Page 1

HOTWIRE 8600

DIGITAL SUBSCRIBER LINE

ACCESS MULTIPLEXER

(DSLAM)

INSTALLATION GUIDE

Document No. 8600-A2-GN20-20

October 1997

Page 2

Copyright 1997 Paradyne Corporation.

All rights reserved.

Printed in U.S.A.

Notice

This publication is protected by federal copyright law. No part of this publication may be copied or distributed,

transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language in any form

or by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties without the

express written permission of Paradyne Corporation, 8545 126th Avenue North, P.O. Box 2826, Largo,

Florida 33779-2826.

Paradyne Corporation makes no representation or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for a particular purpose. Further, Paradyne Corporation

reserves the right to revise this publication and to make changes from time to time in the contents hereof without

obligation of Paradyne Corporation to notify any person of such revision or changes.

Changes and enhancements to the product and to the information herein will be documented and issued as a new

release to this manual.

Warranty, Sales, and Service Information

Contact your sales or service representative directly for any help needed. For additional information concerning

warranty, sales, service, repair, installation, documentation, or training, use one of the following methods:

Via the Internet: Visit the Paradyne World Wide W eb site at http://www.paradyne.com

Via Telephone: Call our automated call system to receive current information via fax or to speak with a

company representative.

— Within the U.S.A., call 1-800-870-2221

— International, call 813-530-2340

T rademarks

All products and services mentioned herein are the trademarks, service marks, registered trademarks or registered

service marks of their respective owners.

Printed on recycled paper

A

October 1997

8600-A2-GN20-20

Page 3

Important Regulatory Information

Important Safety Instructions

1. Read and follow all warning notices and instructions marked on the product or included in the manual.

2. The AC product version is intended to be used with a 3-wire grounding type plug – a plug which has a grounding

pin. This is a safety feature. Equipment grounding is vital to ensure safe operation. Do not defeat the purpose of

the grounding type plug by modifying the plug or using an adapter.

Prior to installation, use an outlet tester or a voltmeter to check the ac receptacle for the presence of earth

ground. If the receptacle is not properly grounded, the installation must not continue until a qualified electrician

has corrected the problem.

If a 3-wire grounding type power source is not available, consult a qualified electrician to determine another

method of grounding the equipment.

3. Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to

protect it from overheating, these slots and openings must not be blocked or covered.

4. Do not allow anything to rest on the power cord and do not locate the product where persons will walk on the

power cord.

5. Do not attempt to service this product yourself, as opening or removing covers may expose you to dangerous

high voltage points or other risks. Refer all servicing to qualified service personnel.

6. General purpose cables are provided with this product. Special cables, which may be required by the regulatory

inspection authority for the installation site, are the responsibility of the customer.

7. When installed in the final configuration, the product must comply with the applicable Safety Standards and

regulatory requirements of the country in which it is installed. If necessary , consult with the appropriate regulatory

agencies and inspection authorities to ensure compliance.

8. A rare phenomenon can create a voltage potential between the earth grounds of two or more buildings. If

products installed in separate buildings are interconnected, the voltage potential may cause a hazardous

condition. Consult a qualified electrical consultant to determine whether or not this phenomenon exists and, if

necessary, implement corrective action prior to interconnecting the products.

9. Input power to the DC voltage configurations of this product must be provided by one of the following: (1) a

National Electrical Code (NEC)/Canadian Electrical Code (CEC) Class 2 circuit for use in North America, or (2) a

certified Safety Extra Low Voltage (SELV) /Limited Power Source (LPS) input for use in the country of installation.

10. In addition, if the equipment is to be used with telecommunications circuits, take the following precautions:

— Never install telephone wiring during a lightning storm.

— Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations.

— Never touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the

network interface.

— Use caution when installing or modifying telephone lines.

— Avoid using a telephone (other than a cordless type) during an electrical storm. There may be a remote risk of

electric shock from lightning.

— Do not use the telephone to report a gas leak in the vicinity of the leak.

8600-A2-GN20-20 October 1997

B

Page 4

Important Regulatory Information

EMI Warnings

!

WARNING:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

The authority to operate this equipment is conditioned by the requirements that no modifications will be

made to the equipment unless the changes or modifications are expressly approved by Paradyne

Corporation.

!

WARNING:

To Users of Digital Apparatus in Canada:

This Class A digital apparatus meets all requirements of the Canadian interference-causing equipment

regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du règlement sur le matérial

brouilleur du Canada.

Notice to Users of the Canadian Telephone Network

The Industry Canada label identifies certified equipment. This certification means that the equipment meets

telecommunications network protective, operational and safety requirements as prescribed in the appropriate Terminal

Equipment Technical Requirements document(s). The Department does not guarantee the equipment will operate to

the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. The

customer should be aware that compliance with the above conditions may not prevent degradation of service in some

situations.

Repairs to certified equipment should be coordinated by a representative designated by the supplier. Any repairs or

alterations made by the user to this equipment, or equipment malfunctions, may give the telecommunications

company cause to request to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility , telephone lines

and internal metallic water pipe system, if present, are connected together. This precaution may be particularly

important in rural areas.

CAUTION:

Users should not attempt to make such connections themselves, but should contact the appropriate electric

inspection authority , or electrician, as appropriate.

The Ringer Equivalence Number (REN) assigned to each terminal device provides an indication of the maximum

number of terminals allowed to be connected to a telephone interface. The termination on an interface may consist of

any combination of devices subject only to the requirement that the sum of the Ringer Equivalence Numbers of all the

devices does not exceed 5.

C

October 1997

8600-A2-GN20-20

Page 5

Important Regulatory Information

CE Marking

When the product is marked with the CE mark, this demonstrates full compliance with the following European

Directives:

— Directive 72/73/EEC – Council Directive of 19 February 1973 on the harmonization of the laws of the member

states relating to electrical equipment designed for use within certain voltage limits, as amended by Directive

93/68EEC.

— Directive 89/336/EEC – Council Directive of 3 May 1989 on the approximation of the laws of the member

states relating to Electro-Magnetic Compatibility (EMC), as amended by Directive 93/68/EEC.

Japan

Class 1 ITE

This is a Class 1 product based on the standard of the Voluntary Control Council for interference by Information

Technology Equipment (VCCI). If this equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective actions.

8600-A2-GN20-20 October 1997

D

Page 6

Contents

About This Guide

Document Purpose and Intended Audience iii. . . . . . . . . . . . . . . . . . . . . . . . .

Document Summary iv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product-Related Documents v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 About the HotWire 8600 DSLAM

What is the HotWire 8600 DSLAM? 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HotWire 8600 DSLAM Components 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HotWire 8600 DSLAM Features 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Configurations 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Installing and Connecting the Hardware

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Package Contents 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking the Hardware 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-installation Considerations 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Tasks 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HotWire 8600 DSLAM Chassis Installation 2-5. . . . . . . . . . . . . . . . . . . . . . . . .

Stacking the 8600 Chassis 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

National Equipment Building Standards (NEBS) 2-7. . . . . . . . . . . . . . . . . . . . .

Connection to the CO Ground Lug 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD Wrist Strip Jack 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interconnecting 8600 Systems 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the 8600 Chassis in a Rack with Threaded Screw Holes 2-10.

Installing the 8600 Chassis in a Rack without Threaded

Screw Holes 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplying Power 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using a Single DC Power Source 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Two DC Power Sources for Power Redundancy 2-14. . . . . . . . . . .

Using Only AC Power Source 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using AC Power with DC Power Backup 2-16. . . . . . . . . . . . . . . . . . . . . . . .

Installing the MCC Card 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing DSL Cards 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying the Installation 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8600-A2-GN20-20

October 1997

i

Page 7

Contents

Making Cable Connections 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Connection Considerations 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to a POTS Splitter or an MDF 2-23. . . . . . . . . . . . . . . . . . . . . .

Connecting the DSL Cards to the Ethernet Hubs or Switches 2-24. . . . . .

Connecting to an SNMP Management System 2-25. . . . . . . . . . . . . . . . . .

Connecting to a Terminal or Laptop Computer 2-26. . . . . . . . . . . . . . . . . . .

Connecting to a Modem for Remote Management 2-27. . . . . . . . . . . . . . .

Connecting to a HotWire 8600 DSLAM Via Telnet 2-28. . . . . . . . . . . . . . . .

3 Initial Setup Instructions

Setting the IP Address and Subnet Mask on the MCC for Remote

Configuration 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 T roubleshooting

Power Failure Troubleshooting Procedures 4-1. . . . . . . . . . . . . . . . . . . . . . . . .

Power LED is OFF 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Alarm LED is ON 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM ALM LED is ON (on a DSL Card) 4-2. . . . . . . . . . . . . . . . . . . . . . . . .

DSL Card is Not Working Properly 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A LEDs

Overview A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HotWire 8600 DSLAM Chassis A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCC Card A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Pinouts

8-Pin Modular Ethernet Connector for MCC Management

Connector Pinouts B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-Pin Modular LAN/WAN Slot Connector Pinouts B-2. . . . . . . . . . . . . . . . . . . .

8-Pin Modular Management In and Out Connector Pinouts B-2. . . . . . . . . . .

8-Pin Modular Serial (Asynchronous Terminal) Connector Pinouts B-3. . . . .

DB25 Adapter Pinouts B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Telco 50-Pin Connector Pinouts for DSL Loops and POTS Splitters B-4. . . .

C Technical Specifications

Glossary

ii

Index

October 1997

8600-A2-GN20-20

Page 8

About This Guide

Document Purpose and Intended Audience

This guide describes how to:

Mount the HotWire 8600 Digital Subscriber Line Access Multiplexer (DSLAM)

chassis in a rack

Stack two to three chassis on a tabletop or desktop

Install the Management Communications Controller (MCC) card

Install the Digital Subscriber Line (DSL) cards

Make cable connections to the CO POTS (Plain Old Telephone Service)

Splitter, MDF, or other demarcation point

Make cable connection to a network management system (NMS), such as a

Simple Network Management Protocol (SNMP) management system

Connect the DSL cards to the Ethernet hubs and switches

Make cable connection to a console, computer, or modem

It is written for administrators and technicians who install devices at the Central

Office (CO) or at an Internet Service Provider (ISP) location adjacent to the CO.

A HotWire 8600 DSLAM system requires an MCC card and at least one DSL

card. Multiple 8600 DSLAMs can share management connectivity through an

MCC card in a single 8600 DSLAM. These additional systems house up to three

DSL cards. It is assumed that you have already purchased the required circuit

cards.

To install the Customer Premises (CP) portion of the HotWire 8600 DSLAM, refer

a

to the

Installation Instructions and HotWire POTS Splitter Customer Premises

Installation Instructions.

ppropriate HotWire Remote Termination Unit (RTU) Customer Premises

8600-A2-GN20-20

October 1997

iii

Page 9

About This Guide

Document Summary

Section Description

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Appendix A

Appendix B

Appendix C

Glossary Defines acronyms and terms used in this document.

Index Lists key terms, acronyms, concepts, and sections in

About the HotWire 8600 DSLAM.

of the HotWire 8600 DSLAM chassis, its components,

and its features.

Installing and Connecting the Hardware.

how to mount the chassis, stack two or more chassis,

install the MCC and DSL cards, and make cable

connections to the network.

Initial Setup Instructions.

the MCC card for remote configuration.

Troubleshooting.

and how to troubleshoot them.

LEDs.

Describes the meaning of the LEDs on the

chassis, and on the MCC and DSL cards.

Pinouts.

connectors on the Interface Panel.

Provides the pin assignments for the

Describes problems that may occur

Technical Specifications.

specifications of the chassis.

alphabetical order.

Describes how to configure

Provides the technical

Provides an overview

Describes

iv

October 1997

8600-A2-GN20-20

Page 10

Product-Related Documents

Document Number Document Title

About This Guide

5020-A2-GN10

5030-A2-GN10

5034-A2-GN10

5216-A2-GN10

5246-A2-GN10

5446-A2-GN10

8000-A2-GB20

8000-A2-GB21

8000-A2-GB24

8000-A2-GB90

HotWire POTS Splitter Central Office Installation

Instructions

HotWire 5030 POTS Splitter Customer Premises

Installation Instructions

HotWire 5034 Indoor POTS Splitter Installation

Instructions

HotWire 5216 Remote Termination Unit (RTU)

Installation Instructions

HotWire 5246 Remote Termination Unit (RTU)

Installation Instructions

HotWire 5446 Remote Termination Unit (RTU)

Customer Premises Installation Instructions

HotWire DSLAM for 8540 and 8546 DSL Cards

User’s Guide

HotWire DSLAM for 8540 and 8546 DSL Cards

Network Configuration Guide

HotWire DSLAM Configuration for 8540 and 8546

DSL Cards Startup Guide

HotWire 8100/8200 Internetworking Packet

Concentrator (IPC) User’s Guide

8000-A2-GN11

8000-A2-GU10

8540-A2-GN10

8546-A2-GN10

For additional product documentation contact your sales or service

representative.

HotWire Management Communications Controller

(MCC) Card Installation Instructions

Special Notice RADSL Connection Considerations

HotWire 8546 Digital Subscriber Line (DSL) Card

Installation Instructions

HotWire 8546 Digital Subscriber Line (DSL) Card

Installation Instructions

8600-A2-GN20-20

October 1997

v

Page 11

About the HotWire 8600 DSLAM

What is the HotWire 8600 DSLAM?

The HotWire 8600 Digital Subscriber Line Access Multiplexer (DSLAM), which

can be installed in the Central Office (CO) or at a customer location adjacent to

the CO, is a low start-up cost alternative to the HotWire 8800 DSLAM chassis.

Through the use of Digital Subscriber Line technology, DSLAM provides

simultaneous high-speed data access (digital) and POTS service (analog) over

the same twisted-pair telephone line. Support of this simultaneous access

requires the installation of POTS splitter equipment at both ends of the line (i.e.,

at the Central Office and at the customer premises).

1

The HotWire 8600 DSLAM can be configured to operate with multiple types of

endpoints installed at the customer end of the telephone loop to allow users at

remote locations to access Internet Service Providers or corporate networks by

means of the DSLAM.

8600-A2-GN20-20

October 1997

1-1

Page 12

About the HotWire 8600 DSLAM

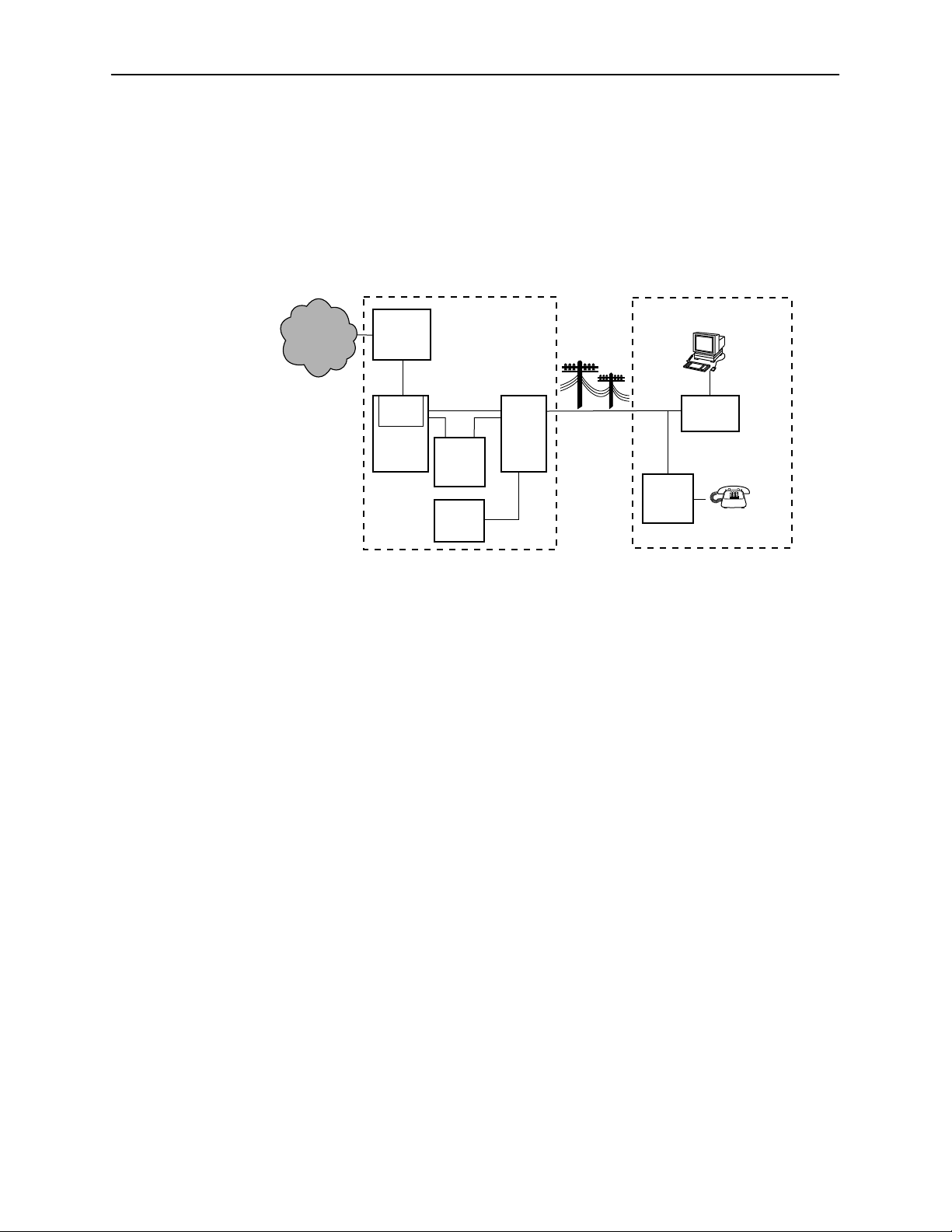

The following illustration shows a high-level view of a HotWire configuration:

NOTE:

You may make cable connections from a DSL card directly to a Main

Distribution Frame (MDF) or through a POTS splitter to an MDF, but not both.

Central Office (CO)

Network

Service

Provider

Legend: DSL - Digital Subscriber Line RTU - Remote Termination Unit

HotWire

8200

IPC

Ethernet

DSL

CARD

DSLAM

MDF - Main Distribution Frame POTS - Plain Old Telephone Service

IPC - Interworking Packet Concentrator

*CO

POTS

Splitter

CO

Switch

MDF

POTS/DSL

Customer Premises (CP)

Interface

RTU

POTS

*CP

POTS

Splitter

Interface

* Optional

Data

Voice

97-15674-01

1-2

October 1997

8600-A2-GN20-20

Page 13

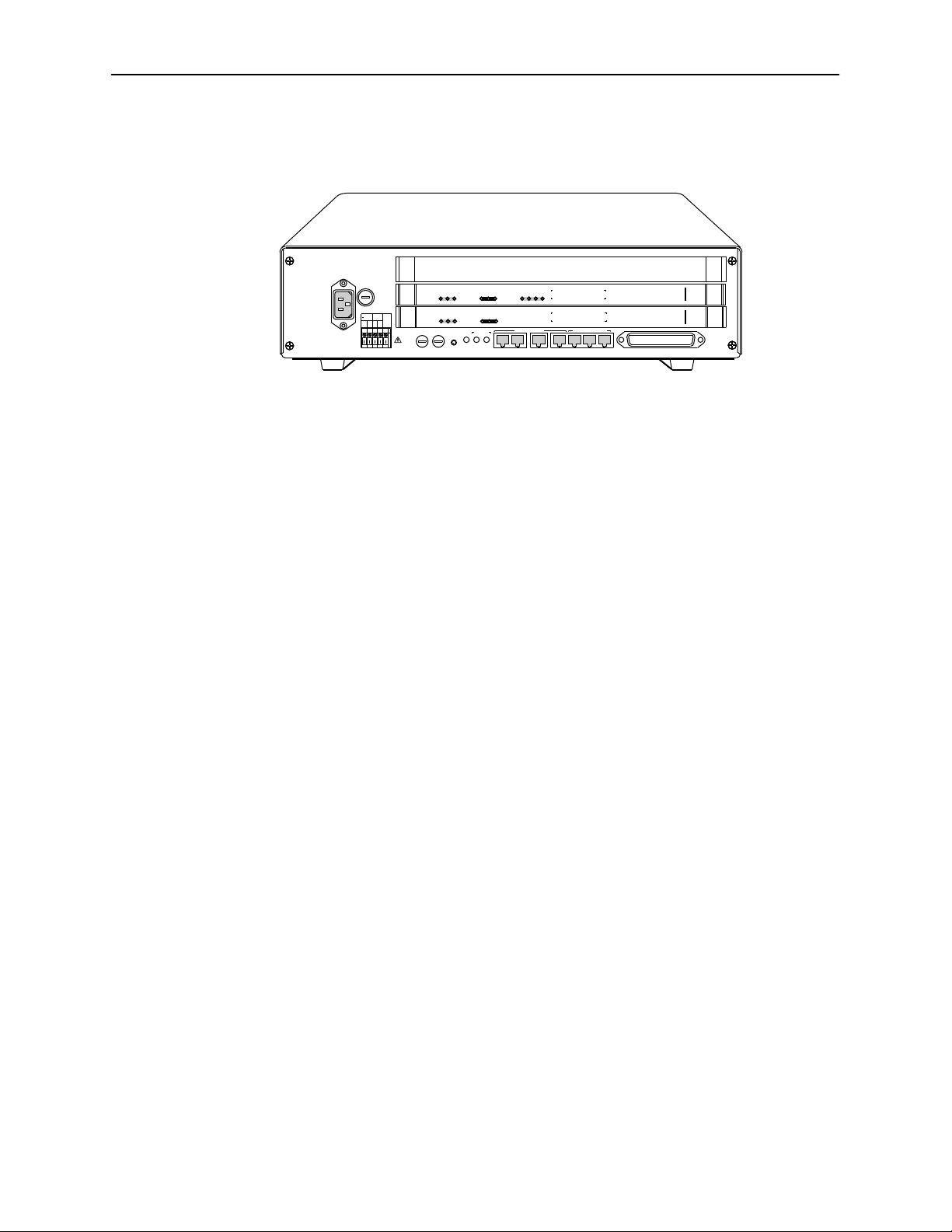

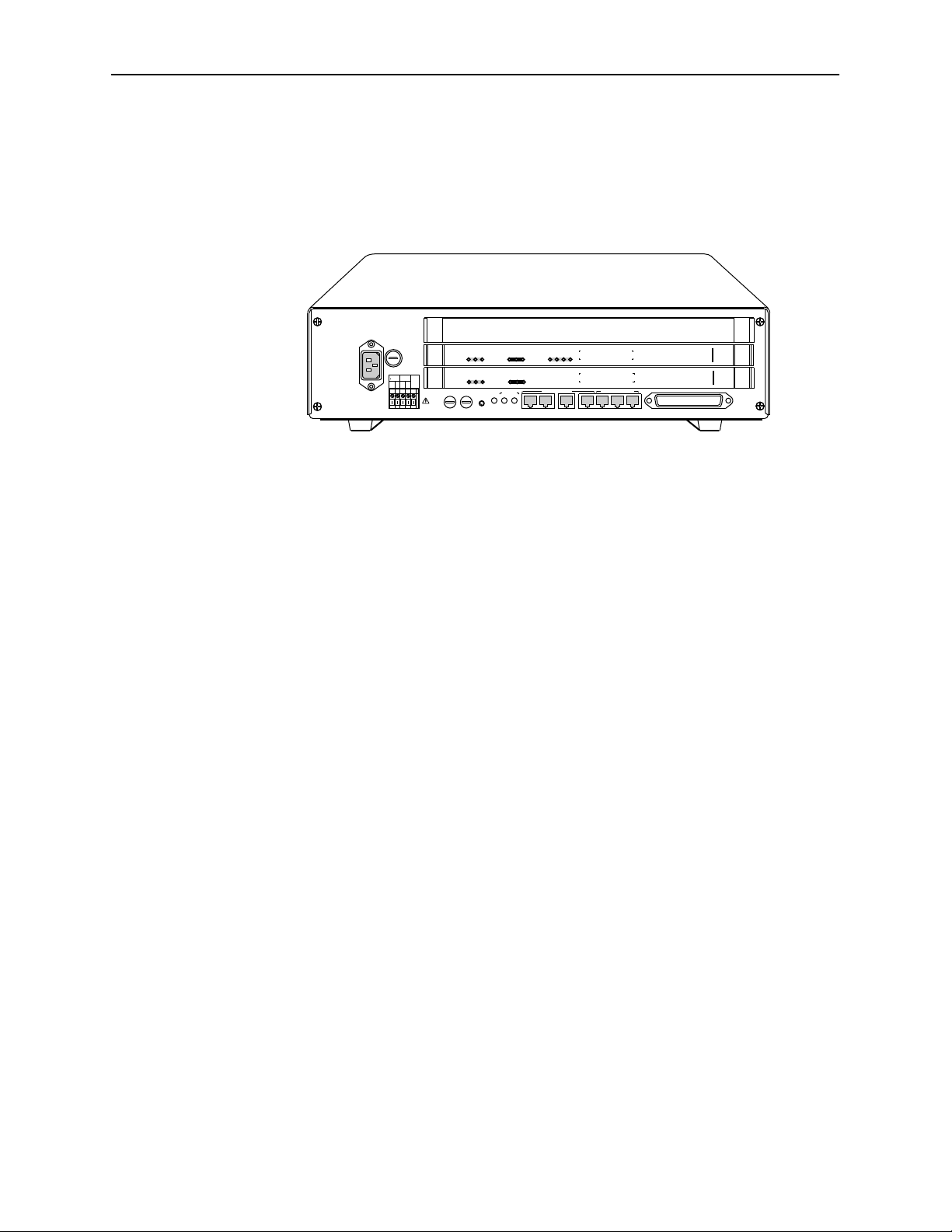

HotWire 8600 DSLAM Components

OK

Alrm

TestTXRX

SYSTEM

ETHERNET

AC

T5A

250V

RTN48V

AAB B

AC

INPUT

48VDC CLASS 2 OR

LIMITED PWR SOURCE

The HotWire 8600 DSLAM consists of the following components:

HotWire 8600 DSLAM base chassis

HotWire 8600 DSLAM is a three-slot chassis designed to house one

Management Communications Controller (MCC) card in the first slot and up

to two DSL cards in the remaining slots. Since the MCC card in the

8600 system can provide management connectivity for up to five other

8600 DSLAMs, these other systems can use the first slot for a DSL card, thus

housing up to three DSL cards.

SYSTEM

SYSTEM

DC FUSES

T4A, MIN. 48V

A

OK

Alrm

OK

Alrm

46

3

2

1

B

POSITION

TestTXRX

ETHERNET

TestTXRX

ETHERNET

DC PWR

FAN

5

.

.

ALM

A

.

.

STACK

Col1234

DSL PORT

Col1234

DSL PORT

Col

B

IN

MANAGEMENT

OUT SERIAL

MCC 1

About the HotWire 8600 DSLAM

8546

RADSL

3

8546

RADSL

2

8000

MCC

LAN/WAN SLOT

2

LINE

3

1

97-15350-01

One Management Communications Controller (MCC) card

The HotWire 8600 DSLAM requires one MCC card mounted in Slot 1 of the

base, or first, chassis in a stack. The MCC card is a processor card that

administers and provides diagnostic connectivity to DSL cards in from one to

six 8600 DSLAMs. It acts as a mid-level manager and works in conjunction

with an SNMP network management system, such as HP OpenView, via its

LAN port. It gathers operational status for each of the DSL cards and

responds to the SNMP requests. It also supports a serial port for local

terminal access.

At least one Digital Subscriber Line (DSL) card

The 8600 DSLAM requires at least one DSL card. Each DSL card contains

four DSL ports, Ethernet interface circuitry, and a processor. The processor

controls the modems and forwards the packet traffic to and from the Ethernet

and DSL interfaces.

NOTE:

You must order the MCC and DSL cards separately. They are not provided

with the chassis.

8600-A2-GN20-20

October 1997

1-3

Page 14

About the HotWire 8600 DSLAM

HotWire 8600 DSLAM Features

The HotWire 8600 DSLAM system has the following features:

Power Redundancy

Two versions of the HotWire 8600 DSLAM chassis are available:

— ac power

— dc power

The ac version can also be connected to a dc source to provide power

redundancy. When using the dc version, two separate dc sources may be

employed to provide power redundancy. If one power source fails, the other

source provides all of the power needed by the system. This is done

automatically without system disruption.

The dc version requires a source of –48 Vdc, while the ac version will

operate from 100 to 250 volts ac, 50 to 60 Hz.

Front-Facing Interface Connections

The interface connections on the front of the chassis allows all interface

cables to be connected and maintained in the front of the chassis for easy

accessibility.

Stackable Chassis for DSL Access Growth

Each chassis is an independent, standalone system. The stackable design

provides for six systems to share management access through a single MCC

card which, in turn, allows an additional slot for a DSL card in each of up to

five additional systems. In a stacked configuration, the first or base chassis is

equipped with an MCC card in Slot 1 leaving Slots 2 and 3 available for up to

two DSL cards, or a maximum of eight DSL ports.

Each additional system will accept up to three DSL cards for a maximum of

12 additional DSL ports.

A HotWire 8600 DSLAM chassis can be added or removed from the stack

without disrupting service to the other items in the stack.

The base system is electrically connected to additional systems by

connecting the 8-pin modular expansion cable provided from the OUT port of

the base chassis to the IN port of the next chassis in the stack.

Hot Swappable Cards

The MCC and DSL cards can be installed and removed from the HotWire

8600 DSLAM chassis without service disruption. You can replace a card

without powering down the chassis and disrupting service to the other cards.

Primary Network Management Support via SNMP

SNMP management of the DSL cards is accomplished over a single Ethernet

connection to the MCC card from a Network Management System (NMS)

(such as Paradyne’s DCE Manager for HP OpenView). The MCC card

gathers all management information for each of the DSL cards and responds

to the SNMP requests on behalf of the cards.

For a list of specific management information bases (MIBs) supported, see

HotWire DSLAM for 8540 and 8546 DSL Cards Network Configuration

the

.

Guide

1-4

October 1997

8600-A2-GN20-20

Page 15

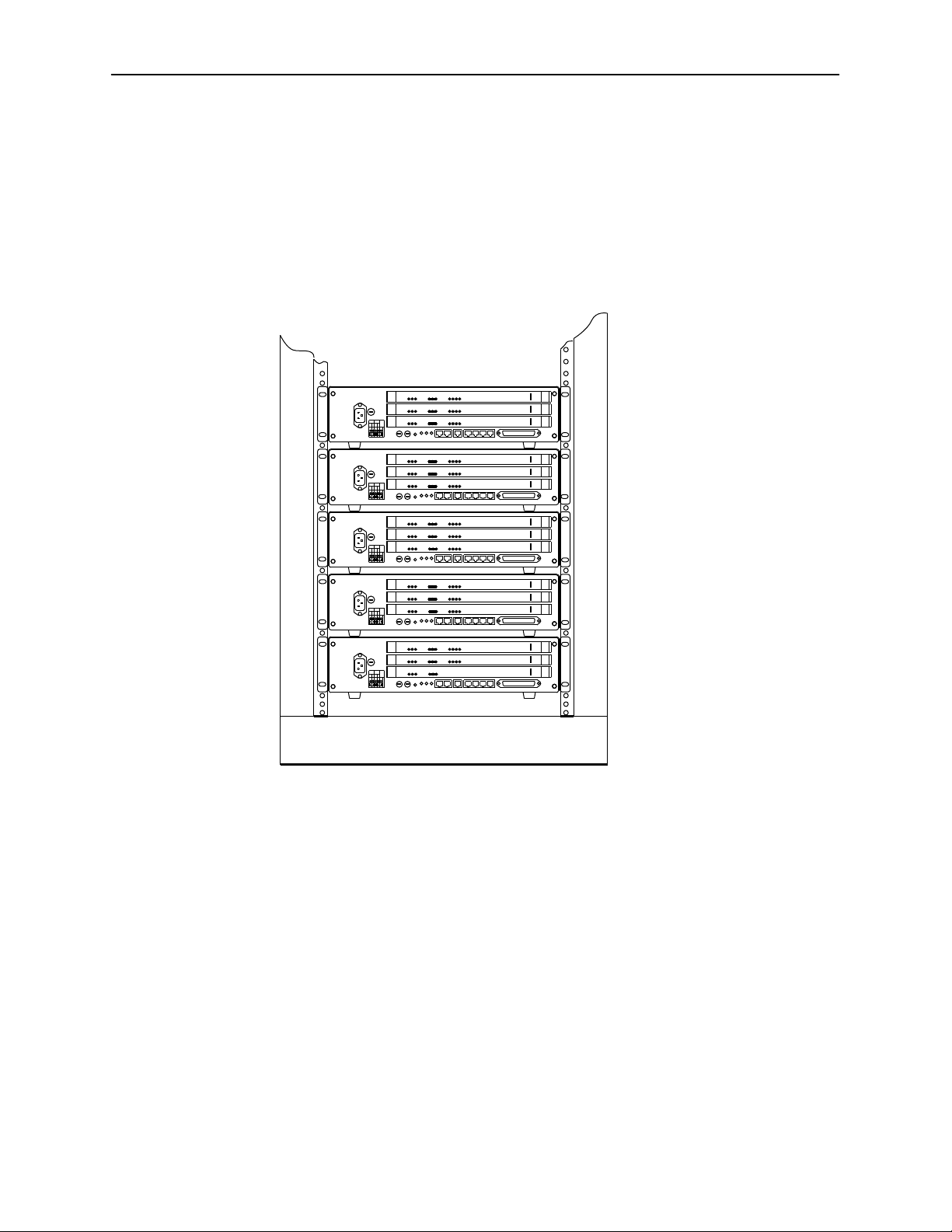

Mounting Configurations

The HotWire 8600 DSLAM chassis can be mounted in any commercial Electronic

Industries Association (EIA) standard 19- or 23-inch rack. Both 19- and 23-inch

rack-mounting hardware is provided with the unit. In a typical mounting

configuration, up to 14 HotWire 8600 DSLAM chassis can be mounted in a 7-foot

rack. Fourteen chassis in a rack provide up to 156 ports. The following illustration

shows the HotWire 8600 DSLAM chassis installed in a rack.

About the HotWire 8600 DSLAM

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

TXRXCol1234

OK

Alrm

Test

SYSTEM

DSL PORT

ETHERNET

8546

RADSL

3

8546

RADSL

2

8546

RADSL

1

8546

RADSL

3

8546

RADSL

2

8546

RADSL

1

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

123

TestTXRX

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

Col

DSL PORT

Col1234

DSL PORT

Col1234

DSL PORT

Col

DSL PORT

Col1234

DSL PORT

Col1234

DSL PORT

Col

4

123

4

OK

Alrm

SYSTEM

OK

Alrm

SYSTEM

OK

Alrm

SYSTEM

OK

Alrm

SYSTEM

OK

Alrm

SYSTEM

OK

Alrm

SYSTEM

OK

Alrm

SYSTEM

8546

RADSL

3

8546

RADSL

2

8546

RADSL

1

8546

RADSL

3

8546

RADSL

2

8546

RADSL

1

8546

RADSL

3

8546

RADSL

2

8000

MCC

1

97-15351

8600-A2-GN20-20

October 1997

1-5

Page 16

About the HotWire 8600 DSLAM

In addition, the HotWire 8600 DSLAM chassis can be placed on a desk or table,

and stacked on top of each other. For stability, do not set more than three

HotWire 8600 chassis on top of each other in a single stack on a desk or table

top. Two physical stacks of three chassis can be interconnected to provide

shared management access for six HotWire 8600 chassis.

97-15355

1-6

October 1997

8600-A2-GN20-20

Page 17

Installing and Connecting the Hardware

Overview

The HotWire 8600 DSLAM chassis can be mounted in a 19- or 23-inch wide rack.

These 8600 chassis can also be placed on a desk or table or stacked on top of

each other. Up to three chassis can be physically stacked on top of each other.

This chapter provides instructions for:

Mounting the DSLAM chassis in a rack

2

Stacking the DSLAM chassis on a desktop or table

Installing the MCC card

Installing the DSL card(s)

Making cable connection to the POTS splitter shelf

Connecting the DSL cards to the Ethernet hubs or switches

Making connection to a console terminal, laptop computer, or modem

NOTE:

In this guide, the term

rack

refers to a CO rack, cabinet, frame, or bay.

8600-A2-GN20-20

October 1997

2-1

Page 18

Installing and Connecting the Hardware

Package Contents

The HotWire 8600 DSLAM chassis, as shipped, consists of the following:

Three Filler Plates installed in Slots 1, 2, and 3.

AC

INPUT

Associated hardware bundled in a plastic bag:

AC

T5A

250V

RTN48V

AAB B

48VDC CLASS 2 OR

LIMITED PWR SOURCE

SYSTEM

SYSTEM

SYSTEM

DC FUSES

T4A, MIN. 48V

A

OK

Alrm

OK

Alrm

OK

Alrm

3

2

B

TestTXRX

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

FAN

5

46

.

.

ALM

.

1

.

STACK

POSITION

DC PWR

A

B

Col1234

DSL PORT

Col1234

DSL PORT

Col

MANAGEMENT

IN

OUT SERIAL

MCC 1

LAN/WAN SLOT

2

8546

RADSL

3

8546

RADSL

2

8000

MCC

LINE

3

1

97-15350-01

— ac power cord (if your chassis has the ac power option)

— Two reversible mounting brackets (for 19- and 23-inch rack mounting)

— One control bus cable (2 1/2 feet in length) for connecting multiple

8600 systems

— Four #10-32 mounting screws and #12-24 speed nuts (for use with racks

without threaded mounting holes), three captive screws, and three cable

ties.

NOTE:

The HotWire 8600 DSLAM chassis requires an MCC card and at least

one DSL card for proper functionality. These cards are

part of the 8600 chassis and must be ordered separately.

Documentation:

— This guide, the

(DSLAM) Installation Guide

You can access the next two documents on the Paradyne World Wide

Web site at http://www.paradyne.com, under Service and Support.

HotWire DSLAM for 8540 and 8546 DSL Cards User’s Guide

—

—

HotWire DSLAM for 8540 and 8546 DSL Cards Network Configuration

Guide

HotWire 8600 Digital Subscriber Line Access Multiplexer

not

provided as

Unpacking the Hardware

When shipped, the HotWire 8600 DSLAM chassis is packed in a cardboard

shipping container. Carefully remove the 8600 chassis from its shipping container

2-2

October 1997

8600-A2-GN20-20

Page 19

and check for physical damage. If the 8600 chassis shows signs of shipping

damage, report this immediately to your shipping and sales representatives.

Pre-installation Considerations

Consider the following before performing installation of the 8600 chassis:

Installation Site

Your installation site should be well-ventilated, clean, and free of

environmental extremes. If you are installing the HotWire 8600 DSLAM

chassis in a Central Office rack, make sure there is 2 to 3 feet of clearance at

the front of the rack in which the 8600 chassis is to be installed to allow

access for the installation of the chassis, circuit cards, and cables.

Power

The ac power version requires a power source of 100 – 250 Vac

@ 50 – 60 Hz; maximum current draw is 3 amps @ 110 Vac.

The dc power version requires a –48 Vdc power source (–40.0 to –60.0 Vdc;

maximum current draw is 2 amps). The size of power source wires must be

between 14 AWG and 18 AWG, and can be either solid or stranded.

However, 16 AWG stranded wire is recommended.

Installing and Connecting the Hardware

Grounding

A ground lug is located at the center of the cover at the rear. It accepts

14 AWG wire.

A non-insulated banana jack is located at the left front side of the unit to

provide a ground for the ESD wrist strap plug.

Stacking

Up to three 8600 chassis may be physically stacked safely on top of each

other. However, for stacks of more than three, start a second stack or mount

in a 19- or 23-inch rack. Contact your sales representative for ordering

information.

Cabling

The following customer-provided cables and cable adapters are required with

this product:

— Plug-ended Telco 50-pin cable for connection from the HotWire 8600

DSLAM Line ports to the CO POTS splitter shelf or MDF.

— 8-pin UTP (Unshielded Twisted Pair) CAT5 modular cable for connection

from each DSL card in the HotWire 8600 DSLAM to the LAN or WAN.

You will need one 8-pin modular cable for accessing the LAN/WAN

circuits of each DSL.

— 8-pin UTP CAT5 modular cable for connection from the HotWire 8600

DSLAM MANAGEMENT MCC port to a 10BaseT hub connector

(connected to an SNMP management system network).

8600-A2-GN20-20

— 14-foot CAT5 serial cable and DB25 adapter are shipped with the MCC

card. For connection to a terminal or computer, you may have to supply a

(female) DB9 to (male) DB25 adapter if your terminal or computer has a

October 1997

2-3

Page 20

Installing and Connecting the Hardware

9-pin serial port. For connection to a modem, you will need a NULL

modem adapter.

CAUTION:

Use of any non-twisted pair wiring arrangements, such as jumpers, can

cause reduction in overall DSL reach performance, even over short

distances. Please refer to the Special Notice shipped with this product.

Installation Tasks

The following table lists the tasks you need to perform.

Task See

1. Mount the 8600 chassis into a

2. Select the stack number.

3. Interconnect the stack.

4. Supply power to the 8600 chassis.

5. Install the MCC card into the base

Pin assignments are described in Appendix B,

Pinouts

.

NOTE:

Each HotWire 8600 DSLAM chassis weighs approximately nine pounds (with

circuit cards) and can be easily installed by one installer.

standard 19- or 23-inch rack, or stack

the 8600 chassis on a desktop or

tabletop.

chassis.

HotWire 8600 DSLAM Chassis Installation

page 2-5

Stacking the 8600 Chassis

Interconnecting 8600 Systems,

Supplying Power

Installing the MCC Card

, page 2-13

, page 2-5

page 2-8

, page 2-18

,

2-4

6. Install the DSL card into the 8600

chassis.

7. (Optional) Connect the 8600 chassis

to a POTS splitter shelf or MDF.

8. Connecting to the Ethernet hub or

switch.

9. (Optional) Connect to an SNMP

management system.

10. Connect to a terminal or laptop . . . . .

computer.

1 1. Verify the hardware installation.

October 1997

Installing DSL Cards

Connecting to a POTS Splitter or an MDF

page 2-23

Connecting the DSL Cards to the Ethernet

Hubs or Switches

Connecting to an SNMP Management

System

Connecting to a Terminal or Laptop

Computer

Verifying the Installation

, page 2-25

, page 2-26

, page 2-19

, page 2-24

, page 2-21

8600-A2-GN20-20

,

Page 21

HotWire 8600 DSLAM Chassis Installation

You will need a large, flat-blade screwdriver and a Phillips screwdriver to install

the 8600 chassis in a commercial EIA-standard 19- or 23-inch rack on a desk or

table.

The HotWire 8600 DSLAM chassis is designed to be stacked one on top of the

other on a desktop or table, or mounted in a 19-or 23-inch rack. Up to three 8600

chassis can be stacked on a table or desktop. Mounting brackets are provided for

mounting in 19- or 23-inch racks.

The following procedures describe how to:

H Stack the 8600 chassis

H Interconnect the chassis

H Install the 8600 chassis into a rack with threaded screw holes

H Install the 8600 chassis into a rack without threaded screw holes

Stacking the 8600 Chassis

Installing and Connecting the Hardware

" Procedure

To stack the 8600 chassis on a desktop or table, select the stack position, and

interconnect the stack:

1. Place the first HotWire 8600 DSLAM chassis on a table or desk.

2. Place the next HotWire 8600 DSLAM chassis directly on top of the first

chassis.

3. Place the next HotWire 8600 DSLAM chassis directly on top of the second

chassis.

8600-A2-GN20-20

October 1997

2-5

Page 22

Installing and Connecting the Hardware

4. Change the setting of the rotary STACK POSITION switch to the appropriate

position of the chassis. Set the switch so that the white line points to the

position number.

— The base chassis containing the MCC card must be set to

Stack Position 1;

— The chassis directly on top of the base chassis must be set to Stack

Position 2;

— The chassis directly on top of chassis #2 must be set to Stack Position 3,

and so on.

Stack Position 2

5A

5

46

3

2

.

1

.

STACK

POSITION

FAN

5

46

.

FAN

5A

3

2

.

1

.

STACK

POSITION

.

ALM

Stack Position 3

.

.

ALM

5

46

.

3

.

2

.

1

5A

.

STACK

POSITION

Base Unit

Stack Position 1

FAN

ALM

97-15372

2-6

October 1997

8600-A2-GN20-20

Page 23

Installing and Connecting the Hardware

National Equipment Building Standards (NEBS)

The following must be taken into consideration for compliance with NEBS

requirements.

Connection to the CO Ground Lug

Procedure

1. Strip back the insulation approximately 1/4- to 3/8-inch on 14 AWG copper

wire.

2. Loosen the screw on the GND lug located on the rear surface at the center of

the HotWire 8600 DSLAM cover.

3. Insert the stripped end of the wire into the open end of the GND lug and

tighten the lug’s screw. Make sure it is making contact with the stripped

portion of the wire.

ESD Wrist Strip Jack

A non-insulated banana jack is located at the left front side of the HotWire 8600

DSLAM to provide a ground for the ESD wrist strap’s plug.

8600-A2-GN20-20

October 1997

2-7

Page 24

Installing and Connecting the Hardware

Interconnecting 8600 Systems

Procedure

To interconnect multiple 8600 systems:

1. Connect the end of an 8-pin modular cable into the Management OUT port of

the base chassis.

2. Dress the 8-pin modular cable to the left and under the chassis, behind the

foot, and up the side of the unit.

3. Plug the other end of the 8-pin modular cable into the Management IN port of

the 8600 chassis above, dressing the cable as in the previous step.

4. Repeat for the next 8600 chassis, connecting the Management OUT port of

Chassis 2 to the Management IN port of Chassis 3.

Refer to Appendix B,

Pinouts

, for pin assignments.

NOTE:

Some installation configurations may require separation of 8600 systems in a

stack and require bus cables other than those provided. These bus cables

must use UTP (Unshielded Twisted Pair) CAT5 cable. The total bus cabling

should not exceed 25 feet.

2-8

October 1997

8600-A2-GN20-20

Page 25

Installing and Connecting the Hardware

The software identifies each circuit card in the stack by a Slot Number. The

following illustration shows the designated number for each DSL card slot in a

stack.

Assigned DSL Slot Numbers

Physically

Assigned

Software

Assigned

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

DSL

MCC

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

16

2

15

1

14

3

13

2

12

1

11

3

10

2

9

1

8

3

7

2

6

1

5

3

4

2

3

1

2

3

1

2

1

Additional

Systems

Base

Chassis

17

3

8600-A2-GN20-20

97-15448-01

NOTE:

This illustration depicts a stack of six HotWire 8600 systems which is valid for

rack mounting. However, the same relationship of software-assigned slot

numbers applies to two stacks of three each, mounted on a desk or table top

and connected by a bus cable.

October 1997

2-9

Page 26

Installing and Connecting the Hardware

Installing the 8600 Chassis in a Rack with Threaded Screw Holes

Procedure

To install the 8600 chassis in a rack that has threaded screw holes:

1. Install the mounting brackets on the 8600 chassis by removing the two front

screws on each side of the unit. You will reuse these screws to secure the

mounting brackets to the 8600 chassis.

— For a 19-inch rack installation, the notched flange of the mounting

bracket is placed against the side of the 8600 chassis.

— For a 23-inch rack installation, the smaller flange of the mounting bracket

is placed against the side of the 8600 chassis.

19-Inch Rack 23-Inch Rack

97-15451

2-10

October 1997

8600-A2-GN20-20

Page 27

Installing and Connecting the Hardware

2. Secure the mounting brackets to the 8600 chassis by using the screws

removed from the sides of the unit.

3. Determine the preferred placement of the 8600 chassis in the rack. Then,

mark the appropriate locations for the mounting screws on the rack.

4. Place the 8600 chassis against the front rails of the rack and secure with the

appropriate mounting screws.

Repeat these steps for each succeeding 8600 chassis.

Front Rail

97-15353

8600-A2-GN20-20

October 1997

2-11

Page 28

Installing and Connecting the Hardware

Installing the 8600 Chassis in a Rack without Threaded Screw Holes

Procedure

To install the 8600 chassis in a rack that does

not

have threaded screw holes:

1. Install the mounting brackets on the 8600 chassis.

— For a 19-inch rack installation, the notched flange of the mounting

bracket is placed against the side of the 8600 chassis.

— For a 23-inch rack installation, the smaller flange of the mounting bracket

is placed against the side of the 8600 chassis.

2. Determine the preferred placement of the 8600 chassis in the rack.

3. Slip a speed nut onto each rail hole selected and align the hole of the speed

nut with the hole in the rail.

Front Rail

Speed

Nut

2-12

97-15354

4. Line up the chassis mounting bracket with the speed nut and start to rotate

the screw into the chassis mounting bracket and the speed nut. Start all four

screws, then tighten all four until each screw head is flush with the chassis

and is securely mounted in the rack.

To install the next 8600 chassis in the same manner, repeat Steps 1 through 4.

October 1997

8600-A2-GN20-20

Page 29

Supplying Power

The HotWire 8600 DSLAM chassis is available in two versions:

H dc power (–40.0 to –60.0 Vdc; maximum current draw is 2 amps)

— The dc version has two separate dc inputs, A and B, to provide power

redundancy.

H ac power (100 – 250V; 50 – 60 Hz; maximum current draw is

3 amps @ 110 Vac)

— The ac version can provide power redundancy if a separate – 48 Vdc

source is connected to the B input terminal.

Using a Single DC Power Source

Procedure

"

To supply –48 Vdc power to the 8600 chassis from a single –48 Vdc power

source:

Installing and Connecting the Hardware

Make sure that the dc power source wires are not powered (i.e., the

circuit breakers are open).

The ends of the power source wires (14 AWG – 18 AWG solid or

stranded wire) must be stripped of insulation. If the wires are not stripped,

strip the tip of each wire (about 1/3-inch in length) before inserting the

wire into the appropriate terminal on the –48V input terminal block.

1. Insert the following wires in the appropriate terminal and securely fasten each

wire by tightening the screw above it. The insulation should be fully within the

terminal block and no bare wire should be exposed outside of the block.

NOTE:

You should clearly label these power source wires as –48V and RTN

respectively.

Insert Power Source A’s . . .

Wire –48V A input terminal.

RTN wire RTN A (return) terminal.

Into the . . .

8600-A2-GN20-20

October 1997

2-13

Page 30

Installing and Connecting the Hardware

2. Dress the wires under the 8600 chassis to the left behind the support foot.

AC

T5A

250V

RTN–48V

AAB B

AC

INPUT

F

G

RTN

B

-48V

A

B

A

48VDC INPUT

48VDC CLASS 2 OR

LIMITED PWR SOUR

97-15446-01

3. Power the HotWire 8600 DSLAM chassis.

4. Make sure the DC PWR A LED on the front panel is ON (green).

Using Two DC Power Sources for Power Redundancy

Procedure

To supply two dc power sources to the 8600 chassis for power redundancy:

Make sure that the dc power source wires are not powered (i.e., the

circuit breakers are open).

The ends power source wires (14 AWG – 18 AWG solid or stranded wire)

must be stripped of insulation to about 1/3-inch in length before plugging

the wires into the appropriate terminal on the –48V input terminal block.

1. Insert the following wires in the appropriate terminal and securely fasten each

wire by tightening the screw directly above it. The insulation should be fully

within the terminal block and no bare wire should be exposed outside of the

block.

NOTE:

You should clearly label these power source wires as –48V and RTN

respectively.

2-14

October 1997

8600-A2-GN20-20

Page 31

Installing and Connecting the Hardware

Insert Power Source. . . Into the . . .

A’s wire –48V A input terminal.

B’s wire –48V B input terminal.

A’s RTN wire RTN A (return) terminal.

B’s RTN wire RTN B (return) terminal.

2. Dress the wires under the 8600 chassis to the left behind the support foot.

AC

T5A

250V

RTN–48V

AAB B

AC

INPUT

F

G

RTN

B

-48V

A

B

A

48VD

48VDC CLASS 2 OR

LIMITED PWR SOURCE

97-15371-01

3. Power the HotWire 8600 DSLAM chassis by closing the circuit breakers or

reinstalling the fuses.

4. Make sure the DC PWR A and DC PWR B LEDs on the front panel are both

ON (green).

8600-A2-GN20-20

October 1997

2-15

Page 32

Installing and Connecting the Hardware

Using Only AC Power Source

Procedure

To supply power to the 8600 chassis using a single ac power source:

1. Plug the ac power cord into the AC INPUT connector on the Interface Panel.

RTN

B

-48V

A

B

A

48VDC INPUT

2. Plug the other end of the ac power cord into your ac power receptacle.

NOTE:

The ac power source should be a non-switched outlet to prevent

accidentally turning off power.

3. Make sure the PWR A LED on the front panel is ON (green).

Using AC Power with DC Power Backup

Procedure

To supply both ac and dc power to the 8600 chassis for power redundancy:

Make sure that the dc power source wires are not powered (i.e., the

circuit breakers are open).

The ends of the dc power source wires (14 AWG – 18 AWG solid or

stranded wire) must be stripped of insulation. If they are not stripped of

insulation, strip the tip of each wire (about 1/3-inch in length) before

plugging the wire into the appropriate connector on the –48V input

terminal block.

F

G

RTN

B

-48V

A

B

A

48VDC INPUT

97-15365

2-16

October 1997

8600-A2-GN20-20

Page 33

Installing and Connecting the Hardware

1. Plug the ac power cord into the AC INPUT connector on the Interface Panel.

2. Insert the following wires in the appropriate terminal and securely fasten each

wire by tightening the screw above it. The insulation should be fully within the

terminal block and no bare wire should be exposed outside of the block.

NOTE:

You should clearly label these power source wires as –48V and RTN

respectively.

Insert Power Source B’s . . .

Into the . . .

Wire –48V B input terminal.

RTN wire RTN B (return) terminal.

3. Dress the wires under the 8600 chassis to the left and behind the front left

support foot.

AC

T5A

250V

RTN48V

AAB B

AC

INPUT

48VDC CLASS 2 OR

LIMITED PWR SOUR

8600-A2-GN20-20

F

G

RTN

B

-48V

A

B

A

48VD

97-15447-01

4. Plug the other end of the ac power cord into your ac power receptacle.

5. Power the HotWire 8600 DSLAM chassis by closing the circuit breakers or

reinstalling the fuses.

6. Make sure the PWR A and DC PWR B LEDs on the front panel are both ON

(green).

October 1997

2-17

Page 34

Installing and Connecting the Hardware

Installing the MCC Card

Use a small- to medium-size flat-blade screwdriver to install the MCC card.

NOTE:

All standalone 8600 chassis (i.e., chassis that are not daisy-chained to other

HotWire 8600 DSLAM chassis) require an MCC card, but only the base

chassis of a multi-system stack requires an MCC card.

Do not discard filler plates. Each slot in the chassis must contain a circuit

card or a filler plate to maintain the required EMI shielding and to prevent air

leakage from the forced air cooling. Air leakage could result in overheating

which may cause the power to the circuit cards to be shut off. Store all

unused filler plates in a safe place. You may need to use the filler plates to

cover open slots in the chassis at a later time.

!

HANDLING PRECAUTIONS FOR

STATIC-SENSITIVE DEVICES

This product is designed to protect sensitive components from damage

due to electrostatic discharge (ESD) during normal operation. When

performing installation procedures, however, take proper static control

precautions to prevent damage to equipment. If you are not sure of the

496-15104

proper static control precautions, contact your nearest sales or service

representative.

Procedure

To install the MCC card in the HotWire 8600 DSLAM chassis:

1. Remove the filler plate from Slot 1 by unscrewing the mounting screws at

each end.

2. Hold the MCC card horizontally with the components on top and insert it into

the left and right card guides of Slot 1 of the base chassis.

OK

Alrm

TestTXRX

INPUT

AC

AC

T5A

250V

RTN48V

AAB B

48VDC CLASS 2 OR

LIMITED PWR SOURCE

SYSTEM

SYSTEM

Col1234

DSL PORT

ETHERNET

OK

Alrm

Test

TXRXCol

ETHERNET

RADSL

8546

MCC

97-15373-01

3

2

1

8000

2-18

October 1997

8600-A2-GN20-20

Page 35

Installing and Connecting the Hardware

3. Carefully slide the MCC card into the slot. Gently, but firmly, push the card

until it engages its mating connectors on the backplane.

4. Press on the right side of the MCC’s front panel with one hand and on the

back of the 8600 chassis with the other until the MCC’s connector seats in its

mating connector.

5. Make sure the OK SYSTEM indicator on the MCC faceplate is ON (green).

if not, refer to Chapter 4,

6. Secure the MCC card by fastening the screws on each end of the faceplate.

Troubleshooting

.

NOTE:

The MCC card may be replaced without disruption to user data (i.e., you can

remove and re-install the MCC card without powering down the 8600 chassis

and disrupting service to the other cards). To remove the MCC card from the

base chassis, unfasten the screws on both ends of the faceplate. Then,

simply push the ejector handles outward and slide the card out.

When swapping the old MCC card with a new MCC card, it is important to

note that the 8600 chassis DSLAM retains the Media Access Control (MAC)

address, also referred to as the physical address. This means that the new

MCC card will have the same MAC address as the old one.

Installing DSL Cards

Use a small- to medium-size flat-blade screwdriver to install the DSL card.

NOTE:

The 8600 chassis are shipped with filler plates in Slots 1, 2, and 3. If the slot

where the DSL is to be installed has a filler plate, it must be removed.

Do not discard filler plates. Each slot in the chassis must contain a circuit

card or a filler plate to maintain the required EMI shielding and to prevent air

leakage from the forced air cooling. Air leakage could result in overheating

which may cause the power to the circuit cards to be shut off. Store all

unused filler plates in a safe place. You may need to use the filler plates to

cover open slots in the chassis at a later time.

!

HANDLING PRECAUTIONS FOR

STATIC-SENSITIVE DEVICES

This product is designed to protect sensitive components from damage

due to electrostatic discharge (ESD) during normal operation. When

performing installation procedures, however, take proper static control

precautions to prevent damage to equipment. If you are not sure of the

496-15104

proper static control precautions, contact your nearest sales or service

representative.

8600-A2-GN20-20

October 1997

2-19

Page 36

Installing and Connecting the Hardware

Pr ocedure

To install a DSL card:

1. Remove the filler plate from the desired slot.

2. Hold the DSL card horizontally with the components on top and insert it into

the left and right card guides.

AC

INPUT

AC

T5A

250V

RTN48V

AAB B

48VDC CLASS 2 OR

LIMITED PWR SOURCE

DC FUSES

SYSTEM

A

SYSTEM

OK

B

OK

Alrm

Alrm

Test

5

46

3

2

1

.

STACK

POSITION

TestTXRX

ETHERNET

DC PWR

FAN

.

.

ETHERNET

ALM

A

.

TXRXCol

B

Col

IN

MANAGEMENT

DSL PORT

OUT SERIAL

123

4

MCC 1

LAN/WAN SLOT

2

3

2

LINE

3

RADSL

1

8000

97-15374-01

3. Slide the DSL card into the slot until it engages the mating connectors on the

backplane.

4. Press on the right side of the DSL’s front panel with one hand and on the

back of the 8600 chassis with the other until the DSL’s connector seats in its

mating connector.

5. Make sure the OK SYSTEM indicator on the DSL card faceplate is ON

(green). For a more detailed explanation of the LEDs on the DSL card, refer

to the appropriate DSL card documentation.

6. Secure the DSL card by fastening the screws on each end of the faceplate.

NOTE:

The DSL cards may be replaced without system disruption (i.e., you can

remove and re-install a card without powering down the 8600 chassis and

disrupting service to the other cards). To remove a DSL card from the

8600 chassis, unfasten the screws on both ends of the faceplate. Then,

simply push the ejector handles outward and slide the card out.

When swapping the old DSL card with a new DSL card, it is important to note

that the 8600 DSLAM retains the Media Access Control (MAC) address, also

referred to as the physical address. This means that the new DSL card will

have the same MAC address as the old one.

2-20

October 1997

8600-A2-GN20-20

Page 37

Verifying the Installation

To verify the hardware installation, observe the following indicators:

The PWR A and/or PWR B LEDs on the front panel must be in the ON state

(green):

— If you are using a single –48 Vdc power source, then only the green

DC PWR A LED will be ON.

— If you are using dual Vdc power sources, then both the green

DC PWR A and DC PWR B LEDs will be ON.

— If you are using a single ac power source, then the green PWR A LED

must be ON.

— If you are using both an ac power source and a –48 Vdc power source,

then both the PWR A and PWR B LEDs must be ON.

The yellow FAN ALM LED on the front panel must be OFF.

Also check the SYSTEM LEDs on the MCC and DSL cards if you have not

done so already. The OK SYSTEM indicators on the cards must be in the ON

state (winking green).

Installing and Connecting the Hardware

If these status indicators fail to appear as described, see Chapter 4,

Troubleshooting

for a complete list of these indicators and their descriptions.

, for troubleshooting procedures. Also refer to Appendix A,

LEDs,

8600-A2-GN20-20

October 1997

2-21

Page 38

Installing and Connecting the Hardware

Making Cable Connections

This section provides the instructions you need to make the necessary cable

connections to:

POTS splitter shelf or MDF

Ethernet hubs or switches

SNMP management system

Terminal, laptop computer, or modem

Special Connection Considerations

There are several steps that you must take to maximize loop reach.

Use only CAT3 or better twisted-pair network connection cables for DSL

Termination Unit connections and interface patch cabling. Untwisted analog

cables of any length anywhere in the loop substantially contribute to crosstalk

and reduced loop reach.

Make sure the main bundle of the loop is standard twisted-pair voice cable

(CAT3).

For multiple DSL circuits in the same main bundle, choose non-adjacent wire

pairs whenever possible.

Use only non-conditioned loops (no load coils, echo suppression, etc.)

Eliminate any non-twisted cable from the loop.

Always keep TIP and RING in the same twisted-cable pair.

2-22

October 1997

8600-A2-GN20-20

Page 39

Connecting to a POTS Splitter or an MDF

You can connect the HotWire 8600 DSLAM chassis to a POTS splitter shelf or to

a Main Distributing Frame (MDF).

NOTE:

If you are connecting the HotWire 8600 DSLAM to a CO POTS splitter, this

procedure assumes that the CO POTS splitter shelf is already installed. For

information on how to install the CO POTS splitter, refer to the

Splitter Central Office Installation Instructions

Procedure

To connect the 8600 chassis to a POTS splitter shelf or MDF:

1. Plug the Telco 50-pin cable into the LINE connector on the front panel of the

8600 chassis.

2. Remove the captive screw on the connector and replace with one of the three

captive screws shipped with the unit. Secure the Telco 50-pin cable by

fastening the captive screw on the left.

Installing and Connecting the Hardware

HotWire POTS

.

3. Tighten the cable tie on the right and cut off any excess cable tie.

4. Make sure the other end is connected to the appropriate POTS splitter shelf,

MDF, or demarcation point.

Refer to Appendix B,

OK

Alrm

TestTXRX

Col1234

SYSTEM

DSL PORT

ETHERNET

AC

OK

Alrm

TestTXRX

Col1234

SYSTEM

T5A

250V

RTN48V

AAB B

AC

INPUT

48VDC CLASS 2 OR

LIMITED PWR SOURCE

ETHERNET

OK

Alrm

TestTXRX

SYSTEM

ETHERNET

DC FUSES

FAN

T4A, MIN. 48V

5

46

.

3

.

2

ALM

.

1

.

A

B

STACK

POSITION

DSL PORT

Col

MANAGEMENT

DC PWR

A

B

MCC 1

IN

OUT SERIAL

Telco 50-Pin

Connector

LAN/WAN SLOT

Pinouts

3

2

, for pin assignments.

8546

RADSL

3

8546

RADSL

2

8000

MCC

1

LINE

Anchor

Mount

8600-A2-GN20-20

October 1997

97-15480-01

2-23

Page 40

Installing and Connecting the Hardware

Connecting the DSL Cards to the Ethernet Hubs or Switches

Procedure

To connect the DSL cards to the Ethernet hubs or switches:

1. Plug the end of an 8-pin modular cable into the appropriate LAN/WAN SLOT

port of the 8600 chassis. For example, if you want to connect to a DSL card

in Slot 2, insert the 8-pin modular cable into the LAN/WAN Slot #2.

2. Run the 8-pin modular cable under the 8600 chassis and behind the left leg.

3. Plug the other end of the cable into your Ethernet hub or switch connector.

Refer to Appendix B,

AC

INPUT

LIMITED PWR SOURCE

Pinouts

AC

T5A

250A

RTN48V

AAB B

48VDC CLASS 2 OR

, for pin assignments.

OK

Alrm

TestTXRX

OK

Alrm

OK

Alrm

46

3

2

1

STACK

POSITION

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

FAN

5

.

.

ALM

.

.

DC PWR

A

B

Col1234

DSL PORT

Col1234

DSL PORT

Col

MANAGEMENT

IN

OUT SERIAL

DC FUSES

T4A, MIN. 48V

A

SYSTEM

SYSTEM

SYSTEM

B

MCC 1

LAN/WAN SLOT

8546

RADSL

3

8546

RADSL

2

8000

MCC

LINE

3

2

1

DC PWR

AINB

To Hub Connector

MANAGEMENT

OUT SERIAL

MCC 1

LAN/WAN SLOT

2

3

97-15375-02

2-24

October 1997

8600-A2-GN20-20

Page 41

Connecting to an SNMP Management System

Procedure

To connect the HotWire 8600 DSLAM base chassis (i.e., the chassis that contains

the MCC card) to an SNMP management system:

1. Plug the end of an 8-pin modular cable into the MANAGEMENT MCC port of

the HotWire 8600 DSLAM base chassis.

2. Dress the 8-pin cable under the 8600 chassis to the left and behind the left

support foot.

3. Plug the other end of the cable into the 10BaseT hub connector to the SNMP

management system network.

INPUT

AC

Pinouts

AC

T5A

250V

RTN48V

AAB B

48VDC CLASS 2 OR

LIMITED PWR SOURCE

Refer to Appendix B,

Installing and Connecting the Hardware

, for pin assignments.

OK

Alrm

TestTXRX

OK

Alrm

OK

Alrm

46

3

2

1

STACK

POSITION

ETHERNET

TestTXRX

ETHERNET

TestTXRX

ETHERNET

FAN

5

.

.

ALM

.

.

DC PWR

A

B

Col1234

DSL PORT

Col1234

DSL PORT

Col

MANAGEMENT

IN

OUT SERIAL

MCC 1

DC FUSES

t4a, MIN. 48V

A

SYSTEM

SYSTEM

SYSTEM

B

LAN/WAN SLOT

8546

RADSL

3

8546

RADSL

2

8000

MCC

LINE

3

2

1

DC PWR

AINB

To SNMP

Management System

MANAGEMENT

OUT SERIAL

MCC 1

LAN/WAN SLOT

2

3

97-15376-02

8600-A2-GN20-20

October 1997

2-25

Page 42

Installing and Connecting the Hardware

Connecting to a Terminal or Laptop Computer

Procedure

To connect the HotWire 8600 DSLAM chassis to a terminal or laptop computer:

1. Connect an 8-pin modular plug-ended serial cable into the MANAGEMENT

SERIAL port of the HotWire 8600.

2. Dress the serial cable under the 8600 chassis, to the left and behind the left

support foot.

3. Plug the other end of the cable into your terminal’s (or computer’s) serial port

using a DB25 (RS-232 male) adapter, supplied with the MCC card. Use a

(female) DB9 to (male) DB25 adapter if necessary.

Refer to Appendix B,

4. Configure your terminal or terminal emulator with the following settings:

— Baud Rate = 9600

— Data Bits = 8

Pinouts

, for pin assignments.

— Parity = No Parity

— Stop Bits = 1

— Flow Control = XON/XOFF

— Terminal Type = VT100

AC

T5A

250V

RTN48V

AAB B

AC

INPUT

48VDC CLASS 2 OR

LIMITED PWR SOURCE

DC PWR

AINB

To Terminal

Serial Port

MANAGEMENT

OUT SERIAL

SYSTEM

DC FUSES

T4A, MIN. 48V

A

SYSTEM

SYSTEM

OK

OK

OK

B

Alrm

TestTXRX

ETHERNET

Alrm

TestTXRX

ETHERNET

Alrm

TestTXRX

ETHERNET

FAN

5

46

.

3

.

2

ALM

.

1

.

STACK

POSITION

Col1234

Col1234

Col

DC PWR

A

B

MCC 1

DSL PORT

DSL PORT

IN

MANAGEMENT

OUT SERIAL

LAN/WAN SLOT

MCC 1

LAN/WAN SLOT

2

8546

RADSL

3

8546

RADSL

2

8000

MCC

LINE

3

2

3

1

97-15377-02

2-26

October 1997

8600-A2-GN20-20

Page 43

Connecting to a Modem for Remote Management

Before connecting the HotWire 8600 DSLAM to a dial up modem, configure the

modem with the following settings:

H Set the modem for auto answer. For example, ATS0=1.

H Turn off character echo. For example, ATE0.

H Enable result codes in originate mode only. For example, ATQ2.

H Set the modem to ignore Data Terminal Ready (DTR). For example, AT&D0.

" Procedure

To connect the HotWire 8600 DSLAM chassis to a dial up modem:

1. Connect an 8-pin modular plug-ended serial cable into the MANAGEMENT

SERIAL port of the HotWire 8600.

2. Dress the serial cable under the 8600 chassis, to the left and behind the

support foot.

Installing and Connecting the Hardware

3. Plug the other end of the cable into your modem’s serial port using a DB25

(RS-232 male) adapter, supplied with the MCC card, and a Null Modem

adapter.

Refer to Appendix B,

Management Serial

DC PWR

AINB

MANAGEMENT

OUT SERIAL

Pinouts

MCC 1

, for pin assignments.

LAN/WAN SLOT

3

2

DB25

Adapter

Dial up

Modem

Null

Modem

97-15481-01

8600-A2-GN20-20

October 1997

2-27

Page 44

Installing and Connecting the Hardware

Connecting to a HotWire 8600 DSLAM Via Telnet

You can connect to a HotWire 8600 DSLAM via a telnet session from either a

workstation or PC that has access to the Management Domain LAN.

Procedure

If you are using a Solaris 2 or SUN OS 4 workstation:

1. Execute a window manager program, such as OpenWin.

2. Execute a terminal emulator program.

3. Set terminal type to VT100.

4. Establish a telnet session by issuing the telnet command and providing the

Management Domain IP address for the MCC card on the command line.

If you are using a PC, establish a telnet session by issuing the telnet command

and providing the Management Domain IP address for the MCC on the command

line.

See Chapter 3 for IP address information.

2-28

October 1997

8600-A2-GN20-20

Page 45

Initial Setup Instructions

Setting the IP Address and Subnet Mask on the MCC

for Remote Configuration

You can fully configure the MCC and DSL cards at the Central Office (CO) using

the console terminal. However, if you want to perform remote card configuration

from a network management workstation via a telnet session, you must set the IP

address and subnet mask of the MCC card using a terminal connected to the

DSLAM’s serial console interface

before

you can configure the cards remotely.

3

This section describes how to set the IP address and subnet mask of the MCC

card. Refer to the

for detailed information on how to completely configure the MCC and DSL cards.

HotWire DSLAM for 8540 and 8546 DSL Cards User’s Guide

8600-A2-GN20-20

October 1997

3-1

Page 46

Initial Setup Instructions

Pr ocedure

To set the IP address and subnet mask from the console terminal:

1. Power up the chassis. After the self-test completes, the Who Am I screen will

appear.

2. From the Who Am I screen, enter the Management Domain IP address of the

MCC card and press the Return key. For example, if the IP address of the

MCC card is 198.152.152.50, type this value at the (nnn.nnn.nnn.nnn):

prompt as illustrated below.

The system automatically calculates the subnet mask based on the IP

address you enter.

3-2

October 1997

8600-A2-GN20-20

Page 47

Initial Setup Instructions

3. Do one of the following at the (nnn.nnn.nnn.nnn): prompt:

— To accept the subnet mask, press Return.

— To enter a different subnet mask, enter a new subnet mask and press

Return.

The system highlights the OK to restart?: prompt.

4. Type y at the yes/no: prompt to restart the card or n to decline the restart. If

you type y, the card restarts. You can now log in remotely using telnet or an

SNMP NMS to configure the cards. Refer to the

and 8546 DSL Cards User’s Guide

for detailed instructions.

HotWire DSLAM for 8540

8600-A2-GN20-20

October 1997

3-3

Page 48

Troubleshooting

Power Failure Troubleshooting Procedures

The following illustrates the steps to take when either the PWR A or PWR B

LEDs, or both, are OFF.

1. Using a voltmeter, check for power at the terminal connections.

— If there is power, call your sales representative for service to the 8600.

2. If there is no power at the terminal, call the appropriate electrician.

4

Power LED is OFF

PROBLEM: One of the DC PWR LEDs is OFF due to a failure in a single

ACTION: Go to the stack to see which chassis has the power failure. To

chassis within a stack.

clear the power alarm, remove the power from the chassis and

disconnect the powered-off chassis from the management

daisy chain (bypassing the failed chassis). Follow the

appropriate power failure troubleshooting procedure described

above.

8600-A2-GN20-20

October 1997

4-1

Page 49

Troubleshooting

Fan Alarm LED is ON

PROBLEM: One of the chassis in the stack is reporting a fan failure

(i.e., the FAN ALM LED of that chassis is on).

A built-in feature shuts off power to the circuit cards if a chassis

overheats because of fan failure. If the temperature in the

chassis reaches 70°C, power to the cards in the chassis is

turned off automatically. Power is turned on when the

temperature drops below 60°C.

ACTION: Go to the stack to see which chassis is reporting the fan alarm.

To clear the fan alarm, contact your service technician to

replace the HotWire 8600 chassis.

SYSTEM ALM LED is ON (on a DSL Card)

PROBLEM: SYSTEM ALM LED is ON and DSL card is inoperative in Slot

ACTION: 1. Using the HotWire DSLAM software, choose Card Selection

from the Main Menu to display the status of each DSL card.

2. If a major alarm is indicated, go to the MCC card and do a

card reset.

– Use HotWire DSLAM software to reset the DSL card.

Go to Configuration/ DSL/Cards/Reset_Slot.

–

– Refer to the

Cards User’s Guide

3.

Remove and reinstall the card.

4. If unable to clear by resetting the card, you may need to

replace the card.

DSL Card is Not Working Properly

PROBLEM: DSL card does not appear to be working properly.

ACTION: 1. Make sure the path to the LAN/WAN hub or switch is OK.

2. Check cables to the hub and make sure connection is

made properly.

n

HotWire DSLAM for 8540 and 8546 DSL

for more information.

4-2

3. Try removing the DSL card from the slot and re-installing

the card into another slot.

4. Replace the DSL card.

October 1997

8600-A2-GN20-20

Page 50

LEDs

Overview

This appendix describes the meaning of the LEDs on the HotWire 8600 DSLAM

chassis and MCC card.

HotWire 8600 DSLAM Chassis

The 8600 chassis allows addressable diagnostic connectivity between the MCC

and each of the DSL cards. It also converts and distributes –48V power to the

cards in the chassis. In addition, it provides fans to cool the circuit cards.

A

The following table describes the meaning and states of the LEDs on the front

panel of the carrier.

LED

DC PWR A Green

DC PWR B Green