Page 1

Technical Documentation

Primus

Anaesthetic Workstation

Revision 6.0

5132.300

9036004

Because you care

Page 2

Page 3

Contents

General

1 Symbols and Definitions 3

2 Notes 3

Function Description

1 General 7

1.1 Medical purpose ..................................................................................................................... 7

1.2 Product classification ............................................................................................................. 8

1.3 Protection classes .................................................................................................................. 8

1.4 Short description of Primus ...................................................................................................9

1.4.1 Ventilator .................................................................................................................. 9

1.4.2 Breathing system ...................................................................................................... 9

1.4.3 Mixer (fresh gas metering) .................................................................................... 10

1.4.4 Monitor control panel .............................................................................................. 11

1.4.5 Options ................................................................................................................... 12

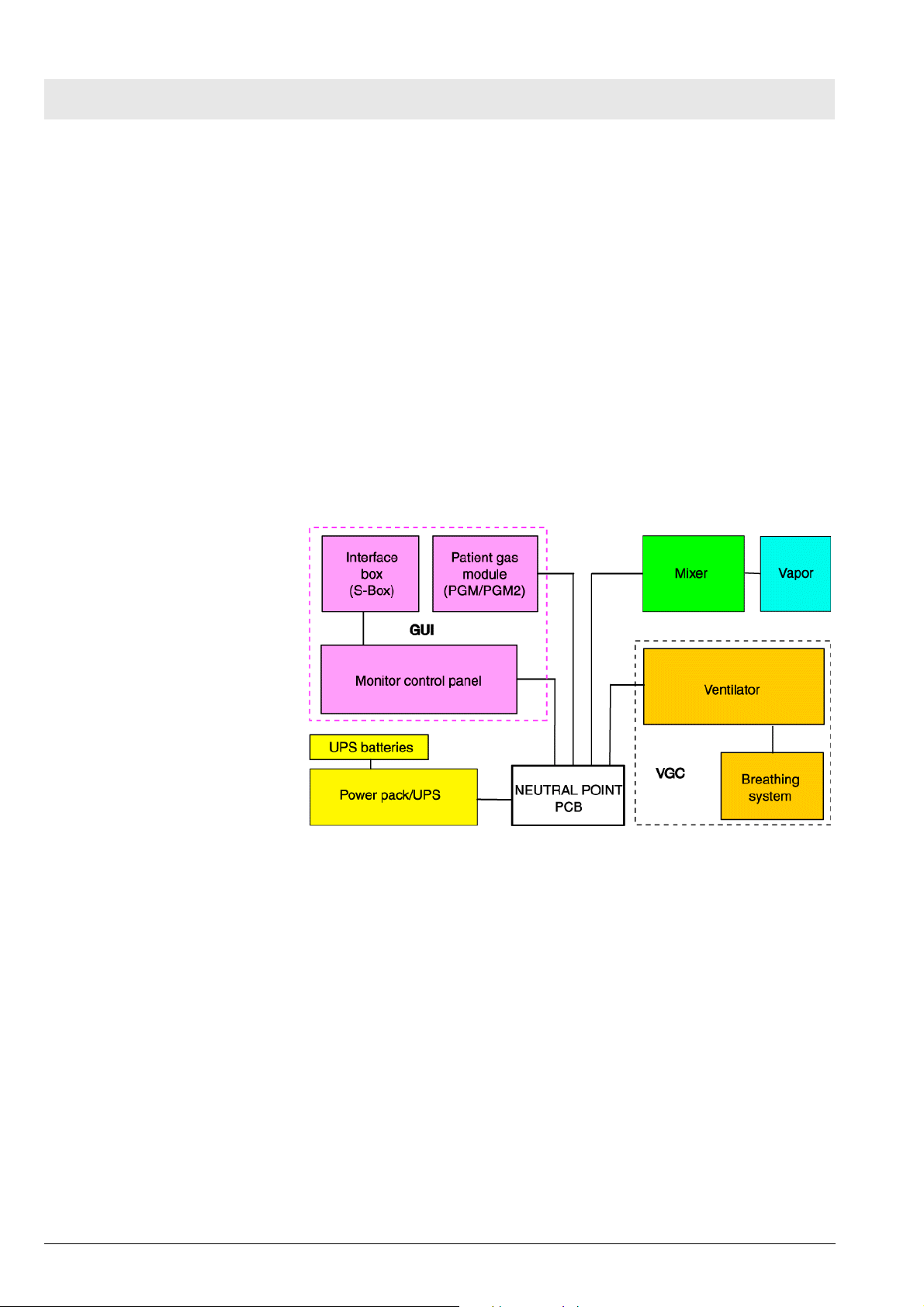

1.5 Primus component structure ............................................................................................... 12

1.5.1 NEUTRAL POINT PCB .......................................................................................... 12

1.5.2 Graphical User Interface (GUI) ............................................................................... 13

1.5.3 Mixer ....................................................................................................................... 13

1.5.4 VGC (Ventilation and Gas Controller) .................................................................... 13

1.5.5 Power pack ............................................................................................................. 13

1.5.6 Cylinder pressure regulator .................................................................................... 13

2 NEUTRAL POINT PCB 15

All rights reserved. Copyright reserved.

K5132300IECIVZ.fm 02.06.06

I

Page 4

Contents

3 GUI 17

3.1 Monitor Control Panel (MoBi) ...............................................................................................17

3.1.1 MONITOR CONTROL PANEL PCB ....................................................................... 19

3.2 S-Box (interface box) ............................................................................................................20

3.2.1 BACKPLANE PCB ..................................................................................................21

3.2.2 SpO2 sampling function (option) .............................................................................22

4 Patient gas module 23

4.1 Version PGM2 ...................................................................................................................... 23

4.1.1 ILCA2 function ........................................................................................................26

4.1.2 PGM2 with Pato O2 sensor ....................................................................................28

4.1.3 PGM2 with Servomex O2 sensor ...........................................................................30

4.1.4 Pneumatics of the PGM2 ........................................................................................32

4.2 Version PGM ........................................................................................................................ 34

4.2.1 PGM pneumatic components ................................................................................. 37

4.3 Operating modes .................................................................................................................. 39

4.3.1 "Reduced Accuracy" mode (PGM only) .................................................................. 39

4.3.2 "ISO" mode (ISO accuracy) (PGM/PGM2) ............................................................. 39

4.3.3 "Full Accuracy" mode (PGM only) ..........................................................................39

4.3.4 "Standby" response of the Primus (PGM/PGM2) ................................................... 39

4.3.5 IRIA/ILCA2 calibration ...........................................................................................39

4.3.6 Auto-Wake-up function ..........................................................................................39

4.3.7 O2 sensor/Servomex ..............................................................................................39

4.4 PGM/PGM2 electronics ........................................................................................................40

4.4.1 MOPS PCB (PGM/PGM2) ......................................................................................40

4.4.2 AMO IRIA PCB (PGM) ............................................................................................40

4.4.3 AMO ILCA2 PCB (PGM2) .......................................................................................40

4.4.4 AMO O2 PUMP PCB (PGM) ..................................................................................40

4.4.5 AMO MFM PCB (PGM2) ........................................................................................40

4.4.6 AMO FLOW ILCA PCB (PGM/PGM2) .................................................................... 41

K5132300IECIVZ.fm 02.06.06

All rights reserved. Copyright reserved.

II

Page 5

Contents

5 Mixer 43

5.1 Operating modes .................................................................................................................. 46

5.1.1 10 VA mode ............................................................................................................ 46

5.1.2 'Normal' mode ........................................................................................................ 46

5.2 Layout ................................................................................................................................... 46

5.2.1 MIXER PCB ............................................................................................................ 46

5.2.2 PRIMUS CPU PCB (mixer) .................................................................................... 47

5.3 Gas inlet block (AIR, O2 and N2O) ...................................................................................... 48

5.3.1 Pneumatic components, gas inlet block ................................................................. 50

5.3.2 Pressure status LEDs ............................................................................................. 52

5.4 Mixer block ........................................................................................................................... 55

5.5 Pneumatic system ................................................................................................................ 56

5.5.1 VMIX valves ........................................................................................................... 57

5.5.2 PDMIX and RM ...................................................................................................... 57

5.5.3 PTANK (pressure sensor) ....................................................................................... 57

5.5.4 VTANK valve .......................................................................................................... 57

5.5.5 VMGS (fresh gas flow valve) .................................................................................. 57

5.5.6 PDMGSHI / PDMGSLO (differential pressure sensors) ......................................... 57

5.5.7 PSYS (pressure sensor) ......................................................................................... 57

5.5.8 VSWAK (A-cone valve) .......................................................................................... 58

5.5.9 VBAK (safety valve) ............................................................................................... 58

5.5.10 TEMPTANK / TEMPBLOCK (temperature sensors) ............................................... 58

5.5.11 VSFC (safety O2 adjuster) ..................................................................................... 58

5.5.12 VO2+ (flush button) ................................................................................................ 58

K5132300IECIVZ.fm 02.06.06

All rights reserved. Copyright reserved.

III

Page 6

Contents

6 VGC 59

6.1 VGC electronics ....................................................................................................................61

6.1.1 VGC POWER PCB .................................................................................................61

6.1.2 PRIMUS ANALOG PCB .........................................................................................61

6.2 Piston cylinder unit (PCU) ....................................................................................................62

6.3 VGC pneumatic block ...........................................................................................................64

6.4 VGC pneumatic system ........................................................................................................65

6.5 Interface plate .......................................................................................................................67

6.6 Breathing system ..................................................................................................................69

6.6.1 Compact breathing system pneumatic components ............................................... 72

6.7 Automatic ventilation ............................................................................................................73

6.7.1 Inspiration ...............................................................................................................73

6.7.2 Expiration ................................................................................................................75

6.8 Manual ventilation .................................................................................................................77

6.8.1 Inspiration ...............................................................................................................77

6.8.2 Expiration ................................................................................................................78

6.9 Spontaneous breathing .........................................................................................................79

6.9.1 Inspiration ...............................................................................................................79

6.9.2 Expiration ................................................................................................................80

7 Ventilation modes with software version 2.n or higher 81

7.1 “Volume Mode” .....................................................................................................................81

7.2 “Pressure Mode” ...................................................................................................................84

7.3 “Pressure Support Mode” .....................................................................................................87

7.4 “Man./Spont Mode” ...............................................................................................................88

7.5 Switching ventilation modes .................................................................................................89

7.6 HLM mode ............................................................................................................................89

IV

K5132300IECIVZ.fm 02.06.06

All rights reserved. Copyright reserved.

Page 7

Contents

8 Power pack 91

8.1 Power pack input .................................................................................................................. 91

8.2 Power switch ........................................................................................................................ 92

8.3 Output voltages and currents ............................................................................................... 92

8.4 Secondary connector ........................................................................................................... 93

8.5 UPS batteries ....................................................................................................................... 93

8.6 Power pack CAN communication ......................................................................................... 94

8.7 Power failure warning ........................................................................................................... 94

9 Operating modes 95

9.1 Cold start .............................................................................................................................. 95

9.2 Standby mode ...................................................................................................................... 95

9.3 Shutdown ............................................................................................................................. 95

9.4 Safety mode ......................................................................................................................... 95

9.4.1 Safety O2 flow ........................................................................................................ 95

9.5 Alarm system ........................................................................................................................ 96

10 Cylinder pressure reducer 97

11 Vaporizer 101

12 Bronchial aspirator 103

12.1 Intended use ....................................................................................................................... 103

12.2 Device types ....................................................................................................................... 103

12.2.1 Variants ................................................................................................................. 103

12.3 Bronchial aspirator with ejector .......................................................................................... 103

12.3.1 Pneumatics (ejector) ............................................................................................ 104

12.4 Bronchial aspirator with vacuum ........................................................................................ 105

12.4.1 Pneumatics (vacuum) ........................................................................................... 106

13 Block diagrams and pneumatic components layout 109

13.1 Introduction ......................................................................................................................... 109

All rights reserved. Copyright reserved.

K5132300IECIVZ.fm 02.06.06

V

Page 8

Contents

Maintenance Procedures

1 Safety precautions 123

2 Rear panel 125

2.1 Rear panel removal ............................................................................................................125

2.2 Rear panel fitting .................................................................................................................125

2.2.1 Rear panel final check ..........................................................................................125

3 Replacing bronchial suction device bacterial filter 127

4 Replacing filter mat on PGM fan 129

5 Replacing bacterial filter and Nafion tube in PGM 131

5.1 Removing the PGM ............................................................................................................131

5.1.1 Removing the PGM housing ................................................................................. 131

5.2 Replacing the bacterial filter ...............................................................................................133

5.3 Replacing the Nafion tube ................................................................................................. 133

5.4 Fitting the PGM housing (new) ...........................................................................................134

6 Cleaning or replacing filter mat in housing cover 137

6.1 Filter mat removal ...............................................................................................................137

6.1.1 Filter mat fitting .....................................................................................................138

7 Replacing filter mat in power pack 139

8 Replacing UPS batteries 141

8.1 Power pack removal ...........................................................................................................141

8.2 Removing UPS batteries ....................................................................................................142

8.3 Fitting UPS batteries ...........................................................................................................144

8.4 Fitting the power pack .........................................................................................................146

VI

K5132300IECIVZ.fm 02.06.06

All rights reserved. Copyright reserved.

Page 9

Contents

9 Cleaning or replacing large and small filter mats in VGC 147

9.1 Removal of large filter mat ................................................................................................. 147

9.1.1 Fitting of large filter mat ........................................................................................ 149

9.2 Removal of small filter mat ................................................................................................. 149

9.2.1 Fitting of small filter mat ....................................................................................... 150

10 Replacing bag upper roller diaphragm 151

11 Replacing the lower rolling seal (VGC) 153

11.1 Removing the VGC ............................................................................................................ 153

11.2 Removing the piston-cylinder unit ...................................................................................... 158

11.2.1 Removing/Fitting the lower rolling seal ................................................................. 162

11.3 Mounting piston-cylinder unit .............................................................................................. 168

12 Replacing pressure regulators PRPN2O, PRPAIR, PRPO2 173

12.1 Removing gas inlet block pressure regulators ................................................................... 173

12.2 Fitting pressure regulators .................................................................................................. 174

13 Replacing CPU PRIMUS PCB lithium battery 179

13.1 Removing mixer ................................................................................................................. 179

13.2 Removing mixer cover ........................................................................................................ 182

13.3 Replacing the lithium battery .............................................................................................. 183

13.4 Fitting mixer cover .............................................................................................................. 184

13.5 Mixer fitting ......................................................................................................................... 184

14 Replacing PEEP diaphragm and MAN/SPONT diaphragm 185

15 Pressure regulator major overhaul 189

15.1 Safety precautions .............................................................................................................. 189

15.2 Required spare parts .......................................................................................................... 190

15.3 Service Equipment Required .............................................................................................. 191

15.4 Removing the pressure regulator ....................................................................................... 192

15.5 Replacing the “Major Overhaul” spare parts set ................................................................. 194

All rights reserved. Copyright reserved.

K5132300IECIVZ.fm 02.06.06

VII

Page 10

Contents

Schematics and Diagrams

1 Primus pneumatic components diagram 203

2 Schematics and Diagrams 209

Annex

Parts catalog

Test List

Technical Information

VIII

K5132300IECIVZ.fm 02.06.06

All rights reserved. Copyright reserved.

Page 11

General

1

Page 12

2

Page 13

Primus General

1 Symbols and Defini-

tions

WARNING

A WARNING statement provides important information about a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION

A CAUTION statement provides important information about a potentially

hazardous situation which, if not avoided, may result in minor or moderate

injury to the user or patient or in damage to the equipment or other property.

NOTE

A NOTE provides additional information intended to avoid inconvenience

during operation.

Definitions according to German standard DIN 31051:

Inspection = examination of actual condition

Maintenance = measures to maintain specified condition

Repair = measures to restore specified condition

Servicing = inspection, maintenance, and repair

2Notes

This Technical Documentation conforms to the IEC 60601-1 standard.

Read each step in every procedure thoroughly before beginning any test.

Always use the proper tools and specified test equipment. If you deviate from

the instructions and/or recommendations in this Technical Documentation,

the equipment may operate improperly or unsafely, or the equipment could

be damaged.

It is our recommendation to use only Dräger parts and supplies.

The maintenance procedures described in this Technical Documentation may

be performed by qualified service personnel only. These maintenance procedures do not replace inspections and servicing by the manufacturer.

The information in this Technical Documentation is confidential and may not

be disclosed to third parties without the prior written consent of the manufacturer.

This Technical Documentation is for the purpose of information only. Product

descriptions found in this Technical Documentation are in no way a substitute

for reading and studying the Instructions for Use/Operating Manual enclosed

with the product at the time of delivery.

All rights reserved. Copyright reserved.

Version 3.0_ Released_Printed on_02.06.06_General_Technical_Documentation.fm

5132.300

3

Page 14

General Primus

Know-how contained in this Technical Documentation is subject to ongoing

change through research and development and Dräger Medical reserves the

right to make changes to this Technical Documentation without notice.

NOTE

Unless otherwise stated, reference is made to laws, regulations or standards (as amended) applicable in the Federal Republic of Germany for

equipment used or serviced in Germany. Users or technicians in all other

countries must verify compliance with local laws or applicable international

standards.

Version 3.0_ Released_Printed on_02.06.06_General_Technical_Documentation.fm

All rights reserved. Copyright reserved.

4

5132.300

Page 15

Function Description

5

Page 16

6

Page 17

Primus Function Description

1 General

1.1 Medical purpose

Primus is an anaesthetic workstation for automatic and manual ventilation

and spontaneous breathing, usable for adults, children and infants.

Application:

– Inhalation anesthesia in rebreathing systems.

– Inhalation anesthesia in virtually closed systems for low-flow and mini-

mum-flow applications.

– Inhalation anesthesia in non-rebreathing systems with separate fresh gas

output for connection of “Bain” or “Magill” system, for example, with a

fresh gas flow of 0.2 L/min to 18 L/min.

Changed ventilation modes (software 2.n or higher):

– Volume-controlled ventilation “Vol u m e Mode”. Switchable functions:

• Synchronization.

• Pressure support (optional).

– Pressure-controlled ventilation “Pressure Mode” Switchable functions:

• Synchronization.

• Pressure support (optional).

– Manual ventilation “MAN”.

– Spontaneous breathing “SPONT”.

– Pressure-assisted ventilation “Pressure Support” (optional).

Ventilation modes (up to software d1.06):

– Volume-controlled ventilation “IPPV, SIMV”.

– Pressure-controlled ventilation “PCV”

– Manual ventilation “MAN”.

– Spontaneous breathing “SPONT”.

Displayed values:

– Peak pressure “Ppeak”, mean pressure “Pmean”, plateau pressure

“Pplat, PEEP”.

– Expiratory minute volume “MV”, tidal volume “VT”, respiratory frequency

“f”.

– Inspiratory and expiratory concentrations of O2, N2O, anesthetic gas and

CO2.

– System compliance and leakage minute volume.

– Functional oxygen saturation “SpO2” and pulse rate (optional).

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

5132.300

7

Page 18

Function Description Primus

Curve diagrams:

– Airway pressure “Paw”.

– Inspiratory and expiratory flow “V”.

– Inspiratory and expiratory concentrations of O2, CO2 and anesthetic gas.

– Plethysmogram (optional).

– P/V loops and flow/V loops (optional in software 2.n or higher).

Bargraph:

– Display of inspiratory tidal volume, expiratory tidal volume and leakage

tidal volume.

– Volumeter.

– Econometer (optional in software 2.n or higher).

Time trends of measured values (trends) are additionally available.

Monitoring:

– By programmable alarm limits which can be adjusted automatically to the

respective ventilation situation.

Monitored parameters:

– Airway pressure “Paw”.

– Expiratory minute volume “AMV”.

– Apnea (deactivated in heart-lung machine mode (HLM mode)).

– Inspiratory and expiratory anesthetic gas concentrations.

– Detection of anesthetic gas mixtures.

– Inspiratory O2 and N2O concentrations (breathing-phase independent

measurement in HLM mode).

– Inspiratory and expiratory CO2 concentrations (breathing-phase indepen-

dent measurement in HLM mode).

– Optional: Oxygen saturation (alarms deactivated in HLM mode), pulse

rate.

1.2 Product classification

– Class II b, according to rules 2, 9 and 11 of the Medical Products Direc-

tive.

1.3 Protection classes – Protection class I, type B according to EN 60601-1.

– With optional SpO2: Protection class I, type BF.

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

All rights reserved. Copyright reserved.

8

5132.300

Page 19

Primus Function Description

1.4 Short description of

Primus

1.4.1 Ventilator

The following sections provide an overview of the Primus components.

Figure 1 Ventilator with breathing system

The electronically controlled and driven ventilator has the following features:

– Tidal volumes of 20 mL (10 mL with software 2.n or higher) to 1400 mL at

frequencies of 3/min to 80/min.

– Peak flow of up to 150 L/min.

– Ventilation modes such as IPPV, PCB, SIMV (plus adjustable trigger, plus

adjustable PEEP) and MAN/SPONT (up to software 1.n).

– Ventilation modes such as volume mode, pressure mode, pressure sup-

port (optional) and MAN/SPONT with switchable synchronization and

pressure assistance (optional).

1.4.2 Breathing system The breathing system comprises the following components:

– Integrated absorber, either reusable or disposable.

– Electronic interfaces for inspiratory and expiratory flow measurement.

– Direct patient section heating is integrated into the valve plate of the

breathing system.

– Pneumatic interface to ventilator.

– Fresh gas isolation and minimized compliance.

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

5132.300

9

Page 20

Function Description Primus

1.4.3 Mixer (fresh gas metering)

The electronic mixer offers the following features:

– Gas metering for O2, N2O and AIR.

– Metering range from 200 mL/min to 18 L/min.

– Alarm monitoring for the pressure values of the central supply (CS) and

the cylinder supply. LEDs on the front panel indicate the pressure status.

– ORC function for low-flow and minimum-flow applications.

– O2 flush and mechanical safety O2 adjuster (see Figure 2).

Figure 2 O2 flush (O2+), mechanical safety O2 adjuster

– Double Vapor plug-in system with interlock.

– Optional external A-cone as fresh gas outlet.

10

5132.300

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

All rights reserved. Copyright reserved.

Page 21

Primus Function Description

1.4.4 Monitor control panel

Figure 3 Monitor control panel

The parameters for fresh-gas flow control, ventilation, and gas monitoring are

displayed on a 12-inch color screen.

The following parameters are monitored:

– Airway pressure.

– Inspiratory and expiratory flow.

– Circle system leakage.

– Inspiratory and expiratory O2 concentration.

– CO2 measurement and anesthetic gas measurement.

– Anesthetic gas detection.

– Quantitative measurement of mixed-gas values and MAC calculation

(age-relevant).

A data view, a trend view (graphical) and a log view can be selected.

As from software release 2.n the following settings are possible:

– Free configuration of 3 real-time curves and different numerical values.

– Body-weight-relevant ventilator presettings (Vt and frequency) and age-

relevant calculation of minimum alveolar concentration (MAC ) according

to “Mapleson” as well as age-relevant scaling of volumeter and influence

on ventilation monitoring.

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

5132.300

11

Page 22

Function Description Primus

The safety concept incorporates the following tests:

– Automatic self-test with mixer test, ventilator test and test of the breathing

system.

– Test and automatic calibration of all sensors.

1.4.5 Options Primus is prepared for future upgrading with the following options:

– Integrated SpO2 measurement.

– Consumption-free O2 measurement (with software 2.n or higher).

– PAW preview – display of expected airway pressure curve when chang-

ing parameters.

– P/V and flow/V loops (with software 2.n or higher).

– Econometer function (with software 2.n or higher).

– Additional ventilation modes (e.g. autoflow, CPAP).

– Additional languages available for display texts.

1.5 Primus component

structure

Figure 4 Primus component structure

In the “Block diagrams” section, you will find a detailed block diagram of the

Primus.

1.5.1 NEUTRAL POINT PCB The NEUTRAL POINT PCB connects the components of the Primus to the

power supply, additional signal wires and the CAN bus.

More details are given in the following section on the NEUTRAL POINT PCB.

12

5132.300

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

All rights reserved. Copyright reserved.

Page 23

Primus Function Description

1.5.2 Graphical User Interface

(GUI)

The GUI has the following components:

– On the Monitor Control Panel (MoBi) the ventilation mode is displayed.

Limit and target values are specified and the ventilation and anesthesia

parameters are displayed.

– S-Box (Interface box). PC interfaces and optional measuring functions

such as SpO2 and BIS

TM

.

– Patient Gas Module (PGM) for measurement of O2, CO2 and anesthetic

gas.

For more details refer to the section headed GUI.

1.5.3 Mixer The mixer comprises the following function units:

– Electronically controlled and monitored mixer.

– Vapor plug-in system for one or two conventional vaporizer types.

– External fresh gas outlet, A-cone (optional).

– Pressure monitoring for CS and compressed gas cylinders.

More details are given in the following section on the mixer.

1.5.4 VGC (Ventilation and

Gas Controller)

The VGC comprises the following function units:

– Electronically controlled and driven ventilator.

– Integrated breathing system for “low flow” and “minimum flow” applica-

tions.

For more details refer to the section headed VGC.

1.5.5 Power pack The power pack comprises:

– Switched-mode power supply unit.

– Uninterruptible power supply (UPS) with one battery pack consisting of

two 12 V lead-gel batteries.

– Battery charging management.

For more details refer to the section headed Power pack.

1.5.6 Cylinder pressure regulator

The cylinder pressure regulators reduce the pressure of the optional compressed gas cylinders.

For more details refer to the section headed Cylinder pressure regulators.

The function description relating to the NEUTRAL POINT PCB follows.

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

5132.300

13

Page 24

Function Description Primus

14

5132.300

Version 2.0_ Released_Printed on_02.06.06_F5132300T01_Allgemeines.fm

All rights reserved. Copyright reserved.

Page 25

Primus Function Description

2 NEUTRAL POINT

PCB

The NEUTRAL POINT PCB is the central signal and voltage distributor.

Figure 5 Location of the Neutral Point PCB

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_02.06.06_F5132300T02_LP_Sternpunkt.fm

5132.300

15

Page 26

Function Description Primus

Figure 6 Component mounting diagram, NEUTRAL POINT PCB, for leg-

end see Table 1

Table 1 Legend to Figure 6

Item Connector

1 Monitor Control Panel (MoBi).

2 Monitor Control Panel (MoBi).

3 Ventilation and Gas Controller (VGC).

4Mixer B.

5Mixer A.

6 Safety O2 flow valve (microswitch).

7 Power switch (main switch).

8 Halogen lamp

9 Jack plug (production tests).

10 PGM.

11 Power pack A.

12 Power pack B.

13 Not assigned.

The function description relating to the GUI follows.

16

5132.300

Version 2.0_ Released_Printed on_02.06.06_F5132300T02_LP_Sternpunkt.fm

All rights reserved. Copyright reserved.

Page 27

Primus Function Description

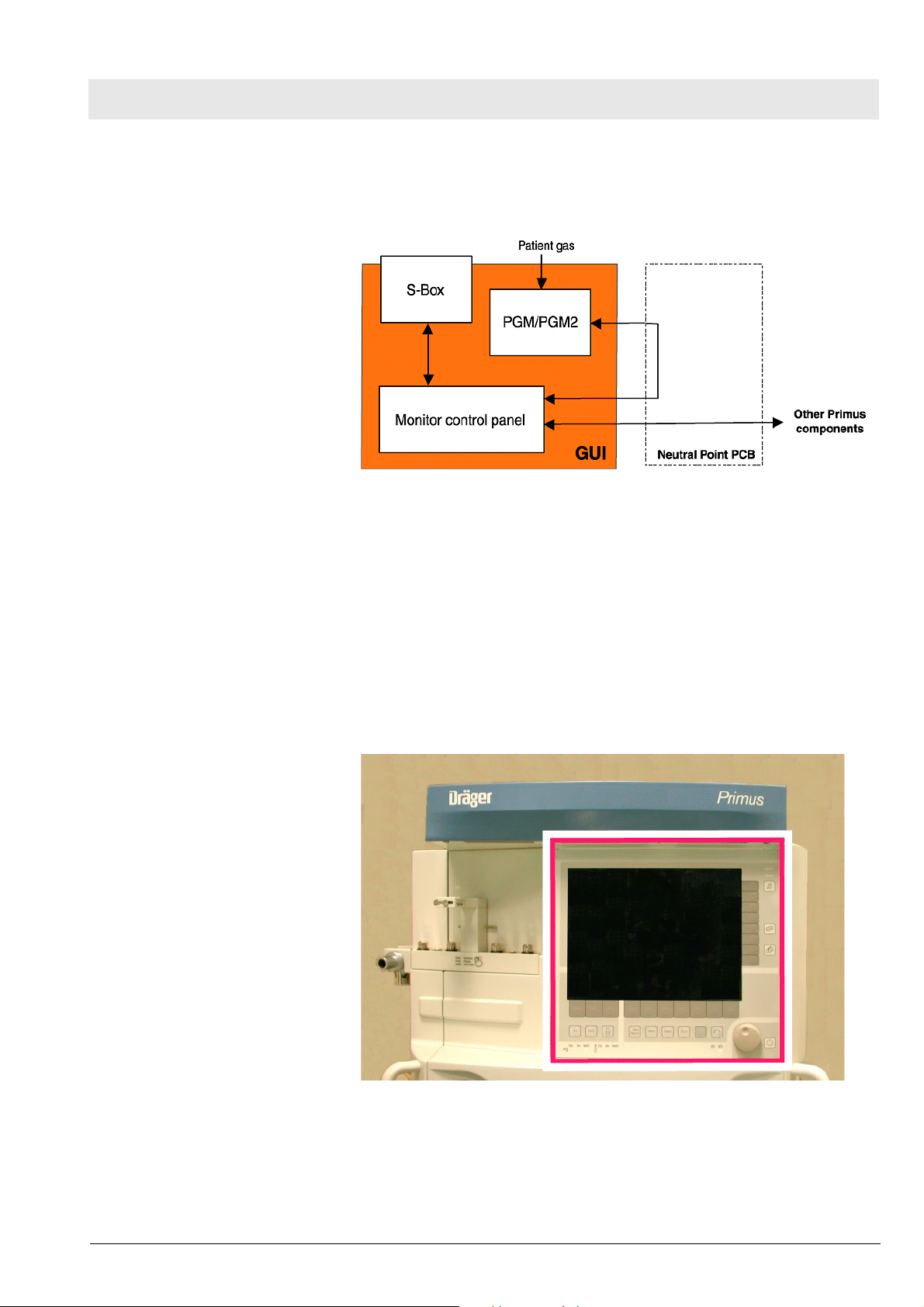

3GUI The following section describes the user interface (“GUI = Graphical User

Interface”).

Figure 7 GUI block diagram

3.1 Monitor Control

Panel (MoBi)

In the “Block diagrams” section, in the block diagram of the Primus, you will

find a block diagram of the GUI.

The GUI has the following components:

– MoBi (monitor control panel).

– S-Box (Interface Box).

– Patient Gas Module (PGM). The function description relating to the

Patienten Gas Module (PGM) follows.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_GUI.fm

All rights reserved. Copyright reserved.

5132.300

Figure 8 Position of Monitor Control Panel (MoBi)

In the “Block diagrams” section, you will find a block diagram of the MoBi.

17

Page 28

Function Description Primus

The user and Primus communicate via the MoBi. The MoBi display presents

system and patient information. It is here that the user sets the parameters

and ventilation modes.

The Patient Gas Module (PGM) is connected to the GUI.

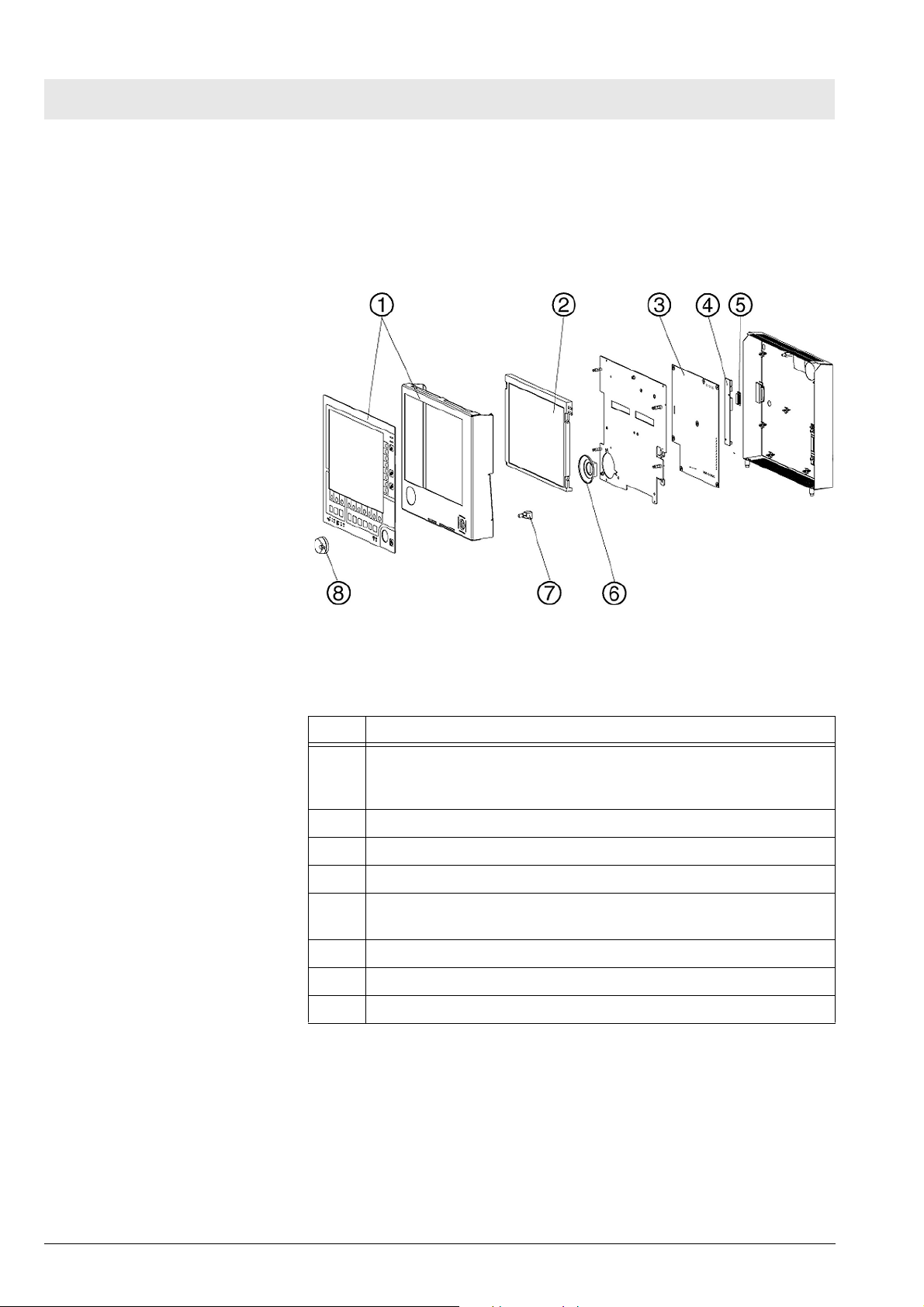

Figure 9 Exploded view of MoBi, for legend see Ta b le 2

Table 2 Legend to Figure 9

Item Components

1 Front panel with membrane keypad. Includes keypad membrane

covering with design imprint, keys, LEDs (e.g. for CS gases), the

carrier plate and the shielding, anti-glare glass screen.

2 12 inch color display (TFT, resolution: 800 x 600).

3 MONITOR CONTROL PANEL PCB (motherboard).

4 Backlight converter (display backlighting).

5 LCD800 PCB (adapter PCB for connection of different makes of

display).

6 Loudspeaker.

7 Rotary transducer.

8 Control knob (central operator control element).

18

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_GUI.fm

All rights reserved. Copyright reserved.

Page 29

Primus Function Description

3.1.1 MONITOR CONTROL

PANEL PCB

The following software is installed on the PCB:

– GUI software.

– Monitoring and evaluation software for the PGM.

– Software for Medibus connections and SpO2.

A 2-processor system is in operation on the PCB. It comprises a Display

Master (DiMa) and a Communication Master (CoMa).

The powerful DiMa processor incorporates the following components:

– Motorola processor (MPC823) with 48 MHz clock frequency and 32-bit

address and data buses.

– Flash-PROM (program memory).

– RAM (data memory).

– CAN controller.

– RS232 interface for in-house development purposes.

– Serial communication channel for Ethernet.

The LCD controller is a programmable logic device (“PLD”). A “DRAM” serves

as the video memory.

The CoMa processor system primarily controls communication with the

other Primus components.

The CoMa incorporates the following components:

– Motorola processor (M68332) with 16.7 MHz clock frequency, internal 32-

bit bus and external 16-bit data bus.

– Flash-PROM (program memory).

– RAM (data memory).

– RS232 interface for communication with the SPO2, PGM and Medibus 1 -

3 modules.

– Real-time clock (RTC).

– Keyboard and rotary knob scan, LED actuation and sound output.

– CAN interface.

Both processor systems communicate by way of a Dual-Port RAM (DPR).

This memory device is battery-buffered. The buffering is provided primarily by

the UPS batteries of the Primus. If they fail, the lithium battery on the MONITOR CONTROL PANEL PCB ensures data is retained.

The operating voltage is provided by an unstabilized voltage of 20 V to 30 V

(Vcc). DC converters on the MONITOR CONTROL PANEL PCB generate all

other voltages on the PCB.

The MoBi is interconnected over the CAN bus with the other components of

the Primus (power pack, mixer and VGC).

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_GUI.fm

All rights reserved. Copyright reserved.

5132.300

19

Page 30

Function Description Primus

3.2 S-Box (interface

box)

Figure 10 Position of S-Box

In the “Block diagrams” section, you will find a block diagram of the S-Box.

20

Figure 11 Layout of the S-Box, for legend see Tab l e 3

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_GUI.fm

All rights reserved. Copyright reserved.

Page 31

Primus Function Description

Table 3 Legend to Figure 11

Item Components

1 Drawer unit components fully mounted.

2 BACKPLANE PCB.

3 SpO2 ADAPTER PCB (SpO2 PCB not shown).

Figure 12 S-Box, block diagram

The S-Box as standard includes the BACKPLANE PCB and thus the externally available Medibus ports (COM 1-3), IV-System (Ethernet for TIVA) and

a CAN port (SABUS exclusively for debug purposes).

The S-Box is prepared for the SpO2 option.

3.2.1 BACKPLANE PCB The BACKPLANE PCB is the base component for additional modules and

the insulated interfaces to external devices.

In the “Block diagrams” section, you will find a block diagram of the BACK-

PLANE PCB

The BACKPLANE PCB has the following functions:

– Electrical isolation and level conversion of the 3 Medibus ports (RS232).

– Connects the MoBi with the CAN (SABUS) and Ethernet (TCP/IP) con-

nectors.

– Connects the optional hardware (SPO2, IV-System) with the MoBi (as

from SW 1.n).

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_GUI.fm

All rights reserved. Copyright reserved.

5132.300

21

Page 32

Function Description Primus

3.2.2 SpO2 sampling function

(option)

The SpO2 sampling function has the following tasks:

– Non-invasive measurement of functional oxygen saturation in the arterial

blood. The upper and lower alarm limits are monitored on the MONITOR

CONTROL PANEL PCB by the CoMa processor.

– Measurement of pulse rate.

– Monitoring of the pulse rate with upper and lower alarm limits.

The SpO2 sensor essentially comprises two LEDs (light-emitting diodes)

which alternatingly emit infrared light with typical wavelengths of 920 nm and

660 nm respectively. An opposing photodetector measures the radiant intensity. The sensor is placed on a part of the body on which arterial blood vessels can be X-rayed, such as the fingers, toes or bridge of the nose.

The new SpO2 sensor “DS-100A” incorporates a memory chip. The Nellcor

module used in the Primus now detects only this SpO2 sensor. The new sensor is identifiable by the fact that all nine pins are present on the connector.

The SpO2 sensor is connected without a pre-amplifier to the module. The

module communicates through a serial port with the MONITOR CONTROL

PANEL PCB. On the BACKPLANE PCB the module is electrically isolated

with 1.5 kV.

The function description relating to the Patienten Gas Module (PGM) follows.

22

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_GUI.fm

All rights reserved. Copyright reserved.

Page 33

Primus Function Description

4 Patient gas module The PGM (patient gas module) or PGM2 is an integral part of the GUI func-

tional unit (see function description GUI.

There are two versions of the patient gas module:

–PGM.

–PGM2.

In the “Block diagrams” section, you will find the block diagrams of the

PGM/PGM2 electronics

Differences between PGM2 and PGM:

PGM PGM2

Anesthetic gas measurement.

O2 sampling. Electrochemical O2 cell. Servomex sensor or

O2 measurement

electronics.

Pump flow. 150 mL 200 mL

Flush flow. 200 mL 250 mL

IRIA. ILCA2.

Pato sensor.

AMO O2 PUMP PCB AMO MFM PCB.

4.1 Version PGM2 The following illustration shows the location of the PGM2 (rear panel of unit is

open).

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

Figure 13 Location of the PGM2

23

Page 34

Function Description Primus

Figure 14 Exploded view of PGM2, for legend see Tabl e 4

Table 4 Legend to Figure 22

Item Component

1 ILCA2 sensor head.

2 Solenoid valve V1.

3 Pump (200 mL).

4 Insulating foil.

5 MOPS PCB (central processor).

6 PCBs mounting frame.

7 AMO ILCA2 PCB (anesthetic gas analysis).

8 AMO Flow ILCA PCB (flow measurement, pump control, and valve

control).

9 AMO MFM PCB (O2 analysis).

10 “Servomex” O2 sensor or “Pato” O2 sensor.

11 Filter mat.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

24

5132.300

Page 35

Primus Function Description

Item Component

12 Bacterial filter.

13 Holder for WaterLock (water trap).

14 WaterLock.

15 Fan.

16 Solenoid valve V2.

17 Adapter board (connection board).

The PGM2 automatically detects and measures the anesthetic gas in use Halothane, Enflurane, Isoflurane, Desflurane or Sevoflurane. It also detects

and measures mixtures of two of the above anesthetic gases. If it encounters

a mixture of more than two anesthestic gases, the warning “AGas mixture” is

delivered.

CO2, O2 and the anesthetic gas mixture are presented as a real-time curve.

Some of the parameters measured by the PGM2 (etCO2, inCO2 etN2O,

inN2O, etO2 and inO2) are presented on the GUI as digital values.

One component of the PGM2 is the water trap. The water trap is accessible

from the front panel. For position see following diagram.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

Figure 15 Position of water trap

25

Page 36

Function Description Primus

4.1.1 ILCA2 function ILCA2 is a gas measuring module for the analgesic N2O, the anesthetic

gases Halothane, Enflurane, Isoflurane, Desflurane and Sevoflurane, and for

measurement of mixtures. ILCA2 conforms to the measurement accuracy

specified by ISO standards.

The ILCA2 module is capable of automatically detecting the above mentioned

gases.

ILCA2 module design

The ILCA2 module principally comprises the following components:

– Sensor head with double-optics, pressure sensor, and electronics.

– Diaphragm pump.

– Pneumatic low pass.

– Solenoid valve for zero calibration.

– Module rack with 3 PCBs.

In the “Block diagrams” section, you will find a block diagram of the ILCA2

module.

Sensor head

The sensor head houses 2 PCBs with the following functions:

– Pre-amplifier PCB for the two multi-channel detectors.

– Base PCB with emitter activation, temperature regulation, absolute pres-

sure measurement and a serial EEPROM holding the serial number, setting and calibration data for operation of the sensor head.

The module rack of the ILCA2 module contains 4 additional PCBs with the

following functions:

– AMO FLOW ILCA PCB - Control of the diaphragm pump and the zero

calibration solenoid. A serial EEPROM stores the necessary data such as

the serial number, hardware/software revision, control parameters etc.

– AMO ILCA2 PCB - Here the necessary supply voltages are generated

and the data transfer from the ILCA2 sensor to the MOPS PCB is implemented.

– AMO MFM PCB - This circuit board amplifies the signal from the Ser-

vomex sensor.

– MOPS PCB - Primarily delivers the data for further processing via an RS

232 interface.

Measurement principle

26

The measurement principle of the ILCA2 module is based on the absorption

of infrared light by the various media (see Figure 16). The sensor head consists of a double measuring head with one emitter each which emits a broad

spectrum of infrared light. The light beam passes through a cuvette, through

which the gas being measured is also drawn by means of a diaphragm pump.

Downstream of the cuvette the light beam hits a multi-channel detector with

IR filters. The filters are dimensioned so that only the light in the absorption

wavelength of the measured gases is transmitted. If a gas is present light is

absorbed. The higher the partial pressure of the gas, the greater the absorption of the light and the smaller the sensor signal.

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 37

Primus Function Description

Figure 16 Principle of multi-channel detector with IR filters

Table 5 Legend to Figure 16

Item Meaning

1 Infrared light.

2 Beam splitter.

3 Sensor chip.

4 Infrared filter.

5 Sensor window.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

27

Page 38

Function Description Primus

4.1.2 PGM2 with Pato

O2 sensor

The oxygen analyser measures the patient's O2 concentration at the Y-piece.

Measurement principle

The oxygen sensor uses the effect that oxygen molecules are attracted very

much more strongly to a magnetic field (paramagnetism) than the molecules

of other gases, which in some cases are repelled by the magnetic field (diamagnetism).

Layout

The Pato houses a cuvette containing a sensor system, the cuvette is located

between two electromagnets.

Figure 17 Pato system structure

Table 6 Legend to Figure 17

Item Component

1 Magnetic system

2 Sensor system

3 Cuvette

4 Magnetic system

This sensor system comprises the gas path (cuvette) and the sensor inside

the measurement compartment.

The measurement compartment is designed as a bulge in the gas path.

The sensor consists of a heating element and thermoelement assembly.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

28

5132.300

Page 39

Primus Function Description

Figure 18 Pato sensor system

Table 7 Legend to Figure 18

Item Name

1 Measurement compartment

2 Heating element and thermoelement assembly

3 Gas path

4 Sensor element

Function

The electromagnets generate an alternating field.

The sampling gas flows through the cuvette and the gas path in the sensor

system.

The heating element heats up the sampling gas to operating temperature, the

thermoelement measures the temperature.

The outer alternating magnetic field influences the mobility of the oxygen contained in the sampling gas.

The changing mobility alters the heat transfer in the sampling gas which

results in the thermoelement measuring a changing temperature.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

The exent of the heat transfer variation depends on the oxygen concentration

in the sampling gas.

The ILCA2 module converts the temperature change in an oxygen concentration value which is then displayed on the connected patient monitor.

29

Page 40

Function Description Primus

4.1.3 PGM2 with Servomex

O2 sensor

The Servomex sensor uses the fact that oxygen molecules have a stronger

paramagnetic characteristic (attracted to a magnetic field) than the molecules

of other gases that are sometimes even diamagnetic (repulsed by a magnetic

field).

The following position numbers refer to Figure 19.

The permanent magnets (7 and 12) in the sensor create a symmetric magnet

field (11). The magnet field contains two nitrogen-filled quartz spheres (9)

arranged in the form of dumbbells. The dumbbell is suspended rotating from

a taut platinum band. A reel of platinum wire is wound around the dumbbell

as a feedback coil (10).

When oxygen flows through the measuring cell (1 and 6), the magnetic field

(11) changes based on the paramagnetic effect of the oxygen dependent on

its concentration. This rotates the quartz spheres (9) of the dumbbells out of

the magnetic field.

A mirror attached to the pivot of the dumbbell (8) reflects a light beam (5) onto

a photocell pair (4). The photocells are connected to an amplifier (3) of which

the output signal supplies the feedback coil (10) of the dumbbell. The dumbbell is rotated back by the current in the feedback coil (10) until the light beam

(5) is illuminating both photocells (4) equally by means of the mirror (8). Then

the system is at equilibrium. The current flowing through the feedback coil

(10) is proportional to the paramagnetism of the oxygen and thus a measure

of the oxgen concentration, which is displayed on the display instrument (2).

30

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 41

Primus Function Description

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

Figure 19 Schematic representation of the Servomex sensor

31

Page 42

Function Description Primus

4.1.4 Pneumatics of the PGM2 In the “Block diagrams” section, you will find a schematic of the PGM2 pneu-

matic components.

Figure 20 Schematic of PGM2 pneumatic components, see legend Ta bl e

10

Table 8 Legend to Figure 24

Item Meaning

1 Sampling gas.

2 Goretex membrane (flow 20 mL).

3 Goretex membrane (flow 180 mL).

4 Water trap.

5 Teflon tube.

6 Nafion tube.

7 ILCA2 solenoid valve (pneutronics).

8 Room air (calibration).

9 Filter.

10 ILCA2 (anesthetic gas analysis).

11 O2 sensor.

12 Solenoid valve (pneutronics).

13 Filter.

14 OLC pump 200 mL (DC diaphragm pump).

32

15 Gas outlet.

C1 Volume.

R1 Restrictor.

R2

P Differential pressure sensor.

The item numbers and abbreviations occurring in this section relate to Figure

24.

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 43

Primus Function Description

The sample gas (1) enters the water trap (4). In the water trap are two Goretex membranes (1, 2). The moisture in the sample gas cannot pass through

the Goretex membranes. This prevents water from reaching the ILCA2 (flow

approx. 180 mL/min). Consequently no water can penetrate the bypass

branch (flow approx. 20 mL/min) either. An approximately 10 cm long Teflon

tube (5) serves as a resistor, and meters the flow in the bypass branch.

If the water in the water tank reaches to the level of the membranes, they are

closed off by the water. An error message is displayed on-screen. A filling

level detector is therefore no longer necessary.

The sample gas flows through the Nafion tube (6) and is additionally dried.

The sample gas then passes on to the ILCA2 solenoid valve (7). Depending

on the valve switching state, either the sample gas (1) or, during calibration,

the room air (8) reaches the ILCA2. The sample gas is fed through the

cuvette (10) of the ILCA2 and passes on to the “Servomex” O2 sensor (11).

When the Primus is in leak test mode, and the PGM2 in standby, the pump

(14) is shut off. Whenever the pump is off, the solenoid valve (12) interrupts

the gas flow to the system. This does not increase the leakage value.

The following low-pass filter comprises the restrictor (R1) and the

volume (C1).

R1 is dimensioned as follows:

– R1 is small enough for the pump not to be placed under unnecessary

strain.

– R1 is large enough so that the pump pressure surges occurring in the

ILCA2 cuvette do not impair the signal ratio and noise ratio in gas sampling.

– The pressure drop at R1 is measured. The measured value is used for

pump control.

The pneumatic low-pass components are integrated into the module housing

of the electronics. The low-pass minimizes the pressure surges generated by

the pump. Downstream of the pneumatic low-pass filter the sample gas

passes to the pump.

The flow through the pump (14) in measuring mode is approx. 200 mL/min

(flush flow approx. 250 mL/min). The supply voltage of the pump is in the

range from 2.5 VDC to 7.5 VDC at a current of up to 150 mA.

Dimensioning of R2:

In a calibration, the switching of the ILCA2 solenoid valve (7) is tested with

the pressure sensor (in the sensor head). In this case the pressure drop via

R2 and the filter (9) must be significantly less than the minimum pressure

drop through the water trap and the sample gas tube. In the event of an error,

an error log entry is generated.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

In substitution for a flowmeter, the pressure is measured with a differential

pressure sensor (P) upstream and downstream of the low pass.

The AMO FLOW ILCA PCB controls the pump with the pressure signal as the

input variable.

33

Page 44

Function Description Primus

In order to ensure an adequate measurement accuracy, an automatic zero

calibration is performed periodically. For this, room air is drawn in by the diaphragm pump through the ILCA2 solenoid (zero calibration valve) and

passed through the sensors. The zero calibration valve is controlled by the

AMO Flow ILCA PCB.

Further measures to safeguard measurement accuracy:

– Heating of the cuvette so the intensity of the light beam is not affected by

condensation. As the temperature also influences the measurement

result, the cuvette temperature is kept constant by means of a control

loop.

– The pressure in the cuvette likewise influences the result. So the pres-

sure is measured and entered as a correction variable into the system.

4.2 Version PGM The following diagram shows the position of the PGM with the rear panel

open.

34

Figure 21 Position of the Patient Gas Module (PGM)

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 45

Primus Function Description

Figure 22 Exploded view of the PGM, legend Table 9

Table 9 Legend to Figure 22

Item Components

1 Connection board.

2 IRIA cuvette.

3 IRIA = “Infrared Rapidly Identifying Analyzer”. Sensor head of

anesthetic gas analyzer.

4 Bacterial filter.

5 Fan.

6 Water trap.

7 Filter mat.

8 O2 cell (fast O2 analysis).

9 MOPS PCB (electronics).

10 AMO IRIA PCB (anesthetic gas analysis).

11 AMO O2 PUMP PCB (O2 analysis).

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

12 Pump.

13 ILCA solenoid valve (room air/sampling gas).

35

Page 46

Function Description Primus

Item Components

14 AMO FLOW ILCA PCB (actuation and monitoring of valve, pump

and flow values).

15 ILCA component carrier (for items 9 - 14).

16 ILCA solenoid valve (leakage).

17 Board (Teflon plate).

The PGM automatically detects and measures the anesthetic gas in use Halothane, Enflurane, Isoflurane, Desflurane or Sevoflurane. It also detects

and measures mixtures of two of the above anesthetic gases. If it encounters

a mixture of more than two anesthestic gases, the warning “AGas mixture” is

delivered.

CO2, O2 and the anesthetic gas mixture are presented as a real-time curve.

Some of the parameters measured by the PGM (etCO2, inCO2 etN2O,

inN2O, etO2 and inO2) are presented on the GUI as digital values.

One component of the PGM is the water trap. The water trap is accessible

from the front panel. For position see following diagram.

36

Figure 23 Location of the water trap

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 47

Primus Function Description

4.2.1 PGM pneumatic components

In the “Block diagrams” section, you will find a schematic of the PGM pneu-

matic components.

Figure 24 Schematic of PGM pneumatic components, legend Table 10

Table 10 Legend to Figure 24

Item Meaning

1 Sampling gas.

2 Goretex membrane (flow 15 mL).

3 Goretex membrane (flow 135 mL).

4 Water trap.

5 Teflon tube.

6 Nafion tube.

7 ILCA solenoid valve (pneutronics).

8 Room air (calibration).

9 Filter.

10 Electrochemical O2 cell (fast O2 analysis).

11 Solenoid valve (pneutronics).

12 Filter.

13 Pump (DC diaphragm pump).

14 Gas outlet.

C1 Volume.

R1 Restrictor.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

R2

P Differential pressure sensor.

The item numbers and abbreviations occurring in this section relate to Figure

24.

37

Page 48

Function Description Primus

The sample gas (1) enters the water trap (4). In the water trap are two Goretex membranes (1, 2). The moisture in the sample gas cannot pass through

the Goretex membranes. This prevents water reaching the IRIA (flow

135 mL/min). Consequently no water can penetrate the bypass branch (flow

approx. 15 mL/min) either. An approximately 9 cm long Teflon tube (5) serves

as a resistor, and meters the flow in the bypass branch.

If the water in the water tank reaches to the level of the membranes, they are

closed off by the water. An error message is displayed on-screen. A filling

level detector is therefore no longer necessary.

The sample gas flows through the Nafion tube (6) and is additionally dried.

The sample gas then passes on to the ILCA solenoid valve (7). Depending on

the valve switching state, either the sample gas (1) or, during calibration, the

room air (8) reaches the IRIA. The sample gas is fed through the IRIA cuvette

and passes on to the O2 sensor (10).

When the Primus is in Leak Test mode, and the PGM in Standby, the pump

(13) is shut off. Whenever the pump is off, the solenoid valve (11) interrupts

the gas flow to the system. This does not increase the leakage value.

The following low-pass filter comprises the restrictor (R1) and the

volume (C1).

R1 is dimensioned as follows:

– R1 is small enough for the pump not to be placed under unnecessary

strain.

– R1 is large enough so that the pump pressure surges occurring in the

IRIA cuvette do not impair the signal ratio and noise ratio in gas sampling.

– The pressure drop at R1 is measured. The measured value is used for

pump control.

The pneumatic low-pass components are integrated into the module housing

of the electronics. The low-pass minimizes the pressure surges generated by

the pump. Downstream of the pneumatic low-pass filter the sample gas

passes to the pump.

The flow through the pump (13) in measuring mode is approx. 150 mL/min

(flush flow approx. 200 mL/min). The supply voltage of the pump is in the

range from 2.5 VDC to 7.5 VDC at a current of up to 150 mA.

Dimensioning of R2:

In a calibration, the switching of the valve is tested with the pressure sensor

in the IRIA. In this case the pressure drop via R2 and the filter (9) must be

significantly less than the minimum pressure drop through the water trap and

the sample gas tube. In the event of an error, an error log entry is generated.

38

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 49

Primus Function Description

4.3 Operating modes

4.3.1 "Reduced Accuracy"

mode (PGM only)

The sampling bank of the PGM/PGM2 is in so-called “Reduced Accuracy”

mode after approx. 5 minutes. During that time, the measured values are outside the specified accuracy. During that time, a calibration of the O-point is

carried out every 2 minutes.

4.3.2 "ISO" mode (ISO accuracy) (PGM/PGM2)

4.3.3 "Full Accuracy" mode

(PGM only)

Following “Reduced Accuracy” mode the sampling bank has ISO accuracy.

After a maximum of 30 minutes the switch is made to “Full Accuracy” mode.

After power-up, the IRIA takes around 30 minutes to reach its operating temperature for maximum accuracy. During this time, a calibration of the O-point

is carried out every 2 hours.

4.3.4 "Standby" response of

the Primus (PGM/PGM2)

The filter wheel in the IRIA (PGM only) and the sampling gas pump are

switched off after approximately 30 minutes. After 90 minutes the emitter and

the heater are shut off. This is done to extend service life and reduce noise.

4.3.5 IRIA/ILCA2 calibration The IRIA/ILCA2 is calibrated automatically. The user cannot initiate manual

calibration. Nor is calibration possible during the ventilator leak test. This prevents a possible increase in volume resulting from intake of ambient air.

4.3.6 Auto-Wake-up function If the Primus is switched to a ventilation mode following a cold-start, the alarm

monitoring is initially disabled. This applies to all the parameters of the CO2

sampling bank except the alarm CO2/AGENT INOP. Alarm monitoring is activated when a respiration phase is detected.

4.3.7 O2 sensor/Servomex The electrochemical O2 sensor and the Servomex sensors are calibrated

during the cold start. In operation, the electrochemical O2 sensor is calibrated

automatically every 8 hours. The Servomex sensor is calibrated every 2

hours. During calibration, the ILCA/ILCA2 solenoid valve is switched to room

air.

When the zero point of the IRIA/ILCA2 is calibrated the plausibility of the

electrochemical O2 sensor signal is also checked. The Servomex sensor is

calibrated with 21% O2.

If non-linearity occurs, the user is offered a 100% O2 calibration. In 100% O2

calibration the user is responsible for connecting 100% O2 to the sampling

line.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

39

Page 50

Function Description Primus

4.4 PGM/PGM2 electronics

4.4.1 MOPS PCB (PGM/PGM2) In the “Block diagrams” section, you will find a block diagram of the MOPS

PCB

“MOPS” stands for “Modular Platform for Sensors”. It is a modular concept by

which suitable sensor components (pneumatic and mechanical components)

can be operated together by way of a processor board.

The resultant arrangements are supported by a software program with a uniform communications interface. In this way, the user is provided with a uniform view of the parameters on offer, irrespective of the components

deployed.

The software is automatically configured for the connected components when

the system starts up.

With this concept, different gas sampling modules (for example “ILCA2” and

“IRIA”) can be configured for specific customer needs using standard components.

The MOPS PCB calculates the values of the patient parameters and controls

the sensor head signals.

4.4.2 AMO IRIA PCB (PGM) “AMO” stands for “Adapter MOPS”. The PCB has the following tasks:

– Convert digital target values from the MOPS PCB into analog voltages for

the IRIA emitter.

– Generate the IRIA supply voltage.

– Data transfer from the IRIA sensor to the MOPS PCB (data evaluation).

4.4.3 AMO ILCA2 PCB (PGM2) “AMO” stands for “Adapter MOPS”. The PCB has the following tasks:

– Convert digital target values from the MOPS PCB into analog voltages for

the ILCA2 emitter.

– Generate the ILCA2 supply voltage.

– Data transfer from the ILCA2 sensor to the MOPS PCB (data evaluation).

4.4.4 AMO O2 PUMP PCB

(PGM)

4.4.5 AMO MFM PCB (PGM2) The PCB has the following task:

The PCB has the following task:

– Transfer the O2 sensor data to the MOPS PCB (data evaluation).

– Transfer the O2 sensor data (Servomex) to the MOPS PCB (data evalua-

tion).

40

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 51

Primus Function Description

4.4.6 AMO FLOW ILCA PCB

(PGM/PGM2)

The AMO FLOW ILCA PCB controls the pump and the valves of the

PGM/PGM2. The PCB is controlled and powered by the MOPS PCB. The

actual regulation of the pump flow is handled by the software of the controller

on the MOPS PCB.

The AMO FLOW ILCA PCB holds the following components:

– A DC/DC converter generates the pump voltage (2.5 - 7.5 V/DC). The

output voltage of the DC/DC converter is controlled with a digital potentiometer on the PCB. The digital potentiometer is regulated by the MOPS

PCB.

– The output stage to operate the valve.

– Service LEDs for the pump voltage, the valves and the supply voltage

– The temperature-compensated differential pressure sensor for flow mea-

surement. The sensor offset is corrected with a digital potentiometer.

– The analog electronics for evaluation of the pump voltage, pump current,

valve current and differential pressure.

The flow is measured by way of the differential pressure of restrictor R1 plus

the upstream (sintered-metal) filter. The measuring range is 0 mbar to 350

mbar.

The AMO FLOW ILCA PCB is connected directly to a 60-pin connector on the

MOPS PCB and is detected automatically by the MOPS PCB.

The function description relating to the mixer follows.

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

5132.300

41

Page 52

Function Description Primus

42

5132.300

Version 5.0_ Released_Printed on_02.06.06_F5132300T03_PGM.fm

All rights reserved. Copyright reserved.

Page 53

Primus Function Description

5 Mixer This section describes the mixer for the AIR, N2O and O2 gases. The newly

generated fresh gas is fed through the vaporizer to the VGC.

Figure 25 Mixer position, with rear panel open

All rights reserved. Copyright reserved.

Version 1.1_ Released_Printed on_02.06.06_F5132300T04_Mischer.fm

5132.300

43

Page 54

Function Description Primus

Figure 26 Mixer without hood, for legend see Tab l e 11

Table 11 Legend to Figure 26

Item Components

1 PRIMUS CPU PCB

2 Gas inlet block

3 Mixer block

4 A-cone valve

5 Fresh gas tank

6 MIXER PCB

44

5132.300

Version 1.1_ Released_Printed on_02.06.06_F5132300T04_Mischer.fm

All rights reserved. Copyright reserved.

Page 55

Primus Function Description

Figure 27 Block diagram of fresh gas metering, legend Table 12

Table 12 Legend to Figure 27

Item Component

1 Monitor Control Panel (MCP)

2 CAN bus

3 Mixer electronics (PRIMUS CPU PCB/MIXER PCB)

4 Fresh gas outlet

5 Fresh gas flow valve

6 Fresh gas tank

7 Gas inlet valves

8 Pressure regulator

The item numbers and abbreviations occurring in this section relate to Figure

27 .

On the MCP (1) the user selects the carrier gas AIR or N2O as well as the

fresh gas flow and the O2 concentration.

A CAN bus (2) transfers the setup parameters to the mixer electronics (3).

The mixer electronics generate the actuation signals for the gas inlet

valves (7).

At the inlet of the fresh gas tank (6) the flow (V) is measured. With the measured flow value the switching times for the gas inlet valves (7) are calculated. The selected gas concentration is set in the fresh gas tank. The

pressure in the tank (6) and at the fresh gas outlet (4) is measured and monitored.

All rights reserved. Copyright reserved.

Version 1.1_ Released_Printed on_02.06.06_F5132300T04_Mischer.fm

5132.300

45

Page 56

Function Description Primus

The fresh gas flow valve (5) delivers the selected fresh gas flow. The flowmeter at the fresh gas outlet (4) regulates the fresh gas flow valve.

5.1 Operating modes The operating mode is regardless of whether the Primus is powered from the

mains via its power plug or is powered up in battery mode.

5.1.1 10 VA mode Internal leakage may mean that the O2 concentration in the Primus is above

21% when operation is begun. “10 VA” mode prevents dangerous operating

states from occurring.

When the power plug is connected to the mains power but the power switch

is not yet switched on, the following safety rule applies:

– A supply voltage of only 10 VA is fed into the interior of the mixer (10 VA

is the product of the no-load voltage and short-circuit current of the supply

voltage “24 V PLUG-IN”. Only the DC/DC converters (-15 V, +15 V) for

the pressure sensor amplifiers are supplied).

– The pressure sensors for the gases from the central supply (CS) system

and the cylinder supply are read and the compressed gas supply status is

indicated by LEDs on the front panel (see 5.3.2 Pressure status LEDs).

When the Primus is switched on at the power switch (mains or battery powered) the following safety rule applies:

– Before other modules receive operating voltage, the fan in the mixer is

switched on for at least 10 seconds. Only then is “Normal” mode activated.

5.1.2 'Normal' mode In this mode the mixer CPU PCB controls normal mixing. All DC/DC convert-

ers (+5 V, +24 V, -15 V, +15 V) are supplied with “24 V SWITCH”.

5.2 Layout

5.2.1 MIXER PCB In the “Block diagrams” section you will find a block diagram of the MIXER

PCB.

The MIXER PCB holds the following components:

– DC/DC converters (+5 V, + 15 V, - 15 V, +24 V) with voltage monitoring

– Amplifiers of the pressure and temperature sensors

– Valve power switch and monitoring circuits

– Fan actuation and monitoring

– Logic device for the safety O2 adjuster

A cable harness connects the mixer with the NEUTRAL POINT PCB and with

the other unit components. By way of the cable harness the mixer receives

the unstabilized 18 V to 30 V supply voltage and the 12 V fan power from the

power pack as well as the CAN bus.

46

The mixer fan is switched on 10 seconds before the other components and is

powered directly by the power pack (see 5.1.1 10 VA mode).

When the fan wheel rotates a proportional square signal is generated

(approx. 90 Hz). This square signal is monitored by the PRIMUS CPU PCB.

5132.300

Version 1.1_ Released_Printed on_02.06.06_F5132300T04_Mischer.fm

All rights reserved. Copyright reserved.

Page 57

Primus Function Description

The valves on the mixer block are actuated by the Master CPU (PRIMUS

CPU PCB). Power drivers on the MIXER PCB operate the valves. When one

of the valves is actuated, the current flows through a shunt. The voltage drop

at the shunt is evaluated by a comparator circuit and monitored by the supervisor processor on the PRIMUS CPU PCB. An exception to this is the fresh

gas flow valve “VMGS”. The proportional valve cannot be monitored by this

procedure.

For safety shut-off of all valves, the supply voltage can be cut to all valves.

5.2.2 PRIMUS CPU PCB

(mixer)

In the “Block diagrams” section you will find a block diagram of the PRIMUS

CPU PCB.

The PRIMUS CPU PCB is based on a 2-processor system with Master and

Supervisor. Both 16-bit processor systems are identical in structure. The

peripherals are controlled by way of an interface.

Each processor has the following components:

–Quartz

– undervoltage detector

– External watchdog

– Flash-PROM

–RAM

– EEPROM (system configuration)

A Dual-Port RAM is placed between the two processor systems for data

exchange. A logic circuit prevents both processors writing to a memory cell

simultaneously.

Each processor system has an isolated serial port and a CAN bus.

Configuration options for the serial port by jumper:

– Independent serial ports, RS232 level, isolation on jack plug.

– Independent serial ports, TTL level, no isolation, output to connector strip.

7-segment displays are provided for visual indication of operating states of

the Master and the Supervisor.

All rights reserved. Copyright reserved.

Version 1.1_ Released_Printed on_02.06.06_F5132300T04_Mischer.fm

5132.300

47

Page 58

Function Description Primus

5.3 Gas inlet block (AIR,

O2 and N2O)

In the “Block diagrams” section you will find a detailed layout of the pneumatic