Page 1

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Operator’s

Instruction

Manual

Part Number: 4117102-007

Fabius GS Software Version 2.1n

Date: 16 January 2004

© 2004 Draeger Medical, Inc.

Rev: —

Fabius GS

®

Warning: For a full understanding of the performance of this anesthesia machine,

the user should carefully read this manual before operating.

Page 2

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Contents

Chapter 1. Introduction

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operator’s Responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Copyright, Trademark, and Limitation of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Symbol Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2. Configurations and Components

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Typical Fabius GS Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3. Operating Concept

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Standard Function Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cross-Functional Controls and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fresh Gas Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fresh Gas Flow Monitoring Resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

APL Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 4. Preparation

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Activating the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Medical Gas Pipeline Supply of O2, N2O, and AIR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cylinders with Pin-index Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Attaching Manual (Ambu) Ventilation Bag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Preparing the Ventilator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Ventilator Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Attaching the CO

Attaching the Inspiratory Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Attaching the Expiratory Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Attaching the Adjustable Pressure Limiting (APL) Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Inserting the Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Attaching the Waste Gas Outlet Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Connecting the Compact Breathing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Connecting the Breathing Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Inserting A New O

Connecting the O2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Connecting the Pressure Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Connecting the Breathing Pressure Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Connecting the APL Bypass and Peep/PMAX Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2 Absorber onto the Compact Breathing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2 Sensor Capsule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

i

Page 4

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Contents

Connecting the Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Installing Anesthetic Gas Scavenging Hose to the Compact Breathing System . . . . . . . . . . . . . . . . . . . . 52

Scavenger System for Fabius GS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Additional Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Daily and Preuse Checkout Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 5. Operation and Shut-down

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Preparation for Transport or Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 6. Monitoring

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Oxygen Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Respiratory Volume Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Breathing Pressure Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Chapter 7. Setup Window (Used During Operation)

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Setup Window Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Volume Alarms On/Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Auto Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Calibrate O2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Activate Desflurane Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Access Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Access Alarm Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Window Deactivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Chapter 8. Standby Mode Functions

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Standby Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Standby Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Chapter 9. Routine Maintenance and Cleaning

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Routine Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Disassembling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Disinfecting/Cleaning/Autoclaving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Maintenance Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Checking Readiness for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Chapter 10. Troubleshooting

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

ii

Page 5

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Contents

Chapter 11. Components

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Compact Breathing System (Top View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Rear View (3-Gas Supply Connections) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Chapter 12. Technical Data

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Appendix. Daily and Preuse Checkout Form

iii

Page 6

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 7

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 1 - Introduction Contents

Introduction

Contents

Overview ................................................................................................................... 3

Recommendations .................................................................................................. 3

Not for Use in Areas of Explosion Hazard .............................................................. 3

Safe Connection with Other Electrical Equipment .................................................. 3

Operator’s Responsibility .......................................................................................... 3

Intended Use ............................................................................................................. 4

Safety Features ......................................................................................................... 4

Copyright, Trademark, and Limitation of Liability ...................................................... 4

Rev: —

Copyright ................................................................................................................ 4

Trademark Notices ................................................................................................. 4

Limitation of Liability ............................................................................................... 4

Symbol Definition ...................................................................................................... 5

Abbreviations ............................................................................................................. 8

General Warnings and Cautions ............................................................................... 9

Part Number: 4117102-007

Fabius GS Operator’s Manual 1

Page 8

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 9

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Overview Chapter 1 - Introduction

Overview

Caution: For your safety and that of your patients,

strictly follow this instruction manual.

Any use of the Fabius GS

and strict observation of these instructions. The unit is

only to be used for purposes specified here.

Recommendations

Because of the sophisticated nature of Draeger

Medical anesthesia equipment and its critical

importance in the operating room setting, it is highly

recommended that only appropriately trained and

experienced professionals, using authentic Draeger

Medical spare parts, be permitted to service and

maintain this equipment. Please contact DrägerService

at (800) 543-5047 or (215) 721-5402 for service of this

equipment.

Draeger Medical also recommends that its anesthesia

equipment be serviced at six-month intervals. Periodic

Manufacturer's Certification Agreements are available

for equipment manufactured by Draeger Medical. For

further information concerning these agreements,

contact DrägerService at (800) 543-5047 or (215) 721-

5402.

®

requires full understanding

are known to the trained operator. Instructions,

warnings, and caution statements are limited,

therefore, to the specifics of the Draeger Medical, Inc.

design. This publication excludes references to

hazards which are obvious to a medical professional,

to the consequences of product misuse, and to

potentially adverse effects in patients with abnormal

conditions. Product modification or misuse can be

dangerous. Draeger Medical, Inc. disclaims all liability

for the consequences of product alterations or

modifications, as well as for the consequences which

might result from the combination of Draeger Medical,

Inc. products with products supplied by other

manufacturers if such a combination is not endorsed

by Draeger Medical, Inc.

The operator of the anesthesia system must recognize

that the means of monitoring and discovering

hazardous conditions are specific to the composition of

the system and the various components of the system.

It is the operator, and not the various manufacturers or

suppliers of components, who has control over the final

composition and arrangement of the anesthesia

system used in the operating room. Therefore, the

responsibility for choosing the appropriate safety

monitoring devices rests with the operator and user of

the equipment.

Rev: —

Part Number: 4117102-007

Not for Use in Areas of Explosion Hazard

The Fabius GS is neither approved nor certified for use

in areas where combustible or explosive gas mixtures

are likely to occur. To avoid explosion hazards,

flammable anaesthetic agents such as ether and

cyclopropane or other flammable substances must not

be used in this machine. Only anaesthetic agents that

comply with the requirements on non-flammable

anaesthetic agents in the IEC Standard, Particular

requirements for the safety of anaesthetic machine,

are suitable for use in this machine.

Safe Connection with Other Electrical

Equipment

Electrical connections to equipment which are not

listed in these Instructions for Use should only be

made following consultations with the respective

manufacturers or an expert and shall be in compliance

with national medical device regulations.

Operator’s Responsibility

The equipment design, the accompanying literature,

and the labeling on the equipment take into

consideration that the purchase and use of the

equipment are restricted to trained professionals, and

that certain inherent characteristics of the equipment

The Fabius GS is equipped to monitor breathing circuit

pressure, exhaled volume and inspired oxygen, and to

sound an alarm when any of these parameters violates

a preset limit. The Fabius GS should not be used if any

of these monitors are not functioning properly. Draeger

Medical, Inc. also recommends that the Fabius GS

only be used to deliver anesthesia and/or mechanical

ventilation in accordance with the guidelines for patient

monitoring published by the American Society of

Anesthesiologists. In addition to volume, pressure, and

oxygen monitoring, these guidelines require the use of

a capnometer to monitor inspired and expired carbon

dioxide as well as other patient monitors including

continuous electrocardiography, pulse oximetry, and

arterial blood pressure monitoring. Anesthetic agent

monitoring and temperature monitoring are also

strongly recommended. The responsibility for the

selection of the best level of patient monitoring belongs

solely to the equipment operator. To this extent, the

manufacturer, Draeger Medical, Inc., disclaims

responsibility for the adequacy of the monitoring

package selected for use with the anesthesia system.

However, Draeger Medical, Inc. is available for

consultation to discuss monitoring options for different

applications.

Fabius GS Operator’s Manual 3

Page 10

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 1 - Introduction Intended Use

Restriction

Caution: Federal law and regulations in the United

States restrict this device to sale by, or on

the order of, a physician.

Intended Use

Fabius GS is an inhalation anesthesia machine for

use in operating, induction and recovery rooms.

It may be used with O

medical gas pipeline system or by externally mounted

gas cylinders.

Fabius GS is equipped with a compact breathing

system, providing fresh gas decoupling, PEEP, and

pressure limitation.

The following ventilation options are available:

• Volume Controlled Ventilation

• Pressure Controlled Ventilation (Optional)

• Pressure Support (Optional)

• Manual Ventilation

• Spontaneous Breathing

Fabius GS is equipped with an electrically driven and

electronically controlled ventilator and monitors for

airway pressure (P), volume (V), and inspiratory

oxygen concentration (FiO

As per EN740 (Anesthetic Workstations and their

Modules- Particular Requirements), additional

monitoring of the concentrations of CO

agent is required when the machine is in use.

Do not use readily flammable anesthetic agents

such as ether, cyclopropane, etc.

2, N2O, and AIR supplied by a

2).

2 and anesthetic

Safety Features

• Monitoring of P, V, FiO2

•O2 SUPPLY LOW alarm

• Integrated S-ORC = Sensitive Oxygen Ratio

Controller (control device to ensure minimum

O

2 concentration of 23 Vol.%).

Per EN740, burns may occur if antistatic or electrically

conductive ventilation tubes are used in combination

with high-frequency electrical surgery equipment.

Therefore, per EN740, these types of breathing tubes

are not recommended.

Caution: Do not use Fabius GS in the environment

of NMR tomography equipment.

Malfunctions may result, thereby

endangering the patient.

Caution: Do not use mobile phones within a distance

of 10 meters from the machine. Mobile

phones can cause malfunctions in electrical

medical equipment, thereby endangering

the patient and the operator.

Copyright, Trademark, and

Limitation of Liability

Copyright

Copyright 2004 by Draeger Medical, Inc. All rights

reserved. No part of this publication may be

reproduced, transmitted, transcribed, or stored in a

retrieval system in any form or by any means,

electronic or mechanical, including photocopying and

recording, without written permission of Draeger

Medical, Inc. The exceptions to this are

“Recommendations for Typical Cleaning and

Disinfection After Use” on page 114 and “Daily and

Preuse Checkout Form” in Appendix A.

Trademark Notices

DrägerService, Fabius GS, and Vitalink are registered

trademarks of Draeger Medical, Inc. Fabius and Vapor

are registered trademarks of Dräger. All other products

or name brands are trademarks of their respective

owners.

Limitation of Liability

Draeger Medical, Inc.'s liability, whether arising from or

related to the manufacture and sale of the products,

their installation, demonstration, sales representation,

use, performance, or otherwise, including any liability

based upon Draeger Medical, Inc.'s product warranty,

is subject to and limited to the exclusive terms of

Draeger Medical, Inc.'s limited warranty, whether

based upon breach of warranty or any other cause of

action whatsoever, regardless of any fault attributable

to Draeger Medical, Inc. and regardless of the form of

action (including, without limitation, breach of warranty,

negligence, strict liability, or otherwise).

Draeger Medical, Inc. shall in no event be liable for any

special, incidental, or consequential damages

(including loss of profits) whether or not foreseeable

and even if Draeger Medical, Inc. has been advised of

the possibility of such loss or damage. Draeger

Medical, Inc. disclaims any liability arising from a

combination of its product with products from another

manufacturer if the combination has not been

endorsed by Draeger Medical, Inc.. Buyer understands

Part Number: 4117102-007

Rev: —

4 Fabius GS Operator’s Manual

Page 11

CUS

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Symbol Definition Chapter 1 - Introduction

that the remedies noted in Draeger Medical Inc.'s

limited warranty are its sole and exclusive remedies.

Furthermore, buyer acknowledges that the

consideration for the products, equipment, and parts

sold reflects the allocation of risk and the limitations

of liability referenced herein.

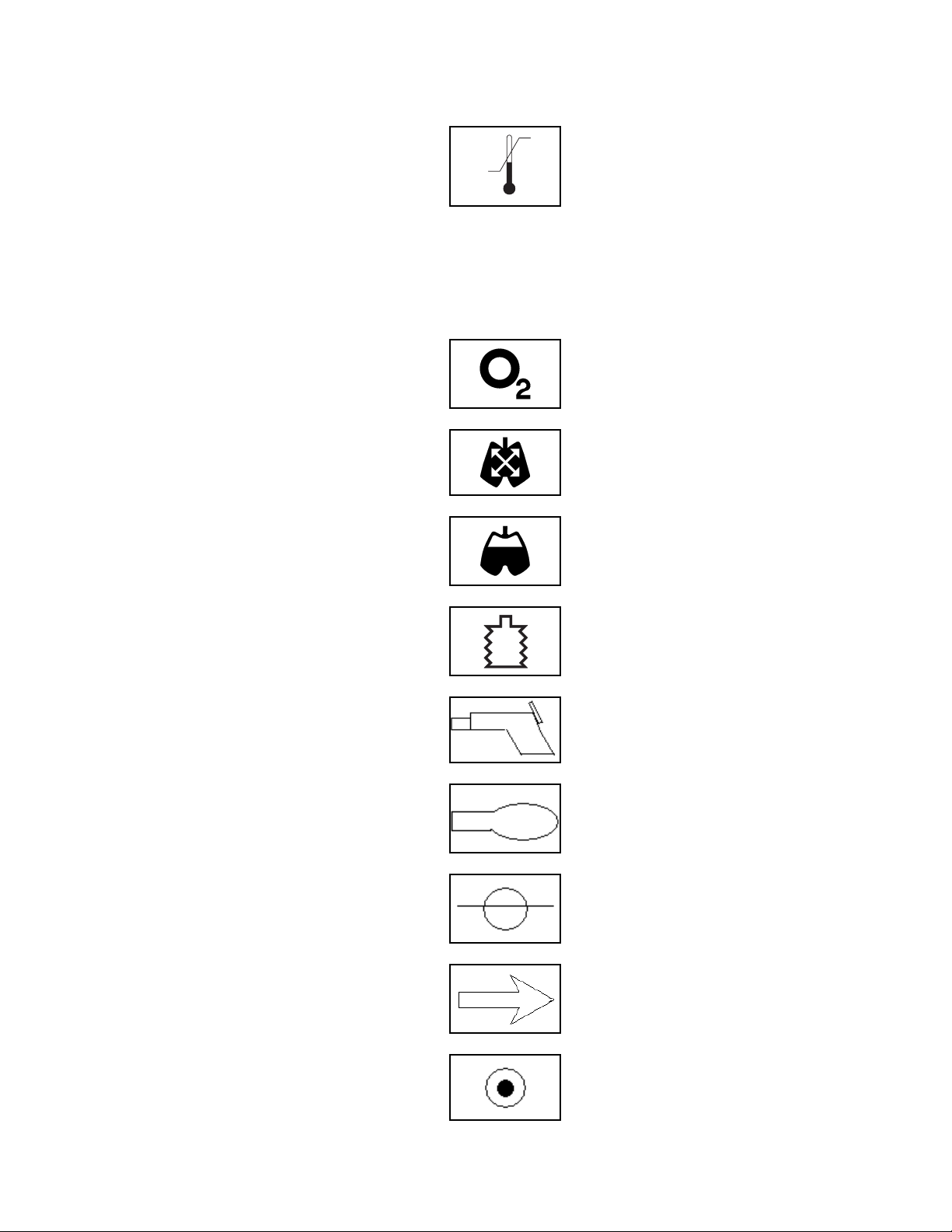

Symbol Definition

The following symbols appear on the labels on the

back of the Fabius GS and are defined below.

Caution: Refer to accompanying documents

before operating equipment.

!

Caution: Risk of electric shock, do not remove

cover. Refer servicing to a

DrägerService representative.

Rev: —

Degree of protection against electric shock: Type B.

Registration Mark

Year Manufactured

The following symbols appear on the shipping

container of the Fabius GS.

This end up.

Handle with care.

Part Number: 4117102-007

Keep dry.

Fabius GS Operator’s Manual 5

Page 12

REV DESCRIPTION DATE BY ECN/DCNAPVD

11-28-00

SAG DLB

00-0922

_

APPROVED

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 1 - Introduction Symbol Definition

Minimum and maximum storage temperatures.

The following symbols are used on other locations of

the Fabius GS to provide quick and easy recognition

of product functions.

Oxygen Concentration Sensor Port

Breathing Pressure Sensor Port

Breathing Volume Sensor Port

60°c

-10°c

Ventilator Port

Pipeline, Gauge, Pipeline Inlet

Breathing Bag

Flowmeter Level Indicator

Indicates Direction

Total Power Applied

Part Number: 4117102-007

Rev: —

6 Fabius GS Operator’s Manual

Page 13

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Symbol Definition Chapter 1 - Introduction

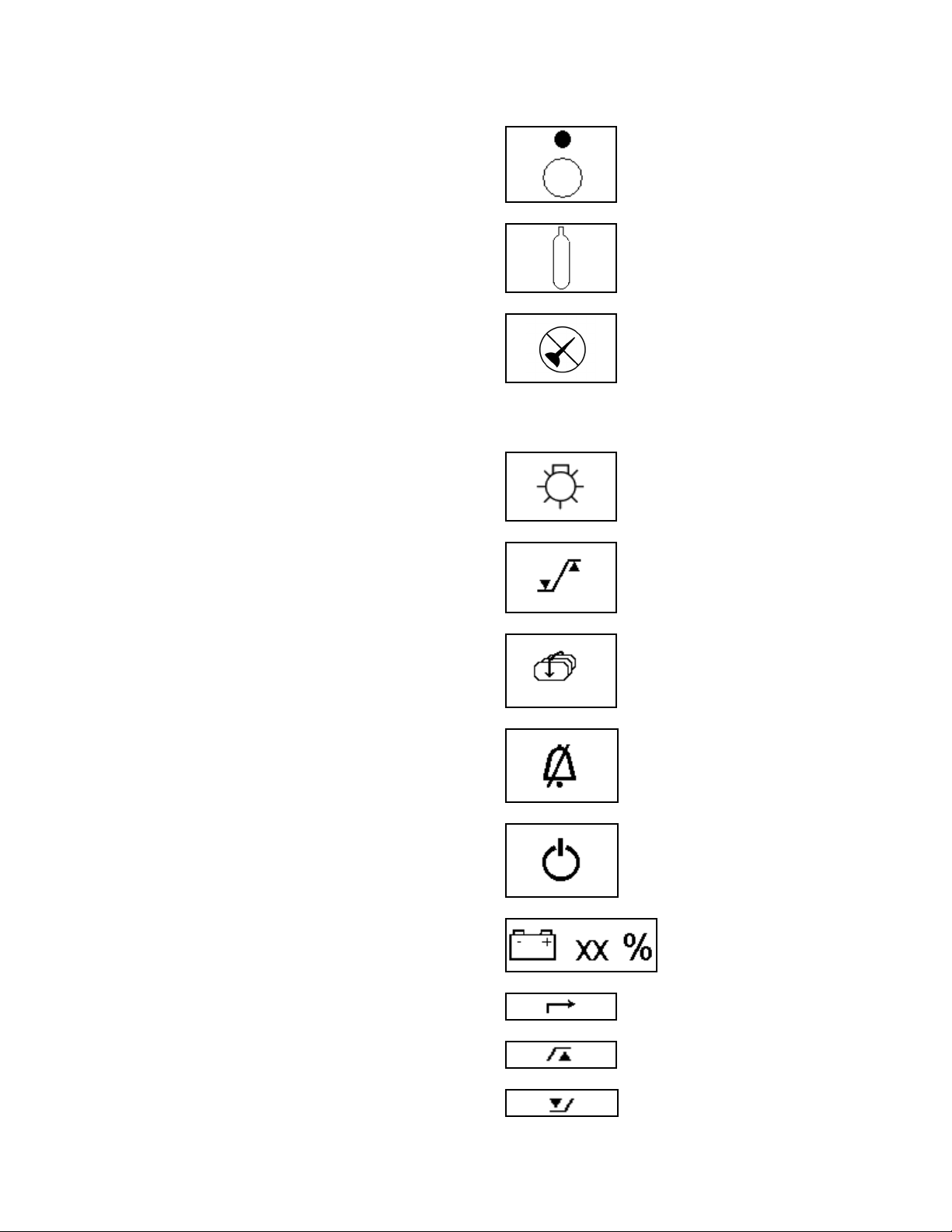

Partial Power Applied

Cylinder Gauge, Remote Cylinder Inlet

Do Not Oil

The following symbols are used on the Fabius GS

monitoring user interface.

Table Top Light

Rev: —

Part Number: 4117102-007

Upper and Lower Alarm Limits

Return to Home Screen

Suppress Alarm Tone for Two Minutes

Standby Mode

Available Operating Capacity of UPS

Close Menu, Back to Previous Menu

Upper Alarm Limit

Lower Alarm Limit

Fabius GS Operator’s Manual 7

Page 14

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 1 - Introduction Abbreviations

Mains Applied/Mains Power

Alarm Off

Setup Screen

Abbreviations

Abbreviation Meaning

FLOW Expiratory flow

FiO

2

Freq Ventilation frequency

Freq Min Minimum ventilation frequency setting for Pressure Support Apnea Ventilation

MAN Manual ventilation

MEAN Mean (airway) pressure

N

O Nitrous Oxide

2

O

2

PAW Airway pressure

PEAK Peak (airway) pressure

PEEP Positive end-expiratory pressure

PINSP Pressure setting in Pressure Control mode or the sum of PSUP and PEEP

PLAT Plateau airway pressure

Pmax Maximum (airway) pressure setting

PSUP Pressure Support

SPONT Spontaneous breathing

TI : TE Ratio of inspiratory to expiratory time

Inspiratory O2 concentration

Oxygen

settings in Pressure Support mode

Part Number: 4117102-007

Rev: —

Tip : Ti Ratio of inspiratory pause time to inspiratory time

UPS Uninterruptible power supply

VAC Vacuum (e.g., for secretion aspiration)

VT Tidal volume

8 Fabius GS Operator’s Manual

Page 15

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

General Warnings and Cautions Chapter 1 - Introduction

Rev: —

Part Number: 4117102-007

General Warnings and Cautions

The following list of warnings and cautions apply to

general operation and maintenance of the

Fabius GS. Warnings and cautions about installing and

operating specific parts appear with those topics.

• A Warning statement gives important information

that, if ignored, could lead directly to personal

injury.

• A Caution statement gives important information

that, if ignored, could lead directly to equipment

damage and indirectly to personal injury.

Warning: Any person involved with the setup,

operation, or maintenance of the

Fabius GS anesthesia system must be

thoroughly familiar with this instruction

manual.

Warning: This anesthesia system will not respond

automatically to certain changes in patient

condition, operator error, or failure of

components. The system is designed to be

operated under the constant surveillance

and control of a qualified operator.

Warning: No third-party components shall be

attached to the anesthesia machine,

ventilator, or breathing system (except for

certain approved exceptions). For more

information, contact your local Authorized

Service Organization or DrägerService at:

DrägerService

Draeger Medical, Inc.

3122 Commerce Drive

Telford, PA 18969

Tel: (215) 721-5402

(800) 543-5047

Fax: (215) 721-5784

Warning: Each institution and user has a duty to

independently assess, based on its, his, or

her unique circumstances, what

components to include in an anesthesia

system. However, Draeger Medical, in the

interest of patient safety, strongly

recommends the use of an oxygen

analyzer, pressure monitor, volume

monitor, and end-tidal CO2 monitor in the

breathing circuit at all times.

Warning: When moving the anesthesia machine,

remove all monitors and equipment from

the top shelf and use only the machine

handles or push/pull bars. The anesthesia

machine should only be moved by people

who are physically capable of handling its

weight. Draeger Medical recommends that

two people move the anesthesia machine

to aid in maneuverability. Exercise special

care so that the machine does not tip

when moving up or down inclines, around

corners, and across thresholds (for

example, in door frames and elevators).

Do not attempt to pull the machine over

any hoses, cords, or other obstacles on

the floor.

Warning: Apply the caster brakes when the

anesthesia machine is in use.

Caution: Although the Fabius GS is designed to

minimize the effects of ambient radiofrequency interference, machine functions

may be adversely affected by the

operation of electrosurgical equipment or

short wave or microwave diathermy

equipment in the vicinity.

Caution: Communications with external equipment

may be temporarily affected by

electromagnetic interference due to the

use of electrosurgical equipment.

Caution: Do not place more than 40 pounds on top

of the Fabius GS monitor housing.

Caution: Never allow the battery to completely

discharge. If the battery does discharge

completely, recharge immediately.

Caution: Front GCX rails have a maximum

accessories weight load of 5 lb./2.3 kg,

extended out at 3 in./7.6 cm from the rail,

at any position on the rail.

Caution: Pressure Support ventilation is triggered

by the patient's spontaneous effort to

breath. Most anesthetic agents will cause

patients to have reduced ventilatory

responses to carbon dioxide and to

hypoxemia. Therefore, patient triggered

modes of ventilation may not produce

adequate ventilation. Additionally, the use

of neuromuscular blocking agents will

interfere with patient triggering.

Fabius GS Operator’s Manual 9

Page 16

Weight

r

Approved

Option

Possible Tip Over

T

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 1 - Introduction General Warnings and Cautions

Fabius GS

Back Left Side

Accessory Option

with Breathing System

Mounted on Left Side

Caution: Possible Tip Ove

Hazard If Mounting Accessories

Exceed Approved Limits.

Mounting Limits

15.0 in.

38.1 cm

10.0 in.

25.4 cm

Mount Arm Length

5.0 in.

12.7 cm

Weight

30 lb. / 13.6 kg

28 lb. / 12.7 kg

26 lb. / 11.8 kg

24 lb. / 10.9 kg

22 lb. / 10.0 kg

20 lb. / 9.1 kg

18 lb. / 8.2 kg

Option

16 lb. / 7.3 kg

14 lb. / 6.4 kg

12 lb. / 5.4 kg

10 lb. / 4.5 kg

Option

Weight

60 lb. / 27.2 kg

55 lb. / 24.9 kg

50 lb. / 22.7 kg

45 lb. / 20.4 kg

40 lb. / 18.1 kg

35 lb. / 15.9 kg

30 lb. / 13.6 kg

25 lb. / 11.3 kg

20 lb. / 9.1 kg

15 lb. / 6.8 kg

10 lb. / 4.5 kg

Approved

Mounting Limits

MAXIMUM WEIGH

PER ARM 30 lb.

COMBINED MULTIPLE

ARM WEIGHTS NOT

TO EXCEED 60 lb. MAX.

5.0 in.

12.7 cm

10.0 in.

25.4 cm

Mount Arm Length

15.0 in.

38.1 cm

Fabius GS

Back Right Side

Accessory Option

with Breathing System

Mounted on Left Side

Caution:

Hazard If Mounting Accessories

Exceed Approved Limits.

Part Number: 4117102-007

Rev: —

10 Fabius GS Operator’s Manual

Page 17

n

10.0 in.

r

A

Caution:

r

T

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

General Warnings and Cautions Chapter 1 - Introduction

Fabius GS

Back Left Side

Accessory Option

with Breathing System

Mounted on Right Side

Caution: Possible Tip Ove

Hazard If Mounting Accessories

Exceed Approved Limits.

pproved

Mounting Limits

15.0 in.

38.1 cm

25.4 cm

Mount Arm Length

5.0 in.

12.7 cm

Option

Weight

60 lb. / 27.2 kg

55 lb. / 24.9 kg

50 lb. / 22.6 kg

45 lb. / 20.4 kg

40 lb. / 18.1 kg

35 lb. / 15.8 kg

30 lb. / 13.6 kg

Optio

25 lb. / 11.3 kg

Weight

20 lb. / 9 kg

15 lb. / 6.8 kg

10 lb. / 4.5 kg

Rev: —

Part Number: 4117102-007

Option

Weight

30 lb. / 13.6 kg

28 lb. / 12.7 kg

26 lb. / 11.7 kg

24 lb. / 10.8 kg

22 lb. / 9.9 kg

20 lb. / 9.0 kg

18 lb. / 8.1 kg

16 lb. / 7.2 kg

14 lb. / 6.3 kg

12 lb. / 5.4 kg

10 lb. / 4.5 kg

Approved

Mounting Limits

MAXIMUM WEIGH

PER ARM 30 lb.

COMBINED MULTIPLE

ARM WEIGHTS NOT

TO EXCEED 60 lb. MAX.

5.0 in.

12.7 cm

10.0 in.

25.4 cm

Mount Arm Length

Fabius GS

Back Right Side

Accessory Option

with Breathing System

Mounted on Right Side

Possible Tip Ove

Hazard If Mounting Accessories

Exceed Approved Limits.

15.0 in.

38.1 cm

Fabius GS Operator’s Manual 11

Page 18

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 19

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 2 - Configurations and Components Contents

Configurations and Components

Contents

Typical Fabius GS Configuration ............................................................................. 15

Components ............................................................................................................ 15

Vaporizers (Optional) ............................................................................................ 15

Dräger Vapor® Interlock System (Optional) ......................................................... 15

Selectatec™* (Optional) ....................................................................................... 16

Auxiliary Oxygen Flowmeter (Optional) ................................................................ 16

Rev: —

Part Number: 4117102-007

Fabius GS Operator’s Manual 13

Page 20

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 21

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Typical Fabius GS Configuration Chapter 2 - Configurations and Components

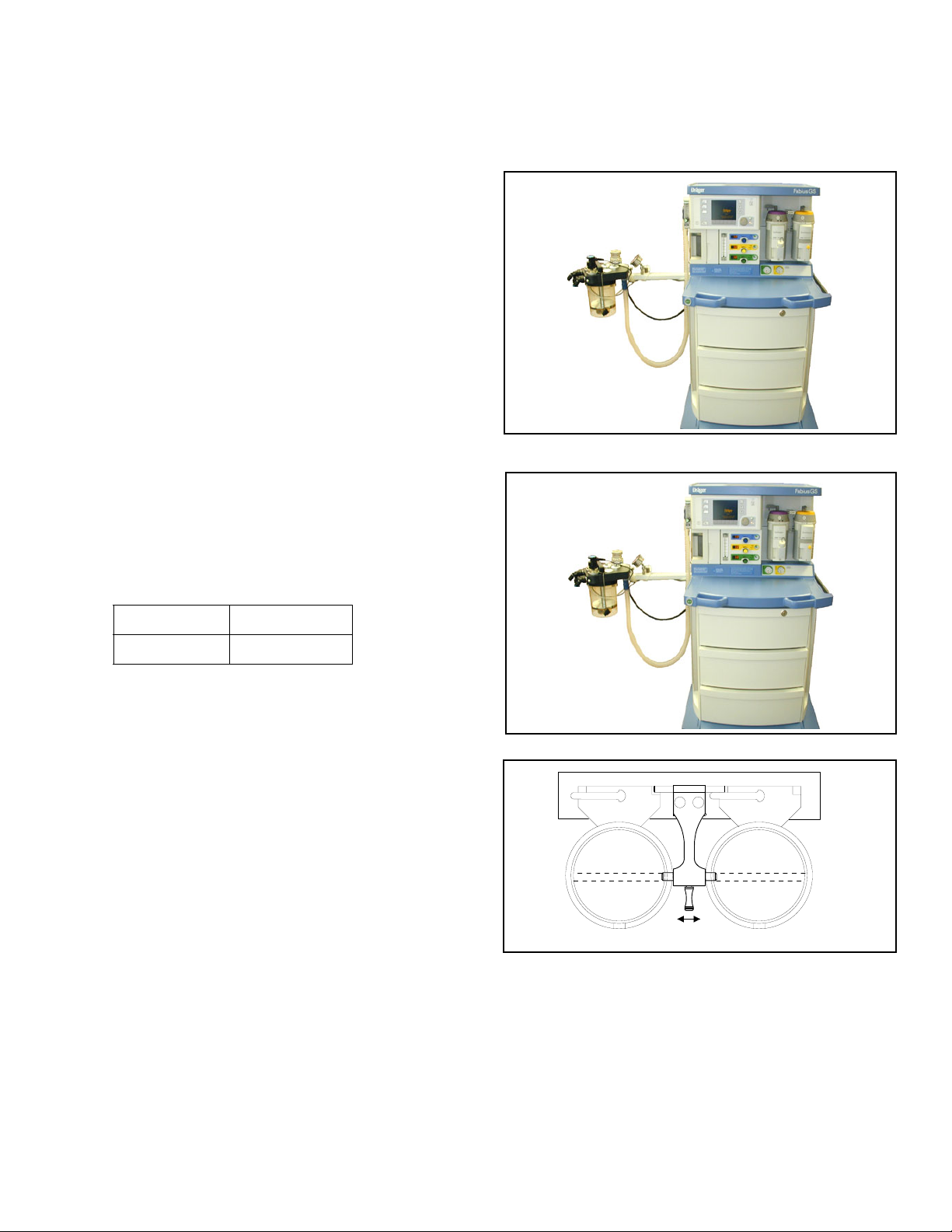

Typical Fabius GS Configuration

Figure 1. Fabius GS Anesthesia Machine The Fabius GS Inhalation Anesthesia Machine is a

modular system consisting of a basic gas-delivery

module with a variety of components and

configuration designs to meet the requirements of

various anesthesia delivery applications.

• 2-gas version (O2 and Air)

• 3-gas version (O2, N2O, and Air)

• pin index cylinder yokes and pressure gauges

Components

Figure 2. Dräger Vapor SystemVaporizers (Optional)

Rev: —

Part Number: 4117102-007

The Dräger Vapor® anesthetic agent vaporizers (1 in

Figure 2) are used to enrich the fresh gas with a

precisely metered quantity of vapor from the liquid

anesthetic agent being used, i.e. Isoflurane,

Halothane, Enflurane, or Sevoflurane.

When using a third-party Desflurane vaporizer:

220 V Mains Devapor*

110 V Mains D-Tec*

* Devapor and D-Tec are available through your local Desflurane

representative.

®

Interlock System

(Optional)

The Fabius GS is configured for two vaporizers. An

interlock system is used to ensure only one vaporizer

can be used at a time.

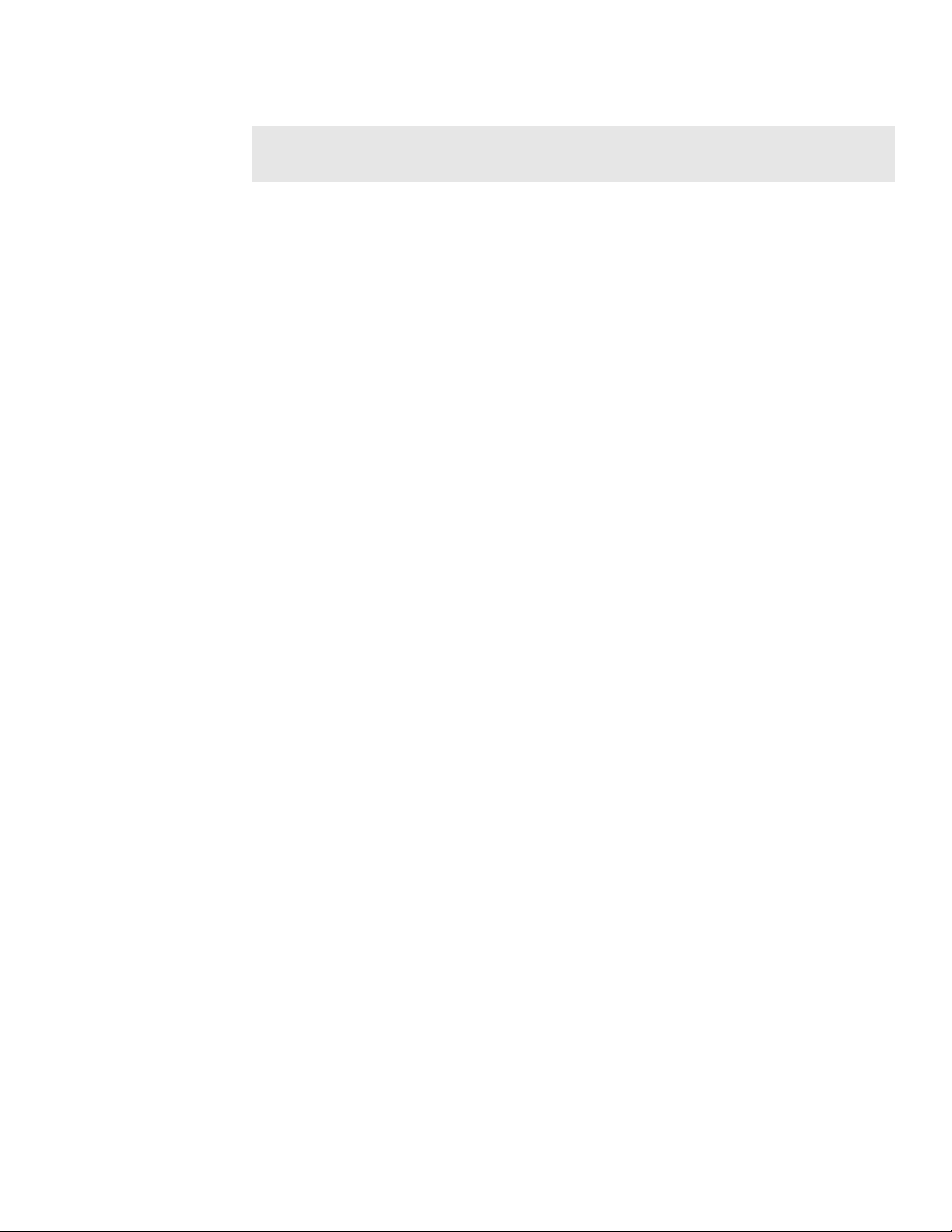

Note that the selector lever (1 in Figure 3) is shown in

the center position. This ensures that both vaporizers

are in the locked position. Also, this is the

recommended position for the selector lever when

moving the Fabius GS.

Moving the selector lever away from the desired

vaporizer allows that vaporizer to be utilized and the

other to be locked out of use.

1 1

Figure 3. Dräger Vapor Interlock SystemDräger Vapor

OP00520

1

Fabius GS Operator’s Manual 15

Page 22

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 2 - Configurations and Components Components

Selectatec

™*

(Optional)

The interlock system for the Selectatec is built into

the vaporizers. When a vaporizer is selected for use,

the interlocking index pins will protrude from the

sides of the vaporizer thereby not allowing the

neighboring vaporizer to be opened. For more

specific information on the Selectatec, refer to the

Selectatec Vaporizer’s instruction manual.

*Selectatec™ is a registered trademark of Datex-Ohmeda.

For the delivery of a metered flow of pure oxygen (for

example, delivery of oxygen through a nasal

cannula), an optional auxiliary oxygen flowmeter

(1 in Figure 4) can be mounted on the left side of the

flowmeter bank. This flowmeter can be used when

the machine is turned off. A zero stop prevents

damage to the flow control valve seat.

Figure 4. Auxiliary Oxygen FlowmeterAuxiliary Oxygen Flowmeter (Optional)

1

16 Fabius GS Operator’s Manual

Part Number: 4117102-007

Rev: —

Page 23

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Contents

Operating Concept

Contents

Overview ................................................................................................................. 19

Standard Function Controls ..................................................................................... 19

Home Key ............................................................................................................. 19

Mains Power Applied LED .................................................................................... 19

Selecting and Confirming ..................................................................................... 19

Tabletop Light Key ................................................................................................ 19

Cross-Functional Controls and Displays ................................................................. 20

Key LED Indicators ............................................................................................... 20

Rev: —

Setup Key ............................................................................................................. 20

Status Bar ............................................................................................................. 21

Monitoring ................................................................................................................ 22

Monitoring Controls .............................................................................................. 22

Monitoring Windows ............................................................................................. 23

Selecting/Setting Monitoring Functions ................................................................ 24

Ventilation ................................................................................................................ 26

Ventilation Controls ............................................................................................... 26

Ventilator Compliance Compensation .................................................................. 26

Ventilation Screens ............................................................................................... 27

Changing Ventilation Modes ................................................................................. 31

Selecting/Setting Ventilation Parameters ............................................................. 35

Fresh Gas Control ................................................................................................... 37

Fresh Gas Flow Monitoring Resolutions ................................................................. 38

Standard Resolution ............................................................................................. 38

High Resolution .................................................................................................... 38

Part Number: 4117102-007

Fabius GS Operator’s Manual 17

APL Valve ................................................................................................................ 39

Page 24

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 25

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Overview Chapter 3 - Operating Concept

Overview

This chapter provides an overview of the user

interface, which enables you to set and view

monitoring, ventilation, and status information using

the respective screens, windows, keys, soft keys,

and the rotary knob. See “Monitoring” on page 67 for

more information.

Figure 5. Ventilation Monitor Screen and System ControlsStandard Function Controls

Home Key

The Home key (1 in Figure 5) displays the main

screen (the screen in Figure 5) from anywhere in the

system.

Rev: —

Mains Power Applied LED

The Mains Power Applied LED (2 in Figure 5), when

illuminated, indicates that the machine is connected

to a Mains power source.

Selecting and Confirming

The rotary knob (3 in Figure 5) is used to select and

confirm functions by:

• Turning (Select)

Turning the rotary knob

• moves the cursor over the system

operating parameters or

• changes the value of a parameter that has

been confirmed for adjustment.

Note: This function is indicated in the examples

and instructions of this manual by

“select.”

• Pressing (Confirm)

Pressing the rotary knob either

1

4

2

3

• confirms the system operating parameter

to be adjusted or

• confirms the change to the selected

Part Number: 4117102-007

operating parameter.

Note: This function is indicated in the examples

and instructions of this manual by

“confirm.”

Tabletop Light Key

The Tabletop Light key (4 in Figure 5) turns on the

tabletop light.

Fabius GS Operator’s Manual 19

Page 26

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Cross-Functional Controls and Displays

Figure 6. Ventilation Monitor Screen and System ControlsCross-Functional Controls and

Displays

Cross-functional controls and displays are used for

both monitoring and ventilation functions.

Key LED Indicators

LED indicators (1 in Figure 6) within keys (Volume

Control, Pressure Control, Pressure Support, Man/

Spont, Alarm Silence, and Standby) illuminate when

that mode or function is selected and operating.

The Setup key is 2 in Figure 6.

1

2

3

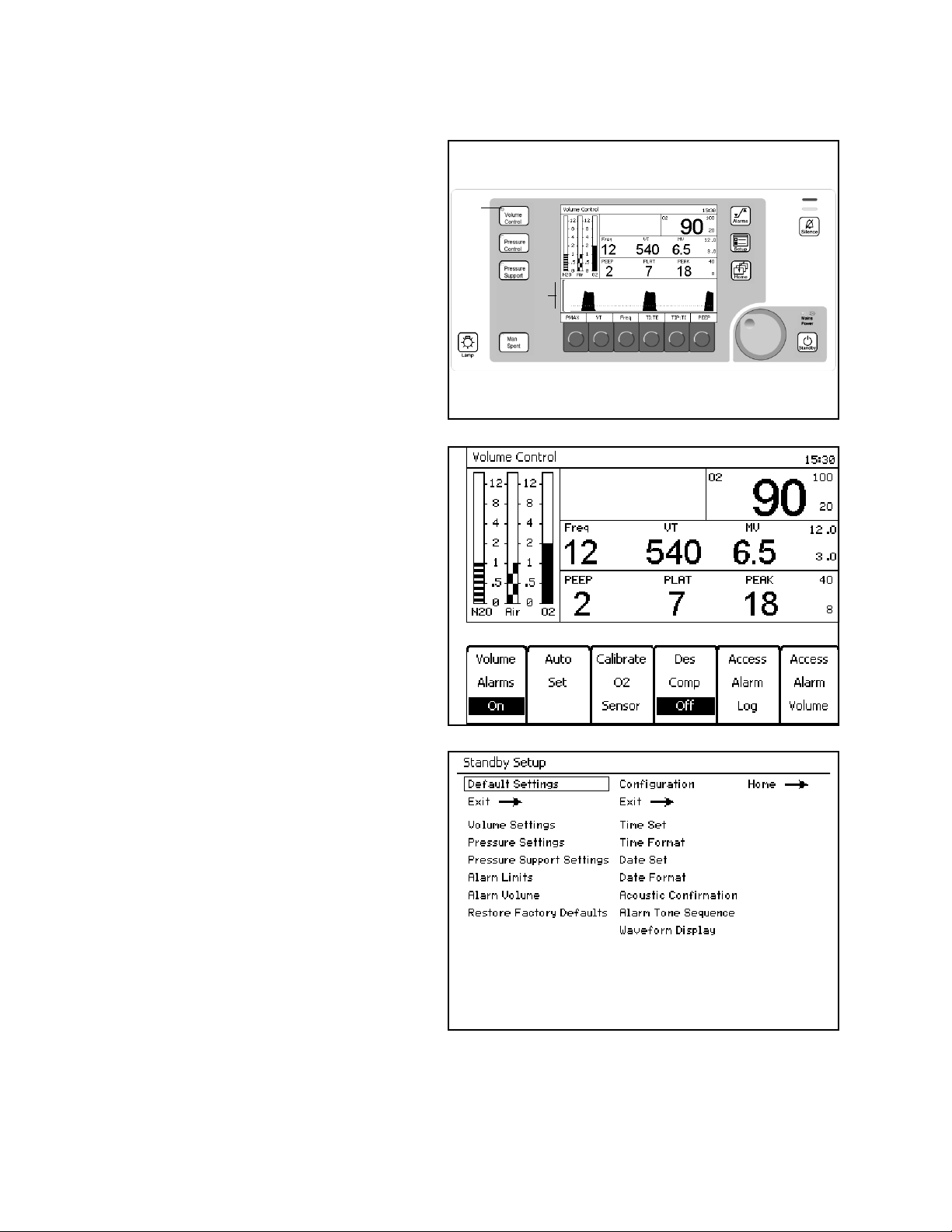

Figure 7. Setup WindowSetup Key

Pressed During A Ventilation Mode

The Setup window (1 in Figure 7) replaces the

Waveform area (3 in Figure 6).

The Setup window enables you to

• perform ventilation functions and

• view and change monitoring settings.

Note: The Volume Alarms On/Off soft key label

does not appear in ManSpont mode because

it is selectable on the ManSpont screen

(Figure 24 on page 30).

The Standby Setup screen (Figure 8) appears. The

Standby Setup screen enables you to define site

defaults and configuration.

1

Figure 8. Standby Setup ScreenPressed During Standby Mode

Part Number: 4117102-007

Rev: —

20 Fabius GS Operator’s Manual

Page 27

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Cross-Functional Controls and Displays Chapter 3 - Operating Concept

Figure 9. Status BarStatus Bar

The following numbers in parenthesis refer to

Figure 9.

Mode Display (1)

Displays the active ventilator mode.

Alarm Silence Status (2)

Displays the time remaining for alarm silence when

the Silence Alarms key is pressed.

Battery Power Level (3)

Displays the status of the reserve power.

Time (4)

Displays the time.

1234

Rev: —

Part Number: 4117102-007

Fabius GS Operator’s Manual 21

Page 28

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Monitoring

Figure 10. Ventilation Monitor Screen and System ControlsMonitoring

Monitoring Controls

LED Indicators

LED lamps (1 in Figure 10) in the upper right corner

of the control panel indicate the degree of urgency of

currently active alarms.

• Warning — Red Blinking

• Caution — Yellow Blinking

• Advisory — Yellow Continuous

Silence Alarms Key

The Silence Alarms key (2 in Figure 10) silences all

active alarm tones for 2 minutes. It resets the silence

time for two minutes each time the key is pressed.

The Alarm Limit key (3 in Figure 10) displays the

Alarm Limits window (1 in Figure 11), which appears

in the same location on all mode screens.

Setup Key

The Setup key (4 in Figure 10) is a cross-functional

control. See “Setup Key” on page 20.

1

3

2

4

Figure 11. Alarm Limit Configure WindowAlarm Limit Key

1

22 Fabius GS Operator’s Manual

Part Number: 4117102-007

Rev: —

Page 29

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Monitoring Chapter 3 - Operating Concept

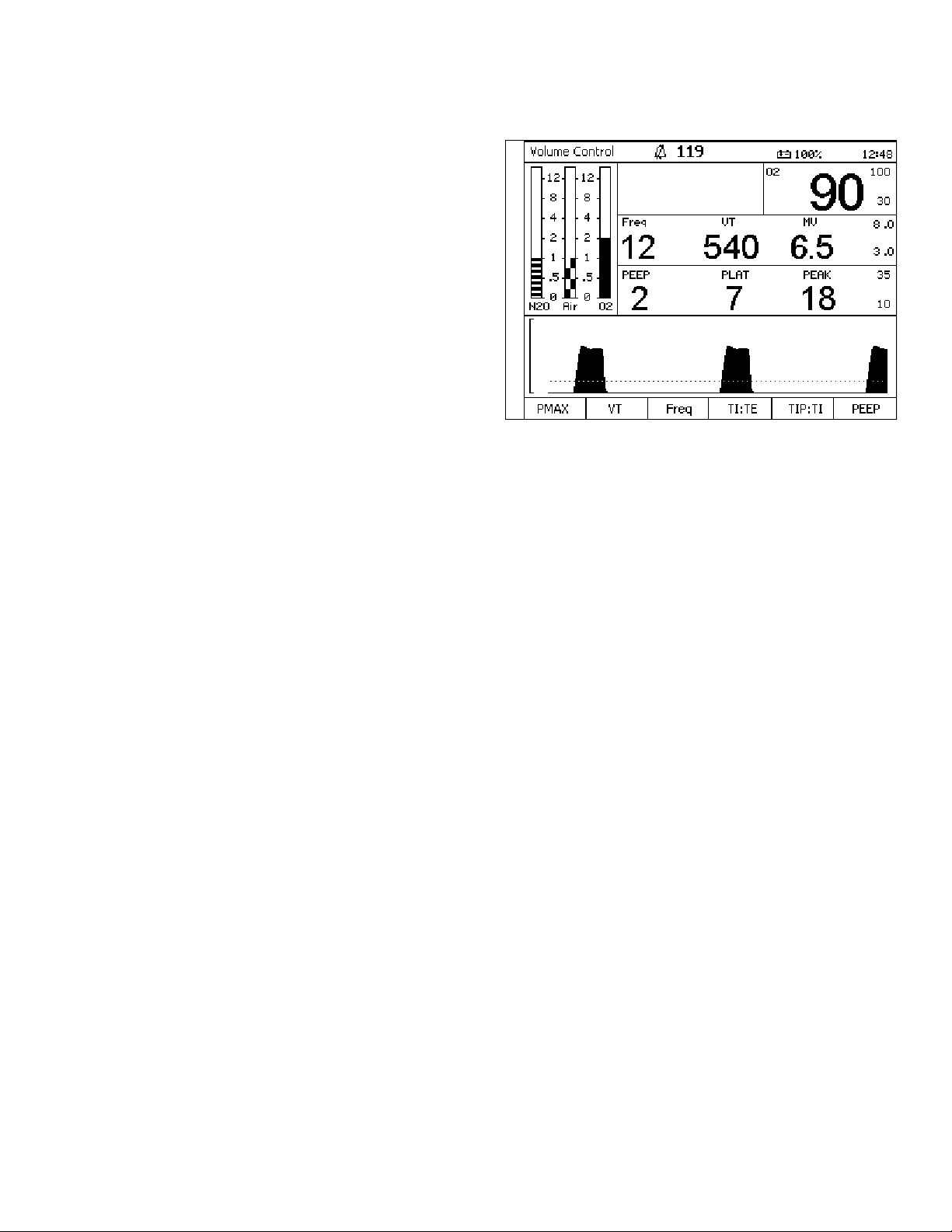

Figure 12. Monitor ScreenMonitoring Windows

The following numbers in boldface refer to

Figure 12.

Alarm Window

The Alarm window (1) displays up to four of the

highest priority alarms.

1

2

3

Oxygen Monitor Window

The Oxygen Monitor window (2) displays the

inspiratory oxygen concentration in units of percent

(%). It also displays the oxygen alarm limits in the farright section of this window.

Respiratory Volume Monitor Window

The Respiratory Volume Monitor window (3) displays

the patient's frequency (breaths per minute) or

respiratory rate, tidal volume, minute volume, the

minute volume high alarm limit, and the minute

volume low alarm limit.

Breathing Pressure Monitor Window

The Breathing Pressure Monitor window (4) displays

the patient's positive end expiratory pressure

(PEEP), mean airway pressure (MEAN) or plateau

airway pressure (PLAT), and peak airway pressure

(PEAK).

Breathing Pressure Trace Window

The Breathing Pressure Trace window (5) displays a

trace, or waveform, of the patient's breathing

pressure.

4

5

Rev: —

Part Number: 4117102-007

Fabius GS Operator’s Manual 23

Page 30

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Monitoring

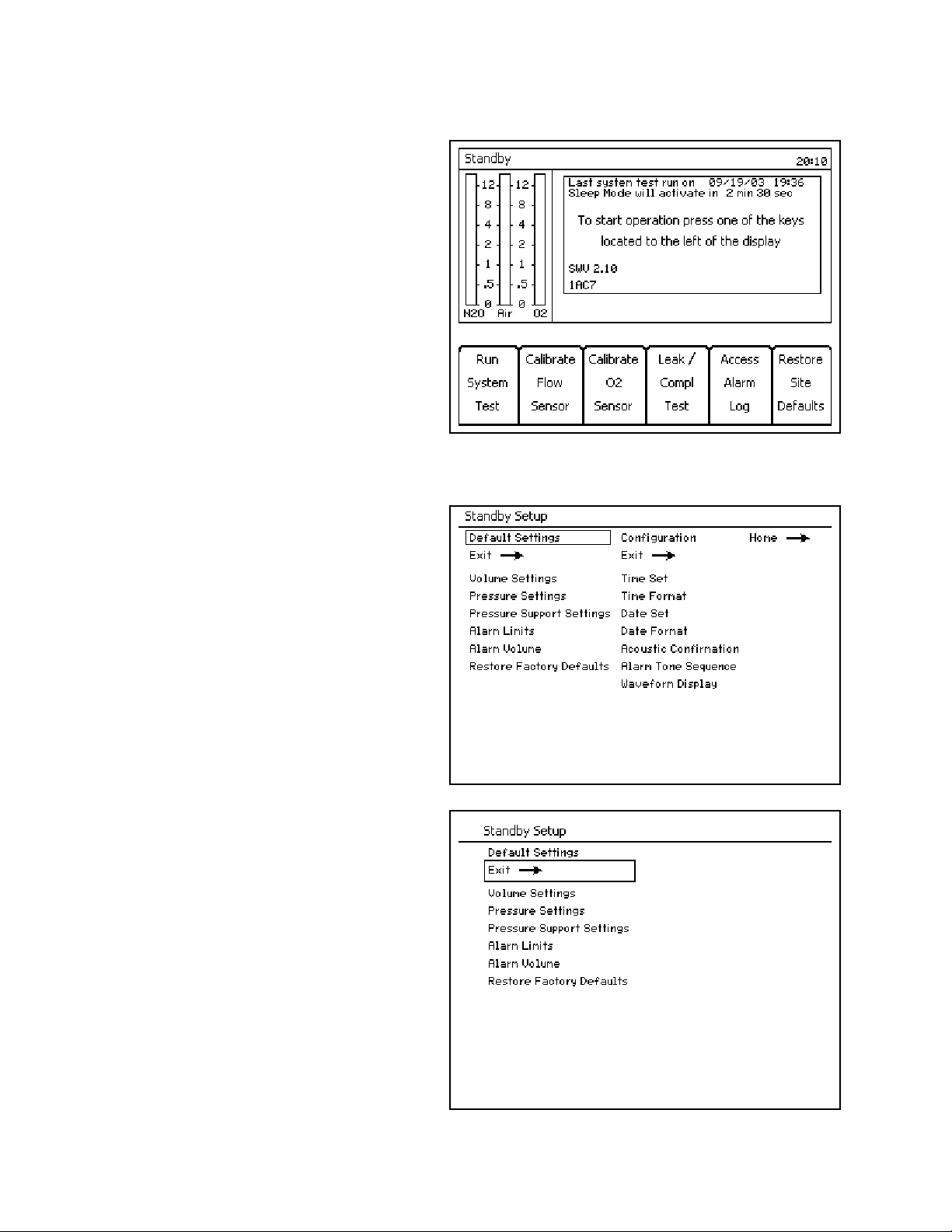

Figure 13. Standby ScreenSelecting/Setting Monitoring Functions

The following example describes changing alarm

limits on the Standby Setup Screen.

Example

1. Press the Setup key while the Standby Screen

(Figure 13) is active. The Standby Setup screen

(Figure 14) replaces the Standby Screen.

2. The rotary knob enables you to select the

“Default Settings” or “Configuration” label.

Select and confirm the “Default Settings” label.

The Default Settings column is selected

(Figure 15).

Note: Selecting and confirming the return arrow

(1 in Figure 14) will deactivate the Standby

Setup screen and activate the Standby

screen (Figure 13).

Figure 14. Standby Setup ScreenNote: Selecting and confirming the return arrow

(1 in Figure 15) will deselect the Default

Settings column and reselect the Default

Settings label as in Figure 14.

1

Figure 15. Standby Setup Screen Default Settings Selected

1

24 Fabius GS Operator’s Manual

Part Number: 4117102-007

Rev: —

Page 31

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Monitoring Chapter 3 - Operating Concept

Figure 16. Standby Setup Screen Default Alarm Limits3. Select and confirm the “Alarm Limits” label.

The Default Alarm Limits window appears

(1 in Figure 16).

1

Rev: —

4. Select the alarm limit value that needs to change

(Figure 17).

5. Confirm the alarm limit value and select a new

value for the alarm limit (ex., in Figure 18, the

value was changed from 30 to 25).

6. Confirm the new value for the alarm limit.

The new alarm limit value is saved and the cursor

moves over the return arrow.

Figure 17. Standby Setup Screen Default Alarm Limits

Select

Figure 18. Standby Setup Screen Default Alarm Limits

Confirm

Part Number: 4117102-007

Fabius GS Operator’s Manual 25

Page 32

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Ventilation

Figure 19. Ventilation Monitor Screen and System ControlsVentilation

Note: Pressure Control and Pressure Support

ventilation modes, described in this manual,

are optional.

1

Ventilation Controls

The following numbers in boldface refer to Figure 19.

Ventilation Mode Keys

Ventilation modes are selected by pressing one of

the ventilation mode keys (1, 2, 3, 4) and are

confirmed by pressing the rotary knob. If the

selection is not confirmed, the ventilation mode will

not change.

Setup Key

The Setup key (5) is a cross-functional control. See

“Setup Key” on page 20.

2

3

4

7

5

6

Standby Key

The Standby key (6) switches the ventilator to

standby mode.

Monitoring and alarms are turned off and the

ventilator stops.

Soft Keys

Soft keys (7) select ventilation parameters and

functions.

Ventilator Compliance Compensation

Ventilator compliance compensation is continuously

applied during Volume Control so that the tidal

volume delivered to the patient corresponds to the Vt

setting. Ventilator compliance is determined during

the leak and compliance test performed from the

Standby mode. To have compliance compensation

work accurately, it is important that the patient hoses

used during the leak/compliance test match the type

of hoses used during the procedure.

Note: When the ventilator settings for Volume

Control cause the ventilator to operate at its

limits of performance, it is not possible for

the Fabius GS to apply compliance

compensation. If the ventilator's performance

limit is reached, it is not possible to

increment the Vt setting via the Volume

Control Settings window.

Part Number: 4117102-007

Rev: —

26 Fabius GS Operator’s Manual

Page 33

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Ventilation Chapter 3 - Operating Concept

Figure 20. Ventilation Monitor Screen and System ControlsVentilation Screens

Soft Key Labels

The following numbers in boldface refer to Figure 20.

Each soft key (1) is associated with a ventilation

parameter (2) that is associated with a specific

ventilation mode (3).

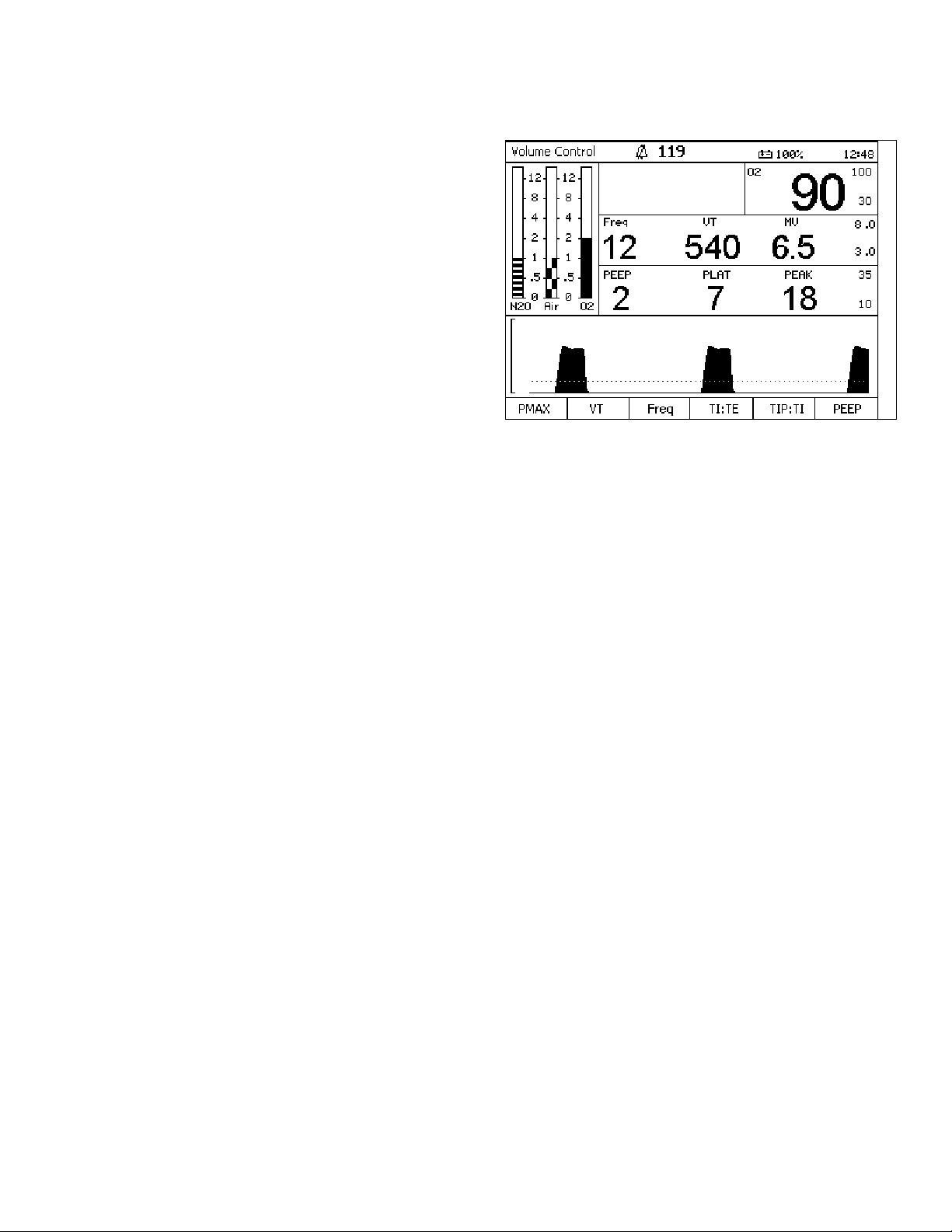

Figure 21. Volume Control Ventilation ScreenVolume Control Mode

The following soft key labels appear from left to right

along the bottom of the Volume Control screen.

See Figure 21.

3

2

1

Rev: —

Part Number: 4117102-007

• P

MAX (maximum ventilation pressure).

The range for P

15 to 70 cmH

MAX is

O.

2

The factory default value is

40 cmH

O.

2

• VT (tidal volume).

The range for VT is 20 mL to 1400 mL.

The factory default value is 600 mL.

• Freq (ventilation frequency).

The range for Frequency is 4 bpm to 60 bpm.

The factory default value is 12 bpm.

• T

I:TE (time ratio between inspiration time and

expiration time phases).

The range for T

I:TE is 4:1 to 1:4.

The factory default value is 1:2.

• T

IP:TI (relative inspiratory pause).

The range for T

IP:TI is 0% to 50%.

The factory default value is 10%.

• PEEP (positive end expiratory pressure).

The range for PEEP is

0 to 20 cmH

2

O.

The factory default value is

0 cmH

O.

2

Fabius GS Operator’s Manual 27

Page 34

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Ventilation

Figure 22. Pressure Control Ventilation ScreenPressure Control Mode

The following soft key labels appear from left to right

along the bottom of the Pressure Control screen.

See Figure 22.

• PINSP (inspiratory pressure setting).

The range for PINSP is

5 to 60 cmH

The factory default value is 15.

• Freq (ventilation frequency).

The range for Frequency is 4 bpm to 60 bpm.

The factory default value is 12 bpm.

• TI:TE (time ratio between inspiration and

expiration phases).

The range for TI:TE is 4:1 to 1:4.

The factory default value is 1:2.

• Insp Flow (maximum rate at which the piston

travels upward to create the target pressure).

The range for Insp Flow is

10 L/min to 75 L/min.

The factory default value is 30 L/min.

2

O.

• PEEP (positive end expiratory pressure).

The range for Peep is

0 to 20 cmH

2

O.

The factory default value is

0 cmH

O.

2

Pressure Support Mode

Pressure Support ventilation is intended to reduce

the work of breathing and is indicated for use only in

patients who are breathing spontaneously. Patients

who are not making spontaneous breathing efforts

are not candidates for Pressure Support ventilation.

Caution: Pressure Support ventilation is

triggered by the patient's

spontaneous effort to breathe. Most

anesthetic agents will cause patients

to have reduced ventilatory

responses to carbon dioxide and to

hypoxemia. Therefore, patient

triggered modes of ventilation may

not produce adequate ventilation.

Additionally, the use of

neuromuscular blocking agents will

interfere with patient triggering.

Part Number: 4117102-007

Rev: —

Apnea Ventilation is a feature within Pressure

Support ventilation. To enable Apnea Ventilation,

adjust the Freq Min setting to a value other than

“OFF.” If the detected patient spontaneous breathing

rate falls below the set value, the ventilator

automatically delivers a Pressure Support breath.

28 Fabius GS Operator’s Manual

Page 35

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Ventilation Chapter 3 - Operating Concept

When delivering Apnea Ventilation, the Fabius GS

uses the Pressure Support settings for PSUP, Insp

Flow, and PEEP.

If two consecutive Apnea Ventilation breaths occur,

the Caution message APNEA VENTILATION !!

appears in the Alarm window. The alarm is cleared

when a spontaneous breath is detected.

Figure 23. Pressure Support Ventilation ScreenThe following soft key labels appear from left to right

along the bottom of the Pressure Support screen.

See Figure 23.

• PSUP (inspiratory pressure setting).

The range for PSUP is

3 to 20 cmH

The factory default value is 10.

• Freq Min (minimum ventilation frequency

setting for Apnea Ventilation)

The range for Freq Min. is

3 to 20 bpm and “OFF.”

The factory default value is 3.

2O.

Rev: —

Part Number: 4117102-007

• Trigger (Trigger Level - patient inspiratory flow

threshold for Pressure Support).

The range for Trigger is

2 to 15 L/min.

The factory default value is 2.

• Insp Flow (maximum rate at which the piston

travels upward to create the target pressure).

The range for Insp Flow is

10 L/min to 85 L/min.

The factory default value is 30 L/min.

• PEEP (positive end expiratory pressure).

The range for Peep is

0 to 20 cmH

2O.

The factory default value is

0 cmH

2O.

Fabius GS Operator’s Manual 29

Page 36

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Ventilation

Figure 24. ManSpont Ventilation ScreenManSpont Mode

The “Apnea Pressure” and “Volume Alarms” labels

appear to the left of their ON/OFF label on the bottom

of the ManSpont screen. See Figure 24. Pressing the

ON/OFF soft key turns the applicable alarm(s) “ON”

or “OFF.”

Figure 25. Standby ScreenStandby Mode

The following soft key labels appear from left to right

along the bottom of the Standby screen.

See Figure 25.

• Run System Test

• Calibrate Flow Sensor

• Calibrate O2 Sensor

• Leak / Compl Test

• Access Alarm Log

• Restore Site Defaults

See “Standby Screen” on page 95 for details.

The Flow Meter Monitor window is a graphical

display of the flow rates of O

, Air, and N2O (L/min)

2

(1 in Figure 26).

Note: On some non-U.S. units of the Fabius GS,

the O2 and N2O virtual flow tubes have

changed positions.

Figure 26. Flow Meter Monitor WindowFlow Meter Monitor Window

Part Number: 4117102-007

1

Rev: —

30 Fabius GS Operator’s Manual

Page 37

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Ventilation Chapter 3 - Operating Concept

Figure 27. Ventilator Mode Change Confirmation Changing Ventilation Modes

Volume Control and Pressure Control

The following example describes changing

• from the present ventilation mode “Volume”

(1 in Figure 27)

• to the desired ventilation mode “Pressure”

(2 in Figure 27) with the desired ventilation

settings (3 in Figure 27).

1. Press the Pressure Control key.

The LED associated with this key starts blinking

(

4 in Figure 27). It remains blinking until the

selected mode of operation is confirmed.

A message appears (

5 in Figure 27) that

provides instructions to confirm the mode

change.

4

5

6

1

2

3

Rev: —

The Waveform window is replaced by the

Ventilator Settings window (

6 in Figure 27)

(Volume and Pressure modes only).

2. If the ventilation settings are correct, confirm the

mode change.

3. If the ventilation settings are not correct, for each

parameter that needs to change, press the

corresponding soft key, select the correct value,

and confirm the change.

4. When the parameter changes are completed,

confirm the ventilation mode change.

After the mode change is confirmed, the

Pressure Control key LED switches from blinking

to constantly on, the ventilator switches to the

selected operating mode, and the waveform is

restored after a short delay.

Part Number: 4117102-007

Fabius GS Operator’s Manual 31

Page 38

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Ventilation

Figure 28. Ventilator Mode Change SettingsVentilator Setting Selection

Selected ventilator settings for the new mode of

operation are automatically derived from the settings

and performance of the last confirmed automatic

ventilation mode. Settings affected in the new mode

will be highlighted (1 in Figure 28).

The settings for Freq., TI : TE, and PEEP are taken

directly from the settings used in the former mode as

applicable.

When changing from Volume Control to Pressure

Control, Pinsp is set to the Plateau pressure

developed in Volume Control.

When changing from Volume Control or Pressure

Support to Pressure Control, the suggested value for

Insp. Flow is either the last used value or the site

default value.

When changing from Pressure Control to Volume

Control, VT is set by dividing the last minute volume

by the respiratory rate.

1

When changing from Pressure Control to Volume

Control, the suggested value for TIP : TI is either the

last used value or the site default value.

When changing from Pressure Control to Volume

Control, PMAX is set 10 cmH2O higher than the

plateau pressure developed during Pressure Control.

When changing from Volume Control or Pressure

Control to Pressure Support, the suggested value for

Insp. Flow is either the last used value or the site

default value.

When changing from Volume Control or Pressure

Control to Pressure Support, the suggested value for

PSUP is either the last used value or the site default

value.

When changing from Volume Control or Pressure

Control to Pressure Support, the suggested value for

Trigger is either the last used value or the site

default value.

Part Number: 4117102-007

Rev: —

32 Fabius GS Operator’s Manual

Page 39

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Ventilation Chapter 3 - Operating Concept

Figure 29. Ventilator Mode Change to Man SpontManSpont

ManSpont (Manual/Spontaneous) is a non-automatic

mode of ventilation. However, the ventilation monitor

and alarms are still operational. In ManSpont mode,

the ventilator piston is moved to its top-most position

to minimize system compliance. Manual ventilation

(with APL valve pressure limit) can be delivered with

the APL valve switch in the MAN position.

Spontaneous ventilation (APL valve wide-open) can

occur with the APL valve in the SPONT position.

The following examples describe changing

1

3

4

Rev: —

• from the present ventilation mode “Volume”

(1 in Figure 29)

• to the desired ventilation mode “ManSpont”

(1 in Figure 30).

1. Press the ManSpont key.

The LED associated with this key starts blinking

(

2 in Figure 29). It remains blinking until the

selected mode of operation is confirmed.

The Waveform window is replaced by the

ManSpont window (

A message appears (

provides instructions to confirm the mode

change.

2. Confirm the mode change. The ManSpont

screen is activated (Figure 30).

After the mode change is confirmed, the

ManSpont key LED switches from blinking to

constantly on and the waveform is restored after

a short delay.

3. Rotate the APL valve knob fully counterclockwise

to release pressure for spontaneous ventilation.

4. Set the appropriate fresh gas flow.

3 in Figure 29).

4 in Figure 29) that

2

Figure 30. ManSpont Ventilation ScreenSpontaneous Breathing

Note: The ManSpont screen enables you to

turn the Apnea Pressure alarm and

Volume alarms ON or OFF.

Part Number: 4117102-007

Fabius GS Operator’s Manual 33

Page 40

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Ventilation

Figure 31. Ventilator Mode Change to Man SpontManual Ventilation

Note: In ManSpont mode, the apnea volume timer

countdown for caution alarms changes from

15 seconds to 30 seconds, and for warning

alarms from 30 seconds to 60 seconds.

1. Press the ManSpont key.

The LED associated with this key starts blinking

(

1 in Figure 31). It remains blinking until the

selected mode of operation is confirmed.

The Waveform window is replaced by the

ManSpont window (

A message appears (

provides instructions to confirm the mode

change.

screen is activated (Figure 32).

After the mode change is confirmed, the

ManSpont key LED switches from blinking to

constantly on and the waveform is restored after

a short delay.

2 in Figure 31).

3 in Figure 31) that

2

1

Figure 32. ManSpont Ventilation Screen2. Confirm the mode change. The ManSpont

3

Note: The ManSpont screen enables you to

turn the Apnea Pressure alarm and

Volume alarms ON or OFF.

3. Adjust the APL valve knob to set the appropriate

value for the maximum ventilation pressure (see

“APL Valve” on page 39).

4. Press the O

the bag.

5. Set the fresh gas flow.

6. Start manual ventilation.

2 flush button, as required, to inflate

Part Number: 4117102-007

Rev: —

34 Fabius GS Operator’s Manual

Page 41

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Ventilation Chapter 3 - Operating Concept

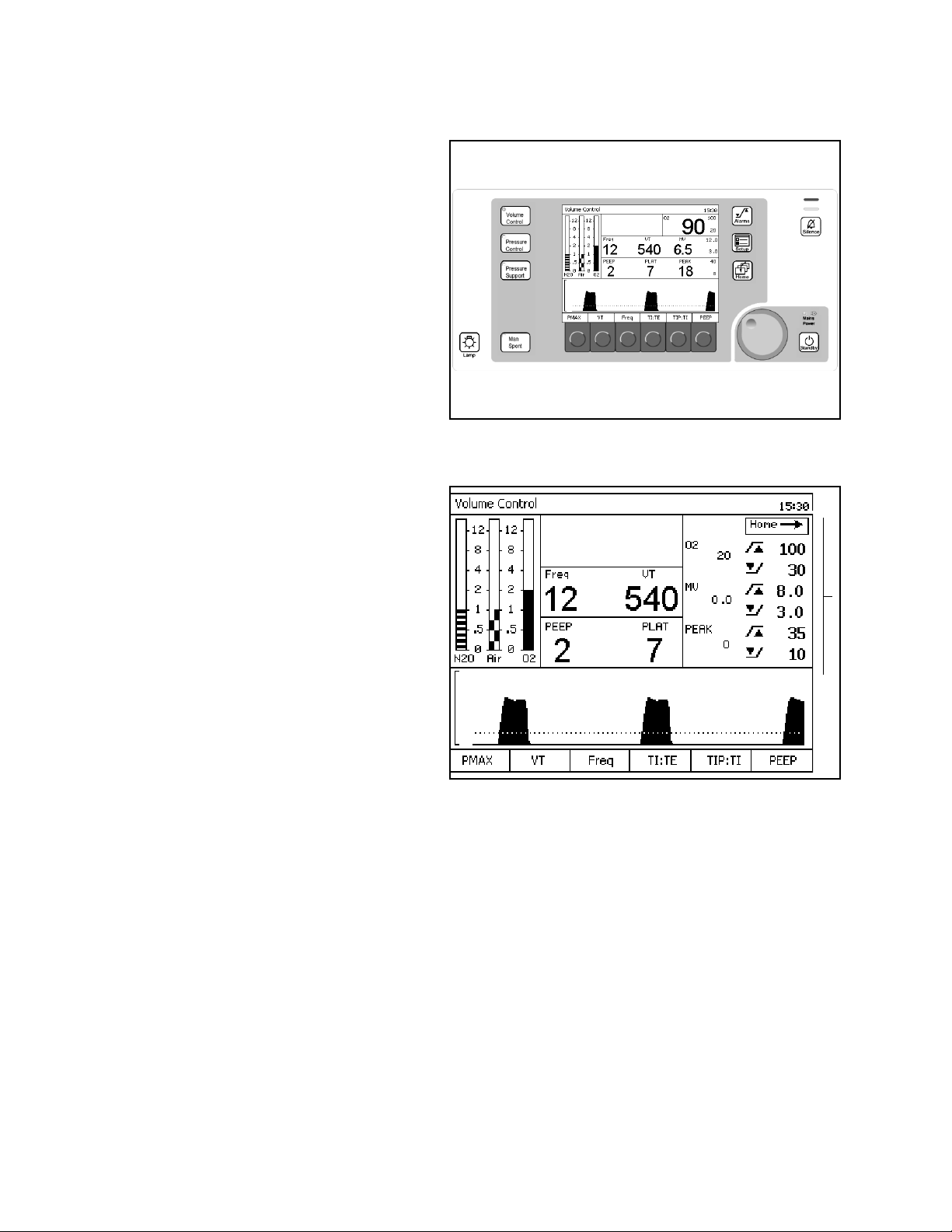

Figure 33. Volume Ventilator Settings WindowSelecting/Setting Ventilation Parameters

1. In Volume Control mode, press the Volume

Control key. The Volume Control Ventilation

Settings window (

Waveform window.

In Pressure Control mode, press the Pressure

Control key. The Pressure Control Ventilation

Settings Window (

Waveform window.

In Pressure Support mode, press the Pressure

Support key. The Pressure Support Ventilation

Settings Window (

Waveform window.

1 in Figure 33) replaces the

1 in Figure 34) replaces the

1 in Figure 35) replaces the

1

Figure 34. Pressure Control Ventilator Settings Window

Rev: —

Part Number: 4117102-007

1

Figure 35. Pressure Support Ventilator Settings Window

1

Fabius GS Operator’s Manual 35

Page 42

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Ventilation

Figure 36. Volume Control Ventilator Label SelectedThe following example continues in Volume Control

mode.

2. Press the VT (tidal volume) soft key.

The Ventilator Settings window appears with the

VT parameter label highlighted (1 in Figure 36).

3. Select a new VT parameter setting.

4. Confirm the new VT parameter setting.

Note: Once the Ventilator Settings window is

activated, it will return to the Waveform

window if 15 seconds pass and neither the

rotary knob nor a soft key is pressed.

If the Home key is pressed, the Ventilator

Settings window will return to the Waveform

window.

In either case, the ventilation parameter will

remain as it was before it was activated in

the Ventilator Settings window.

1

36 Fabius GS Operator’s Manual

Part Number: 4117102-007

Rev: —

Page 43

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fresh Gas Control Chapter 3 - Operating Concept

Fresh Gas Control

The following numbers in boldface refer to Figure 37. Flow is increased when the flow control knobs (N2O (1),

AIR (2), O

The total flow meter (4) displays the flow measurement of all of the applied gases combined.

(3)) are turned counterclockwise.

2

Note: The total flow meter is calibrated for a 50/50 mixture of N

O and O2. The accuracy of the flow meter may

2

degrade with other gas mixtures. (See the Technical Data section for specifications.)

The total flow meter serves two purposes. The total flow meter provides a reference of the total fresh gas applied

to the breathing circuit. (Flow rate measurements for each individual gas; N

O, Air, and O2; are provided by their

2

respective electronic flow indicator.)

Should a fault develop in the electronic flow sensing, digital display, or power circuitry, the total flow meter is still

functional. The measurement will indicate the total flow rate prior to the fault condition.

To adjust the fresh gas ratios while under the fault condition, shut off all flows (O

each gas flow individually. For example, start with 2 L/min O

If 1 L/min of N

plus 1 L/min N

The electronic fresh gas flow indicators (N

O is needed, open the N2O flow control knob until the total flow meter reads 3 L/min - 2 L/min O2

2

O.

2

O (5), AIR (6), O2 (7)) display the flow measurement of each gas.

2

. The total flow meter will read 2 L/min.

2

may be left on), and then restore

2

Note: The electronic fresh gas flow meters are altitude corrected.

The central supply pressure indicators (N

gas entering the Fabius GS from the facility’s pipeline.

The cylinder gauges (O

(11), Air (12)) display the pressure measurement of each gas entering the Fabius GS

2

from cylinders.

The O2 Low Supply Pressure Alarm LED (13) flashes when the O2 supply is below the factory set minimum

pressure, nominally 20 psi (1.4 bar).

Figure 37. Flowmeter and Pressure Gauge Assembly

O (8), AIR (9), O2 (10)) display the pressure measurement of each

2

Rev: —

Part Number: 4117102-007

4

TOTAL

FLOW

±15% FS

5

6

7

L/min

L/min

L/min

13

1

2

3

Pipeline

N O

2

Pipeline

AIR

Pipeline

O

2

8

9

10

11 12

Cylinder

Pressure

O

2

Air

Fabius GS Operator’s Manual 37

Page 44

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Chapter 3 - Operating Concept Fresh Gas Flow Monitoring Resolutions

Figure 38. Standard Resolution Fresh Gas Flow MonitoringFresh Gas Flow Monitoring

Resolutions

The Fabius GS can be configured by your Local

Authorized Service Organization to display fresh gas

flow rates either in a standard resolution mode or in a

high resolution mode.

Standard Resolution

If standard resolution is configured (Figure 38), the

numeric displays (LEDs) for the fresh gas flow rates

support 100 ml/min. increments (format xx.x l/min.)

and the flow meters on the monitor screen indicate a

range of 0 to 12 l/min.

Figure 39. High Resolution Fresh Gas Flow MonitoringHigh Resolution

If high resolution is configured (Figure 39), the

numeric displays (LEDs) for the fresh gas flow rates

support 10 ml/min. increments (format x.xx l/min.)

and the flow meters on the monitor screen indicate a

range of 0 to 10 l/min. with an emphasis on

resolution at the lower end of the scale.

High-resolution data is displayed when all individual

gas flows are below 9.99 l/min.

Switching to standard resolution occurs when the

highest flow rate is greater than 9.99 l/min.

Switching to high resolution occurs when the highest

flow rate drops below 9.00 l/min.

Part Number: 4117102-007

Rev: —

38 Fabius GS Operator’s Manual

Page 45

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

APL Valve Chapter 3 - Operating Concept

Figure 40. APL VavleAPL Valve

The following numbers in boldface refer to Figure 40.

The APL valve (1) has two functions. It limits the

maximum pressure during manual ventilation. It also

exhausts excess gas into the scavenger system

during manual and spontaneous ventilation.

The APL valve is connected to the patient airway

through the ventilator. It functions only when the

ventilator is in ManSpont mode or ventilator override

condition.

The APL valve has a labeled knob (2) for selecting

between spontaneous and manual modes of

ventilation and for indicating approximate pressure

settings.

When the APL valve knob is rotated fully

counterclockwise, pressure is released for