Northern Industrial Tools 45765 User Manual

Item# 145765

Automatic Metal-Cutting Band Saw

User’s Manual

Assembly and Operation Instructions

MADE IN CHINA

Quick-Start Guide

ATTENTION: READ AND FOLLOW UNPACKING & ASSEMBLY GUIDE BEFORE

OPERATION.

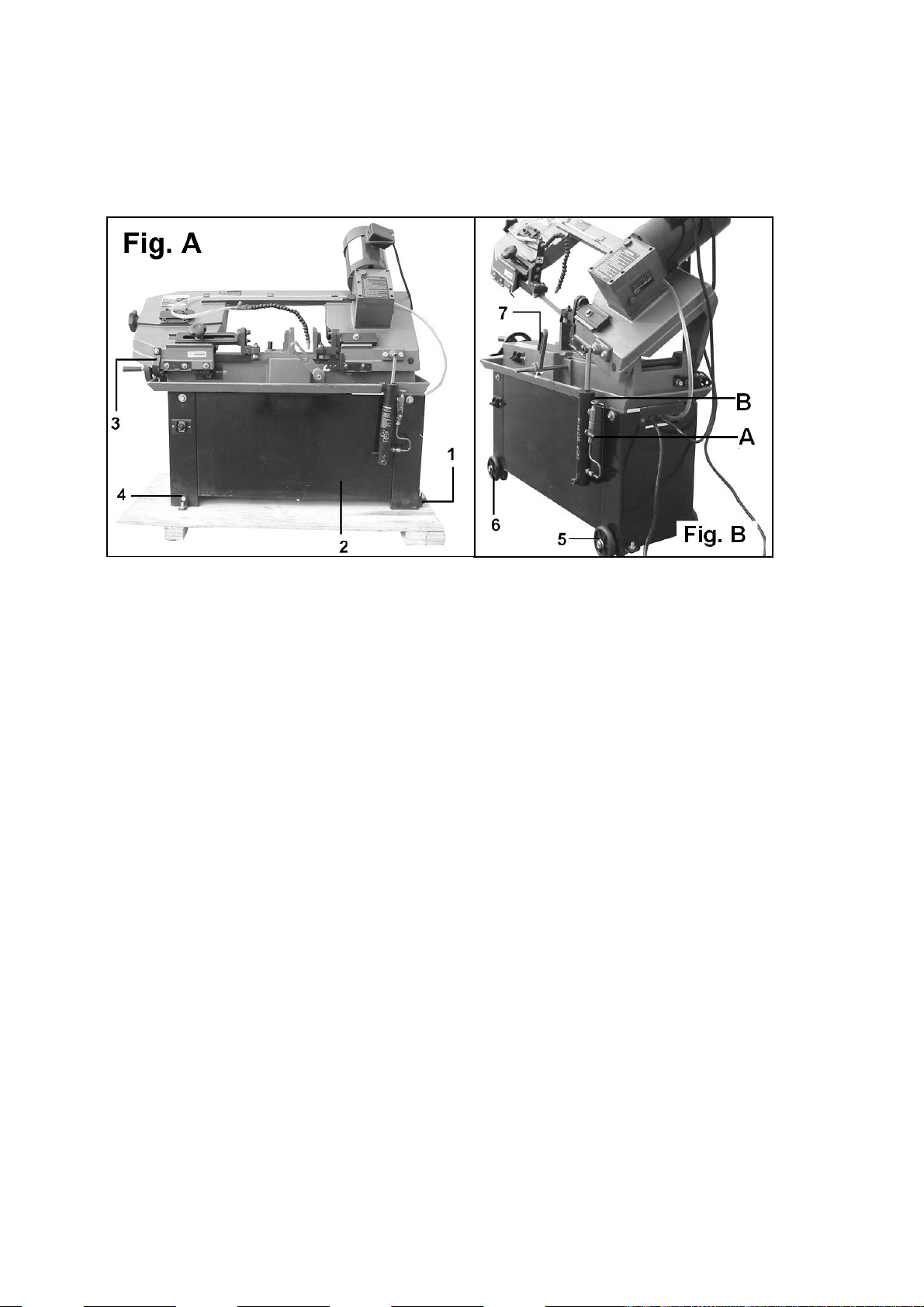

1. Front Locking Bolt 5. Front Wheels

2. Band Saw. 6. Rear Wheels

3. Locking device between saw arch and table. 7. Length-restricting device for workpiece

4. Rear Locking Bolt

UNPACKING

Step 1. Snip the carton wrapping belt near the wooden pallet, pull the nails from the

carton and pallet, then the carton can be taken away.

Step 2. The band saw can be removed from the pallet by removing the bolts and

connecting parts (1 & 4 of Fig. A). Remove the bolt and connecting parts of the locking

device (3 of Fig. A), then the saw arch can be raised.

ASSEMBLY

Step 1. Assemble the front & rear wheels (5 & 6 of Fig. B).

Step 2. By removing the locking device (3 of Fig. A), the saw arch could be raised. The

saw arch will stay in position if the hydraulic valve (A & B of Fig. B) is “Off”. The saw

arch cannot be pressed down by using external force. You must put the hydraulic valve

(A of Fig. B) in “On” position and then switch the flow control (B of Fig. B) to lower the

saw arch. The speed of the saw arch going down depends on the range you choose for

the flow control valve (B of Fig. B).

Note: The hydraulic valve (A of Fig. B) is “Off” when its handle is in horizontal direction,

and “On” when its handle is vertical.

Page 1 of 15

For technical questions and replacement parts, please call 1-800-556-7885.

Thank you very much for choosing a Northern Industrial Product! For future reference, please

complete the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire instruction

sheet to become familiar with this product before you begin using it.

This machine is designed for certain applications only. It is strongly recommended that this machine

is not modified and/or used for any application other than that for which it was designed. If you have

any questions relative to a particular application, DO NOT use the machine until you have first

contacted your dealer to determine if it can or should be performed on the product.

Before using the Automatic Metal-Cutting band Saw, please read the following instructions carefully.

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT

IN SERIOUS PERSONAL INJURY

AS WITH ALL MACHINERY, THERE ARE CERTAIN HAZARDS INVOLVED WITH OPERATION AND USE OF

THE MACHINE. USING THE MACHINE WITH RESPECT AND CAUTION WILL CONSIDERABLY REDUCE THE

POSSIBILITY OF PERSONAL INJURY. HOWEVER, IF NORMAL SAFETY PRECAUTIONS ARE OVERLOOKED

OR IGNORED, PERSONAL INJURY TO THE OPERATOR MAY RESULT.

THIS MACHINE WAS DESIGNED FOR CERTAIN APPLICATION ONLY. WE STRONGLY RECOMMEND THAT

THIS MACHINE NOT BE MODIFIED AND OR USED FOR ANY APPLICATION OTHER THAN FOR WHICH IT

WAS DESIGNED. IF YOU HAVE ANY QUESTIONS RELATIVE TO ITS APPLICATION, DO NOT USE THE

MACHINE UNTIL YOU HAVE HAD DETAIL INSTRUCTION FROM YOUR DEALER.

SAFETY RULES FOR ALL TOOLS

1. For your own safety, read instruction manual before operating the tool. Learn the tools application

and limitations as well as the specific hazards of operating it.

2. Always keep guards in place and in working order.

3. Ground all tools. If tool is equipped with three-prong plug, it should be plugged into a three-hole

electrical receptacle. If an adapter is used to accommodate a two-prong receptacle, the adapter plug

must be attached to a known ground. Never remove the third prong.

4. Always remove adjusting keys and wrenches before operating machine. Form a habit of checking

to see that keys and adjusting wrenches are removed from tool before turning it “on”.

5. Keep work area clean. Cluttered areas and benches invite accidents.

6. Don’t use in dangerous environment. Don’t use power tools in damp or wet locations, or expose

them to rain. Keep work area well lit.

7. Keep children and visitors away. All children and visitors should be kept a safe distance from work

area.

8. Make workshop child-proof with padlocks, master switches, or by removing starter keys.

9. Use the right tool. Don’t force tool or attachment to do a job for which it was not designed.

10. Wear proper apparel. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry that

can get caught in moving parts. Non-slip foot wear is recommended. Wear protective hair covering

to contain long hair.

Page 2 of 15

11. Always wear eye protection, Refer to A.N.S.I Z87.1 Standard for appropriate recommendations.

Also use a face or dust mask if cutting operation is dusty.

12. Always secure work with clamps or a vise. It’s safer than using your hand and frees both hands

to operate tool.

13. Don’t overreach - keep proper footing and balance at all times.

14. Maintain tools in top condition. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

15. Disconnect tools before servicing and when changing accessories such as blades, bits, cutters,

etc.

16. Use recommended accessories. Consult the owner’s manual for recommended accessories.

The use of improper accessories may cause hazards.

17. Avoid accidental starting. Make sure Switch is in “OFF” position before plugging in power cord.

18. Never stand on the tool. Serious injury could occur if the tool is tipped or if the cutting tool is

accidentally contacted.

19. Check damaged parts before further use of the tool. A guard or other part that is damaged

should be carefully checked to ensure that it will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that is damaged should be

properly repaired or replaced.

20. Note direction of feed. Feed work into a blade or cutter against the direction of rotation of the

blade or cutter only.

21. Never leave the tool running unattended. Turn the power off and do not leave the tool until it

comes to a complete stop.

22. Do not operate tool while under the influence of drugs, alcohol or any medication.

23. Make sure tool is disconnected from power supply while motor is being mounted, connected or

reconnected.

ADDITIONAL SAFETY RULES FOR HORIZONTAL BAND SAWS

1. Adjust and position the blade guide arm before starting cut.

2. Keep blade guide arm tight. A loose blade guide arm will affect sawing accuracy.

3. Make sure that blade tension and blade tracking are properly adjusted.

4. Re-check blade tension after initial cut with a new blade.

5. To prolong blade life, always release blade tension at the end of each workday.

6. Make sure blade speed is set correctly for material being cut.

7. Check for proper blade size and type based on the material being cut.

8. Stop the machine before putting material in the vise and clamping it well.

9. Always have stock firmly clamped in vise before starting to cut.

10. Always keep hands and fingers away from the blade.

11. Check coolant daily: Low coolant level can cause foaming and high blade temperatures. Dirty or

weak coolant can clog pump, cause crooked cut, low cutting rate and permanent blade failure. Dirty

coolant can cause the growth of bacteria with ensuing skin irritation.

Page 3 of 15

12. When cutting magnesium never use soluble oils or emulsions (oil-water mix) as water will greatly

intensify any accidental magnesium chip fire. See your industrial coolant supplier for specific coolant

recommendations when cutting magnesium.

13. To prevent corrosion of machine surface when a soluble oil is used as coolant, pay particular

attention to wiping dry the surfaces where fluid accumulates and does not evaporate quickly, such

as between the machine bed and vise.

14. Stop the machine before removing chips.

15. Make all adjustments with the power off.

16. Disconnect machine from power source when making repairs.

17. Shut off power and clean the Band Saw and work area before leaving the machine.

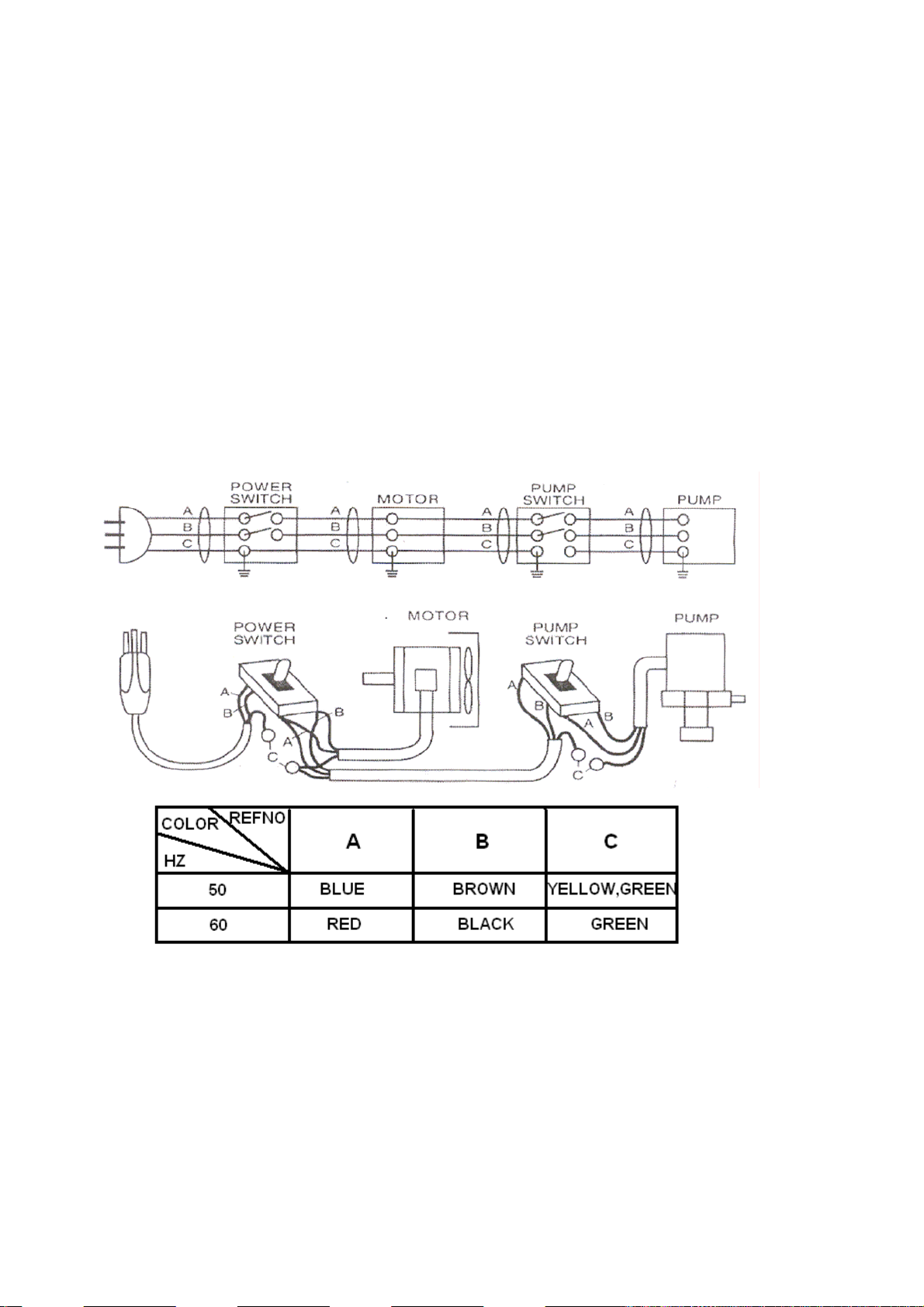

WIRING DIAGRAM

TOGGLE SWITCH SINGLE PHASE

ASSEMBLY

A 1 HP, 1725 motor, split phase or capacitor-start, is recommended for best economical

performance.

The characteristics of this machine:

1. If you want to shift the speed, you may shif

gearbox. And you may cho

ose the appropriate speed in accordance with the material of the

workpiece.

2. After the cut processing is completed, the power will turn off automatically.

t the speed directly by operating the handle beside the

Page 4 of 15

Loading...

Loading...