North Star M459231B.1 Maintenance Manual

Quick Facts

Pump Oil

Check pump oil level before starting.

Use Non-detergent pump oil (part #35605).

Air Filter

Make sure your air filter is clean and particle free.

Replacement air filter (part #35409).

Maximum

Pressure

Maximum pressure = 175 psi

Maintenance

Schedule

Tank:

Drain water daily.

Compressor

Pump:

Oil: change after first 50 hours, then every 3 months or 500 hours.

Read and understand all manuals before operating.

M459231B.1

459231; 5 HP Leeson, 19.2 PSC, 80 gal.

459241; 7.5 HP Leeson, 29.5 PSC, 80 gal.

M35643K.2

®

Electric Stationary Air Compressor

Installation, Operation and Maintenance Manual

To the Owner:

Thank you for purchasing a NorthStar Air Compressor. Your machine is designed for long life, dependability, and

the top performance you demand! Please take time now to read through this manual so you better understand

the machine’s operation, maintenance and safety precautions. Everyone who operates this machine must read

and understand this manual. The time you take now will prolong your machine’s life and prepare you for its safe

operation. Enjoy the exceptional performance of your NorthStar Air Compressor, the industry leader!

The manufacturer reserves the right to make improvements in design and/or changes in specifications at any

time without incurring any obligation to install them on units previously sold.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

2

Table of Contents

Important Safety Instructions

2

Operation

6

Receipt and Inspection

2

Maintenance / Kits & Service Parts

7

Machine Component Identification

3

Exploded View / Component List

8-11

Installation

4, 5

Troubleshooting

12

Wiring Installation

5

Limited Warranty

13

Safety

DEFINITIONS

DANGER!

WILL cause DEATH, SEVERE INJURY or substantial

property damage.

WARNING!

CAN cause DEATH, SEVERE INJURY or substantial

property damage.

CAUTION!

WILL or CAN cause MINOR INJURY or property

damage.

GENERAL SAFETY PRECAUTIONS

NEVER directly inhale compressed air.

NEVER over-pressurize the receiver tank or similar

vessels beyond design limits.

NEVER use a receiver tank or similar vessels that fail to

meet the design requirements of the compressor.

NEVER drill into, weld or otherwise alter the receiver

tank or similar vessels.

NEVER remove, adjust, bypass, change, modify or make

substitutions for safety/relief valves, pressure switches or

other pressure control related devices.

NEVER use air tools or attachments without first

determining the maximum pressure recommended for

that equipment.

NEVER point air nozzles or sprayers toward people or

animals.

NEVER touch the compressor pump, motor or engine or

discharge tubing during or shortly after operation. These

parts become hot.

NEVER operate where flammable or explosive liquids or

vapors such as gasoline, natural gas and solvents are

present.

NEVER remove, paint over, or deface decals. Replace

any missing decals.

NEVER operate with guards or shields removed,

damaged or broken.

ALWAYS follow precautions on container labels before

spraying such as paint , insecticide and weed killer.

ALWAYS wear respirator and safety glasses when

spraying.

ALWAYS wear eye protection when operating or

servicing compressor.

BREATHING AIR PRECAUTION

NorthStar air compressors are not designed, intended

or approved for breathing air. Compressed air should not

be used for breathing air applications unless treated in

accordance with all applicable codes and regulations.

Receipt and Inspection

Ensure adequate lifting equipment is available for

unloading and moving your compressor to the

installation site.

NOTE: Lifting equipment must be properly rated for the

weight of the compressor.

Caution! Do not work on or walk under the compressor

while it is suspended. Before signing the delivery receipt,

inspect for damage and missing parts. If damage or

missing parts are apparent, make the appropriate

notation on the delivery receipt, then sign the receipt.

Immediately contact the carrier for an inspection. All

material must be held in the receiving location for the

carrier’s inspection. Delivery receipts that have been

signed without a notation of damage or missing parts are

considered to be delivered “clear” Subsequent claims are

then considered to be concealed damage claims. Settle

damage claims directly with the transportation company.

If you discover damage after receiving the air

compressor (concealed damage), the carrier must be

notified within 15 day of receipt and an inspection must

requested by telephone with confirmation in writing. On

concealed damage claims, the burden of establishing

that the compressor was damaged in transit reverts back

to the claimant.

Read the compressor nameplate to verify it is the model

ordered, and read the motor nameplate to verify it is

compatible with your electrical conditions. Make sure

electrical enclosures and components are appropriate.

WARNING! The installation should be made by a

qualified electrician.

3

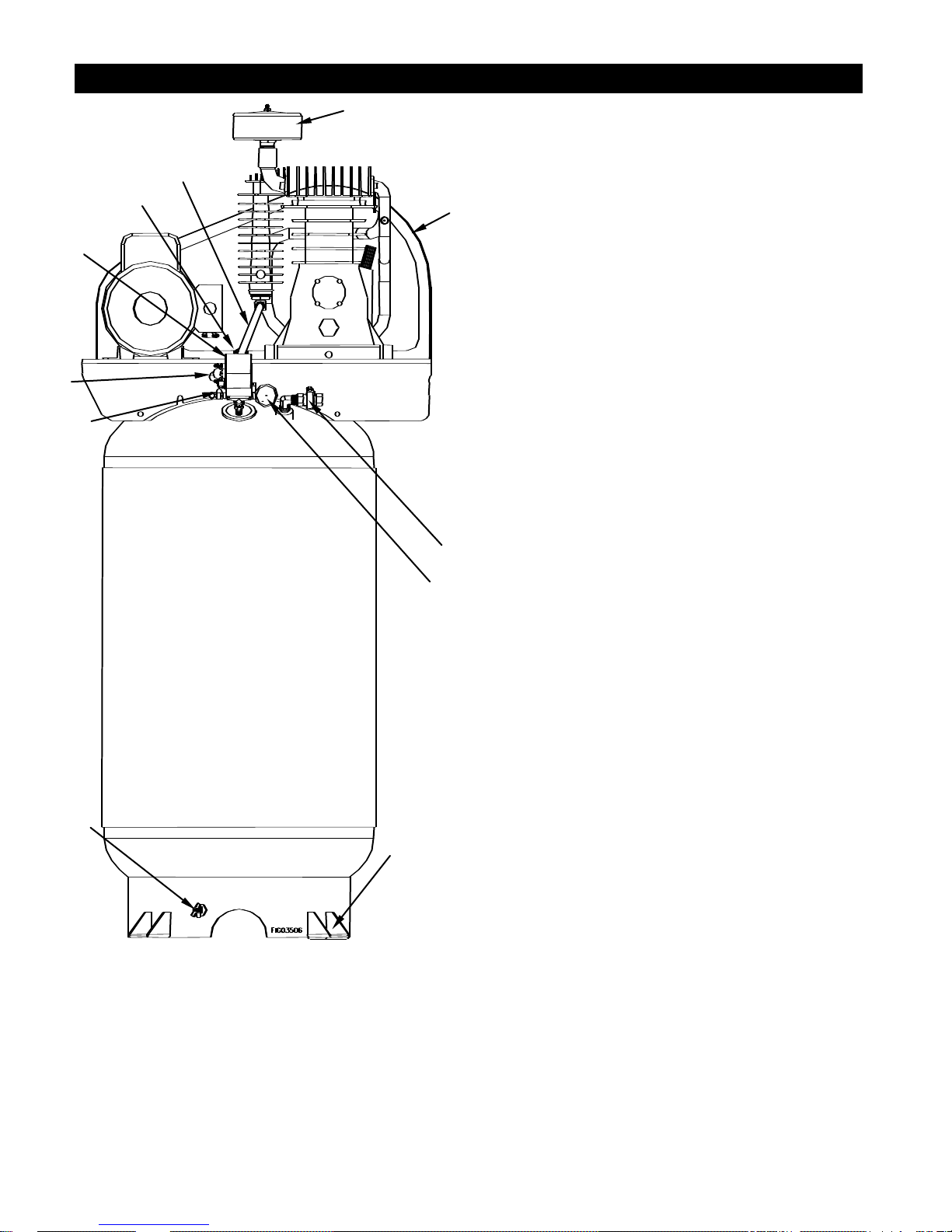

Machine Component Identification

10

9 8 12

11

2

7

1

4

5

6

1.) Air Filter - Make sure your air filter is clean and

particle free.

2.) Belt Guard - Covers the belt, motor pulley and

flywheel. NEVER operate compressor without the

belt guard or guard cover.

4.) Ball Valve - 1/2” NPT outlet.

5.) Pressure Gauge - Easy to read gauge.

6.) Mount Feet - Use an isolation pad system to

increase your compressor life.

7.) Remote Drain Petcock - This valve is located on

the foot ring of the tank. Use this valve to drain

moisture from the tank daily to reduce the risk of

corrosion.

8.) ASME Safety Valve - This valve automatically

releases air if the tank pressure exceeds the preset

maximum.

9.) Unloader - Device on pressure switch which

allows release of pressurized air between the tank

and compressor so motor does not start under load.

10.) Pressure Switch - Auto/Off Switch - In the

“auto” position, the compressor shuts off

automatically when tank pressure reached the

maximum preset pressure. In the “off” position, the

compressor will not operate. This switch should be

in the “off” position when connecting or

disconnecting the power cord from the electrical

outlet. NEVER attempt to adjust the pressure switch.

Tampering with the pressure switch will void ALL

warranties.

11.) Check Valve - One-way valve that allows air to

enter the tank, but prevents air in the tank from

flowing back into the compressor pump.

12.) Discharge Tube - This tube carries

compressed air from the pump to the check valve.

This tube becomes very hot during use. To avoid

the risk of severe burns, never touch the discharge

tube.

4

80-Gallon Tank

Safety Relief

Valve

34796 Pump (Item #459231)

34798 Pump (Item #459241)

Pressure

Switch

Safety

Relief

Valve

Note:

Pressure switch automatically activates the unloader.

SLOPE

TRAP

REGULATOR

FILTER/TRAP

TRAP

OUTLET

VALVE

00855

Installation

SELECTING A LOCATION

Select a well lit indoor area with plenty of space for

proper cooling air flow and accessibility. Locate the

compressor at least 15 inches (38 cm) from walls,

and make sure the power supply is clearly identified

and accessible.

Temperature. Ideal operating temperatures are

between 40 and 100F (4 and 37 C). If

temperatures consistently drop below 32 F (0 C),

install the compressor inside a heated building. If this

is not possible, you must protect safety/relief valves

and drain valves from freezing.

CAUTION!

NEVER operate in temperatures below 15 F (-9C)

or above 125 F (52C).

Humid Areas. In frequently humid areas, moisture

may form in the pump and produce sludge in the

lubricant, causing running parts to wear out

prematurely. Excessive moisture is especially likely

to occur if the compressor is located in an unheated

area that is subject to large temperature changes.

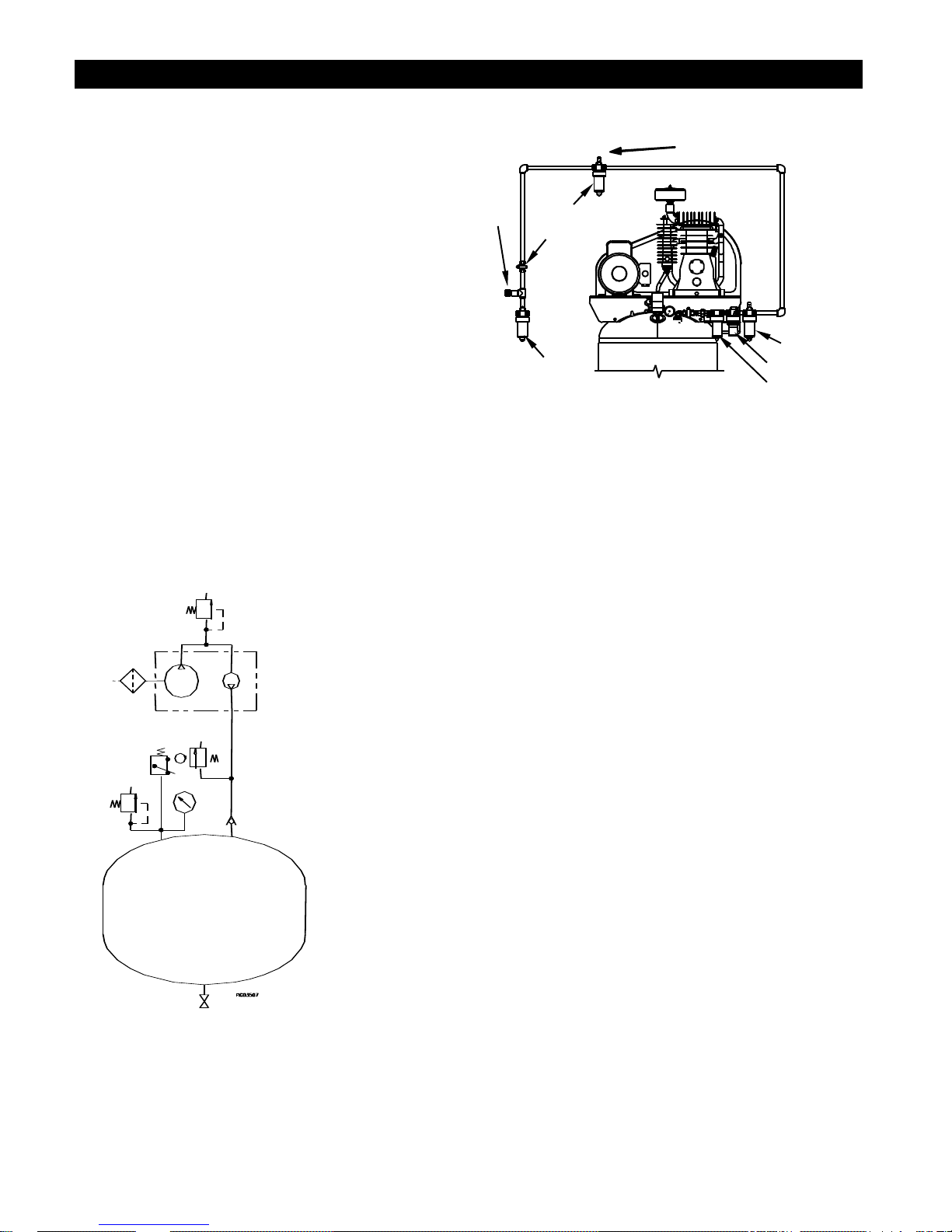

PNEUMATIC SCHEMATIC

INSTALLING DISCHARGE PIPING

CAUTION! If you will be using synthetic lubricant, all

downstream piping material and system components

must be compatible. Refer to suitable list on page 6.

General Requirements. The piping, fittings, etc.

must be certified for at least 4 times the working

pressure. Use hard-welded, threaded steel or copper

pipes and cast iron fittings that are certified safe for

the compressors discharge pressure and

temperature. DO NOT USE PVC PLASTIC. Use pipe

thread sealant on all threads, and make up joints

tightly to prevent air leaks.

Main Air Distribution Line. The main compressed

air distribution line should be of sufficient size to

minimize the pressure drop between the air supply

and the point of use. Slope the piping downward in

the direction of air flow to aid in the removal of

condensation at all drain points along the line. The

piping must be as short and direct as possible, and

adequately braced.

Drip Legs. A drip leg is a pipe extending downward

from the main line to collect condensation. Drip legs

should be at the lowest points in the air line and at

any point where the leg goes around an obstruction.

A drain valve should be installed at the bottom of

each drip leg.

Drop Legs. A drop leg is piping originating from the

main air distribution line that feeds air to an outlet for

tools or other air operated devices. Drop legs are

taken off the top of the main line so that

condensation does not easily flow into them. Drop

legs should be designed so that the air outlet comes

off the side of the drop leg, rather than the bottom.

By doing this, the condensation which is carried from

the main line collects below the outlet and prevents

moisture from entering the tool or device using the

air. A drain valve should be installed on the bottom of

each drop leg.

5

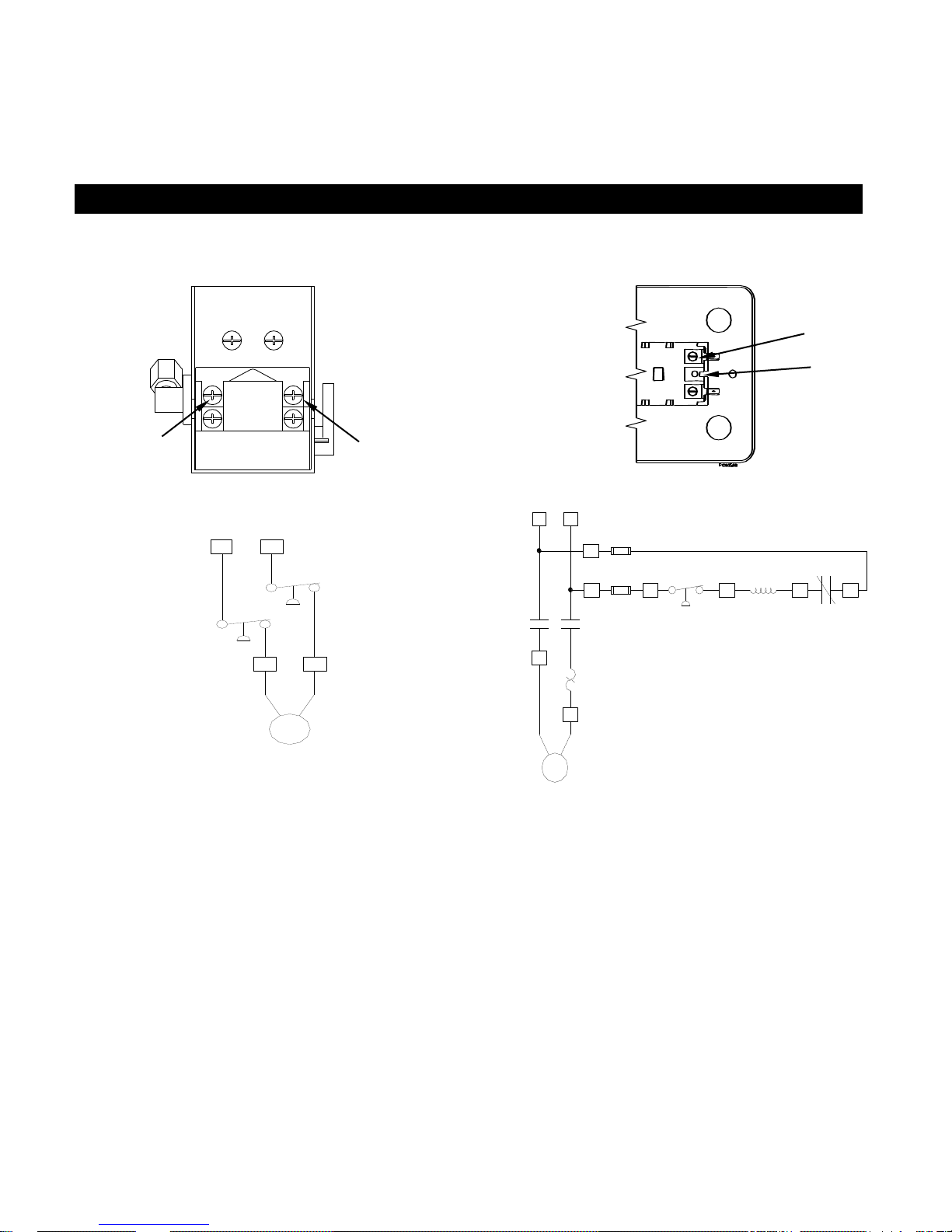

L2

L1

00857

L1

Electrical Service

Customer supplied wires

Pressure

Switch

M

Motor

B1 R1

L2

Pressure

Switch

00865

Motor

Starter

Overload

B1

M

L2

Motor

Starter

Contact

R1

L1

R2

Motor

Starter

Contact

B2

1A

FUSE

B3

R4

Motor

Starter

Coil

R5

Motor

Starter

Overload

R3

Electrical Service

Customer supplied wires

Motor

Pressure

Switch

00865

L2

L1

Condensation Discharge Piping. If installing a

condensation discharge line, the piping must be at

least one size larger than the connection, as short

and direct as possible, secured tightly and routed to

a suitable drain point. Condensation must be

disposed of in accordance with local, state, and

federal laws and regulations.

General. The motor rating, as shown on the motor

nameplate, and the power supply must have

compatible voltage, phase and hertz characteristics.

Wire Size. The electrical wiring between the power

supply and electric motor varies according to motor

horsepower. Power leads must be adequately sized

to protect against excessive voltage drop during

start-up. Information for selecting proper wire size

should be provided by a qualified electrician. If other

electrical equipment is connected to the same circuit,

the total electrical load must be considered in

selecting the proper wire size. Do not use undersized

wire.

NOTE: On units requiring a motor starter, connect

line power to the starter. DO NOT connect the line

power to the pressure switch.

Top View - Pressure Switch

Model 459231

WARNING! If an aftercooler, check valve, block

valve, or any other restriction is added to the

compressor discharge, install a properly sized ASME

approved safety/relief valve between the compressor

discharge and the restriction.

Wiring Installation

Magnetic Starter. If the motor installed on your

compressor has a motor reset button, it does not

require a magnetic starter. If the motor does not

have this button, connect the power leads to the

starter located under the compressor top plate.

Circuit Breaker. Refer to the National Electric

Code to determine the proper circuit breaker rating

required. When selecting a circuit breaker,

remember the momentary starting current of an

electric motor is greater than its full load current.

Time delay or “slow-blow” circuit breakers are

recommended.

WARNING! The installation should be made by a

qualified electrician. If the products must be

reconnected for use on different types of circuits,

the re-connection should be made by qualified

personnel.

Model 459241

Side View - Motor Starter

Loading...

Loading...