Page 1

Oxylog 1000

WARNING!

For a full understanding of the

performance characteristics of this

equipment, the user should carefully

read this manual before use of the

device.

MT-974-2000

Emergency ventilator

Instructions for Use

Page 2

Contents

For Your Safety and that of Your Patients . . . . . . . . . . . . . . . . .3

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Oxylog 1000 Device Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

IPPV controlled ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ventilation with PEEP (Special accessory). . . . . . . . . . . . . . . . . . 9

End-expiratory volume measurement (Special accessory) . . . . .10

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Disinfecting/Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Sterilising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Contents

Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Mounting the ventilation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Installing the Oxylog 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Connecting the O2 supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Checking readiness for operation. . . . . . . . . . . . . . . . . . . . . . .18

Testing ventilation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Testing the »Paw >« alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Testing the »Paw <« alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Checking the »Psupply« alarm . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

What's what . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Front view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Abbreviations and symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Minute volume and O2 concentration as a function of airway pres-

sure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Block circuit diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Order List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

1

Page 3

Contents

This page is intentionally left blank

2

Page 4

For Your Safety and that of Your Patients

For Your Safety and that of Your

Patients

Definitions

WARNING!

A WARNING statement provides important

information about a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION!

A CAUTION statement provides important information about

a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury to the user or patient or in

damage to the equipment or other property.

NOTE:

A NOTE provides additional information intended to avoid

inconvenience during operation.

Strictly follow these Instructions for Use

WARNING!

Strictly follow these Instructions for Use.

Any use of the product requires full understanding and strict

observation of all portions of these instructions.

The device is only to be used for the purpose specified under

"Intended Use" on page 4 and in conjunction with

appropriate patient monitoring (see page 6). Observe all

WARNING and CAUTION statements throughout this

manual and all statements on device labels.

Liability for proper function or damage

The liability for the proper function of the apparatus is

irrevocably transferred to the owner or operator to the extent

that the apparatus is improperly serviced or repaired by

personnel not employed or authorized by DrägerService or if

the apparatus is used in a manner not conforming to its

intended use.

Dräger cannot be held responsible for damage caused by noncompliance with the recommendations given above. The

warranty and liability provisions of the terms of sale and

delivery of Dräger are likewise not modified by the

recommendations given above.

Dräger Medical b.v., Best, the Netherlands

Maintenance

WARNING!

The device must be inspected and serviced regularly by

trained service personnel.

Repair of the device may also only be carried out by trained

service personnel.

Dräger recommends that a service contract be obtained with

DrägerService and that all repairs also be carried out by

them. Dräger recommends that only authentic Dräger repair

parts be used for maintenance. Otherwise the correct

functioning of the device may be compromised.

See chapter "Maintenance Intervals".

Accessories

Do not use accessory parts other than those in the

order list.

3

Page 5

Precautions

Precautions

WARNING!

Standby manual ventilation system

If the life-preserving function of the ventilator is no longer

guaranteed due to a fault, the patient must immediately be

ventilated with an alternative independent ventilating device,

e.g. with a self-filling manual breathing bag.

WARNING!

Do not use this apparatus in explosion hazard areas.

Risk of explosion!

WARNING!

Do not use the equipment in conjunction with magnetic

resonance imaging (MRI, NMR, NMI).

The apparatus may malfunction, causing danger to the

patient.

CAUTION!

Ventilation monitoring

During ventilation, the patient must be constantly

monitored by qualified medical personnel.

Intended Use

Oxylog 1000 – a time cycled, volume constant transport and

emergency ventilator for patients requiring a minute volume

ventilation of at least 3 liters per minute.

General description

Oxylog 1000 is a purely pneumatic-powered transport and

emergency ventilator.

With display

— of inspiratory airway pressure P

with audible and visual alarms for:

— airway pressure P

— airway pressure Paw high

2 supply pressure Psupply low

—O

aw low

aw,

with applications in:

— mobile use in EMS and primary care of emergency patients

— patient transports and transfers by land, sea, or air.

— intra-hospital transfers of ventilated patients

— secondary transfers between hospitals

— the emergency room.

4

Page 6

Operating concept

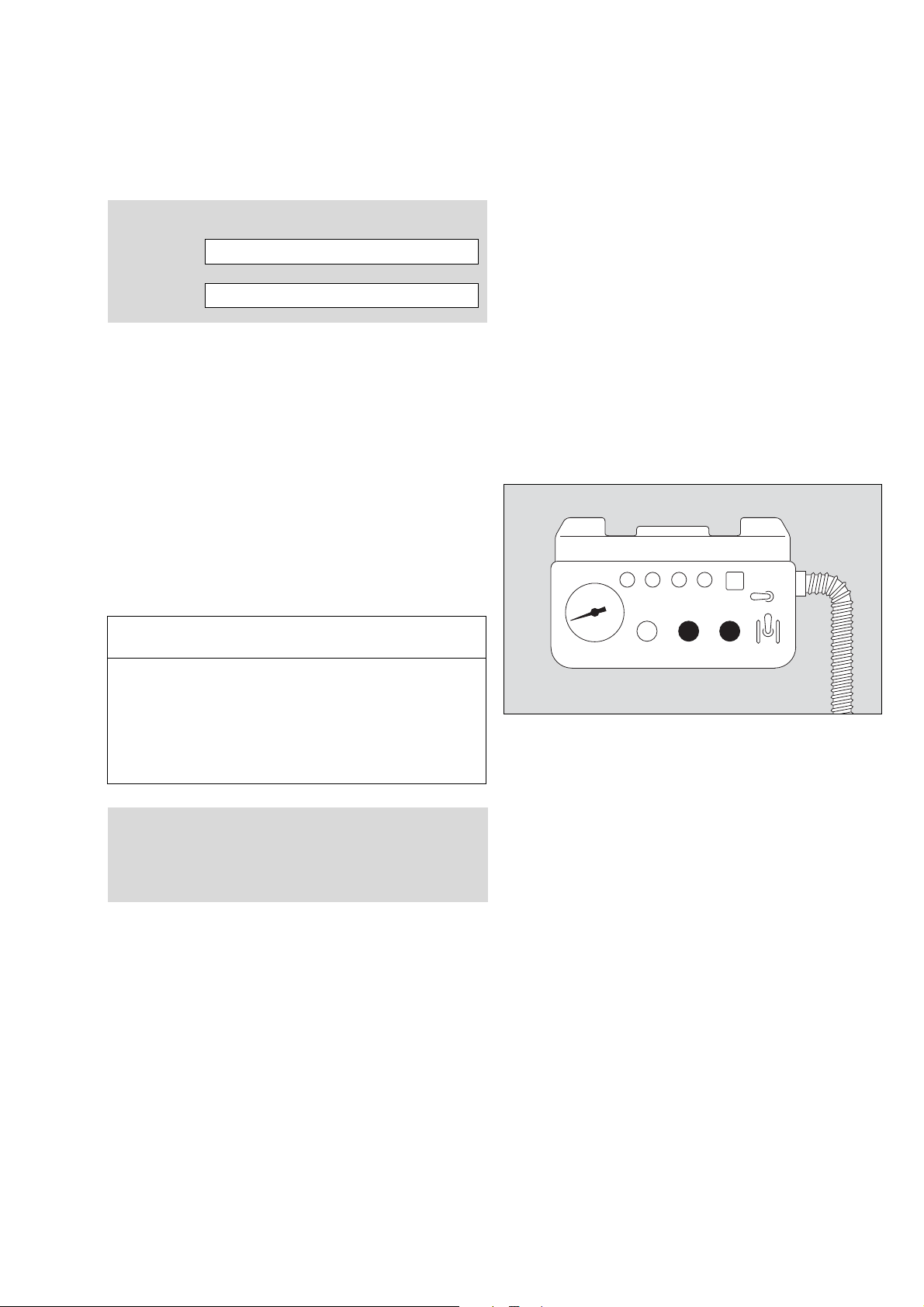

Operating concept

9 8 7 6 5

3

4 1 1 1 2

1 Three rotary control knobs are located in the middle of the

front panel for setting the upper alarm limit for airway

pressure (»Pmax«), the ventilation rate (»Freq.«) and the

minute volume (»MV«).

Uniform colour codes are used to identify different scale

ranges of the »Freq.« and »MV« knobs to help rapid

presetting: with these colour-coded scales, the initial

parameters are adapted to the relevant patient group:

infants (green) / children (blue) / adults (brown).

2 The main switch 0/I for switching the ventilator on and off is

in the bottom right-hand corner of the front panel.

3 With the »Air Mix/No Air Mix« switch, the user can choose

between approx. 60 Vol.% O

4 The pressure gauge shows the inspiratory airway pressure.

NOTE:

The color coded ranges and patient identifications are offered

solely for the convenience of the user for selecting initial

settings. It is ultimately the responsibility of the user to select

the correct settings for each patient.

2 and 100 Vol.% O2.

The flag indicators for the alarms are located above the rotary

control knobs for »Freq.«, »MV« and »Pmax«:

5 »Psupply« flag indicator.

Green if the supply pressure is sufficient, turns red if the

supply pressure is insufficient.

6 Indicator for the upper alarm limit »Paw

Red if the airway pressure exceeds the maximum limit.

7 Indicator for lower alarm limit »Paw

alarm limit is not reached.

8 »

g«button to mute the audio alarm for up to 2 minutes.

9 Indicator »

g« turns yellow when the alarm tone is muted.

>« .

<« turns red if lower

MT-214-99A

5

Page 7

Operation

Operation

Oxylog 1000 Device Check

The device check must be carried out before each use.

Any operation of the device requires thorough knowledge of

the Instructions for Use.

Type

Serial No.

Check the following points before starting up the device:

● O2 pressure supply connected

● Cylinder pressure at least 100 bar or ventilator

connected to the central O

● Ventilation valve and ventilation hose connected

2 supply

Testing correct operation

● Fit the test lung to the ventilation valve.

● Set the device when using a reusable hose:

»MV« approx. 10 L/min

»Freq.« approx. 10 bpm

»

Pmax« approx. 55 mbar

Main switch I (ON)

Switch »

● Set the device when using a disposable hose to the settings

No Air Mix«

as described in the accompanying leaflet of the disposable

hose.

Oxylog 1000 must ventilate the test lung

After 5 ventilation strokes ventilation is

constant, no alarms should occur.

● Squeeze the test lung, so that the airway pressure is approx.

60 mbar.

The »Paw >« indicator turns red,

and the audible alarm is sounded.

● Remove the test lung:

The »Paw <« indicator turns red,

and the audible alarm is sounded.

6

Page 8

Operation

In the event of deviations, see "Troubleshooting", page 21.

Device check completed

Name

Date

Use a prepared, operable and disinfected device.

Care, page 11.

Preparation, page 14.

Checking device ready for operation, page 18.

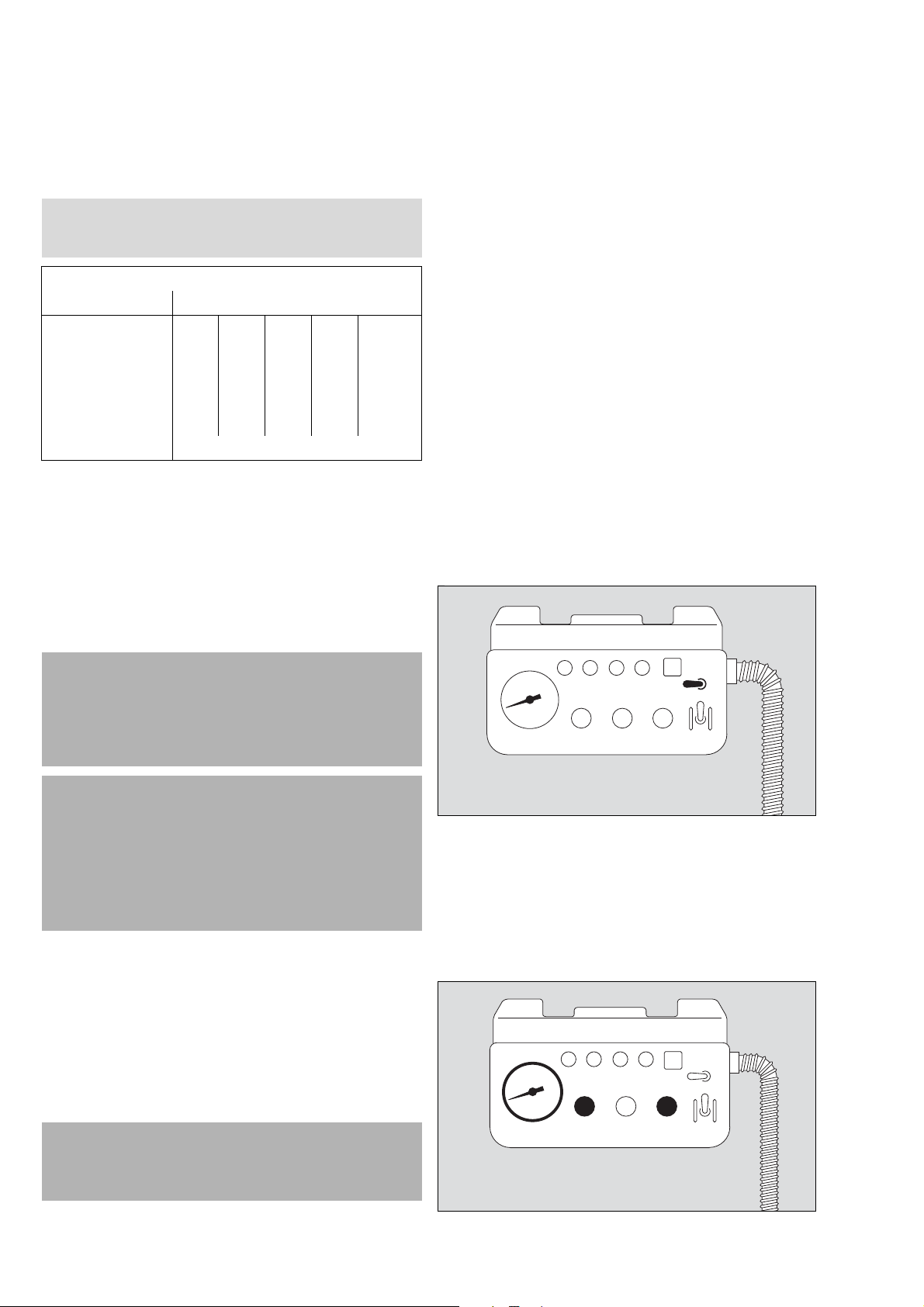

IPPV controlled ventilation

For ventilation frequencies of 4 to 54 breaths per minute.

For rapid presetting, uniform colour-coded scale ranges can

be used for the rotary control knobs for the ventilation rate

Freq. and minute volume MV.

1 Presetting the »Freq.« and »MV« control knobs:

Patient group Freq.

1/min

Green range

28 to 54 3 to 5

MV

L/min

for infants

Blue range

20 to 28 5 to 9

for children

Brown range

4 to 20 9 to 20

for adults

NOTE:

The color coded ranges and patient identifications are offered

solely for the convenience of the user for selecting initial

settings. It is ultimately the responsibility of the user to select

the correct settings for each patient.

D

Oxylog 1000

1

1

002

7

Page 9

Operation

NOTE:

The tidal volume will be equal to the minute volume setting

divided by the rate setting:

Minute volume Ventilator Rate (1/min)

(L/min) 5 10 25 35 54 (max

3 0.60 0.30 0.12 0.09 0.06

7 1.40 0.70 0.28 0.20 0.13

10 2.00 1.00 0.40 0.29 0.13

15 3.00 1.50 0.60 0.43 0.28

20 4.00 2.00 0.80 0.57 0.37

Tidal volume VT (L)

The I/E-ratio is fixed to approximately 1:1.5 and changes

slightly depending on the setting. The I/E-ratio is within the

range considered reasonable for most patients during

emergency care and transport.

)

2 Set the desired O2 concentration with the switch:

Air Mix approx. 60 % O

2 by volume

or

No Air Mix = 100 % O

WARNING!

2 by volume

In Air Mix mode, the applied tidal volume VT is reduced at

high airway pressures due to the physical characteristics of

the injector used for the mixing and the O

2 concentration

increases due to the smaller amount of air intake. (See also

page 28 in the appendix).

WARNING!

In toxic surroundings:

— The patient must be ventilated in No Air mix mode in order

to ensure that toxic constituents are not entrained into the

breathing gas.

— The patient must immediately be transferred to a

breathable atmosphere in order to prevent inhalation of

toxic air when spontaneous breathing resumes.

Set »Pmax«

When the patient is connected:

1 Check the »MV« setting and adjust according to the patient.

2 Check the airway pressure on the pressure gauge.

3 Set desired upper alarm limit »Pmax«.

When the desired upper alarm limit set »Pmax« is reached, the

machine limits the airway pressure increase by blowing off part

of the inspiratory flow. Inspiration is continued by the machine.

WARNING!

Watch the pressure gauge and take note of alarm conditions

in order to recognise incorrect ventilation at an early stage

and prevent danger to the patient.

D

D

2

003

Oxylog 1000

2

3

1

004

8

Page 10

Operation

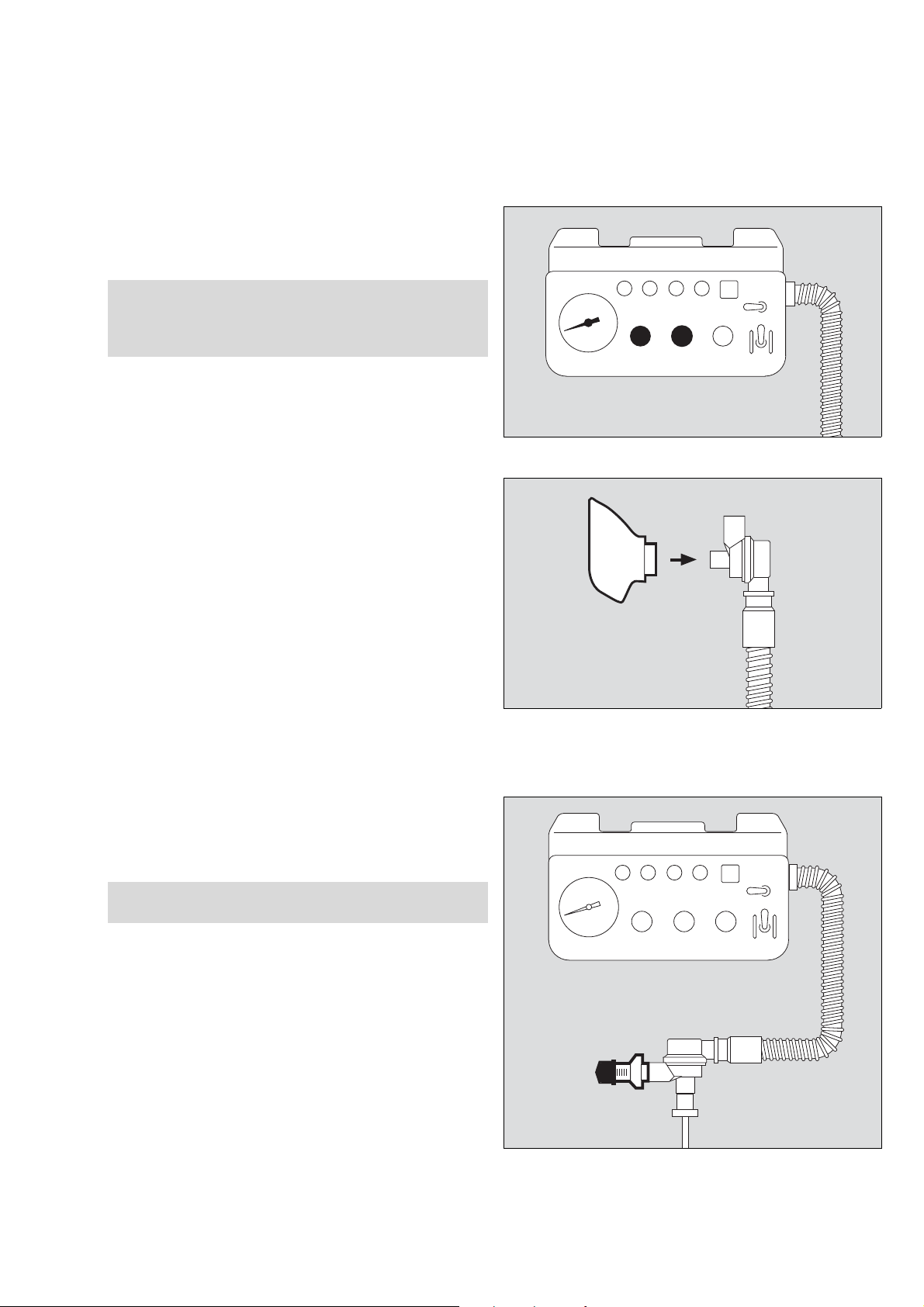

For heart-lung resuscitation

For resuscitation of adults using the "two helper method":

4 Set the »Freq.« knob to the heart symbol H,

5 Set the »Pmax« knob to the heart symbol

H,

approx. 55 mbar.

NOTE:

Airway pressure limiting is now activated. When the peak

pressure limit is reached, tidal volume may not be fully applied

under certain conditions.

Ventilation with a mask

● Connect mask to patient connection on breathing valve.

● Position mask over the face to cover the bridge of the nose

and the chin, to ensure a tight fit.

D

Oxylog 1000

5

4

006

Ventilation with PEEP (Special accessory)

1 Set the PEEP valve to 0 mbar = turn the knob anti-clockwise

as far as it will go and fit it to the expiration connector of the

ventilation valve.

Set PEEP = turn knob. The end-expiratory pressure is

increased by the set PEEP value.

NOTE:

The PEEP pressure is not displayed on the pressure gauge!

D

028028

Oxylog 1000

1

9

Page 11

Operation

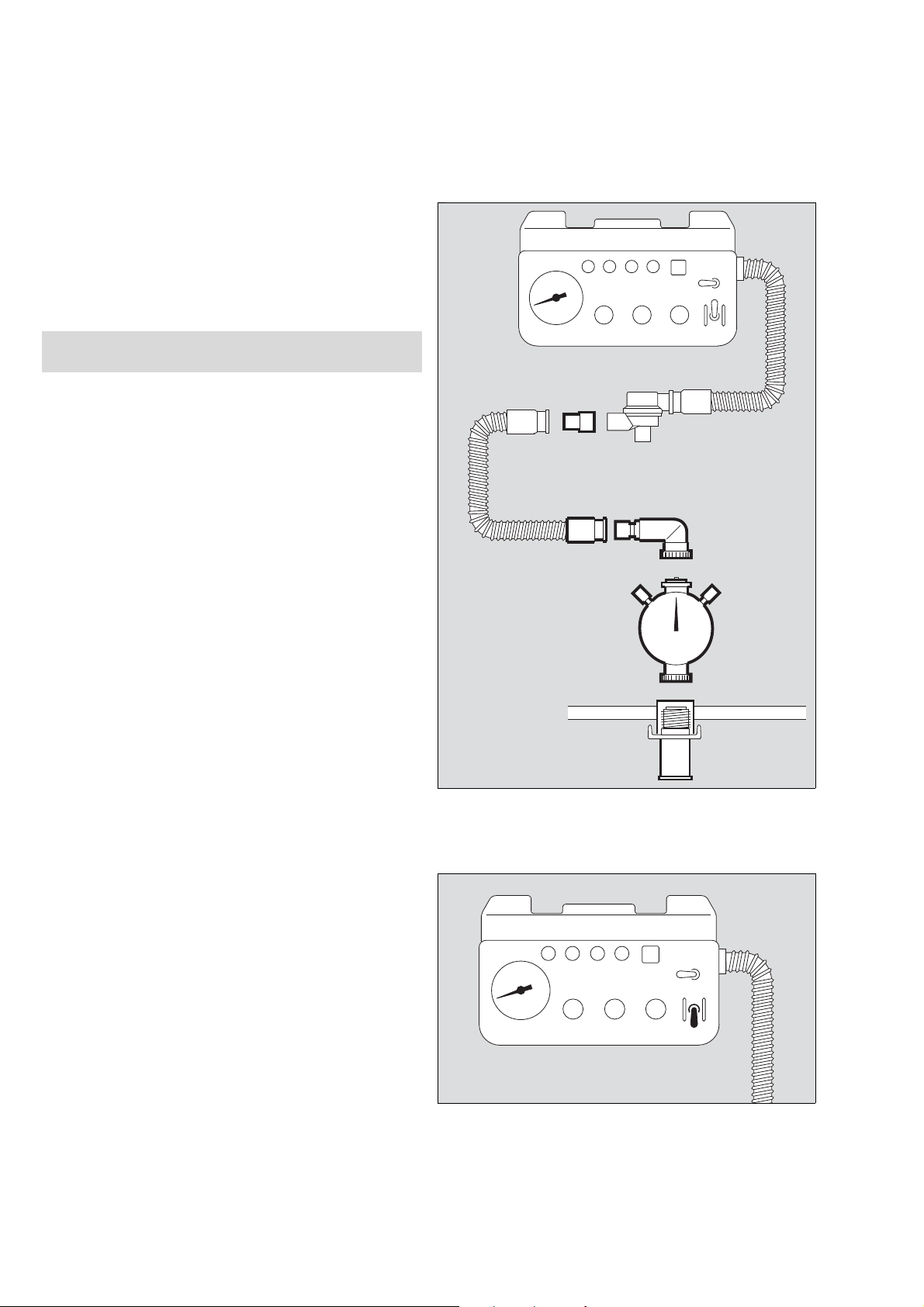

Only for stationary use!

End-expiratory volume measurement (Special

accessory)

To measure the end-expiratory tidal volume and end-expiratory

minute volume.

Cannot be combined with the PEEP valve.

NOTE:

Strictly follow the Instructions for Use of the Volumeter 3000.

2 Clamp the Volumeter 3000 holder to the wall rail.

3 Screw the Volumeter 3000 to the holder.

4 Screw the elbow connector to the Volumeter 3000.

5 Fit adapter to expiration connector of the ventilation valve.

6 Connect the ventilation valve and Volumeter 3000 with

1.5 m long ventilation hose.

D

Oxylog 1000

5

6

4

3

End of operation

After disconnecting the patient:

1 Switch the main switch to 0.

If the Oxylog is supplied by O

● Fully close the cylinder valve.

If the Oxylog is supplied by the central gas supply:

● Remove the gas supply connector.

2 cylinder:

D

2

009

Oxylog 1000

1

010

10

Page 12

Care

Care

● After each operational use of the ventilator, dismantle and

disinfect the reusable ventilation valve and ventilation hose,

the volume metering parts and the reusable PEEP valve.

● The ventilator and compressed gas hoses must also be

cleaned/disinfected if severely soiled.

● Use the single-use system, consisting of the ventilation

valve, the ventilation hose and the single-use PEEP valve,

only once. These parts are marked:

For single use only!

● Dispose of the single-use components in accordance with

local regulations.

Dismantling

● Remove Oxylog 1000 from its holder.

1 Unscrew the O2 compressed gas hose from the

Oxylog 1000.

2 Remove the ventilation hose from the connector on the side

of the ventilator.

CAUTION!

To remove the ventilation hose, always grip it by the sleeve

and not the spiral stiffening ridges.

Otherwise the spiral ridges may be torn, e.g. at the sleeve, or

the hose may be ripped out of the sleeve.

1

2

011

● Remove the ventilation valve from the ventilation hose.

● Pull the PEEP valve out of the ventilation valve,

or

● remove and dismantle the volume metering parts.

012

11

Page 13

Care

Dismantling the ventilation valve

Turn the cover about 45o anti-clockwise = unlock, and remove

the cover.

3 Remove the diaphragm. Do not dismantle any further.

WARNING!

Protect the diaphragm from damage.

WARNING!

Do not allow any foreign matter to enter the housing of the

ventilation valve.

WARNING!

The red non return valve in the diaphragm should not be

removed, damaged or bent.

Otherwise, impaired valve operation will occur, putting the

patient at risk.

1

2

013

Disinfecting/Cleaning

Use only preparations classified as »surface disinfectants« for

disinfecting. For material compatibility, we recommend

preparations based on

—aldehydes,

— alcohols,

— quaternary ammonium compounds.

Due to possible damage to materials, the following

preparations are unsuitable:

— compounds containing alkylamine

— compounds containing phenol

— halogen-releasing compounds

— strong organic acids

— oxygen-releasing compounds.

For users in the Federal Republic of Germany, we recommend

the use of disinfectants listed in the current DGHM list

(DGHM = German Society for Hygiene and Microbiology).

The DGHM list (published by mhp Verlag GmbH, Wiesbaden)

also specifies the active basis of each disinfectant. For

countries where the DGHM list is unavailable, we recommend

products based on the above active bases.

12

Page 14

Care

Wipe disinfecting

Ventilator, O2 compressed gas hose:

● Wipe disinfect with e.g. Buraton 10 F or Terralin. Strictly

follow the Instructions for Use of the disinfectant

manufacturer. Coarse impurities must first be removed with

a disposable cloth.

CAUTION!

Do not allow any liquids to penetrate inside the ventilator or

O

2 compressed gas hose.

Liquid inside the system can impair ventilation.

Immersion disinfecting

Dismantled components of the ventilation valve, ventilation

hose, volume metering parts, not the Volumeter 3000:

● Disinfect in disinfectant bath with e.g. Gigasept FF =

formaldehyde-free.

Strictly follow the Instructions for Use of the disinfectant

manufacturer.

Thoroughly stir the parts in the solution.

Do not clean with hard brushes.

Do not allow any foreign object to enter the inside of the

ventilation valve.

● Rinse thoroughly with Aquadest.

CAUTION!

Allow the parts to dry fully.

If any water remains in the ventilation valve, the ventilation

function may be impaired.

Sterilising

Sterilise as follows if necessary:

Disassembled parts of the breathing valve, ventilation hose

and mask:

● Sterilise in hot steam at 134

accordance with EN 285: at least 3 minutes.

NOTE:

Do not expose the plastic parts to the hot steam for more than

10 minutes, since this can accelerate the ageing of the

materials.

PEEP valve and Volumeter 3000

● treat as specified in their specific Instructions for use.

After care

● Preparation, page 14.

● Connect the O2 supply, page 16.

● Betriebsbereitschaft prüfen, page 18.

o

C. Exposure time in

13

Page 15

Preparation

Preparation

The reusable ventilation hose and the ventilation valve are

supplied with the ventilator.

Alternatively, the optional, pre-assembled singe-use system,

consisting of a ventilation hose and ventilation valve, can be

used. These parts are marked:

For single use only!

Mounting the ventilation valve

1 Check that the red non-return valve is securely seated in the

diaphragm and lies flat on the diaphragm.

WARNING!

The red non return valve in the diaphragm should not be

removed, damaged or bent.

Otherwise, impaired valve operation will occur, putting the

patient at risk.

1

2

2 Insert the diaphragm in the valve housing, with the red non-

return valve facing the housing.

3 The bead of the diaphragm must lie flat and flush on the

edge of the housing.

4 Fit the cover as shown, press down and turn 45° clockwise

to lock.

The inspiration connector and the expiration connector

should be facing one another. The diaphragm should fit into

the housing without creasing.

5 Fit the ventilation hose to the inspiration connector of the

ventilation valve.

4

3

014

5

6 Fit the ventilation hose to the connector on the ventilator.

14

015

6

016

Page 16

Preparation

Mounting the PEEP valve (option)

Both a reusable PEEP valve and a single-use PEEP valve are

available.

The single-use PEEP valve is marked:

For single use only!

● Mount the PEEP valve on the expiration connector of the

ventilation valve.

Measurement of the expiratory volume is not possible when

the PEEP valve is used.

029017

Installing the Oxylog 1000

For stationary use

● Place firmly on a level, non-slip surface, ensuring unit

cannot fall,

or:

● Suspend at the head of the bed,

or:

● Suspend on a wall rail, as illustrated.

For mobile use in vehicles

● Use the vehicle mount

1 Suspend Oxylog 1000 by its bracket on the rod of the

holder.

2 Swivel the ventilator up into the holder until it clicks into

place.

To pull out the ventilator:

3 Press the release catch from underneath.

D

Oxylog 1000

1

3

2

018

15

Page 17

Preparation

Connecting the O2 supply

Take care when handling oxygen.

WARNING!

O2 is highly flammable and intensively propagates any source

of fire.

Do not smoke or allow any naked flame in the vicinity of the

O

2 supply.

Protect O

to intense heat.

WARNING!

Do not oil or grease O2 fittings, such as cylinder valves and

pressure-reducing valves, and do not handle these parts with

greasy hands. Fire risk.

WARNING!

Only open/close cylinder valves by hand, turning evenly.

Never use a tool to open/close the valves.

2 cylinders against falling, and do not expose them

For supply by O

WARNING!

2 cylinder

Use only compressed gas cylinders that conform to national

safety standards and have been duly approved.

Use full cylinders with 200 bar cylinder pressure.

● Screw a pressure-reducing valve onto the O2 cylinder (for

supply pressure 2.7 to 6.0 bar).

WARNING!

Use only pressure-reducing valves with an outlet exhaust

valve that limits the outlet pressure to approx. 5 bar in the

event of failure.

● Connect the Oxylog 1000 to the pressure-reducing valve

with the compressed gas hose.

● Open the cylinder valve by turning slowly as far as it will go.

CAUTION!

Do not insert metering valves or flow meters in the

O

2 supply of the Oxylog 1000.

Risk of impaired function of the ventilator with consequent

danger to the patient.

O2

019

16

Page 18

Preparation

Determining the gas content of the O2 cylinder

Example:

Cylinder pressure measured at the pressure gauge of the

pressure-reducing valve: 200 bar

2 cylinder capacity: 2.5 L

O

Compressed gas content: 2.5 L x 200 bar = approx. 500 L

Estimated operating time of the Oxylog 1000

Example:

Freq. 10 bpm, V

T = 1 L, MV = 10 L/min

Operating time =

Operating time = = approx. 45 min

Compressed gas content [L]

(MV +1*) [L/min]

500

11

If Oxylog 1000 is switched to »Air Mix«, the gas consumption is

reduced by about 50 %, thereby increasing the operating time

to about 90 minutes.

For supply from a central O

● Screw the compressed gas hose to the Oxylog 1000 and

insert the gas connector in the O

2 supply

2 supply socket.

In exceptional cases, the Oxylog 1000 may also be supplied

with compressed air, in which case the O

2 concentration is

always 21 % by volume.

For use with the Dräger Oxator

● Screw the O2 compressed gas hose to the Oxylog 1000.

● Insert the gas connector securely into one of the two O2

ports until it clicks into place.

NOTE:

Strictly follow the Instructions for Use of the Oxator.

_________

* Intrinsic consumption of the device: approx. 1 L/min

020

021

17

Page 19

Checking readiness for operation

Checking readiness for operation

— after changing the ventilation valve,

— after each care and reassembly procedure,

— at the latest every 6 months.

● ocument testing in the medical products book.

Connecting the test lung

The test lung consists of the mask elbow for connecting to the

ventilation valve, the Ø7 catheter connector for simulating the

resistance of the airways and a 2 L breathing bag to simulate

lung compliance.

● Insert the mask elbow of the test lung onto the patient

connector of the ventilation valve.

Switch on the O2 supply

● Open the O2 cylinder supply by turning slowly as far as it

will go

or

● insert the O2 compressed gas connector in the supply

socket until it clicks into place = tapping position.

Testing ventilation function

● Set the ventilator when using a reusable hose:

1 »MV« knob approx. 10 L/min

2 »Freq.« knob approx. 10 bpm

3 »Pmax« knob approx. 55 mbar

4 Main switch I (On)

5 Switch »No Air Mix«

● Set the device when using a disposable hose to the settings

as described in the accompanying leaflet of the disposable

hose.

D Oxylog 1000

5

4

123

022023

● Oxylog 1000 ventilates the test lung.

After 5 ventilation strokes ventilation is constant, no alarms

should occur.

18

Page 20

Checking readiness for operation

Testing the »Paw >« alarm

With the existing setting

1 Keep test lung completely deflated and observe pressure

gauge:

● Oxylog 1000 limits the airway pressure to approx. 55 mbar.

2 The »Paw >« indicator turns red, and the audible alarm is

sounded.

1 Release the test lung.

2 The »Paw >« indicator and audible alarm are deactivated.

D Oxylog 1000

2

Testing the »Paw <« alarm

With the existing setting

3 Remove the test lung from the ventilation valve:

4 The red »Paw

alarm is sounded.

5 Press the »

4 The »Paw

muted for up to 2 minutes.

6 The indicator »

tone has been muted.

3 Refit the test lung:

4 The »Paw <« indicator and audible alarm are deactivated.

<« indicator is displayed, and the audible

g« button,

<« indicator remains red; the audible alarm is

g« turns yellow to indicate that the alarm

1

D

024

456

Oxylog 1000

3

19

025

Page 21

Checking readiness for operation

Checking the »Psupply« alarm

● Switch off the gas supply.

Close the cylinder valve or remove the compressed gas

connector.

1 The colour of the »P

red, but there is no audio alarm in this case.

● Restore the gas supply:

1 The colour of the »P

green.

● Remove test lung from ventilation valve.

supply« indicator changes from green to

supply« indicator changes from red to

D

1

Oxylog 1000

After all tests have been successfully completed, the ventilator

is ready for operation.

026

20

Page 22

Troubleshooting

Troubleshooting

This table is intended to assist the user to detect the

underlying cause in the event of an alarm and to remedy the

situation rapidly.

Fault Cause Remedy

Ventilator does not build up any airway

pressure

»Psupply« indicator red

Ventilator remains on »Inspiration« Supply pressure at ventilator inlet too

Patient cannot exhale, or can only exhale

with difficulty

»

Paw >« indicator red

Audible alarm is sounded

The minute volume is not fully applied

»

Paw <« indicator red

Audible alarm is sounded

Gas capacity of O

Supply pressure at ventilator inlet too

low; no central gas supply or O

empty.

low.

Oxylog 1000 faulty. Call Dräger Service.

Ventilation hose kinked. Route the ventilation hose without

Red non-return valve in the diaphragm is

faulty or »creased«.

Stenosis in the airways. Free the airways.

Ventilation hose kinked. Route the ventilation hose without

Lung compliance reduced. Set the »Pmax« higher.

Patient is "fighting the ventilator" Change the ventilation pattern or sedate

Disconnection/leakage at the patient

connection, ventilation valve or

ventilation hose.

Diaphragm of the ventilation valve

incorrectly fitted or damaged.

Leaky cuff. Inflate the cuff and check for leaks.

2 cylinder fully spent. Immediately connect the ventilator to a

full O

Establish sufficient supply pressure:

2 cylinder

2.7 to 6 bar.

Establish sufficient supply pressure:

2.7 to 6 bar.

kinking it.

Open the ventilation valve and assemble

correctly, see page 14.

kinking it.

the patient.

Ensure that all connections are

leakproof.

Mount the diaphragm correctly, or

replace diaphragm if faulty – see

page 14. Replace the single-use system.

2 cylinder.

21

Page 23

Maintenance intervals

Maintenance intervals

Clean and disinfect the ventilator or parts before each repair,

even if returning components to the factory for repair.

Inspection and servicing

of the ventilator

Pressure-reducing valve Major overhaul in accordance

Disposing of the apparatus

— At the end of the period of use.

— Dispose of Oxylog 1000 correctly, after consulting the

appropriate disposal contractors.

Relevant legal provisions should be complied with.

Every 2 years by trained and

qualified personnel.

with the operating instructions

for the pressure-reducing valve

by trained and qualified

personnel.

22

Page 24

What's what

Front view

What's what

6 7 8 9 10

11

5 4 3 2 1

1 Main switch 0/I

2 »MV« rotary control knob for minute volume

3 »Freq.« rotary control knob for ventilation frequency

4 Rotary control knob for upper alarm limit »Pmax«

5 Pressure gauge for inspiratory airway pressure

6 Indicator »

g« key for muting the audible alarm tone

7 »

8 Indicator »Paw <« (Paw lower alarm limit)

9 Indicator »Paw

10 Indicator »P

11 »Air Mix / No Air Mix« switch

g« to mute audible alarm tone

>« (Paw upper alarm limit)

supply« for supply pressure

MT-214-99A

23

Page 25

What's what

Side view

1 Connection for ventilation hose and ventilation valve

2 Connection for O

2 compressed gas hose

1 2

MT-975-2000

24

Page 26

Technical data

Technical data

Environmental conditions

Operation

Temperature –18 to 50

Atmospheric pressure 700 to 1100 hPa

Humidity 15 % to 95 % r. h.

Storage

Temperature –18 to 70

Atmospheric pressure 700 to 1100 hPa

Humidity 15 % to 95 % r. h.

o

C

o

C

Performance characteristics

Operating principle Flow chopper

Control Timer-controlled, constant volume

Ventilation frequency 4 to 54 bpm ±15 %, at least ± 2 bpm

Breathing time ratio permanently set 1:1.5; tolerance: 1:1.2 to 1:2

*

*

Minute volume 3 to 20 L/min ±20 %, but at least ±1 L/min

O

2 concentration of the ventilation

gas when supplied with O

2

Switch set to »Air Mix« 60 % O2 by vol. ±10 %

for MV greater than 7 L/min

for MV less than 7 L/min:

the O

2 concentration increases up to 100 % O2 by vol.

Switch set to »No Air Mix« 100 % O

Safety valve 80 ±10 mbar

2 by vol.

**

Pressure gauge –10 to 80 mbar

±1.6 % of upper range limit

Main switch I – 0

Patient system consisting of 1.5 m hose with ventilation valve

Compliance approx. 1 mL/mbar

Expiration resistance <6 mbar/L/s

Clearance space approx. 12 mL

Connection for PEEP valve 30 mm cone in accordance with EN 1281-1

* The tolerances indicated apply to the table on page 7 for frequency and minute volume relative to the reference condition NTPD (20 oC,

1013 hPa, dry gas). The tolerances are greater, for physical reasons, if maximum minute volume and maximum frequency are set at the same

time.

** 1 mbar = 0.1 kPa

25

Page 27

Technical data

Alarms

P

supply low Alarm triggered when the supply pressure drops below 2.7 bar

In the case of a slow pressure drop, an audible alarm is also

activated.

Paw high > The visual and audible alarm are activated when the set value is

exceeded.

Range: 25 to 60 mbar ±10 %, but at least ±4 mbar

Paw low

< The visual and audible alarm are triggered if a pressure of

10 mbar ±3 is not exceeded during inspiration.

Audio alarm muting The audible alarm can be muted for up to 2 minutes.

Audible alarm volume >75 dB (A) at a distance of 1 m

*

.

Gas supply

Supply gas Medical O

2,

In exceptional cases: compressed air

Conditioning of supply gas Dry, oil-free, dust-free

Supply From a central O

2 supply system

or

from compressed gas cylinders

Gas pressure 2.7 to 6.0 bar at 60 L/min

O

2 cylinders and pressure-reducing valves Must conform to national safety standards and be duly certified

Pressure-reducing valves Must have an exhaust valve on the outlet side to limit the outlet

pressure to about 5 bar in the event of a fault

O

2 connection NIST O2, NIST AIR/O2, DISS or AFNOR

Gas consumption

Internal control approx. 1.0 L/min

Patient

with »Air Mix« approx. 50 % of the effective minute volume

with »No Air Mix« 100 % of the effective minute volume

Typical operating time for a minute volume of 10 L/min

with 11 L O

2 cylinder / 200 bar approx. 200 minutes without mixing (No Air Mix)

approx. 400 minutes with mixing (Air Mix)

with 2,5 L O

2 cylinder / 200 bar approx. 45 minutes without mixing (No Air Mix)

approx. 90 minutes with mixing (Air Mix)

* 1 bar = 1 kPa x 100

26

Page 28

Technical data

Dimensions (W x H x D) mm 215 x 90 x 215 (without handle)

Weight

Oxylog 1000 (basic unit) 3.15 kg

Ventilation hose, reusable, 1.5 m 0.35 kg

Ventilation valve, reusable 0.06 kg

Single-use hose system

(consisting of ventilation hose and ventilation valve)

Materials used

Ventilator housing Impact-resistant acrylonitrile butadiene styrene (ABS)

Ventilation hose, reusable Silicone rubber

Ventilation valve housing, reusable Polysulphone (PSU), silicone rubber

Single-use hose system Silcone rubber, polycarbonate (PC), polypropylene (PP),

0.11 kg

ethylene vinylacetate (EVA)

Classification

according to Directive 93/42/EC, Appendix IX

UMDNS-Code

Universal Medical Device Nomenclature System

Type of protection IPX4

Class IIb

18 – 098

Abbreviations and symbols

Air Mix Mixing of O

IPPV Intermittent Positive Pressure Ventilation

Freq. Ventilation frequency, strokes per minute

MV Minute volume, L/min

No Air Mix No mixing with ambient air, 100 % O2 by volume

Paw Airway pressure

Paw > Upper alarm limit of airway pressure

Paw < Lower alarm limit of airway pressure

PEEP Positive End Exspiratory Pressure

Pmax Set point for upper alarm limit Paw

Psupply Supply pressure

H

g

Setting symbol for ventilation rate and airway pressure

during heart-lung resuscitation

Audio alarm muting

2 with ambient air, approx. 60 % O2 by vol.

27

Page 29

Appendix

Appendix

Minute volume and O2 concentration as a

function of airway pressure

Air Mix function

Oxylog 1000 supplies the air/O2 mixture (Air Mix) by means of

an injector that draws in additional air from the atmosphere to

generate an air/O

60 % by volume.

Due to the laws of physics, the suction effect of injectors

decreases with increasing back pressure.

With high airway pressures, the minute volume MV set may be

reduced during the Air Mix function, thereby increasing the O

concentration.

At airway pressures up to 20 mbar, the set and applied minute

volume (MV) are the same. An additional increase of airway

pressure by 10 mbar leads to a reduction of the volume

applied by about 10 %. The set minute volume MV should

possibly be increased appropriately.

Since less air is drawn from the atmosphere when there is an

increase in airway pressure, the O

At a low minute volume MV of under 7 L/min, concentrations

of up to 100 % by volume can be attained.

2 mix with an O2 concentration of about

2 concentration increases.

2

No Air Mix function

The applied minute volume MV is not a function of the airway

pressure. The O

Minute volume as a function of ambient air pressure

The applied minute volume MV is also dependent on the

atmospheric pressure of the surrounding area (reference value

1013 hPa). If the atmospheric pressure is reduced by

100 hPa, the supplied minute volume MV is increased by

about 10 %.

2 concentration is always 100 %.

28

Page 30

Block circuit diagram

Appendix

1413

1

10

12

11

Function description of the Oxylog 1000 with reference to the

block circuit diagram

The supply gas, O

filter 1, the on/off switch 2 to the ventilation block 3, which can

optionally be connected to the "Air Mix" module

The minute volume is set by the "MV" valve 5 and controls the

ventilation block 3.

The frequency is set by the "Freq." valve 6 and acts on the

frequency control

system 8.

The upper alarm limit "Pmax" is set with the "Pmax" rotary

knob 9 and opens a valve in the ventilation block 3, so that the

airway pressure is limited during inspiration.

The alarm logic

control" 10 by push-button »

pressed, the yellow indicator »

audible alarm is suppressed for up to 2 minutes.

Additional relief valve 13 is permanently set and opens at a

specified pressure of around 80þmbar.

The emergency air valve 14 permits spontaneous breathing by

the patient in the event of ventilator failure.

2 (or compressed air), is channelled via the

7, which is coupled to the alarm logic

8 is connected to the "audible alarm muting

g« 11. When button »g« 11 is

g« 12 is displayed, and the

2

8

7

9

Pmax Freq. MV

4.

34

Air

Mix

56

MV

04329033

29

Page 31

Order List

Order List

Name and description Part No.

Basic unit

Oxylog 1000

Time-cycled, constant volume emergency

ventilator with alarms for high and low airway

pressure and low supply pressure

Optional accessories

Caddy 57 03 300

Carrying system 1000 2M 86 001

Wall Holder for Carrying System 1000 2M 86 103

Spare bag for Carrying System 1000 AB 41 047

Vehicle bracket 84 12 069

Test lung 84 03 201

Ventilation hose E ISO, reusable, 1.5 m 2M 86 511

Ventilation hose E ISO, reusable, 3.0 m 21 12 760

Ventilation valve, reusable 2M 86 800

Reusable PEEP valve (0 to 10 mbar) 84 07 475

Single-use hose system (25 pieces)

consisting of ventilation hose

with ventilation valve

Single-use PEEP valve (5 to 20 mbar) 2M 86 832

2M 86 105

2M 86 837

Connecting hoses

*

-connecting hoses

CG

Gas Supply System 57 04 500

* Central piped gas supply

30

Page 32

Index

Index

A

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Accessories

Applications

B

Before using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . 4

C

Central O2 supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Checking readiness for operation

Connection O2 supply

D

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Device Check

Disinfecting/Cleaning

Dismantling

Disposing of the apparatus

Dräger Oxator, use of

E

End of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

End-expiratory volume measurement

Environmental conditions

F

Front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

H

Heart-lung resuscitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

I

Immersion disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Oxylog 1000

Intended use

IPPV

M

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

O

Operating concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Order List

P

PEEP valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance characteristics

Pmax

Precautions

S

Side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Sterilising

Symbols

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

T

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Test lung, connecting

Testing the »Paw

Testing the »Paw >« alarm

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

V

Ventilation valve, Dismantling . . . . . . . . . . . . . . . . . . . . . . . . 12

Ventilation with a mask

Ventilation with PEEP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

W

What's what . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wipe disinfecting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

31

Page 33

Index

This page is intentionally left blank

32

Page 34

These Instructions for Use apply only to

Oxylog 1000

with Serial No.:

If no Serial No. has been filled in by

Dräger these Instructions for Use are

provided for general information only and

are not intended for use with any specific

machine or device.

0344

Directive 93/42/EEC

concerning Medical Devices

Dräger Medical b.v.

Kanaaldijk 29

z

5683 CR BEST

The Netherlands

+31 499 331 331

y

FAX +31 499 331 333

medical.best@draeger.com

!

www.draeger-medical.com

90 37 394 - 06 en - GA 5503.410

© Dräger Medical b.v.

5th edition - January 2007

Subject to alteration

Loading...

Loading...