Northern Industrial Tools 142264 User Manual

Item #

142264

660-LB CAPACITY HIGH S P EED

ELECTR I C HOIST

OWNER’S MANUAL

WARNING:

INSTRUCTIONS before operating. Failure to follow the safety

rules and other basic safety precautions may result in

serious personal injury.

Read carefully and understand all

Thank you very much for choosing a NORTHERN TOOL + EQUIPMENT CO., INC. Product! For

future reference, please complete the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This machine is designed for certain applications only. Northern Tool + Equipment cannot be

responsible for issues arising from modification. We strongly recommend this machine is not

modified and/or used for any application other than that for which it was designed. If you have

any questions relative to a particular application, DO NOT use the machine until you have first

contacted Northern Tool + Equipment to determine if it can or should be performed on the

product.

For technical questions please call 1-800-222-5381.

INTENDED USE

The Electric Hoist is used to lift goods more effectively.

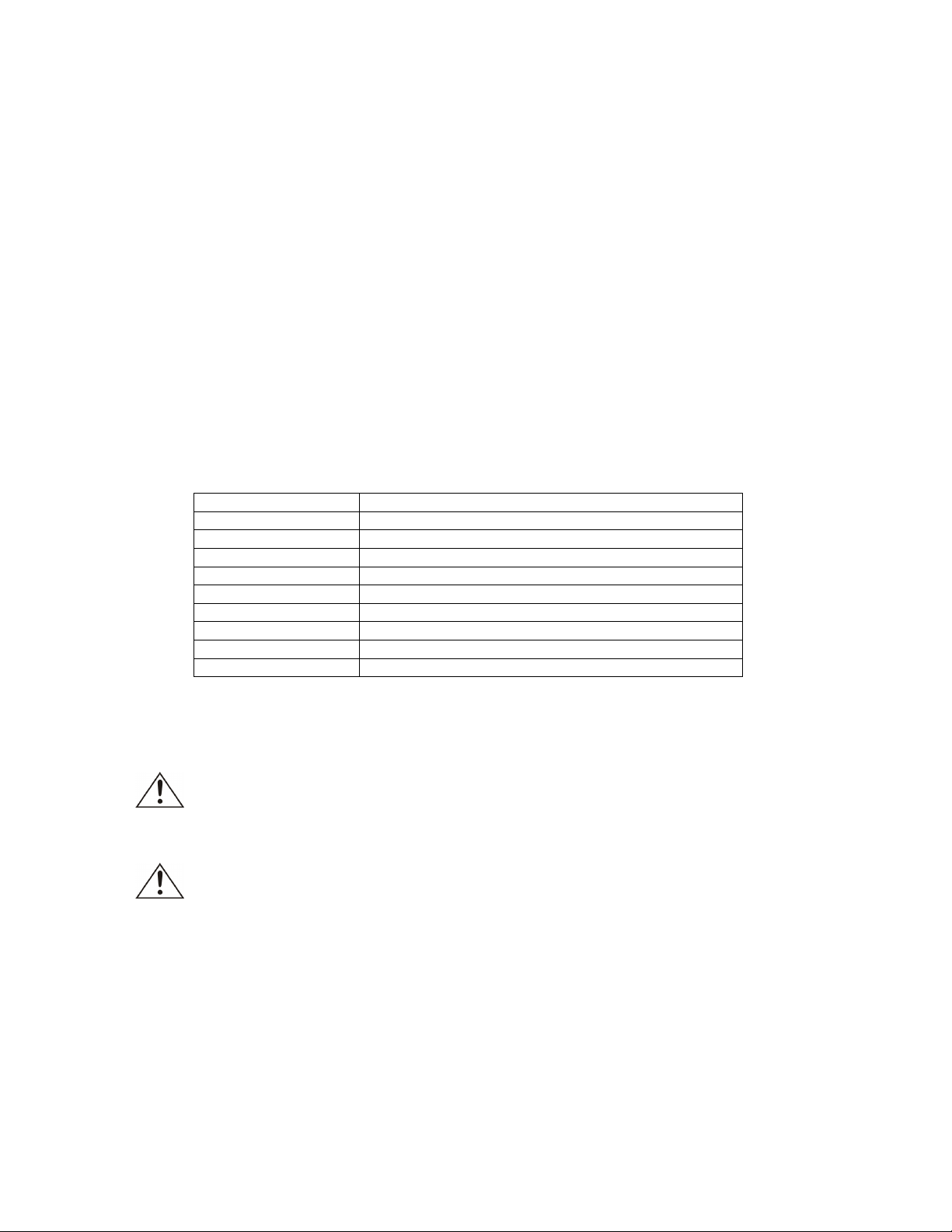

TECHNICAL SPECIFICATIONS

Description Specification

Load capacity 660 lbs.

Lifting height 75 ft.

Lifting speed 65 ft/min

Cable length 82 ft.

Cable diameter 7/32" (6.0mm) anti-twist

Resister cable >=5000 lbs.

Duty circle S3 50%-20 min.

Voltage 220V/60Hz

Motor performance 2 HP

GENERAL SAFETY RULES

WARNING:

below may result in electric shock, fire and/or serious injury.

WARNING:

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

Read and understand all instructions. Failure to follow all instructions listed

The warnings, cautions, and instructions discussed in this instruction

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep work area clean, free of clutter and well lit. Cluttered and dark work areas can cause

accidents.

Page of 13

2

• Do not use your tool where there is a risk of causing a fire or an explosion; e.g. in the

presence of flammable liquids, gasses, or dust. Power tools create sparks, which may ignite the

dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause you

to lose control, so visitors should remain at a safe distance from the work area.

• Be aware of all power lines, electrical circuits, water pipes and other mechanical hazards in

your work area, particularly those hazards below the work surface hidden from the operator’s

view that may be unintentionally contacted and may cause personal harm or property damage.

• Be alert of your surroundings. Using power tools in confined work areas may put you

dangerously close to cutting tools and rotating parts.

ELECTRICAL SAFETY

•

WARNING!

Always check to ensure the power supply corresponds to the voltage on

the rating plate.

• Do not abuse the cord. Never carry a portable tool by its power cord, or yank tool or extension

cords from the receptacle. Keep power and extension cords away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords may cause a fire and

increase the risk of electric shock.

• Grounded tools must be plugged into an outlet properly installed and grounded in accordance

with all codes and ordinances. Never remove the grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to

whether the outlet is properly grounded.

• Double insulated tools are equipped with a polarized plug (one blade is wider than the other).

This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still doesn’t fit, contact a qualified electrician to install a polarized outlet. Do

not change the plug in any way.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators.

There is an increase risk of electric shock if your body is grounded.

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.”

These cords are rated for outdoor use and reduce the risk of electric shock.

• Extension Cord Use.

A. Use only ‘Listed’ extension cords. If used outdoors, they must be marked “For Outdoor Use.”

Those cords having 3-prong grounding type plugs and mating receptacles are to be used

with grounded tools.

B. Replace damaged or worn cords immediately.

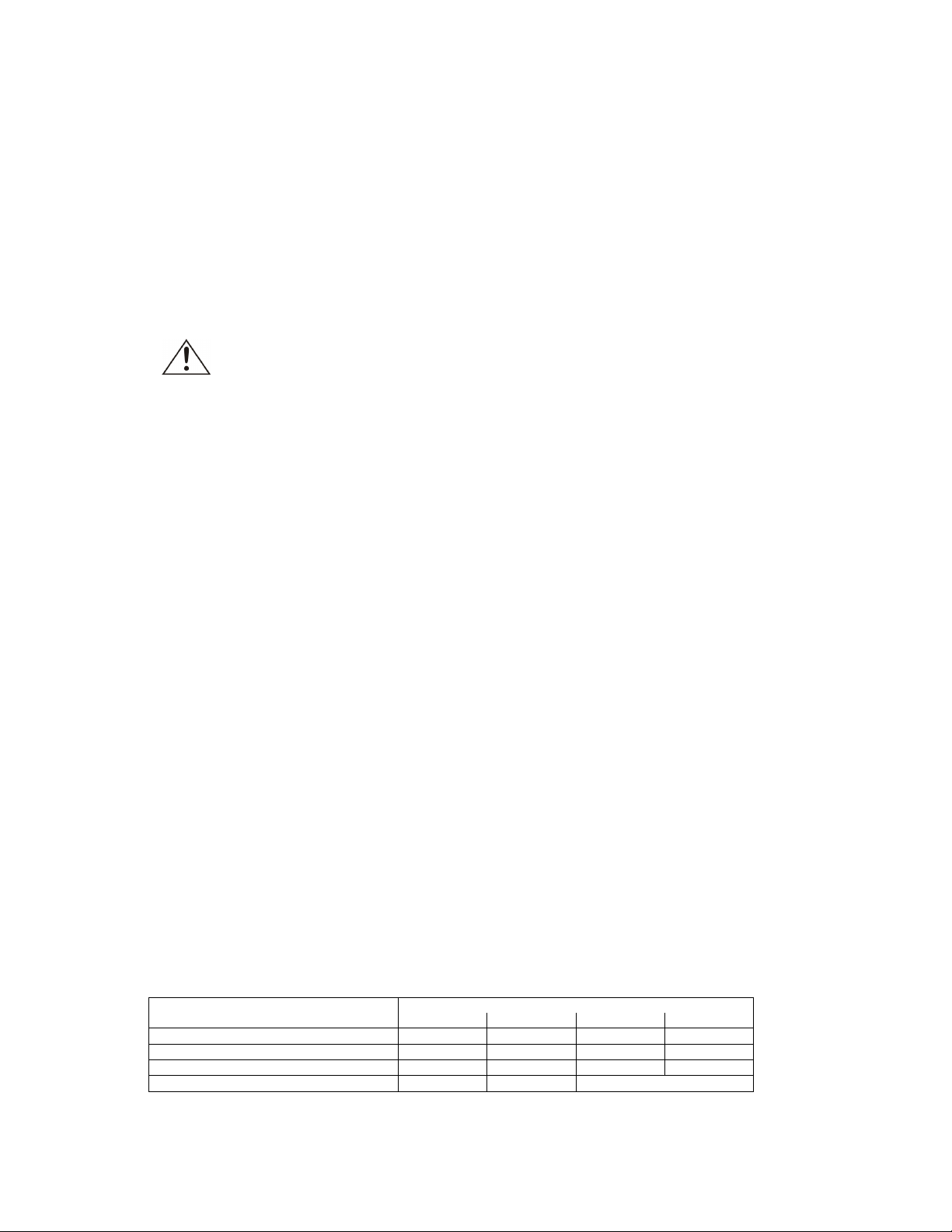

C. Check the name plate rating of your tool. Use of improper size or gauge of extension cord

may cause unsafe or inefficient operation of your tool. Be sure your extension cord is rated

to allow sufficient current flow to the motor. For the proper wire gauge for your tool, see

chart.

CHART FOR MINIMUM WIRE SIZE OF EXTENSION CORD:

25' 50' 100' 150'

Nameplate AMPS

0-6 18 AWG 16 AWG 16 AWG 14 AWG

6-10 18 AWG 16 AWG 14 AWG 12 AWG

10-12 16 AWG 16 AWG 14 AWG 12 AWG

12-16

Be sure to check voltage requirements of the tool to your incoming power source.

14 AWG 12 AWG (NOT RECOMMENDED)

If in doubt, use larger cord.

Page of 13

3

CORD LENGTH

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not let your fingers touch the terminals of plug when installing to or removing from the

outlet.

• Ground fault circuit interrupters. If work area is not equipped with a permanently installed

Ground Fault Circuit Interrupter outlet (GFCI), use a plug-in GFCI between power tool or

extension cord and power receptacle.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught

in moving parts. Air vents often cover moving parts and should be avoided.

• Use safety apparel and equipment. Use safety goggles or safety glasses with side shields

which comply with current national standards, or when needed, a face shield. Use as dust mask

in dusty work conditions. This applies to all persons in the work area. Also use non-skid safety

shoes, hardhat, gloves, dust collection systems, and hearing protection when appropriate.

• Avoid accidental starting. Do not carry the power tool with your finger on the switch. Ensure

the switch is in the off position before plugging tool into power outlet. In the event of a power

failure, while a tool is being used, turn the switch off to prevent surprise starting when power is

restored.

• Do not overreach. Keep proper footing and balance at all times.

• Remove adjusting keys or wrenches before connecting to the power supply or turning on the

tool. A wrench or key that is left attached to a rotating part of the tool may result in personal

injury.

TOOL USE AND CARE

• Do not force the tool. Tools do a better and safer job when used in the manner for which they

are designed. Plan your work, and use the correct tool for the job.

• Never use a tool with a malfunctioning switch. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired by an authorized service representative before using.

• Disconnect power from tool and place the switch in the locked or off position before servicing,

adjusting, installing accessories or attachments, or storing. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

• Secure work with clamps or a vise instead of your hand to hold work when practical. This safety

precaution allows for proper tool operation using both hands.

• Store idle tools. When tools are not is use, store them in a dry, secure place out of the reach of

children. Inspect tools for good working condition prior to storage and before re-use.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may create a risk of injury when used on another

tool.

• Keep guards in place and in working order.

• Never leave tool running unattended.

Page of 13

4

Loading...

Loading...