Page 1

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

KIT,YOKERELOCATIONTOREAR

YOKERELOCATIONPROCEDURE

RETURN TO CD-ROM TABLE OF CONTENTS

1. Disconnectallpipelinehosesand

turntheSystemPowerswitchto

ON.

2. Closeallcylindervalvesexceptthe

O

cylindervalve.

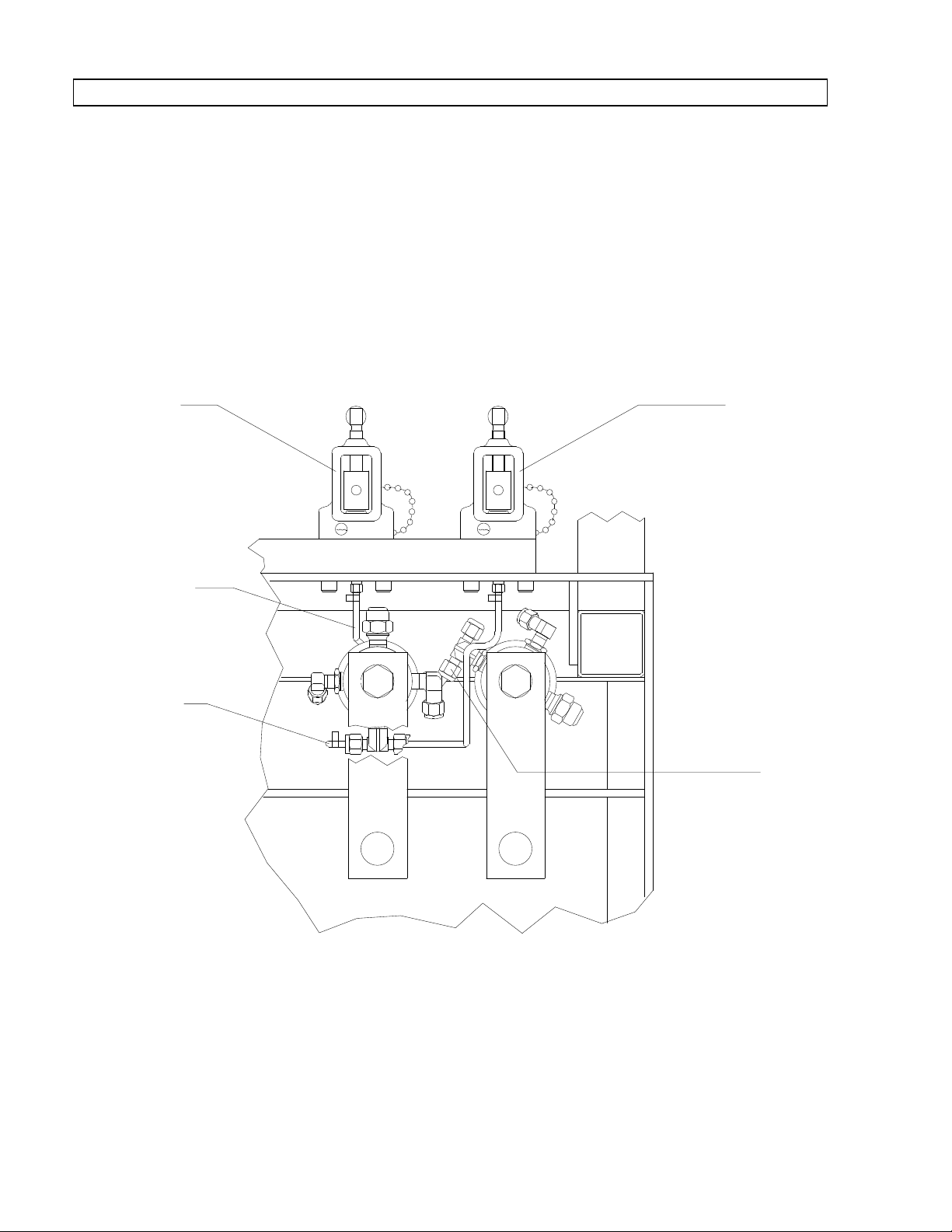

2

3. Settheoxygenflowrateto5l/min.

4. OpentheN

Oflowcontrolvalveto

2

drainpressurefromthesystem.

5. ClosetheO

cylindervalve,and

2

closetheflowcontrolvalves.Press

theO

FLUSHbuttontodrain

2

pressurefromthesystem.

6. TurntheSystemPowerswitchto

STANDBYandremoveACpower

fromthemachine.Disableall

circuitbreakers.

7. Removethescrewssecuringthe

tabletoptothemachine,and

removethetop.

8. Loosenthefittingsateachendof

thetubeconnectingtheoxygen

yoketotheoxygenregulator,and

removethetube.

9. Loosenthefittingsateachendof

thetubeconnectingthenitrous

oxideyoketothenitrousoxide

regulator,andremovethetube.

10. Removethescrewsandwashers

securingtheyokestothemachine;

removetheyokeassembliesand

mountingspacers.

11. Installthenitrousoxideyokeon

therearofthemachine,locatedas

showninFigure1.Formachines

withamountingspacer,usethe

mounting hardware that was

previouslyremoved.Formachines

withoutamountingspacer,usetwo

5/16-24x¾in.skthdscrews(P/N

HW01056).

12. Installtheoxygenyokeontherear

ofthemachine,locatedasshownin

Figure1.Formachineswitha

mountingspacer,usethemounting

hardware that was previously

removedandensurethattheyoke

islevel.Formachineswithouta

mountingspacer,usetwo5/16-24x

¾ in. skt hd screws (P/N

HW01056).

NOTE:

Examinethetubingthatwas

removedanddeterminethetypeof

fittingstobeusedattheregulator

connections.Figure2showsthe

correctassemblyfortwotypesof

compressionfittings.

13. Assemblethecorrectcompression

fittingsonpre-benttube(P/N

4111168 for machines with a

mountingspacer;P/N4108491for

machines without a mounting

spacer).Installthetubefromthe

nitrousoxideyoketothenitrous

oxideregulatorandtightenthe

fittingssecurely.Installablue

"N

O"labeloneachendofthis

2

tube.

1

Page 2

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

YOKE RELOCATION PROCEDURE (continued)

TOP VIEW OF ANESTHESIA MACHINE

WITH TABLE TOP REMOVED

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

N2O YOKE

ASSEMBLY

(RELOCATED)

N2O TUBING

(INSTALL)

O2 TUBING

(INSTALL)

O2 YOKE

ASSEMBLY

(RELOCATED)

N2O

REGULATOR

CONNECTION

SP11001

Figure 1: YOKE RELOCATION AND TUBING CONNECTIONS

2

Page 3

IMPERIAL

TYPE

COMPRESSION NUT

AND FERRULE

COPPER

TUBING

COMPRESSION

NUT

TWO-PIECE

FERRULE

1/8in.

SWAGELOK

TYPE

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

YOKE RELOCATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

Figure 2: COMPRESSION FITTING STYLES

14. Assemble the correct compression

fittings on pre-bent tube (P/N

4111167 for machines with a

mounting spacer; P/N4108492 for

machines without a mounting

spacer). Install the tube from the

oxygen yoke to the oxygen regulator

and tighten the fittings securely.

Install a green "O

" label on each

2

end of this tube.

15. If additional yokes were removed,

install plugs into the regulator

fittings as needed.

16. Install an oxygen cylinder in the O

yoke, and a nitrous oxide cylinder

in the N

O yoke.

2

b. Close the cylinder valve and remove

c. Observe the cylinder pressure

18. Perform the following oxygen

a. Turn the System Power Switch to

b. Connect a 12 inch hose to the

2

c. Set the Man/Auto selector to BAG.

the cylinder from the yoke.

gauge; after two minutes the

pressure shall not drop more than

50 psi.

concentration test:

ON.

inspiratory valve.

17. Performthefollowinghighpressure

leak test for each yoke:

a. Open the cylinder valve and allow

the pressure to stabilize.

3

d. Close the APL valve.

e. Occlude the bag mount.

Page 4

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

YOKE RELOCATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

f. Insert the sensor from a calibrated

MED into the valve dome adaper

O

2

on the inspiratory valve.

g. Close all flow control valves.

h. Install the appropriate cylinder in

each yoke, and open one cylinder

valve for each gas.

i. Depress the O

FLUSH button for

2

15 seconds.

j. Set the oxygen flow to 4 l/min.

k. Within three minutes the O

shall read 97-100% oxygen.

l. Set the nitrous oxide flow to 2

l/min.

PARTS REQUIRED

MED

2

m. The oxygen concentration shall be

64-70%.

n. Set the nitrous oxide flow to 4

l/min.

o. The oxygen concentration shall be

47-53%.

p. Close all flow control valves.

19. Replace the table top on the

machine and secure it with the

screws that were previously

removed.

20. Perform a complete PMS procedure

on the machine.

PART DESCRIPTION PART NUMBER

Tube, 3/16 in. dia. cu "bent" (N2O) (Machines w/ spacer) 4111168

Tube, 3/16 in. dia. cu "bent" (O2) (Machines w/ spacer) 4111167

Tube, 3/16 in. dia. cu "bent" (N2O) (Machines w/o spacer) 4108491

Tube, 3/16 in. dia. cu "bent" (O2) (Machines w/o spacer) 4108492

Screw, 5/16-24 x ¾ in. skt hd (4x) (Machines w/o spacer) HW01056

Nut, 3/16 in. Tubing (4x) 4104716

Ferrule, Two Piece (2x) (Supplied as a set of 10) 4111038

Nut, Fitting, 3/16 Tubing (2x) 4109489

Label, "N2O" Tubing (4x) 4109874

Label, "O2"Tubing 4109871

Plug, Fitting, 3/16 Tube (2x) 4109400

Plug, Fitting, 3/16 Tube (2x) 4106052

4

Page 5

NORTH

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

AMERICAN

DRÄGER

Technical Service Department

22 Commerce Drive

Telford, Pennsylvania 18969

Telephone: (215) 721-5402

(800) 543-5047

Facsimile: (215) 723-5935

Quality Service for Life

®

Part Numbers: SP00110

Rev: Date: November 25, 1992

© 1992 N.A.D., Inc.

Loading...

Loading...