Northern Industrial Tools ST80i User Manual

67 L 23(5$7,1* 0$18$/

Northern Industrial Welding |

|

Operating Instructions and Parts Manual |

ST80i |

Please read and save these instructions. Read through this owner’s manual carefully before using product. Protect yourself and others by observing all safety information, warnings, and cautions. Failure to comply with instructions could result in personal injury and/or damage to product or property. Please retain instructions for future reference.

Welding

Description

ST80i portable DC inverter arc welder AC single phase 120V (110120V), 60HZ . 20 amp time delayed

fuse or circuit breaker is recommended, Overload protection. An ideal stick unit to weld all sorts of carbon steel, stainless steel and DIY jobs.Tig torch option available

Unpacking

1.1 Remove cartons, bags or

Styrofoam containing the welder and accessories. 1.2 Check the contents with the packing list below.

ITEM |

QTY. |

|

Portable Arc Welder |

1 unit |

|

Welding cable with electrode holder |

1pc |

|

Grounding cable with earth clamp |

1pc |

|

Operator’s Manual |

1set |

|

Sample electrodes |

1 bag |

|

Carry strap |

1pc |

1.3 After unpacking unit, inspect carefully for any damage that may have occurred during transit. Check for loose, missing, or damaged parts. Shipping damage claim must be filed with carrier.

1

Northern Industrial Welding |

ST80i |

Operating Instructions and Parts Manual |

|

Specifications and Dimension

MODEL |

|

|

|

ST80i |

|

|

|

|

|||

Power supply (v) |

|

1ph-120V-60HZ |

|

||

No-load voltage (v) |

|

75V |

|

|

|

Output Range (A) |

|

20-75A |

90A Peak |

|

|

Duty cycle (%) |

|

20% @75A |

|

||

Suggested electrode |

|

E6013,E7014,E7018, Stainless steel |

|||

Electrode Diameter (Inch) |

1/16”, 5/64”, 3/32” 1.6mm 2.0mm 2.4mm |

||||

Dimensions |

|

300x120x240MM / 12x5x9 inches |

|||

Length x Width x Height |

|||||

|

|

|

|||

Weight (Ibs) |

|

4.5Kgs |

9.9Lbs |

|

|

Know your Welder |

Power Indicating light |

Thermal protection |

|||

|

Indicating light |

||||

Strap |

|

|

|

Current adjustment |

|

Welding cable and |

|

|

|

Output“-”connector |

|

electrode holder

Output“+”connector

Ground Cable

and clamp

Indicating Light Power, Thermal Protection

There are two indicating lights : power indicator and thermal indicator. When the machine is turned on, the power indicator will be on to show it. When the thermal indictor is on, it shows the machine is overloaded working and the internal temperature is too high. The machine will turn off automatically but the fan will still be working. When the internal temperature is decreased, the machine will turn on automatically.

Current Adjustment

Current adjustment is on the front panel of machine. It is an infinite current output adjustment

Output “+“Connector

This is the connector for welding cable most often when STICK welding. When this machine is used for TIG welding, this connector is for the grounding cable.

Ground Cable and Clamp

The ground cable and clamp is attached to the work piece to complete the flow of current needed to weld.

2

MAX/MIN

Switch

Thermal Indic

Ground Ca

Northern Industrial Welding |

ST80i |

Operating Instructions and Parts Manual |

|

Welding Cable and Electrode Holder

One end of cable is connected to output connectors of the machine. The electrode is clamped in the electrode holder for welding.

Output “-” Connector

This is the connector for grounding cable when STICK welding. When this machine is used for TIG welding, this connector is for the TIG torch

Power Cord

The power cord connects the welder to the 110-120v volt power supply. Plug the 15 amp plug into a 115 volt/20 amp receptable to supply power to the welder

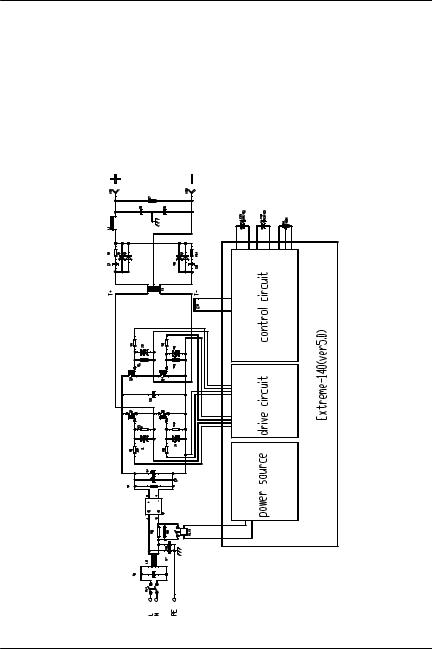

Wiring Diagrams

3

Northern Industrial Welding |

ST80i |

Operating Instructions and Parts Manual |

|

General Safety Information

1.1Your Welding Environment

-Keep the environment you will be welding in free from flammable materials.

-Always keep a fire extinguisher accessible to your welding environment.

-Always have a qualified person install and operate this equipment. -Make sure the area is clean, dry and ventilated. Do not operate the welder in humid, wet or poorly ventilated areas.

-Always have your welder maintained by a qualified technician in accordance with local, state and national codes.

-Always be aware of your work environment. Be sure to keep other people, especially children, away from you while welding.

-Keep harmful arc rays shielded from the view of others.

-Mount the welder on a secure bench or cart that will keep the welder secure and prevent it from tipping over or falling.

1.2Your Welder’s Condition

-Check all cables, power cord and welding cable to be sure the insulation is not damaged. Always replace or repair damaged components before using the welder. -Check all components to ensure they are clean and in good operating condition before use.

1.3 Use of Your Welder

Do not operate the welder if the output cable, electrode, or any part of the system is wet. Do not immerse them in water. These components and the welder must be completely dry before attempting to use it.

-Follow the instructions in this manual. -Keep welder in the off position when not in use.

-Connect ground lead as close to the area being welded as possible to ensure a good ground.

-Do not allow any body part to come in contact with the electrode if you are in contact with the material being welded, ground or electrode from another welder.

-Do not weld if you are in an awkward position. Always have a secure stance while welding to prevent accidents. Wear a safety harness if working above ground.

-Do not drape cables over or around your body.

-Wear a full coverage helmet with shade (see ANSI Z87.1 safety standard) and safety glasses while welding.

-Wear proper gloves and protective clothing to prevent your skin from being exposed to hot metals, UV and IR rays.

-Do not overuse or overheat your welder. Allow proper cooling time between duty cycles.

-Always use this welder in the rated duty cycle to prevent excessive heat and failure.

1.4 Specific Areas of Danger, Caution or Warning

Electrical Shock

Electric arc welders can produce a shock that can cause injury or

death. Touching electrically live parts can cause fatal shocks and severe burns. While welding, all metal components connected to the unit are electrically hot. Poor ground

4

Northern Industrial Welding |

|

|

|

ST80i |

|||||

Operating Instructions and Parts Manual |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||

connections are a hazard, so secure |

toxic. Refer to the material safety |

||||||||

the ground lead before welding. |

data sheet for the manufacturer’s |

||||||||

-Wear dry protective apparel: coat, |

instructions. |

|

|

|

|||||

shirt, gloves and insulated footwear. |

-Do not weld near materials that will |

||||||||

-Insulate yourself from the work piece. |

emit toxic fumes when heated. |

||||||||

Avoid contacting the work piece or |

Vapors from cleaners, sprays and |

||||||||

ground. |

degreasers can be highly toxic when |

||||||||

- Do not attempt to repair or maintain |

heated. |

|

|

|

|||||

the welder while the power is on. |

|

UV and IR Arc Rays |

|||||||

-Inspect all cables and cords for any |

|

|

|

|

|

|

|||

exposed wire and replace |

|

|

|

|

|

|

|||

|

The welding arc |

||||||||

immediately. |

|

||||||||

|

produces ultraviolet (UV) |

||||||||

-Use recommended replacement |

|

||||||||

|

and infrared (IR) rays |

||||||||

cables and cords. |

|

||||||||

that can cause injury to your eyes |

|||||||||

-Always attach ground clamp to the |

|||||||||

and skin. Do not look at the welding |

|||||||||

work piece work table as close to the |

|||||||||

arc without proper eye protection. |

|||||||||

weld area as possible. |

|||||||||

-Always use a helmet that covers |

|||||||||

-Do not touch the electrode and the |

|||||||||

your full face from the neck to top of |

|||||||||

ground or grounded work piece at the |

|||||||||

head and to the back of each ear. |

|||||||||

same time. |

|||||||||

-Use a lens that meets ANSI |

|||||||||

-Do not use a welder to thaw frozen |

|||||||||

standards and safety glasses. For |

|||||||||

pipes. |

|||||||||

welders under 160 Amps output, use |

|||||||||

|

Fumes and Gases |

||||||||

|

a shade 10 lens; for above 160 Amps, |

||||||||

|

|

|

|||||||

|

|

|

use a shade 12. Refer to the ANSI |

||||||

|

-Fumes emitted from the |

standard Z87.1 for more information. |

|||||||

welding process displace |

-Cover all bare skin areas exposed to |

||||||||

clean air and can result in |

the arc with protective clothing and |

||||||||

injury or death. |

shoes. Flame-retardant cloth or |

||||||||

-Do not breathe in fumes emitted by |

leather shirts, coats, pants or |

||||||||

the welding process. Make sure your |

coveralls are available for protection. |

||||||||

breathing air is clean and safe. |

-Use screens or other barriers to |

||||||||

-Work only in a well-ventilated area or |

protect other people from the arc rays |

||||||||

use a ventilation device to remove |

emitted from your welding. |

||||||||

welding fumes from the environment |

-Warn people in your welding area |

||||||||

where you will be working. |

when you are going to strike an arc |

||||||||

-Do not weld on coated materials |

so they can protect themselves. |

||||||||

(galvanized, cadmium plated or |

Fire Hazards |

||||||||

containing zinc, mercury or barium). |

|

|

|

|

|

|

|||

They will emit harmful fumes that are |

|

|

|

|

|

|

|||

Do not weld on containers |

|||||||||

dangerous to breathe. If necessary |

|||||||||

or pipes that contain or |

|||||||||

use a ventilator, respirator with air |

|||||||||

have had flammable, |

|||||||||

supply or remove the coating from the |

|||||||||

gaseous or liquid |

combustibles in |

||||||||

material in the weld area. |

|||||||||

them. Welding creates sparks and |

|||||||||

-The fumes emitted from some |

heat that can ignite flammable and |

|

metals when heated are extremely |

||

|

||

|

5 |

Loading...

Loading...