Page 1

Field

Service

Procedure

Part Number: SP00182

Date: 28 February 2003

© 2003 Draeger Medical, Inc.

Rev: E

Narkomed Mobile/Military

PMC Procedure

Page 2

Page 3

NM MOBILE/MILITARY

PMC PROCEDURE

6.0 PMC PROCEDURE, NARKOMED MOBILE/MILITARY

The procedures in this section shall be performed in their entirety each time a

component is removed, replaced, calibrated, adjusted and during all scheduled

Periodic Manufacturer's Certification (PMC) visits. A PMC Checklist form, P/N

S010211 is available from Draeger Medical, Inc. and shall be completed by the

Technical Service Representative each time a PMC is performed. Steps in the

procedure marked with (

checklist form.

Space is also provided on the PMC checklist form to record the results of a vapor

concentration test. Refer to the current Anesthesia Equipment & Monitoring System

Service Information CD-ROM Service Procedures section for vapor concentration

verification procedures.

NOTE:Test equipment listed below with an asterisk (*) requires calibration at a

maximum interval of one year. Verify the dates on test equipment calibration

labels. DO NOT USE any test equipment having an expired calibration date.

Notify your supervisor immediately if any equipment is found to be out of

calibration. In the space provided at the bottom of the PMC checklist form,

record the Model and ID number of all calibrated test equipment used.

In the space provided at the bottom of the PMC checklist form, record the Model and

ID number of all calibrated test equipment used. Also record the calibration due

dates. Examples are: multimeter, digital pressure meter, Riken gas analyzer, safety

analyzer, volumeter, trace gas analyzer, simulators.

ü) require a response at the corresponding line on the

Test Equipment Required:

• *Electrical Safety Analyzer (Biotek 501 Pro or equivalent)

• *Pressure Gauge with DISS Adapters (P/N 4114807 or equivalent)

• *Flowmeter 0-250 ml min. (P/N S000081 or equivalent)

• *Volume Meter (P/N 2212300 or equivalent)

• *Digital Pressure Manometer (SenSym PDM 200CD or Equivalent)

• *Riken Gas Indicator (Model 18H, or 1802D or equivalent)

•Stop Watch

• Test Lung (P/N 4115128)

Materials Required:

• Breathing Bag 3 liter (P/N 9995330 or equivalent)

• Patient Circuit: Y-piece, elbow, 2x 32” x 22mm hoses

• Hose 22 mm x 32” (P/N 9995132)

• Fresh Gas Outlet Volume Test Device (P/N S010158 or equivalent)

• Fresh Gas Leak Test Adapter (P/N 4115041 or equivalent)

• Volumeter/Fresh Gas Adapter (P/N 4115042)

6-1

Page 4

PMC PROCEDURE (continued)

Materials Required (continued):

• Test Terminal 2x (P/N 4104389 or equivalent)

• Breathing System Leak Test Device (P/N S010159 or equivalent)

• PDM/Suction Adapter (P/N 4115038)

• Scavenger Adapter (P/N 4108114)

• Pressure Monitor Test Adapter (P/N 4115043 or equivalent)

Key test equipment and materials illustrations are shown on following pages.

NM MOBILE/MILITARY

6-2

Page 5

NM MOBILE/MILITARY

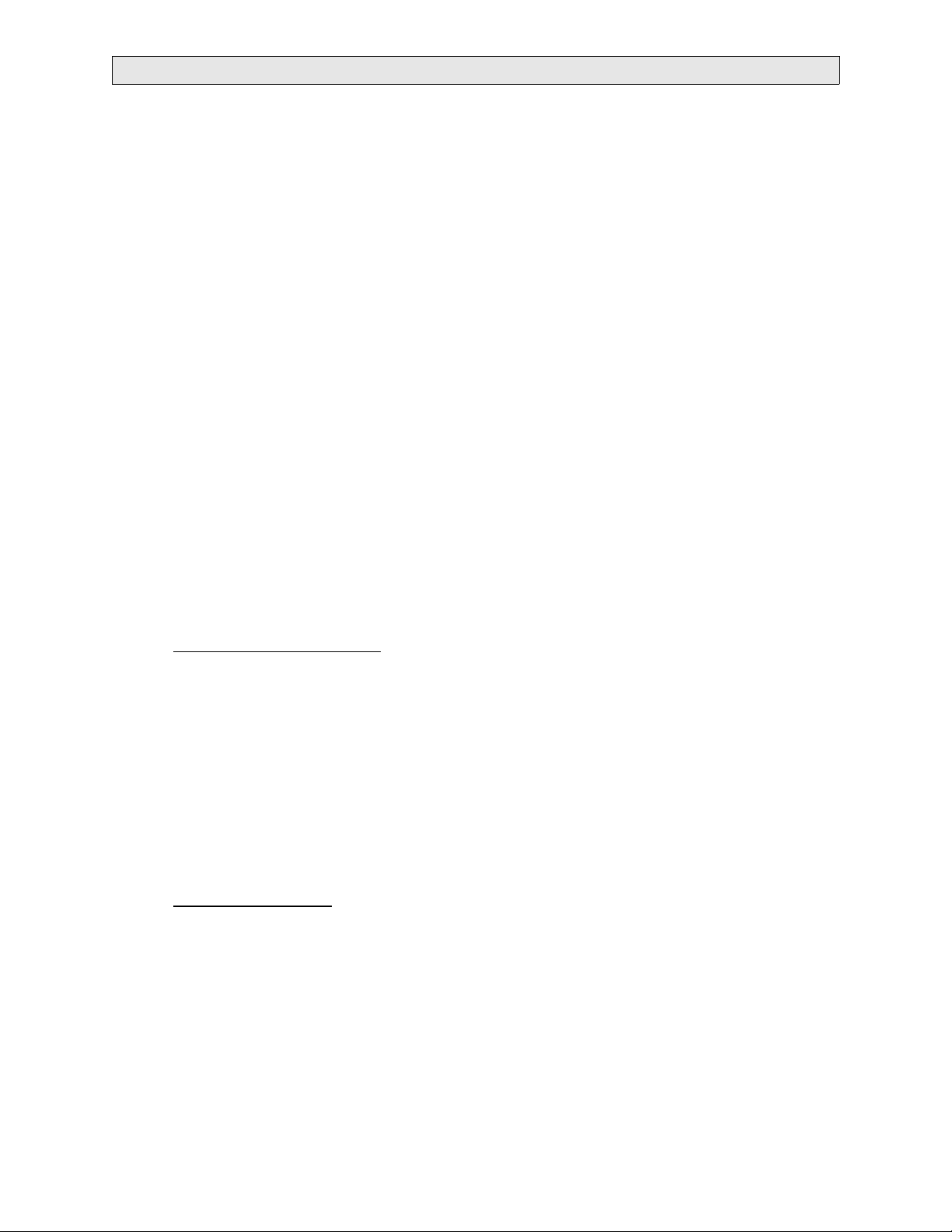

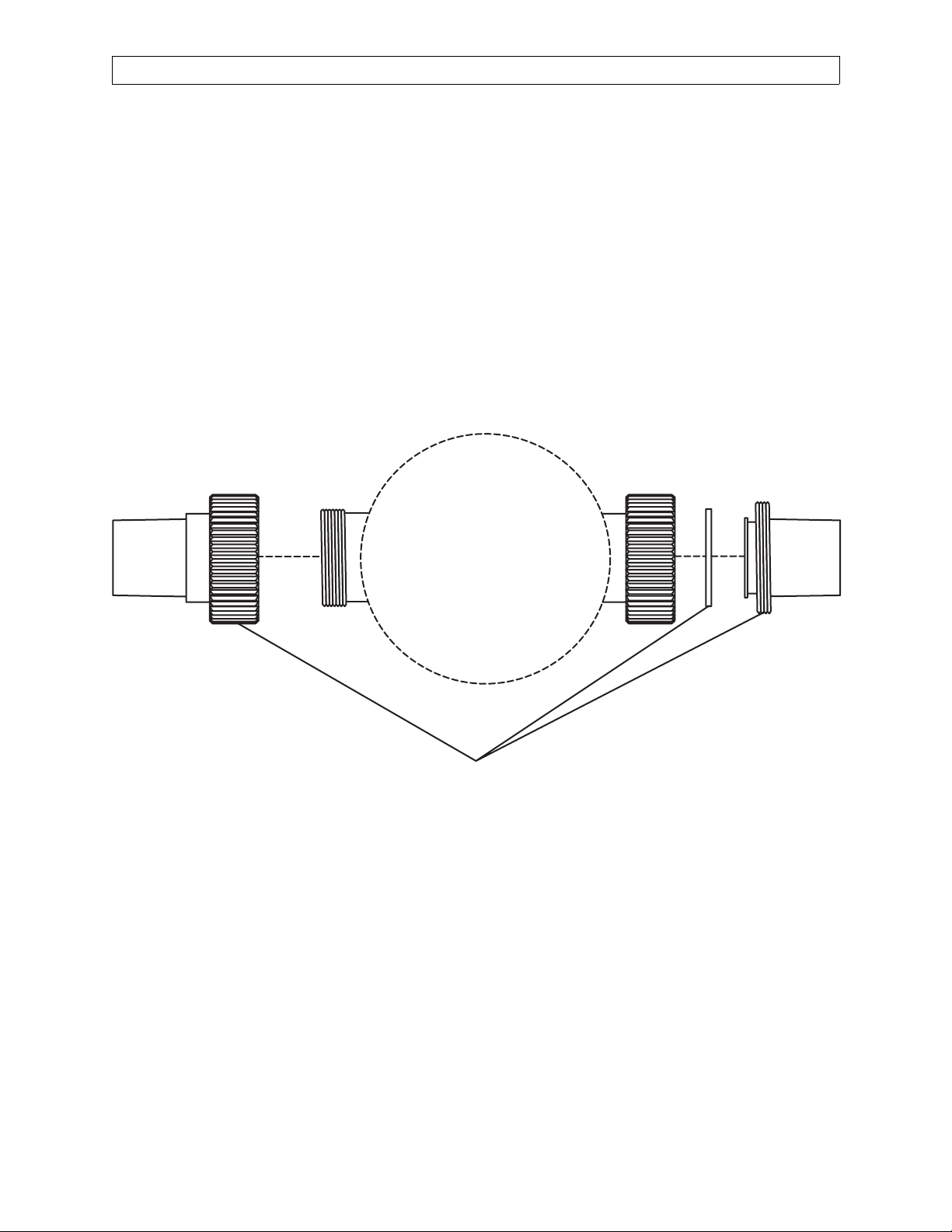

TEST EQUIPMENT AND FIXTURE ILLUSTRATIONS

4115041

FRESH GAS

LEAK TEST DEVICE

PMC PROCEDURE (continued)

TEST TERMINAL

S010158

FRESH GAS OUTLET VOLUME TEST DEVICE

TEST TERMINAL

S010159

BREATHING SYSTEM LEAK TEST DEVICE

4115042

VOLUMETER/

FRESH GAS HOSE

ADAPTER

SP18201

6-3

Page 6

PMC PROCEDURE (continued)

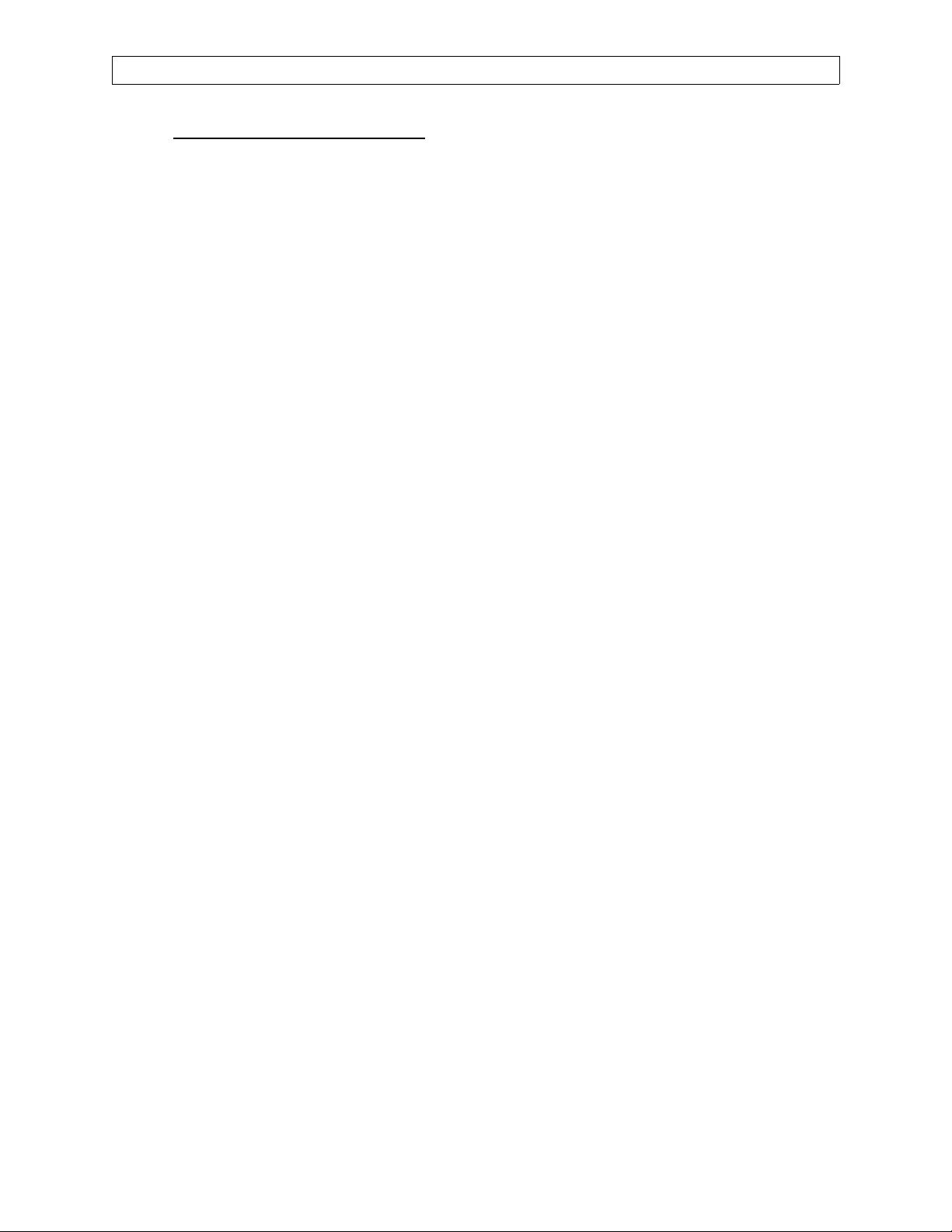

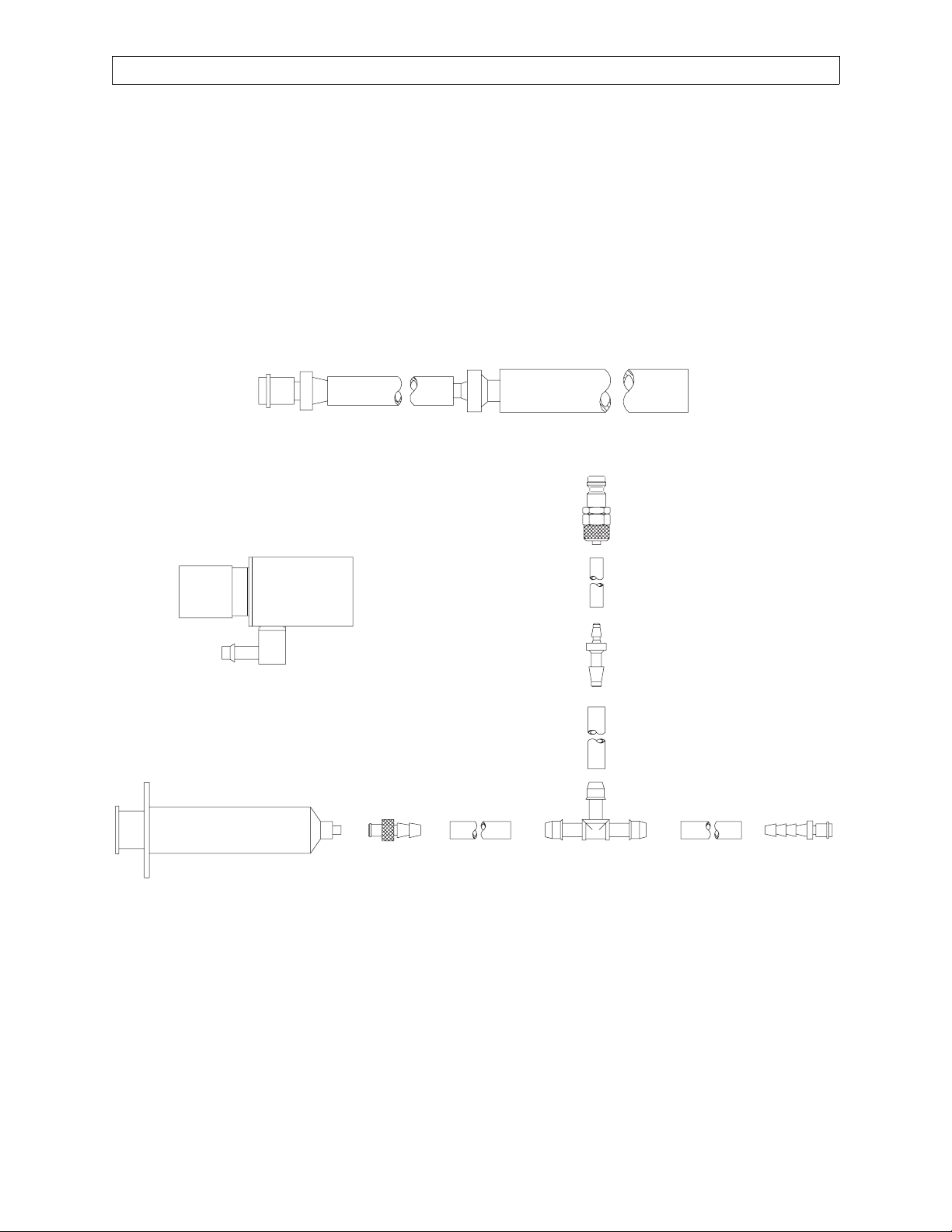

TEST EQUIPMENT AND FIXTURE ILLUSTRATIONS - Continued

4114807 PRESSURE TEST ASSEMBLY , WITH ADAPTERS

NM MOBILE/MILITARY

SP18202

4114830-002 4114830-001

4114830-004 4114830-003

4114830-006 4114830-005

6-4

Page 7

NM MOBILE/MILITARY

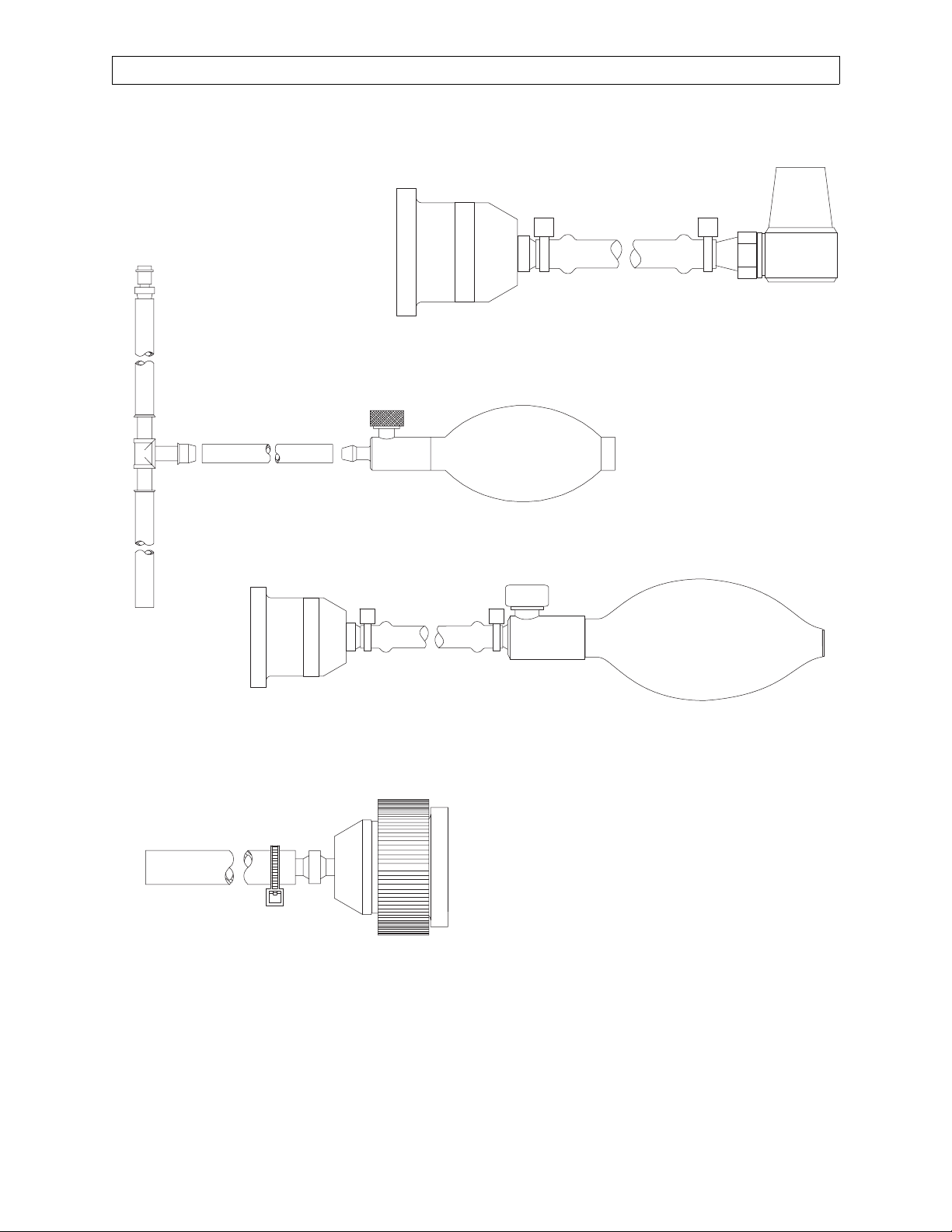

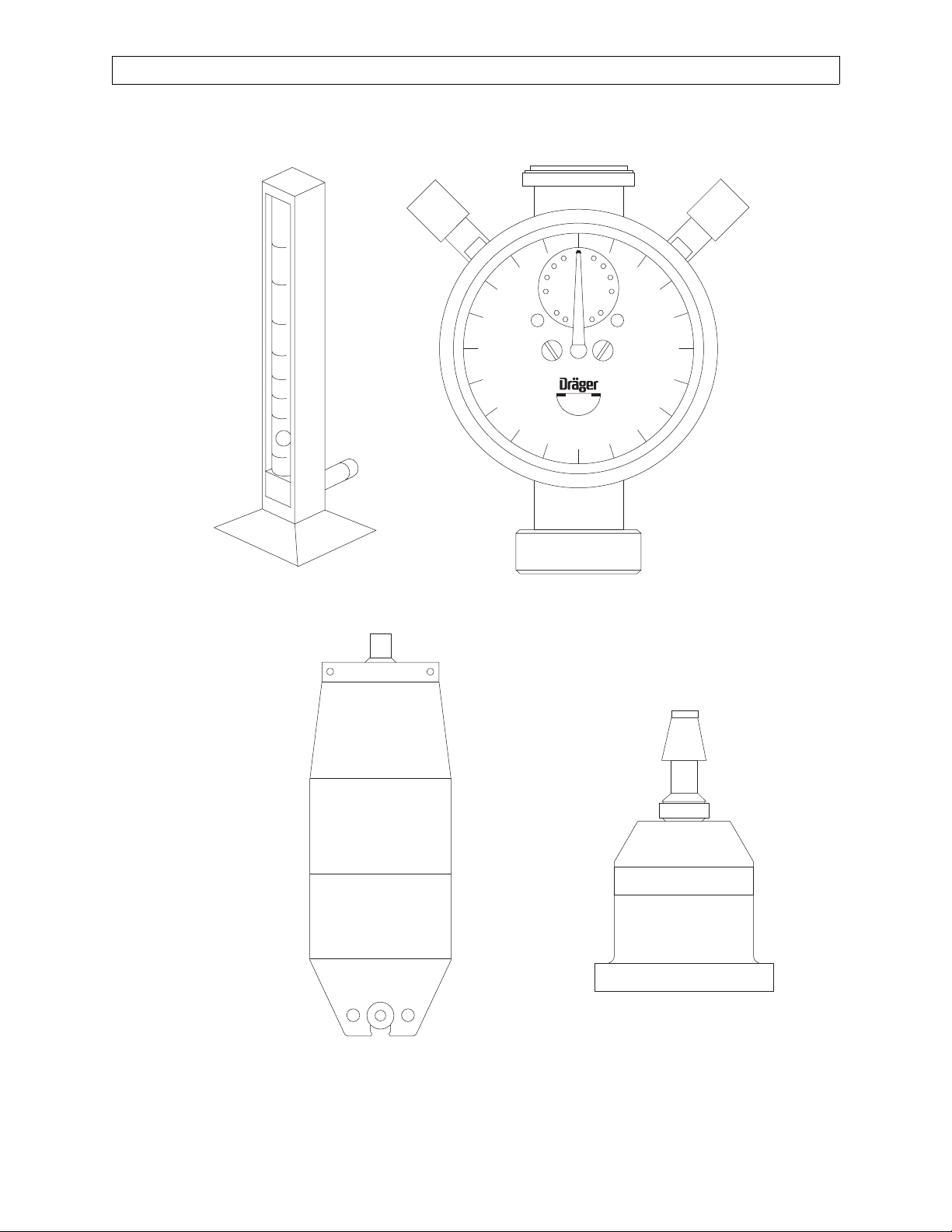

TEST EQUIPMENT AND FIXTURE ILLUSTRATIONS - Continued

PMC PROCEDURE (continued)

SP18203

TEST

VOLUME

METER

4115087 33mm x 22mm ADAPTER

6-5

Page 8

PMC PROCEDURE (continued)

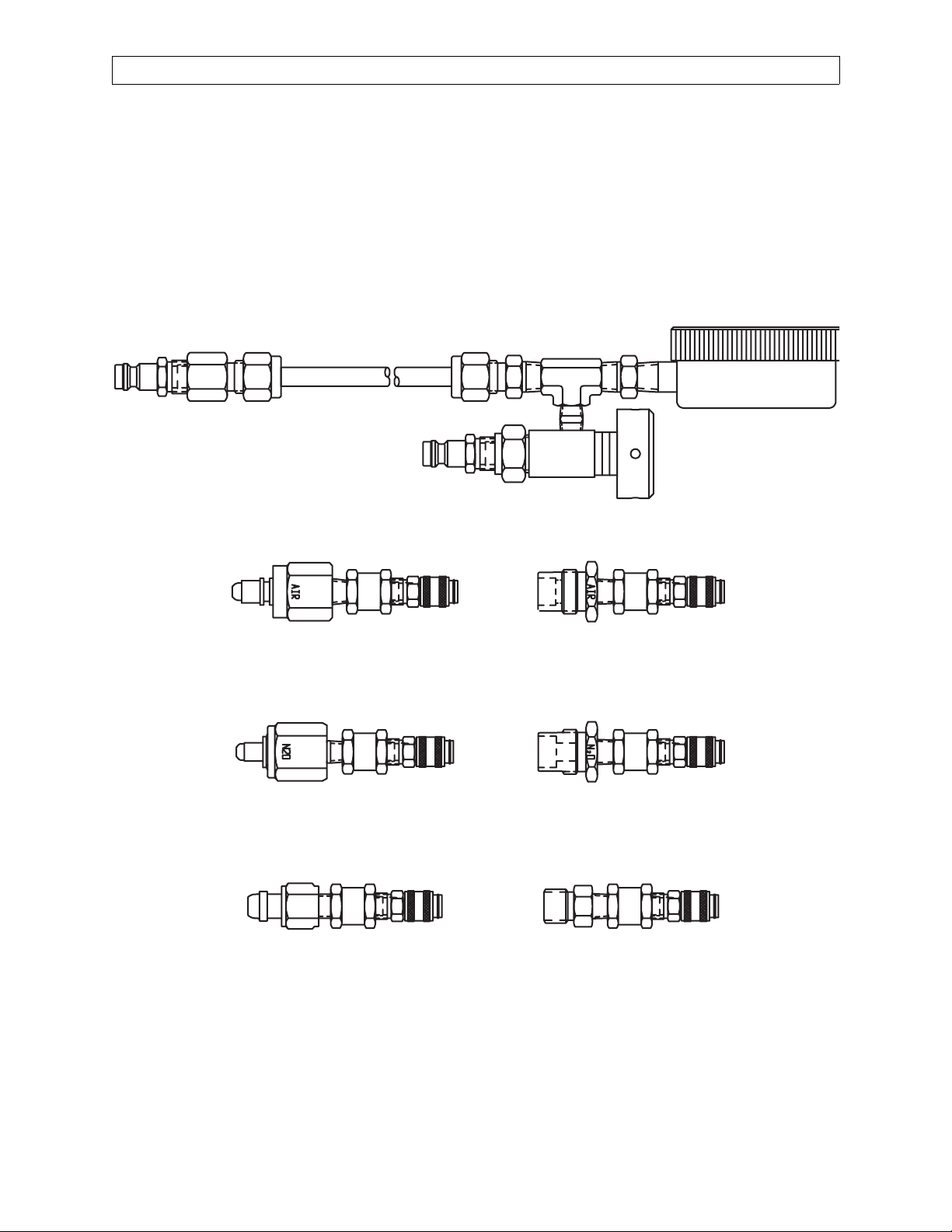

TEST EQUIPMENT AND FIXTURE ILLUSTRATIONS - Continued

PDM TO PATIENT SUCTION ADAPTER

NM MOBILE/MILITARY

4115038

AVENGER

4108114

SCAVENGER ADAPTER

4115043

PDM TO

MONITOR ADAPTER

SP18204

6-6

Page 9

NM MOBILE/MILITARY

TEST EQUIPMENT AND FIXTURE ILLUSTRATIONS - Continued

900

PMC PROCEDURE (continued)

15

Liter

100

S000081

FLOW METER

TEST STAND

800

700

vol/min

600

10

500

5

200

ml

300

400

4104389

TEST TERMINAL

ADAPTER

2212300

MINUTE

VOLUMETER

4115128

SIEMENS TEST LUNG

Rev. D

TEST TERMINAL

SP18205

6-7

Page 10

PMC PROCEDURE (continued)

NM MOBILE/MILITARY

Periodic Manufacturer’s Certification General Instructions

The purpose of these procedures is to provide detailed instructions for performing a Periodic

Manufacturer’s Certification (PMC) inspection on the Narkomed Mobile/Military anesthesia

machine.

A PMC consists of a complete Periodic Manufacturer ’s Service procedure and a certification level

inspection based on Draeger Medical, Inc. Recommendations and equipment performance.

Additional inspections are also performed to ensure proper product labeling.

Several additional documents have been created to assist the technician through the process.

Following is a brief description of the purpose of each document.

Field Service Procedure:

Periodic Manufacturer’s Certification Forms - Part Number SP00175.This procedure illustrates

the sample checklists with typical periodic maintenance items filled in, including vapor

concentration verification tests, parts replaced, general comments and certification levels. Also

included are sample PMC labels marked to show several levels of certifications. An excerpt from

Draeger Medical, Inc.’s Anesthesia System Risk Analysis and Risk Reduction is included, and also

a sample of an Executive Summary to be furnished to the hospital’s Risk Manager or Chief of

Anesthesia.

Field Service Procedure:

DMI Recommendation Guidelines Index Anesthesia Systems - Part Number S010250.This

Guideline was created to provide an assessment of each machine’s certification. It contains

various comprehensive overviews of possible equipment conditions and their associated

certification levels.

The first list in the Recommendation Guidelines is a reference chart for machine certification

based on equipment status. The second is an abbreviated summary of all DMI Recommendations

and Failure Codes including the Condition Number, Equipment Condition, Recommended

Corrections, Certification Code, and Tests Affected when applicable.

There is also a matrix classified as “Failure Codes” which identifies the correct manner in which

to document equipment tests that fail, or were unable to be performed due to circumstances

beyond the control of the service technician performing the inspection. (Ex: Air cylinder supply is

unavailable to perform an Air High Pressure Leak test.) The Failure Codes section also indicates

suggested resolution of the situation. Failure Code numbers begin at 34 and use the same

certification levels strategy, and carry the same weight as NAD Recommendation equipment

condition codes.

The final matrix is the most comprehensive index sorted by machine model and includes

Equipment Condition, Certification Code, and DMI Recommendations. It also specifies any

suggested upgrade path including ordering information that should be taken such as installing a

Bellows with Pressure Limit Control 4109664-S01 Kit, after market modification kit to a machine

not equipped with pressure limit control.

The letters A, B, C, D and the Roman Numerals I, II are used as codes in the individual matrix for

each model of anesthesia machine. The letters A, B, C, and D are used in descending order to

indicate the certification level of the equipment. They are as follows:

A = Certified

B = Certified with Recommendations

C = Conditionally Certified

D = No Certification

6-8

Page 11

NM MOBILE/MILITARY

Roman Numerals I and II do not affect the certification level but rather are provided to give

further instructions to the end user as follows:

I = The system in its present configuration shall only be used with a CO2 monitor

incorporating an apnea warning. The operator of the system is advised to frequently scan

the CO2 readings and alarm thresholds.

II =The present configuration of equipment requires that the unit operate at all times

with an oxygen analyzer that includes a low oxygen warning. The operator of the system

is advised to frequently scan the oxygen readings and alarm limits.

Following is an explanation of machine certification levels:

Certified- No DMI Recommendations or Failure Codes apply to machine being inspected. (Only

item number 33 - "No Recommendations" shall apply for this certification level.)

Certified with Recommendations- A numbered DMI Recommendation or Failure Code with a

code of B applies to the machine being examined.

Conditionally Certified- A numbered DMI Recommendation or Failure Code with a code of BCI

or BCII applies to the machine being examined.

No Certification- A numbered DMI Recommendation or Failure Code with a code of D applies to

the machine being examined.

PMC PROCEDURE (continued)

When multiple recommendations apply, "No Certification" would take precedence over

"Conditionally Certified" and "Certified with Recommendations". "Conditionally Certified" would

take precedence over "Certified with Recommendations".

For example:

A Narkomed 2B could have DMI Recommendation number 21 and Failure Code 61.1 that apply.

21 - No ventilator pressure limit control. Code is B. 61.1 - Enflurane agent is unavailable to test.

Code is BC. Correct certification for this machine is BC, which means CONDITIONALLY

CERTIFIED WITH RECOMMENDATIONS.

A Narkomed 4 could have DMI Recommendation numbers 14 and 21 apply.14 - CO2/Agent

monitor exhaust port is not properly connected to the waste gas scavenger. Code B.

21 - No ventilator pressure limit control. Code B.The correct certification for this machine is B,

which means “CERTIFIED WITH RECOMMENDATIONS”.

A Narkomed 2B, 2C or GS could have DMI Recommendation 30 apply.

30 - Anesthesia machine is equipped with inhalation anesthesia vaporizers without an agent

analyzer in the breathing system. Code B. The correct certification for this machine is B, which

means “CERTIFIED WITH RECOMMENDATIONS”.

A Narkomed 6000 could have no DMI Recommendations or Failure Codes apply. The correct

certification level for this machine is Code A, “CERTIFIED”.

The correct certification for this machine is A, which means "CERTIFIED".

Code, D also means "NO CERTIFICATION", also means the machine shall not receive a

Periodic Manufacturer's Certification label. The machine shall receive a "WARNING This System Is Not Certified" label, P/N 4114857. This label shall be placed at a prominent location on the right side of the machine after all other previous PM and "Vigi-

®

lance Audit

Validation" labels have been removed.

6-9

Page 12

PMC PROCEDURE (continued)

NM MOBILE/MILITARY

PM Certification Procedure for Narkomed Mobile/Military Anesthesia System

1. Use the PM Certification form for Narkomed Mobile/Military Anesthesia Systems (P/

N 4115597).

2. Completely fill in the header information.

3. All Narkomed Mobile/Military machines are equipped with Humphrey valves. No

“MJV-2 LUBRICATION” is needed to be performed for this type of anesthesia

machine.

4. Replace the VENTILATOR RELIEF VALVE DIAPHRAGM every 12 months in

accordance with SP00075. Place a check mark and the replacement date at “VENT

VALVE REPLACEMENT” line on the Periodic Manufacturer’s Certification form.

5. If machine is equipped with a HALOTHANE Dräger Vapor 19 or 19.1 vaporizer,

determine if vaporizer must be inspected for soil condition one. Check the serial

number plate located on the rear of the vaporizer for a plus (+) preceding the serial

number. A HALOTHANE vaporizer serial number not preceded with a (+) must be

tested for soil in accordance with SP00073. If vaporizer does not need to be inspected,

indicate so with a plus (+) next to the “Vapor Inspection (H)” line on the Vigilance

Audit form. If vaporizer is soil condition 0, indicate so with “SOIL 0” written next to

the “Vapor Inspection (H)” line on the Vigilance Audit form. If vaporizer is soil

condition one, indicate so with “SOIL 1” written next to the “Vapor Inspection (H)” line

on the Vigilance Audit form. Place a “CAUTION DO NOT USE” label (part # 4114327)

on the vaporizer, and issue a departmental alert. The TSR shall also seek permission

from the equipment operator to remove the failed vaporizer from the machine and

apply a replacement vaporizer or an adapter block onto the mount. All “SOIL 1”

vaporizers must be removed from service for machine to receive certification.

6. Perform the vapor concentration test on all Dräger vapor vaporizers in accordance

with SP00073 at a six month maximum interval. Perform the vaporizer concentration

test on all Desflurane vaporizers in accordance with SP00091 for fixed mount

vaporizers and SP00189 for user removable D-tec vaporizers at a six month maximum

interval. For every vaporizer tested, fill out a "VAPOR VAPORIZER CALIBRATION

CHECK" label (part # S010016). Information on this label shall include your

signature, type of agent, date tested, a No Agent To Test or the test results @ 1%, 2.5%,

4% for H, E, I, or S vaporizers, or @ 4%, 10%, 12%, 16% for Desflurane vaporizers, and

a PASS or FAIL indication. This label shall be attached to the upper right side of the

vaporizer. If vaporizer fails the concentration verification, internal leak, or exclusion

system tests, check "NO" in the "RECOMMENDED FOR USE" section on the PM

Certification form. Place a "CAUTION DO NOT USE" label (part # 4114327) on the

vaporizer, and issue a departmental alert. The TSR shall also seek permission from

the customer to remove the failed vaporizer from the machine and install a

replacement vaporizer or an adapter block onto the mount. All nonfunctional

vaporizers must be removed from service for machine to receive certification.

6-10

Page 13

NM MOBILE/MILITARY

7. Proceed with PM Certification procedure. If any tests fail refer to the "Failure Codes"

listing in DMI Recommendations Guidelines Index (P/N S010250) to determine

correct certification level starting point. Failure codes shall be documented on the

"RECOMMENDATIONS / GENERAL COMMENTS" section of the PM Certification

form and on the Executive Summary. If a test fails that has not been identified by the

"Failure Codes" list, consult with Draeger Medical, Inc. to assess the proper

certification level.

8. Based on the "EQUIPMENT CONDITION" inspect the machine for any "DMI

RECOMMENDATIONS" that would apply. Use the Narkomed Mobile/Military section

of the "RECOMMENDATION GUIDELINES INDEX" (P/N S010250). Note all

applicable DMI recommendations on the Executive Summary. NOTE: If using a

carbon form, indicate the Equipment Condition number and to see reverse side under

the "RECOMMENDATIONS / GENERAL COMMENTS" section of the form.

9. Determine the correct certification level of the machine based on the combined lowest

common denominator of "Equipment Conditions" and "Failure Codes". If the machine

is at least conditionally certified fill out the "PM CERTIFICATION" label. Check the

box(s) on the validation label where appropriate. Write the month and year, (three

months from date of PM Certification) next to "NEXT VISIT DUE:". If certification

level is "D", machine shall not receive a "PM CERTIFICATION" label. Any machine

not receiving a PM Certification label shall receive a "WARNING NOT CERTIFIED"

label, P/N 4114857. This label shall be placed at a prominent location on the left side

of the machine after all other previous PMS and Vigilance Audit Validation labels

have been removed.

PMC PROCEDURE (continued)

10.In the "CERTIFICATION LEVEL" section of the PM Certification form, record the

last visit certification level, the current certification level and the next visit due month

and year, (three months from date of PM Certification) in the spaces provided.

11.If applicable, remove the previous PM CERTIFICATION VALIDATION label and

attach the new label (P/N S010006 w/phone #, or S010007 w/o phone #) in a prominent

location on the rear of the anesthesia machine.

12.Check the appropriate boxes on the "PM CERTIFICATION NOTICE" label, (part #

S010011). If the machine is not certified, the last box of this notice label shall be

marked. Attach this notice near the flowmeter shield of the anesthesia machine.

13.Have the customer sign each PM Certification form or the Executive Summary, and

review any Failure Codes equipment conditions and DMI Recommendations with the

customer.

14.Return top copy to Draeger Medical, Inc. Service Department, keep middle copy for

service organization records, give bottom copy to customer.

6-11

Page 14

PMC PROCEDURE (continued)

(

ü) 6.1 SELF-DIAGNOSTICS

6.1.1 Turn the System Power switch to ON and verify the "ON" LED is

lighted?

6.1.2 Verify all LED's on the keypad and ventilator displays are lit.

6.1.3 Verify that the following is displayed on the Display:

FIRMWARE PASS

RAM PASS

VIDEO PASS

A/D CONVERTER PASS

AUDIO - PRIMARY PASS

BACKUP PASS

SERIAL I/O PASS

CLOCK PASS

NON-VOLATILE MEMORY PASS

FUNCTIONAL

NM MOBILE/MILITARY

NARKOMED

COPYRIGHT 1997-1998 NAD. INC.

VERSION X.XX NARKOMED

SOFTWARE ID: XXXX

ü) 6.1.4 Record the machine software version on the header of the checklist form.

(

6.2 ELECTRICAL SAFETY- One Year Service Interval; Due Date ______

(

ü) 6.2.1 Battery Check & Ground Continuity

6.2.1.1 Unplug the AC power cord for all devices mounted to the

machine that may provide an alternate path to earth ground,

such as a Desflurane vaporizer.

6.2.1.2 Unplug the machine’s AC power cord and plug the power cord of

the safety analyzer into this AC receptacle.

NOTE: Do not plug the safety analyzer power cord into a line isolation

monitor circuit, as inaccurate readings may occur.

NOTE: The BIOTECH 501 PRO will automatically test the source

outlet for open ground (or ground resistance of 31 Ohms or

higher), reverse polarity, open neutral and open line. (The latter

two conditions will prevent the analyzer from powering up.)

6.2.1.3 Is the green "AC POWER" LED off? __ (Y)

6.2.1.4 Does the "AC PWR FAIL" message appear in the Advisory

display? __ (Y)

6-12

Page 15

NM MOBILE/MILITARY

T

SPIROMED

6.2.1.5 Press and hold the "BATTERY TEST" button.

6.2.1.6 Is green Battery Test LED lighted? __ (Y)

6.2.1.7 Release the "BATTERY TEST" button.

6.2.1.8 Turn on the safety analyzer and configure it to measure

6.2.1.9 Plug the machine’s AC power cord into the safety analyzer.

6.2.1.10 Apply the analyzer’s test lead to a cylinder yoke bolt.

6.2.1.11 What is the value displayed on the safety analyzer? ___ ohm (0-

PMC PROCEDURE (continued)

“Resistance” according to the manufacturers documentation.

Attach a test lead to the “SINGLE LEAD” connector of the

analyzer. Connect the other end of the test lead to the AC

receptacle ground socket on the safety analyzer. Verify a

displayed resistance of 0.00 ohms or, if necessary, calibrate the

unit according to manufacturers documentation.

0.1)

ü) 6.2.2 Circuit Isolation

(

6.2.2.1 Disconnect the respiratory volume sensor cord from the

interface panel.

6.2.2.2 Using a multimeter set to its

highest resistance range apply the

test leads between the yoke bolt

and circuit common at the volume

interface test pin. Use the position

indicated on the illustration for

the ultrasonic flow sensor

connector. Use the 12 o’clock

position for the Spiromed

connector. There shall be no continuity between these two

points. Refer to illustrations for proper pin locations.

6.2.2.3 Reconnect the respiratory volume

sensor cord to the interface panel.

6.2.3 Chassis Leakage Current

6.2.3.1 Apply the analyzer test lead to a

cylinder yoke bolt.

6.2.3.2 Configure the safety analyzer to

the measure “CHASSIS LEAKAGE CURRENT” according to

the manufacturers documentation.

EY

P15005A

KEY

SP15005

ULTRASONIC

TES

PIN

TEST

PIN

6-13

Page 16

PMC PROCEDURE (continued)

6.2.3.3 Record the total leakage current with the Polarity and Ground

switches set as follows:

NM MOBILE/MILITARY

Ground

(ü) 6.2.3.3.1 Normal Normal

ü) 6.2.3.3.2 Open Normal

(

(

ü) 6.2.3.3.3 Open Reversed

(

ü) 6.2.3.3.4 Normal Reversed

6.2.3.4 Verify that the leakage current is 100* microamps or less in

each of the switch positions (110 microamps or less for the 220/

240 volt power supply option).

6.2.3.5 300 microamps if external monitors are plugged into

convenience receptacles.

6.2.3.6 Shut off and unplug the safety analyzer. Remove the anesthesia

machine plug from the analyzer and plug it back into the

original AC receptacle.

ü) 6.3 CONFIGURATION

(

6.3.1 Press the CONFIG key.

6.3.2 The CONFIGURE screen is displayed.

Polarity

6.3.3 Verify the correct Time and Date.

6.3.4 Press the exit key to exit the function.

6.4 SERVICE DATA

6.4.1 Press and hold the Oxygen High Limit key and the Volume Low Limit

key, and then press the UP ARROW key.

6.4.2 The Main Service Screen shall appear.

6.4.3 Select and enter the Service Log.

6.4.4 Verify any pertinent information from the Service Log. Contact the

Draeger Medical, Inc. Technical Service Department if necessary.

6.4.5 Press EXIT to return to the Main Service screen.

6.4.6 Using the arrow keys, select the SRVC Service Code.

6.4.7 Press the SELECT key and enter your Technical Service Rep. I.D.

number.

6-14

Page 17

NM MOBILE/MILITARY

ü) 6.4.8 Press the RESET key. This resets the last service date to the current

(

PMC PROCEDURE (continued)

date and resets the hours run since last service to zero.

6.4.9 Press the PMS SCHED key.

(

ü) 6.4.10 Select and enter the month of the next service due date.

NOTE: The internal clock of the machine limits the amount of date advance to a

maximum of six months from the current service date.

6.4.11 Press the EXIT key to return the main service screen. If not performing

monitor calibrations, press the EXIT key again to return to normal

operation mode.

6.5 CALIBRATIONS - One Year Service Interval; Due Date ______

6.5.1 To bring up the Oxygen Monitor Service Screen, press the Mon Cal key.

6.5.2 Remove the Oxygen sensor from the Breathing Pressure Hose Assembly,

and remove the Oxygen Sensor capsule from the Oxygen Sensor

Housing.

ü) 6.5.3 When the CURRENT CELL A and CURRENT CELL B readings have

(

stabilized, press the ZERO key and verify that the new offset values are

stored.

NOTE: The higher the offset, the higher the calculated O

2 concentration appears

at high concentrations.

6.5.4 Put the Oxygen Sensor capsule into the Oxygen Sensor Housing.

6.5.5 Press the PRES MON key.

6.5.6 Remove Breathing Pressure Hose Assembly from Inspiratory Valve dome

to expose the Breathing Pressure Sensor line to ambient pressure.

6.5.7 Let the Current Pressure Value stabilize and press the ZERO key to

store the value.

6.5.8 Remove Breathing Pressure Sensor line from the machine.

6.5.9 Connect a Pressure Monitor Adapter, (P/N 4115043) and calibrated

manometer to the Breathing Pressure quik connect on the machine

monitor interface.

NOTE: Zero manometer prior to connecting to monitor interface. Slight pressure

will be noticed on manometer when connected to monitor interface, DO

NOT re-zero manometer.

6-15

Page 18

PMC PROCEDURE (continued)

NM MOBILE/MILITARY

6.5.10 Pressurize the circuit to 50 cm H

2O and allow the [Current Value] to

stabilize.

ü) 6.5.11 Press the SPAN key and verify that the new span values are stored.

(

6.5.12 Release the pressure, disconnect the manometer and test fixture,

reconnect the Breathing Pressure Sensor line to the quik connect on the

machine monitor interface and insert the Breathing Pressure Hose

Assembly into Inspiratory Valve dome.

6.5.13 Press EXIT to return to the Main Service screen.

6.5.14 Press EXIT to return to normal operation.

(ü) 6.6 ABSORBER INSPECTION

Absorber System Inspection and Maintenance

6.6.1 Remove the O

2 Sensor Housing and/or Oxygen Sensor Plug and

Breathing Pressure Hose Assembly from the inspiratory valve dome and

examine the O-rings on each assembly. Replace O-rings as necessary.

6.6.2 Remove the Inspiratory and the Expiratory valve domes.

6.6.3 Are any pins on the valve crater damaged? Inspiratory ___ (N)

Expiratory ___ (N) Replace complete valves as necessary.

6.6.4 Are any pins on the valve domes damaged? Inspiratory ___ (N)

Expiratory ___ (N) Replace complete valves as necessary.

6.6.5 Is the valve disc in good condition? Inspiratory ___ (Y) Expiratory ___ (Y)

Replace as necessary.

6.6.6 Are the valve dome washers in good condition? ___ (Y) Replace washers

as necessary.

6.6.7 Reinstall the Inspiratory and Expiratory valve domes.

ü) 6.6.8 Ultrasonic Flow Sensor (Mobile Only)

(

6.6.8.1 Remove the Ultrasonic Flow Sensor connector hose.

6.6.8.2 Are the connector hose, connector, and O-ring components in

good condition? ___ (Y) Replace components as necessary.

6.6.8.3 Remove the Expiratory valve.

6.6.8.4 Is the washer under the valve in good condition? ___ (Y) Replace

washer as necessary.

6-16

Page 19

NM MOBILE/MILITARY

6.6.8.5 Remove the PEEP valve.

6.6.8.6 Is the washer under the PEEP valve in good condition? ____(Y)

6.6.8.7 Reattach the PEEP valve.

6.6.8.8 Reattach the Expiratory valve.

6.6.8.9 Remove the Ultrasonic Flow Sensor from the mounting bracket

6.6.8.10 Remove the flow housing/transducer assembly from the

6.6.8.11 Remove both transducers from the flow housing; examine each

6.6.8.12 Reattach the Ultrasonic Flow Sensor to the mounting bracket.

PMC PROCEDURE (continued)

Replace washer as necessary.

electronics housing.

O-ring and condition of all components, replace O-rings as

necessary, then reassemble the Ultrasonic Flow Sensor.

6.6.8.13 Reattach the connector hose between the Ultrasonic Flow

Sensor and Expiratory valve.

(

ü) 6.6.9 Spiromed Sensor (Military Only)

6.6.9.1 Remove the expiratory valve.

6.6.9.2 Is the washer under the valve in good condition? ___ (Y) Replace

washer as necessary.

6.6.9.3 Remove the Spiromed Sensor.

6.6.9.4 Is the washer under the sensor in good condition? ___ (Y) Replace

washer as necessary.

6.6.9.5 Remove the PEEP valve.

6.6.9.6 Is the washer under the PEEP valve in good condition? ____(Y) Replace

washer as necessary.

6.6.9.7 Reattach the PEEP valve.

6.6.9.8 Locate the four lateral holes at the sides of the Spiromed Sensor

marked by arrows.

Caution: Use only the Sensor Lubrication Kit (P/N 2218180) for the following

procedure.

6-17

Page 20

PMC PROCEDURE (continued)

6.6.9.9 Dip the tip of the pipette into the lubricant and draw lubricant into the

pipette by pulling the pin backwards.

6.6.9.10 Insert the pipette into one of the four holes as far as it will go. Push the

pin forward to its stop to inject lubricant into the hole.

6.6.9.11 Repeat the previous 2 steps for lubrication of the three remaining

holes.

6.6.9.12 Wipe any lubricant residue from the exterior of the sensor.

6.6.9.13 Reattach the Spiromed Sensor to the PEEP valve.

6.6.9.14 Reattach the Expiratory valve to Spiromed Sensor.

6.6.9.15 Remove the Inspiratory valve assembly.

6.6.9.16 Is the washer under the valve in good condition? ___ (Y) Replace

washer as necessary.

NM MOBILE/MILITARY

6.6.9.17 Reinstall the Inspiratory valve.

6.6.9.18 Is there a wing nut on each absorber rod? ___ (Y)

6.6.9.19 Inspect the following: canister, canister gaskets, dust cup and O-ring,

and soda lime.

6.6.9.20 Are the canister, canister gaskets, dust cup and O-ring, and soda lime

in good condition? ___ (Y) Replace components as necessary.

6.6.9.21 Verify the cm H2O gauge is at zero (0) and readjust/replace as

necessary.

NOTE: The small slotted screw is the zero adjustment.

6.6.9.22 Reinstall the Breathing Pressure Hose Assembly into the Inspiratory

valve dome.

6.6.9.23 Reinstall the O2 Sensor plug into the Breathing Pressure Hose

Assembly.

6.6.9.24 Remove the Freshgas Hose Assembly from the FRESHGAS OUTLET.

6.6.9.25 Is the Freshgas Hose Assembly and Freshgas Outlet in good condition?

___ (Y)

6.6.9.26 Reconnect the Freshgas Hose Assembly to the FRESHGAS OUTLET.

6-18

Page 21

NM MOBILE/MILITARY

ü) 6.7 HIGH PRESSURE LEAK

(

PMC PROCEDURE (continued)

NOTE: Minimum cylinder pressures required for High Pressure Leak tests are:

N2O: 600 psi;

O

2, Air: 1000 psi.

6.7.1 Turn the machine to Standby.

6.7.2 Verify the Auxiliary Oxygen flow control valve is closed

6.7.3 Disconnect all pipeline supply hoses at the wall outlets.

6.7.4 Open then close and remove each cylinder. And if applicable remove the

yoke plug from each additional yoke assembly.

6.7.5 Note the reading on each of the cylinder pressure gauges and start a stop

watch.

6.7.6 Are there two (2) yoke index pins installed securely in each yoke? ___(Y)

6.7.7 Is the proper gas I.D. label affixed to each yoke? ___ (Y)

6.7.8 After two (2) minutes, is the pressure loss equal to or less than 50 PSI?

___(Y)

6.7.9 Verify the presence of only one (1) cylinder washer, then reattach and

secure the cylinders to each yoke assembly, then open each cylinder

valve.

6.8 BREATHING SYSTEM

6.8.1 Absorber & Freshgas Leak/ Vaporizer Leak

6.8.1.1 Close all flow control valves.

6.8.1.2 Set the AUTO/BAG selector to BAG.

6.8.1.3 Close the APL valve.

6.8.1.4 Interconnect the inspiratory valve and expiratory port (on the

Ultrasonic Flow Sensor) or the expiratory valve, as applicable,

with a 22 mm hose (P/N 9995132).

6.8.1.5 Attach a Freshgas Leak Test Adapter (P/N 4115041), Test

Terminal Adapter (P/N 4104389), and Digital Pressure

Manometer to the bag mount.

6.8.1.6 Apply 50 cm H

2O test pressure to the absorber system and start

a stop watch.

6-19

Page 22

PMC PROCEDURE (continued)

NM MOBILE/MILITARY

6.8.1.7 Is the pressure on the manometer within 49 to 51 cm H

(Y)

6.8.1.8 Is the pressure displayed on the Breathing Pressure Gauge +/- 3

2O of the value displayed on the test manometer?___(Y)

cm H

(

ü) 6.8.1.9 After thirty (30) seconds, is the pressure displayed on the

manometer equal to or greater than 40 cm H

2O? ___(Y)

6.8.1.10 If applicable, turn on the vaporizer to the first graduated

marking. Reapply 50 cm H

2O of pressure to the system and

start a stopwatch.

ü) 6.8.1.11 After thirty (30) seconds, is the vaporizer test pressure

(

displayed on the manometer equal to or greater than 40 cm

2O? ___(Y). Turn off the vaporizer.

H

(

ü) 6.8.2 APL Valve

6.8.2.1 Open the APL valve to its stop.

6.8.2.2 Verify Scavenger is active.

2O? ___

6.8.2.3 Turn the System Power switch to ON.

6.8.2.4 Set the Oxygen flow to 8 l/min.

6.8.2.5 Is the test pressure within 0 to 3 cm H

6.8.2.6 Remove Freshgas Leak Test Adapter (P/N 4115041), Test

ü) 6.8.3 O2 Flush

(

6.8.3.1 Attach a 33 mm x 22 Female Adapter (P/N 4115087) to the top

6.8.3.2 Remove the ventilator hose from the absorber and bellows, and

6.8.3.3 Connect test volumeter to the end of ventilator hose.

6.8.3.4 Close the APL valve.

6.8.3.5 Press and hold the O

2O? ___ (Y)

Terminal Adapter (P/N 4104389), and Digital Pressure

Manometer (P/N PDM 200CD) from the bag mount.

port of the test volumeter.

connect to the Bag Mount terminal.

2 FLUSH button for 6 seconds; multiply

the value obtained by 10.

6-20

Page 23

NM MOBILE/MILITARY

6.8.3.6 Is the calculated Oxygen flush flow rate within 45 to 65 l/min.?

___ (Y)

6.8.3.7 After releasing the flush, does the flow of Oxygen stop

immediately? ___ (Y)

6.8.3.8 Reattach ventilator hose between absorber and bellows

ventilator terminals.

6.8.3.9 Remove all test equipment. Remove 22mm hose from

inspiratory valve and expiratory port on the Ultrasonic Flow

Sensor or the expiratory valve, as applicable.

ü) 6.8.4 Expiratory Valve Leak

(

6.8.4.1 Connect a 22 mm hose (P/N 9995132) between the Inspiratory

valve and the bag mount.

6.8.4.2 Connect a test terminal (P/N 4104389) to the expiratory port on

the Ultrasonic Flow Sensor.

PMC PROCEDURE (continued)

6.8.4.3 Connect a 0-250 ml/min. flowmeter (P/N S000081) to the test

terminal.

6.8.4.4 Turn up the Oxygen flow until the system pressurizes to 30 cm

2O. Adjust the APL valve as necessary to maintain 30 cm

H

2O.

H

6.8.4.5 Is the value indicated on the flowmeter within 0 to 60 ml/min.?

___ (Y)

6.8.4.6 Turn off O

2 flow. Fully close APL valve.

6.8.4.7 Remove all test equipment.

(

ü) 6.8.5 Inspiratory Valve Leak

6.8.5.1 Turn the System Power switch to Standby.

6.8.5.2 Connect a test terminal (P/N 4104389) to the Inspiratory valve.

6.8.5.3 Connect a Fresh Gas Leak Adapter (P/N 4115041) and

manometer to the test terminal on the Inspiratory valve.

6.8.5.4 Connect another test terminal to the bag mount.

6.8.5.5 Connect a 0-250 ml/min. flowmeter (S000081) to the test

terminal on the bag mount.

6-21

Page 24

PMC PROCEDURE (continued)

NM MOBILE/MILITARY

6.8.5.6 Pressurize the test circuit to 30 cm H

6.8.5.7 Is the value indicated on the flowmeter within 0 to 60 ml/min.?

___ (Y)

6.8.5.8 Turn the system power switch to ON.

6.8.5.9 Remove all test equipment.

(

ü) 6.8.6 Absorber PEEP Valve

6.8.6.1 Open the APL valve.

6.8.6.2 Disconnect the pressure line going to the Breathing Pressure

gauge and connect to a test manometer.

6.8.6.3 Connect a Fresh Gas Outlet Volume Test Device (S010158) to

the Fresh gas outlet.

6.8.6.4 Install a test breathing circuit or disposable breathing circuit

onto the Inspiratory and Expiratory valves of the absorber.

6.8.6.5 Connect the test terminal, of the Fresh Gas Outlet Volume Test

Device, to the Y-piece of the breathing circuit.

2O.

6.8.6.6 Set the O

6.8.6.7 Adjust the absorber PEEP valve clockwise to the maximum

position.

6.8.6.8 Does the PEEP valve adjust smoothly? ___ (Y)

6.8.6.9 Is the maximum PEEP indicated on the test gauge greater than

15 cm H

6.8.6.10 Adjust the absorber PEEP valve counterclockwise to its

minimum position.

6.8.6.11 Is the PEEP indicated on the test gauge less than or equal to 3

cm H

6.8.6.12 Close the O

6.8.6.13 Remove the test equipment and reconnect the pressure line to

the Breathing Pressure gauge.

6.9 OXYGEN ANALYZER

2 flow to 5 l/min.

2O? ___ (Y)

2O? ___(Y)

2 flow control valve.

6.9.1 Press the Cal key.

6-22

Page 25

NM MOBILE/MILITARY

PMC PROCEDURE (continued)

NOTE: Ensure that the sensor has stabilized in ambient air for several

minutes.

ü) 6.9.2 After calibration is completed, is the O2 concentration 21%? ___ (Y)

(

6.9.3 The warning message INSP O

2 LOW shall appear on the central alarm

display, and an audible alarm shall sound.

6.9.4 Press the ALARM SILENCE key and verify the audio alarm is silenced.

6.9.5 Remove the Breathing Pressure Hose Assembly from the Inspiratory

valve dome.

6.9.6 Place the Oxygen Sensor housing directly into the Inspiratory valve

dome.

6.9.7 Verify the AUTO/BAG selector is set to BAG.

6.9.8 Close the APL valve.

6.9.9 Attach a 22 mm hose (P/N 9995132) to the Inspiratory valve.

6.9.10 Attach a Breathing System Leak Test Device (P/N S010159) to the bag

mount.

6.9.11 Press the O

6.9.12 After 20 seconds, is the O

2 Flush.

2 concentration within 90 to 100 %? ___ (Y)

6.9.13 Release the O

2 Flush, does the flow cease immediately? ___ (Y)

6.9.14 Set the Oxygen flow to 8 l/min.

(

ü) 6.9.15 After 1 minute, is the O2 concentration within 97 to 100 %? ___ (Y)

6.10 FLOWMETERS & CONCENTRATIONS

ü) 6.10.1 Oxygen Flowmeter

(

6.10.1.1 Is it possible to adjust the flow of Oxygen over the full range of

the flowmeters? ___ (Y)

6.10.1.2 Set the Oxygen flow to 4 l/min.

6.10.1.3 Is the correct flow control knob and label attached to the

Oxygen flow control valve? ___ (Y)

6-23

Page 26

PMC PROCEDURE (continued)

(

ü) 6.10.2 Air Flowmeter

6.10.2.1 If not configured with an Air Cylinder yoke, attach the Air

Pipeline hose.

6.10.2.2 Is it possible to adjust the flow of the Air over the full range of

the flowmeter? ___ (Y)

6.10.2.3 Set the Air flow to 2 l/min.

NM MOBILE/MILITARY

6.10.2.4 After the value stabilizes, is the O

77 %? ___ (Y)

6.10.2.5 Close the Air flow control valve.

6.10.2.6 Is the correct flow control knob and label attached to the Air

flow control valve? ___ (Y)

6.10.3 Nitrous Oxide Flowmeter

6.10.3.1 Set the Nitrous Oxide flow to 2 l/min.

6.10.3.2 After the value stabilizes, is the O

70 %? ___ (Y)

6.10.3.3 Is the correct flow control knob and label attached to the

Nitrous Oxide flow control valve? ___ (Y)

6.10.3.4 Is it possible to adjust the flow of nitrous oxide over the full

range of the flowmeter? ___ (Y)

ü) 6.10.4 Oxygen Ratio Control

(

2 concentration within 71 to

2 concentration within 64 to

6.10.4.1 Open the Nitrous Oxide flow control valve to the stop position.

6.10.4.2 After the value stabilizes, is the O

2 concentration within 21 to

29 %? ___ (Y)

6.10.4.3 Set the Oxygen flow to 2 l/min.

6.10.4.4 After the value stabilizes, is the O

2 concentration within 21 to

29 %? ___ (Y)

6.10.4.5 Set the Oxygen flow to 1 l/min.

6.10.4.6 After the value stabilizes, is the O

2 concentration within 21 to

29 %? ___ (Y)

6.10.4.7 Close the Oxygen flow control valve.

6-24

Page 27

NM MOBILE/MILITARY

6.10.4.8 Close the Nitrous Oxide flow control valve.

ü) 6.10.5 Auxiliary Oxygen Flowmeter

(

6.10.5.1 Connect a test manometer to the Auxiliary Oxygen outlet using

a PDM/Suction adapter (P/N 4115038).

PMC PROCEDURE (continued)

6.10.5.2 Slowly open flowmeter valve until a pressure of 50 cm H

2O is

achieved.

6.10.5.3 Close flowmeter valve.

6.10.5.4 After 10 seconds, is the pressure within 40 to 60 cm H

2O? ___

(Y)

6.10.5.5 Remove the test manometer and adapter.

6.10.5.6 Is it possible to adjust the Auxiliary Oxygen flowmeter over the

full range of the flowmeter? ___(Y)

6.10.5.7 Set the Auxiliary O

2 flow rate to 5 L/min.

6.10.5.8 Hold the Oxygen sensor at the Auxiliary Oxygen flowmeter

outlet.

6.10.5.9 After the value stabilizes, is the O

2 concentration within 80 to

100 %? ___ (Y)

6.10.5.10Reinstall the Breathing Pressure Hose Assembly.

6.10.5.11Insert the Oxygen sensor into the Breathing Pressure Hose

Assembly.

6.10.5.12Close the Auxiliary Oxygen flow control valve.

6.11 HIGH PRESSURE REGULATORS – Six Month Service Interval; Due Date ______

ü) 6.11.1 N2O Regulator- if applicable

(

NOTE: Minimum cylinder pressure for N2O regulator test is 600 psi.

6.11.1.1 Configure the test gauge (P/N 4114807) using a N2O nut/stem

DISS connector (P/N 4114830-004) on the hose, and N2O DISS

body connector (P/N 4114830-003) on the valve body side. If the

machine is configured with CSA style fittings reverse the

position of the connectors.

6.11.1.2 Connect the test fixture hose to the machine’s Nitrous Oxide

pipeline inlet.

6-25

Page 28

PMC PROCEDURE (continued)

6.11.1.3 Connect the Nitrous Oxide pipeline supply hose to the test

fixture.

6.11.1.4 Open the Nitrous Oxide and the Oxygen cylinder valves.

6.11.1.5 Set the Oxygen and Nitrous Oxide flows to 4 l/min.

6.11.1.6 Depress the push button on the test device.

6.11.1.7 Release the push button. After the pressure decay stabilizes, is

the regulator output pressure within 40 to 49 psi? ___ (Y)

6.11.1.8 Remove the test fixture.

NOTE: If a pressure decrease does not occur, either the hospital’s

supply pressure is too low or the regulator pressure is set too

high.

(

ü) 6.11.2 O2 Regulator

NM MOBILE/MILITARY

NOTE: Minimum cylinder pressure for O

6.11.2.1 Configure a test gauge (P/N 4114807) using an O

DISS connector (P/N 4114830-006) on the hose and an O

2 regulator test is 1000 psi.

2 nut/stem

2 DISS

body connector (P/N 4114830-005) on the valve body side. If the

machine is configured with CSA style fittings reverse the

position of the connectors.

6.11.2.2 Connect the test fixture hose to the machine’s Oxygen pipeline

inlet.

6.11.2.3 Connect the Oxygen pipeline supply hose to the test fixture.

6.11.2.4 Set the Oxygen flow to 4 l/min.

6.11.2.5 Depress the push button on the test device.

6-26

Page 29

NM MOBILE/MILITARY

6.11.2.6 Release the push button. After the pressure decay stabilizes, is

NOTE: If a pressure decrease does not occur, either the hospital’s

PMC PROCEDURE (continued)

the regulator output pressure within tolerance given in the

following table? ___ (Y)

supply pressure is too low or the regulator pressure is set too

high.

Cylinder Pressure

psi

2000 38 to 44 41 to 47

1800 39 to 45 42 to 48

1600 40 to 46 43 to 49

1400 41 to 47 44 to 50

1200 42 to 48 45 to 51

1000 43 to 49 46 to 52

ü) 6.12 LOW O2 SUPPLY – Six Month Service Interval; Due Date ______

(

USA Compensated Regulator

output tolerances

CSA Compensated Regula-

tor output tolerances

6.12.0.1 Close the Oxygen Cylinder valve and drain Oxygen cylinder

pressure.

6.12.0.2 Depress the push button on the test device.

6.12.0.3 Adjust the Oxygen flow to 500 ml/min.

6.12.0.4 Release the test device push button.

6.12.0.5 Is the pressure on the test gauge when the LO O

2 SUPPLY

message appears on the monitor within 34 to 40 psi? ___ (Y)

6.12.0.6 Close O

2 Flow control valve.

6.12.0.7 Remove the test equipment.

6.13 OXYGEN SUPPLY FAILURE PROTECTION

6.13.1 Connect all pipeline supplies.

(

ü) 6.13.2 *Is the flow of Oxygen 150 to 200 ml/min.? ___ (Y)

6.13.3 Open the Nitrous Oxide flow control valve.

(

ü) 6.13.4 *Is the flow of Nitrous Oxide within 375-750 ml/min.? ___ (Y)

6-27

Page 30

PMC PROCEDURE (continued)

NM MOBILE/MILITARY

6.13.5 Adjust the Oxygen, Nitrous Oxide and AIR gases to 4 l/min.

6.13.6 Disconnect the Oxygen pipeline supply and close the Oxygen cylinder

valve.

(

ü) 6.13.7 Do all fresh gas flows cease when the Oxygen pressure is depleted?

___(Y)

6.13.8 Reconnect the Oxygen pipeline supply.

6.13.9 Close all cylinder valves and then disconnect the Nitrous Oxide pipeline

supply.

6.13.10 Drain the cylinder contents then reconnect the pipeline supplies.

6.13.11 Close all flow control valves.

* Nitrous Oxide Bypass flow and Minimum Oxygen flow specifications

are given @ 50 psi. Pipeline pressure deviations may affect these tests.

6.14 PRESSURE MONITOR

6.14.1 Disconnect the Breathing Pressure Sensor line from the Breathing

Pressure interface on the machine.

6.14.2 Connect a PDM to Monitor Adapter (P/N 4115043) and test manometer

to the Breathing Pressure interface on the machine.

6.14.3 Adjust the test pressure to 0 cm H

2O.

6.14.4 Simultaneously turn “ON” the ventilator and start a stopwatch.

(

ü) 6.14.5 Does the APNEA PRESSURE alarm appear on the alarm display as a

CAUTION within 13 to 17 seconds? ___ (Y)

ü) 6.14.6 Increase the test pressure slowly. Does the APNEA PRESSURE alarm

(

deactivate within 10 to 14 cm H

2O? ___ (Y)

6.14.7 First decrease the pressure then increase the test pressure above the

threshold line shown on the display, and begin timing with a stopwatch.

(

ü) 6.14.8 Does the CONTINUOUS PRES alarm appear as a warning within 13 to

17 seconds? ___ (Y)

ü) 6.14.9 Decrease the pressure slowly. Does the CONTINUOUS PRES alarm

(

deactivate within 10 to 14 cm H

(

ü) 6.14.10 Increase the test pressure slowly. Does a VENT PRESS HI alarm

activate as a warning alarm within 47 to 53 cm H

2O? ___ (Y)

2O? ___ (Y)

6-28

Page 31

NM MOBILE/MILITARY

ü) 6.14.11 Increase the sub-atmospheric test pressure slowly. Does the SUB ATM

(

PRES warning alarm activate within –7 to –13 cm H

PMC PROCEDURE (continued)

2O? ___ (Y)

6.14.12 Turn the ventilator “OFF”.

6.14.13 Open APL valve.

6.14.14 Remove the test equipment and reconnect the Breathing Pressure

Sensor line to the Breathing Pressure interface on the machine.

6.15 VENTILATOR

NOTE: Readjustment of inspiratory flow to limit the inspiratory plateau may be

required to reduce erratic tidal volumes and breath rates caused by

artifact volumes.

6.15.1 Remove the bellows vent hose and the scavenger hose at the ventilator

relief valve. Remove the bellows sub-assembly and remove bellows.

6.15.2 Visually inspect the bellows for deterioration particularly at it’s seems

and corrugations. Replace as necessary.

6.15.3 Verify the presence and condition of it’s sealing O-ring. Replace as

necessary. Reassemble all components.

6.15.4 Set O

2/AIR mode switch to “O2”.

6.15.5 Turn the ventilator “ON”.

6.15.6 Set the FREQUENCY to 10 BPM.

(

ü) 6.15.7 Press and hold the EXTENDED RANGE switch and set the I:E ratio to

2:1. Using a stopwatch, time the extended I:E ratio. Is the inspiratory

time within 3.6 to 4.4 seconds and the expiratory time within 1.8 to 2.2

seconds? ___ (Y)

ü) 6.15.8 Set the I:E RATIO to 1:2. Using a stopwatch, time the I:E ratio. Is the

(

inspiratory time within 1.8 to 2.2 seconds and the expiratory time within

3.6 to 4.4 seconds? ___ (Y)

6.15.9 Adjust the Oxygen flow to 500 ml/min.

6.15.10 Set the Tidal Volume to 1200.

6.15.11 Attach a patient circuit to the absorber system.

6.15.12 Set the pressure limit control to MAX.

6.15.13 Adjust the Inspiratory Flow to the bottom of the LOW zone.

6-29

Page 32

PMC PROCEDURE (continued)

6.15.14 Occlude the Y-piece.

NM MOBILE/MILITARY

6.15.15 Press the O

6.15.16 Adjust the Inspiratory Flow until a peak pressure of 80 cm H

2 Flush momentarily to inflate the bellows.

2O is

achieved.

ü) 6.15.17 Set the Pressure Limit Control to within the 30 range. Readjust within

(

the band as necessary to achieve proper value, is the peak pressure at

the 30 range within 27 to 33 cm H

(

ü) 6.15.18 Set the Pressure Limit Control to the MIN position. Is the peak pressure

at the MIN range within 0 to 15 cm H

2O? ___ (Y)

2O? ___ (Y) Return the Pressure

Limit control to MAX.

6.15.19 On the Military machine, loosen the expiratory valve dome. On the

Mobile machine, disconnect the hose between the expiratory valve and

the ultrasonic flow sensor and blow into it.

ü) 6.15.20 Does the Reverse Flow message appear on the display? ___ (Y)

(

6.15.21 Reconnect the hose between the expiratory valve and the flow sensor.

6.15.22 On the Military machine, insert a test minute volumeter between the

Spiromed and the absorber dome. On the Mobile machine, insert a test

minute volumeter between the exhalation valve and PEEP valve.

6.15.23 Open the Y-piece.

6.15.24 Turn the ventilator off and press the ALL STBY key to clear alarms.

6.15.25 Turn the ventilator “ON” and start a stop watch.

6.15.26 Does APNEA-VOLUME appear as a Caution within 13 to 17 seconds?

___ (Y)

6.15.27 Attach a 3 liter breathing bag to the Y-piece.

NOTE: Bag should be placed on a flat horizontal surface to reduce artifact

volume.

6.15.28 Press the O

2 Flush momentarily to inflate the bellows.

6.15.29 Set the Inspiratory Flow to the MED and readjust as necessary to fully

collapse the bellows.

(

ü) 6.15.30 Observe the operation of each unidirectional valve disc at eye level and

make sure the inspiratory valve disc raises only during the inspiration

phase, and the expiratory valve raises only during the exhalation phase.

6-30

Page 33

NM MOBILE/MILITARY

ü) 6.15.31 Is the tidal volume on the volume monitor and on the test volumeter

(

PMC PROCEDURE (continued)

within 20 % of each other? ___ (Y)

6.15.32 Does the volume monitor display 10 BPM? ___ (Y)

6.15.33 Does the display correctly track the Breathing Pressure waveform? ___

(Y)

6.15.34 Verify AIR pipeline hose is connected.

(

ü) 6.15.35 Set O2/AIR mode switch to “AIR”. Does ventilator continue to cycle

properly. ___(Y)

6.15.36 Set O

2/AIR mode switch back to “O2”.

6.16 BELLOWS ADULT

(

ü) 6.16.1 What is the tidal volume indicated on the test volumeter within 960 to

1440 ml? ___ (Y)

ü) 6.16.2 Does the bellows remain fully inflated during the expiratory pause

(

phase? ___ (Y)

6.16.3 Remove the ventilator hose from the bellows hose terminal.

6.16.4 Attach a test terminal to the bellows hose terminal.

6.16.5 Connect a 0-250 ml/min. flowmeter (P/N S000081) to the test terminal.

6.16.6 Set the FREQUENCY to 1 BPM.

(

ü) 6.16.7 Is the drive gas leakage indicated during the inspiratory phase within 0

to 50 ml/min.? ___ (Y)

6.16.8 Remove the test equipment from the ventilator hose terminal and

reconnect the ventilator hose to the bellows ventilator hose terminal.

6.16.9 Set the FREQUENCY to 10 BPM.

6.16.10 Adjust the O

2 flow to 8 l/min.

6.16.11 Adjust the Tidal Volume to maximum.

6.16.12 Press the O

2 Flush momentarily to inflate the bellows.

6.16.13 Adjust the INSPIRATORY FLOW to fully compress the bellows.

(

ü) 6.16.14 Is the Tidal Volume on the test volumeter greater than or equal to 1400

ml? ___(Y)

6-31

Page 34

PMC PROCEDURE (continued)

(

ü) 6.16.15 Is the PEEP value displayed on the monitor within 0 to 3 cm H2O? ___

NM MOBILE/MILITARY

(Y)

6.16.16 Remove the breathing bag from the Y-piece and replace it with a test

lung.

6.16.17 Adjust the O

2 flow to 300 ml/min.

6.16.18 Adjust the Tidal Volume to 200 ml.

6.16.19 Does the bellows stop adjust smoothly and engage properly? ___ (Y)

6.16.20 Adjust the INSPIRATORY FLOW to fully compress the bellows.

(

ü) 6.16.21 Is the Tidal Volume on the test volumeter within 125 to 250 ml? ___ (Y)

6.16.22 Close the Oxygen flow control valve.

6.16.23 Remove the test lung and set the AUTO/BAG selector to BAG.

6.16.24 Press the Alarms All Standby key.

6.17 SCAVENGER- Six Month Service Interval; Due Date ______

NOTE: If the ambient air in the local environment contains a significant amount of

dust and lint, the cleaning frequency must be increased to compensate for

these conditions.

(

ü) 6.17.1 Scavenger - Passive Mode

6.17.1.1 Remove the scavenger hoses and drain all accumulated

moisture. Inspect all scavenger hoses for deterioration and

replace as necessary. Reinstall hoses and bag.

6.17.1.2 Ensure that the suction needle valve (not used in passive mode)

is closed.

6.17.1.3 Positive Pressure Test:

6.17.1.3.1 Connect a 19mm scavenger hose between the Vent

Relief valve and the top port of the scavenger.

Connect another 19 mm scavenger hose between

APL valve and the second scavenger port.

6.17.1.3.2 Interconnect the inspiratory valve and expiratory

valve or expiratory port on the ultrasonic flow sensor,

if applicable with a 22 mm hose (P/N 9995132).

6.17.1.3.3 Set Man/Auto valve to “Auto”.

6-32

Page 35

PMC PROCEDURE (continued)

6.17.1.3.4 Verify PEEP valve is at minimum (counter-

NM MOBILE/MILITARY

clockwise).

6.17.1.3.5 Set O

2 Flow to 8 l/min.

6.17.1.3.6 Occlude the bottom 19 mm connector (EXHAUST).

6.17.1.3.7 After the bellows inflates, the flow of oxygen will exit

the system through the positive pressure safety relief

valve.

6.17.1.3.8 Is the pressure displayed on absorber cm H

is less than or equal to 5 cm H

(

ü) 6.17.2 Scavenger - Suction Mode

6.17.2.1 Remove the scavenger hoses and drain all accumulated

moisture. Inspect all scavenger hoses and scavenger bag for

deterioration and replace as necessary. Reinstall hoses and bag.

6.17.2.2 Remove the filter from the negative pressure relief valve. Clean

and reinstall the filter.

6.17.2.3 Negative Pressure Test:

6.17.2.3.1 Interconnect the inspiratory valve and expiratory

valve or expiratory port on the ultrasonic flow sensor,

if applicable with a 22 mm hose (P/N 9995132).

2O gauge

2O?___(Y)

6.17.2.3.2 Set Man/Auto valve to “BAG” position

6.17.2.3.3 Fully open APL valve.

6.17.2.3.4 Attach a Breathing System Leak Test Device (P/N

S010159) to the bag mount (occlude bag mount).

6.17.2.3.5 Verify Suction system is active. Adjust needle valve

to allow typical suction through scavenger.

6.17.2.3.6 Verify all flow control valves are closed.

6.17.2.3.7 Install scavenger adapter (P/N 4108114) between

either of the 19 mm scavenger connectors and

scavenger hose. Connect a manometer to the hose

barb on the scavenger adapter and observe reading

on manometer. The manometer shall indicate a

pressure less than or equal to 0.5 cm H

2O.

6-33

Page 36

PMC PROCEDURE (continued)

6.17.2.4 Positive Pressure Test:

6.17.2.4.1 Fully close scavenger needle valve.

NM MOBILE/MILITARY

6.17.2.4.2 Push the O

2 flush to inflate scavenger bag. Open

oxygen flow control valve to 8 l/min.

6.17.2.4.3 Verify reading on manometer is less than or equal to

5 cm H

2O.

6.17.2.4.4 Remove all test equipment. Adjust scavenger needle

valve to allow typical suction through scavenger.

6.18 FINAL TESTS

(

ü) 6.18.1 Is the machine's Operator's Instruction manual in close proximity of the

machine? ___ (Y)

6.18.2 Verify all cylinder pressure gauges indicate zero.

6.18.3 Verify the pipeline hoses are connected to the hospital pipeline.

6.18.4 Verify the APL valve knob is turned completely counterclockwise (fully

open).

6.18.5 Place the AUTO/BAG selector in the BAG position.

6.18.6 Verify the ventilator hose is connected between the AUTO/BAG valve

and bellows ventilator hose terminal.

6.18.7 Verify the Breathing Pressure Sensor line is connected to the Breathing

Pressure interface on the machine.

6.18.8 Verify the Oxygen sensor is removed from the inspiratory valve dome.

6.18.9 Verify that the Inspiratory valve dome is plugged.

6.18.10 Verify that the machine is plugged into a live A/C receptacle.

6-34

Page 37

Page 38

DrägerService is a division of

Draeger Medical, Inc.

3122 Commerce Drive

Telford, PA 18969

Tel: (215) 721-5402

(800) 543-5047

Fax: (215) 721-5784

Web: www.draegermedical.com

Printed in the U.S.A.

Loading...

Loading...