Page 1

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

KIT,MINO2FLOWELIMINATION

CONVERSIONPROCEDURE:2GASMACHINES

RETURN TO CD-ROM TABLE OF CONTENTS

WARNING: DONOTinstalltheMinimumO

FlowEliminationonmachineshavingalowflow

2

oxygenratiocontroller(ORC)P/N4113229.

NOTE: Thefollowingprocedureappliesto2gasmachines.SkiptoPage5for3and4gas

machines.

1. TurntheSystemPowerswitchto

STANDBYandremoveACpower

fromthemachine.

8. Cutanytiestrapssecuringthe

flexibletubing,andremovethe

tubingalongwiththeassociatedtee

fitting.

2. Close all cylinder valves and

disconnectallpipelinesupplies.

9. Removethehosebarbfittingfrom

therightsideofthe4-wayfitting,

3. Removethebackcoverofthe

flowmeterhousing.

andinstallawasher(P/N4102165)

andplug(P/N4103801)asshownin

thelowerviewofFigure1.

4. Removethebackcoverofthevapor

box to gain access to the

ORM/ORMC.

10. Connecta35in.lengthofflexible

tubing(P/NML08003)andpress-on

hoseclamptothehosebarbatthe

5. Removethepress-onhoseclamp

O

restrictorhousing.

2

anddisconnecttheflexibletubing

fromtherightside(viewedfrom

therear)oftherestrictorhousing4wayfitting.SeeFigure1,upper

view. (Earlier machines are

configuredwitha3-wayfitting.)

11. Connecttheotherendofthetubing

tothehosebarbattheO

porton

2

theORMorORMC.Installagreen

O

label(PN4109871)ateachend

2

ofthetubing.

6. Removethepress-onhoseclamp

anddisconnecttheflexibletubing

fromthehosebarbattheO

restrictorhousing.

7. Removethepress-onhoseclamp

anddisconnecttheflexibletubing

fromtheO

portattheORMor

2

ORMC.SeeFigure2.

12. Restorepowertothemachineand

re-connectthepipelinesupplies(or

2

openthecylindervalves).

NOTE: Forlatermachineswithout

the O

O ratio alarm

2/N2

lamp,skiptoStep15.

1

Page 2

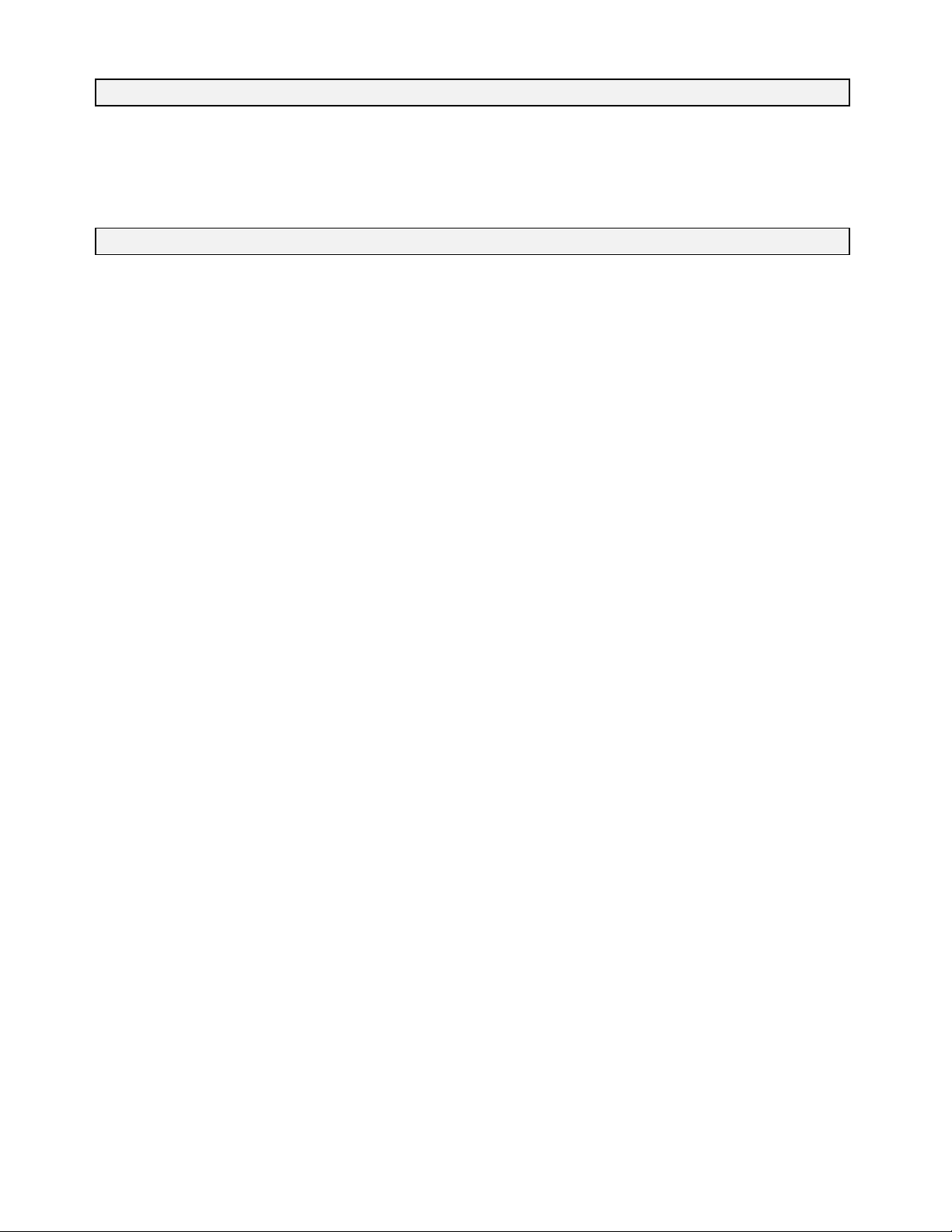

REAR VIEW OF FLOWMETER HOUSING

TEE FITTING

(REMOVE)

TUBING

FROM O2

RESTRICTOR

(REMOVE)

TUBING

FROM

ORMC TO O2

RESTRICTOR

(INSTALL)

PLUG (INSTALL)

WASHER (INSTALL)

O2

RESTRICTOR

CONNECTION

TUBING

(REMOVE)

HOSE BARB

FITTING

(REMOVE)

EARLIER MACHINES

CONFIGURED WITH

3-WAY FITTING

SP89001

TUBING

FROM

ORMC

(REMOVE)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONVERSION PROCEDURE: 2 GAS MACHINES (continued)

Figure 1: TUBING REMOVAL/INSTALLATION (MIN. O2FLOW ELIMINATION)

2

Page 3

SP89002

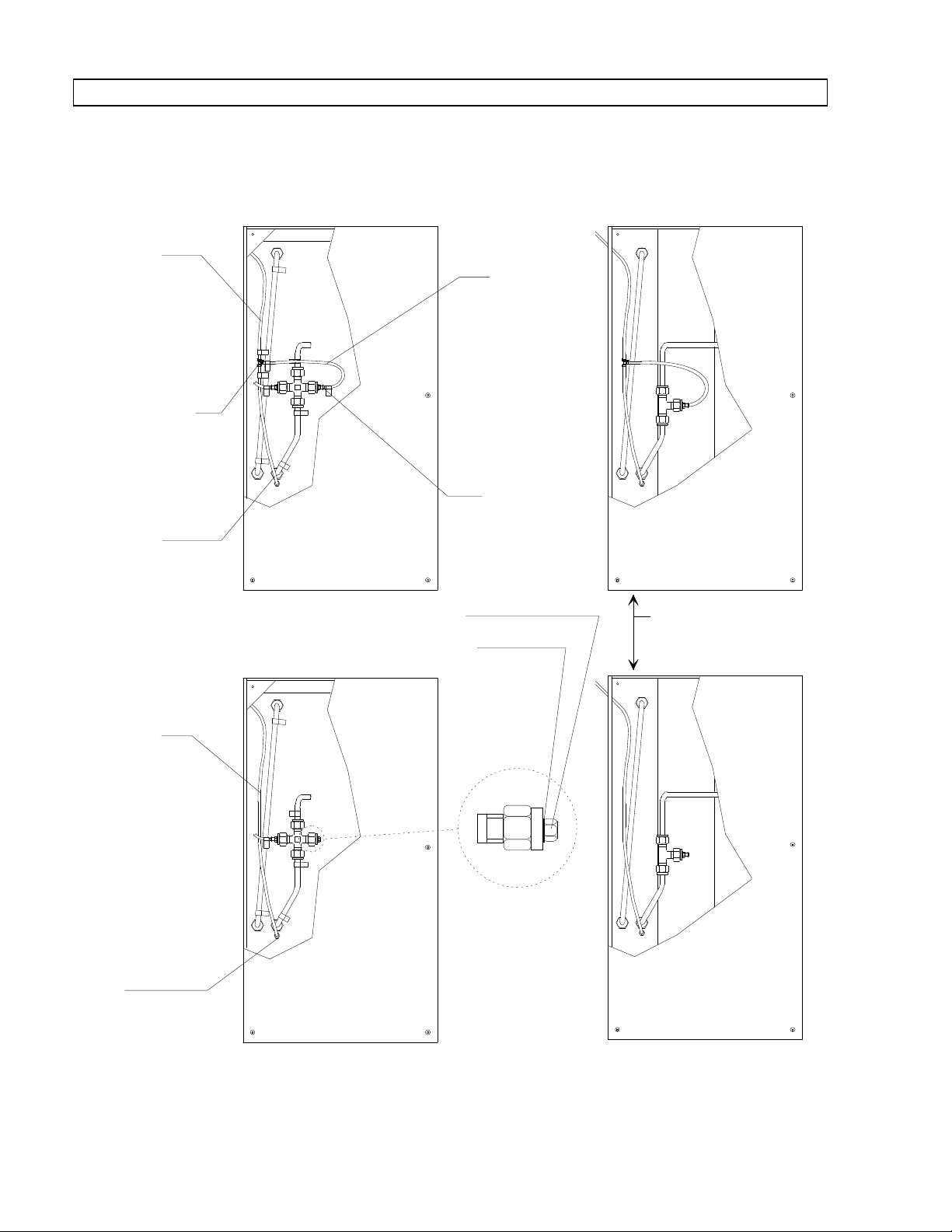

VAPOR BOX TOP VIEW

OXYGEN RATIO

MONITOR CONTROLLER

O2

CONNECTION

MPL SWITCH

ADJUSTMENT

(TURN CLOCKWISE TO

DECREASE SETPOINT)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONVERSION PROCEDURE: 2 GAS MACHINES (continued)

Figure 2: ORMC O2CONNECTION AND MPL SWITCH LOCATION

3

Page 4

LABEL

FRONT VIEW OF MACHINE

7/8"

1/8"

SP89003

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONVERSION PROCEDURE: 2 GAS MACHINES (continued)

13. Open the N

several turns. Slowly open the O

flow control valve and observe the

O

O ratio alarm lamp.

2/N2

The alarm lamp should be lighted

when the N

ml/min.

Slowly close the O

valve; the alarm lamp should be off

when the N

ml/min.

O flow control valve

2

O flow is above 800

2

flow control

2

O flow is below 700

2

14. If necessary, adjusttheMPL switch

2

on the ORM or ORMC (see Figure

2) until the alarm lamp responds as

noted in Step 13.

15. Reinstall the vapor box back cover,

and reinstall the flowmeter housing

back cover.

16. Install the Minimum Flow

Elimination label on the front of

the machine at the top right of the

flowmeter housing - positioned as

shown in Figure 3.

17. Perform a complete PMS on the

machine.

Figure 3: MIN. O2FLOW ELIMINATION - LABEL LOCATION

4

Page 5

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONVERSION PROCEDURE: 3 AND 4 GAS MACHINES

1. Turn the System Power switch to

STANDBY and remove AC power

from the machine.

2. Close all cylinder valves and

disconnect all pipeline supplies.

3. Remove the back cover of the

flowmeter housing.

4. Remove the back cover of the vapor

box to gain access to the

ORM/ORMC.

5. Remove the press-on hose clamp

and disconnect the flexible tubing

from the side hose barb on the

minimum flow cut-off valve.

Refer to Figure 1 for machines with

Air.

Refer to Figure 2 for machines

without Air. (Earlier machines may

be configured as shown in the

alternate view.)

8. Cut any tie straps securing the

flexible tubing, and remove the

tubing along with the associated tee

fitting.

9. Remove the hose barb fitting from

the minimum flow cut-off valve,

and install a washer (P/N 4102165)

and plug (P/N 4103801) as shown in

the lower view of Figure 1 and

Figure 2.

10. Connect a 35 in. length of flexible

tubing (P/N ML08003) and press-on

hose clamp to the hose barb at the

O

restrictor housing.

2

11. Connect the other end of the tubing

to the hose barb at the O

port on

2

the ORM or ORMC. Install a green

O

label (PN 4109871) at each end

2

of the tubing.

12. Restore power to the machine and

re-connect the pipeline supplies (or

open the cylinder valves).

6. Remove the press-on hose clamp

and disconnect the flexible tubing

from the hose barb at the O

restrictor housing.

7. Remove the press-on hose clamp

and disconnect the flexible tubing

from the O

port at the ORM or

2

ORMC. See Figure 3.

NOTE: For later machines without

the O

2

lamp, skip to Step 15.

13. Open the N

several turns. Slowly open the O

O ratio alarm

2/N2

O flow control valve

2

2

flow control valve and observe the

O

O ratio alarm lamp.

2/N2

5

Page 6

CONVERSION PROCEDURE: 3 AND 4 GAS MACHINES (continued)

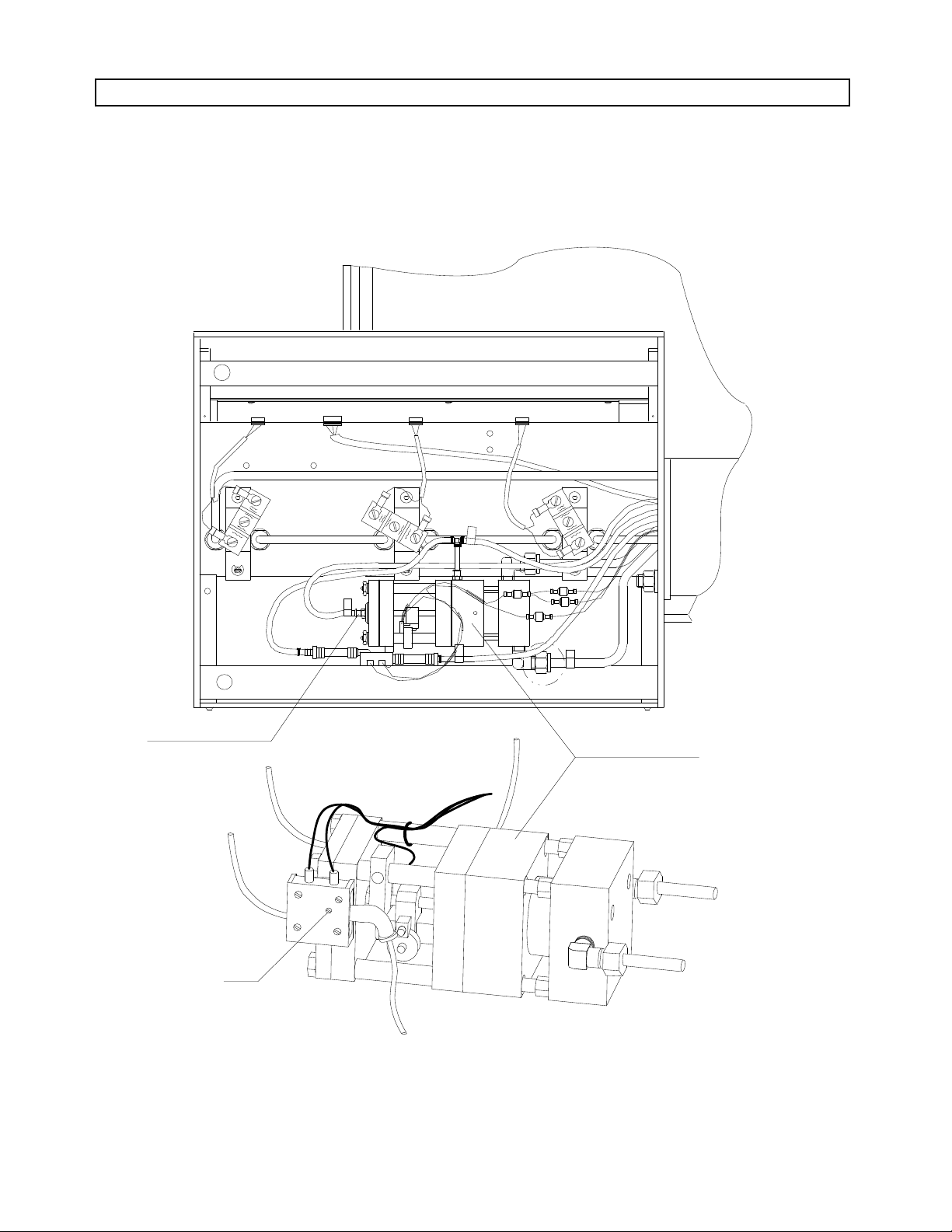

REAR VIEW OF FLOWMETER HOUSING

TUBING FROM

ORMC (REMOVE)

TEE FITTING

(REMOVE)

TUBING FROM

O2 RESTRICTOR

(REMOVE)

TUBING FROM

ORMC TO O2

RESTRICTOR

(INSTALL)

PLUG

(INSTALL)

WASHER

(INSTALL)

O2 RESTRICTOR

CONNECTION

TUBING (REMOVE)

HOSE BARB

FITTING (REMOVE)

MINIMUM FLOW

CUTOFF VALVE

SP90002

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

Figure 1: TUBING REMOVAL/INSTALLATION,3&4GASMACHINES WITH AIR

(MIN. O

FLOW ELIMINATION)

2

6

Page 7

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONVERSION PROCEDURE 3 AND 4 GAS MACHINES (continued)

REAR VIEW OF FLOWMET ER HOU SING

MINIMUM FLOW

CUTOFF VALVE

TUBING FROM

ORMC (REMOVE)

TEE FITTIN G

(REMOVE)

TUBING (REMOVE)

HOSE BARB

FITTING (REMOVE)

TUBING FROM

O2 RESTRI CT OR

(REMOVE)

TUBING FROM

ORMC T O O2

RESTRICT OR

(INSTALL)

PLUG

(INSTALL)

EARLIER MACHINE

CONFI GURA T I ON

WASHER

(INSTALL)

O2 REST RI CT OR

CONNECTION

SP90001

Figure 2: TUBING REMOVAL/INSTALLATION,3&4GASMACHINES WITHOUT AIR

(MIN. O

FLOW ELIMINATION)

2

7

Page 8

SP89002

VAPOR BOX TOP VIEW

OXYGEN RATIO

MONITOR CONTROLLER

O2

CONNECTION

MPL SWITCH

ADJUSTMENT

(TURN CLOCKWISE TO

DECREASE SETPOINT)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONVERSION PROCEDURE: 3 AND 4 GAS MACHINES (continued)

Figure 3: ORMC O2CONNECTION AND MPL SWITCH LOCATION

8

Page 9

LABEL

FRONT VIEW OF MACHINE

7/8"

1/8"

SP89003

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONVERSION PROCEDURE: 3 AND 4 GAS MACHINES (continued)

The alarm lamp should be lighted

when the N

O flow is above 800

2

ml/min.

Slowly close the O

flow control

2

valve; the alarm lamp should be off

when the N

O flow is below 700

2

ml/min.

14. If necessary, adjust the MPL switch

on the ORM or ORMC (see Figure

3) until the alarm lamp responds as

noted in Step 13.

15. Reinstall the vapor box back cover,

and reinstall the flowmeter housing

back cover.

16. Install the Minimum O

2

Flow

Elimination label on the front of

the machine at the top right of the

flowmeter housing - positioned as

shown in Figure 4.

17. Perform a complete PMS on the

machine.

Figure 4: MIN. O2FLOW ELIMINATION - LABEL LOCATION

9

Page 10

NORTH

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

AMERICAN

DRÄGER

Technical Service Department

3122 Commerce Drive

Telford, PA 18969

(215) 721-5402

(800) 543-5047

(215) 723-5935 Fax

Quality Service for Life

SM

Part Number: SP00089

Rev: B

Date: July 10, 1996

© 1996 N.A.D., Inc.

Loading...

Loading...