Page 1

Dräger Medizintechnik

D

Contents

1 General Information About the Dräger Service Mode 3

1.1 Definition of the Original Status ...................................................................................3

1.2 Calibration Functions ..................................................................................................... 4

1.3 Reaction in the Event of a Technical Error (TE) ........................................................4

1.4 Error Messages During a Specific Test ......................................................................5

1.4.1 Power Supply Low .........................................................................................5

1.4.2 Pressure Low ..................................................................................................5

1.4.3 Pressure High .................................................................................................5

1.4.4 Mode Switch Position (IPPV/CPAP) .........................................................5

1.4.5 Mode Switch Position (IPPV/CPAP) .........................................................5

1.5 Tests in the Dräger Service Mode ...............................................................................6

2 Starting / Exiting the Customer Service Mode (CSM) 7

2.1 Test 001: Adjusting the Language ...............................................................................8

2.2 Test 002: Testing the Gas Supply ............................................................................. 10

2.3 Test 003: Position of the Pneumatic Switch (IPPV/CPAP) ..................................11

2.4 Test 004: Setting the Minute Volume Limits ............................................................12

2.5 Test 005: Buzzer Test, LED Test, and LCD Test .................................................... 13

2.6 Test 006: Adjusting and Reading Out the

Potentiometers f, VT, Tinsp, and Pmax 14

2.7 Test 007: Tachypnea Monitoring Configuration ..................................................... 15

3 Starting / Exiting the Extended Service Mode (ESM) 16

3.1 Test 011: Calibrating the Pressure Sensors P-Supply and P-LA ........................17

3.2 Test 012: Calibrating the Minute Volume Valve ...................................................... 18

3.3 Test 013: Adjusting and Displaying the Flow ......................................................... 20

3.4 Test 014: Reading in the Analog Channels ............................................................ 22

3.5 Test 015: Testing Basic Flow ..................................................................................... 26

For internal use only. Copyright reserved.

GBR5673100SM1IVZ.fm

5673.100 MicroVent 09/97 Service Mode Page I

Page 2

Dräger Medizintechnik

Contents

3.6 Test 016: Testing the Autozero Solenoid Valve ...................................................... 28

3.7 Test 017: Displaying and Calibrating the Autozero Offset .................................. 29

3.8 Test 018: Testing the Pressure Sensor Paw and

Triggering the Minute Volume Valve 30

3.9 Test 019: Testing the Expiratory Solenoid Valve .................................................... 33

3.10 Test 020: Testing the ASB Solenoid Valve ............................................................. 34

3.11 Test 021: Testing the Supply Pressure .................................................................... 35

3.12 Test 022: Testing the Minute Volume Valve (Slow) ............................................... 36

3.13 Test 023: Testing the Minute Volume Valve (Fast) ................................................. 37

D

3.14 Test 024: Testing the Differential Pressure Sensor ∆P and

Testing the Flow Measurement 38

3.15 Test 025: Testing the Pressure Switch PEEP-ASB .............................................. 40

4 Technical Error (TE) List 41

For internal use only. Copyright reserved.

GBR5673100SM1IVZ.fm

5673.100 MicroVent 09/97 Service Mode Page II

Page 3

1 General Information About the Dräger Service Mode

You can operate the Dräger Service Mode with the Info key and the Reset key. These keys

allow you to change the set values, to scroll through tests, or to confirm execution of a

specific test. The Dräger Service Mode is subdivided into the Customer Service Mode

(CSM) and the Extended Service Mode (ESM). The working language used throughout the

Dräger Service Mode is English.

The Dräger Service Mode in the MicroVent includes 20 tests:

• The first six tests (Test 001 through Test 006) are specifically designed for the customer

(CSM), but can also be used by Dräger service technicians.

• The other fourteen tests (Test 011 through Test 024) are part of the Extended Service

Mode (ESM) which is used to carry out calibrations. These tests are only accessible to

Dräger service technicians. To do so, the Dräger service technician must enter a

numeric code.

1.1 Definition of the Original Status

Each function in the Dräger Service Mode can be carried out separately. At the beginning of

the Dräger Service Mode and after completion of a specific test, the MicroVent enters one of

the following original status.

Table 1: Original Status of the Micro Vent in the Dräger Service Mode

I:E solenoid valve Off (expiration)

PN solenoid valve Off (PEEP is inactive)

Autozero solenoid valve Operated automatically

Exp. solenoid valve Off (normal position = expiration)

ASB solenoid valve Off (ASB is inactive)

MV valve Closed

Alarm LED Off

Buzzer Off

LCD backlight On

Paw alarm Deactivate

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 3

Page 4

1.2 Calibration Functions

The following table lists the four calibration functions available in the Dräger Service Mode.

The data is stored in the EEPROM:

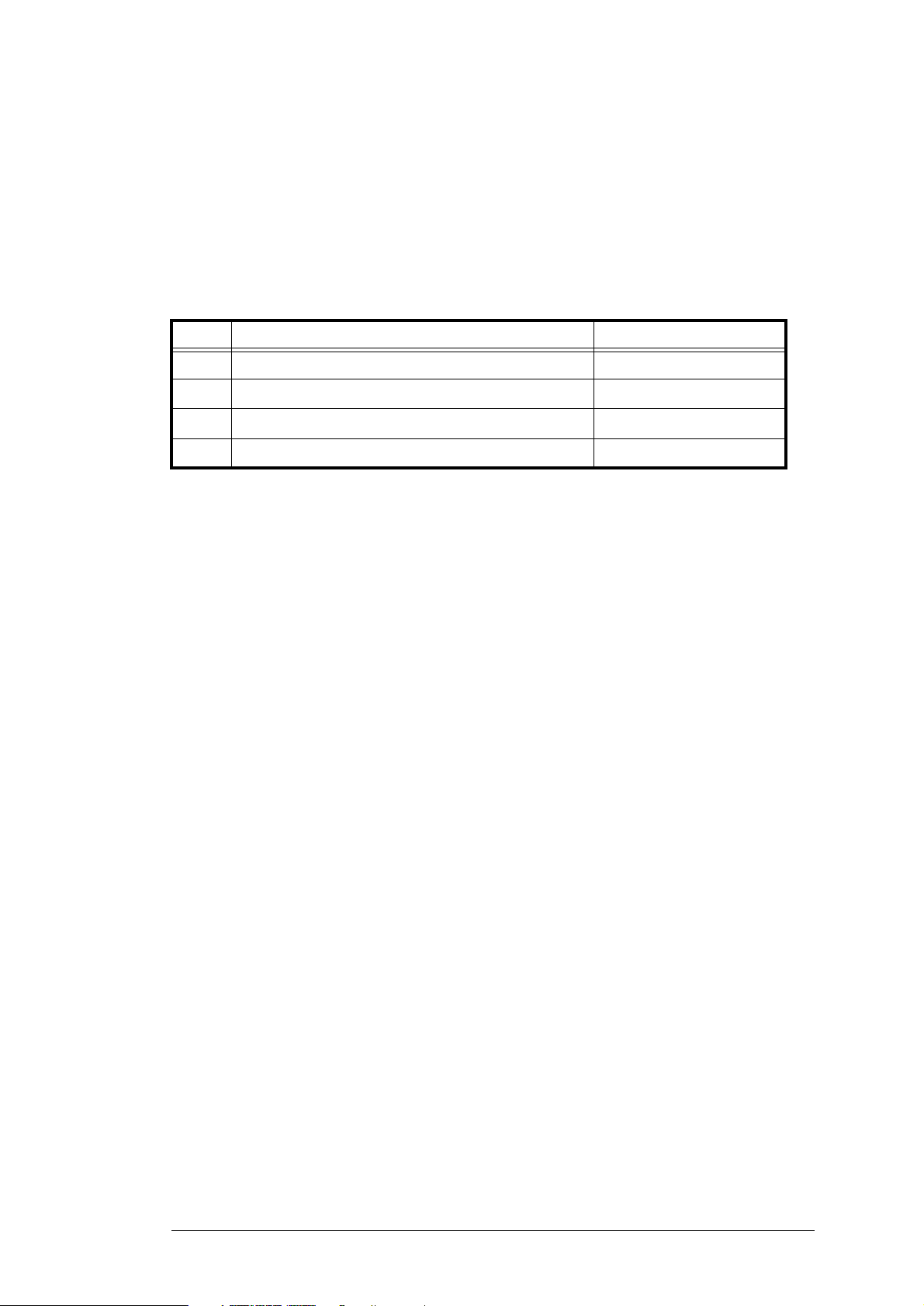

Table 2: Calibration Functions in the Dräger Service Mode

No. Function Mode Test No.

1 Adjusting the Language CSM/ESM 001

2 Calibrating the Pressure Sensors (Pvers, PLA) ESM 011

3 Calibrating the Minute Volume Valve ESM 012

4 Calibrating the Autozero Offset ESM 017

Caution:

After installing a new Control PCB, perform the calibration functions (Nos. 1 through 4)

specified in the table above.

After installing a new Sensor PCB, perform Test 011 “Calibrating the Pressure Sensors PSupply and P-LA”.

1.3 Reaction in the Event of a Technical Error (TE)

If the MicroVent detects a technical error, it will show the error number on the display. The

technical error and the name of the current test are displayed alternately at 2-second

intervals. In the event of a technical error, all tests can be carried out normally. The message

on the display disappears as soon as the technical error has been corrected.

A new Control PCB will generate the error No. 16 (invalid check sum in the EEPROM) before

initial calibration. This technical error will disappear as soon as all data has been calibrated.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 4

Page 5

1.4 Error Messages During a Specific Test

If the system detects and displays an error, you must confirm this error by pressing the Info

key and the Reset key simultaneously. Once the error has been removed, the specific test

can be selected and carried out again.

All potential errors and their cause are listed below:

1.4.1 Power Supply Low

Problem

Accu/Bat. empty

1.4.2 Pressure Low

Problem

Pressure low

1.4.3 Pressure High

Problem

Pressure high

No external power supply connected. The internal

power supply is no longer sufficient for safe

operation.

Gas supply pressure is too low.

A gas supply source is connected although no

pressure is required for this test.

1.4.4 Mode Switch Position (IPPV/CPAP)

Problem

The mode switch is not in the correct position.

Pos. IPPV/SIPPV

1.4.5 Mode Switch Position (IPPV/CPAP)

Problem

The mode switch is not in the correct position.

Pos. SIMV/CPAP

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 5

Page 6

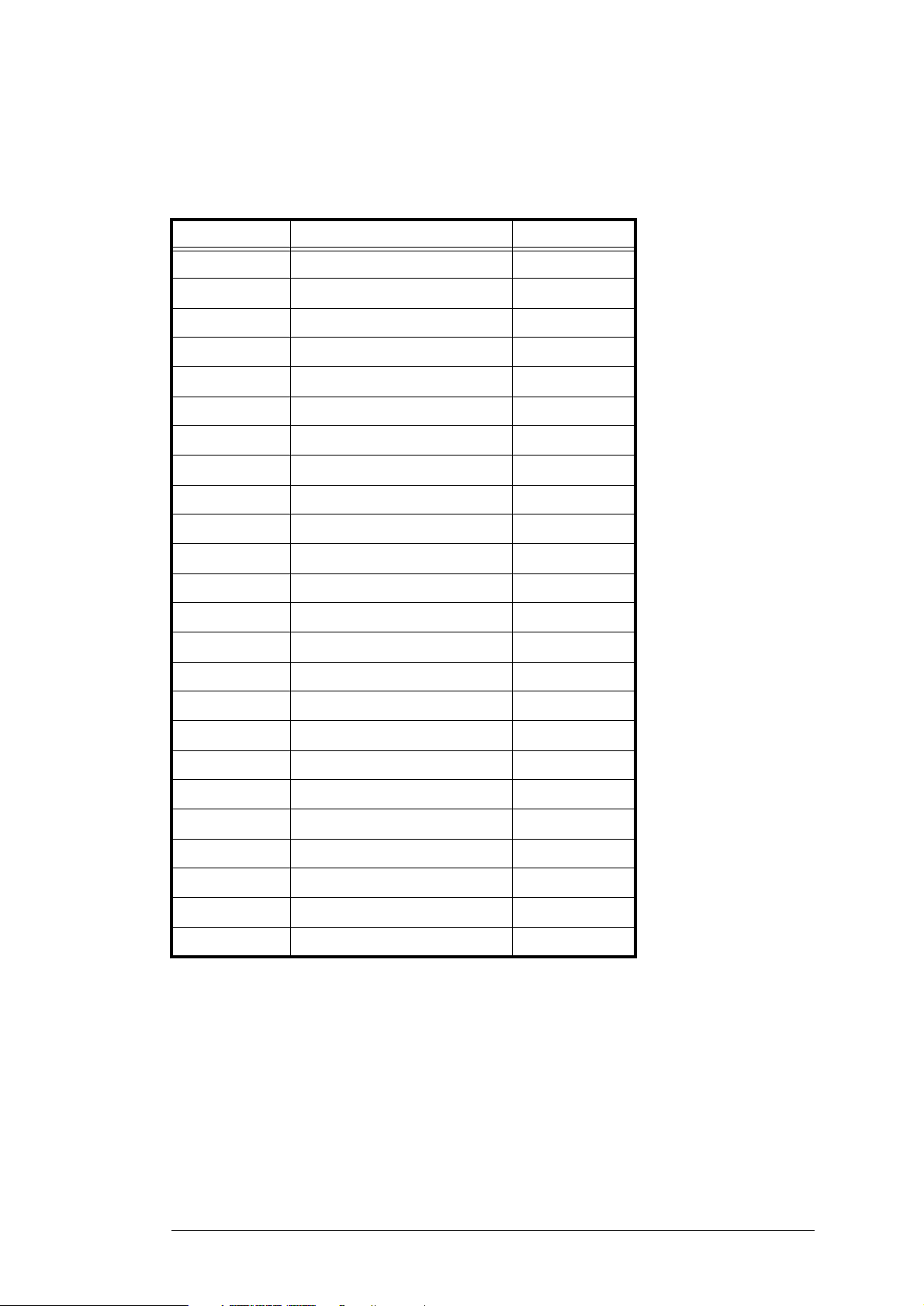

1.5 Tests in the Dräger Service Mode

Table 3: Service Mode Tests

Test number Test Name Mode

001 Adjust language CSM

002 Supply pressure CSM

003 Mode switch CSM

004 Adjust MV limits CSM

005 Buzzer & LED test CSM

006 Adjust f, V

, Ti, Pmax CSM

T

007 TACHYPNEA ALARM CSM

008 to 010 Not assigned

011 Calibration PSWI ESM

012 Calibration MV valve ESM

013 Flow set & measure ESM

014 Analog inputs ESM

015 Test basic flow ESM

016 Test autozero valve ESM

017 Autozero meas & cal. ESM

018 Set MV valve, Paw ESM

019 Test EXP valve ESM

020 Test ASB valve ESM

021 Test supply pressure ESM

022 Test MV valve slow ESM

023 Test MV valve fast ESM

024 Flow measurement ESM

025 Test pressure switch ESM

026-255 Not assigned

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 6

Page 7

2 Starting / Exiting the Customer Service Mode (CSM)

☞

Important:

In the Customer Service Mode (CSM), only Test 001 through Test

006 are accessible to the customer or Dräger service technician.

The other tests are deactivated.

Test 007 is only available in US software version.

• Turn the potentiometers for frequency f and for tidal volume VT clockwise as far as they

will go.

• Press and hold the Info key and the Reset key simultaneously and switch on the

MicroVent.

Display:

C u s t o m e r

Customer Service Mode (CSM)

Se r v i c e - M o d e

• Release the two keys.

Display:

A d j u s t l a n g u a g e

< – 0 0 1 + >

• Press the Reset key or the Info key to select Test 001 through Test 007.

• Press the Reset key and the Info key simultaneously to activate the respective test.

• Press the Reset key and the Info key simultaneously again to return to the Customer

Service Mode (CSM).

Exiting the Customer Service Mode (CSM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 7

Page 8

2.1 Test 001: Adjusting the Language

This test allows you to adjust the language to be used during the MicroVent operation.

• Press the Reset key to select the desired language.

Display:

d e u t s c h

or

e n g l i s h

or

f r a n c a i s

or

e s p a n o l

or

s u o m e k s i

or

p o r t u g u e s e

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 8

Page 9

or

i t a l i a n o

or

a m e r i c a n e n g l i s h

or

f r a n c a i s f r a n c e

or

n e d e r l a n d s

• Press the Info key and the Reset key simultaneously to adjust the desired language.

The MicroVent returns automatically to the Customer Service Mode (CSM).

Exiting the Customer Service Mode (CSM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 9

Page 10

2.2 Test 002: Testing the Gas Supply

The pressure sensors must have been calibrated (test 011 in Extended Service Mode) befre

selecting test 002.

• Press the Reset key to select Test 002.

• Press the Info key and the Reset key simultaneously to activate Test 002.

Display:

P r e s s u r e h i g h

The gas supply pressure is sufficient.

or

P r e s s u r e l o w

The gas supply pressure is too low or the

device is not connected to a gas supply source.

• Press the Info key and the Reset key simultaneously to return to the Customer Service

Mode (CSM).

Exiting the Customer Service Mode (CSM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 10

Page 11

2.3 Test 003: Position of the Pneumatic Switch (IPPV/CPAP)

This test allows you to check position of the IPPV/CPAP mode switch is checked. The

respective position is shown on the MicroVent display. The pressure sensors must have been

calibrated (test 011 in Extended Service Mode) befre selecting test 003.

If the pressure in the device is too low, or if the device is not connected to a gas supply

source, the warning “Problem pressure low” will appear. The problem must then be rectified

(establish gas supply) and subsequently confirmed with the Info and Reset key before test

003 can be called up again.

• Press the Reset key to select Test 003.

• Press the Info key and the Reset key simultaneously to activate Test 003.

Display:

P o s. I P P V / S I P P V

or

P o s. S I M V / C P A P

• Press the Info key and the Reset key simultaneously to return to the Customer Service

Mode (CSM).

Exiting the Customer Service Mode (CSM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 11

Page 12

2.4 Test 004: Setting the Minute Volume Limits

This test allows you to check the settings of the minute-volume double-potentiometer

(plausibility test).

• Press the Reset key to select Test 004.

• Press the Info key and the Reset key simultaneously to activate Test 004.

Display:

M V – l o w = X X . X X

M V – h i g h = X X . X X

• Adjust the values listed in the table below using the potentiometer and check the values

shown on the display.

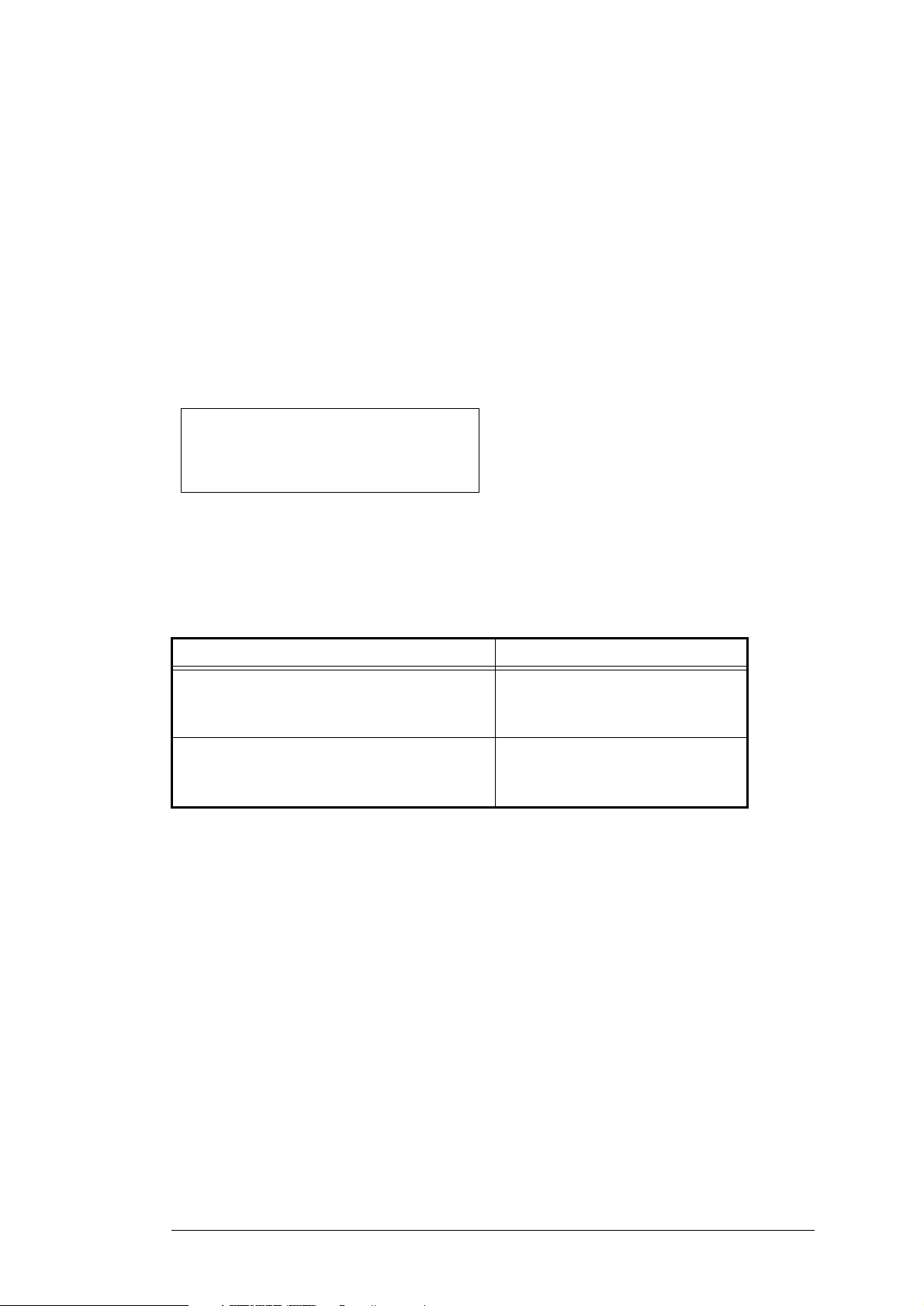

Table 4: Minute Volume Alarm Limit Settings

Values Adjusted with the Potentiometer Values shown on the Display

MV - high 2 L/min

10 L/min

20 L/min

MV - low 2 L/min

10 L/min

20 L/min

1.9 to 2.1 L/min

9.5 to 10.5 L/min

19 to 21 L/min

1.9 to 2.1 L/min

9.5 to 10.5 L/min

19 to 21 L/min

• Press the Info key and the Reset key simultaneously to return to the Customer Service

Mode (CSM).

Exiting the Customer Service Mode (CSM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 12

Page 13

2.5 Test 005: Buzzer Test, LED Test, and LCD Test

This test allows you to check the audible and visible signals. The LEDs of the

internal/external power supply, the alarm LED and the backlight of the display come on. The

buzzer is activated and the pixels of the display are triggered.

• Press the Reset key to select Test 005.

• Press the Info key and the Reset key simultaneously to activate Test 005.

Display:

I N F O T E S T O N

R E S E T T E S T O F F

• Press the Info key to start Test 005.

• Press the Reset key to stop Test 005.

• Press the Info key and the Reset key simultaneously to return to the Customer Service

Mode (CSM).

Exiting the Customer Service Mode (CSM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 13

Page 14

2.6 Test 006: Adjusting and Reading Out the Potentiometers f, VT, Tinsp, and Pmax

This test allows you to compare the positions of the potentiometers f, VT, Tinsp and, Pmax

with the values shown on the display.

• Press the Reset key to select Test 006.

• Press the Info key and the Reset key simultaneously to activate Test 006.

• Change the potentiometer settings for the frequency f, the tidal volume VT, the inspiratory time Tinsp, and the maximum pressure Pmax (see Table below).

The changed values are shown on the display.

Display:

F = X X. XX V T = X . X X X

T i = X . X P = X X . X

Table 5: Potentiometer Settings: f, VT, Tinsp and Pmax

Settings on the MicroVent: Values on the Display

f = 5 min

= 10 min

60 min

-1

-1

-1

VT = 0.1 L

= 0.8 L

1.5 L

= 0.2 s

T

insp

= 1 s

= 3.0 s

Pmax = 20 mbar

= 40 mbar

= 60 mbar

5.00 to 5.13 min

9.88 to 10.17 min

59.00 to 61.00 min

0.1 to 0.11 L

0.79 to 0.81 L

1.48 to 1.50 L

0.18 to 0.22 s

0.9 to 1.1 s

2.8 to 3.20 s

20.0 to 20.6 mbar

39.6 to 40.4 mbar

59.4 to 60.0 mbar

-1

-1

-1

• Press the Info key and the Reset key simultaneously to return to the Customer Service

Mode (CSM).

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 14

Page 15

Exiting the Customer Service Mode (CSM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

2.7 Test 007: Tachypnea Monitoring Configuration

This test is only available in the US software version. It enables the tachypnea monitoring to

be activated and deactivated. An alarm is given if the patient exceeds a spontaneous

breathing frequency of 30 min.

• Press Reset key to select test 007.

• Simultaneously press Info and Reset keys to activate test 007.

Display:

T a c h y p m e a a l a r m

I N A C T I V E

-1

over a period of 3 minutes.

• Press Reset key to activate alarm.

T a c h y p m e a a l a r m

A C T I V E

• Press Info key to deactivate alarm.

T a c h y p m e a a l a r m

I N A C T I V E

• Simultaneously press Info and Reset keys to return to Customer Servcie Mode (CSM)

Exit from Customer Servcie Mode

• Switching the MicroVent off and on again effects return to normal MicroVent operation.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 15

Page 16

3 Starting / Exiting the Extended Service Mode (ESM)

In addition to the tests in the Customer Service Mode (CSM) (Test 001 through 006), you

have access to the fourteen tests in the Extended Service Mode (ESM) (Test 011 through

Test 024). The remaining Tests 025 through 255 are not assigned. To start the Extended

Service Mode (ESM), you must enter a specific numeric code.

• Turn the potentiometers for the frequency f and the tidal volume VT clockwise as far as

they will go.

• Press and hold the Info key and the Reset key simultaneously and switch on the

MicroVent.

Display:

C u s t o m e r

Customer Service Mode (CSM)

S e r v i c e Mo d e

• Release the Info key and the Reset key.

A d j u s t l a n g u a g e

< – 0 0 1 + >

• Adjust the number “222” using the Info key or the Reset key.

•Press the Info key and the Reset key simultaneously for approx. 5 seconds to start

the Extended Service Mode (ESM).

E x t e n d e d D r ä g e r

Se r v i c e M o d e

• Select the desired test with the Info key or the Reset key.

• Press the Info key and the Reset key simultaneously to activate the desired test.

• Press the Info key and the Reset key simultaneously again to return to the Extended

Service Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 16

Page 17

3.1 Test 011: Calibrating the Pressure Sensors P-Supply and P-LA

This test allows you to calibrate the MicroVent pressure sensors. Proceed as follows:

• Disconnect the MicroVent from the gas supply.

• Adjust the mode switch to IPPV.

• Select the Extended Service Mode (ESM).

• Select Test 011.

• Activate Test 011.

Display:

R e m o v e P r e s s u r e

• Simultaneously press Info and Reset keys to start calibration.

The pressure sensors are exposed to atmospheric pressure. The I:E valve switches over to

inspiration and, at the same time, opens the minute volume valve. The Offsets of the pressure

sensors are then stored in the EEPROM.

C A L I B R A T I O N

P_V E R S P _L A

• As soon as the pressure has been decreased in the system, press the Info key and the

Reset key simultaneously to store the calibration values.

The MicroVent returns automatically to the Extended Service Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 17

Page 18

3.2 Test 012: Calibrating the Minute Volume Valve

During the calibration sequence (Test 012), you will be prompted to perform specific steps.

The displayed flow value (Nom.) is the calibration point. At the beginning of calibration, the

most recent stored flow value is adjusted. You can change this value by pressing the Reset

key or the Info key. You cannot stop the calibration process, once it has started.

At each calibration point, the flow is to be adjusted by pressing the Info or Reset key such

that the flow value displayed on the external flowmeter matches the corresponding flow value

(Nom.) on the MicroVent display.

Tes t Setup

Wall supply connection

3–6 bar

D

Pmax

Micro Vent

L

G

g

40

20

D

0

mbar

V

40

30

60 mbar

20

Info

15

f

60

10

80- 10

5

MV

Y

10

8

50

6

4

2

→

12

20 L/min

VT

20

0,5

40

0,1

60

0CPAP

ASB

20

14

10

16

18

30

5

35 mbar

0

min

Reset

Tinsp

1,0

1

2

PEEP

CPAP

1,5 L

3 s

0,2

5

10

15

mbar30

Inspiratory hose

SIMV

CPAP

IPPV

SIPPV

°

r

Flow sensor

Flowmeter

10 to 120 L/min

• Adjust the mode switch to IPPV.

• Adjust the rotary knob for PEEP/CPAP to 0 mbar

• Adjust the rotary knob for ASB to 0 mbar

• Select the Extended Service Mode (ESM).

• Select Test 012.

• Activate Test 012.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 18

Page 19

Important:

Allow the MicroVent to stabilize at each calibration point. Watch the

corresponding scale (Air or O

Display:

A d j u s t P E E P =

on the flowmeter.

2)

0 mbar (cm H

2

O) !

• Simultaneously press Info and Reset keys to call up calibration point.

N o m. = X X L / m i n

E N T E R = c a l. P o i n t

• If necessary, press the Info key or the Reset key to adjust the flow such that the value

shown on the display matches that indicated on the external flow meter.

• Press the Info key and the Reset key simultaneously to store the points (see the

following table) in the EEPROM.

Calibration

Tolerances of the set flow values SW-Version

values

10 L/min

15 L/min

30 L/min

50 L/min

60 L/min

70 L/min *

9.5 - 10.5 L/min

14.5 - 15.5 L/min

29.4 - 30.6 L/min

49.0 - 51.0 L/min

58.8 - 61.2 L/min

68.6 - 71.4 L/min

1.10, 1.21

1.21

1.10, 1.21

1.10, 1.21

1.10

1.10, 1.21

* If the calibration values (70 L/min) are not obtained, store the highest calibration values.

The last calibration point is calibrated and the MicroVent returns automatically to the

Extended Service Mode (ESM)

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 19

Page 20

Exiting the Extended Service Mode (ESM)

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

3.3 Test 013: Adjusting and Displaying the Flow

This test allows you to adjust the flow in steps of 100 mL. The measured flow is continually

displayed.

The I:E valve is switched on at the beginning of the test and switched off again at the end of

the test.

Tes t Setup

Wall supply connection

3–6 bar

Pmax

D

30

Info

40

20

D

f

60

0

V

40

60 mbar

20

10

80- 10

mbar

5

→

CPAP

MV

Y

10

12

8

50

6

4

20 L/min

2

XX.XX

15

V

T

20

40

60

0

ASB

14

10

16

18

5

0

T

1,0

0,5

1,5 L

0,1

PEEP

20

5

CPAP

30

35 mbar

Micro Vent

L

G

g

min

Reset

insp

1

3 s

0,2

10

15

mbar30

r

SIMV

CPAP

2

IPPV

SIPPV

°

Flowmeter

10 up to 120 L/min

Flow sensor

• Adjust the mode switch to IPPV.

• Adjust the rotary knob for PEEP/CPAP to 0 mbar

Inspiratory hose

• Adjust the rotary knob for ASB to 0 mbar

• Select the Extended Service Mode (ESM).

• Select Test 013.

• Activate Test 013.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 20

Page 21

Display:

N o m. = X X . X L / m i n

A c t . = + X X. X L / m i n

• Adjust the flow values (Nom.) with the Info key or the Reset key (see the following table)

and check the display (Act.) on the MicroVent and with the external flowmeter.

Table 6: Flow Settings

Adjusted flow (Nom.) Flowmeter

10 L/min 9.0 to 11.0 L/min

15 L/min 14.0 to 16.0 L/min

30 L/min 27.6 to 32.4 L/min

50 L/min 46.0 to 54.0 L/min

60 L/min 55.2 to 64.8 L/min

70 L/min 64.4 to 75.6 L/min

• Press the Info key and the Reset key simultaneously to finish Test 013.

The MicroVent automatically returns to the Extended Service Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 21

Page 22

3.4 Test 014: Reading in the Analog Channels

You can display the desired analog channel by pressing the Info key or the Reset key. The

displayed measured value is continually re-calculated. A total of eighteen values are

displayed. A total of eighteen values is displayed (1023 LSB correponds to 5.0 V).

• Select the Extended Service Mode (ESM).

• Select Test 014.

• Activate Test 014.

☞

Caution:

The values shown in the following table apply to an operational

MicroVent equipped with a fully charged and connected

rechargeable battery pack.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 22

Page 23

Table 7: Designation of the Analog Channels

No. Designation Remark

1 Poti _Pmax Front potentiometer, max. ventilation pressure.

2 Poti_Ti Front potentiometer, inspiratory time.

3 Poti_VT Front potentiometer, tidal volume.

4 Poti_f Front potentiometer, frequency.

5Poti MV Potentiometer for definition of the MV valve’s position.

6 P_ Flow Differential pressure of the flow measurement.

7 Paw Airway pressure.

8 Kontr_ VPSchalt Switched 5 V voltage supply.

9 MV low Front potentiometer, lower limit of minute volume.

10 MV high Front potentiometer, upper limit of minute volume.

11 Kontr VBat Rechargeable-battery or normal battery supply voltage.

12 Kontr Vext External power supply.

13 Kontr VAlm Power supply (batteries).

14 Kontr 5 V Internal 5 V of power supply.

15 P_Versorgung Supply pressure sensor.

16 P_Reserve

17 P_LA Lung demand valve pressure-supply sensor.

18 Akku Temp Temperature-sensor rechargeable battery.

Display:

P O T I P M A X

X X X ( X . X X X V )

P O T I T I

X X X ( X . X X X V )

P O T I V T

Left potentiometer stop: < 0.5 V

Right potentiometer stop: approx. 4.5–5.0

Left potentiometer stop: < 0.5 V

Right potentiometer stop: approx. 4.5–5.0

Left potentiometer stop: < 0.5 V

Right potentiometer stop: approx. 4.5–5.0

X X X ( X . X X X V )

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 23

Page 24

P O T I F

X X X ( X . X X X V )

Left potentiometer stop: < 0.5 V

Right potentiometer stop: approx. 4.5–5.0

P O T I M V

X X X ( X . X X X V )

P _ F L O W

X X X ( X . X X X V )

P _ A W

X X X ( X . X X X V )

K O N T R . V P S C H A L T

X X X ( X . X X X V )

M V _ L O W

X X ( X . X X X V )

M V _ H I G H

X X X ( X . X X X V )

This value is calculated from the position of the

MV valve. (This value isn´t defined).

Unpressurized 2.5 V ±150 mV.

Unpressurized 0.9 V ±0.1 V (offset).

Supply voltage

5 V (tolerance: ±0.1 V)

Left potentiometer stop: < 0.5 V

Right potentiometer stop: approx. 4.5–5.0

Left potentiometer stop: < 0.5 V

Right potentiometer stop: approx. 4.5–5.0

K O N T R _ V B A T

X X X ( X . X X X V )

K O N T R _ V E X T

X X X ( X . X X X V )

K O N T R _ V A I M N

X X ( X . X X X V )

K O N T R _ 5 V.

X X X ( X . X X X V )

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Supply voltage

Internal NiCd battery (approx. 9 V)

Supply voltage

12 V (tolerance: ±1 V)

Supply voltage

5 V (tolerance: ±0.1 V)

or

Internal AlkMn batteries

Monitoring

5V (tolerance: ±0.25V)

Service Mode

< 1 V if Internal AlkMn

battery pack isn´t

installed.

Page 24

Page 25

P _ V E R S O R GU N G

Pressure sensor (P-supply):

(back pressure of the pressure regulator)

X X X ( X . X X X V )

The indicated value X.XXX V corresponds to the

calculated background of the pressure regulator

Example:

(in volts).

Background = indicated value minus the offset

• Disconnect gas supply.

• Note the Offset-Value of the

voltage (0.64 V).

(1 bar is equivalent to approx. 460 mV)

Offset = value indicated while the gas supply is

disconnected

• Connect gas supply.

• Note the measured value of the

voltage (1.456 V).

• Formula:

pressure result in Volt (1.456 V) – Offset value (0.64 V) = 0.816 V.

• Formula:

0.816 V : 0.460 V (fixed value) <–> 1.773 bar (back pressure of the pressure

regulator).

P _ R E S E R V E

(not used in the Dräger Service Mode.)

X X X ( X . X X X V )

P _ L A

X X X ( X . X X X V )

A K K U _ T E M P

Mode switch at position IPPV (< 2 V).

Mode switch at position SIMV (> 2 V).

Rechargeable-battery temperature sensor (NTC)

Charging/temperature monitoring

X X X ( X . X X X V )

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 25

Page 26

3.5 Test 015: Testing Basic Flow

The basic flow supplied by the fixed restrictor R4 is to be checked in switch setting

IPPV/SIPPV.

The basic flow is fixed adjusted. It is measured continuously and displayed in the bottom line

of the display. The basic flow should pass through the inspiratory hose, the expiratory hose

and the ventilation valve. The desired value of the basic flow is shown in the top line of the

display.

Tes t Setup

Wall supply connection

3–6 bar

Pmax

D

30

Info

40

20

D

60

0

80- 10

mbar

V

20

CPAP

MV

40

Y

10

50

6

4

60 mbar

XX.XX

15

f

V

10

5

T

20

1,0

0,5

40

1,5 L

0,1

60

→

0

12

14

16

18

20 L/min82

PEEP

ASB

20

CPAP

10

30

5

35 mbar

0

Micro Vent

L

G

g

min

Reset

T

insp

5

SIMV

CPAP

1

2

3 s

0,2

IPPV

SIPPV

10

15

°

mbar30

Inspiration hose

Flow sensor

Seal connection with hand

• Set the mode switch to IPPV/SIPPV.

r

Flow sensor

Y-piece

• Adjust the rotary knob for PEEP/CPAP to 0 mbar

• Adjust the rotary knob for ASB to 0 mbar

• Select the Extended Service Mode (ESM).

• Select Test 015.

• Activate Test 015.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 26

Page 27

Display:

N o m. = 4 . . . 7 L / m i n

A c t . = + X . X L / m i n

Nominal value of the basic flow

Actual value of the basic flow

The basic flow should be 4 to 7 L/min.

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

The following error message appears if the pneumatic switch is set to SIMV/CPAP.

P r o b l e m:

Remedy: You must exit the test, remove

the fault (by setting the mode switch to

P o s . S I M V / C P A P

SIMV/CPAP), and restart the test.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 27

Page 28

3.6 Test 016: Testing the Autozero Solenoid Valve

This test allows you to check the function of the Autozero solenoid valve. You can hear the

switching sound of the ASB solenoid valve. You can measure the valve voltage directly at the

Autozero solenoid valve. It should be 6 V ±0.5 V. You do not need to connect the device to a

gas supply to perform this test.

• Select the Extended Service Mode (ESM).

• Select Test 016.

• Activate Test 016.

Display:

I N F O: P o s . A C T I V E

R E S E T: P o s I N A C T

• Press the Info key to switch on the Autozero solenoid valve.

P o s. A C T I V E

R E S E T: P o s I N A C T

•Press the Reset key to switch off the Autozero solenoid valve.

P o s. I N A C T I V E

I N F O: P o s . A C T I V E

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 28

Page 29

3.7 Test 017: Displaying and Calibrating the Autozero Offset

In the IPPV mode, the MicroVent ventilates the patient with the frequency (f), the tidal volume

), and the inspiratory time (Tinsp) values. The alarm messages are not active. The current

(V

T

offset (act. Offs) of the flow-measurement pressure sensor (Autozero) is displayed

continually in the lower section of the display. The filtered offset (fil. Offs) is indicated in the

top line of the display. The filtered offset compensates for the occurring fluctuations and has

a greater stability. A new Autozero value is calculated at one to two minute intervals.

• Adjust the mode switch to IPPV.

• Select the Extended Service Mode (ESM).

• Select Test 017.

• Activate Test 017.

Display:

f i l . O f f s = X . X X X V

a c t . O f f s = X . X X X V

filtered offset (fil. Offs)

current offset (act. Offs)

• Press the Reset key to calibrate the default offset (2.5 V).

f i l . O f f s = X . X X X V

c a l . d e f a u l t . O f f s

The filtered offset (fil. Offs) and the current offset (act. Offs) have the same voltage value. The

voltage should be approx. 2.5 V.

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 29

Page 30

3.8 Test 018: Testing the Pressure Sensor Paw and Triggering the Minute Volume Valve

No control of the minute capacity valve occurs in this test. If no key is pressed, the motor will

stop. You can open or close the minute volume valve by pressing the Info key or the Reset

key.

Caution:

The minute volume valve might get stuck. To avoid this, do not

move the minute volume valve completely to its mechanical stops.

Carefully open or close the minute volume valve.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 30

Page 31

Tes t Setup

Wall supply connection

3–6 bar

Pmax

D

Info

40

20

D

f

60

0

V

40

10

80- 10

mbar

5

→

CPAP

MV

Y

10

12

50

6

4

60 mbar3020

20 L/min82

XXX

15

V

T

20

1,0

0,5

40

1,5 L

0,1

60

0

14

16

18

PEEP

ASB

20

CPAP

30

5

35 mbar100

Micro Vent

L

G

g

min

Reset

r

Tinsp

5

SIMV

CPAP

1

2

3 s

0,2

IPPV

SIPPV

10

15

°

mbar30

Y-piece

Flow sensor

• Set the mode switch to IPPV.

• Adjust the rotary knob for PEEP/CPAP to 0 mbar

Manometer

–30 to 120 mbar

connector 8400904

Flowmeter

10 to 120 L/min

hose clamp

• Adjust the rotary knob for ASB to 0 mbar

• Select the Extended Service Mode (ESM).

• Select Test 018.

• Activate Test 018.

Display:

M V - P o t i = X X X X X

P a w = X X X m b a r

Measured value of the Paw pressure

sensor (mbar)

• Adjust a flow of 50 L/min with the Reset key.

• Adjust a pressure of 40 mbar via an external manometer using a hose clamp .

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 31

Page 32

The Micro Vent displays a ventilation pressure of 40 mbar ±2 mbar.

• Press the Info key or the Reset key to open or close the minute volume valve.

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 32

Page 33

3.9 Test 019: Testing the Expiratory Solenoid Valve

During this test, the expiratory valve can be switched on and off. Possible positions are: ASB

or Normal. The switching action of the expiratory solenoid valve is audible. The valve voltage

can be measured directly at the expiratory solenoid valve. The valve voltage should be 6 V

±0.5 V. You do not need to connect the MicroVent to a gas supply source in order to perform

this test.

• Select the Extended Service Mode (ESM).

• Select Test 019.

• Activate Test 019.

Display:

I N F O : P o s A S B

R E S E T : P o s N O R M A L

• Press the Info key to switch on the expiratory solenoid valve.

Display:

P o s i t i o n ASB

R E S E T : P o s N O R M A L

• Press the Reset key to switch off the expiratory solenoid valve.

Display:

P o s i t i o n N O R M A L

I N F O : P o s A S B

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 33

Page 34

3.10 Test 020: Testing the ASB Solenoid Valve

During this test, the ASB solenoid valve can be switched on and off. The switching action of

the ASB solenoid valve is audible. The valve voltage can be measured directly at the ASB

solenoid valve. The valve voltage should be 6 V ±0.5 V. You do not need to connect the

MicroVent to a gas supply source in order to perform this test.

• Select the Extended Service Mode (ESM).

• Select Test 020.

• Activate Test 020.

Display:

I N F O : Pos ACTIVE

R E S E T : Pos NOT AC

• Press the Info key to switch on the ASB solenoid valve.

Display:

P o s ACTIVE

R E S E T : ASB NOT AC

• Press the Reset key to switch off the ASB solenoid valve.

Display:

Pos NOT ACTIVE

INFO : A S B ACTIVE

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 34

Page 35

3.11 Test 021: Testing the Supply Pressure

During this test, the minute volume valve delivers an adjustable nominal flow. This nominal

flow is indicated in the top line of the display. The specified flow can be adjusted in 100-mL

steps using the Info key or the Reset key.

The pressure measured downstream of the pressure regulator is shown on the bottom line of

the display. The influence of an increasing flow on the internal pressure is observable.

• Select the Extended Service Mode (ESM).

• Select Test 021.

• Activate Test 021.

Display:

F l o w = 1 . 0 L / m i n

P r e s = X. X X X b a r

Adjustable nominal flow

Back pressure of the pressure regulator

• Press the Reset key and adjust a flow of 40 L/min.

The Micro Vent must display a value of approx. 1.6 bar (1.5 to 1.7 bar).

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

Important:

☞

Alarm message: Pressure low.

If the measured pressure falls below the alarm limit, the test is

aborted and the alarm Pressure low is given.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 35

Page 36

3.12 Test 022: Testing the Minute Volume Valve (Slow)

During this test, the minute volume valve control is switched off. The minute volume valve can

be opened or closed slowly by hand.

Caution:

The minute volume valve might get stuck in the mechanical stop. To

avoid this, do not move the minute volume valve completely to its

mechanical stops. Open or close the minute volume valve carefully.

• Select the Extended Service Mode (ESM).

• Select Test 022.

• Activate Test 022.

Display:

I N F O M V c l o s e

R E S E T M V o p e n

• Press the Info key to slowly close the minute volume valve.

• Press the Reset key to slowly open the minute volume valve.

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 36

Page 37

3.13 Test 023: Testing the Minute Volume Valve (Fast)

During this test, the minute volume valve control is switched off. The minute volume valve can

be opened or closed fast by hand.

Caution:

The minute volume valve might get stuck in the mechanical stop. To

avoid this, do not move the minute volume valve completely to its

mechanical stops. Open or close the minute volume valve carefully.

• Select the Extended Service Mode (ESM).

• Select Test 023.

• Activate Test 023.

Display:

I N F O M V c l o s e

R E S E T M V o p e n

• Press the Info key to fast close the minute volume valve.

• Press the Reset key to fast open the minute volume valve.

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 37

Page 38

3.14 Test 024: Testing the Differential Pressure Sensor ∆P and

Testing the Flow Measurement

This test allows you to adjust a simple ventilation pattern. No alarms are given during this test.

You can toggle between the minute volume (Nom. and Act.) and the tidal volume (Insp and

Exp) on the display.

Tes t Setup

D

Pmax

30

Micro Vent

L

G

g

Info

40

20

D

f

60

mbar

60 mbar

10

80- 10

5

→

0

CPAP

MV

Y

10

12

8

50

14

6

18

4

20 L/min

2

0

V

40

20

XX.XX

15

V

T

20

0,5

40

0,1

60

ASB

20

10

16

5

35 mbar

0

min

Reset

T

insp

1,0

1

1,5 L

3 s

0,2

PEEP

5

CPAP

10

30

15

mbar30

r

SIMV

CPAP

2

IPPV

SIPPV

°

Y-piece

Flow sensor

Wall supply connection

3–6 bar

sponatenous breathing set 8403201

• Set the mode switch to IPPV.

• Select the Extended Service Mode (ESM).

• Select Test 024.

• Activate Test 024.

-1

• Adjust the frequency to 15 min

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

and the VT to 1 L/min.

Service Mode

Page 38

Page 39

Display:

N o m. = 1 5 . 0 0 L / m i n

A c t . = X . X X L / m i n

Nominal value calculated from VT and f

Measured flow value (13.7 to 16.3 L/min)

• Press the Info key to display the current tidal volume (the last applied respiratory stroke).

Display:

I n s p = X X X m L

E x p = X X X m L

Inspiratory tidal volume

Expiratory tidal volume

• Press the Info key and the Reset key simultaneously to return to the Extended Service

Mode (ESM).

Exiting the Extended Service Mode (ESM).

• Switch the MicroVent off and on again to return to the MicroVent normal operating

mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 39

Page 40

3.15 Test 025: Testing the Pressure Switch PEEP-ASB

This test is only available from SW-Version 1.21. The digital signal (ON/OFF) of the pressure

switch PEEP-ASB is shown on the display.

• Select the Extended Service Mode (ESM)

• Adjust the rotary knob for PEEP/CPAP to 10 mbar

• Adjust the rotary knob for ASB to 5 mbar

• Select Test 025

• Activate Test 015

Display:

PRESS - SWITCH OFF

• Adjust the rotary knob for ASB to 15 mbar

Display:

PRESS - SWITCH ON

• Press the INFO key and the RESET key simultaneously to return to the Extended Service

Mode (ESM)

Exiting the Extended Service Mode (ESM)

• Switch the MicroVent off and on again to return the MicroVent normal operating mode.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 40

Page 41

4 Technical Error (TE) List

Table 8: Possible Errors in the Micro Vent

TE no. Alarm Cause Remedy

1 A/D WANDLER

Electronics Replace electronics.

TIMEOUT

2 KONTR_5 V Electronics Replace electronics.

3 POTI MV high Resistance outside range,

cable harness

Check the cable

harness and the

connector. If

necessary, replace the

front panel.

4 POTI MV low Resistance outside range,

cable harness

Check the cable

harness and the

connector. If

necessary, replace the

front panel.

5 KONTR_VPSCHALT Electronics Replace electronics.

6 KONTR_VEXT Incorrect ext. voltage Check ext. voltage

7 TASTE_LCD_HG Key sticks Check, if necessary,

replace the front plate

8 TASTE RESET Key sticks Check, if necessary,

replace the front plate

9 BEIDE TASTEN Key sticks Check, if necessary,

replace the front plate

11 POTI F Resistance outside range,

cable harness

Check the cable

harness and the

connector. If

necessary, replace the

front panel.

12 POTI VT Resistance outside range,

cable harness

Check the cable

harness and the

connector. If

necessary, replace the

front panel.

13 POTI Tinsp Resistance outside range,

cable harness

Check the cable

harness and the

connector. If

necessary, replace the

front panel.

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 41

Page 42

Table 8: Possible Errors in the Micro Vent

14 POTI_PMAX Resistance outside range,

cable harness

Check the cable

harness and the

connector. If

necessary, replace the

front panel.

15 EEPROM WRITE-

ERROR

16 EEPROM

CHECKSUMME

Electronics Calibrate, otherwise

replace electronics.

Electronics Calibrate, otherwise

replace electronics.

17 MV-VENTIL MV valve sticks Check, if necessary,

replace the valve

18 POTI_MV Tolerance Check, if necessary,

replace electronics.

19 SW WATCHDOG EPROM, electronics Replace EPROM or

electronics.

20 IRAM Electronics Replace electronics.

21 XRAM Electronics Replace electronics.

22 EPROM EPROM Replace EPROM

23 EEPROM PTC

EEPROM Replace electronics

FEHLER

For internal use only. Copyright reserved.

GBR5673100SM1.fm

R 5673.100 MicroVent 09/97

Service Mode

Page 42

Loading...

Loading...