North Star NSWHCW Installation Manual

Designed, Engineered &

Assembled in the U.S.A.

Model NSWHCW

How to install, operate

and maintain your Central

Water Filtration System

If you have any questions or concerns when

installing, operating or maintaining your central

water filtration system, call our toll free number:

1-800-972-0135

or visit www.northstarwater.com

When you call, please be prepared to provide

the model and serial number of your product,

located on the rating decal on back of the cover.

System tested and certified by NSF International

against NSF/ANSI Standard 42

for the reduction of chlorine taste and odor,

and certified to NSF/ANSI Standard 372.

System tested and certified by the Water Quality

Association against CSA B483.1.

Manufactured and warranted by

North Star Water Treatment Systems

1890 Woodlane Drive

Woodbury, MN 55125

Installation and Operation Manual

7360671 (Rev. F 3/8/19)

TABLE OF CONTENTS

Page

pecifications & Performance Claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

S

Central Water Filtration System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Inspect Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ow a Central Water Filtration System Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

H

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

nstallation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

I

Programming the Central Water Filtration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Start Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Customizing Features / Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Care of Your Central Water Filtration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-19

Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-3/8”

IN – OUT

27-1/2”

Dimensions

10-1/8”

IN

13-7/16”

OUT

TOP VIEW

33-3/4”

SIDE VIEW

2

FRONT VIEW

FIG. 1

Specifications & Performance Claims

This system has been tested according to NSF/ANSI 42 for the reduction of chlorine taste and odor. The concentration of the indicated substance in water entering the system was reduced to a concentration less than or equal to the

permissible limit for water leaving the system, as specified in NSF/ANSI 42.

While testing was performed under standard laboratory conditions, actual performance of the system may vary

ased on local water conditions.

b

SPECIFICATIONS

Model NSWHCW

Rated Service Flow Rate 6.0 gpm (22.7 L/min.)

Pressure Drop at Rated Service Flow

Pressure Drop at 9.6 gpm

Water Pressure Limits (minimum / maximum)

Water Temperature Limits (minimum / maximum) 40 - 100 °F (5 - 38 °C)

Drain Flow Rate 3.4 gpm

0.50 ppm

0.75 ppm

Rated Capacity at Chlorine Concentration** of: 1.0 ppm

1.5 ppm

2.0 ppm

Sediment Removal with 30-40 micron particle size 95% or more

Sediment Removal with 40-50 micron particle size 99% or more

10 psig

15 psig

(206.8 - 861.8 kPa)

* (68.9 kPa)

* (103.4 kPa)

30 - 125 psi

2,280,000 gal.*

1,520,000 gal.*

1,140,000 gal.*

760,000 gal.*

570,000 gal.*

* From independent laboratory test data.

** Typical residential chlorine concentration is 0.5 to 1.0 ppm.

This system conforms to NSF/ANSI Standard 42 for the specific performance claims

as verified and substantiated by test data.

PERFORMANCE CLAIMS

Substance

Chlorine 2.0 ±10% mg/L 50% 82.8%

Influent

Challenge Level

Reduction

Requirement

Average Percent

Removal

Questions? Call Toll Free 1-800-972-0135 or visit www.northstarwater.com

When you call, please be prepared to provide the model and serial number,

located on the rating decal on back of the cover.

3

Central Water Filtration System Safety

Your safety and the safety of others are very important.

e have provided many safety messages in this manual and on your appliance. Always read and obey all safety

W

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING”

These words mean:

You can be killed or seriously injured if you don’t

immediately

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

In the state of Massachusetts: The Commonwealth of Massachusetts plumbing code 248-CMR shall

be adhered to. A licensed plumber shall be used for this installation.

follow instructions.

Before You Start

= Do not turn the Central Water Filtration System upside down, drop, or set on sharp protrusions.

= The Central Water Filtration System has a maximum allowable inlet water pressure of 125 psi and a minimum of

30 psi. If daytime pressure is over 80 psi, nighttime pressure may exceed the maximum. Use a pressure reducing valve if necessary (Adding a pressure reducing valve may reduce the flow.). If your home is equipped with a

back flow preventer, an expansion tank must be installed in accordance with local codes and laws.

= The Central Water Filtration System works on 24V DC electrical power, supplied by a direct plug-in power supply

(included). Be sure to use the included power supply and plug it into a nominal 120V, 60 Hz household outlet

that is in a dry location only, grounded and properly protected by an overcurrent device such as a circuit breaker

or fuse.

= Do not use the Central Water Filtration System with water that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

European Directive 2002/96/EC requires all electrical and electronic equipment to be disposed of accord-

ing to Waste Electrical and Electronic Equipment (WEEE) requirements. This directive or similar laws

are in place nationally and can vary from region to region. Please refer to your state and local laws for

proper disposal of this equipment.

4

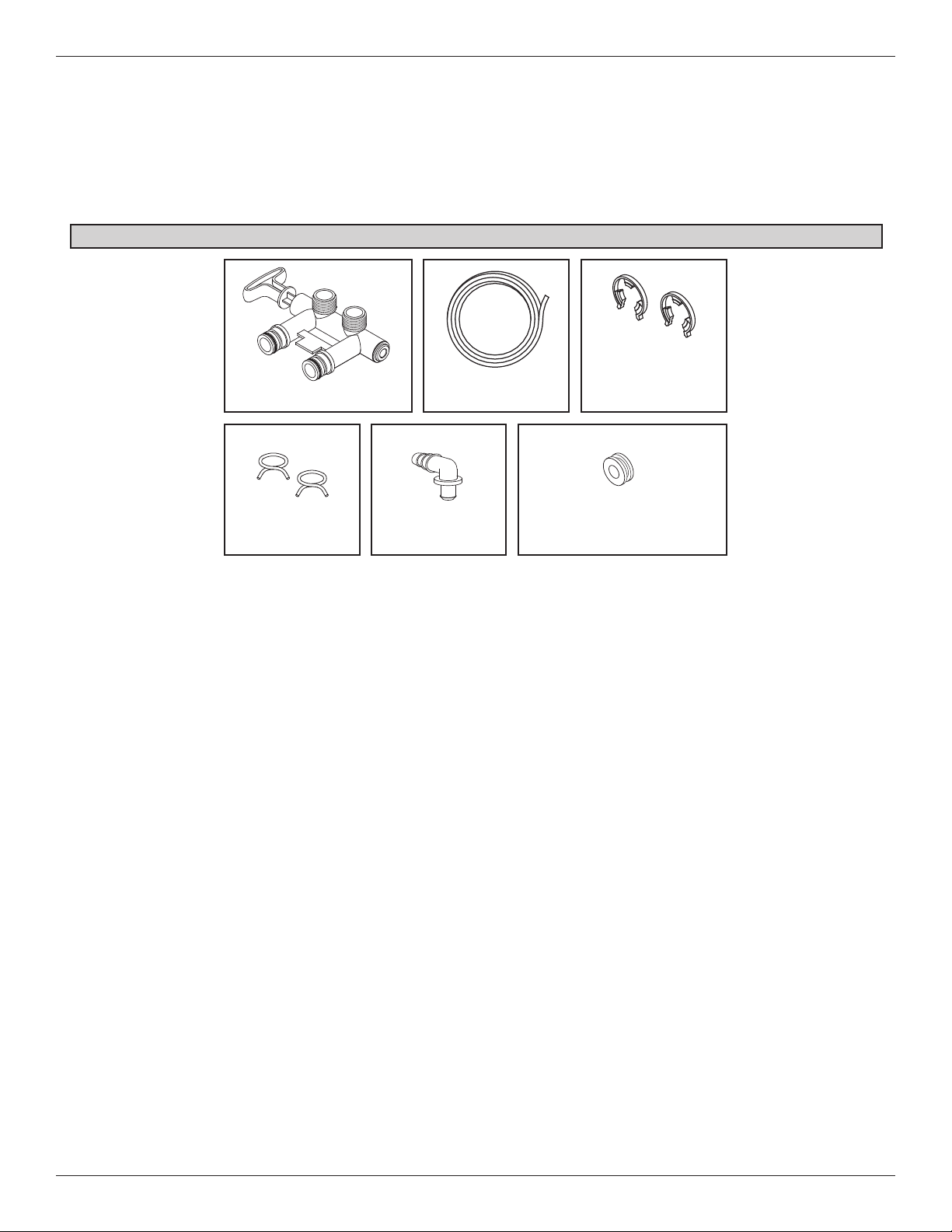

Inspect Shipment

The parts required to assemble and install the Central

Water Filtration System are included with the unit.

Thoroughly check the Central Water Filtration System

for possible shipping damage and parts loss. Also

inspect and note any damage to the shipping carton.

Packing List

Bypass Valve

Hose Clamps

Adaptor Elbow

Remove and discard (or recycle) all packing materials.

To avoid loss of small parts, we suggest you keep the

small parts in the parts bag until you are ready to use

them.

Clips

(shipped installed on

Drain Hose

North Star Water Softeners)

the softener’s valve)

Grommet (used for

FIG. 2

How a Central Water Filtration System Works

NORMAL OPERATION

During normal operation water enters the Central

Water Filtration System and flows through several filtration processes where tastes, odors and sediment

are reduced.

CLEAN RINSE CYCLE

A Clean Rinse cycle will automatically be initiated

based on how the controller has been programmed.

The Clean Rinse cycle lifts and expands the media

bed to rejuvenate the media and then repacks the bed

for continued use. During the Clean Rinse cycle, dirt,

sediment, etc. are flushed from the Central Water

Filtration System down the drain.

APPLICATIONS FOR A CENTRAL WATER

FILTRATION SYSTEM

= Do not use the Central Water Filtration System with

water that is microbiologically unsafe or of unknown

quality without adequate disinfection before or after

the system.

= The Central Water Filtration System may not be an

effective treatment method for water sources with a

hydrogen sulfide problem (rotten egg odor or taste)

If your water has hydrogen sulfide, contact a water

treatment expert or call 1-800-972-0135.

= The Central Water Filtration System will not remove

iron and is not intended to replace iron treatment

equipment.

= Although the Central Water Filtration System has

sediment filter capabilities, additional sediment filtration may be needed in problem water applications.

5

Installation Requirements

LOCATION REQUIREMENTS

Consider the following when selecting an installation

location for the Central Water Filtration System.

= Do not operate the Central Water Filtration System

where freezing temperatures occur. Do not attempt

to treat water over 100ºF (38ºC). Freezing temperatures or hot water damage voids the warranty.

= To condition all water in the home, install the

Central Water Filtration System close to the water

supply inlet, and before all other plumbing connections, except outside water pipes.

= For a home with municipal water supply, install the

Central Water Filtration System between the home’s

incoming water supply and the water softener, if one

is being used (See Figure 3A). If the home has well

water, reverse the order of the Central Water Filtra tion System and the water softener (See Figure 3B).

= A nearby drain is needed to carry away Clean

Rinse discharge water. Use a floor drain, laundry

THE PROPER ORDER TO INSTALL WATER TREATMENT EQUIPMENT

Untreated Water to

Cold Water

to House

Hot Water

to House

Outside Faucets

tub, sump, standpipe, or other options (check your

local codes). See "Air Gap Requirements" and

Valve Drain Requirements" sections. If a drain is

"

not available, it is still possible to operate the

Central Water Filtration System in a manual Clean

Rinse mode. See “Operating in Manual Clean

Rinse Mode.” The automatic Clean Rinse must be

disabled if the Central Water Filtration System will

not be connected to a drain (See Page 7).

= The Central Water Filtration System works on 24V

DC electrical power, supplied by a direct plug-in

power supply (included). Provide a 120V, 60 Hz

electrical outlet in accordance with NEC and local

codes.

= Do not install the Central Water Filtration System on

a hot water line (See Figures 3A & 3B, below).

= Avoid installing in direct sunlight. Excessive sun

heat may cause distortion or other damage to nonmetallic parts.

City Water Supply

Optional

Sediment

Filter

Cold Water

to House

Hot Water

to House

Water

Heater

Water

Heater

Untreated Water to

Outside Faucets

Central

Water

Filtration

System

Water

Softener

Water

Softener

Central

Water

Filtration

System

Optional

Sediment

Filter

6

Pressure

Tank

Well Water Supply

Well

Pump

FIG. 3A

OR

FIG. 3B

Installation Requirements

PLUMBING CODES

All plumbing must be completed in accordance with

national, state and local plumbing codes.

n the state of Massachusetts: The Commonwealth

I

of Massachusetts plumbing code 248-CMR shall

be adhered to. A licensed plumber shall be used

for this installation.

AIR GAP REQUIREMENTS

A drain is needed for Clean Rinse discharge water. A

floor drain, close to the Central Water Filtration

System, is preferred. A laundry tub, standpipe, etc.

are other drain options. Secure valve drain hose in

place. Leave an air gap of 1-1/2” between the end of

the hose and the drain. This gap is needed to prevent

backflow of sewer water into the Central Water

Filtration System . Do not put the end of the drain

hose into the drain.

CONNECTING VALVE TO DRAIN

VALVE DRAIN REQUIREMENTS

Using the flexible drain hose (included), measure and

cut to the length needed. Flexible drain hose is not

allowed in all localities (check your plumbing codes). If

local codes do not allow use of a flexible drain hose, a

rigid valve drain run must be used. Purchase a compression fitting (1/4 NPT x 1/2 in. minimum tube) and

1/2" tubing from your local hardware store. Plumb a

rigid drain as needed (see Figure 4, below).

NOTE: Avoid drain hose runs longer than 30 feet.

Make the valve drain line as short and direct

as possible.

It is recommended that the Central Water Filtration

System be installed near a drain. However, if a drain

is not available, it is still possible to operate the

Central Water Filtration System in a manual Clean

Rinse mode. See “Operating in Manual Clean Rinse

Mode” section. The automatic Clean Rinse function

must be disabled if the Central Water Filtration System

will not be connected to a drain.

Hose

Clamp

Drain

Fitting

Valve

Drain

Hose

Tie or wire

tubing in

place

To drain point other

than floor drain.

Support tubing in

place as needed.

Install adaptor

elbow using hose

clamp. Aim noz-

zle down toward

center of drain

1-1/2”

air gap

SUBSTITUTING RIGID DRAIN LINE

1/4 NPT Threads

Barbs

1/2” Outside Dia.

Clip

Cut barbs from

drain fitting (pull

clip to remove fit-

ting from valve)

1-1/2”

air gap

Comp Fitting. 1/4

NPT x 1/2” O.D.

Tube (not included)

1-1/2”

air gap

Copper Tube

(not included)

Drain grate with 1”

dia. hole in center

FLOOR DRAIN

7

LAUNDRY TUB STANDPIPE

FIG. 4

Installation Requirements

Electrical Shock Hazard

Prior to installation on metallic plumbing,

securely install two grounding clamps and a

#4 copper wire per installation instructions.

Failure to follow these instructions can result

in death or electrical shock.

3 VALVE BYPASS

INLET - OUTLET PLUMBING OPTIONS

Always install either a single bypass valve (provided),

as shown in Figure 7, or, if desired, parts for a 3 valve

bypass system (not included) can be purchased and

assembled, as shown in Figure 6. Bypass valves

allow you to turn off water to the Central Water

Filtration System for maintenance if needed, but still

have water in house pipes.

Use either:

= Copper pipe

= Threaded pipe

= PEX (Crosslinked Polyethylene) pipe

= CPVC plastic pipe

= Other pipe approved for use with potable water

IMPORTANT: Do not solder with plumbing attached to

the single bypass valve. Soldering heat

will damage the plastic valve.

CROSS OVER

Main Water Pi

Treated

Water from

Valve

OUTLET

pe

Untreated

Water to

Valve

INLET

In what direction

does the water flow?

Be sure to plan

piping so water

flow is to the

Central Water

Filtration System

valve INLET.

Plan a crossover

if flow is from left

to right.

Central Water Filtration

System

OUTLET

Central Water Filtration

System

INLET

CONNECTING PLUMBING TO VALVE

OUT

IN

Clips

Pipes

1” NPT Sweat

Adapter (2)

(not included)

Use Teflon® tape,

pipe joint compound or both

Bypass

Valve

Valve

Inlet

FIG. 6

FIG. 7

To Central Water

Filtration System

FIG. 5

8

Loading...

Loading...