NORTH AMERICAN DRÄGER Zeus User manual

Technical Documentation

Zeus

Anesthetic workstation

Revision 3.0

5133.001

9036190

Because you care

Contents

General

1 Symbols and Definitions 3

2 Notes 3

3 Abbreviations and Definitions 5

Function Description

1 General information about Zeus 9

1.1 Intended use (summary from the Instructions for Use manual) ............................................. 9

1.2 Product classification .............................................................................................................. 9

1.3 Protection classes .................................................................................................................. 9

1.4 Brief description of the system ............................................................................................. 10

2 Anaesthetic Gas Box 13

2.1 General introduction ............................................................................................................. 13

3 PCB Box 15

3.1 DIANA PCB .......................................................................................................................... 15

3.2 VERONA PCB ...................................................................................................................... 16

3.3 Vent Power PCB ................................................................................................................... 18

3.4 External Flow PCB ............................................................................................................... 19

4 CS Module 23

4.1 Purpose ................................................................................................................................ 23

4.2 Gas supply ........................................................................................................................... 23

4.3 DAGMAR mixed gas metering unit ...................................................................................... 26

5 DIVA Anaesthetic Metering Unit 29

5.1 General introduction ............................................................................................................. 29

5.2 DIVA supply module .............................................................................................................30

All rights reserved. Copyright reserved.

K5133001IECIVZ.fm 03.05.06

I

Contents

5.3 DIVA metering module ..........................................................................................................33

6 Zeus Gas Measuring Module (GMZ) 39

6.1 General introduction .............................................................................................................39

7 Patient Gas Analyzer (PGA) 41

7.1 General .................................................................................................................................41

7.2 IRIA .......................................................................................................................................41

7.3 ILCA 2 ...................................................................................................................................43

7.4 Servomex or Pato ................................................................................................................44

8 System Gas Analyser (SGA) 49

8.1 General introduction .............................................................................................................49

8.2 ILCA ......................................................................................................................................50

8.3 OxyTrace ..............................................................................................................................54

9 Power supply unit 57

9.1 General .................................................................................................................................57

9.2 Mains power input ................................................................................................................57

9.3 Output voltages .....................................................................................................................58

9.4 Uninterruptible power supply ................................................................................................59

10 Dräger Water Trap 61

11 Blower 63

11.1 General introduction .............................................................................................................63

11.2 Function ................................................................................................................................63

12 Breathing System 67

12.1 General introduction .............................................................................................................67

12.2 Components in the breathing system and their functions ....................................................68

12.3 Function ................................................................................................................................70

II

K5133001IECIVZ.fm 03.05.06

All rights reserved. Copyright reserved.

Contents

13 Hermes Computer with Monitor 73

13.1 General ................................................................................................................................. 73

13.2 CPCI computer ..................................................................................................................... 73

13.3 Display screen ...................................................................................................................... 74

Maintenance Procedures

1 Water trap 79

1.1 Replacement interval ............................................................................................................ 79

1.2 Replacing or draining the water trap .................................................................................... 79

2 Blower spindle 81

2.1 Replacement interval ............................................................................................................ 81

2.2 Replacing the blower spindle ............................................................................................... 81

3 Filter mat in the power supply unit 83

3.1 Replacement interval ............................................................................................................ 83

3.2 Location ................................................................................................................................ 83

3.3 Removing the cover .............................................................................................................83

3.4 Replacing the filter mat ......................................................................................................... 83

4 Filter mat in the GMZ 85

4.1 Replacement interval ............................................................................................................ 85

4.2 Replacing the filter mat ......................................................................................................... 85

5 Removing/fitting the breathing system 87

6 Diaphragm mounts in the breathing system 89

6.1 Replacement interval ............................................................................................................ 89

6.2 Removing the breathing system ........................................................................................... 89

6.3 Replacing the diaphragm mount .......................................................................................... 89

6.4 Fitting the breathing system ................................................................................................. 91

All rights reserved. Copyright reserved.

K5133001IECIVZ.fm 03.05.06

III

Contents

7 Flow sensor “SpiroLife” in the breathing system 93

7.1 Replacement interval ............................................................................................................93

7.2 Replacing the “SpiroLife” flow sensor ...................................................................................93

8 Sampling-gas return-line filter 95

8.1 Replacement interval ............................................................................................................95

8.2 Replacing the filter ................................................................................................................95

9 Sintered-metal filters of the CS connections 97

9.1 Replacement interval ............................................................................................................97

9.2 Replacing the sintered-metal filters ......................................................................................97

10 Pressure regulators on the gas inlet block 99

10.1 Replacement interval ............................................................................................................99

10.2 Location ................................................................................................................................99

10.3 Disassembly .........................................................................................................................99

10.4 Replacing the pressure regulators ......................................................................................102

11 Batteries of the uninterruptible power supply 105

11.1 Replacement interval ..........................................................................................................105

11.2 Location ..............................................................................................................................105

11.3 Replacing the rechargeable batteries .................................................................................105

IV

K5133001IECIVZ.fm 03.05.06

All rights reserved. Copyright reserved.

Contents

Schematics and Diagrams

1 Schematics and diagrams 109

Annex

Technical Documentation acc. to EMV standard IEC/EN 60601-1-2: 2001

Test List

Spare Parts Catalogue

K5133001IECIVZ.fm 03.05.06

All rights reserved. Copyright reserved.

V

Contents

VI

K5133001IECIVZ.fm 03.05.06

All rights reserved. Copyright reserved.

General

1

2

Zeus General

1 Symbols and Defini-

tions

WARNING

A WARNING statement provides important information about a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION

A CAUTION statement provides important information about a potentially

hazardous situation which, if not avoided, may result in minor or moderate

injury to the user or patient or in damage to the equipment or other property.

NOTE

A NOTE provides additional information intended to avoid inconvenience

during operation.

Definitions according to German standard DIN 31051:

Inspection = examination of actual condition

Maintenance = measures to maintain specified condition

Repair = measures to restore specified condition

Servicing = inspection, maintenance, and repair

2Notes

This Technical Documentation conforms to the IEC 60601-1 standard.

Read each step in every procedure thoroughly before beginning any test.

Always use the proper tools and specified test equipment. If you deviate from

the instructions and/or recommendations in this Technical Documentation,

the equipment may operate improperly or unsafely, or the equipment could

be damaged.

It is our recommendation to use only Dräger parts and supplies.

The maintenance procedures described in this Technical Documentation may

be performed by qualified service personnel only. These maintenance procedures do not replace inspections and servicing by the manufacturer.

The information in this Technical Documentation is confidential and may not

be disclosed to third parties without the prior written consent of the manufacturer.

This Technical Documentation is for the purpose of information only. Product

descriptions found in this Technical Documentation are in no way a substitute

for reading and studying the Instructions for Use/Operating Manual enclosed

with the product at the time of delivery.

All rights reserved. Copyright reserved.

Version 3.0_ Released_Printed on_03.05.06_K5133001_General_Technical_Documentation.fm

5133.001

3

General Zeus

Know-how contained in this Technical Documentation is subject to ongoing

change through research and development and Dräger Medical reserves the

right to make changes to this Technical Documentation without notice.

NOTE

Unless otherwise stated, reference is made to laws, regulations or standards (as amended) applicable in the Federal Republic of Germany for

equipment used or serviced in Germany. Users or technicians in all other

countries must verify compliance with local laws or applicable international

standards.

Version 3.0_ Released_Printed on_03.05.06_K5133001_General_Technical_Documentation.fm

All rights reserved. Copyright reserved.

4

5133.001

Zeus Function Description

3 Abbreviations and

Definitions

A-Box Anaesthetic Gas Box

APL Adjustable Pressure Limit

CAN Controller Area Network

CPCI Compact Peripheral Component Interconnect

DAGMAR Digital Advanced Gas Mixer for Anesthesia Require-

ments

DIANA DIgita ANaesthestic controller in A-Box

DIVA Digital Injection of Volatile Agent

DUMA Flowmeter for volatile anaesthetic

DVI Digital Video Interface

EEPROM Electrically Eraseable Programmable Read Only

Memory

Flash-ROM Flash Read Only Memory

GMZ Gas Measuring module Zeus

HERMES Display and operating unit of Zeus

ILCA Infrared Low Cost Analyzer

IRIA Infrared Rapidly Identifying Analyzer

MIB Management Information Base

MIR Mid Infrared Range

MISO Master Input Slave Output

MOSI Master Output Slave Input

NIR Near Infrared Range

PLD Programmable Logic Device

PWM Pulse Width Modulation

RAM Random Access Memory

SDRAM Synchronous Dynamic RAM

SNMP Simple Network Management Protocol

SPI Serial Peripheral Interface

SRAM Static RAM

TFT Thin Film Transistor

TIVA Total IntraVenous Anesthesia

UART Universal Asynchronous Receiver/Transmitter

USB Universal Serial Bus

UPS Uninterruptible Power Supply

Zeus Name of anaesthetic workstation

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_03.05.06_F5133001_abbreviations.fm

5133.001

5

Function Description Zeus

Version 1.0_ Released_Printed on_03.05.06_F5133001_abbreviations.fm

All rights reserved. Copyright reserved.

6

5133.001

Function Description

7

8

Zeus General

1 General information

about Zeus

Figure 1 View of the Zeus anesthesia workstation

1.1 Intended use (summary from the

Instructions for Use

manual)

1.2 Product classifica-

Zeus is an integrated anesthesia workstation for inhalation and intravenous

anesthesia. Zeus is used

– in operating rooms as well as in induction and recovery rooms

– in adults, children and neonates

– with anesthetic agents Isoflurane, Sevoflurane and Desflurane

– with gas mixtures O2/AIR, O2/N2O

– in partial rebreathing to complete rebreathing mode

– for operation with external fresh-gas outlet - non-rebreathing systems

– for inhalation anesthesia, balanced and intravenous anesthesia

Class II b according to the Directive 93/42 EEC, Annex IX.

tion

1.3 Protection classes Class I according to EN 60601-1.

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_03.05.06_F5133001_ZEUS_General_about.fm

5133.001

9

General Zeus

1.4 Brief description of

the system

1.4.1 Configuration The Zeus anesthesia workstation can be subdivided into the display and con-

The integrated anesthetic workstation Zeus includes the following components:

– Windows NT computer with system display unit for operation of therapy

control and monitoring

– electronic gas and anesthetic agent flow control with closed-loop control

system

– electronically controlled and driven blower with rebreathing system

– airway monitoring

– hemodynamics monitoring module

The following extensions are available as optional features:

– Dräger syringe pumps for intravenous anesthesia

trol unit HERMES and the anesthetic gas box (A-Box).

HERMES is a PC based system for display and control of the A-Box or other

connected front-end units, such as the parameter box for measurement of

hemodynamic values. In addition, HERMES provides all external interfaces

of the Zeus anesthesia workstation, e.g. printer and serial ports.

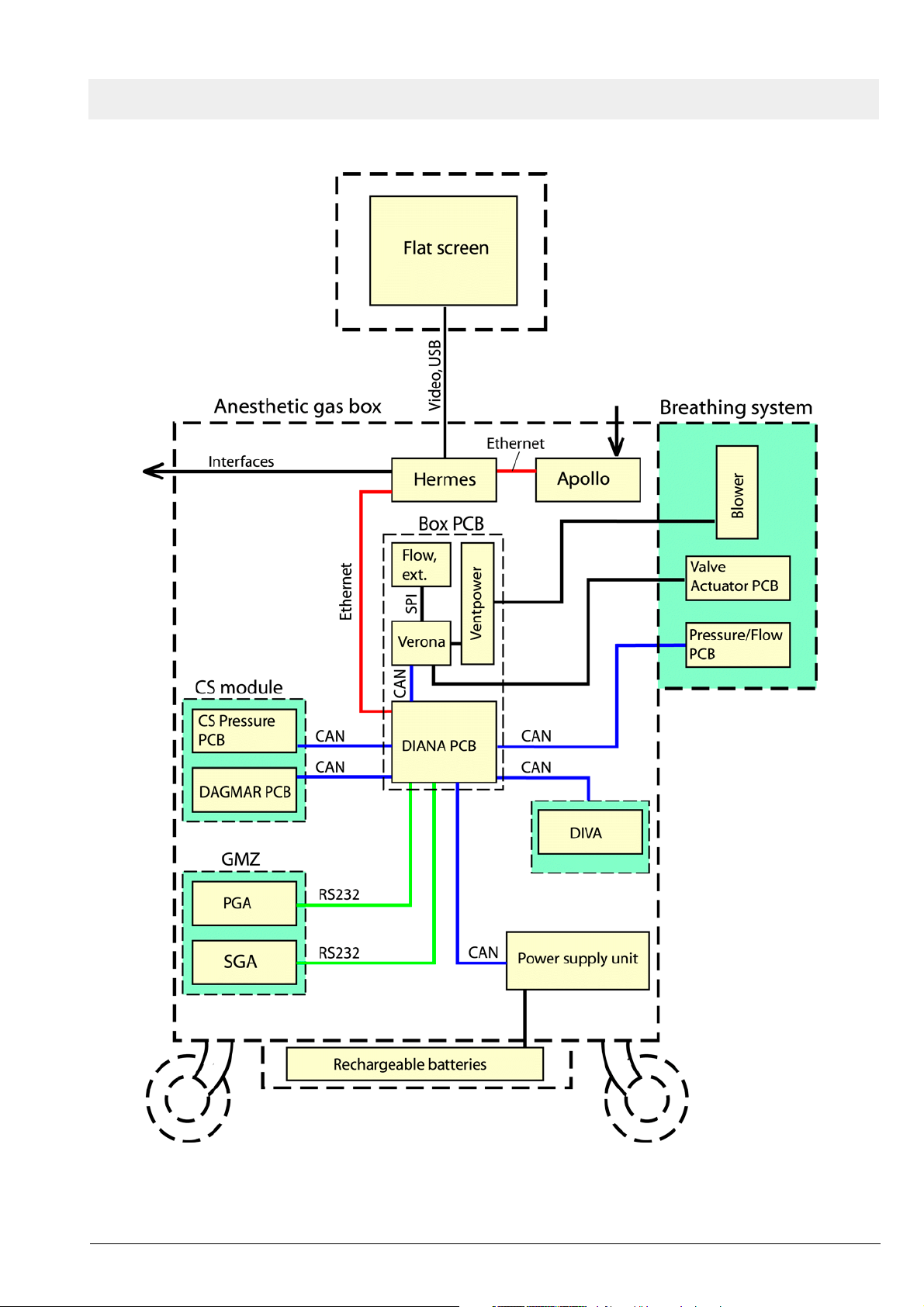

The anesthetic gas box (Figure 2) contains the actuators required for the system, the mixed-gas flow control, the anesthetic-agent flow-control, the breathing system, the lung ventilator and the monitoring system. The anesthetic gas

box also comprises slots and interfaces for future optional features.

1.4.2 The most important

external characteristics

The anesthetic workstation Zeus has an excellent ergonomic design. This

includes, for example:

– A system display unit mounted on a hinged arm that allows a 180° rota-

tion. A second flat display (optional feature) can be arranged on top of the

system display unit.

– A housing shape that is suitable both for left-hand/right-hand operation.

This includes, besides the rotatable system display unit, a push-through

work top and a push-through drawer. The absorber can be viewed easily

from both sides.

– Concealed, left-hand and right-hand rails for mounting of accessories.

– O2 flush buttons that can be operated on left-hand side and right-hand

side.

– A central locking brake for trolley castors that can be operated from both

sides.

10

5133.001

Version 2.0_ Released_Printed on_03.05.06_F5133001_ZEUS_General_about.fm

All rights reserved. Copyright reserved.

Zeus General

Figure 2 System overview

All rights reserved. Copyright reserved.

Version 2.0_ Released_Printed on_03.05.06_F5133001_ZEUS_General_about.fm

5133.001

11

General Zeus

12

5133.001

Version 2.0_ Released_Printed on_03.05.06_F5133001_ZEUS_General_about.fm

All rights reserved. Copyright reserved.

Zeus Function Description

2 Anaesthetic Gas

Box

2.1 General introduction

The anaesthetic gas box comprises the trolley and the housing of the Zeus.

Apart from the monitor, it includes all the components required to operate the

functions of the Zeus. They include:

– Power supply unit

– Hermes computer

– PCB box

– CS module (CS = Central Supply)

– DIVA (digital anaesthetic metering unit)

– GMZ (Zeus gas measuring module)

– Blower (ventilator)

– Breathing system

Version 1.0_ Released_Printed on_03.05.06_F5133001_anaesthesiagasbox_General_about.fm

All rights reserved. Copyright reserved.

5133.001

13

Function Description Zeus

14

5133.001

Version 1.0_ Released_Printed on_03.05.06_F5133001_anaesthesiagasbox_General_about.fm

All rights reserved. Copyright reserved.

Zeus Function Description

3 PCB Box The PCB box is a housing system for PCBs in the Zeus. It principally com-

prises the Transfer PCB, which performs the function of a motherboard. The

Transfer PCB accommodates additional PCBs: the standard Zeus PCBs as

well as PCBs for later options.

At present the PCB box holds the following PCBs:

– DIANA PCB

– VERONA PCB

– Vent Power PCB

– External Flow PCB

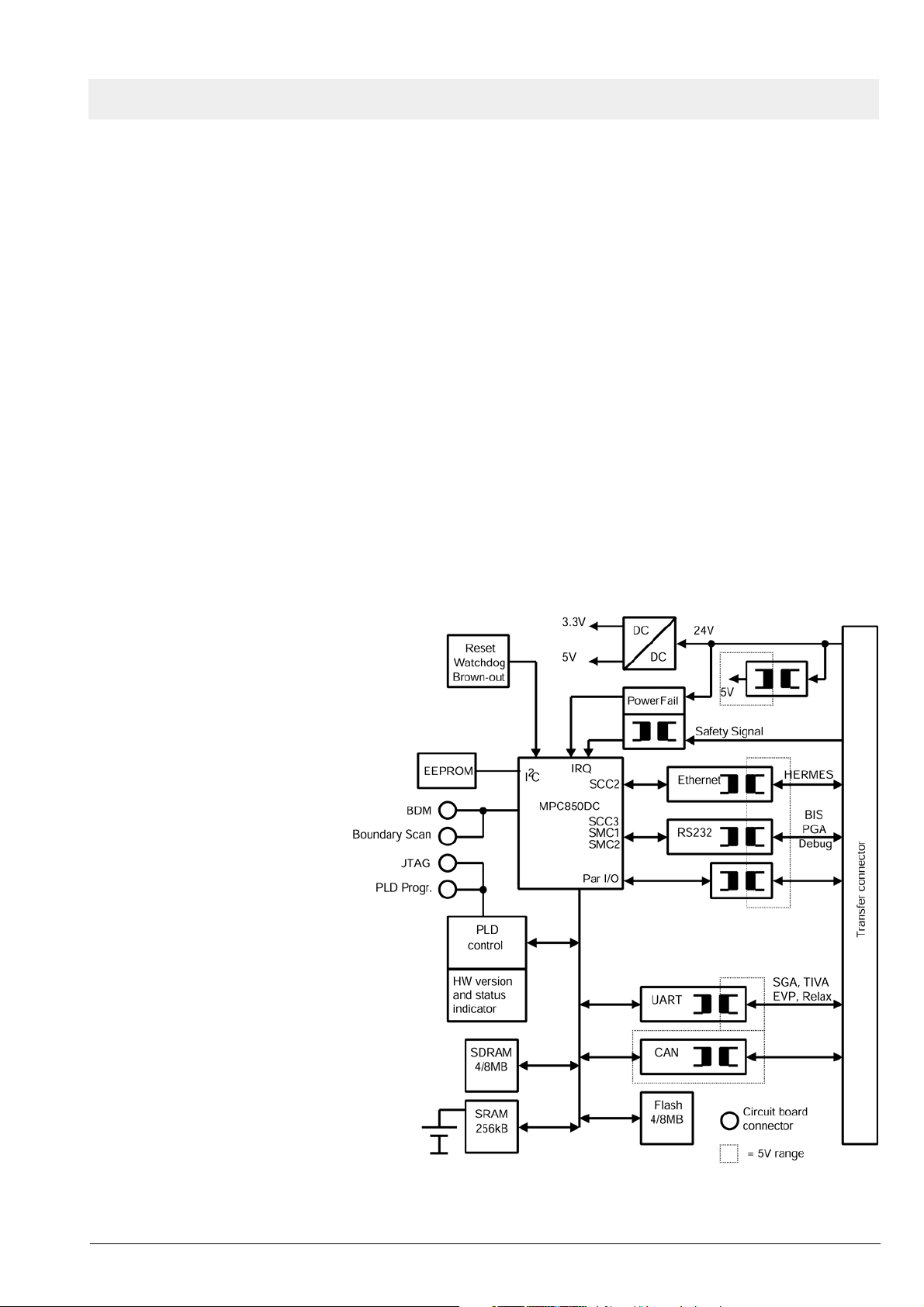

3.1 DIANA PCB

3.1.1 Purpose The DIANA PCB handles the communication of all system processors with

the HERMES via an Ethernet link. By way of the Transfer PCB the relevant

signals of various modules and the 24 V supply are routed to the DIANA

PCB. The internal 3.3 and 5 V operating voltages are generated on the

DIANA PCB by means of DC/DC-converters.

3.1.2 Function The central module of the DIANA PCB is the processor MPC 850 (Figure 3).

Figure 3 Block diagram of the DIANA PCB

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

5133.001

15

Function Description Zeus

The operating program is located in a 4 or 8 MB Flash-ROM which is loaded

into a 4 or 8 MB SDRAM as appropriate during start-up. Key software components can be stored in a 256 kB SRAM which is battery-buffered to protect

against failure of the operating voltage. Key parameters can additionally be

saved to an EEPROM via an I2C-port.

In addition to the memory modules, a CAN-controller and a four-way-UART

are also connected to the system bus. The modules are selected by way of a

PLD. The CAN-controller handles most of the communication with the other

processors in the overall system with the aid of the installed SABUS-protocol.

The four-way UART handles the communication with the ILCA module and

with any subsequent add-ons. An Ethernet controller handles the communication with the HERMES system. The IRIA module and a serial port for Service are connected via an electrical isolator directly to the processor. The

power supply unit generates a Power Fail signal indicating failure of its primary voltage (240 V mains voltage). The 24 V is also monitored in order to

utilize time reserves prior to total failure of the supply voltage for regulation

shutdown of the processor. An additional integrated module monitors the

3.3 V supply (Brown-Out monitor).

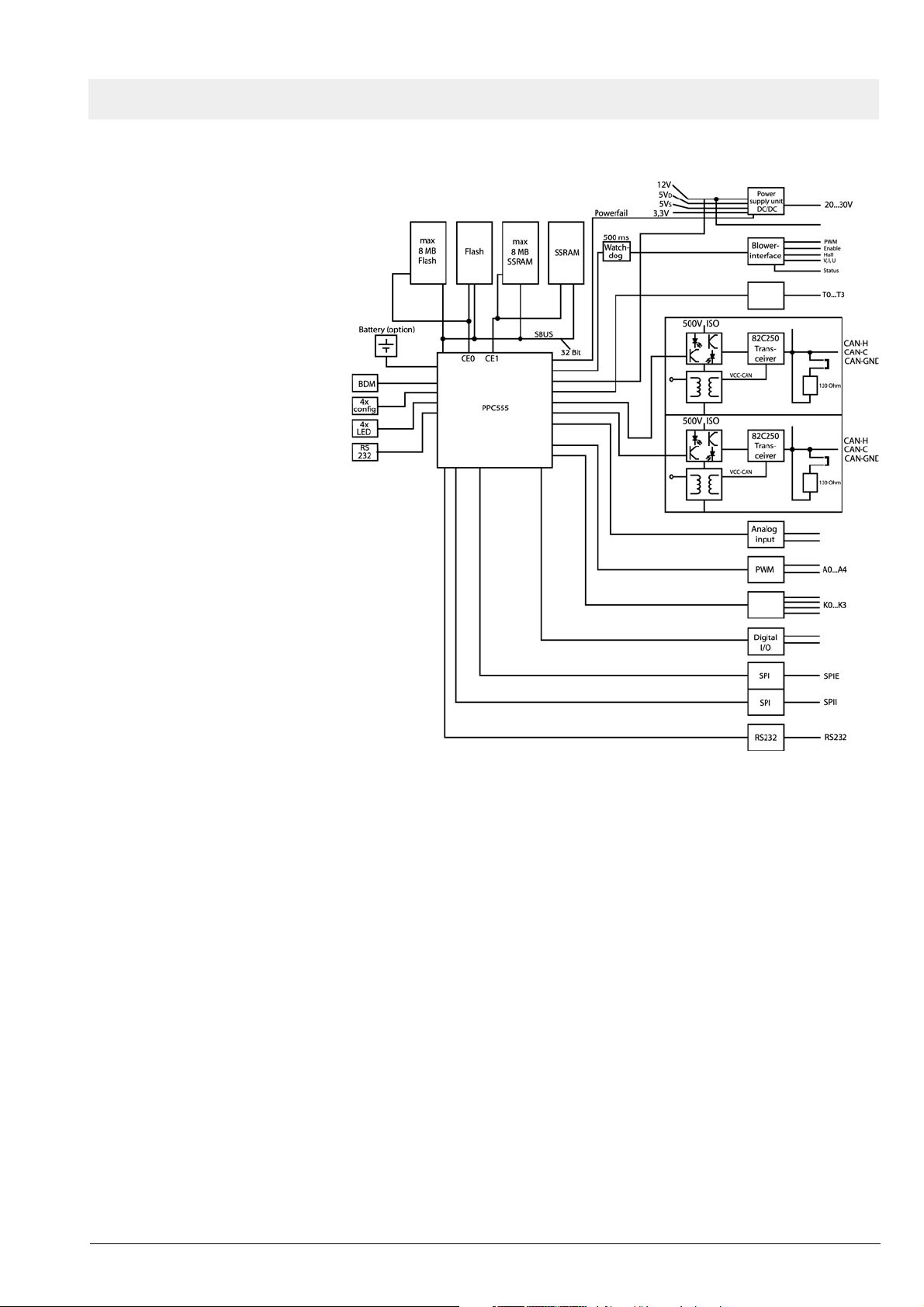

3.2 VERONA PCB

3.2.1 Purpose The VERONA PCB is required in the ZEUS to control the ventilator and to

interface to the CAN bus. For this, a microcontroller system based on the

PPC555 is used.

3.2.2 Function The circuit is operated with a 24 V supply (Figure 4).

16

5133.001

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

All rights reserved. Copyright reserved.

Zeus Function Description

Figure 4 Block diagram of the VERONA PCB

The voltage supply is fed in via an EMC-filter and monitored by the controller.

The controller PPC555 has an internal RAM which can be optionally batterybuffered. The following operating voltages are generated on the PCB:

– 3.3 V for microcontroller

– 5 V for temperature sensors

– 5 V for digital modules

– 12 V for pressure sensors

The processor system has two serial ports (max 115 kbaud). Two CAN-interfaces actively support the Full CAN V2.0A and V2.0B-protocol at up to 1Mb/s.

The CAN-buses are each isolated from the rest of the system and from each

other by an isolating voltage of at least 500 V AC. Optocouplers are used to

isolate the signals. To activate the blower motor the board has a dedicated

interface. The power electronics for the blower are located on the Vent Power

PCB. For speed evaluation the three TTL-signals Hall-A, Hall-B and Hall-C

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

5133.001

17

Function Description Zeus

are delivered by the motor electronics. The motor temperature is evaluated,

as are the other temperature sensors. 6 LEDs are provided for output of status signals. The following LEDs are interesting for service work:

– 12 V supply voltage = LED V405

– 5 V supply voltage = LED V402

If only LED V302 of the 4 LEDs between the SUB-D connectors is lit the hardware is in test mode.

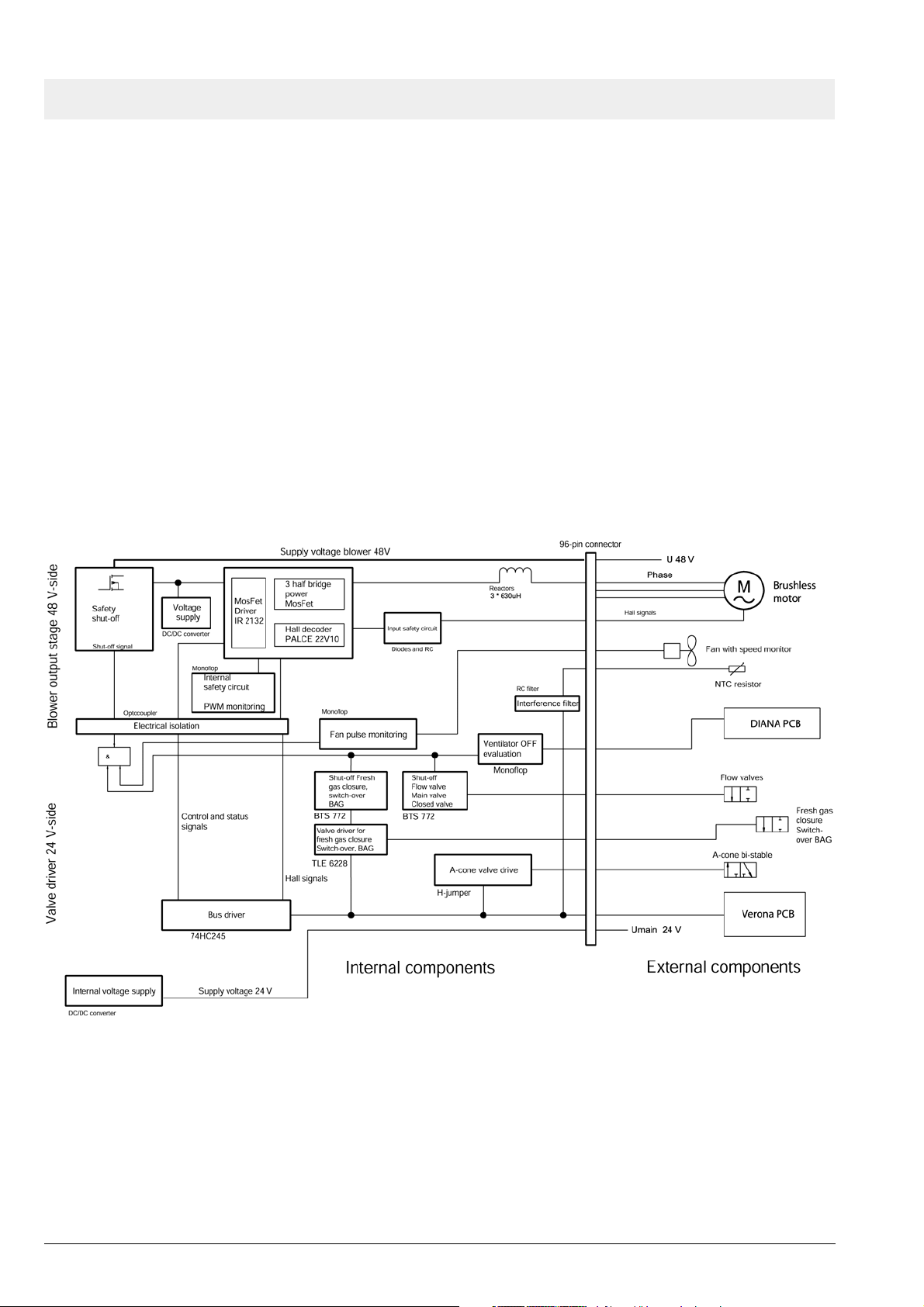

3.3 Vent Power PCB

3.3.1 Purpose The Vent Power PCB contains the power electronics to activate the blower

and the external valves. It provides the link between the valve control and the

pneumatic system.

3.3.2 Function The respective power stages can be disabled by an external signal (Figure

5).

Figure 5 Vent Power PCB block diagram

This signal is generated by an independent monitoring computer. In addition

to the power stages, the sender information from the TurboVent and the status signals of the various output stages are processed and passed on for

evaluation to the TurboVent control computer. The supply voltage of the TurboVent is 48 V DC and that of the valves is normally 24 V. Because of the different supply voltages and the substantial peak currents in the TurboVent

activation circuit these blocks are electrically isolated by optocoupler.

18

5133.001

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

All rights reserved. Copyright reserved.

Zeus Function Description

The supply voltage for the TurboVent is externally stabilised in the power

supply unit to 48 V and has a current limit of 3 A. An external 68000 uF

capacitor is included to deal with the high peak currents of the motor.

The function of the blower power stage is to provide phase-adjusted activation of the motor coil with the aid of the Hall sensors built into the motor and to

control the speed of the motor. The Hall signals are formatted by an inverter

and passed to the Hall decoder. This module decodes the Hall signals of the

motor and codes the activation signals of the MOSFET driver from them. The

power MOSFETs are activated by a MOSFET driver. The output stage comprises 3 half-bridges each with two identical n-channel MOSFETs. At a TurboVent electronics supply voltage below 38 V a protective circuit disables the

MOSFET activation. As the motor is run in a highly dynamic mode at high

speeds, the power stage is rated for a peak power output of approximately

480 W. The mean load in operation is approximately 100 W.

The fan delivers one pulse per fan wheel revolution. This pulse is filtered by

an RC element and routed to a retriggerable monoflop. If the pulses are not

received, the monoflop drops out and disables the power electronics for the

TurboVent. This ensures that the TurboVent is only activated when the fan is

running. This prevents harmful overheating or excessive oxygen concentration build-up at the TurboVent motor.

The Vent Power PCB also contains the activation electronics for the valves in

the breathing system and their interface to the TurboVent control computer.

Additionally, the Ventilator-OFF signal is evaluated by the DIANA PCB to cut

the power to the driver stages.

The A-cone valve is a single-turn bipolar valve. The turn must be activated in

bipolar mode by a voltage pulse. This valve driver is independent of the Ventilator-OFF signal.

The power electronics for the flow valves are located directly at the pneumatic interface underneath the valves, and not on this PCB. However, the

valves are shut off by the Ventilator-OFF signal by way of a HIGH-side FET

switch on this module. The switch cuts the supply voltage to the flow valves.

The valves, seal, fresh gas, switch-over and BAG are controlled by a low-side

MOSFET switch. This module has a monitoring output which is routed to the

TurboVent control computer. The monitoring covers short-circuit and open

load.

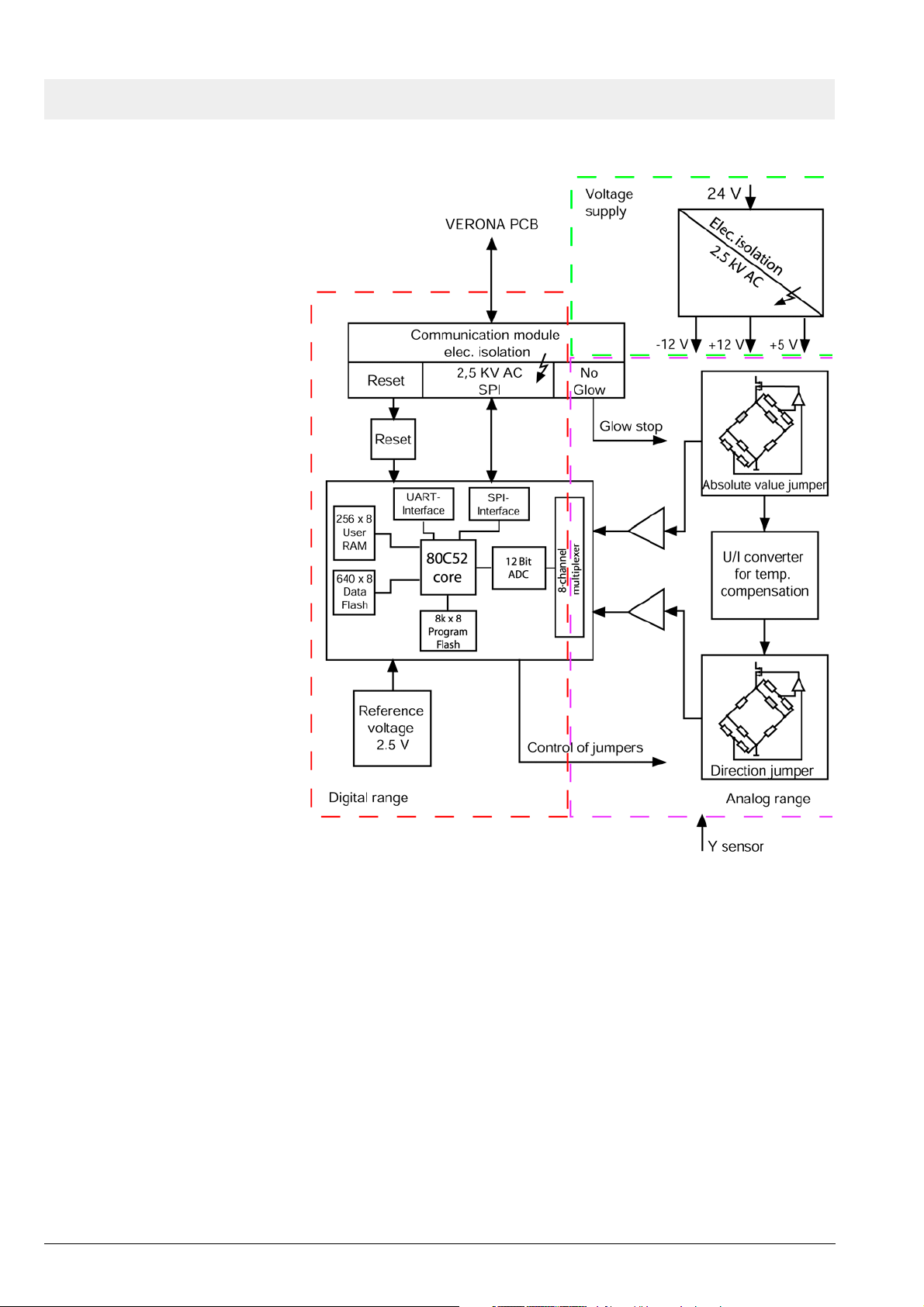

3.4 External Flow PCB

3.4.1 Purpose The “Alveon” flow sensor is designed for adult patient-local directional flow

measurement and is built into the patient Y-piece. The External Flow PCB

digitises the sensor signals and supplies the data via SPI.

3.4.2 External Flow PCB function

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

5133.001

The External Flow PCB circuitry is divided into 3 areas (Figure 6):

– Supply voltage with electrical isolation from the overall system

– Analog measurement processing

– Digital measurement processing with data interface and electrical isola-

tion from VERONA PCB via SPI

19

Function Description Zeus

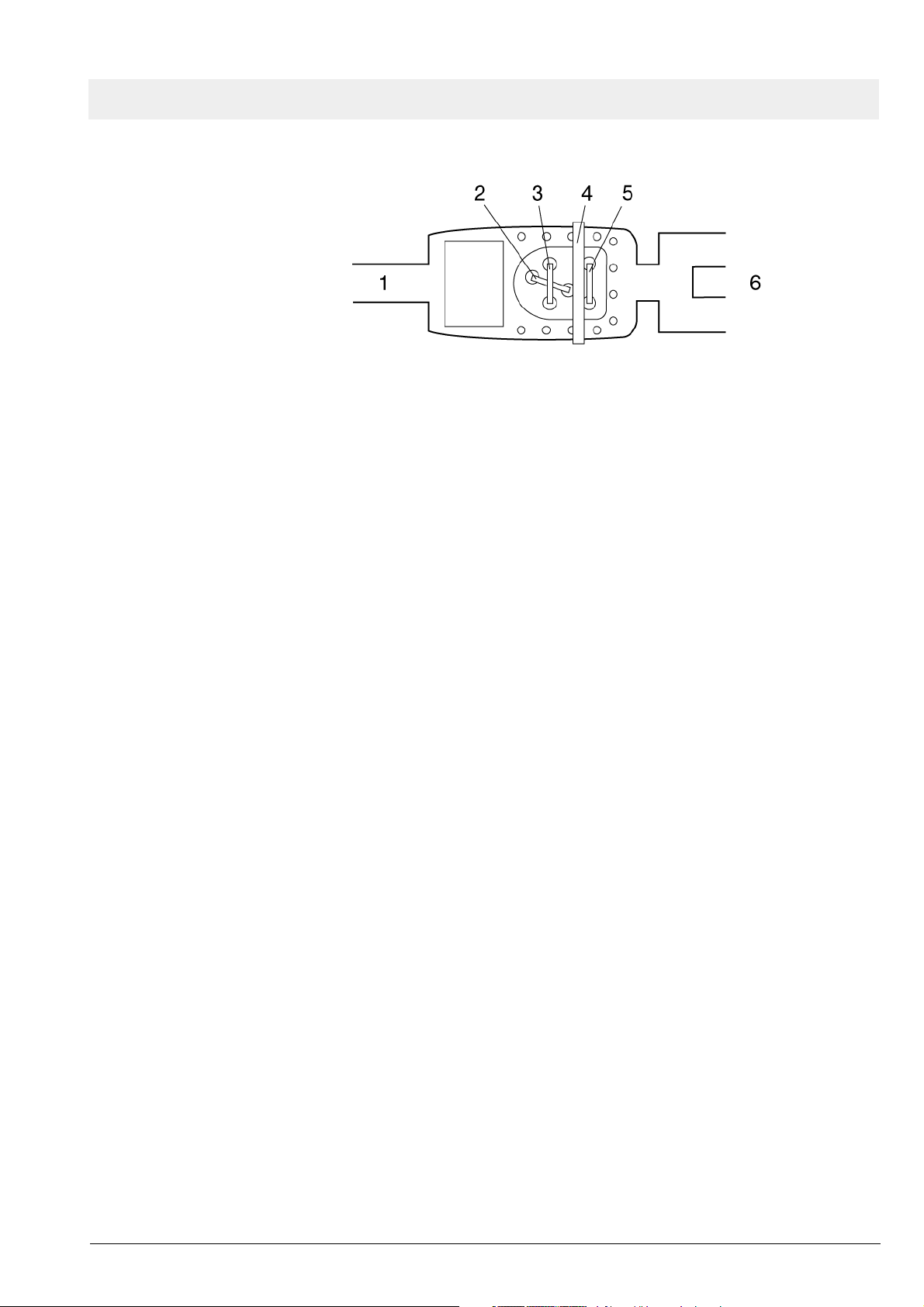

3.4.3 Sensor measurement

principle

20

Figure 6 External Flow PCB block diagram

The “Alveon” flow sensor is based on the principle of a filament anemometer

(Figure 7). In conjunction with the Zeus anaesthetic workstation, the measur-

ing wire (2) is used for compensation of the breathing gas, the measuring

wire (3) for “flow measurement” and the measuring wire (5) with the shading

(4) for detecting the direction of flow.

5133.001

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

All rights reserved. Copyright reserved.

Zeus Function Description

Figure 7 “Alveon” flow sensor layout

All rights reserved. Copyright reserved.

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

5133.001

21

Function Description Zeus

22

5133.001

Version 1.0_ Released_Printed on_04.05.06_F5133001_PCB_Box.fm

All rights reserved. Copyright reserved.

Loading...

Loading...