1

M47500A.2

ITEM NUMBER: 47500 & 47501

SERIAL NUMBER: _____________

Owner’s Manual

Electric Stationary Air Compressor

(230V, single phase/60 gallon, 3 HP and 5 HP)

Instructions for Installation/Set-up, Operation, Maintenance, & Storage

This NorthStar® belt-driven compressor has a single-stage 2-cylinder pump (Model 47500) or single-stage 3-cylinder

pump (Model 47501), made with heavy-duty cast iron cylinders for long life, and a compact design rated for 135

maximum PSI. Its continuous-duty rating ensures long-lasting performance, and its cast iron pump head ensures

superior heat dissipation.

Read and understand this Owner’s Manual completely before using. Keep this manual for future review. Failure to

properly set up, operate and maintain the compressor in accordance with this manual could result in serious injury or

death to operator or bystanders.

WARNING: SPECIAL HAZARDS

Injection Injury: High-pressure air stream can pierce skin and underlying tissues, leading to serious injury and possible

amputation. Such an injection injury can result in blood poisoning and/or severe tissue damage.

Flying Debris: High-pressure air stream can cause flying debris and possible surface damage.

Not For Breathing Air: NorthStar compressors are NOT designed, intended, or approved for supplying breathing air. No

compressed air should be used for breathing unless air is treated in accordance with applicable standards.

Fire/Explosion: Sparks from air powered tool heads or attachments can ignite fuel or other flammable liquids or vapors in

the vicinity. Exceeding the maximum pressure for air tools or attachments could cause them to explode.

Burns: Compressor pump, motor and discharge tubing are hot surfaces that can cause burn injuries.

Electric Shock: Operating equipment in wet conditions or where not properly grounded can cause electric shock.

Detailed safety information about these hazards appears throughout this manual.

Equipment Protection Quick Facts

Inspect Upon Delivery: FIRST! Inspect for missing or damaged components. See “Initial Set-Up” section for where

to report missing or damaged parts.

Check Pump Oil: Pump is shipped with oil. Check the pump oil level before starting. See “Preparing for Operation”

section of this Owner’s Manual for capacity and viscosity.

Use Mechanical Lifting Equipment: Compressor is shipped on a pallet and is too heavy to handle manually. Use

proper lifting equipment for unloading and moving to installation site.

Install Using a Qualified Electrician: All wiring, grounding, and electrical connections must be made by a qualified

electrician. Install according to local and national codes.

Install a Regulator: We recommend installing a regulator on the compressor at each distribution point to maintain

constant pressure in the outlet hose line and provide reduced pressure appropriate for air tool being used.

Run Pump Unloaded for Break-in Period: Before initial use, open ball valve and run compressor for 30 minutes to

break in pump parts.

Follow Maintenance Schedule: Pump, air filter, and tank require periodic inspection and servicing to provide

efficient function and long life. See “Maintenance Schedule” for frequency of servicing.

2

Table of Contents

Equipment Protection Quick Facts ........................................................................................................................................ 1

Table of Contents ........................................................................................................................................................ 2

About Your Air Compressor ....................................................................................................................................... 4

Specifications .............................................................................................................................................................. 5

Component Identification ........................................................................................................................................... 6

Safety Signal Words .................................................................................................................................................... 7

Hazard Signal Word Definitions ............................................................................................................................................ 7

Safety Labeling ............................................................................................................................................................ 8

Safety Decal Locations ......................................................................................................................................................... 8

Safety Decals ........................................................................................................................................................................ 9

Initial Set-Up .............................................................................................................................................................. 10

Step 1. Inspect & Unpack ...................................................................................................................................................... 10

Step 2. Assembly ................................................................................................................................................................... 10

Attach Air Filter.................................................................................................................................................................... 10

Attach Regulator (Recommended) ...................................................................................................................................... 10

Step 3. Select Suitable Location ........................................................................................................................................... 11

Step 4. Permanent Mounting ................................................................................................................................................ 11

Step 5. Installing Distribution Piping ................................................................................................................................... 12

Step 6. Wiring Installation ..................................................................................................................................................... 12

Electric Compatibility ........................................................................................................................................................... 12

Wire Size ............................................................................................................................................................................. 12

Circuit Breaker .................................................................................................................................................................... 13

Pressure Switch Wiring ....................................................................................................................................................... 13

............................................................................................................................................................................................ 13

Grounding ........................................................................................................................................................................... 13

Model #47500 and #47501 (230 Volt; 3 / 5 HP) .................................................................................................................. 14

*Circuit Breaker ................................................................................................................................................................... 14

**Wire Size .......................................................................................................................................................................... 14

*Voltage .............................................................................................................................................................................. 14

*Circuit Breaker ................................................................................................................................................................... 15

**Wire Size .......................................................................................................................................................................... 15

*Voltage .............................................................................................................................................................................. 15

Operation ................................................................................................................................................................... 16

Follow Operation Safety Rules ............................................................................................................................................. 16

Prepare for Operation ............................................................................................................................................................ 16

Check/Add Oil to the Pump ................................................................................................................................................. 16

Proper Air Hose and Tool Use .............................................................................................................................................. 17

Pressure Control Related Devices ...................................................................................................................................... 17

Compressor - Tool Requirements ....................................................................................................................................... 17

Attaching/Disconnecting Air Hose and Tools ...................................................................................................................... 17

Using Compressor for Spraying ........................................................................................................................................... 18

Flammable Materials ........................................................................................................................................................... 18

Moisture in Compressed Air ................................................................................................................................................ 18

Shutdown ............................................................................................................................................................................... 18

Procedure ........................................................................................................................................................................... 18

For Malfunction During Operation ....................................................................................................................................... 18

Maintenance & Repair ............................................................................................................................................... 19

3

Maintenance Schedule Summary ............................................................................................................................. 19

Detailed Instructions – Maintenance & Repair ........................................................................................................ 19

Inspect Safety/Relief Valve ................................................................................................................................................. 19

Inspect Air Filter .................................................................................................................................................................. 19

Keep Compressor Clean ..................................................................................................................................................... 19

Inspect Compressor for Air Leaks ....................................................................................................................................... 20

Change Pump Oil ................................................................................................................................................................ 20

Drain Receiver Tank and Inspect Tank ............................................................................................................................... 20

Check Drive Belt for Tension and Alignment....................................................................................................................... 20

Keep Compressor Clean ..................................................................................................................................................... 21

Troubleshooting ........................................................................................................................................................ 22

Parts List – Model 47500 Rev A.2 ............................................................................................................................. 23

Parts List – Model 47500 Rev A.2 ............................................................................................................................. 24

792363 Pump Exploded View ................................................................................................................................... 25

792363 Pump Parts List ............................................................................................................................................ 26

792363 Pump Kit List ................................................................................................................................................ 27

Parts List – Model 47501 Rev A.2 ............................................................................................................................. 28

Parts List – Model 47501 Rev A.2 ............................................................................................................................. 29

792373 Pump Parts List ............................................................................................................................................ 30

792373 Pump Parts List ............................................................................................................................................ 31

792373 Pump Parts List ............................................................................................................................................ 32

Appendix A: Lubricants and Compatibility ............................................................................................................. 33

Alternate Lubricants ............................................................................................................................................................ 33

Limited Warranty ....................................................................................................................................................... 34

4

About Your Air Compressor

Thank you for purchasing a NorthStar air compressor! It

is designed for long life, dependability, and top

performance.

Intended Use. Provides compressed air used primarily

for operating air tools and pressurizing other objects

that require high air pressure, such as tires. Do not

use for low-pressure objects such as balloons, air

mattresses, and sport balls, which can explode

quickly and easily. Special precautions are

necessary when used for cleaning to prevent flying

debris hazards. It is not to be used to supply

breathing air.

Supplies Required. Normal operation will require you

to supply:

Pressure regulator (recommended)

Pump oil

Personal protection equipment

See “Specifications” section for more detail.

Site Location. Install in enclosed building only. See

“Select Suitable Location” on page 11 for more

information.

Personal Protection. Wear safety apparel during

operation, including safety glasses with side and top

protection.

Adult Control Only. Only trained adults should set up

and operate the air compressor. Do not let children

operate.

Under The Influence. Never operate, or let anyone else

operate, the air compressor while fatigued or under

the influence of alcohol, drugs, or medication.

Keep this manual for reference and review.

ATTENTION: Rental Companies and Private

Owners who loan this equipment to others!

All persons to whom you rent/loan this air compressor

must have access to and read this Owner’s Manual.

Keep this manual with the air compressor at all times

and advise all persons who will operate the machine to

read it. You must also provide personal instruction on

how to safely set-up and operate the air compressor

and remain available to answer any questions a

renter/borrower might have. Owner’s Manuals are

available from NorthStar at 1-800-270-0810.

For any questions, comments, problems or part orders,

call NorthStar at 1-800-270-0810.

5

Specifications

MODEL

Model #

47500

47501

FLOW OUTPUT

Max. Pressure Rating

135 PSI

135 PSI

Volume Rating @ 90PSI

11.3 CFM

15.5 CFM

Receiver Capacity

60 gal.

60 gal.

Power Requirements

Dedicated NEMA

Receptacles

6-30R

6-30R

Volts

230V

230V

Amps

20A

30A

Motor

Horsepower

3 HP

5 HP

DIMENSIONS / COMPONENTS

Length

24.25”

24.25”

Width

23”

23”

Height

71”

63”

Weight

251 lbs.

340 lbs.

Mounting Hole Diameter

.56”

.56”

Suggested Mount Bolt

Diameter

7/16”

7/16”

SUPPLIES REQUIRED (not included)

Pump Oil

(shipped with oil, but refills

required)

SAE 30 non-detergent pump oil

(#4043)

SAE 30 non-detergent pump oil

(#4043)

Pump Oil Capacity

15.6 oz.

23.7 oz.

6

Component Identification

1. Lifting Eyes: May also be used as tie down locations.

2. Pressure Gauge: Air filled gauge. Shows pressure in

receiver tank.

3. Ball Valve: On/Off control for pressurized air supply from

receiver tank (not the output pressure). A regulator and/or

quick connect fittings can attach to its ½” NPT outlet. A

regulator should be installed for pressure regulation

purposes.

4. Air Receiver / Storage Tank: 80 gallon ASME certified

tank.

5. Tank Drain Valve: Used to remove moisture from air after

compressor is shut off and air emptied from tank. Drain

moisture daily after each use.

6. ASME Safety/Check Valve: Automatically releases air if

tank exceeds preset pressure max. of 200 PSI. A check

valve is a pressure release port. Pull valve pin to relieve

pressure from receiver tank.

7. Pressure Switch-Auto/Off switch: In AUTO

position, compressor shuts off automatically when

tank pressure reaches maximum preset pressure

(approximately 135 PSI). In OFF position, compressor

will not operate. Switch should be in OFF position

when connecting or disconnecting power cord from

electrical outlet. NEVER attempt to adjust this

pressure switch.

8. Discharge Tube: Carries compressed air from pump to

safety/check valve, and then to the storage tank. It

becomes very hot during use and can cause severe burns.

Never touch.

9. Unloader: Vents discharge air to atmosphere in start/stop

operation.

10. Magnetic Oil Drain Plug: Removal allows for drainage of

oil from pump. Attracts metal particles that could damage

pump.

11. Air Compressor Pump: Shipped with oil.

12. Compressor Air Filter: Keep clean and particle free. See

“Pump Explosion and Pump Parts List” for replacement

part number.

13. Belt Guard: Covers belt, engine pulley and flywheel.

NEVER operate compressor without belt guard in place.

3

1 2 4

8

9

5

6

7

11

13

10

12

7

Safety Signal Words

DANGER

WARNING

CAUTION

CAUTION

NOTICE

Hazard Signal Word Definitions

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER (red) indicates a hazardous situation, which if

not avoided, will result in death or serious injury.

WARNING (orange) indicates a hazardous situation,

which if not avoided, could result in death or serious

injury.

CAUTION (yellow), used with the safety alert symbol,

indicates a hazardous situation, which if not avoided,

could result in minor or moderate injury.

CAUTION (yellow), without the safety alert symbol, is

used to address practices not related to personal injury.

NOTICE is used to address practices not related to

personal injury.

8

Safety Labeling

On-Product Warning Labels

Location

Part numbers

Description

1

792161

Air Compressor Instructions

2

792174

Breathing Hazard

3

792175

Belt Hazard

4

792176

Burn Hazard

5

792177

Corrosion Hazard

6

789060

Electrical Shock Hazard

1

2 3 6

5

4

Safety Decal Locations

WARNING:

ALWAYS make sure safety labels are in place and in good condition. If a safety label is missing or not legible, order new labels

from NorthStar Product Support at 1-800-270-0810.

9

Safety Decals

1

2

6

3

4

5

To order replacement safety labels, call NorthStar Product Support

at 1-800-270-0810.

10

Initial Set-Up

Plastic plug

Base

Air Filter

Housing

Washer

Wing Nut

Grip here

to tighten

Step 1. Inspect & Unpack

Upon receipt, inspect air compressor for missing or

damaged parts. Verify that it is the compressor you

ordered.

See “Component Identification” section of this manual

for a diagram of the compressor and its components.

For missing or damaged components, please

contact NorthStar Product Support at 1-800-270-

0810.

If complete, fill out product serial number

information. See “Limited Warranty” section of

this manual.

Step 2. Assembly

Attach Air Filter

1. Remove air filter from manual bag.

2. Remove plastic plug from air compressor inlet.

(Figure 1)

Figure 3

Figure 4

5. Replace air filter housing and washer. Secure

with wing nut, hand tighten only. (Figure 5)

Figure 1

3. Unscrew wing nut, remove washer and air filter

housing from base. (Figure 2)

Figure 2

4. Screw base into air compressor inlet as shown.

Tighten with appropriate tool on specified

location. (Figure 3 & Figure 4)

Figure 5

Attach Regulator (Recommended)

We recommend using a regulator with this compressor

since the pre-set tank pressure ranges between 105 and

135 PSI and is usually greater than what is needed by

tools.

Without the addition of a regulator, the pressure switch

will maintain a tank pressure within the pre-set range

that has a max of 135 PSI. This is considered an overly

high pressure for many tools. A user-installed regulator

can maintain a lower constant pressure in the outlet

hose line and prevent over pressurization of tools.

WARNING: Bursting hazard

Too much air pressure causes a hazardous risk of

bursting. Check the manufacturer’s maximum pressure

rating for air tools and accessories. Regulators must

never be set to exceed the maximum pressure rating of

tank or tools.

11

Step 3. Select Suitable Location

WARNING: Lifting hazard

The compressor is heavy. Ensure that proper lifting

equipment is available to unload and move compressor

to installation site.

Location Criteria:

Enclosed building only.

Where no flammable vapors, dusts, and gases

are present.

At least 15” away from walls and other objects.

Away from other heat-generating equipment.

Away from dusty/dirty conditions.

In a well illuminated area.

Where proper wire size is already, or can be

made, available.

Positioning:

The compressor should be mounted on a dry,

firm, and level surface. It must sit level and be

stabilized since it will slide or shift during

operation if not secured.

Airflow:

Provide access to adequate, clean and

unobstructed airflow for cooling and air supply.

Remember the supply air is passing through the

compressor supply hoses and tools. These can

be damaged or have a shortened life if unclean

air is present or air filter is not clean and

functioning properly.

Do not allow debris to accumulate or block

airflow.

Do not operate with a tarp, blanket, or cover

surrounding the machine, which blocks air flow.

Do not place any objects against or on top of the

unit, which can also block airflow or damage unit.

Electrical:

MUST be connected to a 230 Volt, single-phase

outlet having operating capacity of 20 amp (Model

#47500, 3 HP) or 30 amp (Model #47501, 5 HP).

Wiring:

Proper wire size should take into consideration

length from distribution panel.

See Step 6, “Wiring Installation” for more

information.

Ideal operating temperatures:

40 and 100F (4 and 37C).

Operating Limitations:

15F (-9C) or above 125F (52C).

If temperatures consistently drop below 32 F (0C),

install within an enclosed heated building. If this is not

possible, protect the safety/relief and drain valves from

freezing.

Note: Excessive moisture is likely to occur if unit is

stored in an unheated area subject to large

temperature changes. Moisture forming in pump can

produce sludge in the oil, causing parts to wear out

prematurely. Excessive condensation on the pump

when it cools down is a sign that this may be

occurring.

Step 4. Permanent Mounting

You will permanently mount the compressor after

selecting the location in Step 3.

1. On a concrete pad or other stable mounting

platform, drill 3 holes according to the mounting

dimensions given in the diagram below. (Figure 6)

Figure 6

2. Unbolt the compressor feet by removing the

fasteners. Discard them after removal. (Figure

7)

Figure 7

3. Lift and remove the compressor from the pallet

using a hoist and lifting eyes provided.

4. Situate unit in chosen location and bolt in place.

(Use 7/16” bolts and washers. Make sure bolts

are long enough to provide a good anchor

point.) Bolt it in place to prevent unit from

12

vibrating excessively. Use metal shims under

the “short” feet if necessary.

5. A rubber isolation mat or pads may be used

under each mounting foot to reduce vibration.

Step 5. Installing Distribution Piping

The stationary compressor can utilize the same type of

properly rated, single flexible hose, as is used on

portable air compressors. However, many purchasers

will prefer to utilize the stationary unit through a

permanently installed distribution system serving several

points within a facility. The design, installation and

usage of stationary compressed air distribution systems

has been the subject of extensive industrial, trade and

government attention, as can be seen within many

private and government websites.

An example of the typical components used in a

permanent distribution system are shown in Figure 8.

regulating the distribution line pressure at the

compressor outlet to under 150 PSI (usually in the 90120 PSI range) is mandatory for many compressed air

piping systems.

NorthStar recommends that you contact plumbers or

mechanical contractors with expertise in compressed air

systems to plan and/or install your distribution system.

WARNING: Bursting hazard

This unit can produce pressures in excess of 135 PSI,

which is beyond the capabilities of many piping types

and pipe fittings. Failure of undersized and/or

inadequate distribution components can lead to serious

injury.

WARNING: Restriction hazard

If an aftercooler, check valve, block valve, or any other

restriction is added to the compressor discharge, install

a properly sized ASME approved pressure safety/relief

valve between the compressor discharge and the

restriction.

Step 6. Wiring Installation

Wiring should be installed by a qualified electrician.

Installations must be in accordance with all applicable

local, state, and federal regulations.

WARNING: Electrical Shock Hazard

Improper electrical grounding can result in a risk of

electric shock. Electrical installation and service of the

230V, single-phase box (30 or 40 amp) MUST be made

by a qualified electrician. If the compressor must be

reinstalled at a different location, the re-connection

should also be made by qualified personnel. The

compressor motor may not start or may burn out

prematurely if adequate amperage is not available.

Figure 8

It should be obvious that there is considerable

complexity in designing and installing such a system.

Controlling the pressures, moisture in the air, drying

components, contaminants, lubrication, as well as

choosing and sizing the piping for the system, requires

the expertise of persons or firms familiar with such

designs and their installation.

A very significant safety issue arises when one is

distributing line pressure air throughout a facility, which

is over 150 PSI. Standard components, steel pipe

fittings and many plastic compressed air piping systems

are only rated to 150 PSI and cannot be safely used in

such distribution systems. In such cases, immediately

Electric Compatibility

The motor rating, as shown on the motor nameplate,

and the building power supply must have compatible

voltage, phase and hertz characteristics.

Wire Size

The electrical wiring required between the building’s

power supply and the electric motor varies according to

motor horsepower. Power leads must be adequately

sized to protect against excessive voltage drop during

start-up. High voltage drops can cause motor to

overheat and fail. A qualified electrician should provide

information for selecting proper wire size. If other

electrical equipment is connected to the same circuit,

the total electrical load must be considered in selecting

the proper wire size. DO NOT use undersized wire.

13

CAUTION: Inadequate wiring hazard

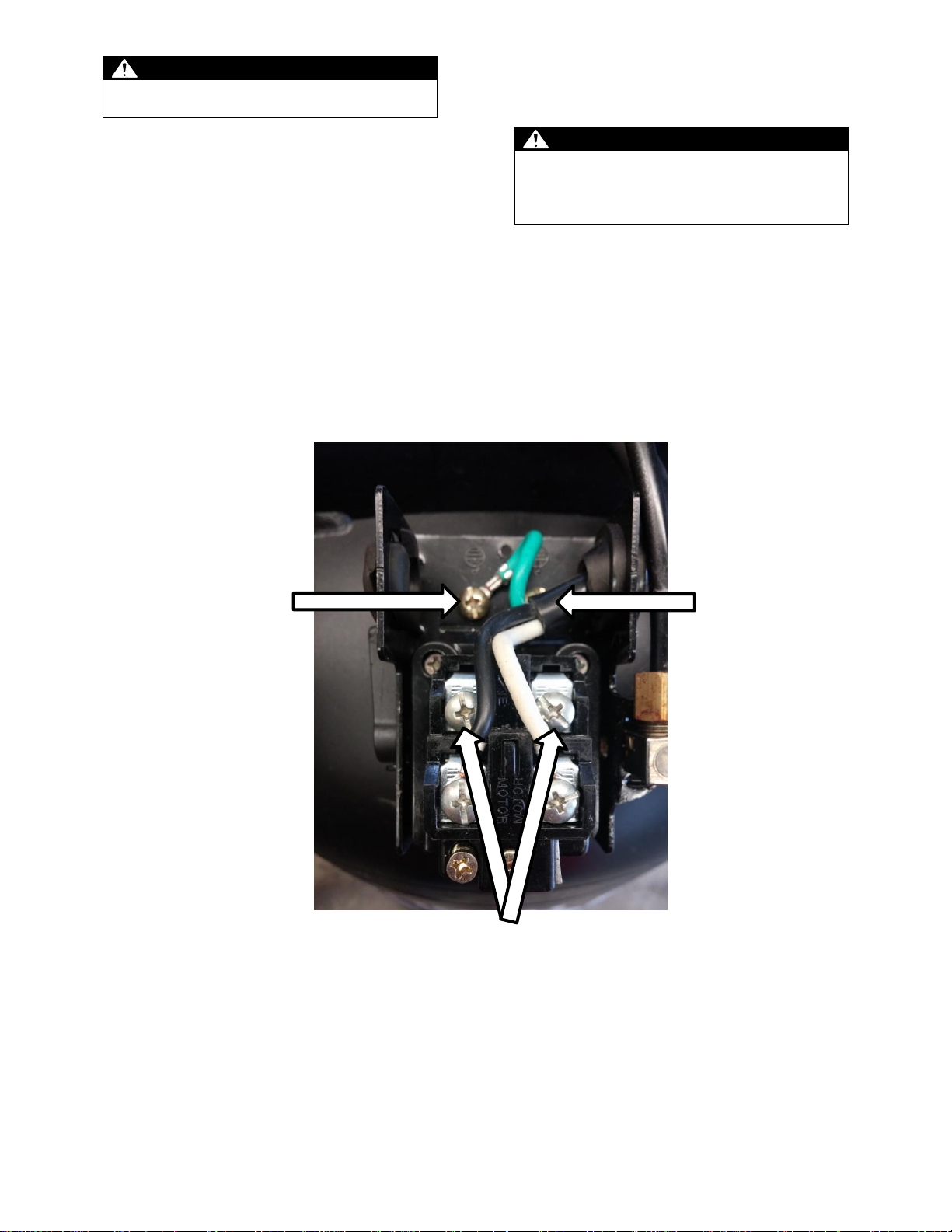

Connect ground wire

from power source here

Connect 230V wires from

Wires from motor

Overheating, short-circuiting and fire damage will result

from inadequate wire sizing.

Circuit Breaker

Your electrician will need to refer to the National Electric

Code to determine the proper circuit breaker rating

required. When selecting a circuit breaker, remember

the momentary starting current of an electric motor is

greater than its full load current. Time-delay or “slowblow” circuit breakers are recommended.

Pressure Switch Wiring

See below image for proper pressure switch wiring. See

figures 9 and 10 for detailed wiring schematic.

power source here

Grounding

This product and its associated conduit and junction box

must be grounded. Do not ground to a gas supply line.

WARNING: Electrical shock hazard

Improperly grounded motors are shock hazards. Make

sure all equipment is properly grounded. Check with a

qualified electrician if you are in doubt as to whether the

outlet is properly grounded.

14

Model #47500 and #47501 (230 Volt; 3 / 5 HP)

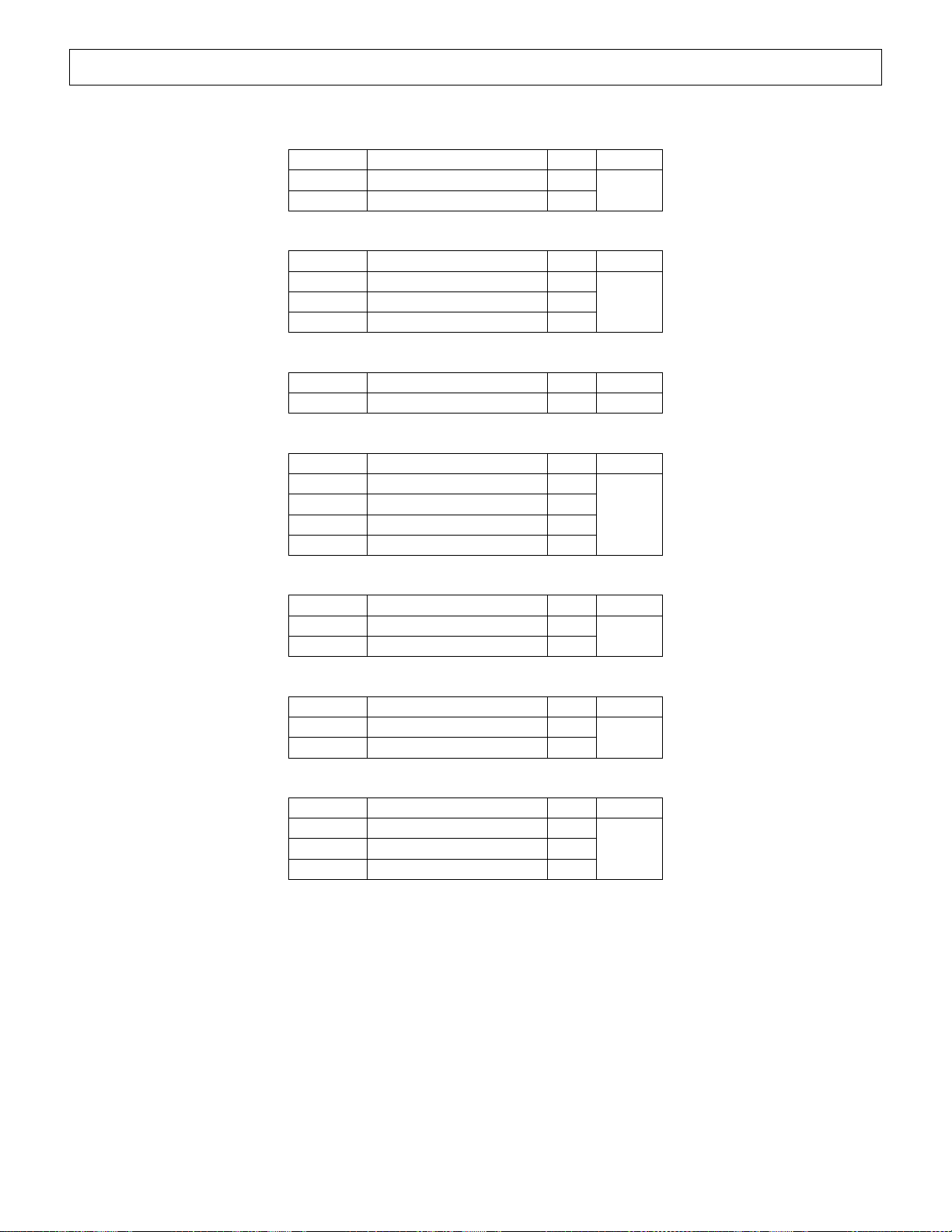

*Circuit Breaker

You will recognize this unit since it has a motor reset

button. The power lines should be connected directly to

the pressure switch (Figure 9 and 10).

Your electrician will need to refer to the National Electric Code to determine the proper circuit breaker rating required. When

selecting a circuit breaker, remember the momentary starting current of an electric motor is greater than its full load current. Timedelay or “slow-blow” circuit breakers are recommended.

**Wire Size

The electrical wiring required between the building’s power supply and the electric motor varies according to motor horsepower.

Power leads must be adequately sized to protect against excessive voltage drop during start-up. High voltage drops can cause

motor to overheat and fail. A qualified electrician should provide information for selecting proper wire size. If other electrical

equipment is connected to the same circuit, the total electrical load must be considered in selecting the proper wire size. DO NOT

use undersized wire.

*Voltage

MUST be connected to a 230 Volt, single-phase outlet having operating capacity of 20 amp (Model #47500, 3 HP) or 30 amp

Model 47500 View - Pressure Switch

Figure 9

15

*Circuit Breaker

Model 47501 View - Pressure Switch

Your electrician will need to refer to the National Electric Code to determine the proper circuit breaker rating required. When

selecting a circuit breaker, remember the momentary starting current of an electric motor is greater than its full load current. Timedelay or “slow-blow” circuit breakers are recommended.

**Wire Size

The electrical wiring required between the building’s power supply and the electric motor varies according to motor horsepower.

Power leads must be adequately sized to protect against excessive voltage drop during start-up. High voltage drops can cause

motor to overheat and fail. A qualified electrician should provide information for selecting proper wire size. If other electrical

equipment is connected to the same circuit, the total electrical load must be considered in selecting the proper wire size. DO NOT

use undersized wire.

*Voltage

MUST be connected to a 230 Volt, single-phase outlet having operating capacity of 20 amp (Model #47500, 3 HP) or 30 amp

Figure 10

16

Operation

Oil Cap

Sight

Glass

Drain Plug

Breather Cap

Magnetic

Drain Plug

Follow Operation Safety Rules

Before starting the compressor, review the safety rules

found below and throughout the manual.

WARNING

Failure to follow safety rules may result in serious injury

or death to the operator or bystanders.

Instruct Operators. Owner must instruct all operators in

safe set-up and operation. Do not allow anyone to

operate the compressor who has not read the

Owner’s Manual.

Safety Guarding. Only operate with safety covers,

guards and barriers secured and in good working

order.

Moving Parts. Keep hands, feet, hair and apparel away

from moving parts. Never remove any guards while

the unit is operating. Do not reach into an air vent or

cavity, as they may cover dangerous moving parts.

Ear Protection. Hearing can be damaged from

prolonged, close-range exposure to the noise level

produced by this compressor. Ear plugs or other

hearing protection is recommended for persons

working who are exposed within 15-20 feet of the

running compressor for an extended period of time.

Eye Protection. Wear ANSI/OSHA required “Z87.1”

safety glasses when operating or servicing the

compressor. Pressurized air spray from this unit can

cause severe injury to the eyes. Also, small objects

will become airborne as the air spray contacts them.

Respirator. Wear a respirator when using the

compressed air for spraying. Spray in a well ventilated area to prevent health and fire hazards.

Prepare for Operation

Make sure that any regular maintenance has been

performed as prescribed in “Maintenance & Repair”

section.

Drain receiver tank of any moisture.

Inspect for oil leaks.

Check for any unusual noise/vibration.

Ensure the area around compressor is free from

rags, tools, debris and flammable or explosive

materials.

Ensure belt guards and covers are securely in

place.

WARNING: Entanglement hazard

Do NOT operate with protective covers or guards

removed. Beneath these covers are high speed moving

components, which can entangle the operator or

bystanders. Entanglement in this equipment may result

in serious injury, amputation or death.

Check/Add Oil to the Pump

Check the oil level in the pump. Use sight glass for

pump oil level. Add oil as needed.

Engine: See engine Owner’s Manual for capacity and

recommended oil type for your expected ambient

conditions.

WARNING: Burn hazard

Never open oil port while compressor is running. Hot oil

can spray over face and body.

CAUTION: Inadequate lubrication hazard

Never operate compressor with inadequate lubricant.

This will cause overheating and severe damage to the

engine and pump.

Figure 11

47500 Model Pump: The compressor pump capacity is

15.6 oz. Use SAE 30 non-detergent pump oil prior to

break-in. You may use synthetic lubricants after 50 hour

break-in. See “Lubricants and Compatibility” for a list of

suitable and alternative lubricants.

17

Figure 12

Magnetic Drain Plug

Drain Plug

Oil Cap

Breather Cap

Sight Glass

On

Off

47501 Model Pump: The compressor pump capacity is

23.7 oz. Use SAE 30 non-detergent pump oil prior to

break-in. You may use synthetic lubricants after 50 hour

break-in. See “Appendix A: Lubricants and

Compatibility” for a list of suitable and alternative

lubricants.

CAUTION: Synthetic lubrication damage

If you will be using a synthetic lubricant, all downstream

piping material and system components must be

compatible.

Start-Up Procedures

CAUTION: Break-in period

Before initial use, open the ball valve and run the

compressor without air tools attached and through open

air line for 30 minutes to break-in pump parts.

1. Verify that the pressure switch is in the OFF

position. (Figure 13)

2. Turn regulator counter clockwise to close, if installed.

3. Verify that the pressure gauge reads zero.

4. Open the ball valve so that air flow is permitted.

5. Turn the pressure switch to the AUTO position.

6. Adjust regulator to desired pressure, if installed.

7. Allow pressure in receiver tank to build.

Note: This electric model is equipped with a pressure

switch that automatically turns the motor off when the

tank pressure reaches its preset level. Once air

Figure 13

pressure in the tank drops to a preset low level, the

pressure switch automatically turns the motor back on.

WARNING: Overheating

This compressor is equipped with “auto shut off”.

However, failure to allow adequate cooling ventilation or

a restriction in the intake airflow may cause the

machine to overheat.

WARNING: Inflatables/Low PSI tire

Never use compressor to inflate small low-pressure

objects, i.e., balloons/inflatables, small or low volume

PSI tires. It is easy to over-pressurize them, causing

them to rupture. Identify the inflation capacity of an

object prior to filling it with air. Use a gauge to check the

pressure regularly when inflating anything.

Proper Air Hose and Tool Use

Pressure Control Related Devices

Never remove, adjust, bypass, change, modify or make

substitutions for safety/relief valves, pressure switches

or other pressure control related devices. Pressurizing

beyond the limits of the compressor could result in an

explosion.

WARNING: Overpressurization hazard

NEVER over-pressurize the receiver tank or air tools

beyond nameplate capacity. Exceeding the pressure

rating could cause them to explode or fly apart.

Compressor - Tool Requirements

Compressor and attachments must be sized properly

for pressure and air volume.

Consider the maximum pressure requirements and

air volume requirements of each. (The volume rating

of your compressor is listed in the “Specifications”

section.)

CAUTION: Tool overpressure hazard

Do not operate this unit with any tool rated less than the

maximum operating pressure of the unit (135 PSI)

unless a properly sized regulator limiting pressure is

used before the tool.

Attaching/Disconnecting Air Hose and Tools

CAUTION: High pressure stream hazard

High-pressure air stream can pierce skin and underlying

tissues, leading to serious injury and possible

amputation. Such an injection injury can result in blood

poisoning and/or severe tissue damage. High-pressure

air stream can also cause flying debris and possible

surface damage.

On a fixed line distribution system the flexible hosing

and tools would typically be connected at a terminating

point. In some cases where a fixed system does not

exist, the flexible hosing can be attached to the quick

18

connect fitting on the main compressor outlet or after the

Collar

Coupler

Quick Disconnect

Socket

Correct

Insertion

Not Fully

Inserted

Collar Seated

Collar NOT Seated

Tool

user installed regulator.

CAUTION: Air tools hazard

Do not attach air tools to open end of the hose until

start-up is completed and the unit checks out OK.

Quick Connect Procedure:

Keep finger off tool or activation switch until ready

to use.

Pull quick connect collar back (Figure 14a).

Push hose or attachment firmly against stop.

Let go of collar (Figure 14a).

Pull and rotate slightly (hose or attachment) to

assure a tight connection.

WARNING: Projectile hazard

Air tool or attachment can become a projectile and

cause serious personal injury or damage if not securely

attached to the air hose.

Figure 14a

the tank. Part of the moisture will be discharged in the

outlet air.

When using a paint spray or sandblast gun, this water

will be carried from the tank through the hose, and out of

the gun as droplets mixed with the spray material. If this

is not acceptable for your application, an external air

dryer must be added to the system.

Shutdown

Procedure

When you are finished using the compressor:

1. Move the pressure switch to the OFF position.

2. Close the ball valve to stop airflow.

3. Unplug the power cord.

4. Operate tools briefly to release live pressure

5. Disconnect all tools.

6. Drain air receiver tank by pulling safety relief

valve.

7. After all storage air is discharges, disconnect

hoses and open the ball valve.

8. Once the tank pressure gauge registers under 10

PSI, open the drain valve on the bottom of the

tank to drain condensation moisture.

WARNING: Risk of bursting

Drain air receiver tank daily or after each use to prevent

moisture buildup in the air tank. Serious injury or death

may occur from a tank explosion caused by moisture

induced tank corrosion.

Figure 14b Figure 14c

Using Compressor for Spraying

Flammable Materials

Always follow precautions on container labels or MSDS’

before spraying flammable materials, such as paint.

Moisture in Compressed Air

Moisture in supply air when compressed will form into

droplets as it leaves air compressor pump and enters

receiver tank. When humidity is high or when a

compressor is in continuous use for an extended period

of time, a significant amount of moisture will collect in

For Malfunction During Operation

Immediately turn off the compressor if any of the

following conditions arise during operation:

Excessive change in motor speed, slow or fast

Overheating

Excessive vibration

Unusual noise

Flame or smoke

Air leakage

Pull ring on safety valve to immediately relieve pressure.

WARNING: Shutdown hazards

Do not leave an operating machine unattended. Always

shut the machine OFF and relieve the pressure before

leaving the machine. NEVER disconnect the highpressure outlet hose from the unit while the tank and air

line are pressurized. A hazardous high pressure air

stream will result as receiver tank is quickly emptied.

19

Maintenance & Repair

Item

Frequency

Inspect safety/relief valves

Weekly

Check pump oil level

Weekly

Inspect air filter

Weekly

Replace every 12 months or 1000 hours of

use

Inspect for air leaks

Monthly

Change pump oil/ Clean magnetic drain plug

After first 50 hours of use

Every 3 months or 500 hours of use

Inspect & drain receiver tank

Daily

Check drive belt tension and alignment

Monthly

Dust/debris removal

Monthly

WARNING: Maintenance hazards

ALWAYS disconnect, lock out and tag the main power supply and then release air pressure from the receiver tank before

cleaning, adjusting, or servicing the compressor. Make sure all guards and shields are replaced before re-starting.

Maintenance Schedule Summary

See detailed instructions for each maintenance item below.

Detailed Instructions – Maintenance & Repair

NOTICE

Dispose of used motor and pump oil in a manner that is

compatible with the environment and in accordance

with local, state, and federal laws and regulations.

Take used oil in a sealed container to your local

recycling center or service station for reclamation.

Do not throw it in the trash, pour it on the ground, or

No Modifications. Never modify or alter the

compressor in any way. Modifications can create

serious safety hazards and will void the warranty.

Inspect Safety/Relief Valve

This valve should be inspected and tested on a weekly

basis. The safety valve automatically releases air if the

tank pressure exceeds the preset maximum.

pour it down a drain.

Check the safety/relief valve by pulling the rings.

It is spring loaded and should not be stuck but

come out about ¼” and then snap back into

position when released.

Replace safety/relief valves that do not operate

freely with a valve of the same pressure rating.

WARNING: Safety/Relief valve hazards

If the safety/relief valve does not work properly, overpressurization may occur causing air tank rupture or

explosion. Occasionally pull the ring on the safety valve

to make sure the safety valve operates freely. If the

valve is stuck or does not operate smoothly, it must be

replaced with a valve having the same pressure rating.

Inspect Air Filter

Inspect the compressor’s air filter on a weekly basis. A

dirty air filter will not allow the air compressor to operate

at full capacity.

Clean air filter if dirty and restricted air flow.

Replace the air filter every 12 months or 1000

hours.

Note: Do not operate with the air filter removed.

Keep Compressor Clean

Do not allow air intakes to become blocked. If dust or

debris accumulates in the compressor, clean with a

damp cloth or soft bristle brush.

Note: Do not spray compressor with a garden hose or

pressure washer. Water may enter the compressor

and cause damage to the motor and pump.

20

Inspect Compressor for Air Leaks

Full

Add

Inspect system for air leaks on a monthly basis. To test:

Squirt soapy water around joints during

compressor operation and watch for bubbles.

Developing bubbles indicate a leak is present.

Tighten fittings, if necessary.

Change Pump Oil

WARNING: Burn hazard

Never open oil fill port while compressor is running. Hot

oil can spray over face and body.

After the first 50 hours of use then every 3 months or

500 hours, change pump oil while crankcase is still

warm. (See “Appendix A: Lubricants” for suitable

alternatives.)

1. Remove the oil fill and drain plugs. Collect the oil

in a suitable container.

2. Replace the oil drain plug and refill compressor

crankcase with clean oil.

3. Replace the oil fill plug.

4. Start the unit and run for several minutes. Shut

down the air compressor and recheck the oil

level. If necessary, add more oil. (Figure 15)

Check Drive Belt for Tension and Alignment

CAUTION: Pulley/sheave hazard

Improper pulley/sheave alignment and belt tension can

result in motor overload, excessive vibration and

premature belt and/or bearing failure. To prevent this

from happening, check the pulley/sheave alignment and

belt tension on a regular basis.

Belts will stretch from normal use. When properly

adjusted, a 5 lb. force applied to the belt between the

motor pulley and the pump will deflect the belt about ½”.

To align and adjust drive belt tension:

1. Remove the belt guard cover.

2. Loosen the four fasteners securing the motor to

the compressor unit.

3. Slide the motor to achieve proper belt tension.

(Usually 1/8” to 1/4” is sufficient.) The belt must

be properly aligned before refastening the motor.

4. To align belt, lay a straight edge against the face

of the compressor sheave (flywheel) touching the

rim at two places. (Figure 16)

Figure 15

Drain Receiver Tank and Inspect Tank

Drain water from the receiver tank daily. Water left in the

tank can cause the tank to weaken and corrode,

increasing the risk of tank rupture. Badly rested receiver

tanks must be replaced.

NorthStar recommends a tank inspection after every 2

years of service. See “Inspection of Unfired Pressure

Vessels,” volumes 2-9, August 2001, Bill McStraw

(available on-line at NTIS).”

WARNING: Air tank hazards

Failure to replace a rusted air receiver tank will

eventually result in tank rupture or explosion, which

could cause substantial property damage, severe

personal injury, or death. Never modify or repair a tank.

Obtain replacement from service center.

Figure 16

5. Adjust the motor pulley by shifting the motor so

that the belt runs parallel to the straight edge.

6. If necessary, use a gear puller to move the motor

pulley. Tighten set screw after motor pulley is

positioned.

7. Check for proper belt tension. (Figure 17)

Figure 17

8. Tighten the four fasteners holding the motor to

the top plate while tension and alignment is

maintained.

9. Attach the belt guard cover.

21

Keep Compressor Clean

Do not allow air intakes to become blocked. If dust or

debris accumulates in the compressor, clean the

compressor with a damp cloth or soft bristle brush.

Note: Do not spray compressor with a garden hose or

pressure washer. Water may enter the compressor

and cause damage to the engine and pump.

Contact NorthStar Product Support at 1-800-270-0810

for any questions, problems, or parts orders.

IMPORTANT

If a part needs replacement, only use parts that meet

the manufacturer’s part number specifications.

Replacement parts that do not meet specifications may

result in a safety hazard or poor operation of the

compressor. Major service, including installation or

replacement of parts, should be made by a qualified

electrical service technician.

22

Troubleshooting

PROBLEM

POSSIBLE CAUSE

Motor does not turn.

A,B,C,D,E

Motor overload trips or draws excessive current.

D, G, M

Excessive noise, vibration, knocking or rattling.

H, I, K, L,N, O, P, R, W

Lights flicker or dim when running.

C, D, E, J, M

Air delivery drops off.

I, J, L, M, N, O, P, R, W, X, Y

Compressor does not come up to speed.

C, D, F, H, L, M, P

Compressor is slow to come up to speed.

C, D, F, H, L, M, N

Compressor will not unload cycle.

I, N, P, R

Compressor will not unload when stopped.

I, N, P, R

Excessive starting or stopping.

D, E, G, P, S, U

Moisture in crankcase, “milky” substance in oil.

T

Oil in discharge air.

V

Safety/relief valve “pops”.

N, O, P

Low interstage pressure.

Y

High interstage pressure.

X

POSSIBLE CAUSE

POSSIBLE SOLUTION

A.) Circuit breaker on motor tripped.

Push button located on back of motor.

B.) Supply line circuit breaker tripped.

Reset circuit breaker.

C.) Wiring or electric service panel too small.

Install properly sized wire or service box. Contact electrician.

D.) Compressor wired incorrectly.

Check wiring, contact electrician.

E.) Poor contact on motor terminals or starter connections.

Ensure good contact on motor terminals or starter

connections.

F.) Compressor viscosity too high for ambient temperature

Drain existing lubricant and refill with proper lubricant.

G) Poor ground.

Check all ground connections.

H.) Belt tension too tight or sheaves not aligned

Check tension/ alignment.

i.) Air leaks in discharge piping

Check tubing connections, Tighten joints or replace as

required.

J.) Poor power regulation

Contact power company.

K.) Compressor components leaky, broken, loose

Inspect components. Clean or replace as required.

L.) Loose flywheel or motor pulley, excessive end play in

motor shaft or loose drive belts

Check flywheel, motor pulley, crankshaft drive belt

tension/alignment. Replace or repair as required.

M.) Leaking check valve or check valve seat blown out

Replace check valve.

N.) Clogged or dirty inlet and/or discharge line

Clean or replace.

O.) Defective safety/relief valve

Replace.

P.) Pressure switch unloader leaks or does not work

Realign stem or replace.

Q.) Inadequate ventilation around flywheel

Relocate compressor for better air flow.

R.) Leaking, broken or worn inlet unloader parts at check

valve

Inspect parts and replace as required.

S.) Excessive condensation in receiver tank

Drain receiver tank.

T.) Detergent lubricant in crankcase.

Replace with proper lubricant.

U.) Light duty cycle

Increase duty cycle.

V.) Lubricant level too high

Drain excess lubricant.

W.) Worn cylinder finish

Deglaze cylinder with 180 grit flex-hone.

X,) Low pressure inlet valve leaking

Inspect, clean or repair as required.

Y.) High pressure inlet valve leaking

Inspect, clean or repair as required.

This section provides a list of the more frequently encountered compressor malfunctions, their causes and corrective

actions. Some corrective actions can be performed by the operator or maintenance personnel, but others may require

assistance of a qualified electrician or Service Center.

23

Parts List – Model 47500 Rev A.2

Note: NorthStar tank decal part # 789000 (no shown)

24

Parts List – Model 47500 Rev A.2

Ref#

Part#

Description

Qty Ref#

Part#

Description

Qty

1

792363

Pump *

1 17

Kit # 4

Tube Fitting

1 2 N/A

Tank

1 18

792367

Electric Cable

1 3 792364

Motor **

1 19

792368

Pulley 1 4

792365

Oil Drain Plug Extender

1 20

792369

Service Valve

1

5

See Pump

Oil Drain Plug

1 21

792370

Belt A51

1 6 Kit # 1

Pressure Switch

1 22

792371

Belt Guard Assembly

1 7 792366

Pressure Relief Valve

1 23

See Pump

Air Filter Housing

2

8

Kit # 1

Plug 2

24

See Pump

Filter Element

2 9 Pressure Gauge

1

25

Kit # 1

Kit # 5

Adaptor

2

10

Nipple

1 11

See Pump

Magnetic Drain Plug

1 26

792372

Belt Guard Bottom Cover ***

1

12

Kit # 2

Check Valve

1 27

Kit # 5

Water Drain Valve

1

13

Nipple

1 28

Washer

1

14

Kit # 3

Elbow

1 29

Kit # 4

Straight Tube Fitting

1

15

Discharge Tube

1 30

Kit # 4

Water Drain Tube

1

16

Tube w/Ferrules & Nuts

1

Kit # 1

Kit # 4

Pressure Switch Kit - # 792377

Drain Tube Kit - # 792380

Ref#

Description

Qty

Kit Qty

Ref#

Description

Qty

Kit Qty

6

Pressure Switch

1 1

17

Tube Fitting

1 1 8

Plug

2 29

Straight Tube Fitting

1 9 Pressure Gauge

1 30

Water Drain Tube

1

10

Nipple

1 Kit # 5

25

Adaptor

1 Drain Valve Kit - # 792381

Kit # 2

Ref#

Description

Qty

Kit Qty

Check Valve Kit - # 792378

25

Adaptor

1

1

Ref#

Description

Qty

Kit Qty

27

Water Drain Valve

1

12

Check Valve

1 1

28

Washer

1

13

Nipple

1

Kit # 3

Tube Kit - # 792379

Ref#

Description

Qty

Kit Qty

14

Elbow

1 1

15

Discharge Tube

1 16

Tube w/Ferrules & Nuts

1

Note: Kit Qty is the number of kits needed to repair unit

*Fastener Kit for Pump - # 792384 Qty

Bolt 5/16 x 1 -1/4 T18/in Grade 5 4

Nut T18/in flange lock 4

**Fastener Kit for Motor - # 792385 Qty

Bolt 5/16 x 1 T18/in Carriage Grade 5 4

Nut T18/in flange lock 4

***Fastener Kit for Belt Guard - # 792386 Qty

Bolt 5/16 x 1T18/in Grade 2 7

Nut T18/in flange lock 3

Fender washer 5/16 3

Washer 5/16 SAE 4

25

792363 Pump Exploded View

26

792363 Pump Parts List

Ref#

Part#

Description

Qty

1

Kit # 1

Cylinder head

2 2 Allen bolt set

8 3 789354

Air filter 2 4

789355

Filter element

2

5

See part # 6

Kit # 2

Cylinder head gasket

2

6

792324

In.& ex. valve assembly

2

7

See part # 6

Kit # 2

Valve seat gasket

2

8

Kit # 3

Stud Screw

8 9 Kit # 4

Cylinder

2

10

Kit # 2

Kit # 4

Kit # 5

Cylinder gasket

2

11

792325

Kit # 4

Kit # 5

Piston ring kit

2

12

Kit # 4

Piston 2 13

792326

Rod

2

14

N/A

Crankcase

1

15

788879

Oil draining plug

1

16

Kit # 2

Front cover gasket

1

17

N/A

Front cover

1

18

N/A

Hex bolt 4 19

788880

Oil sight gauge

1

20

789386

Oil cap 1 21

792328

Bearing 1 22

N/A

Crankshaft and balancer

1

23

792329

Bearing 1 24

Kit # 2

Rear bearing seat gasket

1

25

N/A

Rear bearing seat

1

26

N/A

Hex bolt 4 27

Kit # 2

Oil seal

1

28

788882

Breather

1

29

789366

Pulley 1 30

Kit # 6

Fender washer

1

31

Hex bolt

1

32

Kit # 7

Exhaust elbow

1

33

Exhaust pipe

1

34

Discharge tube set

1

35

See part # 6

In.& ex. valve seat

2

36

See part # 11

Compression ring

4

37

See part # 11

Oil control ring

2

38

789384

Magnetic plug

1 * 789524

Wing nut, air filter

2

27

792363 Pump Kit List

Kit # 1

Cylinder Head and Bolt Kit - # 789336

Ref#

Description

Qty

Kit Qty

1

Cylinder head

1 2 2

Allen bolt set

4

Kit # 2

Gasket Kit - # 789339

Ref#

Description

Qty

Kit Qty

5

Cylinder head gasket

2 1 7

Valve seat gasket

2

10

Cylinder gasket

2

16

Front cover gasket

1

24

Rear bearing seat gasket

1

27

Oil seal

1

Kit # 3

Screw Kit - # 789358

Ref#

Description

Qty

Kit Qty

8

Stud Screw

4

2

Kit # 4

Cylinder and Piston Kit - # 789342

Ref#

Description

Qty

Kit Qty

9

Cylinder

1 2 10

Cylinder gasket

1

11

Piston ring kit

1

12

Piston

1

Kit # 5

Piston Ring Kit - # 789359

Ref#

Description

Qty

Kit Qty

10

Cylinder gasket

1

2

11

Piston ring kit

1

Kit # 6

Washer and Bolt - # 789367

Ref#

Description

Qty

Kit Qty

30

Fender washer

1 1 31

Hex bolt

1

Kit # 7

Exhaust Fitting and Tube Kit - # 792347

Ref#

Description

Qty

Kit Qty

32

Exhaust elbow

1 1 33

Exhaust pipe

1

34

Discharge tube set

1

Note: Kit Qty is the number of kits needed to repair pump

28

Note: NorthStar tank decal part # 789000 (no shown)

Parts List – Model 47501 Rev A.2

29

Parts List – Model 47501 Rev A.2

Ref#

Part#

Description

Qty Ref#

Part#

Description

Qty

1

792373

Pump *

1 17

Kit # 3

Tube w/Ferrules & Nuts

1 2 N/A

Tank

1 18

Kit # 1

Pressure Gauge

1 3 792374

Motor **

1 19

Kit # 4

Tube Fitting

1 4 792375

Pulley

1 20

792376

Belt A48

1 5 Kit # 1

Pressure Switch

1 21

792372

Belt Guard Bottom Cover ***

1 6 792366

Pressure Relief Valve

1 22

792371

Belt Guard Assembly

1 7 792340

Oil Drain Plug Extender

1 23

See Pump

Air Filter Housing

2 8 Kit # 1

Plug 2

24

See Pump

Filter Element

2 9 792369

Service Valve

1

25

Kit # 1

Kit # 5

Adaptor

2

10

Kit # 1

Nipple

1 11

792367

Electric Cable

1 26

See Pump

Magnetic Drain Plug

1

12

See Pump

Oil Drain Plug

1 27

Kit # 5

Water Drain Valve

1

13

Kit # 2

Check Valve

1 28

Washer

1

14

Kit # 3

Elbow

1 29

Kit # 4

Straight Tube Fitting

1

15

Discharge Tube

1 30

Kit # 4

Water Drain Tube

1

16

Kit # 2

Nipple

1

Kit # 1

Kit # 4

Pressure Switch Kit - # 792377

Drain Tube Kit - # 792380

Ref#

Description

Qty

Kit Qty

Ref#

Description

Qty

Kit Qty

5

Pressure Switch

1 1

19

Tube Fitting

1 1 8

Plug

2 29

Straight Tube Fitting

1

10

Nipple

1 30

Water Drain Tube

1

18

Pressure Gauge

1 Kit # 5

25

Adaptor

1 Drain Valve Kit - # 792381

Kit # 2

Ref#

Description

Qty

Kit Qty

Check Valve Kit - # 792378

25

Adaptor

1 1 Ref#

Description

Qty

Kit Qty

27

Water Drain Valve

1

13

Check Valve

1 1

28

Washer

1

16

Nipple

1 Kit # 3

Tube Kit - # 792382

Ref#

Description

Qty

Kit Qty 14

Elbow

1 1

15

Discharge Tube

1

17

Tube w/Ferrules & Nuts

1

Note: Kit Qty is the number of kits needed to repair unit

*Fastener Kit for Pump - # 792384 Qty

Bolt 5/16 x 1 -1/4 T18/in Grade 5 4

Nut T18/in flange lock 4

**Fastener Kit for Motor - # 792385 Qty

Bolt 5/16 x 1 T18/in Carriage Grade 5 4

Nut T18/in flange lock 4

***Fastener Kit for Belt Guard - # 792386 Qty

Bolt 5/16 x 1T18/in Grade 2 7

Nut T18/in flange lock 3

Fender washer 5/16 3

Washer 5/16 SAE 4

30

792373 Pump Parts List

*Wing nut for # 30 not shown

31

792373 Pump Parts List

Ref#

Part#

Description

Qty

1

Kit # 1

Cylinder head

3 2 Allen bolt set

12 3 792324

In.& ex. valve assembly

3 4 Kit # 3

Stud Screw

12 5 Kit # 4

Cylinder

3

6

Kit # 2

Kit # 4

Kit # 5

Cylinder gasket

3

7

792325

Kit # 4

Kit # 5

Piston ring kit

3

8

Kit # 5

Piston

3

9

792332

Rod

2

10

N/A

Crankcase

1

11

788879

Oil draining plug

1

12

788880

Oil sight gauge

1

13

789386

Oil cap 1 14

792333

Bearing

1

15

N/A

Crankshaft and balancer

1

16

789384

Magnetic plug

1

17

792329

Bearing

1

18

Kit # 2

Rear bearing seat gasket

1

19

N/A

Rear bearing seat

1

21

N/A

Hex bolt 4 22

Kit # 2

Oil seal 1 20

788882

Breather

1

23

789349

Pulley 1 24

Kit # 6

Fender washer

1

25

Hex bolt 1 26

792335

Rod 1 27

Kit # 7

Exhaust elbow

1

28

Exhaust fitting

1

29

792336

Discharge tube

2

30

789354

Air filter 3 31

789355

Filter element

3

32

Kit # 7

Exhaust fitting

1

*

789524

Wing nut, air filter

3

32

792373 Pump Parts List

Kit # 1

Cylinder Head and Bolt Kit - # 789336

Ref#

Description

Qty

Kit Qty

1

Cylinder head

1 3 2

Allen bolt set

4

Kit # 2

Gasket Kit - # 792342

Ref#

Description

Qty

Kit Qty

6

Cylinder gasket

3 1 18

Rear bearing seat gasket

1

22

Oil seal

1

Kit # 3

Screw Kit - # 789358

Ref#

Description

Qty

Kit Qty

4

Stud Screw

4

3

Kit # 4

Cylinder and Piston Kit - # 792343

Ref#

Description

Qty

Kit Qty

5

Cylinder

1 3 6

Cylinder gasket

1

7

Piston ring kit

1

8

Piston

1

Kit # 5

Piston Ring Kit - #792344

Ref#

Description

Qty

Kit Qty

6

Cylinder gasket

1

3

7

Piston ring kit

1

Kit # 6

Washer and Bolt - # 789367

Ref#

Description

Qty

Kit Qty

24

Fender washer

1 1 25

Hex bolt

1

Kit # 7

Exhaust Fitting Kit - # 792345

Ref#

Description

Qty

Kit Qty

27

Exhaust elbow

1

1

28

Exhaust fitting

1

32

Exhaust fitting

1

Note: Kit Qty is the number of kits needed to repair pump

33

Appendix A: Lubricants and Compatibility

Suitable

Not Recommended

Viton®, Teflon®, Epoxy

(Glass Filled), Oil

Resistant Alkyd,

Fluorosilicone,

Flourocarbon,

Polysulfide, 2Component

Urethane, Nylon,

Delrin®, Celcon®, High

Nitrile Rubber (Buna N.

NBR more than 36

Acrylonite),

Polyurethane,

Polyethylene,

Epichlorohydrin,

Polyacrylate, Melamine,

Polypropylene, Baked

Phenolics, Epoxy,

Modified Alkyds

(® indicates trademark

of DuPont Corporation)

Neoprene, Natural

Rubber, SBR Rubber,

Acrylic Paint, Lacquer,

Varnish, Polystyrene,

PVC, ABS,

Polycarbonite, Cellulose

Acetate, Latex, EPR,

Acrylics, Phenoxy,

Polysulfones, Styrene

Acrylonitile (San), Butyl

Temperature around

Compressor

Viscosity Grade

ISO

SAE

Below 40ºF (4ºC)

60

20

40ºF to 80ºF

(4ºC to 27ºC)

100

30

80ºF to 100ºF

(27ºC to 38ºC)

150

40

The following table lists materials that are suitable or not

recommended for use with synthetic oil. As some oil

escapes into the compressed air, all components that

come into contact with the air (i.e., piping, filters, hoses,

tools, etc) must be compatible with synthetic oil.

NorthStar recommends using synthetic oil after the first

50 hour break in period.

Alternate Lubricants

You may use a petroleum-based lubricant that is

premium quality, does not contain detergents, contains

only anti-rust, anti-oxidation, and anti-foam agents as

additives, has a flashpoint of 440ºF (227ºC) or higher,

and has an auto-ignition point of 650ºF (343ºC) or

higher.

See the petroleum lubricant viscosity table below. The

table is intended as a general guide only. Heavy-duty

operating conditions require heavier viscosities.

Refer specific operating conditions to NorthStar Product

Support at 1-800-270-0810.

34

Limited Warranty

NorthStar Warranty

Item #

Consumer Warranty Period

Commercial Warranty Period

47500

47501

4 years from date of purchase by user

2 years from date of purchase by user

Dear Valued Customer:

The NorthStar Product you just purchased is built with the finest material and craftsmanship. Use this product properly and enjoy the benefits

from its high performance. By purchasing a NorthStar product, you show a desire for quality and durability. Like all mechanical equipment this

unit requires a due amount of care. Treat this unit like the high quality piece of machinery it is. Neglect and improper handling may impair its

performance. Please thoroughly read the instructions and understand the operation before using your product. Always contact NorthStar

Product Support at 1-800-270-0810 prior to having any service or warranty work performed, as some services performed by parties other than

NorthStar approved service centers may void this warranty. This warranty is in lieu of any other warranty expressed or implied and NorthStar

assumes no other responsibility or liability outside that expressed within this warranty.

Limited Warranty

NorthStar shall warranty any piece of equipment manufactured, or parts of equipment manufactured, to be free from defects in material or

workmanship for a period of:

“Consumer use” means personal residential household use by a consumer. “Commercial use” means all other uses, including use for

commercial, income producing or rental purposes or when purchased by a business.

This warranty applies to the original purchaser of the equipment (verification of purchase, in the form of a receipt, is the responsibility of the

buyer), is non-transferable, and covers parts and labor. Parts will be replaced or repaired at no charge, except when the equipment has failed

due to lack of proper maintenance. If a part is no longer available, the part may be replaced with a similar part of equal function. Any misuse,

abuse, alteration or improper installation or operations will void warranty. Determining whether a part is to be replaced or repaired is the sole

decision of NorthStar. NorthStar will not provide for replacement of complete products due to defective parts. Any costs incurred due to

replacement or repair of items outside of a NorthStar approved facility is the responsibility of the buyer and not covered under warranty.

Transportation costs to and from service center is the responsibility of the customer.

In addition to the normal warranty, NorthStar shall warrant any normal wear item from defects in material or workmanship for a period of 90

days from the date of purchase by user. Normal wear items include, but are not limited to, belts and filter elements.

This warranty specifically excludes the following; failure of parts due to damage caused by accident, fire, flood, windstorm, acts of God,

applications not approved by NorthStar in writing, corrosion caused by chemicals, use of replacement parts which do not conform to

manufacturer’s specifications, damage related to rodent and/or insect infestation and damage caused by vandalism. Additional exclusions:

loss of running time, inconvenience, loss of income, or loss of use, including any implied warranty of merchantability of fitness for a specific

use. Also, Power Equipment needs periodic parts and service to perform well, and this warranty does not cover instances when normal use

has exhausted the life of a component or the motor.

This warranty does not cover any personal injury or damage to surrounding property caused by failure of any part. Repair or replacement of

parts does not extend the warranty period.

Please fill in the following information and have it on hand when you call in on a warranty claim.

Customer Number: ______________________________________________________________

Date of Purchase: _______________________________________________________________

NorthStar Serial Number: _________________________________________________________

Item Number: __________________________________________________________________

35

This page left intentionally blank

36

Assembled by

Northern Tool & Equipment Company, Inc.

Burnsville, MN 55306

NorthernTool.com

Loading...

Loading...