Northern Industrial Tools 123006 User Manual

2 HP / 4 GALLON

AIR COMPRESSOR

OPERATING MANUAL

Item # 123006

READ ALL INSTRUCTIONS

BEFORE OPERATING

SAVE THESE INSTRUCTIONS

Thank you for purchasing your Northern Industrial

Air Compressor. Before attempting to operate your

new tool please read these instructions thoroughly.

You will need these instructions for the safety

warnings, precautions, assembly, operation and

maintenance procedures.

WARNING: The warnings, cautions and

instructions discussed in this instruction manual

cannot cover all possible conditions or situations

that could occur. It must be understood by the

operator that common sense and caution are

factors which cannot be built into this product, but

must be supplied by the operator.

TABLE OF CONTENTS

Description Page #

Specifications .......................................1

Safety rules ..........................................2

Know Your Tool.....................................3

Getting Started .....................................3

Assembly..............................................3

Operation..............................................4

Maintenance.........................................6

Troubleshooting....................................7

Parts List and Diagram.........................8

TM

SPECIFICATIONS

Motor...................................120V ~ 60Hz

.......................................2

HP

Weight.................................59.5 lbs

Tank Capacity .....................4 Gallon

Air Pressure ........................115 psi

CFM ....................................5.5 CFM@40 psi

............................................3.5 CFM@90 psi

CSA Listed..........................

1

SAFETY RULES

1. Know your tool. Read this manual carefully.

Learn the tool’

well as specific potential hazards peculiar to it.

2. Ground all tools. If the tool is equipped with threepin plug, it should be plugged into a three-pin

electrical socket. Never remove the ground pin.

3. Avoid body contact with grounded surfaces such

as pipes, radiators, ranges, and refrigerators.

There is an increased risk of electric shock if

your body is grounded.

4. Do not expose tool to moisture. Don’t use this

tool in damp or wet locations. Keep out of rain.

5. Do not abuse cord. Never use the cord to carry

tools or pull the plug from an outlet. Keep cord

away from heat, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electric shock.

6. Remove adjusting keys or wrenches before

turning the tool on. A wrench or key that is left

attached to a moving part of the tool may result

in personal injury.

7. Keep work area clean and well lit. Cluttered or

dark work areas invite accidents.

8. Keep children away. All children should be kept

away from the work area. Never let a child

handle a tool without strict adult supervision.

9. Do not operate this tool if under the influence of

alcohol or drugs. Read warning labels on

prescriptions to determine if your judgment or

reflexes are impaired while taking drugs. If there

is any doubt, do not attempt to operate.

10. Use safety equipment. Eye protection should be

worn at all times when operating this tool. Use

ANSI approved safety glasses. Everyday

eyeglasses are NOT safety glasses. Dust mask,

non-skid safety shoes, hard hat, or hearing

protection should be used in appropriate

conditions.

ear proper apparel. Loose clothing, gloves,

W

1.

1

neckties, rings, bracelets, or other jewelry may

present a potential hazard when operating this

tool. Please keep all apparel clear of the tool.

Don’t overreach. Keep proper footing and

12.

balance at all times when operating this tool.

Always disconnect the tool from power source

13.

before making any adjustments, storing,

servicing, or changing accessories. Such

preventative safety measures reduce the risk of

starting the tool accidentally

14. Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it was designed.

15. Do not use the tool if the switch does not turn it

on and off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

s applications and limitations, as

.

Check for damage. Check your tool regularly. If

16.

part of the tool is damaged it should be carefully

inspected to make sure that it can perform its

intended function correctly. If in doubt, the part

should be repaired. Refer all servicing to a

qualified technician. Consult your dealer for advice.

17. Keep away from flammables. Do not attempt to

operate this tool near flammable materials or

combustibles. Failure to comply may cause

serious injury or death.

18. Store idle tools out of the reach of children and

untrained persons. Tools may be dangerous in

the hands of untrained users.

19. Maintain tools with care. Keep tools sharp and

clean. Properly maintained tools, with sharp

cutting edges, are less likely to bind and are

easier to control.

20. Never exceed the pressure rating of any

component in system.

21. Protect material and air lines from damage or

puncture. Keep hose and power cable away

from sharp objects, moisture, chemicals, oil, etc.

22. Check condition of hoses before each use. Do

not use a damaged hose. If hose is damaged,

replace immediately.

23. Read, understand and comply with all warning

labels on unit.

24. Drain tank of moisture after each use. If

Compressor is not to be used for extended

periods of time, leave tank drain valve open to

allow moisture to completely drain from tank.

25. Do not tamper with Safety Valve. The Safety

Valve is factory set for your model air

compressor. Any use adjustments to Safety

Valve will automatically void warranty.

26. Air compressors get hot while in operation.

NEVER touch the motor, discharge tubing or

compressor pump while in operation.

27. The Compressor operates automatically while

the motor is turned on.

Compressed air from the unit may contain

28.

carbon monoxide. Air produced is not suitable

for breathing purposes.

Always use a respirator when spraying paint

29.

or chemicals.

30. The air pressure switch is set at the factory for

optimum performance of your equipment. Never

attempt to bypass or remove this switch as

serious damage to equipment or personal injury

could result from excessive air pressure.

2

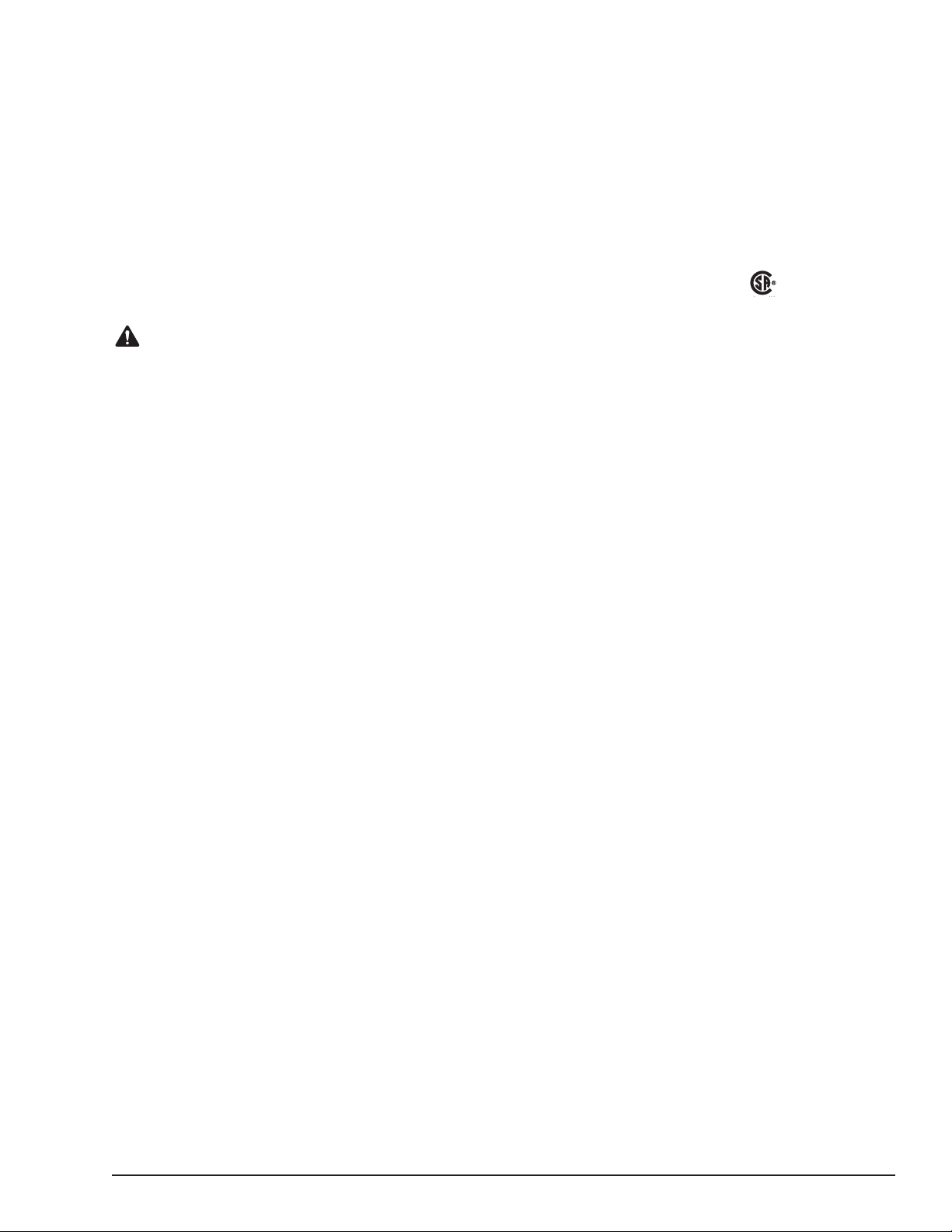

KNOW YOUR COMPRESSOR

Air

Filter

Oil

Breather

Cap

Safety

Valve

Handle

Power Switch

Air Regulator

Air

Chuck

Pressure

Gauges

Note: Always make sure that compressor Power

Switch is in the OFF position before

performing any maintenance or plugging the

compressor into a power supply.

Pressure Gauges: These dual gauges indicate the

amount of air pressure built up in the air tank, as

well as the air pressure being delivered to the air

chuck.

Safety Valve: The Safety Valve device relieves

pressure from the Air Tank in the event of excessive

pressure build up. The Safety Valve is preset at

factory. Do not attempt to make any adjustments to

the Safety Valve. Periodically pull ring on the Safety

Valve end to check that it is working properly.

Air Tank: Powder coated steel tank, with a 4 gallon

capacity

, stores the compressed air until it is needed.

GETTING STARTED

Before operating your tool, check the contents of

the box to make sure you have everything you will

need.

Air

Tank

Tank Drain Valve

(located on tank bottom)

Figure 1. Air Compressor

Handle: Convenient, rubber gripped handle allows

for easy transport of your air compressor.

Air Regulator: The air regulator controls the air

flow pressure. Turn regulator clockwise to increase

air pressure, counter-clockwise to decrease air

pressure.

Air Chuck: Convenient quick disconnect air chuck

allows for fast, easy connection to an air hose.

Tank Drain Valve: The Tank Drain Valve can be

opened to allow moisture and compressed air to be

ank.

T

released from the

Air

WARNING! Tank Drain Valve should always be

opened slowly to avoid damage to equipment and

possible injury.

Air Filter: This heavy duty metal air filter keeps

your compressor running cleanly, by filtering out

impurities.

Oil Breather Cap: As the compressor motor

operates pressurized air must be released from the

crank case. The oil breather cap allows built up air

to escape, while shielding your air compressor from

airborne impurities.

Power Switch: The red tipped power switch turns the

air compressor on and off. When switch is in horizontal

position, compressor is turned ON. When switch is in

vertical position, compressor is turned OFF

.

Items included in the box:

Air Compressor

Air Filter

Oil Breather Cap

Bottle of Oil

Owner’s Manual

ASSEMBLY

NOTE: Before performing any assembly or

maintenance make sure compressor is turned off

and unplugged from the power supply.

Installing the Oil and Oil Breather Cap

Your air compressor is shipped without oil in the

crankcase. BEFORE STARTING THE AIR

COMPRESSOR YOU MUST ADD OIL TO THE

CRANKCASE AS DESCRIBED BELOW:

Place compressor on level ground.

1.

Remove the Oil Shipping Plug from the Oil Fill

2.

hole, located on the top of the crankcase cover

at the rear of the air compressor

Slowly pour the oil into the Oil Fill hole, until the

3.

oil level rises to the center of the red dot on the

Oil Sight Glass.

Note: This compressor uses only SAE 5W

motor oil.

4. Install the Oil Breather Cap into the Oil Fill hole.

Firmly hand tighten the Oil Breather Cap by

turning clockwise.

(See Figure 2)

.

-30

3

Loading...

Loading...