Page 1

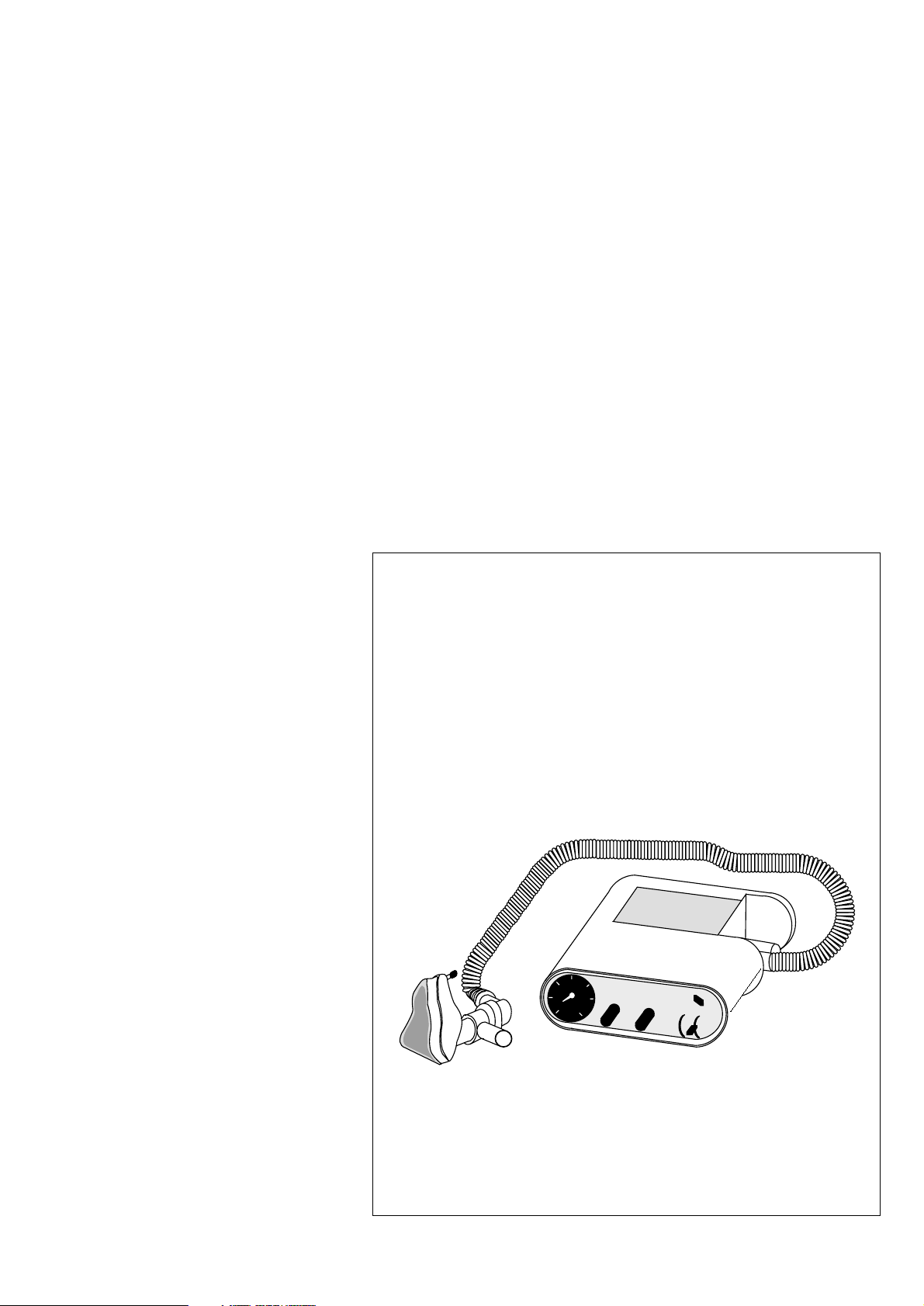

Oxylog

Emergency Ventilator

Technical

Documentation

Page 2

Copyright by Dräger Medical AG & Co. KGaA, Lübeck, Federal Republic of Germany.

Copying is prohibited for commercial purposes.

Attention is to be paid to the Operating Manual.

This technical documentation does not replace the Operating Manual.

The warranty and liability conditions of the general terms and conditions for business transactions of DrägerMedical AG & Co. KGaA are not extended by this technical documentation.

Safety Regulations:

Reference is hereby made to the observance of the relevant safety provisions, such as in Germany the Medical Equipment Ordinance (Medizingeräteverordnung), the Pressure Container

Ordinance (Druckbehälterverordnung), the Technical Rules for Pressurised Gases (Technische Regeln Druckgase) or the Occupational Health and Safety Provisions (Unfallverhütungsvorschriften).

Insofar as reference is made to laws, regulations or standards, these are based on the legal

system of the Federal Republic of Germany.

Follow your local laws and regulations.

Page 3

Contents

General

1 About This Service Manual 4

1.1 Definitions .........................................................................................................................5

2 For Your Safety and that of Your Patients 7

2.1 Strictly follows the Instructions for Use ......................................................................7

2.2 Maintenance .....................................................................................................................7

2.3 Accessories ......................................................................................................................7

2.4 Liability for proper function or damage .......................................................................7

3 Intended use 8

3.1 Oxylog with spontaneous breathing attachment (option) .......................................8

4 Inspection intervals 9

5 Checking readiness for use 10

5.1 Checking ventilation frequency ................................................................................. 10

5.2 Checking safety valve .................................................................................................. 10

5.3 Checking minute volume and compressed-gas supply .........................................11

6 Technical data 12

6.1 Materials used ................................................................................................................14

6.2 Dimensions and weights ..............................................................................................14

6.3 Oxylog with spontaneous breathing attachment ....................................................14

7 Cleaning/disinfection/sterilisation 15

7.1 Cleaning ......................................................................................................................... 15

7.2 Disinfection .................................................................................................................... 16

For internal use only. Copyright reserved.

GBK5503140IECIVZ.fm

7.3 Sterilisation .....................................................................................................................17

5503.140 Oxylog 04.97 Contents Page I

Page 4

Contents

8 Prior to renewed use with patient 17

Functional Description

1 Gas supply 18

2 Pneumatic control 19

2.1 Oxylog ............................................................................................................................. 19

2.2 Oxylog Samsomatik ..................................................................................................... 20

Test List

1 Test Equipment 29

2 Checking general condition 30

3 Checking O

pressure reducer 30

2

4 Functional test 31

4.1 Checking I:E ratio ..........................................................................................................31

4.2 Checking frequency setting ........................................................................................31

4.3 Checking O

concentration ....................................................................................... 32

2

4.4 Checking minute-volume flow setting ...................................................................... 33

4.5 Checking safety valve .................................................................................................. 34

4.6 Checking ventilation pressure gauge ...................................................................... 34

5 Put functional device at the customer’s disposal. 35

For internal use only. Copyright reserved.

GBK5503140IECIVZ.fm

6 Test performed 35

5503.140 Oxylog 04.97 Contents Page II

Page 5

Contents

Fault-Cause-Remedy

1 Fault - Cause - Remedy 36

Changes

1 Type of Changes 37

Appendix

1 Abbreviations 38

2 Spare parts list Oxylog / Oxylog Samsomatic 39

For internal use only. Copyright reserved.

GBK5503140IECIVZ.fm

5503.140 Oxylog 04.97 Contents Page III

Page 6

General

1 About This Service Manual

This service manual conforms with the International Standard IEC 601-1.

This service manual does not replace the Instruction for Use.

Read through each step in every procedure thoroughly before beginning any test. Always use

the proper tools and specified test equipment. If you deviate from the instructions and/or

recommendations in this service manual, you may cause the equipment to operate improperly

or unsafely, or damage the equipment itself.

Use only genuine spare parts manufactured or sold by Dräger Medical AG & Co. KGaA as

listed in the spare parts list.

The test list of this service manual does not replace inspections and servicing by

DrägerMedical AG & Co. KGaA.

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 4

Page 7

1.1 Definitions

DANGER:

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING:

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION:

CAUTION indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury. CAUTION is also used to alert against unsafe

practices.

J

NOTICE:

NOTICE is used to provide information that can help avoid damaging the

product or property as a result of misuse.

IMPORTANT:

IMPORTANT is used to provide additional information, operating tips or

maintenance suggestions.

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 5

Page 8

Inspection = examination of actual condition

Service = measures to maintain specified condition

Repair = measures to restore specified condition

Maintenance = inspection, service, and repair, where necessary

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 6

Page 9

2 For Your Safety and that of Your Patients

2.1 Strictly follows the Instructions for Use

Any use of the apparatus requires full understanding and strict observation of these

instructions. The apparatus is only to be used for purposes specified here.

2.2 Maintenance

The apparatus must be inspected and serviced regulary by trained service personnel at 2

years intervals (and a record kept).

Repair and general overhaul of the apparatus may only be carried out by trained service

personnel. We recommend that a service contract be obtained with DrägerService® and

that all repairs also be carried out by them. Only authentic Dräger spare parts may be used

for maintenance.

Observe chapter “Maintenance Intervals”.

2.3 Accessories

Do not use accessory parts other than those in the order list.

2.4 Liability for proper function or damage

The liability for the proper function of the apparatus is irrevocably transferred to the owner or

operator to the extent that the apparatus is serviced or repaired by personnel not employed

or authorized by DrägerService® or if the apparatus is used in a manner not conforming to

its intended use.

Dräger Medical AG & Co. KGaA cannot be held responsible for damage caused by noncompliance with the recommendations given above. The warranty and liabililty provisions of

the terms of sale and delivery of Dräger Medical AG & Co. KGaA are likewise not modified by

the recommendations given above.

Dräger Medical AG & Co. KGaA

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 7

Page 10

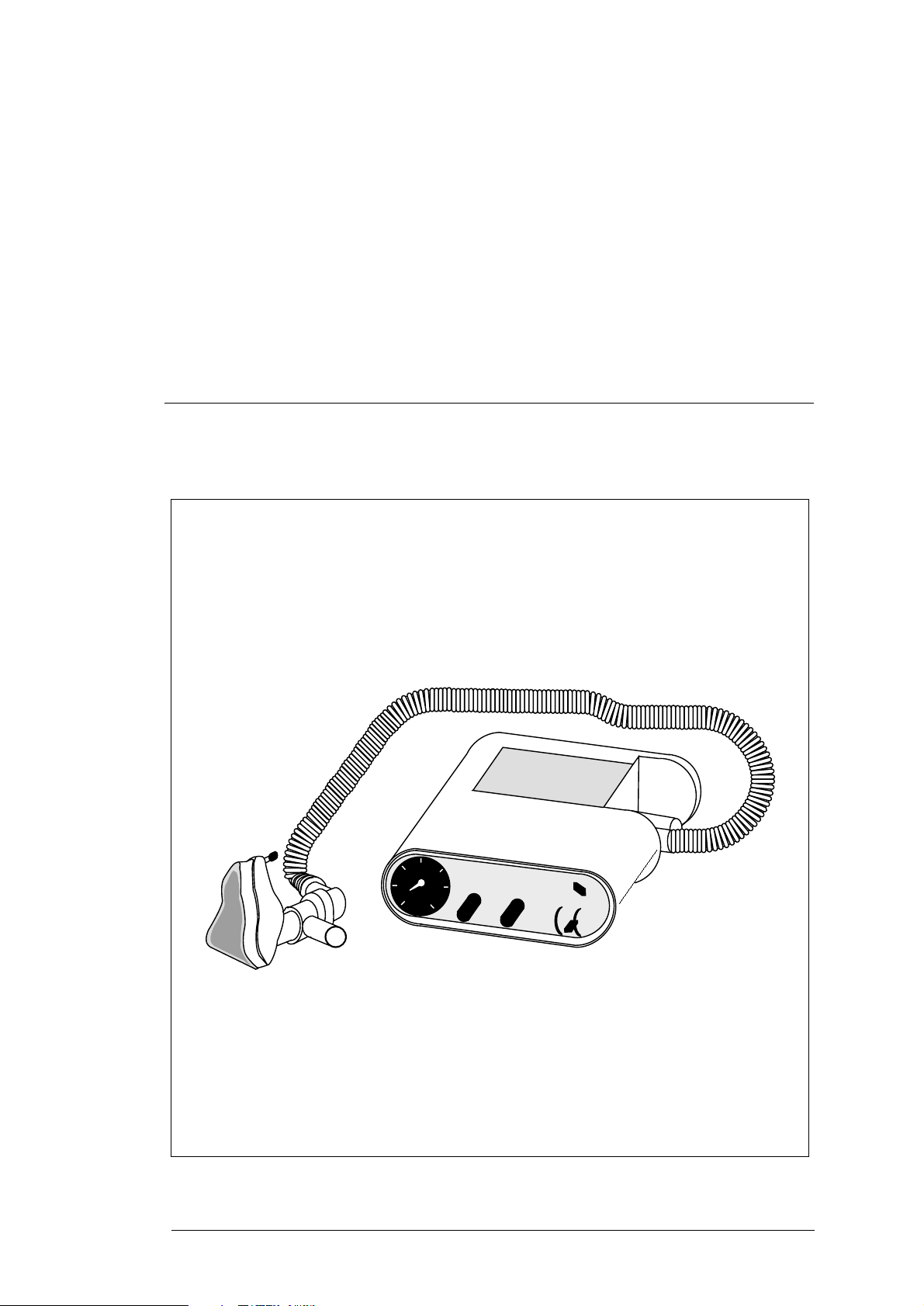

3 Intended use

The Oxylog is a ventilator for the controlled, time-cycled ventilation with constant volume of

infants as of a body weight of 5 kg and adults.

The unit is envisaged for mobile use in rescue operations, for transportation to a hospital in

rescue vehicles or by helicopter, for moving patients to a different hospital by road or air, for

ventilation of emergency admissions and for in-hospital transfer of patients receiving

ventilation, e.g. from operating theatre to intensive-care ward.

3.1 Oxylog with spontaneous breathing attachment (option)

Oxylog with spontaneous breathing attachment for time-cycled, constant-volume ventilation

and spontaneous breathing in a toxic atmosphere.

The Oxylog with spontaneous breathing attachment consists of the following:

• Oxylog with no Air Mix switch with demand regulator connected in parallel

• Ventilation valve with expiratory non-return valve

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 8

Page 11

4 Inspection intervals

IMPORTANT:

Before being serviced or sent in for repair, the unit (or the appropriate

components) must be cleaned and disinfected in line with hospital

regulations and the instructions given in this documentation.

Inspection intervals (Oxylog)

Inspection Every 6 months by specially trained personnel

Inspection intervals (Oxylog Samsomatik)

Inspection Every 2 years by specially trained personnel

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 9

Page 12

5 Checking readiness for use

• Readiness for use is always to be checked after unit upkeep. The unit must be fully

assembled before being tested.

• Performance of the tests is to be recorded in the logbook.

5.1 Checking ventilation frequency

• Make the following settings on the Oxylog:

Pneum. main switch I (on)

MV 3 L/min

Ventilation frequency 15 min

Switch No Air Mix

• Seal off ventilation valve at patient connection.

• Use stopwatch to measure time t for 10 full cycles.

-1

• Determine ventilation frequency f as follows:

f = –––––– min

-1

The Oxylog should switch at a ventilation frequency of between 13 and 17 min.-1.

5.2 Checking safety valve

• Retain the same unit settings.

• Seal off ventilation valve at patient connection.

The max. ventilation pressure should be 50 - 80 mbar.

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 10

Page 13

5.3 Checking minute volume and compressed-gas supply

• Insert catheter connector (size 5) in patient connection of ventilation valve.

• Use the following table to check the max. inspiration pressure on the airway pressure

gauge.

MV Airway pressure

7L/min 4 - 8mbar

15 L/min 15 - 24 mbar

20 L/min 28 - 38 mbar

The Oxylog should switch at regular intervals from inspiration to expiration.

The setting MV = 20 L/min. provides an indirect check on proper operating conditions (min.

2 bar with 60 L/min. on Oxylog).

• Remove catheter connector (size 5) from patient connection.

The unit is ready for operation.

60

t/10

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 11

Page 14

6 Technical data

Operating principle Flow chopper

Control Time-cycled, volume-constant

Ventilation frequency 10 - 35 min

I:E ratio 1:1,5 ±10%

Minute volume (MV) 2 - 20 L/min ±15%, infinitely variable

O2 concentration of ventilation gas using O2 as drive:

-1

±20%, infinitely variable

Switch set to Air Mix 55 Vol.% O

MV < 7 L/min, O

±10% (with MV > 7 L/min), with

2

concentration increases

2

up to 80 vol.%

Switch set to No Air Mix 100 vol.% O

2

Safety valve:

Opening pressure 50 mbar to 80 mbar

Airway pressure reading Pressure gauge -10 to +80 mbar ±2,5% of

full scale value

Drive gas O

or air

2

Quality Dry, oil/dust-free, from central supply or

compressed-gas cylinders

Pressure at device inlet min. 2, max. 6 bar with a flow rate

of 60 L/min

Gas consumption:

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

Control approx. 0,8 L/min

MV (Air Mix) approx. 50% of set MV

MV (No Air Mix) approx. 100% of set MV

Typical operating time

(No Air Mix)

5503.140 Oxylog 04.97 General Page 12

With 3L cylinder/200 bar, MV = 10 L/min

54 min

Page 15

Pneumatic main switch I−0

Patient system Comprises 1.1 m silicone hose and

ventilation valve

Compressible volume approx. 0,3 mL/mbar

Inspiration resistance 3 mbar/L/s

Expiration resistance 3 mbar/L/s

Dead-space volume approx. 12 mL

Ambient conditions - operation:

Temperature −5 °C to +50 °C

Humidity 0 to 100% relative humidity

Ambient pressure 600 to 1200 mbar

Vibration Tested as per MIL STD 810 C 514.2-III, curve

M (helicopter)

In toxic atmosphere Switch set to No Air Mix, controlled ventilation

in the case of apnoea.

CAUTION:

Danger of poisoning! In the event of ongoing or resumed spontaneous

breathing, toxic air is drawn in with the Oxylog, which can result in

poisoning. For ventilation in a toxic atmosphere, use is to be made of the

special Oxylog with spontaneous breathing attachment.

Ambient conditions - storage:

Temperature −20 °C to +70 °C

Humidity 0 to 100% relative humidity

Ambient pressure 600 to 1200 mbar

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 13

Page 16

6.1 Materials used

Oxylog housing Oxylog Impact-proof ABS

(acrylonitrile-butadiene-styrene)

Ventilation hose Silicone rubber

Ventilation valve:

Housing PSU (polysulfone)

Control diaphragm Silicone rubber

6.2 Dimensions and weights

Dimensions (W x H xD) 200 x 80 x 200 mm

Weight approx. 2 kg

6.3 Oxylog with spontaneous breathing attachment

Spontaneous breathing attachment:

Opening pressure Opening pressure 0 to −4 mbar

Max. output 100 L/min at −7 mbar

Oxylog:

No Air Mix switch Ambient air is not sucked in

+30

Pressure limitation valve 50

Ventilation valve With additional expiratory non-return valve

mbar

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 14

Page 17

7 Cleaning/disinfection/sterilisation

• Always clean and disinfect Oxylog after ventilation.

7.1 Cleaning

• Strip down Oxylog.

• Disassemble ventilation valve into its component parts.

IMPORTANT:

Do not remove red non-return valve from yellow control valve.

• Clean disassembled components in warm running water or in water containing

detergent.

• Thoroughly rinse components in running water and then dry them off.

The component parts can also be washed in the Dräger Purfactor“, which ensures that the

material is disinfected and dried.

• Wipe over the surface of the unit with a soft cloth soaked in detergent.

NOTICE:

J

Material damage! Petroleum, ether or similar solvents may damage the

plastic housing of the unit. Never use petroleum, ether or the like for

cleaning purposes.

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 15

Page 18

7.2 Disinfection

7.2.1 Use of liquid disinfectant

• Disinfect the cleaned and dried components of the patient system in a cold disinfectant

solution.

• Thoroughly rinse the components in water and then dry them off.

7.2.2 Disinfection by wiping

• Wipe over the surface of the Oxylog with liquid disinfectant.

Dräger Medical AG & Co. KGaA recommends consulting the "List of officially tested and

approved disinfectants and disinfection methods" as well as the current list of disinfection

procedures checked in line with the "Guidelines for testing chemical disinfectants" and

deemed suitable by the German Hygiene and Microbiology Association.

7.2. 3 Disinfection in Dräger Aseptor

• Disinfect the cleaned and dried components of the patient system and the Oxylog in line

with the Dräger Aseptor“ instructions for use.

NOTICE:

J

Material damage! Parts made of silicone rubber may be damaged in the

Dräger Aseptor

Aseptor

®

®

. Never disinfect ventilation hose and masks in the Dräger

.

®

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 16

Page 19

7.3 Sterilisation

• Sterilise the following in superheated steam at 134°C:

− Cleaned and dried components of patient system

− Component parts of ventilation valve

− Ventilation hose

• Plastic and rubber mouldings are always to be disassembled for sterilisation purposes.

NOTICE:

J

Equipment damage! Moisture ingresses into the unit on sterilising it in an

autoclave or immersing it in a disinfection bath. This can lead to damage.

Never sterilise Oxylog in an autoclave or immerse it in disinfectant

solution.

8 Prior to renewed use with patient

• Assemble unit.

• Check that unit is ready for operation.

GBK5503140A01.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 General Page 17

Page 20

Functional Description

1 Gas supply

The gas is either supplied from a central gas supply system (CS) or from a gas cylinder with

pressure reducer.

Operation of the Oxylog ventilator requires a pressure of between 2 and 6 bar (O2 or compressed air) with a flow rate of 60 L/min.

NOTICE:

J

Equipment damage! Dust, oil and moisture may impair the function of the

unit or damage it. Make exclusive use of dry medical gases which are free

from dust and oil.

GBF5503140T01.fm 19.04.99

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 18

Page 21

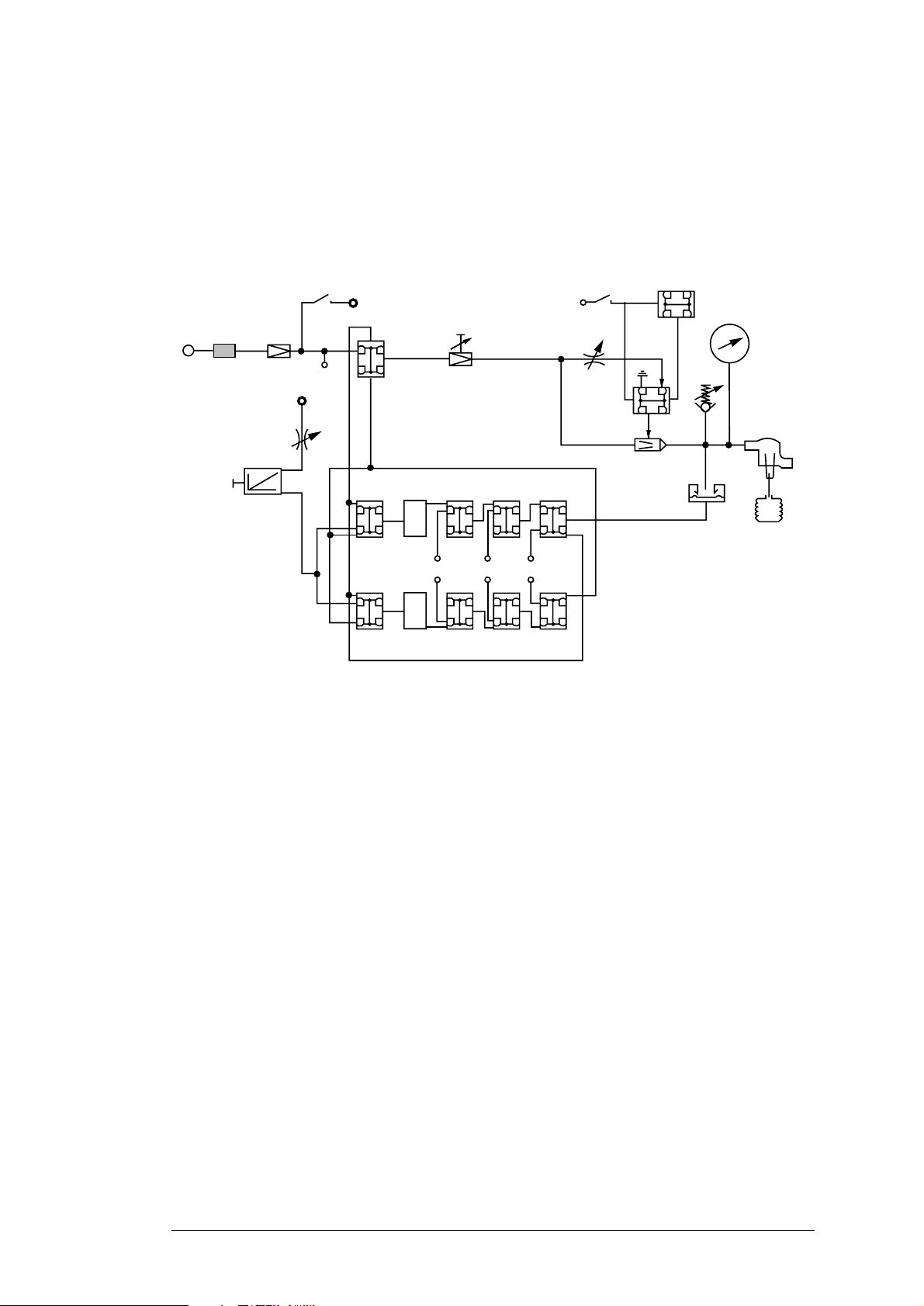

2 Pneumatic control

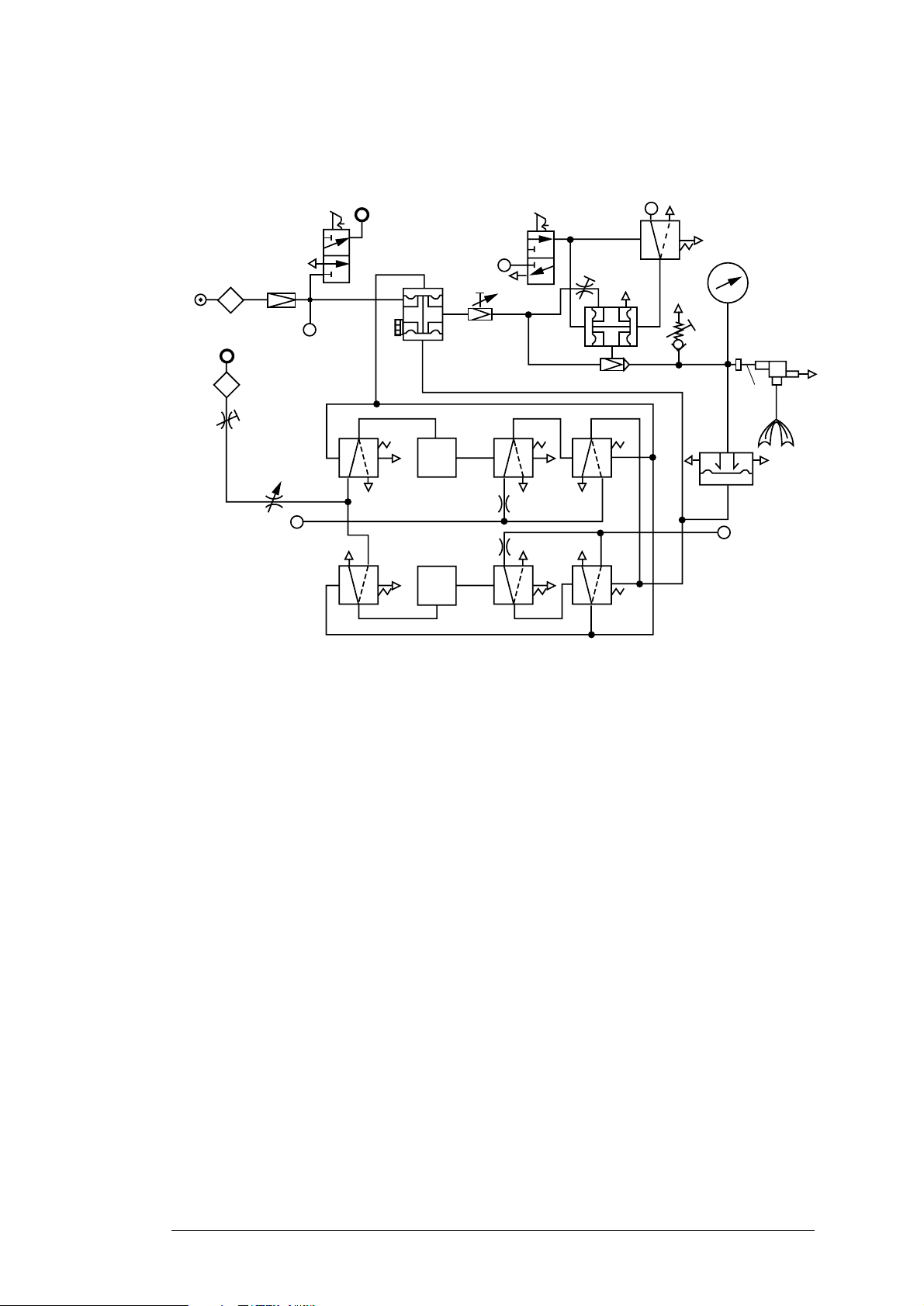

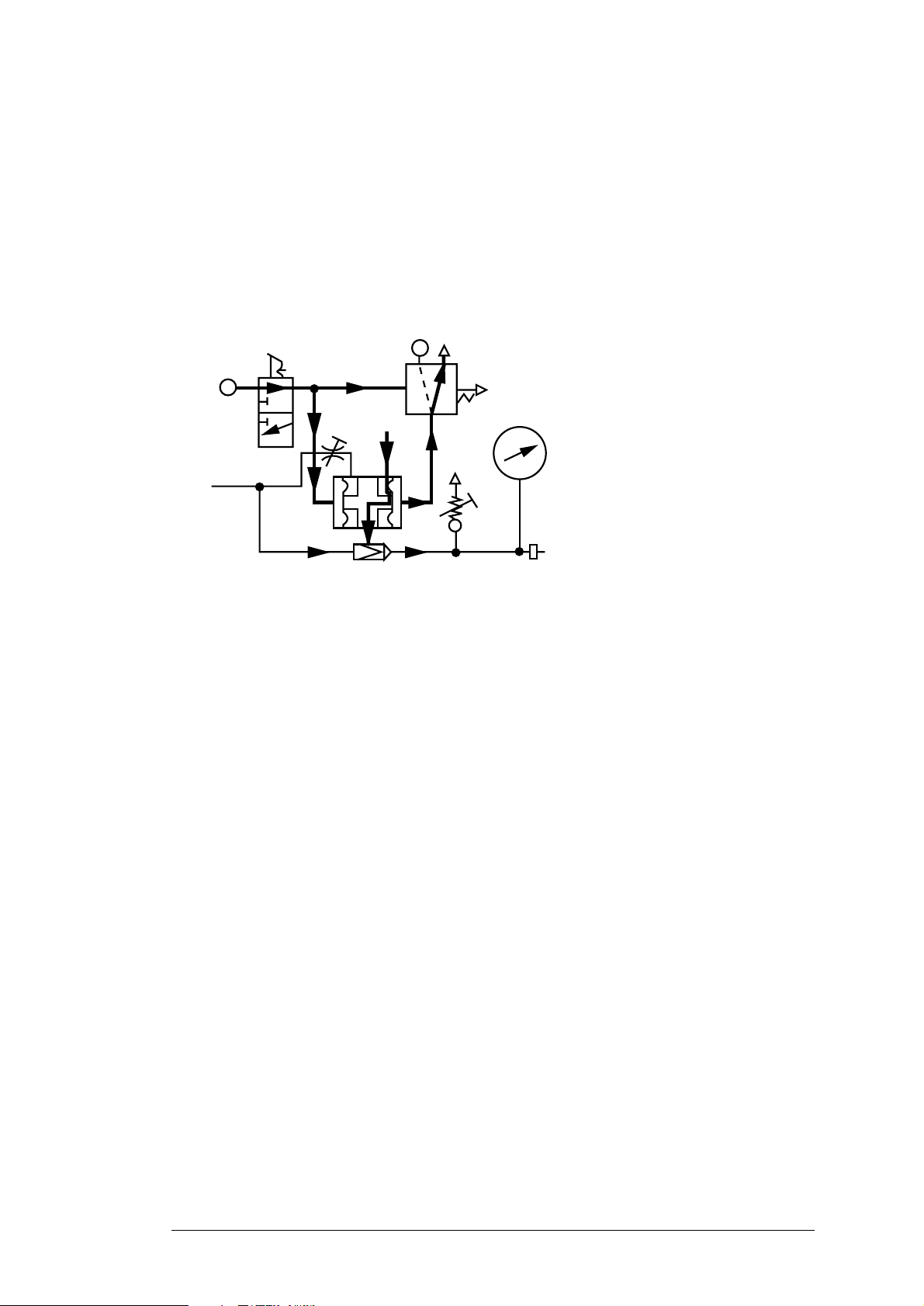

2.1 Oxylog

4

1

23

13

5

17

ABC

EFGH

Abb. 1: Block diagram of Oxylog

14

15

7

6

8

16

9

D

K

12

10

L

18

11

1 Gas connection 15 Vessel

2 Filter 16 Intake

3 Pressure reducer 17 Metering unit

4 On/off switch 18 Ventilation valve

5 Distributor O A Amplifier relay

6 AMV adjuster B Amplifier relay

7 Air Mix/No Air Mix switch C Amplifier relay

8 Metering unit D Amplifier relay

9 Injector E Amplifier relay

10 Relief valve F Amplifier relay

11 Vent valve G Amplifier relay

12 Pressure gauge H Amplifier relay

13 Frequency adjuster K Amplifier relay

14 Vessel L 3/2-way valve

GBF5503140T01.fm 19.04.99

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 19

Page 22

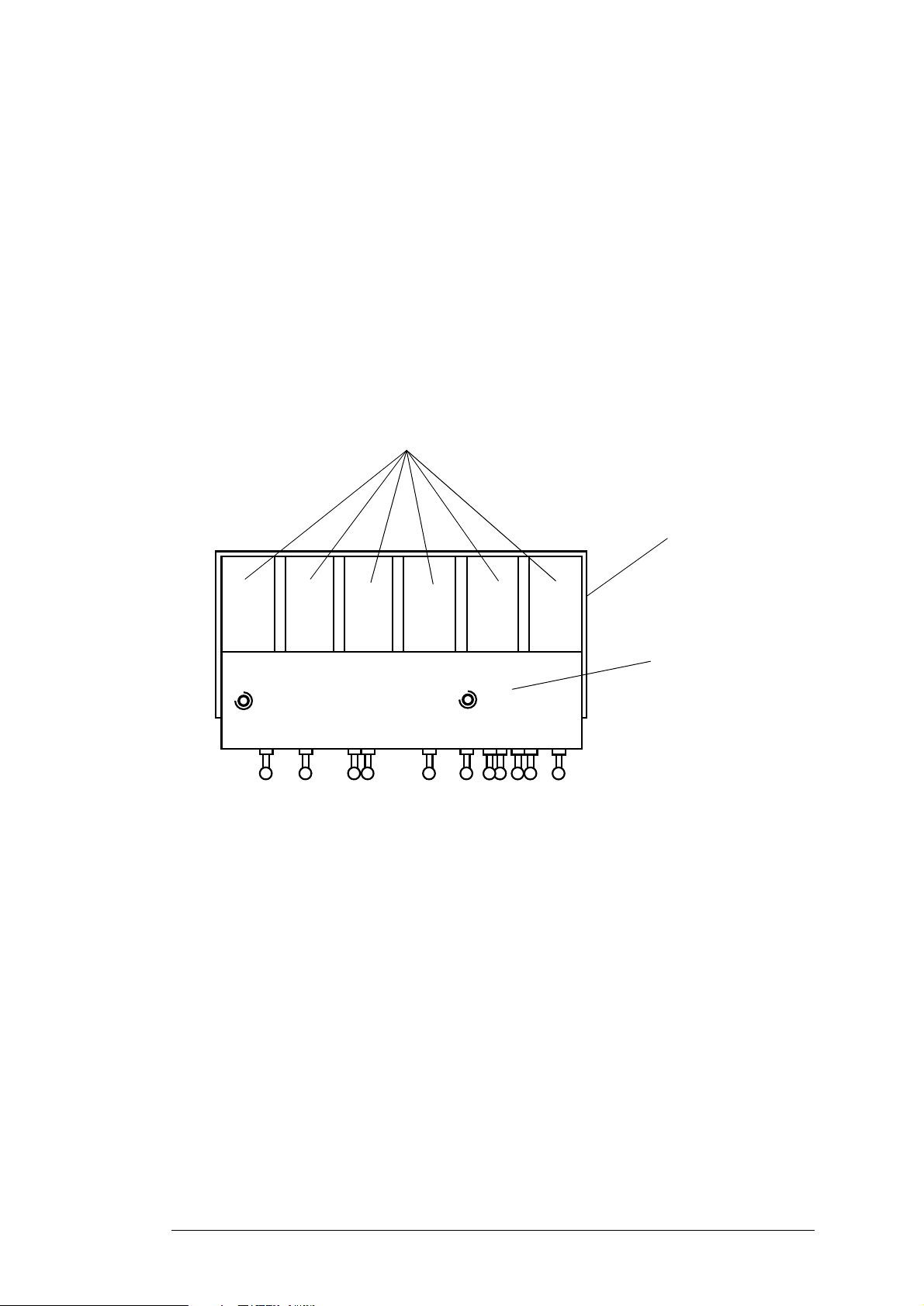

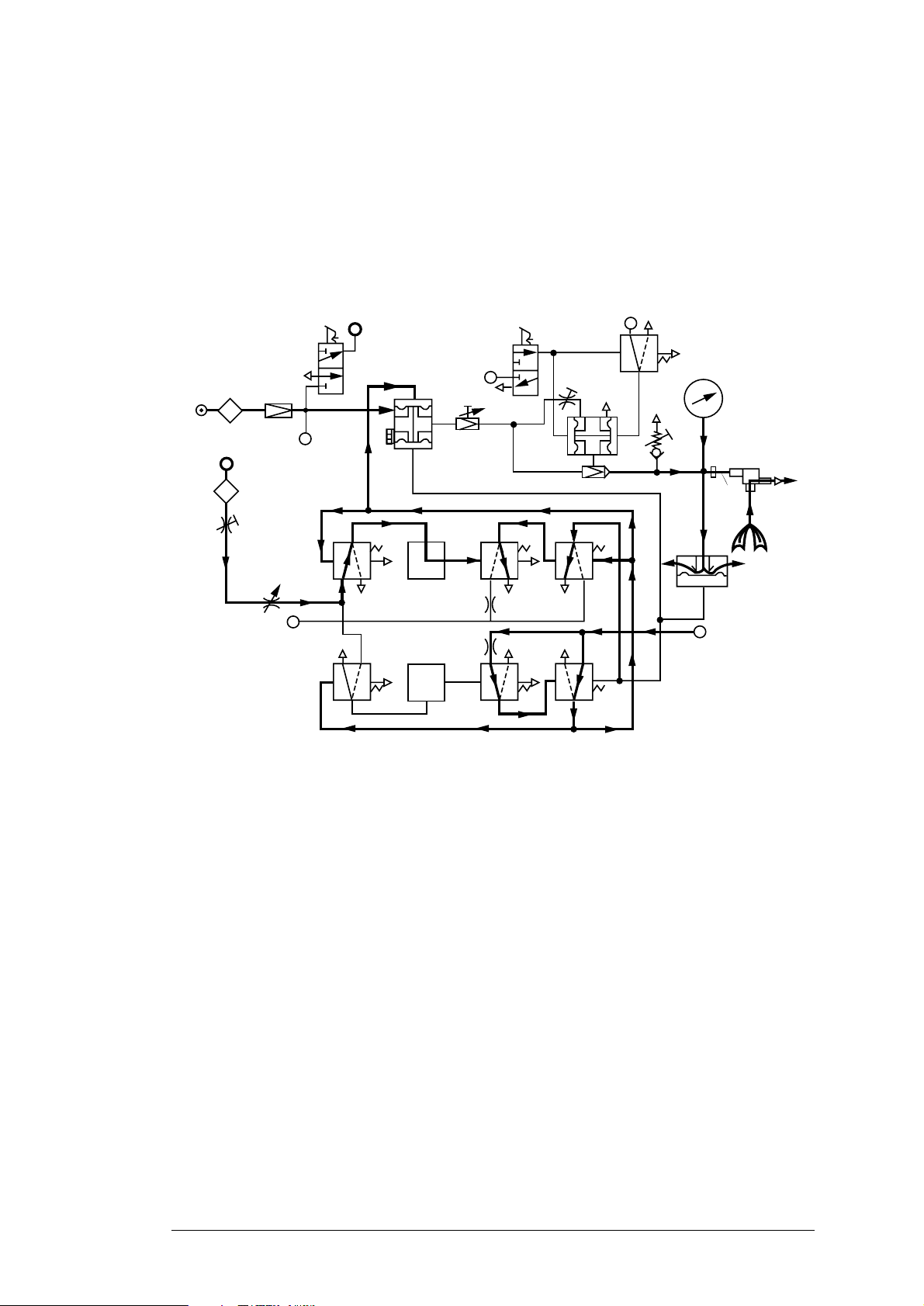

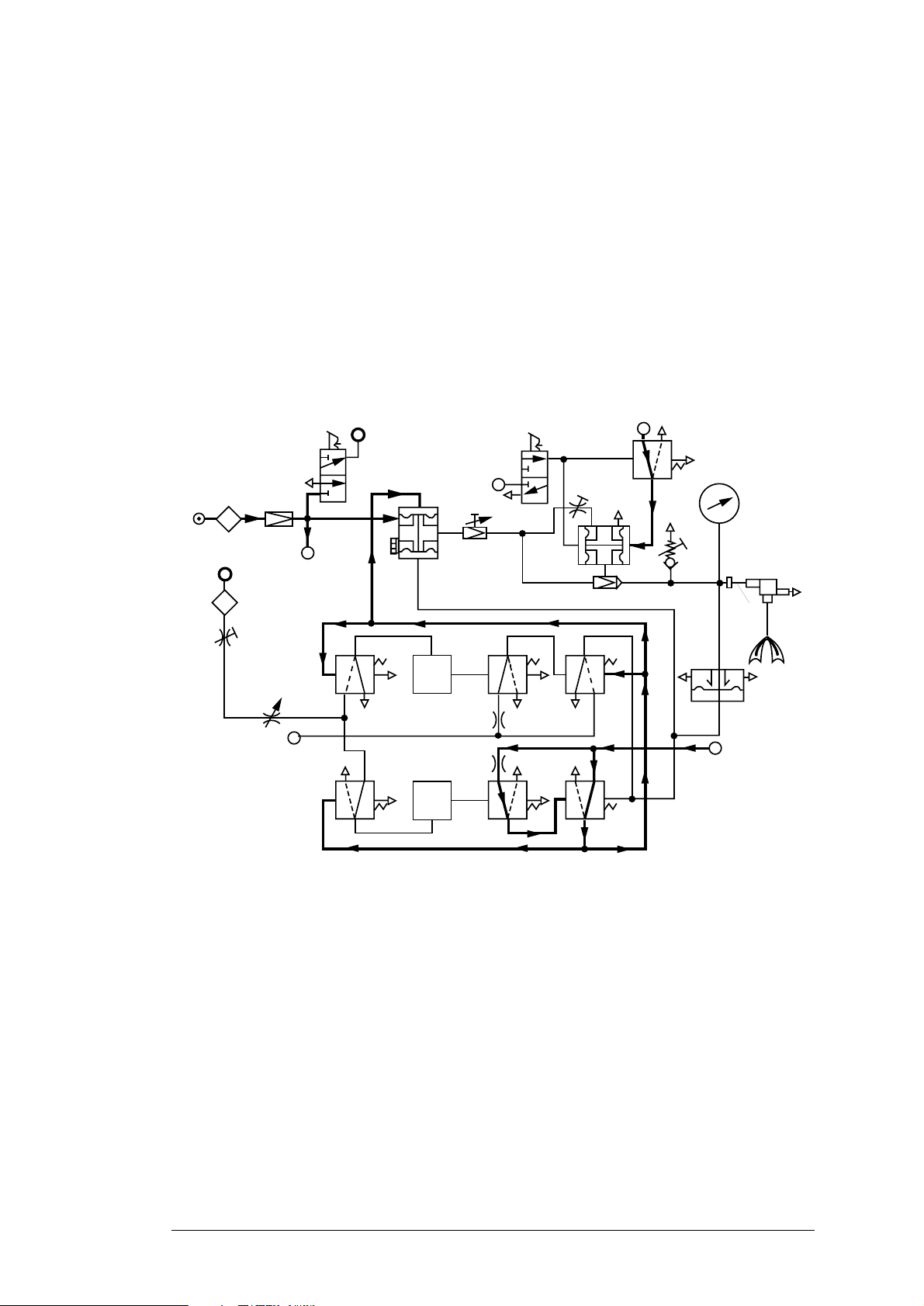

2.2 Oxylog Samsomatik

Microswitches 1 - 6 are grouped on an interconnection plate (pneumatic plate).

The internal connections in the block obviate the need for interconnection of the individual

microswitches with hoses. The microswitches are held in position in the block by a clamp.

Microswitches 2 and 5 were specially selected for their switching properties (switching pressure).

Microswitches

Clamp

3651 42

Abb. 2: Interconnection plate

Block

GBF5503140T01.fm 19.04.99

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 20

Page 23

A1

F2

VD

F1

DR

FD

S1

S2

9

WV1

MV

1

V1

2

D2

D3

3

D1

WV2

I

SV

PA

DM

BV

SS

EV

456

V2

Abb. 3: Block diagram of Oxylog (Samsomatik)

A Gas connection I Injector

F1 Filter DM Pressure gauge

F2 Filter PA Patient outlet

DR Pressure regulator SS Silicone hose

S1 On/off switch BV Ventilation valve

S2 Air-Mix/No Air Mix switch EV Vent valve

MV Minute volume valve V1 Vessel 1

WV1 3/2-way valve V2 Vessel 2

WV2 3/2-way valve 1 Microswitch

VD Pre-metering unit 2 Microswitch

D1 Metering unit 3 Microswitch

GBF5503140T01.fm 19.04.99

D2 Metering unit 4 Microswitch

D3 Metering unit 5 Microswitch

FD Frequency valve 6 Microswitch

SV Safety valve 9 Microswitch

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 21

Page 24

2.2.1 Unit switched off

Oxygen or compressed air flows via the connection A through the filter F1 to the pressure

regulator DR, which provides a constant gas pressure of 1.5 bar. This pressure is applied to

the on/off switch S1, to the distributor O and to the 3/2-way valve WV1.

S1

F1

A

F2

VD

DR

123

FD

4

WV1

MV

V1

D2

D3

V2

S2

D1

65

WV2

I

9

DM

SV

PA

BV

SS

EV

GBF5503140T01.fm 19.04.99

Abb. 4: Gas supply (unit switched off)

2.2.2 No Air Mix switch setting

The distributor applies the gas to all points marked O. This switches the time cycling to expiration, the 3/2-way valve WV1 is disabled and the 3/2-way valve WV2 is set to No Air Mix.

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 22

Page 25

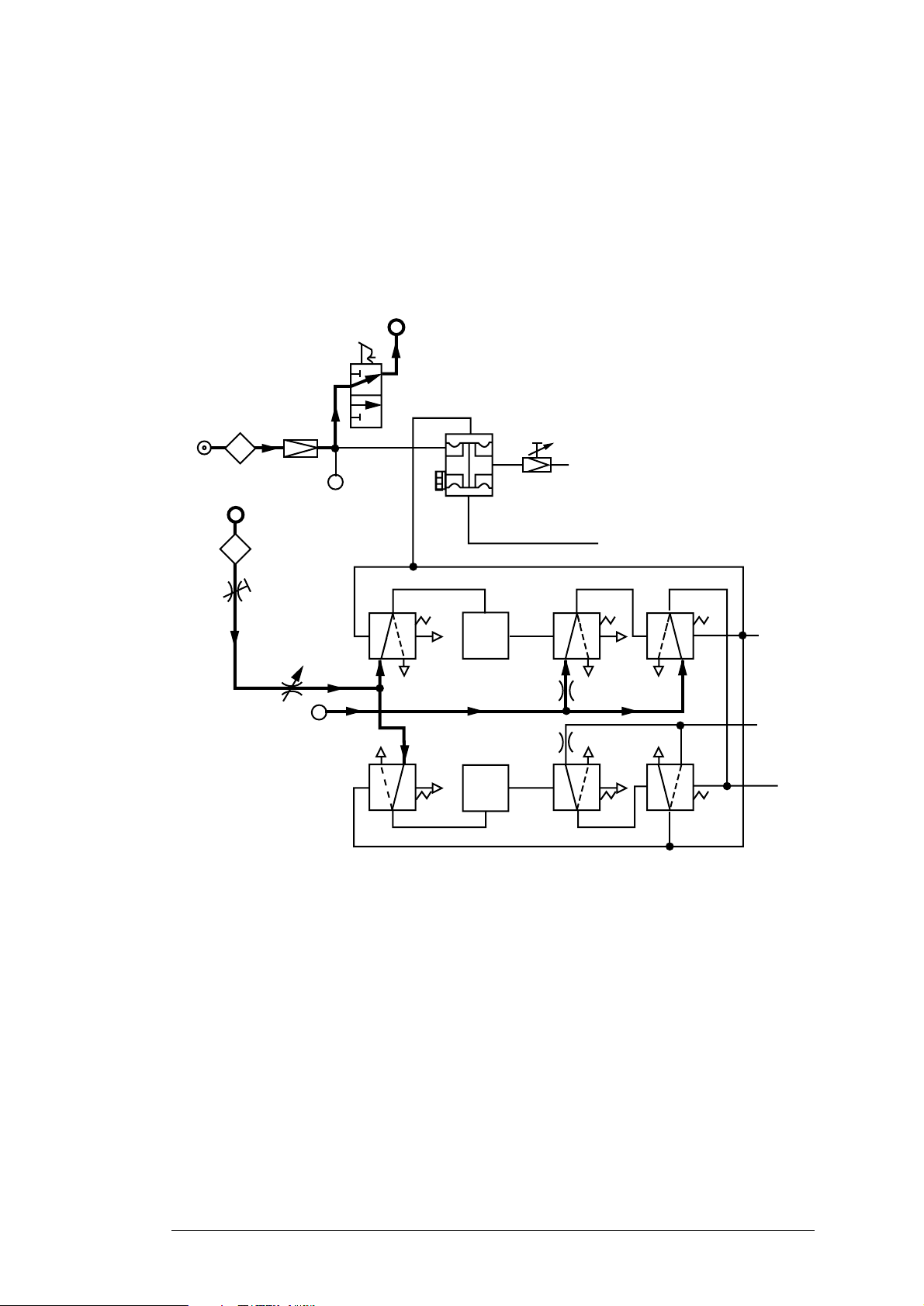

2.2.3 Unit switched on

After switching on the switch S1, gas flows to the distributor O and from there through the filter F2, the pre-metering unit VD and the frequency valve FD to the time-cycling microswitches

1 and 4. At the same time, gas is routed to the microswitches 2 and 3.

S1

F1

DR

MV

A

F2

VD

WV1

1

V1

2

3

FD

4

V2

5

6

GBF5503140T01.fm 19.04.99

Abb. 5: Gas supply (unit switched on)

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 23

Page 26

2.2.4 Inspiration

Microswitch 4 causes the vessel V2 to be filled as far as the switching point of microswitch 5.

Microswitch 5 is vented. Microswitch 6 is also vented and its output thus depressurised (expiration signal blocked).

Microswitch 3 causes the inspiration signal to be passed to the 3/2-way valve WV1, to the

vent valve EV and to the microswitch 6. Vent valve EV is closed.

The 3/2-way valve WV1 opens. The gas applied flows through the minute volume valve MV,

the metering unit D1, the 3/2-way valve WV2 and the injector I to the patient.

S2

9

WV1

MV

D1

WV2

DM

V1

SV

I

23

PA

SS

BV

EV

5

6

Abb. 6: Inspiration

The minute volume valve MV operates on the pressure regulator principle. The setting

governs the flow. The output capacity of injector I is the same in both switch settings (Air

Mix/No Air Mix).

GBF5503140T01.fm 19.04.99

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 24

Page 27

2.2.5 Air Mix switch setting

In the Air Mix switch setting, gas flows through the switch S2 to the 3/2-way valve WV2 and

to the microswitch 9. Microswitch 9 switches to ventilation.

The 3/2-way valve WV2 switches over; the intake to injector I switches to ambient air.

S2

9

D1

DM

WV2

I

Abb. 7: Air Mix switch setting

SV

PA

GBF5503140T01.fm 19.04.99

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 25

Page 28

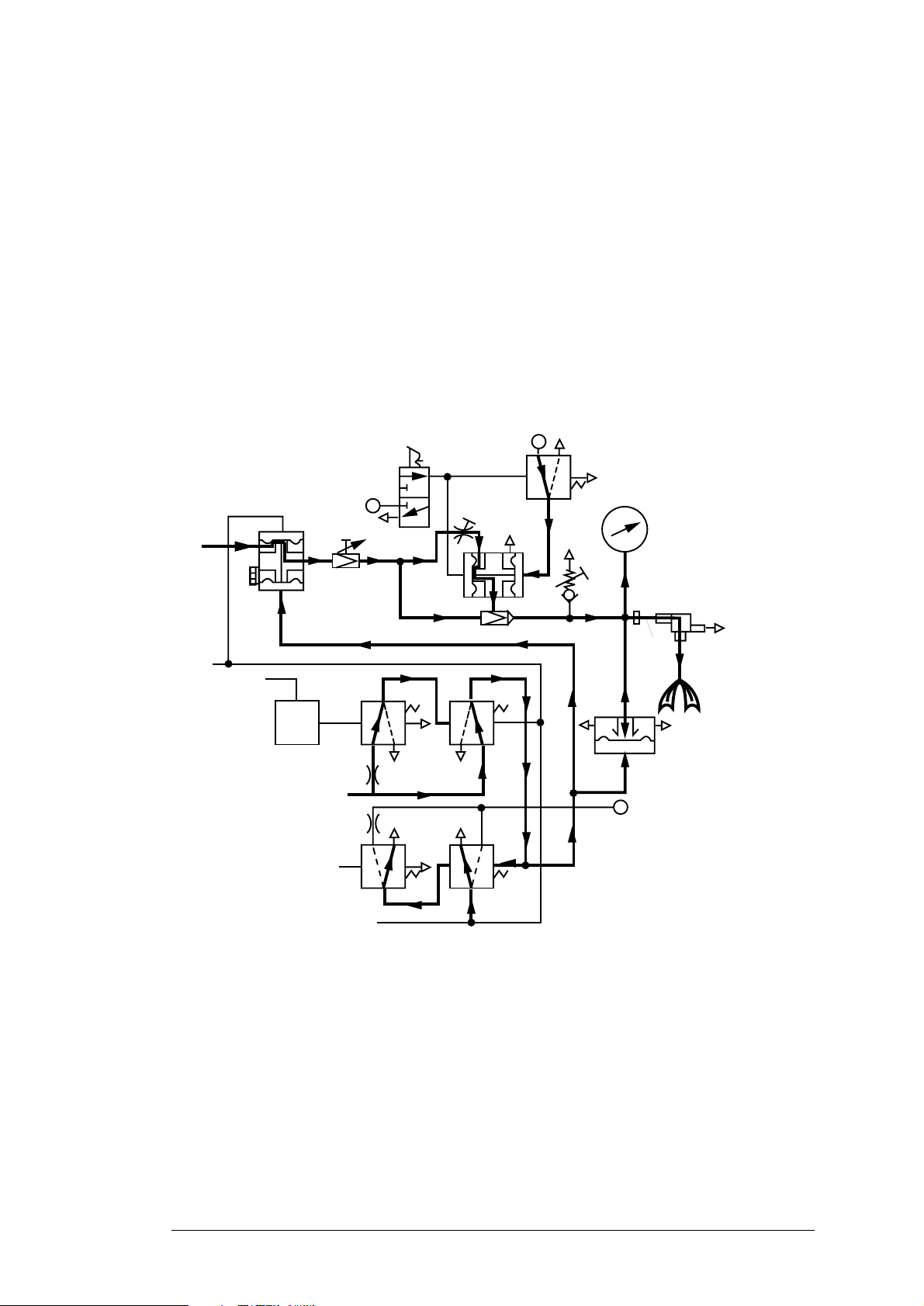

2.2.6 Expiration

As soon as the reversing pressure is attained at microswitch 2 (delayed by filling time of vessel V1), microswitch 2 switches to venting and thus causes microswitch 3 to be vented as

well. The expiration signal is passed to the microswitches 3, 4 and 5 and at the same time to

the 3/2-way valve WV1. Microswitches 3, 4 and 5 switch over. The 3/2-way valve WV1 is

reversed and the flow of gas to the patient is blocked. The vent valve EV relieves the tubing

system (unit tubing from 3/2-way valve WV1 and patient hose to ventilation valve). The patient

can exhale to the atmosphere through the ventilation valve BV.

S1

F1

A

F2

VD

DR

1

FD

4

WV1

MV

V1

D2

D3

V2

S2

9

D1

PA

DM

BV

SS

EV

WV2

SV

I

2

5

3

6

GBF5503140T01.fm 19.04.99

Abb. 8: Expiration

At the same time, microswitch 4 fills the vessel V2 as far as the switching point of microswitch 5. Switching to inspiration then takes place.

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 26

Page 29

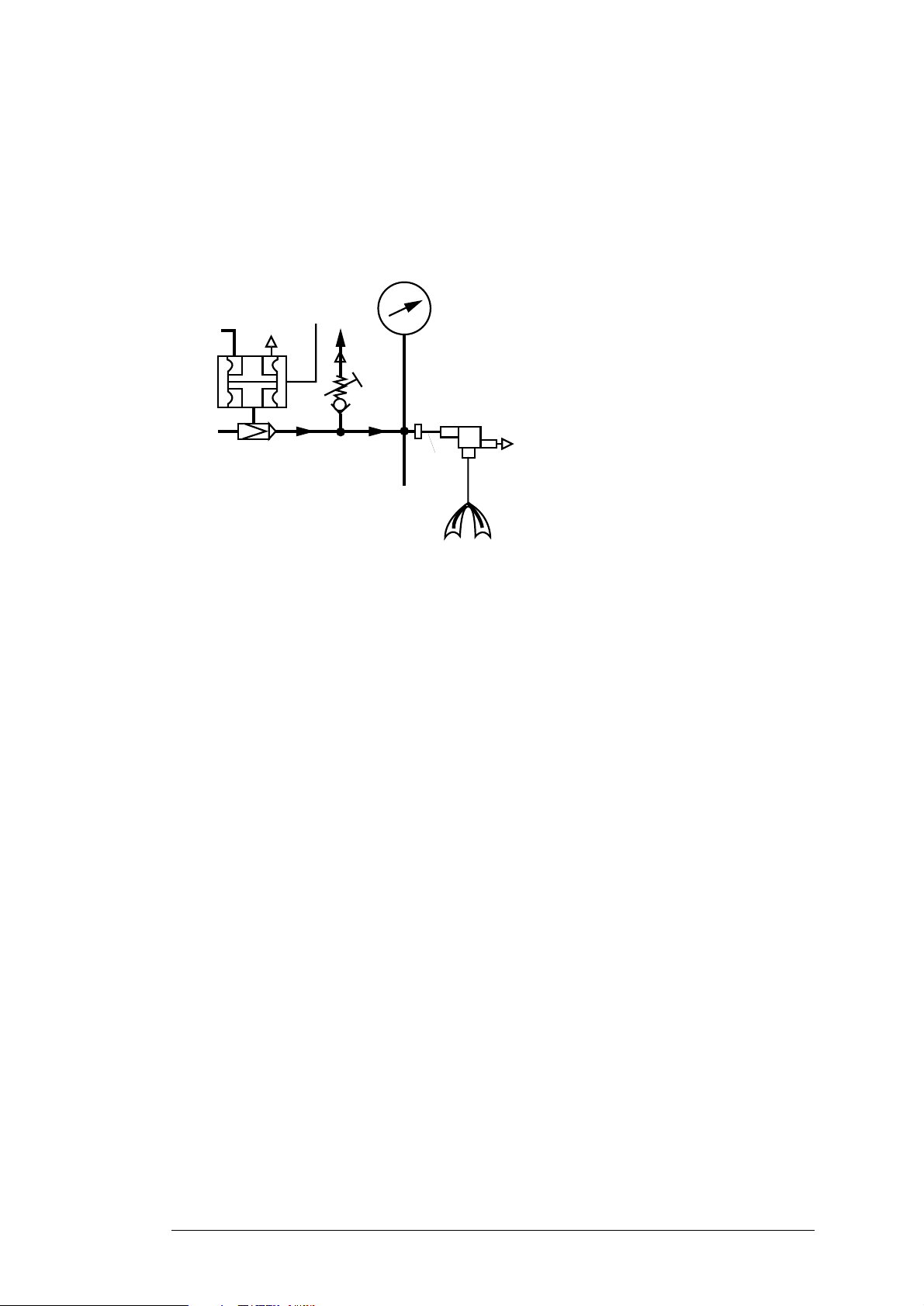

2.2.7 Pressure limitation

To protect the patient, a max. ventilation pressure of 80 mbar is set on the safety valve SV.

WV2

SV

I

Abb. 9: Pressure limitation

DM

PA

BV

SS

GBF5503140T01.fm 19.04.99

Schutzvermerk DIN 34 beachten. Copyright reserved.

5503.140 Oxylog 04/97 Functional Description Seite 27

Page 30

Test List

Oxylog

Serial no.:

Installation site:

—————————

—————————

Folder no.:

5503

Revision:

11.95

GBK5503140TL1.fm 19.04.99

Copyright reserved. Reproduction allowed for non-commercial purposes only.

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Mappennr Gerätename Ausgabe Test List Page 28

Page 31

1 Test Equipment

GBK5503140TL1.fm 19.04.99

Copyright reserved. Reproduction allowed for non-commercial purposes only.

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Mappennr Gerätename Ausgabe Test List Page 29

Page 32

2 Checking general condition

• Check the following components. There must not be any signs of

damage:

− Housing, general

-compressed-air connecting hose, 1.5 m

− O

2

-compressed-air connecting hose, 3 m

− O

2

− CS O

− CS O

-compressed-air connecting hose, 3 m

2

-compressed-air connecting hose, 5 m

2

− Ventilation valve

− Diaphragm

− Ventilation hose

− Masks

− Carrying strap

− Oxylog baseplate (if applicable)

− Oxylog case (if applicable)

− Oxylog back pack (if applicable)

3 Checking O2 pressure reducer

• Check seal. There must not be any signs of damage.

GBK5503140TL1.fm 19.04.99

• Renew strainer every 2 years.

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Copyright reserved. Reproduction allowed for non-commercial purposes only.

Mappennr Gerätename Ausgabe Test List Page 30

Page 33

4 Functional test

• Carry out the following measurements with O2 at a supply pressure of

2 - 6 bar.

4.1 Checking I:E ratio

• Make the following Oxylog settings:

No

Air Mix

10

• Create the following test set-up:

1

10

Oxylog

p= 2 bis 6 bar

p = 2 - 6 bar

• Use the following formula to check the I:E ratio (check value):

Check value =

The check value must be between 0.6 and 0.74.

4.2 Checking frequency setting

• Make the following Oxylog settings:

Inspiration time

Expiration time

No

Air Mix

15

1

10

GBK5503140TL1.fm 19.04.99

The test set-up remains the same.

The frequency must be between 13 and 17 min

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Copyright reserved. Reproduction allowed for non-commercial purposes only.

Mappennr Gerätename Ausgabe Test List Page 31

-1

Page 34

4.3 Checking O2 concentration

• Set frequency on Oxylog to 10 min-1.

• Create the following test set-up:

Oxydig

Test

Oxylog

p = 2 - 6 bar

p= 2 bis 6 bar

4.3.1 Checking O2 concentration with Air Mix

• Set minute volume of 7 L/min. on Oxylog.

adapter

Oxydig must display 55 ± 9 % by vol. O

4.3.2 Checking O

concentration with No Air Mix

2

.

2

• Set minute volume of 20 L/min. on Oxylog.

Oxydig must display 100 −2 % by vol. O

.

2

GBK5503140TL1.fm 19.04.99

Copyright reserved. Reproduction allowed for non-commercial purposes only.

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Mappennr Gerätename Ausgabe Test List Page 32

Page 35

4.4 Checking minute-volume flow setting

• Set frequency of 10 min.-1 on Oxylog.

• Create the following test set-up:

R

Flowmeter

Oxylog

p = 2 - 6 bar

p= 2 bis 6 bar

• With a minute volume of 2.5 L/min., use variable restrictor R to set a

resistance of 5 ± 0.5 mbar (check on unit pressure gauge).

• Check minute volume with No Air Mix.

MV 2,5 (left stop) 5,5–7,8 L/min

MV 7 15,5–19,5 L/min

MV 15 33–42 L/min

MV 20 44–56 L/min

• Check minute volume with Air Mix.

MV 7 15–20 L/min

GBK5503140TL1.fm 19.04.99

MV 15 32–43 L/min

MV 20 42,5–57,5 L/min

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Copyright reserved. Reproduction allowed for non-commercial purposes only.

Mappennr Gerätename Ausgabe Test List Page 33

Page 36

4.5 Checking safety valve

• Make the following Oxylog settings:

No

Air Mix

var

1

10

• Create the following test set-up:

Oxylog

p = 2 - 6 bar

p= 2 bis 6 bar

Ventilation valve

Pressure gauge

Bellows K

Bellows E

IMPORTANT:

Use bellows K (infants) for testing with MV of 3 L/min.

Use bellows E (adults) for testing with max. MV.

The safety valve must open at 55 +22/-3 mbar.

4.6 Checking ventilation pressure gauge

• Take reference measurement.

Tolerance: ± 2.5 % of full scale valu

GBK5503140TL1.fm 19.04.99

Copyright reserved. Reproduction allowed for non-commercial purposes only.

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Mappennr Gerätename Ausgabe Test List Page 34

Page 37

5 Put functional device at the customer’s disposal.

6 Test performed

Date: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Name: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

GBK5503140TL1.fm 19.04.99

Copyright reserved. Reproduction allowed for non-commercial purposes only.

This Test List does not replace inspections and servicing by Dräger Medical AG & Co. KGaA

Mappennr Gerätename Ausgabe Test List Page 35

Page 38

Fault-Cause-Remedy

1 Fault - Cause - Remedy

The following table is designed to provide assistance with detection and rectification of

possible faults.

Fault Error Remedy

Unit does not build up

pressure.

Unit remains set on inspiration.

Patient cannot exhale or

only with difficulty.

No gas in cylinder. Immediately connect unit to

a fresh gas cylinder.

Insufficient gas pressure

at unit inlet.

Yellow control diaphragm

in ventilation valve twisted

Establish adequate supply

pressure: 2 - 6 bar.

Open up ventilation valve

and assemble correctly.

or deformed.

Insufficient supply pressure.

Establish adequate supply

pressure: 2 - 6 bar

Fault in Oxylog. Call in DrägerService.

Ventilation hose kinked. Ensure proper hose rou-

ting.

Red non-return valve in

yellow control diaphragm

Open up ventilation valve

and assemble correctly.

missing or crumpled.

GBK5503140F01.fm 19.04.99

For internal use only. Copyright reserved.

5503.^40 Oxylog 04.97 Fault-Cause-Remedy Page 36

Page 39

Changes

1 Type of Changes

This technical documentation is valid for the technical equipment type 8409520.

Type of Change Date

GBK5503140AE1.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 Changes Page 37

Page 40

Appendix

1 Abbreviations

ABS Acrylonitrile-butadiene-styrene copolymer

CGS Central gas supply

DIN German Industrial Standard

IEC International Electrotechnical Commission

I:E Inspiration/expiration ratio

MIL US-Military Standard

MV Minute volume

OP Operating room

O

2

Oxygen

PSU Polysulfone

VDE Association of German Electrical Engineers

GBK5503140AH1.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 Appendix Page 38

Page 41

2 Spare parts list Oxylog / Oxylog Samsomatic

GBK5503140AH1.fm 19.04.99

For internal use only. Copyright reserved.

5503.140 Oxylog 04.97 Appendix Page 39

Page 42

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Ausgabe/Edition

04.06.96

Seite/Page 1 von 36

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 43

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Diese Ersatzartikelliste gilt für Sachnummer:

This spare parts list is valid for part no.:

Sach-Nr.

Part No.

8404400

Benennung

Description

OXYLOG

OXYLOG

Ausgabe/Edition

04.06.96

Seite/Page 2 von 36

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 44

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Inhaltsverzeichnis der Bilder

Summary of pictures

Bild

Picture

Bezeichnung

Description

1 OXYLOG

BASIC UNIT OXYLOG

2 AMV-VENTIL

AMV-VALVE

3 MV-VENTIL

VALVE

4 VENTILGRUPPE

VALVE GROUP

5 INJEKTOR,KOMPL.

INJECTOR,CPL.

Sach-Nr.

Part No .

8404440

8404453

8409001

8404550

8403012

Ausgabe/Edition

04.06.96

Seite/Page 3 von 36

E-Liste

Spare parts list

6 HALTER MIT KLAUE

HOLDER WITH CLAMP

7 BEATMUNGSVENTIL

RESPIRATION VALVE 2

8 VERSCHLAUCHUNGSSCHEMA OXYLOG

PIPING-SCHEMATIC OXYLOG

9 TRAGEGURT

CARRYING STRAP

10 DRUCKBEGRENZUNGSVENTIL

PRESSURE LIMITING VALVE

11 OXYLOG *FRANZOESISCH*

OXYLOG (FRENCH)

12 UMRUESTSATZ SPONTANATMUNG

MODIF.SET SPONT.BREATH.OXYLOG

8405009

8406600

8404434

8404773

8405390

8405777

8407896

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 45

DrägerService Medizintechnik

G

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

OXYLOG Bild/Picture 1

BASIC UNIT OXYLO

Ausgabe/Edition

04.06.96

Seite/Page 4 von 36

Datei/File: 55031.001

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 46

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

1-59 OXYLOG-GRUNDEINHEIT

Benennung

Description

BASIC UNIT OXYLOG

1 GEHAEUSE,VOLLST. (OXYLOG)

HOUSING,CPL. (OXYLOG)

2 SENKSCHRAUBE AM4X16DIN963-A2

COUNTER SUNK AM4X16DIN963-A2

3 KURZBETRIEBSANLEITUNG (OXYLOG)

OPERATING INSTRUCTIONS(OXYLOG)

4 SIEBEINSATZ

SCREEN INSERT

5 O-RING

O-RING SEAL

Sach-Nr.

Part No.

8404440

1329332

Ausgabe/Edition

04.06.96

Seite/Page 5 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

8410975

8404771

R22028 10

2M12839 10

6 DRUCKANSCHLUSS,UGR.

DELIVERY CONNECTION

DIN 914-M5X12-45H/155

ohne Abbildung

DIN 914 M5X12-45H/155

without illustration

7 FILTER,UGR.

FILTER

8 DICHTRING

PACKING RING

9 PATIENTENANSCHLUSS,UGR.

PATIENT CONNECTION

10 VOLUMEN 3,2 CCM

VOLUME 3,2 CCM

11 VOLUMEN 4,8 CCM

VOLUME 4,8 CCM

12 DISTANZBOLZEN

DISTANT BOLT

13 SCHRAUBE AM 4X8 DIN 84-A4 NG

CHEESE HEAD SCREW AM4X8 DIN84

8404446

1306383

8405272

2M01524 10

8404443

8403026

8403025

2M07604

1330659 25

14 FILTERGEHAEUSE

FILTER HOUSING

15-18 WINKELTUELLE M 6X0,5

ANGULAR PORCELAIN BUSH M 5X0,5

15 SCHEIBE

WASHER

16 TUELLE

SOCKET

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

8404438

8402398

8402392 10

8402397

Page 47

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

17 SCHEIBE

WASHER

18 BOLZEN

BOLT

19 VENTILGRUPPE

VALVE GROUP

20 VERTEILER,UGR.

DISTRIBUTOR

21 SCHRAUBE

SCREW

22 RING

RING

Sach-Nr.

Part No.

8402396

8404550

8404465

Ausgabe/Edition

04.06.96

Seite/Page 6 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

8402395 10

8403057 5

8404988 10

23 DRUCKREGLER

PRESSURE REGULATOR

24 TUELLE

SOCKET

25 DIN 914-M5X12-45H/155

DIN 914 M5X12-45H/155

26 DIN 84-AM3X6-A4

SCREW M3X6 DIN 84-A4

27 SETZMUTTER

NUT

28 SCHRAUBE

SCREW

29 3/2-WEGEVENTIL

3/2-PORT DISTRIBUTING VALVE

30 MUTTER BM3 DIN 439-A4/051

NUT BM3 DIN 439-A4/051

31 DIN 84-AM3X30-A2

DIN 84-AM3X30-A2

32 ZYLINDERSCHRAUBE AM 3X12 DIN84

CHEESE HEAD SCREW AM3X12 DIN84

8402745

8404508

1306383

1330810

CH17646

8403020

8403006

1334743

1333828

1304232 2

33 DOSIERUNG

DOSAGE

15,35 TUELLE M 6X0,5

SOCKET M 6X0,5

35 TUELLE

SOCKET

36 SETZMUTTER

NUT

8402393

CH18043

8403795

8402394

37 EINSCHUB 8404449 10

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 48

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

PLUG-IN UNIT

38 SCHRAUBE 00003

SCREW 00003

39 FEINDOSIERVENTIL (OXYLOG)

PRECISION METERING VALVE

40 SCHLAUCHVERSCHRAUBUNG

THREADED HOSE COUPLING

41 SCHWENKVERSCHRAUBUNG

SWIVELLING SCREW-FITTING

42 AMV-VENTIL

AMV-VALVE

42 MV-VENTIL

MV-VALVE

Sach-Nr.

Part No.

8404453

Ausgabe/Edition

04.06.96

Seite/Page 7 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

1330802 100

8404454

8402032 5

8402034

8409001

43 3/2-WEGE-VENTIL

3/2-PORT DISTRIBUTING VALVE

44 SH-SCHELLE DIN 3017-AL50-70-W3

SH-CLAMP

45 MANSCHETTE

PACKING

46 DRUCKMESSER

PRESSURE GAUGE

47 BLECH

SHEET METAL

48 SENKSCHRAUBE AM3X6 DIN963-A4 B

COUNTERS.SCREW AM3X6DIN963-A4

49 MUTTER

NUT

50 VERSTAERKERRELAIS

AMPLIFIER RELAIS

51 VERSTAERKERRELAIS

AMPLIFIER RELAY

52 FRONTSCHILD

FRONT PANEL

8402441

1336681

8404463

7275094

8404077

1287400

8402484

M22260

M25716 10

8404770

53-57 DREHKNOPF CO,SCHWARZ

CONTROL KNOB CO,BLACK

53 KAPPE CO,SCHWARZ

CAP CO,BLACK

54 MUTTER

NUT

55 EINLAGE

INSERT

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

M24628

M24418

M24403

M24629 10

Page 49

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

56 DREHKNOPF-GEHAEUSE CO SW,UGR.

CONTROL KNOB HOUSING CO SW

57 SPANNZANGE TV

COLLET CHUCK

58 BOLZEN

BOLT

59 E-SET DRUCKREGLER (KNOCKS)

REP.SET PRESS.REGULAT.(KNOCKS)

59 E-SET DRUCKREGLER (LORCH)

REP.SET PRESSURE REGULAT(LORCH

Sach-Nr.

Part No.

M24624

M19191

8404076

Ausgabe/Edition

Seite/Page 8 von 36

Bestell-Nr.

Order-Code

8406678

8411142

04.06.96

Packung

Quantity

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 50

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

AMV-VENTIL Bild/Picture 2

AMV-VALVE

Ausgabe/Edition

04.06.96

Seite/Page 9 von 36

Datei/File: 55031.002

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 51

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

1-19 AMV-VENTIL

Benennung

Description

AMV-VALVE

1 DIN 84-AM3X30-A2

DIN 84-AM3X30-A2

2 ZYLINDERSCHRB.AM3X25 DIN84 NG

CHEESE HEAD SCREW AM3X25 DIN84

3 SCHRAUBE NG

SCREW

4 SCHEIBE

WASHER

5 FEDER

SPRING

Sach-Nr.

Part No.

8404453

1333828

1333801

D21045

2M08869

Ausgabe/Edition

04.06.96

Seite/Page 10 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

8402392 10

6 BOLZEN

BOLT

7 GEHAEUSE

HOUSING

8 KUGEL 4 MM III DIN 5401

BALL 4 MM III DIN 5401

9 MEMBRAN,UGR.

DIAPHRAGM

10 BUCHSE

SOCKET

11 FEDER

SPRING

12 GEHAEUSE

HOUSING

13 EINSATZ NG

INSERT

14 GEWINDESTIFT

THREADED PIN

15 3M6X30 DIN 7-A4

3M6X30 DIN 7-A4

8404456

8404455

1270621

8404457

8403492

8405189

8403489

E22265

1323253 30

1290150

16 M3X10 DIN 427-A4

M3X10 DIN 427-A4

17 SPINDEL

SPINDLE

18 SCHAFTSCHRAUBE M3X6DIN427-A4TV

HEADLESS SCREW M3X6 DIN427-A4

19 DIN 913-M4X12-45H/155

DIN 913-M4X12-45H/155

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

1334190

8403491

1300059

1328298

Page 52

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

20-33 FEINDOSIERVENTIL (OXYLOG)

Benennung

Description

PRECISION METERING VALVE

20 ZYL.SCHRB.AM3X8 DIN84-A4/051

CH.HEAD SCR.AM3XDIN84-A4/051

21 VERSCHLUSS

LOCK

22 RUNDSCHNURRING

TOROIDAL SEALING RING

23 FEDER

SPRING

24 O-RING

O-RING SEAL

Sach-Nr.

Part No.

2M03494

Ausgabe/Edition

04.06.96

Seite/Page 11 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

8404454

1330799 25

8403493

M11995 5

E20566 5

25 KONUSTEIL

CONICAL PART

26 GEHAEUSE

HOUSING

27 EINSATZ NG

INSERT

28 GEWINDESTIFT

THREADED PIN

29 M3X10 DIN 427-A4

M3X10 DIN 427-A4

30 3M6X30 DIN 7-A4

3M6X30 DIN 7-A4

31 SPINDEL

SPINDLE

32 SCHAFTSCHRAUBE M3X6DIN427-A4TV

HEADLESS SCREW M3X6 DIN427-A4

33 DIN 913-M4X12-45H/155

DIN 913-M4X12-45H/155

8403494

8404459

E22265

1323253 30

1334190

1290150

8404460

1300059

1328298

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 53

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

MV-VENTIL Bild/Picture 3

VALVE

Ausgabe/Edition

04.06.96

Seite/Page 12 von 36

Datei/File: 55031.013

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 54

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

1-20 MV-VENTIL

Benennung

Description

MV-VALVE

1 SCHRAUBE

SCREW

2 SCHEIBE

WASHER

3 FEDER ZUM SI-VENTIL

SPRING FOR SAFETY VALVE

4 STOESSEL

TAPPET

5 DIN 84-AM3X30-A2

DIN 84-AM3X30-A2

Sach-Nr.

Part No.

8408977

8408967

D06169

8408999

1333828

Ausgabe/Edition

Seite/Page 13 von 36

Bestell-Nr.

Order-Code

8409001

04.06.96

Packung

Quantity

6 ZYLINDERSCHRB.AM3X25 DIN84 NG

CHEESE HEAD SCREW AM3X25 DIN84

7 KUGEL 4 MM III DIN 5401

BALL 4 MM III DIN 5401

8 GEHAEUSEKOPF

HOUSING TOP

9 MEMBRAN,UGR.

DIAPHRAGM

11 BUCHSE

SOCKET

12 FEDER

SPRING

13 GEHAEUSE

HOUSING

14 SPINDEL

SPINDLE

15 3M6X30 DIN 7-A4

3M6X30 DIN 7-A4

16 DIN 913-M4X12-45H/155

DIN 913-M4X12-45H/155

1333801

1270621

8408963

8404457

8403492

8405189

8403489

8403491

1290150

1328298

17 SCHAFTSCHRAUBE M3X6DIN427-A4TV

HEADLESS SCREW M3X6 DIN427-A4

18 M3X10 DIN 427-A4

M3X10 DIN 427-A4

19 EINSATZ NG

INSERT

20 GEWINDESTIFT

THREADED PIN

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

1300059

1334190

E22265

1323253 30

Page 55

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

VENTILGRUPPE Bild/Picture 4

VALVE GROUP

Ausgabe/Edition

04.06.96

Seite/Page 14 von 36

Datei/File: 55031.003

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 56

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

1-24 VENTILGRUPPE

Benennung

Description

VALVE GROUP

1 ELEMENTENSOCKEL

ELEMENT-BASE

2 DICHTUNG

GASKET

3 VENTILKOERPER

VALVE BODY

4 VENTILTELLER NG

VALVE DISK

5 MEMBRAN

DIAPHRAGM

Sach-Nr.

Part No.

8404550

8404439

8403018

8403017

Ausgabe/Edition

04.06.96

Seite/Page 15 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

8403433 10

8403014 10

6 DECKEL,UGR.

COVER

7 ZYLINDERSCHRB.DIN84-AM3X20-A2

CH.HEAD SCREW DIN84-AM3X20-A2

8 GEWINDESTIFT

THREADED PIN

9 3/2-WEGEVENTIL

3/2-PORT DISTRIBUTING VALVE

10 ZYLINDERSCHRB.AM3X25 DIN84 NG

CHEESE HEAD SCREW AM3X25 DIN84

11-16 DOSIERTUELLE NG

METERING NOZZLE

11 SCHEIBE

WASHER

12 TUELLE

SOCKET

13 SCHEIBE

WASHER

14 BOLZEN

BOLT

8404757

1333798

1323253 30

8403006

1333801

8403320

8402392 10

8402397

8402395 10

8403321

15 SCHRAUBE

SCREW

16 O-RING

O-RING SEAL

17 INJEKTOR, KOMPL. (OXYLOG)

INJECTOR, CPL. (OXYLOG)

18 ANSCHLUSS

CONNECTION

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

8403322

RM07823 10

8403012

8404437

Page 57

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

11-13,19 WINKELTUELLE M 6X0,5

8,20-23 SICHERHEITSVENTIL

Benennung

Description

ANGULAR PORCELAIN BUSH M 5X0,5

19 BOLZEN

BOLT

SAFETY VALVE

20 GEHAEUSE,UGR.

HOUSING

21 FEDERAUFNAHME

SPRING SEAT

22 FEDER

SPRING

Sach-Nr.

Part No.

8402396

8404750

2M17674

Ausgabe/Edition

04.06.96

Seite/Page 16 von 36

Bestell-Nr.

Order-Code

8402398

8404749

M08902 5

Packung

Quantity

23 SCHRAUBE

SCREW

24 DIN 84-AM3X30-A2

DIN 84-AM3X30-A2

2M17675

1333828

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 58

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

INJEKTOR,KOMPL. Bild/Picture 5

INJECTOR,CPL.

Ausgabe/Edition

04.06.96

Seite/Page 17 von 36

Datei/File: 55031.004

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 59

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

1-9 INJEKTOR, KOMPL. (OXYLOG)

INJECTOR, CPL. (OXYLOG)

1 SPANNSCHRAUBE

STRAINING SCREW

2 DRUCKDUESE NG

PRESSURE NOZZLE

3 MISCHDUESE

MIXING NOZZLE

4 SCHEIBE

WASHER

5 VENTILTELLER

VALVE PLATE

Sach-Nr.

Part No.

8402481

8403010

8403011

8408899

Ausgabe/Edition

04.06.96

Seite/Page 18 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

8403012

8403009 2

6 RUNDSCHNURRING

TOROIDAL SEALING RING

7 BUCHSE

SOCKET

8 PRAEZISIONS-O-RING

PRECISION O-RING SEAL

9 RUNDSCHNURRING

TOROIDAL SEALING RING

10-14 3/2-WEGEVENTIL

3/2-PORT DISTRIBUTING VALVE

10 SCHRAUBE 00003

SCREW 00003

11 DECKEL,UGR.

COVER

12 MEMBRAN

DIAPHRAGM

13 M3X10 DIN 551-A4

M3X10 DIN 551-A4

14 GEHAEUSE

HOUSING

M18445 10

8403007

M14545 10

D16558 10

8403006

1329987 50

8403074

8403004 2

1334239

8403002

15-17 DOSIERUNG

DOSAGE

15 GEHAEUSE,UGR.

HOUSING

8403798

16 O-RING

O-RING SEAL

17 DOSIERKEGEL

METERING CONE

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

8403797

8403795

8403962 5

Page 60

DrägerService Medizintechnik

P

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

HALTER MIT KLAUE Bild/Picture 6

HOLDER WITH CLAM

Ausgabe/Edition

04.06.96

Seite/Page 19 von 36

Datei/File: 55031.005

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 61

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

1-18 HALTER MIT SCHIENENKLAUE

1-11 HALTER

Benennung

Description

SUPPORT WITH CLAMP

HANDLE

1 WANNE NG

TROUGH

2 BOLZEN

BOLT

3 SCHRAUBE AM4X6 DIN963-A4/051

SCREW AM4X6 DIN 963-A4/051

4 FEDERRING B 4 DIN 127

SPLIT WASHER B4 DIN 127

Sach-Nr.

Part No.

8405008

8404572

1315781

Ausgabe/Edition

04.06.96

Seite/Page 20 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

8405009

8404560

1331345 50

5 6KT.MUTTER M4 DIN934-A4/051

HEXAGON NUT M4 DIN 934-A4/051

6 SCHEIBE A 4,3 DIN 125-A2

WASHER A 4,3 DIN 125-A2

7 SCHEIBE B 4,3 DIN 9021-A4 NG

WASHER B 4,3 DIN 9021-A4

8 B 3,9X22 DIN 7971-A2

B 3,9X22 DIN 7971-A2

9 ZYL.-BLECHSCHRB.B3,5X16 NG

CHEESE HEAD B3,5X16

10 ZYLINDERSCHRB.AM4X20DIN84-A4

CYLIND.HEAD SCREW AM4X20 DIN84

11 SCHRAUBE AM 4X40 DIN 84

SCREW AM 4X40 DIN 84

12 AM5X12 DIN 963-A2

AM5X12 DIN 963-A2

13-16 SCHIENENKLAUE (GESCHRAUBT)

CLAW

13 PUFFER NG

BUFFER

1328956 20

1327542 20

1331914

1334964

1334956

1328980 10

1298712

1330225

M20650

M20646

14 KLEMMSCHRAUBE

ADJUSTING SCREW

15 HALTER

SUPPORT

M20651

16 SICHERUNGSSCHEIBE 5 DIN 6799

THRUST WASHER

17 FEDERRING B 5 DIN 127 NG

SPLIT WASHER B5 DIN 127

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

M20647

1326406 50

1300849

Page 62

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

18 M5 DIN 546-MS

M5 DIN 546-MS

Sach-Nr.

Part No.

1256637

Ausgabe/Edition

Seite/Page 21 von 36

Bestell-Nr.

Order-Code

04.06.96

Packung

Quantity

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 63

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

BEATMUNGSVENTIL Bild/Picture 7

RESPIRATION VALVE 2

Ausgabe/Edition

04.06.96

Seite/Page 22 von 36

Datei/File: 55031.006

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 64

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

1-4 BEATMUNGSVENTIL 2

RESPIRATION VALVE 2

1 DECKEL

COVER

2,3 MEMBRAN,UGR.

DIAPHRAGM

2 MEMBRANE

DIAPHRAGM

3 MEMBRANE

DIAPHRAGM

4 VENTILGEHAEUSE

VALVE BOX

Sach-Nr.

Part No.

8403206

8403395

Ausgabe/Edition

04.06.96

Seite/Page 23 von 36

Bestell-Nr.

Order-Code

8406600

8406585

8403552 2

8406595

Packung

Quantity

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 65

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

VERSCHLAUCHUNGSSCHEMA OXYLOG Bild/Picture 8

PIPING-SCHEMATIC OXYLOG

Ausgabe/Edition

04.06.96

Seite/Page 24 von 36

Datei/File: 55031.007

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 66

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

1-9 VERSCHLAUCHUNGSSCHEMA OXYLOG

PIPING SCHEME OXYLOG

1 T-STUECK

T-PIECE

2 KREUZSTUECK

CROSS PIECE

3 SCHLAUCH 4X1,5-SI 50 SH A NF

HOSE 4X1,5-SI 50 SH A NF

4 ROHR 6X1 DIN73378-PA 12 W NF.

TUBE 6X1 DIN73378-PA 12 W NF.

5 SCHLAUCH 2X1 SI NF

HOSE 2X1 SI NF

Sach-Nr.

Part No.

8404434

Ausgabe/Edition

04.06.96

Seite/Page 25 von 36

Bestell-Nr.

Order-Code

8401083

8401071

1190520

1202618

1180614 25

Packung

Quantity

6 SCHLAUCH 2X1-SIGN RT

HOSE 2X1-SIGN RED

7 SCHLAUCH 2X1-SIGN BL

HOSE 2X1-SIGN BL

8 SCHLAUCH 2X1-SIGN GN

HOSE 2X1-SIGN GREEN

9 SCHLAUCH 2X1-SIGN GE

HOSE 2X1-SIGN YELLOW

1204793 5

1204785 5

1204807 5

1204831 5

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 67

DrägerService Medizintechnik

P

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

TRAGEGURT Bild/Picture 9

CARRYING STRA

Ausgabe/Edition

04.06.96

Seite/Page 26 von 36

Datei/File: 55031.008

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 68

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

1+2 TRAGERIEMEN

Benennung

Description

CARRYING STRAP

1 LASCHE

BRACKET

2 GURT

BELT

Sach-Nr.

Part No.

8405179

8404078

Ausgabe/Edition

Seite/Page 27 von 36

Bestell-Nr.

Order-Code

8404773

04.06.96

Packung

Quantity

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 69

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

DRUCKBEGRENZUNGSVENTIL Bild/Picture 10

PRESSURE LIMITING VALVE

Ausgabe/Edition

04.06.96

Seite/Page 28 von 36

Datei/File: 55031.009

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 70

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

1-7 DRUCKBEGRENZUNGSVENTIL

PRESSURE LIMITING VALVE

1 BUEGEL

CLIP

2 SENKSCHRAUBE AM 3X4 DIN 63

COUNTERSUNK SCREW AM 3X4DIN963

3 SCHRAUBE

SCREW

4 SPRENGRING

XYZ

5 FEDERAUFNAHME,UGR.

SPRING RECEIVER

Sach-Nr.

Part No.

8405392

1308459

8405393

8405457

Ausgabe/Edition

Seite/Page 29 von 36

Bestell-Nr.

Order-Code

8405390

RM08289

04.06.96

Packung

Quantity

6 STOESSEL

TAPPET

7 AUFNAHME,UGR.

RECEIVER

8405394

8405391

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 71

DrägerService Medizintechnik

)

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

OXYLOG *FRANZOESISCH* Bild/Picture 11

OXYLOG (FRENCH

Ausgabe/Edition

04.06.96

Seite/Page 30 von 36

Datei/File: 55031.010

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 72

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

1-9 OXYLOG (FRANZOESISCH)

OXYLOG (FRENCH)

1-4 OXYLOG

OXYLOG

1 OXYLOG-GRUNDEINHEIT

BASIC UNIT OXYLOG

2 VERBINDUNGSSCHLAUCH -SILIKON-

SILICONE HOSE ADULT 1,1M

3 BEATMUNGSVENTIL 2

RESPIRATION VALVE 2

4 TRAGERIEMEN

CARRYING STRAP

Sach-Nr.

Part No.

8405777

8404400

8404440

Ausgabe/Edition

Seite/Page 31 von 36

Bestell-Nr.

Order-Code

8404063

8406600

8404773

04.06.96

Packung

Quantity

5-10 UMRUESTSATZ OXYLOG (FRANZ.)

MODIF.SET OXYLOG (FRENCH)

5 DRUCKBEGRENZUNGSVENTIL

PRESSURE LIMITING VALVE

6 FRONTSCHILD,FRANZ.

FRONT PANEL, FRENCH

7 UMRUESTANWEISUNG

CONVERSION INSTRUCTIONS

8 KURZ-BETRIEBSANLEITUNG, FRZ.

OPERATING INSTR.,FRENCH

9 BA 5503.1 F OXYLOG

BA 5503.1 F OXYLOG

10 ADAPTER-AIR-LIQUIDE

ADAPTER-AIR-LIQUIDE

1-4,6A,

7A,8-10

6A,7A,

8-10

OXYLOG 30 (FRANZOESISCH)

OXYLOG 30 (FRENCH)

UMRUESTSATZ OXYLOG 30(FRANZ.)

MODIF.SET OXYLOG 30 (FRENCH)

6A FRONTSCHILD OXYLOG 30 (FRZ.)

FRONT PANEL OXYLOG 30 (FRENCH)

8405304

8405390

8403028

8405297

8403029

9027742

8405301

8405778

8405299

8405298

7A UMRUESTANWEISUNG OXYLOG 30*FRZ

CONVERSION INSTR.OXYLOF 30,FR.

1-4,8A OXYLOG (ENGLISCH)

OXYLOG (ENGL.)

8A KURZ-BA OXYLOG (ENGLISCH)

ABBR.OP.MANUAL OXYLOG(ENGL.)

1-4, 6B-9BOXYLOG (SPANISCH)

OXYLOG (SPAN.)

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

8405302

8405790

8405446

8405800

Page 73

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

6B-9B UMRUESTSATZ OXYLOG (SPANISCH)

Benennung

Description

MODIFICATION SET OXYLOG(SPAN.)

6B FRONTSCHILD, SPANISCH

FRONT PANEL, SPANISH

7B UMRUESTANWEISUNG *SPANISCH*

CONVERSION INSTRUCTIONS, SPAN.

8B KURZ-BETRIEBSANLEITUNG,SPAN.

OPERATING INSTRUCTIONS,SPANISH

9A BA 5503.1 S OXYLOG

OPERAT.INSTR. 5503.1 S OXYLOG

Sach-Nr.

Part No.

8405801

8403030

8405789

8403031

9027743

Ausgabe/Edition

Seite/Page 32 von 36

Bestell-Nr.

Order-Code

04.06.96

Packung

Quantity

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 74

DrägerService Medizintechnik

G

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

UMRUESTSATZ SPONTANATMUNG Bild/Picture 12

MODIF.SET SPONT.BREATH.OXYLO

Ausgabe/Edition

04.06.96

Seite/Page 33 von 36

Datei/File: 55031.012

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 75

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

1-45 RS SPONTANATMUNG-DRELOBA

1-38 LUNGENAUTOMAT (UGR.) NG

Benennung

Description

MODIF.SET SPONT.BREATH.DRELOBA

LUNG DEMAND VALVE

1 SCHRAUBE 00001

SCREW 00001

2 B4 DIN 137-NICHTROST.ST

B4 DIN 137-STAINLESS STEEL

4 DECKEL

COVER

6 E-SET MEMBRAN (R27929)

REP.SET DIAPHRAGM (R27929)

Sach-Nr.

Part No.

8407896

8408505

1335308

8407848

R23692

Ausgabe/Edition

04.06.96

Seite/Page 34 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

1330055 20

7 ZYLINDERSCHRB.AM3X25 DIN84 NG

CHEESE HEAD SCREW AM3X25 DIN84

8 GEHAEUSE,UGR.

HOUSING

9 GEWINDESTIFT M3X6 DIN551-A2

SET SCREW M3X6 DIN551-A2

10 SCHRAUBTUELLE

SCREW SOCKET

11-15 SICHERHEITSVENTIL NG

SAFETY VALVE

11 VENTILSCHRAUBE

VALVE SCREW

12 FEDER NG

SPRING

13 FEDERAUFNAHME

BUFFER BLOCK

14 DICHTSCHEIBE

SEALING WASHER

15 VENTILGEHAEUSE

VALVE HOUSING

1333801

8408037

1334220

8407834

8407320

8401739

2M03627

8401737

8401738

8407319

16-22 VENTILSTUECK,VOLLST.

VALVE PIECE, CPL.

16-22,31 E-SET VENTILSTUECK,VOLLST.

REP.SET VALVE PIECE

16 KRATEREINSATZ

CRATER INSERT

17 KIPPHEBEL

LEVER, CPL.

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

R50520

R23694

R50521

R27999

Page 76

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

Benennung

Description

18 FEDER

SPRING

19 GEHAEUSE FUER PA80

HOUSING FOR PA 80

20 RUNDSCHNURRING

TOROIDAL SEALING RING

21 TUELLE

SOCKET

22 UEBERWURFMUTTER

UNION NUT

23 SCHLAUCHKLEMME

HOSE CLAMP

Sach-Nr.

Part No.

R50479

R50478

R20476

Ausgabe/Edition

04.06.96

Seite/Page 35 von 36

Bestell-Nr.

Order-Code

Packung

Quantity

R28133 10

R50522

R27810 10

24-30 DRUCKGASANSCHLUSS,KPL.UGR. NG

COMPRESSED GAS CONNECTION

24 SCHLAUCH 6X3 - PVC

HOSE 6X3 - PVC

25 FASSUNG SCHLAUCHHUELSE

HOLDER FOR HOSE SOCKET

26 UEBERWURFMUTTER NG

UNION NUT

27 SCHLAUCHTUELLE

HOSE SOCKET

28 DICHTRING

PACKING RING

29,30 DRUCKGASANSCHLUSS, UGR.

COMPRESSED GAS CONNECTION

30 O-RING

O-RING SEAL

31 O-RING

O-RING SEAL

32 SCHLAUCH 12X3

HOSE 12X3

8408303

1181106

M26950 10

M19098

8408293

M05128 20

8408301

2M12839 10

R20771 10

1198912

33,34 PATIENTENGASANSCHLUSS NG

PATIENT GAS SUPPLY

34 DICHTRING

PACKING RING

35 KABELBINDER (2,4X92LG)

CABLE CLIP (2,4X92)

36 DICHTRING

WASHER

8407893

2M01524 10

8712007 25

R22078 10

38 GEWINDEKONUS 8407832

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 77

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.1

Spare parts list

OXYLOG

OXYLOG

Position

Item No.

39-42 BEATMUNGSVENTIL M.R-VENTIL

40,41 MEMBRAN,UGR.

Benennung

Description

THREADED CONE

RESPIRATION VALVE

39 DECKEL

COVER

DIAPHRAGM

40 MEMBRANE

DIAPHRAGM

41 MEMBRANE

DIAPHRAGM

42 VENTILGEHAEUSE, KOMPL.

VALVE BOX, CPL.

Sach-Nr.

Part No.

8403206

8403395

Ausgabe/Edition

04.06.96

Seite/Page 36 von 36

Bestell-Nr.

Order-Code

8408568

8406585

8403552 2

8408569

Packung

Quantity

43 DRAEGER-MASKE GR.3-ISO

DRAEGER MASK SIZE 3-ISO

44 SCHELLE

CLIP

45 ANSCHLUSS

CONNECTION

46 VERBINDUNGSSCHLAUCH -SILIKON-

SILICONE HOSE ADULT 1,1M

M25574

M21610 10

M27691

8404063

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 78

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

Ausgabe/Edition

04.06.96

Seite/Page 1 von 44

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 79

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

Diese Ersatzartikelliste gilt für Sachnummer:

This spare parts list is valid for part no.:

Sach-Nr.

Part No.

8409520

Benennung

Description

OXYLOG

OXYLOG

Ausgabe/Edition

04.06.96

Seite/Page 2 von 44

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 80

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

Inhaltsverzeichnis der Bilder

Summary of pictures

Bild

Picture

Bezeichnung

Description

1 OXYLOG M.BEATMUNGSZUBEHOER

OXYLOG

2 OXYLOG SAMSOMATIC

OXYLOG S

3 VENTILGRUPPE

VALVE ASSEMBLY

4 MV-VENTIL

MV-VALVE

5 FEINDOSIERVENTIL

PRECISION METERING VALVE

Sach-Nr.

Part No .

8409520

8408500

8409597

8409001

8409090

Ausgabe/Edition

04.06.96

Seite/Page 3 von 44

E-Liste

Spare parts list

6 INJEKTOR,KOMPL.

INJECTOR,CPL.

7 SCHLAEUCHE SAMSOMATIC

HOSES SAMSOMATIC

8 BEATMUNGSVENTIL

RESPIRATION VALVE 2

9 ZUBEHOER FUER TRAGEPLATTE

ACCESSORIES CARRYING PLATE

10 ZUBEHOER FUER RUCKSACK

ACCESSORIES BACKPACK

11 ZUBEHOER FUER KOFFER

ACCESSORIES CASE

12 ZUBEHOER FUER KOFFER

ACCESSORIES CASE

13 SUJECTOR 2000 SEKRETABSAUGUNG

SUJECTOR 2000 ASPIRATOR

14 RESUTATOR 2000 ERWACHSENE

RESUTATOR 2000 ADULTS

15 OXIDEM 2000 DEMAND-VENTIL

OXIDEM 2000 DEMAND-VALVE

8403012

8408694

8406600

8410221

8410222

8410223

8410223

2120232

2120046

2120070

16 UMRUESTSATZ SPONTANATMUNG

MODIF.SET SPONT.BREATH.OXYLOG

17 TRAGEPLATTE MIT OXYLOGHALTER

CARRYING PLATE WITH OXYLOG SUPPORT

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

8407896

8412148

Page 81

DrägerService Medizintechnik

G

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

OXYLOG M.BEATMUNGSZUBEHOER Bild/Picture 1

OXYLO

Ausgabe/Edition

04.06.96

Seite/Page 4 von 44

Datei/File: 550314.001

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 82

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

Position

Item No.

Benennung

Description

1-4 OXYLOG

OXYLOG

1 TRAGERIEMEN

CARRYING STRAP

2 OXYLOG S

OXYLOG S

3 VERBINDUNGSSCHLAUCH -SILIKON-

SILICONE HOSE ADULT 1,1M

4 BEATMUNGSVENTIL 2

RESPIRATION VALVE 2

Sach-Nr.

Part No.

8408500

Ausgabe/Edition

Seite/Page 5 von 44

Bestell-Nr.

Order-Code

8409520

8404773

8404063

8406600

04.06.96

Packung

Quantity

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 83

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

OXYLOG SAMSOMATIC Bild/Picture 2

OXYLOG S

Ausgabe/Edition

04.06.96

Seite/Page 6 von 44

Datei/File: 550314.002

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

Page 84

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

Position

Item No.

1-59 OXYLOG S

Benennung

Description

OXYLOG S

1 GEHAEUSE,VOLLST. (OXYLOG)

HOUSING,CPL. (OXYLOG)

2 SENKSCHRAUBE AM4X16DIN963-A2

COUNTER SUNK AM4X16DIN963-A2

3 KURZ-BETRIEBSANLEITUNG NG

OPERATING INSTRUCTIONS

4 SIEBEINSATZ

SCREEN INSERT

5 O-RING

O-RING SEAL

Sach-Nr.

Part No.

8408500

1329332

Ausgabe/Edition

04.06.96

Seite/Page 7 von 44

Bestell-Nr.

Order-Code

Packung

Quantity

8410975

8409596

R22028 10

2M12839 10

6 DRUCKANSCHLUSS,UGR.

DELIVERY CONNECTION

6.1 DIN 914-M5X12-45H/155

DIN 914 M5X12-45H/155

7 FILTER,UGR.

FILTER

8 DICHTRING

PACKING RING

9 PATIENTENANSCHLUSS,UGR.

PATIENT CONNECTION

10 VOLUMEN, VOLLST. 2,3 ML NG

VOLUME, CPL. 2,3 ML

11 VOLUMEN,VOLLST.4,8 ML

VOLUME, CPL. 4,8 ML

12 DISTANZBOLZEN

DISTANT BOLT

13 SCHRAUBE AM 4X8 DIN 84-A4 NG

CHEESE HEAD SCREW AM4X8 DIN84

14 FILTERGEHAEUSE

FILTER HOUSING

8404446

1306383

8405272

2M01524 10

8404443

8409099

8409111

2M07604

1330659 25

8404438

15-18 WINKELTUELLE M 6X0,5

ANGULAR PORCELAIN BUSH M 5X0,5

15 SCHEIBE

WASHER

16 TUELLE

SOCKET

8402397

17 SCHEIBE

WASHER

Druckdatum: 19.04.1999 Änderungen vorbehalten

Printed Subject to change without notice

8402398

8402392 10

8402395 10

Page 85

DrägerService Medizintechnik

DrägerService Medical Division

Ersatzartikelliste 5503.14

Spare parts list

OXYLOG (SAMSOMATIK)

OXYLOG (SAMSOMATIC)

Position

Item No.

Benennung

Description

18 BOLZEN

BOLT

19 VENTILGRUPPE

VALVE ASSEMBLY

20 VERTEILER,UGR.

DISTRIBUTOR

21 SCHRAUBE

SCREW

22 RING

RING

23 DRUCKREGLER

PRESSURE REGULATOR

Sach-Nr.

Part No.

8402396

8409597

8404465

Ausgabe/Edition

04.06.96

Seite/Page 8 von 44

Bestell-Nr.

Order-Code

Packung

Quantity

8403057 5