NORTH AMERICAN DRÄGER Evita 4 User manual

PMS Procedure

Evita XL

Notes on field of application: Tests marked with the "check" symbol are

listed in the Inspection Report. The test results are to be documented in

the Inspection Report. This Test Certificate applies to software version

5.n.

Evita XL 1/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Unit configuration1

General1.1

The basic unit configuration covers the following components:

EvitaXL

Trolley

Ventilation tubing system

Expiratory valve

Temperature sensor (option)

CO2 sensor (option)

Serial number (SN)1.2

EvitaXL1.2.1

Serial number (SN) of EvitaXL (Note: The serial number is located on the

rating plate.

Expiratory valve 11.2.2

Serial number (SN) of expiratory valve 1

Expiratory valve 21.2.3

Serial number (SN) of expiratory valve 2

Expiratory valve 31.2.4

Serial number (SN) of expiratory valve 3

CO2 sensor (option)1.2.5

Serial number (SN) of CO2 sensor

Control panel1.2.6

Serial number (SN) of control panel

Software version1.3

[__________txt]

[__________txt]

[__________txt]

[__________txt]

[__________txt]

[__________txt]

Unit software version1.3.1

Plug the power plug of the device into the socket-outlet.

Switch on the device.

The unit completes its self-test.

Set unit to operating mode.

Press "System Setup" button. The "System Setup" window is shown on

the display.

Press "Service" softkey.

Read and note down the software version from the display.

Operating hours1.4

Evita XL 2/549006816

04.03 Released

[__________txt]

Schutzvermerk DIN 34 beachten. Copyright reserved.

Unit operating hours1.4.1

Plug the power plug of the device into the socket-outlet.

Switch on the device.

The unit completes its self-test.

Set unit to operating mode.

Press "System Setup" button. The "System Setup" window is shown on

the display.

Press "Service" softkey.

Read and note down the operating hours from the display.

DC module (Evita 4 with XL option)1.5

Indicate by a tick in the Inspection Report if the option is installed. (Note:

The DC module is identifiable by the cable connections for the external

battery)

Evita Link (option)1.6

Indicate by a tick in the Inspection Report if the option is installed. (Note:

On the Communication PCB the "2xRS232", "2xCAN" and "1x analog

output" sockets are fitted.)

[__________h]

[__________OK]

[__________OK]

NeoFlow (option)1.7

Indicate by a tick in the Inspection Report if the option is installed. (Note:

On the PCB the "NeoFlow sensor" socket is fitted.)

PPS (option)1.8

Indicate by a tick in the Inspection Report if the option is installed. (Note:

During operation, press the "Ventilator Settings" button and the "More"

softkey. If the "PPS" softkey is installed, the option is available.

ATC (Evita 4 with "XL" option)1.9

Indicate by a tick in the Inspection Report if the option is installed. (Note:

During operation, press the "Ventilator Settings" button, the "BIPAP"

softkey and the "Additional Setting" softkey. If the "ATC" softkey is

installed, the option is available.

IFCO Carrier PCB (option)1.10

Indicate by a tick in the Inspection Report if the option is installed. (Note:

On the PCB the "Nurse Call" socket is fitted.)

Mask ventilation (option)1.11

Indicate by a tick in the Inspection Report if the option is installed. (Note:

During operation, press the "Start/Standby" button and the "Tube/Mask"

softkey. If the "Mask (NIV)" softkey is installed, the option is available.

[__________OK]

[__________OK]

[__________OK]

[__________OK]

[__________OK]

Capno Plus (option)1.12

Indicate by a tick in the Inspection Report if the option is installed. (Note:

On the CO2 Carrier PCB the socket for the CO2 connection is fitted.)

Evita XL 3/549006816

04.03 Released

[__________OK]

Schutzvermerk DIN 34 beachten. Copyright reserved.

Maintenance parts2

General2.1

Fitting of maintenance parts is classified as repair and is therefore not

included in the inspection price. Special agreements with the customer

shall be taken into consideration. Performance of the maintenance work

involved is described in the service documentation.

Maintenance intervals2.2

12-month set 41147612.2.1

The 12-month set 4114761 is applicable only to the USA. Enter date of

next change in Inspection Report field. This date must be transferred to a

new Inspection Report of the unit.

1-year maintenance interval2.2.2

Enter date of next change in Inspection Report field. This date must be

transferred to a new Inspection Report of the unit.

Diaphragm2.2.2.1

Number: 1

Order no.: 8410181

Maintenance interval in months: 12

Replace diaphragm in expiratory valve.

Sealing washer2.2.2.2

Number: 1

Order no.: 8407979

Maintenance interval in months: 12

Replace sealing washer in expiratory valve.

[__________]

[__________dat]

[__________]

[__________]

24-month set 41147622.2.3

The 12-month set 4114762 is applicable only to the USA. Enter date of

next change in Inspection Report field. This date must be transferred to a

new Inspection Report of the unit.

2-year maintenance interval2.2.4

INFO:

At the 2-yearly maintenance the spare parts listed under step 2.2.2 must

additionally be replaced.

Enter date of next change in Inspection Report field. This date must be

transferred to a new Inspection Report of the unit.

Lithium battery2.2.4.1

Number: 1

Order no.: 1835343

Maintenance interval in months: 24

Replace lithium battery on CPU 68332 PCB.

Evita XL 4/549006816

04.03 Released

[__________]

[__________dat]

[__________]

Schutzvermerk DIN 34 beachten. Copyright reserved.

External rechargeable battery (option)2.2.4.2

Number: 2

Order no.: 1843303

Maintenance interval in months: 24

Replace external rechargeable battery in trolley.

Filter2.2.4.3

Number: 2

Order no.: 8408208

Maintenance interval in months: 24

Replace filter in Dräger gas connection block.

Filter2.2.4.4

Number: 2

Order no.: 8408208

Maintenance interval in months: 24

Replace filter in FAS gas connection block.

Flat seal2.2.4.5

Number: 1

Order no.: 8408204

Maintenance interval in months: 24

[__________]

[__________]

[__________]

[__________]

Replace flat seal in Dräger gas connection block.

O-ring2.2.4.6

Number: 2

Order no.: 8411516

Maintenance interval in months: 24

Replace O-ring in FAS gas connection block.

Rechargeable battery2.2.4.7

Number: 2

Order no.: 1845284

Maintenance interval in months: 24

Replace rechargeable battery in DC module (power supply unit).

6-year maintenance interval2.2.5

INFO:

When performing the 6-year maintenance, replace also the spare parts

listed under test steps 2.2.2 and 2.2.4.

Enter date of next change in Inspection Report field. This date must be

transferred to a new Inspection Report of the unit.

[__________]

[__________]

[__________dat]

Evita XL 5/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Diaphragm2.2.5.1

Number: 2

Order no.: 8411513

Maintenance interval in months: 72

Replace diaphragm in FAS gas connection block.

Valve tappet2.2.5.2

Number: 2

Order no.: 8411514

Maintenance interval in months: 72

Replace valve tappet in FAS gas connection block.

Pressure regulator2.2.5.3

Number: 2

Order no.: 8408205

Maintenance interval in months: 72

Replace pressure reducer on Dräger gas connection block.

Real-time clock2.2.5.4

Number: 1

Order no.: 1837087

Maintenance interval in months: 72

[__________]

[__________]

[__________]

[__________]

Replace real-time clock on CPU 68332 PCB.

Cleaning intervals2.3

INFO:

Careful vacuum the pneumatics with a vacuum cleaner at each

inspection or maintenance.

Pneumatics2.3.1

Remove the two screws (front and rear left) and raise the electronics unit.

Carefully clean out the pneumatics unit with a vacuum cleaner.

Lower the electronics unit and affix it to the pneumatics unit by the two

screws.

Calibration intervals2.4

PEEP/PIP valve2.4.1

INFO:

Calibrate the PEEP/PIP valve on every inspection! The PEEP/PIP valve

calibration procedure is described in the Repair Instructions.

Calibration of the PEEP/PIP valve was successful (Note: The PEEP/PIP

valve calibration procedure is described in the Repair Instructions.

[__________OK]

[__________OK]

Evita XL 6/54

Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Electrical safety3

Visual check3.1

Power cable3.1.1

The unit's power cable is undamaged.

[OK]

Screw-type terminal of power cable3.1.2

The screw-type terminal of the power cable is undamaged.

[OK]

Power switch3.1.3

The power switch with mechanical interlock is undamaged. The

protective cap of the power switch drops down over the switch after it is

switched on.

[OK]

CO2 sensor (option)3.1.4

The CO2 sensor, the housing and the connecting cable are undamaged.

[OK]

Fuse links3.1.5

The fitted fuse links match the ratings indicated on the power supply unit.

[OK]

[__________OK]

General note3.2

WARNING:

If the unit is connected to a network, it must be disconnected from the

network before testing its electrical safety. Otherwise other devices that

are connected to the network could be damaged.

The following section details the additional tests of electrical safety to

VDE 0751 and IEC 60601-1/UL 2601. Which standard is applied

depends on the relevant national regulations.

If necessary, make the following settings for the unit on the measuring

devices: Protection class ”SK 1”, safety class ”BF”.

Internal rechargeable battery (if installed)3.2.1

Unplug connector of external battery (option) from power supply unit.

Switch on the device.

Set controlled ventilation.

Unplug the power plug of the device from the socket-outlet.

The unit continues ventilating without interruption.

Operate the unit with the internal rechargeable battery until the battery

capacity is used up (Note: The capacity of the internal rechargeable

battery is enough to power the unit for 10 minutes).

[OK]

Evita XL 7/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Mains failure alarm and data saving3.2.2

INFO:

The unit must operate without mains power supply until the internal

battery (if fitted) is discharged. Only then is the power failure alarm given!

Precondition: The unit is connected to the compressed gas and mains

power supply and switched on.

Set the unit to "controlled ventilation" mode.

Interrupt the mains power supply.

The audible power failure alarm sounds.

Restore the mains power supply.

Following a short self-test, the unit must restart in the ventilation mode

selected in step 1.

Electrical safety according to VDE 07513.3

Preconditions for testing of electrical safety:

If the "external battery" option is installed, unplug the red connection

("external battery" option) from the power supply unit (Note: The red

connector is plugged into the rear of the power supply unit).

Discharge the internal battery (DC module) by unplugging the unit's

mains power cable and leaving the unit running for about 10 minutes.

[__________OK]

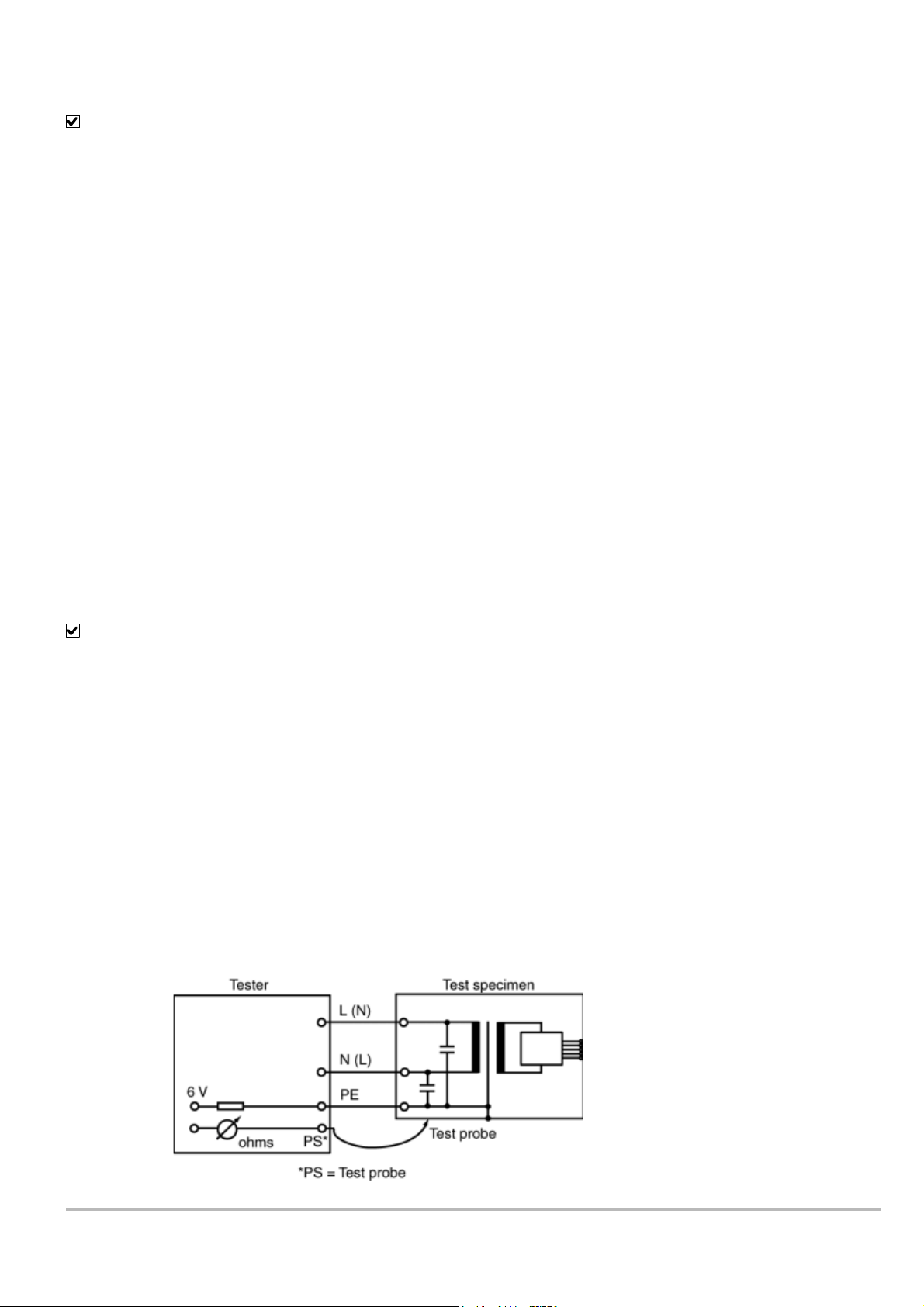

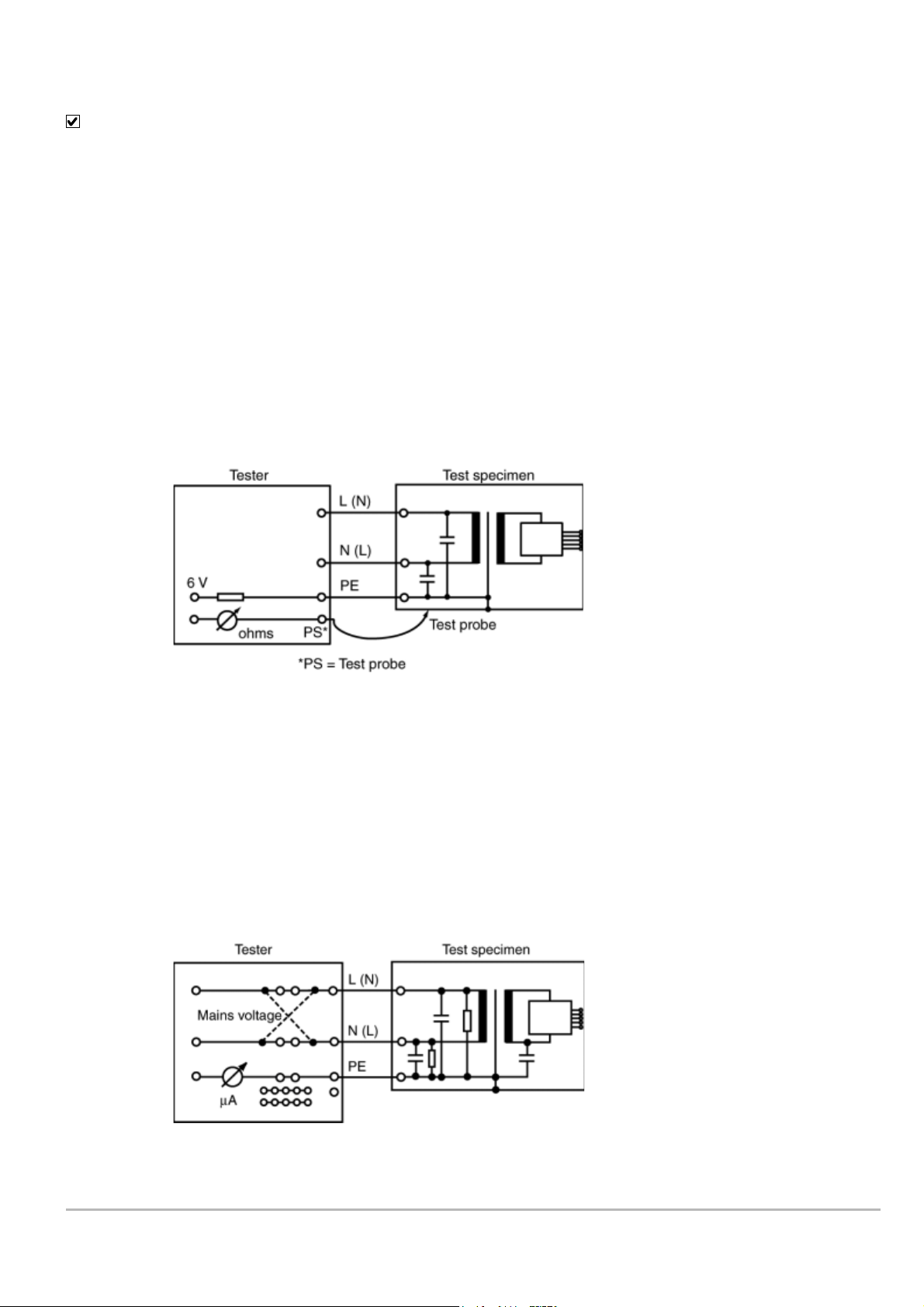

Protective earth conductor resistance3.3.1

WARNING:

Test the PE resistance with the power cable connected!

A test alternating voltage of approx. 6 V is connected via a current limiter

to the protective conductor of the test specimen. The test probe scans

the conductive parts of the test specimen. The PE resistance is derived

from the flowing current and the voltage connected to the test specimen.

The PE current is min. 10 A.

Connect the test probe to the following test points one after the other:

Power supply unit earthing studs

Pneumatics (gas connection and metal connectors)

Inspiratory block

Front panel (screws)

Rails (on side of unit)

The protective earth conductor resistance must not exceed 0.3 ohms in

each case.

[__________Ohm]

Evita XL 8/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

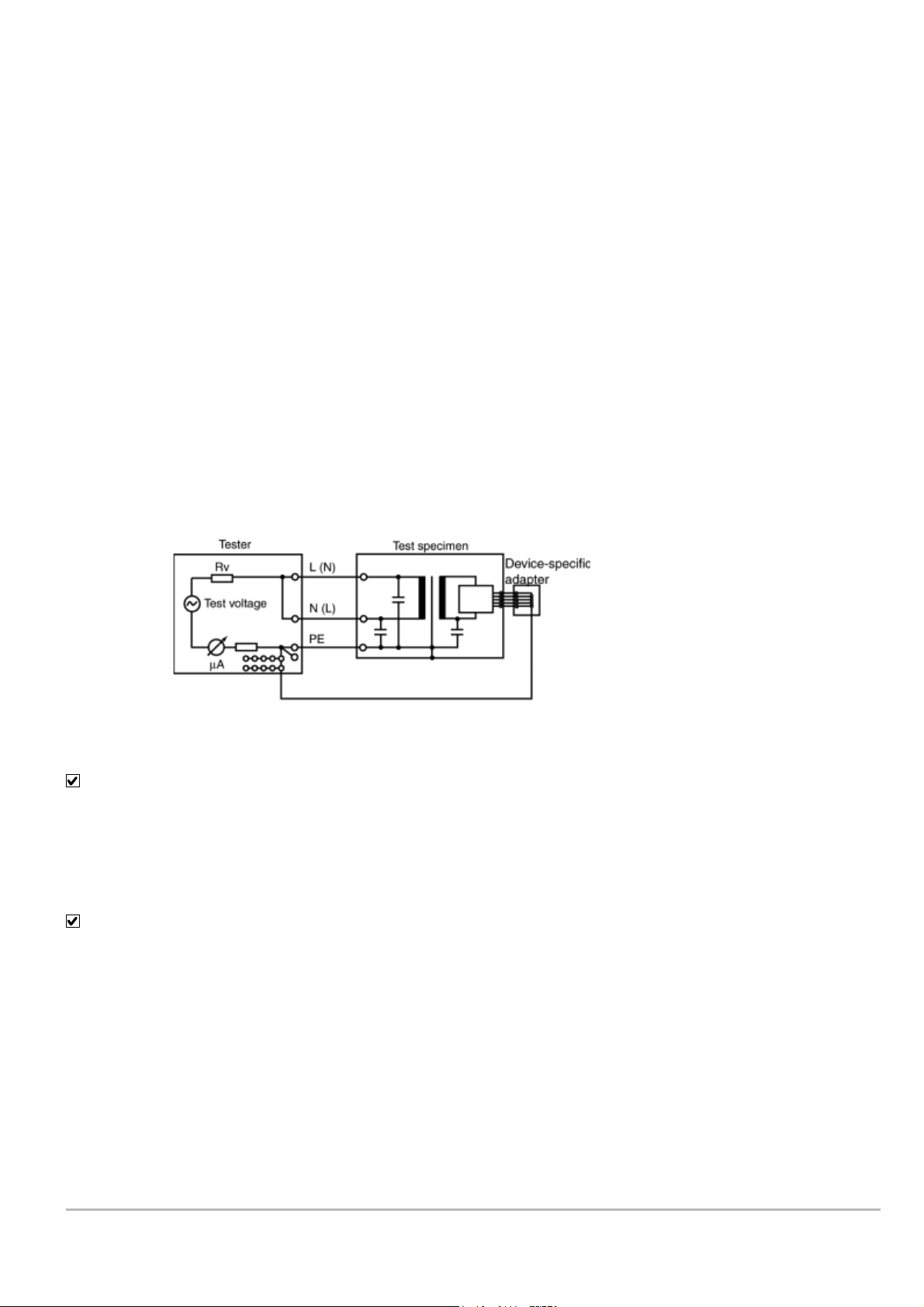

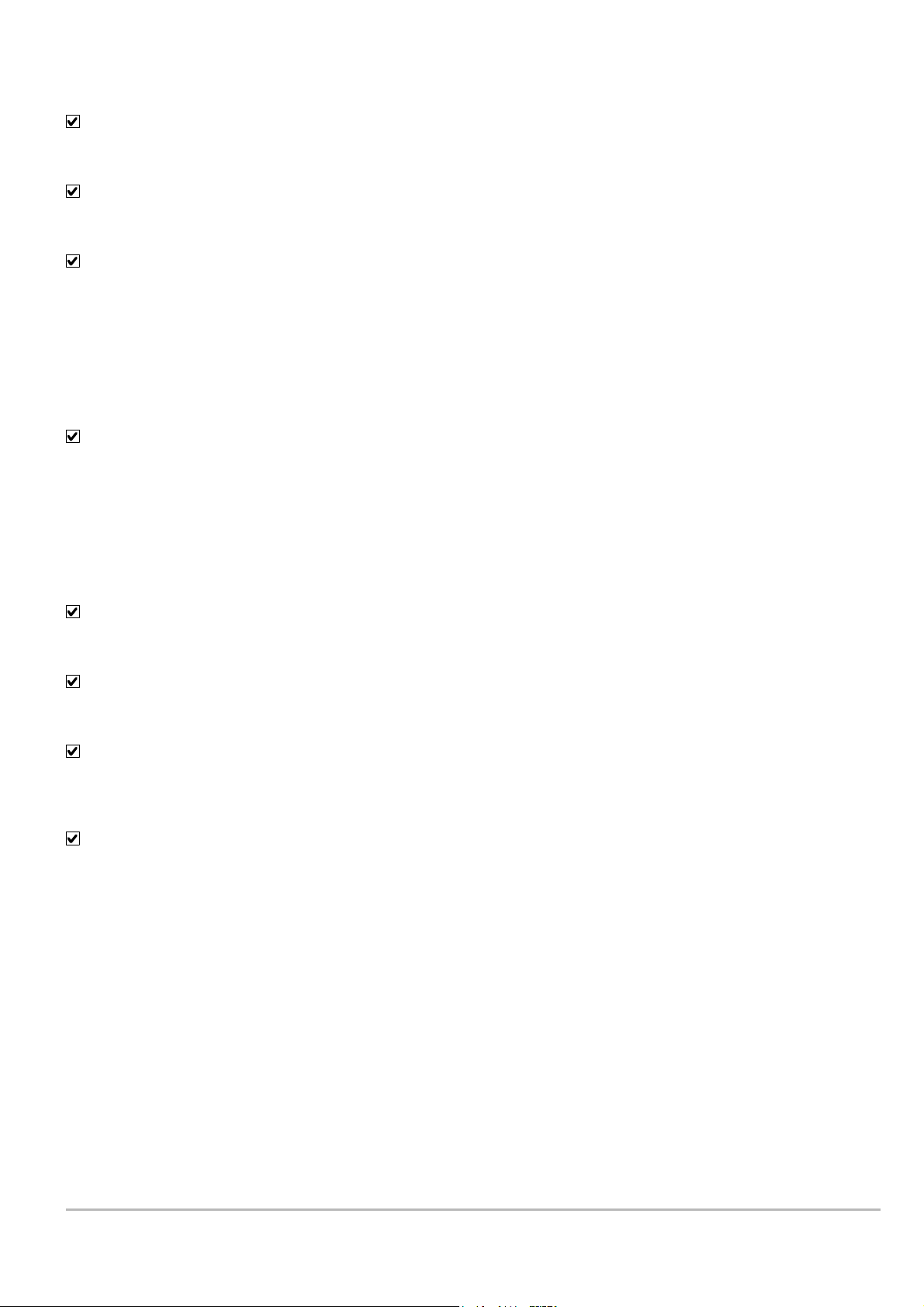

Equivalent device leakage current3.3.2

INFO:

The precondition for the test is that the unit has been operated with no

mains voltage and no external rechargeable battery until the internal

battery is flat and the acoustic power failure warning sounds!

Do not establish the test set-up until the audible power failure alarm

sounds continuously (Note: The display must be blank.).

A test voltage in the amount of the mains voltage is connected between

the shorted mains connection, the measuring device (tester) and the

protective conductor of the test specimen. The current flowing from the

live components via the insulation, the capacitors and the shorted user

ports to the protective conductor is the equivalent device leakage current.

The contacts of the ILV interface are shorted and earthed. To achieve

this make the following connection:

Connect ILV connection and ground stud with cable 7910393. (Note: As

an alternative, the socket of the temperature module and the earthing

stud can be interconnected with cable 7910364.)

The value of the re-measurement may exceed the initial measured value

by max. 50%, but must not exceed 1000 µA.

Initial measured value3.3.2.1

INFO:

Each initial measured value should be included in a new Inspection

Report.

The initial measured value must not exceed 1000 µA.

Repeat measurement3.3.2.2

The value of the re-measurement may exceed the initial measured value

by max. 50%, but must not exceed 1000 µA.

[__________µA]

[__________µA]

Evita XL 9/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

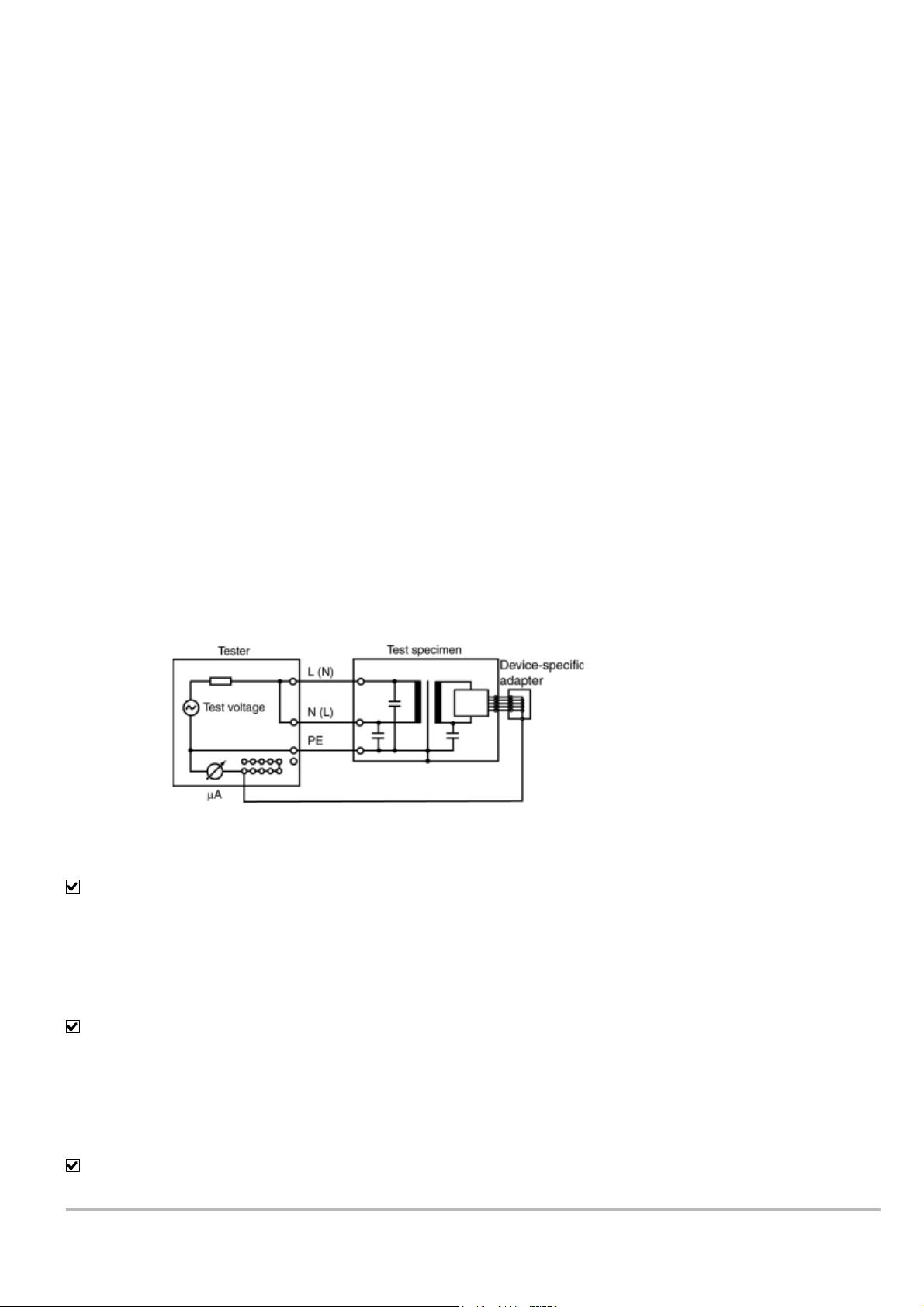

Equivalent patient leakage current3.3.3

INFO:

Do not switch off the unit. The precondition for the test is that the unit has

been operated with no mains voltage and no external rechargeable

battery until the internal rechargeable battery is flat and the acoustic

power failure warning sounds!

Do not establish the test set-up until the audible power failure alarm

sounds continuously (Note: The display must be blank.).

A test voltage in the amount of the mains voltage is connected between

the shorted mains connection, the measuring device (tester) and the

shorted sensor cables of the test specimen. The current flowing from the

live components via the insulation, the capacitors and the shorted user

ports is the equivalent patient leakage current.

The measurement is taken between the shorted sensor contacts and the

earthing stud of the power supply unit with the power plug contacts

shorted and earthed.

To achieve this make the following connections:

Create connections between the tester and the test specimen for the

"equivalent patient leakage current test".

Interconnect ILV port and tester with cable 7910393.

Alternatively: Interconnect socket of temperature module and tester with

cable 7910364.

The value of the re-measurement may exceed the initial measured value

by max. 50%, but must not exceed 5000 µA.

Initial measured value3.3.3.1

INFO:

Each initial measured value should be included in a new Inspection

Report.

The initial measured value must not exceed 5000 µA.

Repeat measurement3.3.3.2

The value of the re-measurement may exceed the initial measured value

by max. 50%, but must not exceed 5000 µA.

[__________µA]

[__________µA]

Trolley multiple socket strip (option)3.3.4

Fuse links3.3.4.1

The fuse links match the ratings on the rating plate.

Evita XL 10/549006816

[__________OK]

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Protective earth conductor resistance3.3.4.2

The protective earth conductor resistance of the socket outlets must not

exceed 0.3 ohms in each case.

Equivalent device leakage current3.3.4.3

INFO:

The test is carried out without the EvitaXL (Evita 4 with "XL" option) or

other units.

The value of the re-measurement may exceed the initial measured value

by max. 50%, but must not exceed 100 µA.

Initial measured value3.3.4.4

INFO:

Each initial measured value should be included in a new Inspection

Report.

The initial measured value must not exceed 100 µA.

Repeat measurement3.3.4.5

The value of the re-measurement may exceed the initial measured value

by max. 50%, but must not exceed 100 µA.

[__________Ohm]

[__________µA]

[__________µA]

Electrical safety to IEC 60601-1/UL 26013.4

Preconditions for testing of electrical safety:

If the "external battery" option is installed, unplug the red connection

("external battery" option) from the power supply unit (Note: The red

connector is plugged into the rear of the power supply unit).

Discharge the internal battery (DC module) by unplugging the unit's

mains power cable and leaving the unit running for about 10 minutes.

Evita XL 11/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Protective earth conductor resistance3.4.1

WARNING:

Test the PE resistance with the power cable connected!

A test alternating voltage of approx. 6 V is connected via a current limiter

to the protective conductor of the test specimen. The test probe scans

the conductive parts of the test specimen. The PE resistance is derived

from the flowing current and the voltage connected to the test specimen.

The PE current is min. 10 A.

Connect the test probe to the following test points one after the other:

Power supply unit earthing studs

Pneumatics (gas connection and metal connectors)

Inspiratory block

Front panel (screws)

Rails (on side of unit)

The protective earth conductor resistance must not exceed 0.3 ohms in

each case.

[__________Ohm]

Earth leakage current3.4.2

Mains voltage is applied to the mains connection of the test specimen as

a test voltage. The test specimen is in operational condition. The current

flowing from the live components via the insulation and the capacitors to

the protective earth conductor is the earth leakage current.

In response to the first fault condition (S.F.C. = Single Fault Condition)

the neutral conductor circuit is opened.

Switch the power switch to "ON".

Evita XL 12/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Normal condition N.C. (IEC)3.4.2.1

The earth leakage current must not exceed 500 µA.

Normal condition N.C. (UL)3.4.2.2

The earth leakage current must not exceed 1000 µA.

Single fault condition S.F.C. (IEC)3.4.2.3

Open circuit in neutral conductor.

The earth leakage current must not exceed 500 µA.

Subsequently the earth leakage current test is repeated with the power

plug rotated. (Note: This condition can be established internally on some

testers.)

Single fault condition S.F.C. (UL)3.4.2.4

Open circuit in neutral conductor.

The earth leakage current must not exceed 1000 µA.

Subsequently the earth leakage current test is repeated with the power

plug rotated. (Note: This condition can be established internally on some

testers.)

[__________µA]

[__________µA]

[__________µA]

[__________µA]

Normal condition N.C. (IEC)3.4.2.5

The earth leakage current must not exceed 500 µA.

Normal condition N.C. (UL)3.4.2.6

The earth leakage current must not exceed 1000 µA.

Normal condition N.C. (IEC)3.4.2.7

Open circuit in neutral conductor.

The earth leakage current must not exceed 500 µA.

Single fault condition S.F.C. (UL)3.4.2.8

Open circuit in neutral conductor.

The earth leakage current must not exceed 1000 µA.

[__________µA]

[__________µA]

[__________µA]

[__________µA]

Evita XL 13/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

.

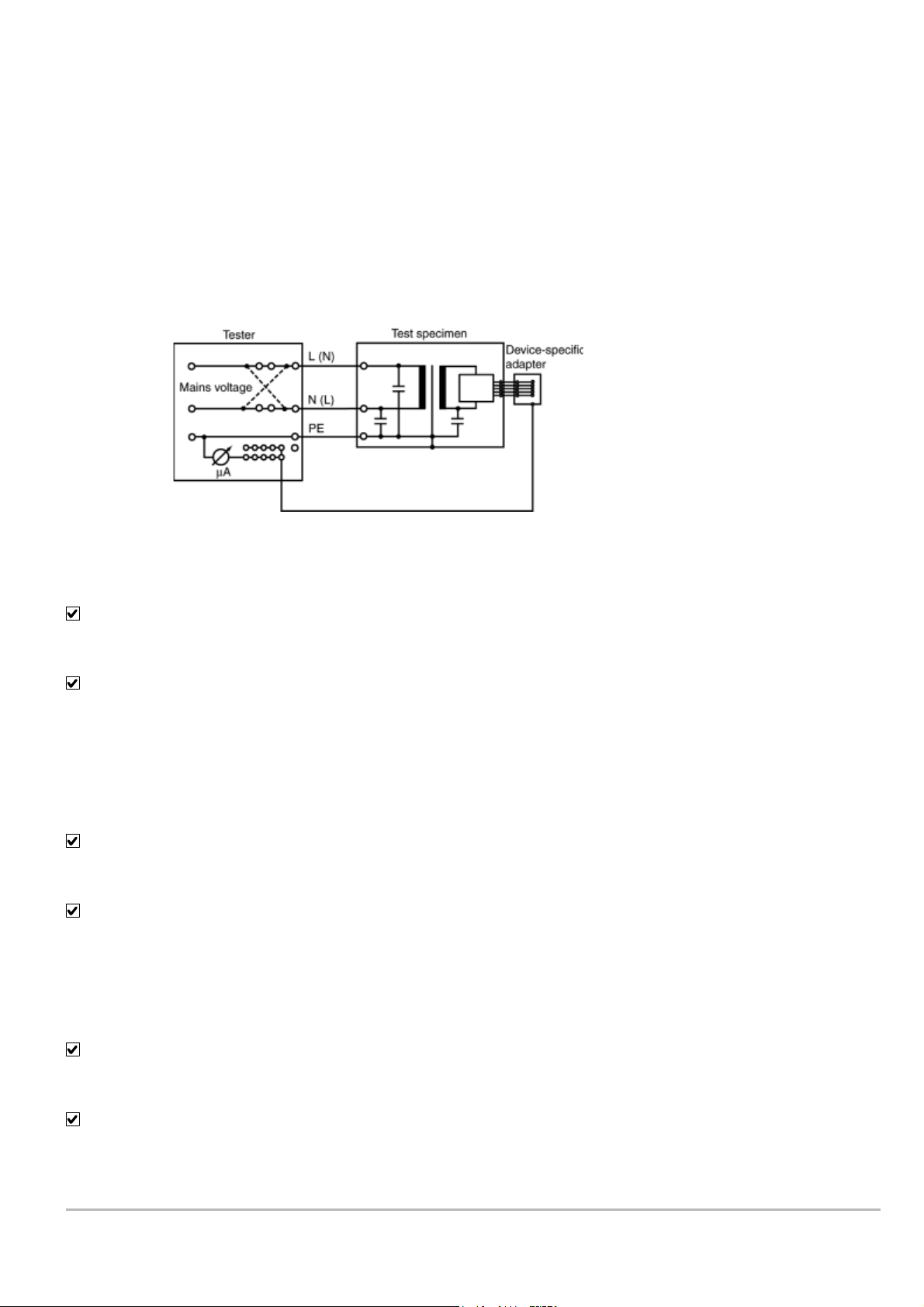

Patient leakage current, ILV port3.4.3

Mains voltage is applied to the mains connection of the tester as a test

voltage. The current flowing from the shorted user ports to the protective

conductor is the patient leakage current.

In response to the first fault condition (S.F.C. = Single Fault Condition)

the neutral conductor circuit is opened.

Interconnect ILV port and tester with cable 7910393.

Switch the power switch to "ON".

Normal condition N.C.3.4.3.1

The patient leakage current must not exceed 100 µA.

Single fault condition S.F.C.3.4.3.2

Open circuit in neutral conductor.

The patient leakage current must not exceed 500 µA.

Subsequently the patient leakage current test is repeated with the power

plug rotated. This condition can be established internally on some testers

Normal condition N.C.3.4.3.3

The patient leakage current must not exceed 100 µA.

Single fault condition S.F.C.3.4.3.4

Open circuit in power cable conductor.

The patient leakage current must not exceed 500 µA.

[__________µA]

[__________µA]

[__________µA]

[__________µA]

Trolley multiple socket strip (option)3.4.4

Fuse links3.4.4.1

The fuse links match the ratings on the rating plate.

Protective earth conductor resistance3.4.4.2

The protective earth conductor resistance of the socket outlets must not

exceed 0.3 ohms in each case.

Evita XL 14/549006816

04.03 Released

[__________OK]

[__________Ohm]

Schutzvermerk DIN 34 beachten. Copyright reserved.

Earth leakage current (N.C.)3.4.4.3

The earth leakage current must not exceed 50 µA.

Single fault condition (S.F.C.)3.4.4.4

Open circuit in neutral conductor.

The earth leakage current must not exceed 100 µA.

[__________µA]

[__________µA]

Evita XL 15/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Function and condition test4

Accompanying documents4.1

Instructions for Use4.1.1

Instructions for Use are available according to user (Note: Comply with

national laws and standards!).

[OK]

Instructions for Use of options4.1.2

Instructions for Use of options are available according to the user (Note:

Comply with national laws and standards!).

[OK]

Medical Products Logbook (applicable to Germany only)4.1.3

The Medical Products Logbook is available according to the user (Note:

Comply with national laws and standards!).

[OK]

Visual check4.2

Check condition of unit and essential accessories.

Housing4.2.1

The housing is not damaged or dirty. The housing shows no corrosion

damage. Also repair any paintwork damage.

[OK]

[__________OK]

[__________OK]

Operating and display elements4.2.2

The operating and display elements are not damaged or dirty.

[OK]

Labelling4.2.3

The labelling, including on adhesive option labels, is complete and legible

[OK]

AIR and O2 compressed gas ports4.2.4

The AIR and O2 compressed gas ports are undamaged.

[OK]

PCBs4.2.5

The PCBs are all affixed by two screws to the unit.

[OK]

Sockets (sensor, communication)4.2.6

The connectors on the PCBs are undamaged.

[OK]

Power pack4.2.7

The power supply unit is not damaged or dirty.

[OK]

Evita XL 16/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

DC connection for external battery (option)4.2.8

The DC connection is undamaged.

[OK]

Remote socket (optional)4.2.9

INFO:

If a remote socket is installed on the Evita 4 with the "XL" option, it must

be closed off by a cap. There must also be a warning label affixed next to

the remote socket.

The remote socket is closed off by a cap. The cap is undamaged.

The warning notice is legible, and not dirty or damaged.

[OK]

Cooling air fan4.2.10

The cooling air fan is not damaged or dirty. The cooling air fan rotates

smoothly. Clean out the cooling air fan with a vacuum cleaner if it is dirty.

[OK]

Cooling air filter4.2.11

The cooling air filter is not damaged, dirty or squashed. Replace the

cooling air filter as necessary.

[OK]

Remove the front panel (control panel) to perform the following steps.

Cover4.2.12

The cover to the right of the inspiratory block is undamaged.

[OK]

Remove the screw from the cover and lay the cover aside.

Room air filter4.2.12.1

The room air filter F3.1 in the cover is not damaged, dirty or squashed.

Replace the room air filter as necessary.

[OK]

Fan4.2.12.2

The fan behind the cover is not damaged or dirty. The fan rotates

smoothly and is not dirt clogged. Vacuum the fan to clean it as necessary

[OK]

O2 amplifier with non-return valve4.2.12.3

Unscrew O2 amplifier with non-return valve.

The O2 amplifier with non-return valve D3.1 is not damaged or dirty.

[OK]

O2 sensor capsule4.2.12.4

Check expiry date of O2 sensor capsule. Replace the O2 sensor capsule

as necessary.

[OK]

Evita XL 17/549006816

04.03 Released

Schutzvermerk DIN 34 beachten. Copyright reserved.

Lip seal (O2 sensor mount)4.2.12.5

The lip seal of the O2 sensor mount in the inspiratory block is

undamaged. Replace the lip seal as necessary.

[OK]

Seal4.2.12.6

The seal between the inspiratory block and the O2 amplifier is

undamaged. Replace the seal as necessary.

[OK]

Insert O2 sensor capsule into inspiratory block.

Fit O2 amplifier with non-return valve on unit.

Inspiratory socket4.2.12.7

The inspiratory socket is not dirty or damaged.

[OK]

Nebuliser port4.2.12.8

The nebuliser port is identified by a nebuliser icon. The nebuliser port is

not dirty or damaged.

[OK]

Fit cover on unit.

Expiratory block4.2.13

flow sensor4.2.13.1

The flow sensor is undamaged.

[OK]

Flow sensor mount4.2.13.2

The flow sensor mount is not dirty or damaged.

[OK]

Joint seal4.2.13.3

The joint seal between the flow sensor and the expiratory valve is

undamaged and the connector seal is correctly seated.

[OK]

Evita XL 18/549006816

04.03 Released

Loading...

Loading...