Page 1

SERVICEPROCEDUREFORINSTALLING:

KITPARTNUMBER KITDESCRIPTION

S4112109-001 Kit,SuctionSystemPiping-DISSBody

S4112109-002 Kit,SuctionSystemPiping-DISSNut

S4112029-003 Kit,SuctionSystemPiping-NISTBody

INSTALLATIONPROCEDURE

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

1. TurntheSystemPowerswitchto

STANDBY,andremoveACpower

fromthemachine.

2. Close all cylinder valves and

disconnectthepipelinesupplies.

3. Removethetabletopfromthe

machine.

4. Removethebackcoverfromthe

flowmeterhousing.

5. Remove the hole plugs from

locationsA,B,CandDonthe

machineasshowninFigure1.

(Somemachinesmaynothavethe

twosmallplugs.)

6. Installthevacuumlabel(P/N

4108447)onthesiderailofthe

machinewithfourdrivescrews

(P/NHW11000).

7. InstallaDISSvacuumfeedthru

fitting(P/N4107958)attheholein

thesiderailofthemachine,and

secureitwithalockwasher(P/N

HW65012)and -18nut(P/N

HW52002)asshowninFigure2.

8. ForKitS4112109-001:

InstalltheDISSvacuumfeedthru

fitting(P/N4107958)intothehole

inthebackrailofthemachine,and

secureitwithalockwasher(P/N

HW65012)and -18nut(P/N

HW52002)asshowninFigure2.

ForKitS4112109-002:

Installthe¼NPTFx -18adapter

(P/N4103915)intotheholeinthe

backrailofthemachineandsecure

theadapterwithalockwasher(P/N

HW65012)and -18nut(P/N

HW52002)asshowninFigure2.

Assemble the DISS nut (P/N

4103122)andDISSvacuumfemale

fitting(P/N4103878),andthread

thefittingintotheadapter.Usea

smallamountofLocquicPrimerT

#747andLoctite#271(red)onthe

threads.

ForKit4112109-003:

InstalltheN.I.S.T.vacuummale

connector(P/N4110389)intothe

holeinthebackrailofthemachine

andsecuretheconnectorwitha

lockwasher(P/NHW65012)and 18nut(P/NHW52002)asshownin

Figure2.

1

Page 2

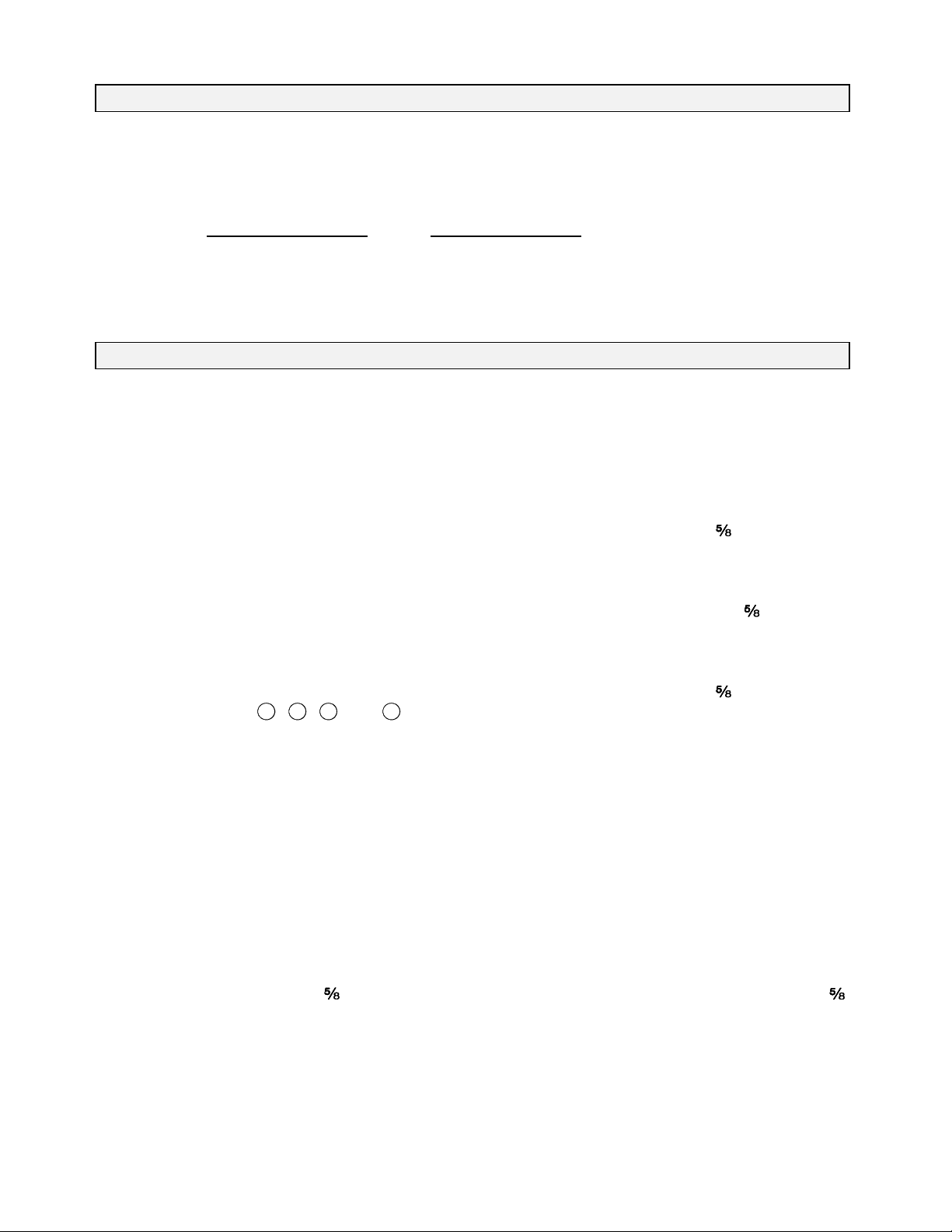

RIGHT SIDE

VIEW OF MACHINE

SP10201

A

B

C

D

REAR VIEW

OF MACHINE

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

Figure 1: LOCATION OF HOLE PLUGS

2

Page 3

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

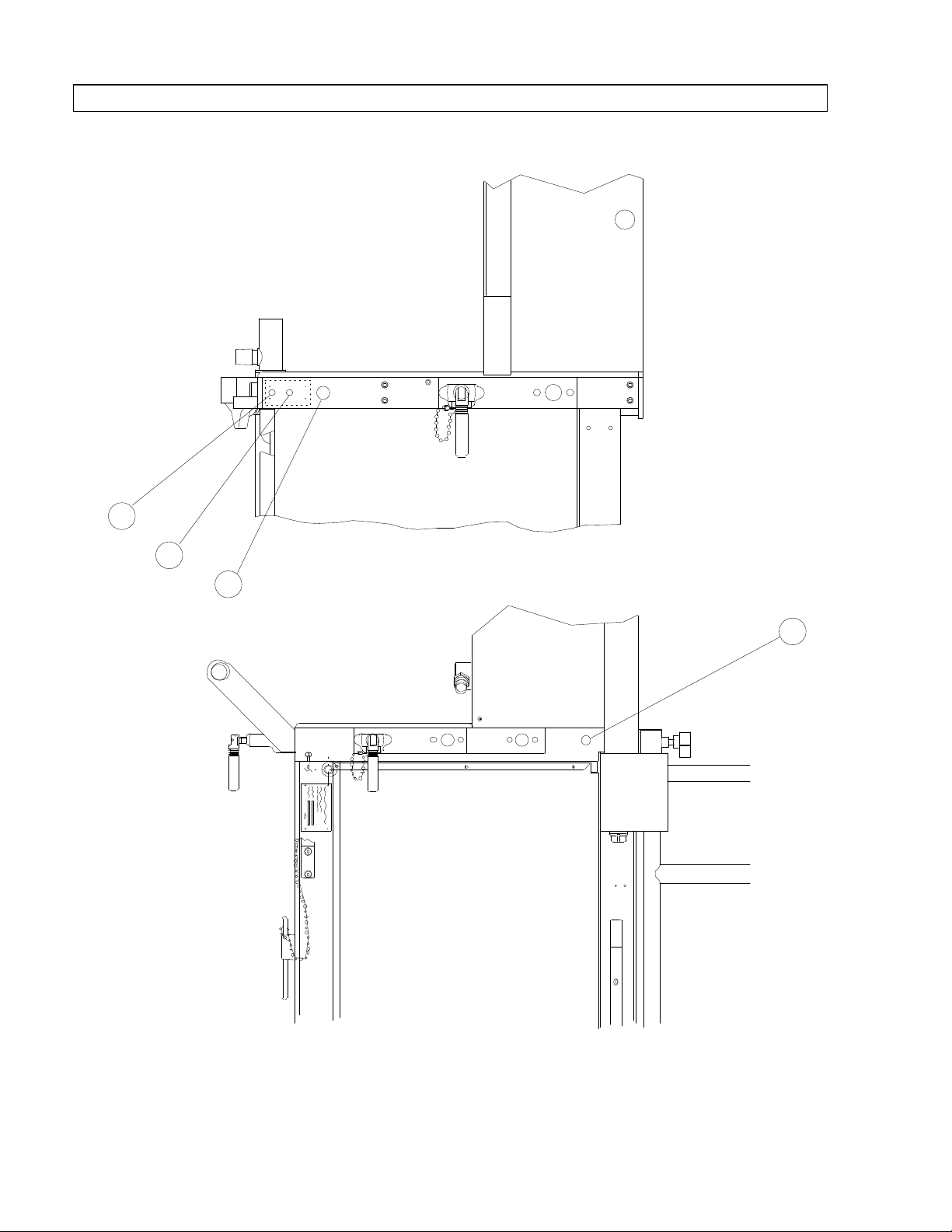

FEED THRU

VACUUM

DISS FITTING

STRAIGHT

FITTING

VIEW FOR KIT

S4112109-001

(DISS BODY)

ADAPTER

FITTING

STRAIGHT

FITTING

DISS VACUUM

FEMALE FITTING

DISS NUTSTRAIGHT

VIEW FOR KIT

S4112109-002

(DISS NUT)

NIST

VACUUM MALE

CONNECTOR

STRAIGHT

FITTING

FEED THRU

VACUUM

DISS FITTING

COPPER TUBE

TUBING LABEL

NUT (2X)

LOCKWASHER (2X)

Figure 2: SUCTION SYSTEM PIPING INSTALLATION

3

VIEW FOR KIT

S4112109-003

(NIST BODY)

LOCATION OF DISS

VACUUM FITTING AND

LABEL ON RIGHT

SIDE FRAME RAIL

DRIVE SCREWS (4X)

VACUUM LABEL

SP10202

Page 4

SP10203

COPPER

TUBING

COMPRESSION

NUT

TWO-PIECE

FERRULE

1/8in.

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

9. Thread a ¼ in. tube x MPT

straight fitting into the back of each

feedthru fitting or connector. Use a

small amount of Loctite #271 (red)

on the threads.

10. Install a ¼ in. dia. copper tube (P/N

4103919) between the straight

fittings.

Ensure that the tube is routed

correctly under the inner frame rail

as shown in Figure 2, and ensure

that the Swagelok fittings are

correctly assembled at the tube

ends before tightening the

compression nuts. See Figure 3.

11. Install a VAC label (P/N 4112127)

at each end of the tube.

Figure 3: ASSEMBLY OF SWAGELOK FITTINGS

12. Connect a test fixture with a cm

H

O gauge and squeeze bulb to one

2

end of the vacuum fittings. Occlude

the other fitting and pressurize the

piping to 50 cm H

O. The pressure

2

shall not drop more than 10 cm

H

O per minute.

2

4

13. Reinstall the table top, and

reinstall the flowmeter housing

back cover.

14. Perform a complete PMS on the

machine.

Page 5

NORTH

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

AMERICAN

DRÄGER

Technical Service Department

3122 Commerce Drive

Telford, PA 18969

(215) 721-5402

(800) 543-5047

(215) 723-5935 Fax

Quality Service for Life

®

Part Number: SP00102

Rev: A

Date: April 8, 1994

© 1994 N.A.D., Inc.

Loading...

Loading...