North Star NST30ED, NST45ED1, NST70ED1 User Manual

Designed, Engineered &

Assembled in the U.S.A.

Models NST30ED

NST45ED1

NST70ED1

How to install, operate

and maintain your Demand

Controlled Water Softener

If you have any questions or concerns when

installing, operating or maintaining your water

softener, call our toll free number:

1-800-972-0135

or visit www.northstarwater.com

When you call, please be prepared to provide

the model and serial number of your product,

found on the rating decal, located on the back

of the controller top cover.

Systems tested and certified by NSF International

against NSF/ANSI Standard 44

for hardness reduction and efficiency,

and certified to NSF/ANSI Standard 372.

Systems tested and certified by the Water Quality

Association against CSA B483.1.

Manufactured and warranted by

North Star Water Treatment Systems

1890 Woodlane Drive

Woodbury, MN 55125

Installation and Operation Manual

7366546 (Rev. E 9/1/18)

TABLE OF CONTENTS

Page

pecifications & Performance Claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

S

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ypical Installation Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

T

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

rogramming the Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

P

Controller Features / Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Inspect Shipment

The parts required to assemble and install the water

softener are included with the unit. Thoroughly check

the water softener for possible shipping damage and

parts loss. Also inspect and note any damage to the

shipping carton.

Packing List

All Models:

Model NST30ED:

Remove and discard (or recycle) all packing materials.

To avoid loss of small parts, we suggest you keep the

small parts in the parts bag until you are ready to use

them.

Adaptor ElbowHose Clamps

GrommetDrain Hose

Models NST45ED1:

& NST70ED1:

Bypass Valve

Bypass Valve Clips

Clips

2

Installation

Adaptors

O-rings

FIG. 1

Specifications & Performance Claims

hese models are efficiency rated. The efficiency rating is valid only at the minimum salt dose. The softeners have

T

a demand initiated regeneration (D.I.R.) feature that complies with specific performance specifications intended to

inimize the amount of regenerant brine and water used in its operation.

m

hese softeners have a rated softener efficiency of not less than 3,350 grains of total hardness exchange per pound

T

of salt (based on sodium chloride) and shall not deliver more salt than its listed rating or be operated at a sustained

aximum service flow rate greater than their listed rating. These softeners have been proven to deliver soft water

m

for at least ten continuous minutes at the rated service flow rate. The rated salt efficiency is measured by laboratory

tests described in NSF/ANSI Standard 44. These tests represent the maximum possible efficiency that the system

can achieve. Operational efficiency is the actual efficiency after the system has been installed. It is typically less

than the rated efficiency, due to individual application factors including water hardness, water usage, and other contaminants that reduce a softener's capacity.

Model NST30ED NST45ED1 NST70ED1

Model Code SR30 SR45 SR70

11,800 @ 2.3 lbs.

Rated Softening Capacity (Grains @ Salt Dose)

Rated Efficiency

(Grains/Pound of Salt @ Minimum Salt Dose)

Water Used During Regeneration @ Minimum

Salt Dose

Total Water Used Per Regeneration @ Maximum

Salt Dose

Rated Service Flow Rate 7.3 gpm 10.0 gpm 13.5 gpm

Amount of High Capacity Ion Exchange Resin 0.78 cu. ft. 1.26 cu. ft. 1.94 cu. ft.

Pressure Drop at Rated Service Flow 15.0 psig 11.2 psig 15.0 psig

Intermittent Flow rate @ 15 psi* 7.3 gpm 12.1 gpm 13.5 gpm

Water Supply Max. Hardness 90 gpg 120 gpg 120 gpg

Water Supply Max. Clear Water Iron 8 ppm** 12 ppm** 19 ppm**

Water Pressure Limits (minimum / maximum) 20 - 125 psi***

Water Temperature Limits (minimum / maximum) 40 - 120 °F

Minimum Water Supply Flow Rate 3 gpm

Maximum Drain Flow Rate 2.0 gpm 2.0 gpm 3.0 gpm

25,300 @ 7.4 lbs.

30,200 @ 12.5 lbs.

5,090 @ 2.3 lbs. 5,070 @ 2.6 lbs. 5,080 @ 4.1 lbs.

3.2 gal. /

1,000 grains

39.5 gallons 56.0 gallons 101 gallons

13,300 @ 2.6 lbs.

35,700 @ 9.9 lbs.

45,300 @ 17.2 lbs.

4.1 gal. /

1,000 grains

20,800 @ 4.1 lbs.

55,100 @ 15.2 lbs.

70,000 @ 26.4 lbs.

4.3 gal. /

1,000 grains

*Intermittent flow rate does not represent the maximum service flow rate used for determining the softeners’ rated

capacity and efficiency. Continuous operation at flow rates greater than the service flow rate may affect capacity

and efficiency performance.

**Capacity to reduce clear water iron is substantiated by laboratory test data. State of Wisconsin requires addi-

tional treatment if water supply contains clear water iron exceeding 5 ppm.

***Canada working pressure limits: 1.4 - 7.0 kg/cm

These systems conform to NSF/ANSI 44 for the specific performance claims as verified and substantiated by

test data.

Variable Salt Dose: The salt dose is selected by the electronic controls at regeneration time based on the amount

needed.

2

.

3

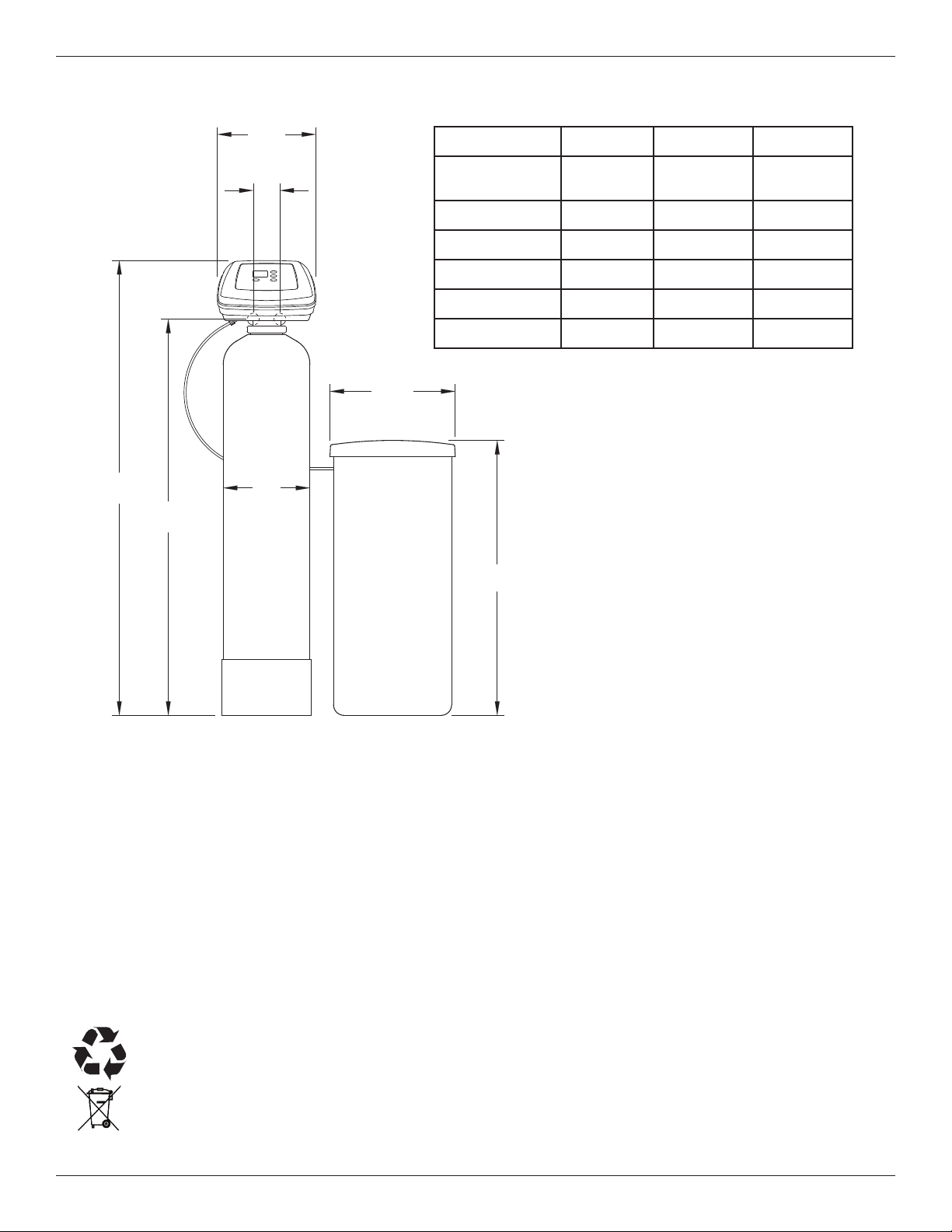

18"

DIA.

39"

C

14"

3-3/4"

OUTLET

INLET

INLET -

OUTLET

A

B

Dimensions

A

INLET -

OUTLET

B

E

ominal Resin

D

OUTLET

INLET

18”

dia.

N

Tank Size

Dimension A

Dimension B

Dimension C

Dimension D

Dimension E

NST30ED NST45ED1 NST70ED1

” dia.

8

x 40”

8-3/4” 50” 65-3/4”

4

41-1/4” 41-1/4” 57”

8-1/4” dia. 10-1/2” dia. 12-1/4” dia.

3-3/8” 3-3/4” 3-3/4”

11-1/2” 14” 14”

0” dia.

1

x 40”

2” dia.

1

x 54”

C

39”

FIG. 2

= The water softener requires a minimum water flow of 3 gallons per minute at the inlet. Maximum allowable inlet

water pressure is 125 psi. If your house water pressure is over the maximum, install a pressure reducing valve in

the water supply pipe to the system (Adding a pressure reducing valve may reduce the flow). If your home is

equipped with a back flow preventer, an expansion tank must be installed in accordance with local codes and laws.

= The water softener works on 24V DC electrical power, supplied by a direct plug-in power supply (included). Be

sure to use the included power supply and plug it into a nominal 120V, 60 Hz household outlet that is in a dry

location only, grounded and properly protected by an overcurrent device such as a circuit breaker or fuse.

= Do not use this system to treat water that is microbiologically unsafe or of unknown quality without adequate dis-

infection upstream or downstream of the system.

European Directive 2002/96/EC requires all electrical and electronic equipment to be disposed of accord-

Before You Start

ing to Waste Electrical and Electronic Equipment (WEEE) requirements. This directive or similar laws are

in place nationally and can vary from region to region. Please refer to your state and local laws for proper disposal of this equipment.

4

Installation Requirements

LOCATION REQUIREMENTS

Consider all of the following when selecting an installation location for the water softener.

= Do not locate the water softener where freezing

temperatures occur. Do not attempt to treat water

over 120ºF. Freezing temperatures or hot water

damage voids the warranty.

= To condition all water in the home, install the water

softener close to the water supply inlet, and

upstream of all other plumbing connections, except

outside water pipes. Outside faucets should remain

on hard water to avoid wasting conditioned water

and salt.

= A nearby drain is needed to carry away regenera-

tion discharge (drain) water. Use a floor drain,

laundry tub, sump, standpipe, or other options

(check your local codes). See "Air Gap

Requirements" and "Valve Drain Requirements"

sections.

= The water softener works on 24V DC electrical

power, supplied by a direct plug-in power supply

(included). Provide nearby a 120V, 60 Hz electrical

outlet, in accordance with national and local codes.

= Always install the water softener between the water

inlet and water heater. Any other installed water

conditioning equipment should be installed between

the water inlet and water softener (See Figure 4

below).

= Avoid installing in direct sunlight. Excessive sun

heat may cause distortion or other damage to nonmetallic parts.

PLUMBING CODES

All plumbing must be completed in accordance with

national, state and local plumbing codes.

In the state of Massachusetts: The Commonwealth

of Massachusetts plumbing code 248-CMR shall

be adhered to. A licensed plumber shall be used

for this installation.

AIR GAP REQUIREMENTS

A drain is needed for regeneration water (See Figure

3). A floor drain, close to the water softener, is preferred. A laundry tub, standpipe, etc. are other drain

options. Secure valve drain hose in place. Leave an

air gap of 1-1/2” between the end of the hose and the

drain. This gap is needed to prevent backflow of

sewer water into the water softener. Do not put the

end of the drain hose into the drain.

1-1/2”

air gap

FLOOR DRAIN

Drain

Hose

1-1/2”

air gap

Drain

Hose

1-1/2”

air gap

LAUNDRY TUBSTANDPIPE

Drain

Hose

FIG. 3

Cold Water

to House

Hot Water

to House

THE PROPER ORDER TO INSTALL WATER TREATMENT EQUIPMENT

Untreated Water to

Outside Faucets

Water

Heater

Water

Softener

Optional

Sediment

Filter

5

Pressure

City Water Supply

Tank

Well Water Supply

OR

Well

Pump

FIG. 4

Soft

W

ater

Typical Installation Illustrations

MA

I

N

W

A

T

ER

PI

PE

CROSSOVER

se if water supply flows from the left.

Hard

Water

U

Include single or 3-valve bypass.

120V,

60 Hz

Outlet

1” NPT Sweat

Adaptor (2)

not included

1” NPT

Installation

Adaptor (2) *

O-ring Seal (2) *

Bypass Valve *

Valve

INLET

Clip (4) *

Hard

Hard Water to

outside faucets

Water

From

Softener

Outlet

To

Softener

Inlet

INSTALLATION USING 3-VALVE BYPASS

MA

IN

WA

T

E

R

PIPE

Soft

Water

BYPASS

Valve

OUTLET

Valve

INLET

Valve

Soft

ater

W

Water

Hard

Models NST45ED1 & NST70ED1

1” NPT Sweat

Adaptor (2)

not included

Bypass Valve *

Valve

INLET

* Included with softener. Pipe and

Model NST30ED

fittings supplied by installer.

For soft water SERVICE:

- Open the inlet and outlet valves

- Close the bypass valve

For hard water BYPASS:

- Close the inlet and outlet valves

- Open the bypass valve

6

1” NPT Sweat

Adaptor (2)

not included

Clip (2) *

1” NPT

Installation

Adaptor (2) *

not included

w/ NST30ED

O-ring Seal (2)

Valve

INLET

FIG. 5

Installation Instructions

1. TURN OFF WATER SUPPLY

a. Close the main water supply valve near the well

pump or water meter.

b. Shut off the electric or fuel supply to the water

heater.

c. Open high and low faucets to drain all water from

the house pipes.

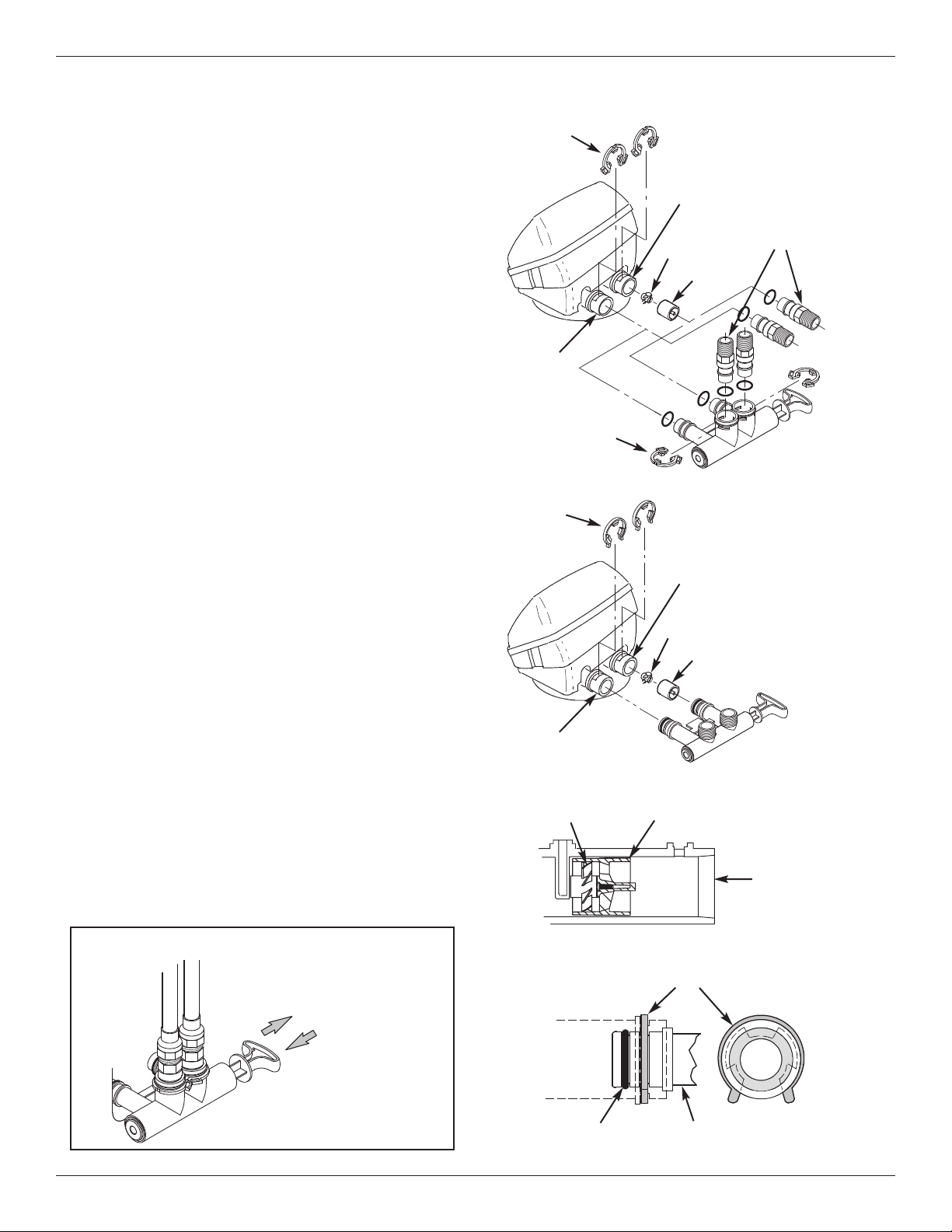

2. INSTALL BYPASS VALVE AND/OR

PLASTIC INSTALLATION ADAPTORS:

a. If installing a single bypass valve, push the bypass

valve, with lubricated o-ring seals in place, into the

valve inlet and outlet ports (See Figures 5 & 7A/7B).

- OR -

b. If installing a 3-valve bypass system, slide plastic

installation adaptors, with lubricated o-ring seals in

place, into the valve inlet and outlet ports (See

Figures 5 & 7A).

c. Make sure the turbine and support are firmly in

place in the valve outlet, as shown in Figure 8.

Blow into the valve port and observe the turbine for

free rotation.

d. Snap the two large plastic clips in place on the inlet

and outlet ports, from the top, down (See Figure 9).

Make sure they snap into place. Pull on the bypass

valve, or installation adaptors, to make sure they

are held securely in place.

3. MOVE THE UNIT INTO INSTALLATION

POSITION

a. Move the water softener into the desired location.

Set it on a solid, level surface.

IMPORTANT: Do not place shims directly under the

salt storage tank to level the softener.

The weight of the tank, when full of

water and salt, may cause the tank to

fracture at the shim.

Clip (2)

INLET

Clip (2)

INLET

Turbine

Clip (2)

Models NST45ED1

& NST70ED1

OUTLET

Turbine

Support

Plastic

nstallation

i

adaptors

FIG. 7A

Model NST30ED

OUTLET

Turbine

Support

Bypass

Valve

FIG. 7B

Turbine Support Assembly

Valve Outlet

Bypass

Valve

SINGLE BYPASS VALVE

Pull out for “Service”

(Soft water)

Push in for

“Bypass”

FIG. 6

FIG. 8

Clip

END VIEWSIDE VIEW

O-ring

7

Bypass valve or

plastic adaptor

FIG. 9

Installation Instructions

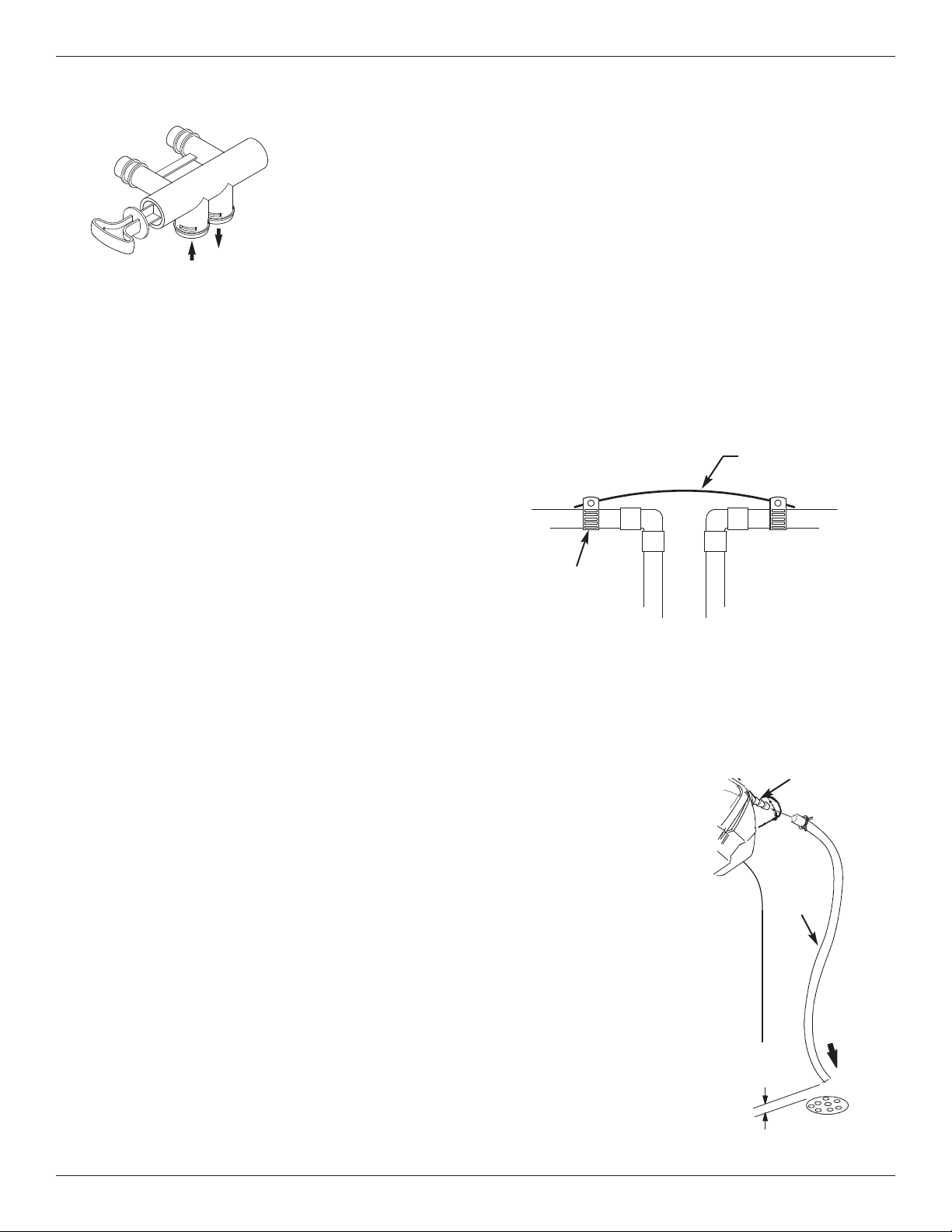

urn the bypass

T

valve downward if

onnecting to floor

c

level plumbing

OUTLET

INLET

4. COMPLETE INLET AND OUTLET

PLUMBING

Pipe fittings must be 3/4” minimum.

Use:

= Copper pipe

= Threaded pipe

= PEX (Crosslinked Polyethylene) pipe

= CPVC plastic pipe

= Other pipe approved for use with potable water

IMPORTANT: Do not solder with plumbing attached to

installation adaptors and single bypass

valve. Soldering heat will damage the

adaptors and valve.Measure, cut, and

loosely assemble pipe and fittings from

the main water pipe to the inlet and outlet ports of the water softener valve. Be

sure to keep fittings fully together, and

pipes squared and straight.

Be sure hard water supply pipe goes to the water softener valve inlet side.

NOTE: Inlet and outlet are marked on the water sof-

tener valve. Trace the water flow direction to

be sure hard water is to inlet.

IMPORTANT: Be sure to fit, align and support all

plumbing to prevent putting stress on

the water softener valve inlet and outlet.

Stress from misaligned or unsupported

plumbing may cause damage to the

valve.

Complete the inlet and outlet plumbing for the type of

pipe you will be using.

FIG. 10

5. COLD WATER PIPE GROUNDING

The house cold water pipe (metal only) is often used

as a ground for the house electrical system, The 3valve bypass type of installation, shown in Figure 5,

will maintain ground continuity. If you use a plastic

bypass valve at the unit, continuity is broken. To

restore the ground, do the following:

Purchase and securely install two grounding clamps

and a #4 copper wire across the location where the

softener will be, tightly clamping it at both ends, as

shown in Figure 11.

NOTE: Check local plumbing and electrical codes for

proper installation of grounding. The installation must conform to them.

Ground Wire

(not included)

Clamp

(2 - not included)

FIG. 11

6. INSTALL VALVE DRAIN HOSE

a. Measure, cut to needed length and connect the 3/8"

drain line (provided) to the water softener valve

drain fitting. Use a hose clamp to hold the hose in

place.

NOTE: Avoid drain hose

runs longer than 30

feet. Avoid elevating the hose more

than 8 feet above

the floor. Make the

valve drain line as

short and direct as

possible.

NOTE: If codes require a

rigid drain line see

Figure 13.

b. Route the drain hose or

copper tubing to the

floor drain. Secure

drain hose. This will

prevent “whipping'' during regenerations. See

“Air Gap Requirements"

section.

1-1/2”

Air Gap

Drain Fitting

on valve

Valve

Drain

Hose

To

Floor

Drain

FIG. 12

8

Loading...

Loading...