal supply water meter or well supply pressure tank.

CONDITIONING HOT WATER ONLY: Connect the system, to the water supply pipe, before (upstream) the

water heater.

CAUTIONS: (1) Do not install the conditioner after,ordownstreamfromthe water heater. Hot water will

damage inner parts of the system, and may cause the loss of the water softening resin bed. (2) To reduce

the risk of hot water flowing backwards, into the conditioner, piping between the conditioner and water heater should be as long as possible.

DRAIN: A drain is needed nearby the conditioner, capable of carrying away backwash water at the rate of flow

listed in the specifications. A floor drain is preferred. Other approved drain points are acceptable, if they do

not cause a back---pressure on the conditioner drain hose or pipe.

ELECTRICAL: The system works on 24 volts only. A transformer is included to reduce 120V--- 60Hz electrical

power. An approved, grounded outlet is needed within 10’ of the conditioner controller for the transformer. The

conditioner includes a 10’ power cable to connect between the transformer and the controller. The controller

may be mounted in any convenient location. You may either fasten to a wall using the mounting holes molded

in the controller case, or wrap a chain around the tank and connected to the mounting holes on controller case.

SPACE REQUIREMENTS: Be sure to allow sufficient area around the resin and brine tanks for refilling with

salt and other service. Minimum floor space and other dimensions are shown on page 6.

8

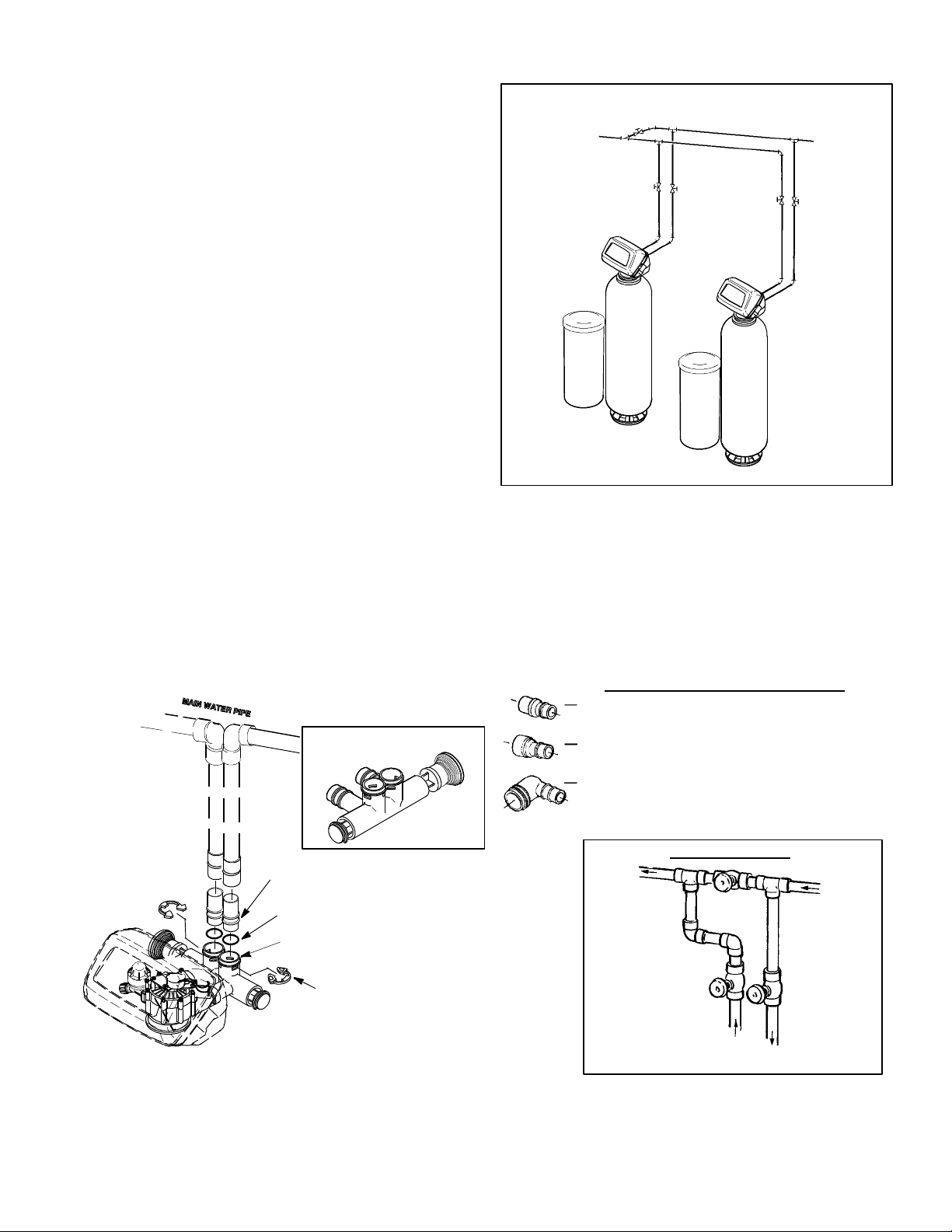

MATERIALS YOU MAY NEED

Use the drawing at the right as a guide for your installation. The drawing shows typical connection using

fittings included with the system, and with optional

SOFT

WATER

Figure 4

HARD

WATER

items available.

J Be sure to install a 3 --- valve bypass system, or use

the optional bypass valve, #7195408.Bypass

valves allow you to turn off water to the system, for

servicing, while having full--- line bypass to the establishment.

J A 5/8” minimum inside diameter hose or pipe is re-

quired for the valve drain (see page 11). The drain fitting has standard garden hose threads, and hose

barbs. Adaptors are available from most hardware

stores to convert the fitting to accept rigid pipe. A garden hose is also needed for the drain on brine tanks.

J For in and out pipes to the conditioner, use copper,

CPVC plastic or threaded pipe and fittings. Avoid joining copper and galvanized together as corrosion will

occur rapidly. Included inlet and outlet adaptors are

1” male copper. Optional fittings available are shown in Figure 5.

J Multiple Tank Installations: To promote equal water flow, inlet and outlet plumbing configuration to each

valve should be as identical as possible. Use the same fittings and pipe lengths for each connection.

TYPICAL INLET-- OUTLET PLUMBING CONNECTIONS

Figure 5

SOFT

WATER

*included with conditioner

HARD

WATER

BYPASS VALVE #7195408

1” copper tube (2) *

o--ring seal (2) *

Bypass Valve

clip (4) *

OPTIONAL INLET/OUTLET FITTINGS

#7104546 CPVC Nipple --- Use in place of

included copper inlet and outlet tubes.

#7129211 Adaptor Fitting, 1–1/2” (2) -- - Use in

place of included copper inlet and outlet tubes.

#7120259 Elbow --- Extends inlet and/or outlet in

any 90° direction.

SOFT

WATER

3 --- V A LV E BY P A S S

outlet valve

bypass

valve

FROM

outlet

HARD

WATER

inlet valve

TO inlet

9

INSTALLATION STEPS

PIPING ASSEMBLY NOTES AND CAUTIONS:

S BE SURE to close the main water supply valve before beginning.

S BE SURE to plumb so hard water flows to the valve inlet fitting.

S CAUTION: When soldering, make sub--- assemblies as needed to prevent soldering heat damage to the

conditioner valve or bypass valve. Be sure soldered piping has cooled before connecting to the conditioner.

S UseTeflontapeorpipejointcompoundonexternalpipethreads.

S Lubricate o---ring seals with high quality silicone grease.

1. Looking at the illustrations on page 9, and observing the notes above, run piping from the main water sup-

ply pipe to the valve inlet. Then, run return piping from the valve outlet to the supply pipe. Be sure to include

a3---valvebypass,oruseoneoftheoptionalbypassvalves.

Note: When working with soldered copper, be sure to observe the caution above to avoid damage to non ---me-

tallic parts.

Important: Support in and out piping in an acceptable manner, to prevent weight stress on the conditioner

valve.

2. Move the brine tank assembly into position nearby the resin tank. Enough tubing is included to allow locating

the tank up to 10 ’ away from the resin tank (Figure 6).

3a. Connect Tubing --- Model PA071: Thread the brine tube through the hole of the brine tank sidewall. Fasten

tubing to the nozzle assembly (Figure 6) using the compression nut--- ferrule, tightening securely, by hand only.

3b. Connect Tubing --- All other models: Verify that the proper nozzle & venturi are installed in nozzle assembly.

If not, replace with correct pair.

Model Venturi Nozzle

PA101, PA131 Almond White

PA191, PA251 & PA321 Gray Gray

¡ Install two elbows (in separate parts bag with the brine tank) into the top and botto m of the nozzle assembly (Figure 6).

© Using tubing inserts and compression nuts, fasten lengths of tubing to the two elbows.

¢ Connect tubing from the bottom of thenozzle assembly, to thetop adaptor on thefront of thecondition-

er valve assembly. Use a tubing insert and compression nut (tighten securely) as shown in the inset drawing.

£ Do the same to connect tubing from the top of the nozzle, to the bottom check valve fitting on the front

of the conditioner valve assembly.

continued

insert

adaptor

drain

hose

fitting

hose

nozzle/venturi

nut--ferrule

brine

valve tubing

brinewell

grommet

overflow

hose

adaptor

drain

hose

Figure 6

adaptor

check

valve

pressure

brine return

nozzle

assembly

elbow (2)

nut

grommet

overflow

BRINE TANK

to floor

drain

10

BRINE TANK

to floor

drain

INSTALLATION STEPS

4. Push theelbow fitting, with garden hose threads on

one end, into the grommet in the sidewall of a round

brine tank. Attach a length of drain hose to the fitting

as follows.

Attachalengthof5/8”I.D.gardenhosetotheelbow

and run to the floor drain.

Important: This gravity drain is a safeguard to carry

away excess water if the brine tank should overfill.

5. Install Valve Drain Hose: The drain fitting accepts

a 5/8” I.D. minimum drain hose, either garden hose

connection, or hose onto a barb fitting (Figure 7). To

use the garden hose threads, cut the barbed section

of the elbow off with a hack---saw.

Attach the drain hose to the drain elbow. If using the

barbs, install an automotive type clamp to secure the

hose to the elbow. Place the other end of the hose at

the drain point, and observe the following.

S Fastenthehoseinplaceat the drain point. Pres-

surized water, exiting the hose during regenerations, could cause it to ‘‘whip’’.

S Provide an air ---gap of at least 1–1/2” between the

end of the hose and the floor drain cover . The air --gap prevents a possible back siphon if sewer water should backup.

S Forlongerorraiseddrainhoseruns,a3/4”dia.

hose (minimum) is recommended to reduce

b a c k --- pr e s s ur e . Ba c k --- p r e s s u r e ca n r e s t r i c t fl o w

through the nozzle/venturi, affecting brine draw.

S If codes require a rigid drain pipe, purchase a gar-

den hose thread by compression fitting, available

from most hardware stores.

drain fitting

valve drain

hose

single

Bypass

Valve

drain

elbow

valve

drain

hose

Figure 7

garden hose x

compression

adaptor (typical)

clip

flow

plug

drain

elbow

FLOOR

DRAIN

Figure 8

11

3 --- V a l v e B y p a s s

D for SERVICE:

--- O p e n the inlet and outlet valves.

--- C lo s e the bypass valve.

D for BYPAS S:

--- C lo s e the inlet and outlet valves.

--- O p e n the bypass valve.

outlet

valve

PULL OUT

for service

PUSH IN

for bypa ss

bypass

valve

inlet

valve

Loading...

Loading...