Page 1

555-7101-217

555-7101-217

CallPilot

Installation and Configuration

Part 2: 1001rp Server Hardware Installation

Product release 2.02 Standard 1.0 May 2003

Page 2

P0605618

Page 3

CallPilot

Installation and Configuration

Part 2: 1001rp Server Hardware Installation

Publication number: 555-7101-217

Product release: 2.02

Document release: Standard 1.0

Date: May 2003

Copyright © 2003 Nortel Networks, All Rights Reserved

Printed in Canada

Information is subject to change without notice. Nortel Networks reserves the right to make

changes in design or components as progress in engineering and manufacturing may

warrant.

The process of transmitting data and call messaging between the CallPilot server and the

Meridian 1 switch or Succession CSE 1000 system is proprietary to Nortel Networks. Any

other use of the data and the transmission process is a violation of the user license unless

specifically authorized in writing by Nortel Networks prior to such use. Violations of the

license by alternative usage of any portion of this process or the related hardware

constitutes grounds for an immediate termination of the license and Nortel Networks

reserves the right to seek all allowable remedies for such breach.

This page and the f ollowing p age are co nsider ed the titl e page, an d contain Nortel Ne tworks

and third-party trademarks.

Page 4

*Nortel Networks, the Nortel Networks logo, the Globemark, and Unified Networks, BNR,

CallPilot, DMS, DMS-100, DMS-250, DMS-MTX, DMS-SCP, DPN, Dualmode, Helmsman,

IVR, MAP, Meridian, Meridian 1, Meridian Link, Meridian Mail, Norstar, SL-1, SL-100,

Succession, Supernod e, Symposium , Telesis, and Unity are trademarks o f Nortel Net works.

3COM is a trademark of 3Com Corporation.

ACCENT is a trademark of Accent Software International Ltd.

AMDEK is a trademark of Amdek Corporation.

AT&T is a trademark of American Telephone and Telegraph Corporation.

ATLAS is a trademark of Quantum Corporation.

ATRIA is a trademark of Pure Atria Corporation.

BLACKBERRY is a trademark of Research in Motion Limited.

CASEWARE is a trademark of Caseware International, Inc.

CONTINUUS is a trademark of Continuus Software Corporation.

CRYSTAL REPORTS is a trademark of Seagate Software Inc.

DEFINITY is a trademark of Avaya Inc.

DIALOGIC is a trademark of Dialogic Corporation.

EUDORA is a trademark of Qualcomm.

EXCHANGE.NET , INTERNET EXPLORER, LINKEXCHANGE, MICROSOF T, MICROSOFT

EXCHANGE SERVER, MS-DOS, OUTLOOK, POWERPOINT, WINDOWS, WINDOWS

MEDIA, and WINDOWS NT are trademarks of Microsoft Corporation.

GROUPWISE and NOVELL are trademarks of Novell Inc.

HITACHI is a trademark of Hitachi Limited.

INTEL is a trademark of Intel Corporation.

LOGITECH is a trademark of Logitech, Inc.

NETSCAPE COMMUNICATOR is a trademark of Netscape Communications Corporation.

PCANYWHERE is a trademark of Symantec Corporation.

PROMARK and RHOBOT are trademarks of DMI Promark, Inc.

RADISYS is a trademark of Radisys Corporation.

SLR4, SLR5, and TANDBERG are trademarks of Tandberg Data ASA.

SYBASE is a trademark of Sybase, Inc.

UNIX is a trademark of X/Open Company Limited.

US ROBOTICS, the US ROBOTICS logo, and SPORTSTER are trademarks of US

Robotics.

VOICEBRIDGE is a trademark of Voice Technologies Group Inc.

Page 5

Publication history

May 2003

October 2002

Release 2.02, Standard 1.0 of CallPilot Installation

and Configuration, Part 2: 1001rp Server

Hardware Installation is issued for general release.

Information on single-point grounding has been

added to Chapter 4, “Installing the server and

connecting the peripheral devices”.

Standard 1.0 of CallPilot Installation and

Configuration, Part 2: 1001rp Server Hardware

Installation is issued for general release.

Part 2: 1001rp Server Hardware Installation v

Page 6

Publication history Standard 1.0

vi CallPilot

Page 7

Contents

1 1001rp server description 9

Server features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Slot assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IRQ mapping table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Network connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Supported peripheral devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 Preparing for installation 25

Installation overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unpacking the 1001rp server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Removing the front bezel and server cover . . . . . . . . . . . . . . . . . . . . . . . . 31

Inspecting the server interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3 Power supply installation 37

Safety precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Section A: Installing the power supply modules (AC or DC) 39

Installing the second power supply module (AC or DC) . . . . . . . . . . . . . . 40

Section B: Setting up DC power source for a 1001rp DC

server 43

DC wire gauge tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DC rack cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

About the Power Distribution Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Bringing power and ground into the PDU . . . . . . . . . . . . . . . . . . . . . . . . . 50

Part 2: 1001rp Server Hardware Installation vii

Page 8

Contents Standard 1.0

4 Installing the server and connecting the peripheral

devices 53

Installing the server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Preparing the modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Connecting peripherals to the server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connecting the server to the ELAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connecting the server to the CLAN (optional). . . . . . . . . . . . . . . . . . . . . . 64

Installing the Nortel Networks software feature key adapter. . . . . . . . . . . 66

Connecting the server to power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Index 75

viii CallPilot

Page 9

Chapter 1

1001rp server description

In this chapter

Server features 10

Slot assignments 14

IRQ mapping table 17

Network connectivity 19

Supported peripheral devices 24

Part 2: 1001rp Server Hardware Installation 9

Page 10

1001rp server description Standard 1.0

Server features

Introduction

This section provides a general overview of the 1001rp server.

Server dimensions and weight

Height 32 cm (12.5 in.)

Width 48.3 cm (19 in.)

Depth (distance from front to back)

without front bezel

with front b ezel

Weight of fully loaded system 45.5 kg (100 lbs)

49.5 cm (19.5 in.)

53.3 cm (21 in.)

10 CallPilot

Page 11

May 2003 1001rp server description

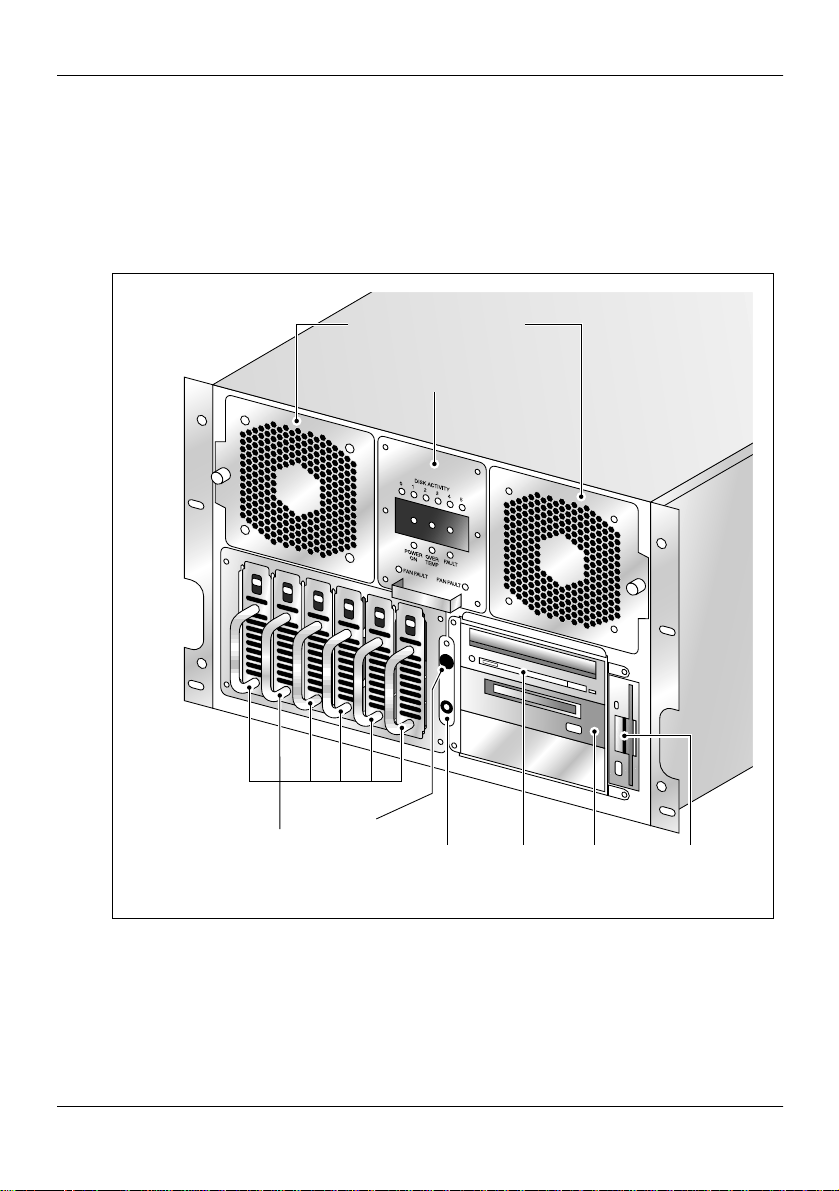

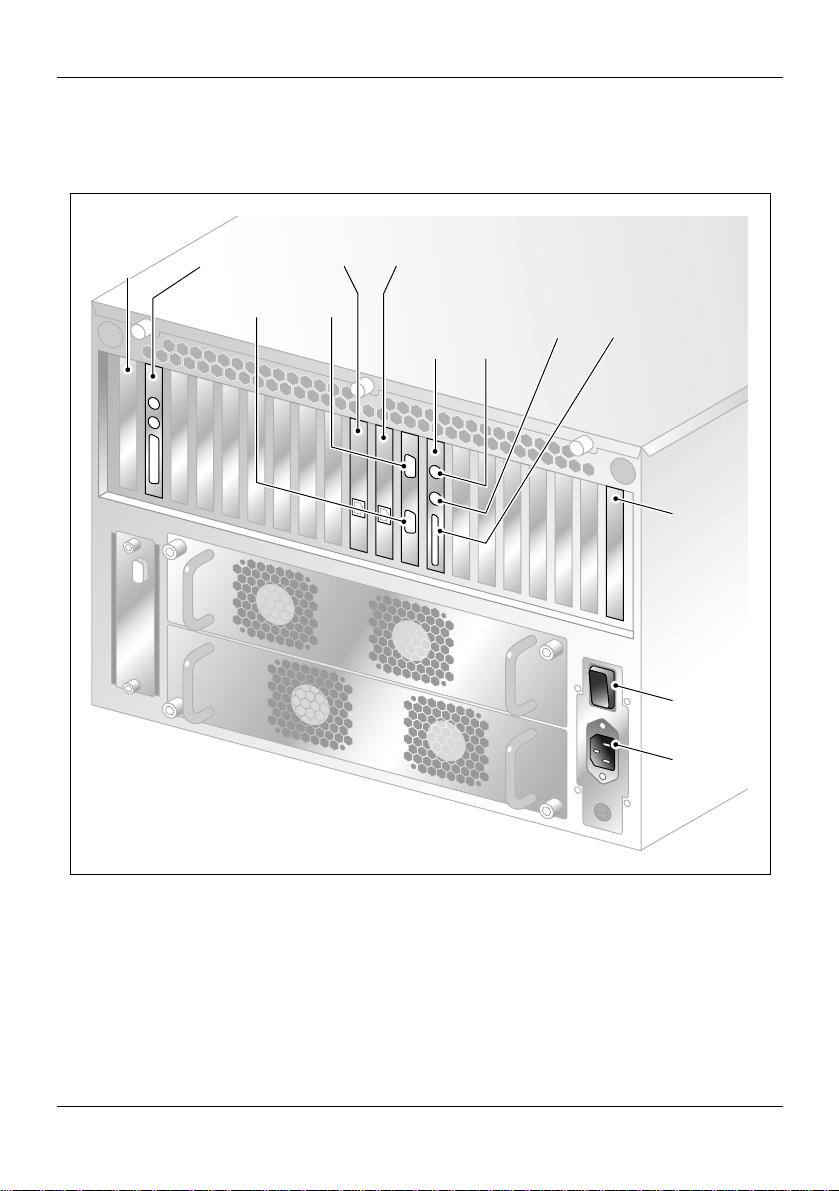

Front panel features (front view without the front bezel)

The front view of the 1001rp se rver chassis shows redundant dua l fans to the

left and the right of the status panel. The left drive bay holds six SCSI hard

drives with hot-plug gabl e car rier s. The me dia dr ive ba y, located to the right ,

houses the CD-ROM, tape drive, and floppy disk drive.

Hot-swap fan modules

Status panel

5-pin

Hot-swap

hard disk

drives

keyboard

connector

(Not used)

Reset

button

CD-ROM

drive

Tape

drive

Floppy

disk drive

G100697

Alarm board

The alarm board is located under the baseboard. It connects to the status

display panel on the front.

Part 2: 1001rp Server Hardware Installation 11

Page 12

1001rp server description Standard 1.0

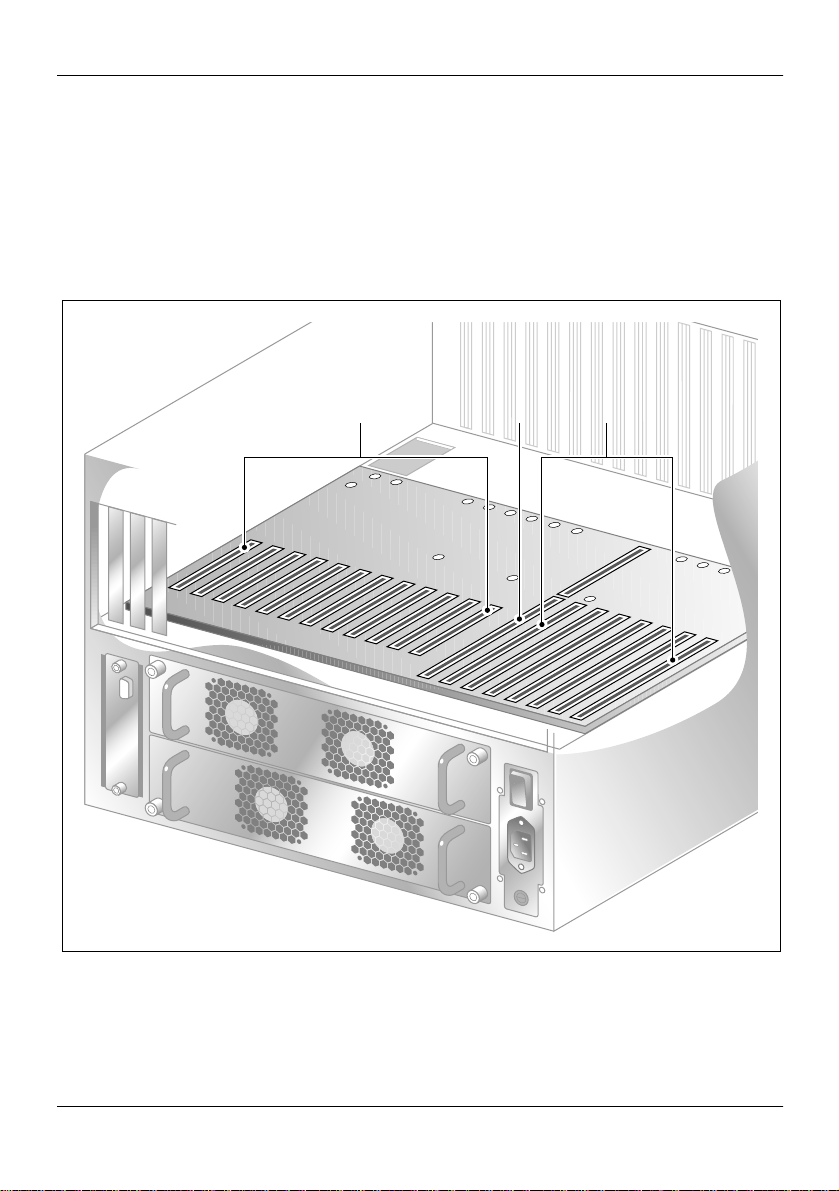

Rear panel diagram

Note: The following diagram shows the slot locations in the rear panel:

Slot 20

Video

card

CLAN

card

COM2COM1

ELAN

card

SBC

card

(slot 8)

PS/2

Keyboard

PS/2

Mouse

Parallel

port (LPT1)

Slot 1

Power

switch

Power

input

G101720

The above diagram shows the power switch and power input for an AC

server. The rest of the diagram is the same for AC or DC servers.

12 CallPilot

Page 13

May 2003 1001rp server description

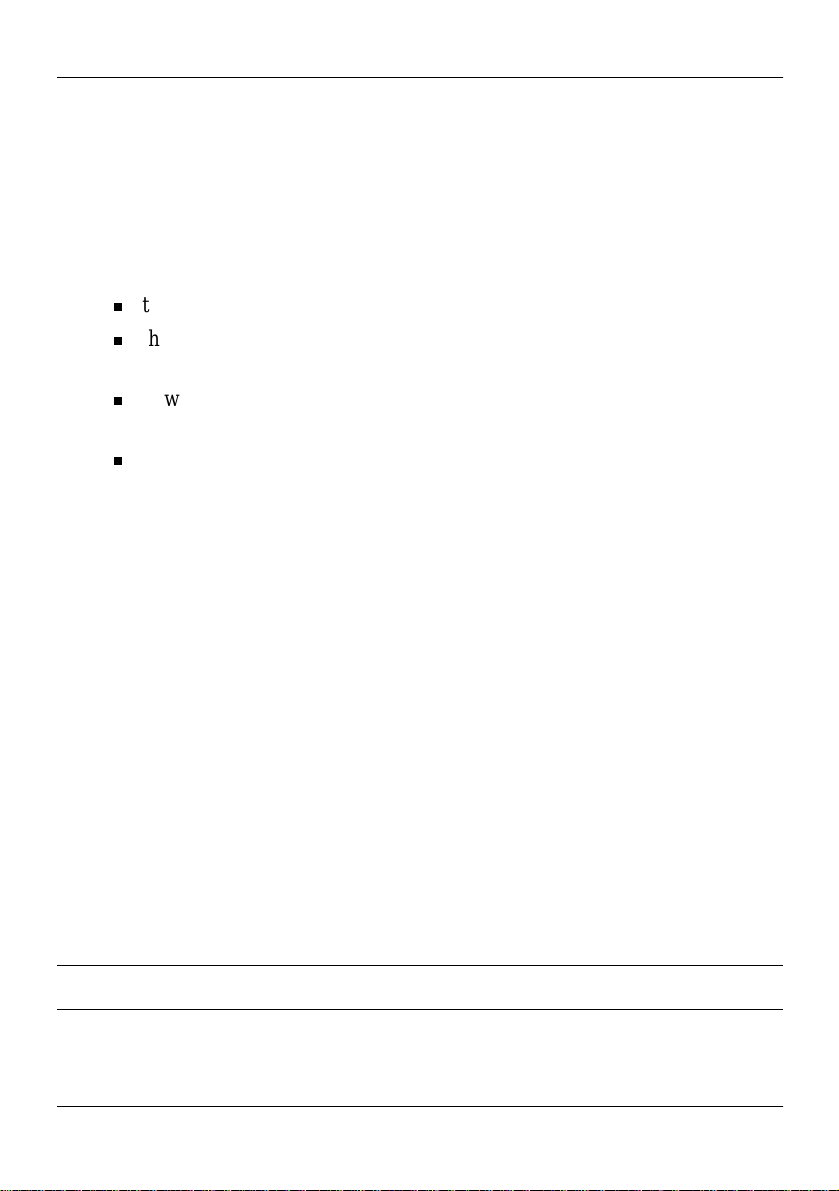

Overhead view of empty server showing PCI and ISA

connectors

The following diagram shows the location of the PCI, SBC, and ISA

connectors inside th e se rver. The view i n the dia gram is from the rear of the

server. For slot assignments, see “Slot assignments” on page 14. You must

be able to identify slot locations fo r later steps in the CallPilot installa tion.

PCI

connectors

SBC

connector

ISA

connectors

G101740

Part 2: 1001rp Server Hardware Installation 13

Page 14

1001rp server description Standard 1.0

Slot assignments

Introduction

The slot assignment tables show the following:

the physical location of boards inside the server, relative to other boards

the order in which boards are installed (for example, board #1, 2, 3, and

so on)

how the boards are represented in some CallPilot Manager applications

(such as the Maintenance Administration page)

the maximum capacity for each switch connectivity

Note: Your server may vary depending on what was ordered from Nortel

Networks. Therefore, your server may not have all of the slots populated.

Slot definition and slot numbering

In these tables, the term “slot” refers to the available slot openings in the

chassis, not the PCI or ISA connectors inside the server.

Look at the serve r fr om the r ear (see “Rear pane l diagra m” on page 12). Th e

slots are numbered from right to left, 1 to 20. Now, look at the server from

the front. The slots are numbered from left to right.

1001rp slot assignments

CallPilot-

Slot

number

Slot 1 BRD01 Not used Not used

Slot 2 BRD02 Not used Not used

14 CallPilot

assigned board

a

label

Meridian 1 Succession CSE 1000

Page 15

May 2003 1001rp server description

CallPilot-

Slot

number

assigned board

a

label

Meridian 1 Succession CSE 1000

Slot 3 BRD03 Not used Not used

Slot 4 BRD04 Not used Not used

Slot 5 BRD05 Not used Not used

Slot 6 BRD06 Not used Not used

Slot 7 BRD07 Not used Not used

Slot 8 BRD08 Single Board Computer Single Board Computer

Slot 9 BRD09 Reserved for COM1 and

COM2 I/O bracket

Reserved for COM1 and

COM2 I/O bracket

Slot 10 BRD10 ELAN Network card ELAN Network card

Slot 11 BRD11 CLAN Network card CLAN Network card

b

Slot 12

Slot 13 BRD13 MPB16-4 board #2

BRD12 MPB16-4 board #1 MPB16-4 board #1

MPB16-4 board #2

(optional)

(optional)

Slot 14 BRD14 Not used Not used

Slot 15 BRD15 Not used Not used

Slot 16 BRD16 Not used Not used

Slot 17 BRD17 Not used Not used

Slot 18 BRD18 Not used Not used

Slot 19 BRD19 VGA card (monitor

connection)

VGA card (monitor

connection)

Part 2: 1001rp Server Hardware Installation 15

Page 16

1001rp server description Standard 1.0

CallPilot-

Slot

number

assigned board

a

label

Meridian 1 Succession CSE 1000

Slot 20 BRD20 PCI RAID controller PCI RAID controller

a. On some CallPilot Manager applications, the CallPilot-assigned board label

appears. This label corresponds to the slot number. For example, BRD12 refers to

the board in slot 12.

b. For Meridian 1 and Succession CSE 1000, the first MPB16-4 board must be

installed in slot 12.

16 CallPilot

Page 17

May 2003 1001rp server description

IRQ mapping table

Introduction

The following table displays the assignments for each Interrupt Request

Line (IRQ) with the associated slot or device. You do not need this

information for installation, but you may need it for troubleshooting.

Note: IRQs 9, 10, 11, and 15 are assigned to system PCI slots rather than to

specific d evices.

IRQ Slot or device

0Timer

1 Keyboard

2System / Unused

3 Serial port 2 (COM2)

4 Serial port 1 (COM1)

5Available

6 Floppy controller

7 Parallel port (LPT1)

8Real Time Clock

9 Assigned to slots 9, 15, and 20

10 Assigned to slots 10, 13, and 19

11 Assigned to slots 11, 14, and 17

12 PS/2 mouse

Part 2: 1001rp Server Hardware Installation 17

Page 18

1001rp server description Standard 1.0

IRQ Slot or device

13 Math coprocessor

14 Primary EIDE controller

15 Assigned to slots 12, 16, and 18

18 CallPilot

Page 19

May 2003 1001rp server description

Network connectivity

Introduction

This section describes how the 1001rp server can be integrated into your

network. The integration depends on the type of switch you are using.

ATTENTION

Note: The diagrams show a tower server. However, the same configuration

applies to the 1001rp server.

To secure the CallPilot server from unauthorized access,

ensure that the CallPilo t network is inside your

organization’s firewall.

Part 2: 1001rp Server Hardware Installation 19

Page 20

1001rp server description Standard 1.0

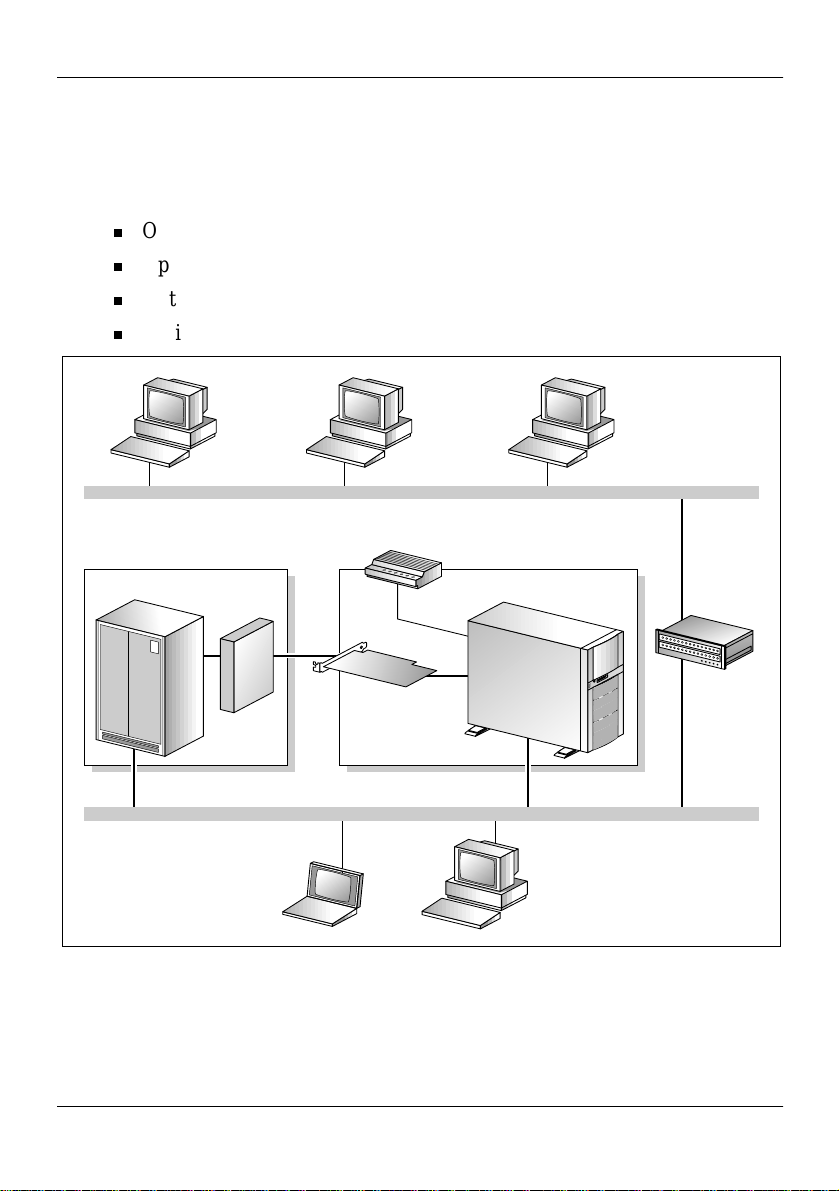

Sample network setup: Meridian 1

The following diagram shows a CallPilot server sample network setup with

a Meridian 1 switch. The Meridian 1 switch can be one of the following:

Option 11C or Option 11C Mini

Option 51C

Option 61C

Options 81 and 81C

Meridian 1 switch

Desktop

client PC

MGate

card

Desktop

client PC

Customer LAN (optional)

Modem

MPB16-4

board

Embedded LAN

Laptop

Web-enabled

administrative

PC

CallPilot server

Router or

Ethernet

switch

(optional)

Web-enabled

administrative

PC

G101626

20 CallPilot

Page 21

May 2003 1001rp server description

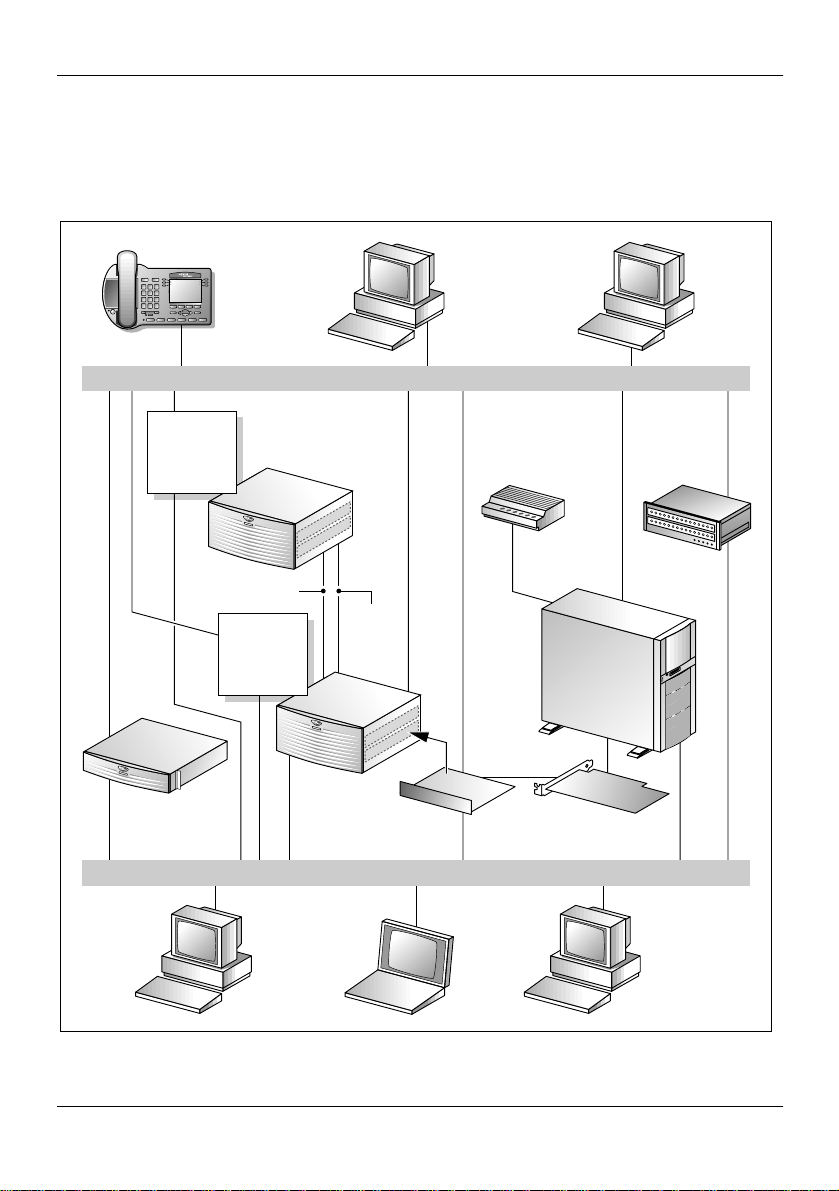

Sample network setup: Succession CSE 1000

The following diagram shows a CallPilot server network setup with a

Succession CSE 1000 system:

Telephony LAN/Customer LAN (10/100BaseT or 100BaseT)

Internet

Telephony

Gateway

Line Card

Succession

CSE 1000

Call Server

i2004

Internet

phonesets

Succession

CSE 1000 Media

Gateway Expansion

CE-MUX

Internet

Telephony

Gateway

Line Card

Succession

CSE 1000

Media

Gateway

Embedded LAN (10BaseT)

DS-30x

Web-enabled

CallPilot

administrative

PC

MGate

card

Modem

Desktop

client

PC

Router or

Ethernet

switch

(optional)

CallPilot

server

MPB16-4

board

Optivity

Telephony

Manager

PC

Laptop

Web-enabled

CallPilot

administrative

PC

G101636

Part 2: 1001rp Server Hardware Installation 21

Page 22

1001rp server description Standard 1.0

In this illustration, the telephony LAN (TLAN) provides IP connectivity

between the Succession CSE 1000 system and the i2004 Internet phonese ts.

The connection between the Call Server and Media Gateway can be pointto-point, or it can be through the LAN, if the system is installed in a

distributed data network.

For information about the Succession CSE 1000 system and i2004 Internet

phoneset bandwidth and network requirements, refer to the Succession

Communication Server for Enterpri se 1000 Planning and Installati on Guide

(NTP 553-3023-210).

Switch connectivity

For more details about how the 1001rp server and switch connection is

establish ed, refer to P art 3 of the CallPilot Installation and Configuration

binder.

CallPilot ELAN and CLAN network setup

The 1001rp server pro vides 10- o r 100Bas e-T Ethern et connect ivity t hrough

network interface cards (NIC) installed in the server. See “Slot assignments”

on page 14 for details on the l ocation of ne twork cards . The funct ion of each

network card is described below:

One network card provides connectivity to the ELAN.

For information about the ELAN’s purpose and requirements, see

“About the ELAN” in Part 1 of the CallPilot In stallation and

Configuration binder.

A second network card is optional.

This optional NIC is required only for Meridian 1 or Succession

CSE 1000 systems that require a CLAN connection (in addition to the

ELAN connection). The CLAN provides data connectivity between

desktop and web messaging clients, web-enabled administrative PCs,

and the CallPilot server.

22 CallPilot

Page 23

May 2003 1001rp server description

Network requirements

Appropriate networking equipment must be available for both the CLAN

and ELAN.

The CLAN and ELAN must be properly configured for correct CallPilot

operation. To ensure correct configuration, Nortel Networks recommends

that you consult a network specialist.

ATTENTION

For important con side ratio ns abou t usin g the EL AN in

your network, see “About the ELAN” in Part 1 of the

CallPilot Installation and Configuration binder.

Remote access connectivity

The RS-232 COM 1 connector on the rear of the 100 1rp ser ve r pr ovides the

connection to an external modem. The modem allows administrators and

technical support personnel to administer the 1001rp server from a remote

location.

pcAnywhere is used to establish the remote access connection to the server.

Part 2: 1001rp Server Hardware Installation 23

Page 24

1001rp server description Standard 1.0

Supported peripheral devices

Introduction

This section identifies external devices that are supported by the 1001rp

server. The following table describes the supported peripheral devices:

Device Description

Modem A 56 Kbps external modem (NTRH9078) provides

remote access to the 1001rp server. The modem connects

to the RS-232 COM1 connector on the rear of the ser ver.

Since the modem is an externa l device, it requires i ts own

AC power source.The 33.6 Kbps modem (NTRH9016) is

also supported, but has been replaced by the 56 Kbps

modem for new systems.

Ethernet hub A 10BaseT Ethernet hub provides the ELAN connection

between the 1001rp server and the Meridian 1 switch or

Succession CSE 1000 system. The customer can supply

a hub from third-party vendors or purchase the 3Com

10BaseT Ethernet hub (NTRH9017) from Nortel

Networks.

Since the hub is an external device, it requires an AC

power source.

Monitor, keyboard,

and mouse

14" monitor: NTRH901 1

Since the monitor is an external device, it requires its

own AC power source.

Keyboard: NTRH9013

Mouse: NTRH9014

24 CallPilot

Page 25

Chapter 2

Preparing for installation

In this chapter

Installation overview 26

Unpacking the 1001rp server 29

Removing the front bezel and server cover 31

Inspecting the server interior 35

Part 2: 1001rp Server Hardware Installation 25

Page 26

Preparing for installation Standard 1.0

Installation overview

Introduction

This section provides an overvi ew of the step s requir ed to inst all the 1001rp

server and peripheral devices.

Installation checklist

The following checklist iden ti fi es the tasks that must be performed when

installing the CallPilot server. For detailed instructions, see Chapter 4,

“Installing the server and connecting the peripheral devices.”

When you are finished, c ontinue with Part 3 of the CallPi lot Installat ion and

Configuration binder.

Step Description Check

1 Ensure that you have reviewed the “Installing CallPilot” section

❒

in Part 1 of the CallPilot I nstallatio n and Configura tion binder,

and completed stage 1 of the “Installation checklist.”

2 Unpack the server, and ensure you have all the items you need

❒

(see page 29).

Complete the following checklists that are provided in Part 1 of

the CallPilot Installation and Configuration binder:

“CallPilot software media and documentation checklist”

“CallPilot server hardware checklist”

3 Remove the front bezel and server cover, and inspect the

❒

interior (see pages 31 and 35).

4 Replace the server cover. ❒

5 Install th e power supply modules in the server (see page 4 0). ❒

26 CallPilot

Page 27

May 2003 Preparing for installation

Step Description Check

6 For a DC-powered server, set up the DC power source (see

❒

page 43).

7 Place the 1001rp server in the chosen location (see page 54). ❒

8 Replace the front bezel (see page 34). ❒

9 Set the DIP switches on the modem (see page 57). ❒

10 Connect the 1001rp server and devices as follows:

Connect the monitor, keyboard, and mouse (see page 59). ❒

Connect the modem (see page 60). ❒

Connect the 1001rp server to the ELAN hub (Meridian 1 or

❒

Succession CSE 1000 only) (see page 62).

Connect the 1001rp server to the CLAN hub (optional) (see

❒

page 64).

Install the software feature key ada pter (see page 66). ❒

Connect the power cords for all devices, and then power

❒

them up.

11 Start the 1001rp server (see page 68). ❒

Part 2: 1001rp Server Hardware Installation 27

Page 28

Preparing for installation Standard 1.0

Conventions for warnings

You may encounter the following types of warnings in this guide. Do not

ignore them.

DANGER

.

.

.

ATTENTION

Risk of electric shock

Warns you of an immediate electrical hazard which, if not

avoided, will result in shock, serious injury, or death.

WARNING

Risk of personal injury

Warns you of a situation in which you can be injured if

instructions are not followed exactly as stated.

CAUTION

Risk of equipment damage

Alerts you to situati ons where data can be lost or damaged,

equipment can be damaged, actions can result in service

interruption, and productive time can be lost.

Provides infor mation that is essenti al to th e comp letio n

of a task.

28 CallPilot

Page 29

May 2003 Preparing for installation

Unpacking the 1001rp server

Introduction

Follow this procedure to unpack the server and peripherals.

WARNING

.

Risk of personal injury

The 1001rp CallPilot server weighs approximately 34 kg

(75 lbs) as shipped from manufacturing. To prevent personal

injury, have someone help you to unpack and position the

server.

To unpack the equipment

ATTENTION

1 Carefully open the cardboard carton containing the server.

2 Remove the server from the carton and set it on the floor.

3 Carefully open the cartons containing the monitor, keyboard, mouse,

modem, and ELAN hub (if supplied), and set the peripherals aside.

As you unpack ea ch ite m, che ck it off again st the

packing list, a s well as a gain st the fo llowin g

checklists provi ded in Part 1 o f the CallP ilot

Installation a nd Con figur ation binder:

“CallPilot software media and documentation

checklist”

“CallPilot server hardware checklist”

4 Put all manuals, CD-ROMs, operating system disks, any disks for

peripherals, and the Windows NT emergency repair disk in a safe place.

Part 2: 1001rp Server Hardware Installation 29

Page 30

Preparing for installation Standard 1.0

5 Save all packing materials and cartons in case you must return any

equipment to the carrier.

What’s next?

Remove the server cover so that you can inspect the interior of the server.

See “Removing the front bezel and server cover” on page 31.

30 CallPilot

Page 31

May 2003 Preparing for installation

Removing the front bezel and server cover

Introduction

To access the server interior, you must remove both the front bezel and the

server cover.

To remove the front bezel, see page 32.

To remove the server cover, see page 33.

To replace the front bezel, see page 34.

About the front bezel doors

Two locked doors on the front of the server cover the front panel, including

the CD-ROM drive and tape drive.

These doors are part of the front bezel, which covers the front of the server.

You must unlock the front bezel doors before you can remove the front

bezel.

Part 2: 1001rp Server Hardware Installation 31

Page 32

Preparing for installation Standard 1.0

To remove the front bezel

CAUTION

.

Do not attem pt to move o r lift the server before rem oving the

front bezel; the server can disengage from the bezel and fall.

1 Unlock and open the double doors of the front bezel. See “A” in the

diagram below.

2 Firmly grasp the front bezel by the hand-holds on either side of the

chassis, and pull the front bezel from the chassis.

A

Risk of equipment damage

B

G101733

32 CallPilot

Page 33

May 2003 Preparing for installation

To remove the server cover

DANGER

.

High current inside the chassis can cause severe injury.

CAUTION

Risk of equipment damage

Risk of electric shock

.

Take precautions to protect internal components. Electrostatic

discharge (ESD) can r ender boar ds damaged or u nusable. Wear

an ESD wrist strap.

1 Remove the front bezel (see page 32).

2 Loosen the three thumbscrews at the rear of the top cover.

3 Remove the server cover by pulling the cover toward the rear of the

chassis, and then lifting it up and off.

4 Clip the lead from your ESD wrist strap to an unpainted metal section of

the chassis.

What’s next?

Continue with “Inspecting the server interior” on page 35.

Part 2: 1001rp Server Hardware Installation 33

Page 34

Preparing for installation Standard 1.0

To replace the front bezel after installation is complete

When the CallPilot server installation is complete and the server is in its

final location, replace the front bezel.

1 Align the front bezel with the ball studs located at each faceplate corner.

See the diagram below:

Clips inside

front bezel

G101734

2 Apply pressure evenly until the bezel snaps onto each ball stud.

3 Close and lock the double doors of the front bezel.

34 CallPilot

Page 35

May 2003 Preparing for installation

Inspecting the server interior

Introduction

You should perform a visual inspection for loose components, foreign

matter, or shipping damage inside the server.

CAUTION

.

Risk of equipment damage

When work ing with interior components, use an ESD wrist

strap to protect static-sensitive components.

To inspect the server interior

1 Carefully check all the cards to ensure they are fully seated on the

baseboard.

2 Check for any loose wires or foreign objects, such as loose screws,

inside the chassis.

3 Review the slot locations (see “Slot definition and slot numbering” on

page 14).

4 Do one of the following:

IF THEN

you observe any damage contact your Nortel Networks

technical support representative.

components have become

loose

secure them.

Refer to the procedures in Part 5 of

the CallPilot Installation and

Configuration binder.

Part 2: 1001rp Server Hardware Installation 35

Page 36

Preparing for installation Standard 1.0

IF THEN

you are satisfied that the

1001rp server has arrived

at your site undamaged

replace the server cover and

proceed with the hardware

installation.

See “Installation checklist” on page

26.

Note: Do not reinstall the front

bezel until the server is in its final

location and the CallPilot

installation is compl ete .

36 CallPilot

Page 37

Chapter 3

Power supply installation

In this chapter

Safety precautions 38

Section A: Installing the power supply modules (AC or DC) 39

Installing the second power supply module (AC or DC) 40

Section B: Setting up DC power source for a 1001rp DC server 43

DC wire gauge tables 44

DC rack cabling 46

About the Power Distribution Unit 48

Bringing power and ground into the PDU 50

Part 2: 1001rp Server Hardware Installation 37

Page 38

Power supply installation Standard 1.0

Safety precautions

Equipment handling guidelines

External power equipment, such as an uninterruptible power supply (UPS),

is usually very heavy. This equipment requires special handling procedures

and additional personnel for unloading and installation. Be aware of weight

distribution, and prevent the equipment room floor from being overly

stressed.

Safety information

In DC systems, locate the service panel near the entry to the room

containing the DC power system that supplies the server.

DANGER

.

Risk of electric shock

Procedures involving electrical connections must only be

performed by qualified personnel.

Ensure that you obey all displayed warning notices on power

equipment and connections.

38 CallPilot

Page 39

May 2003 Power supply installation

Section A: Installing the power

supply modules (AC

or DC)

In this section

Installing the second power supply module (AC or DC) 40

Part 2: 1001rp Server Hardware Installation 39

Page 40

Power supply installation Standard 1.0

Installing the second power supply module (AC or DC)

Introduction

One power supply module is shipped installed. The second power supply

module is shipped uninstalled and must be installed as part of the CallPilot

installation.

AC versus DC systems

The power supply modules are similar in appearance for both AC and DC

1001rp servers. The procedures in this section apply to both AC and DC

1001rp servers.

About the power supply module

After the server is powered up (later i n this gui de), the p ower sup ply module

LED indicates its status.

A green LED indicates that th e power suppl y module is worki ng properly. If

the LED on the power supply mo dule is unlit or red, t he module i s fail ing or

has failed. Other indicators are an alarm sounding and the power supply

LED on the status display on the front of the server turning red.

40 CallPilot

Page 41

May 2003 Power supply installation

The diagram below shows the location of the power supply modules in a

server that has both power supply modules installed:

Power supply modules

G101751

Part 2: 1001rp Server Hardware Installation 41

Page 42

Power supply installation Standard 1.0

To install the power supply module

DANGER

.

Risk of electric shock

High current inside the chassis can cause severe injury.

The server is shipped with one power supply modul e instal led in the bottom

power supply bay. You must install the second power supply module, as

described here:

1 Align the power supply module with the top power supply bay.

2 Slide the power supply module into the bay until the module is secured

by its connector.

Use some force, if necessary.

3 Secure the power supply module to the chassis with two thumbscrews at

the corners of the power supply faceplate.

What’s next?

Do one of the following:

IF THEN

this is an AC-powered server continue with Chapter 4, “Installing

the server and connecting the

peripheral devices,” on page 53.

this is a DC-powered server continue with Section B: “Setting up

DC power source for a 1001rp DC

server,” on page 43.

42 CallPilot

Page 43

May 2003 Power supply installation

Section B: Setting up DC power

source for a 1001rp DC

server

In this section

DC wire gauge tables 44

DC rack cabling 46

About the Power Distribution Unit 48

Bringing power and ground into the PDU 50

Part 2: 1001rp Server Hardware Installation 43

Page 44

Power supply installation Standard 1.0

DC wire gauge tables

Introduction

The tables in this section specify the DC power feed wire requirements.

Cabinet and module DC feed recommended wire gauge

specifications

Length #10 AWG #8 AWG #6 AWG

Junction

box #4

AWG

Junction

box #4

AWG

0–30 m (100 ft) yes yes yes yes yes

0–45 m (150 ft) no yes yes yes yes

0–75 m (250 ft)nonoyesyesyes

0–135 m (450 ft) no no no yes yes

0–210 m (700 ft) no no no no yes

Over 210 m (700 ft) no no no no no

Notes:

1. Cabinet and module ground wire specification is #10 AWG insulated

green safety ground wire.

2. Cabinet conduit can be 1.91 cm (0. 75 in.) or 3.18 cm (1.25 i n.), a nd must

be insulated from cabinet ground.

44 CallPilot

Page 45

May 2003 Power supply installation

Metric wire conversion

AWG N o.

Industry standard

nominal (sq mm)

Resistance at 20° C

(Ohm/100 m)

235 0.05

425 0.08

616 0.13

810 0.20

10 6 0.33

12 4 0.63

14 2.5 1.00

16 1.5 1.40

18 1 2.00

20 0.75 2.90

22 0.5 4.60

Part 2: 1001rp Server Hardware Installation 45

Page 46

Power supply installation Standard 1.0

DC rack cabling

The following diagram shows typical rack power cabling:

-48VDC A

-48VDC B

Server Server

Primary

PDU

Monitor Switch

External

Modem

External UPS

(Optional)

ELAN

Hub

See note

External

power feed

(110/220

VAC, 220

optional)

46 CallPilot

Page 47

May 2003 Power supply installation

-48VDC power distribution rationale

Minimum installation is one Power Distribution Unit (PDU) with four

48VDC branch circuits fused at 20 amperes.

The customer must be able to shut off any branch, and every unit at the

site will continue to function properly.

DC-powered configuration fits into this scheme as follows:

Each PDU receives four branch circuits.

Each server receives a feed from each PDU and a different branch

circuit.

In this fashion, with dual hot-swappable power supplies, there is no

single point of fail ure in the power syst em. For example , you can remove

any power supply, including a PDU, and everything continues to work.

This is applicable t o either North Americ an or Europ ean ins tallation sites

(with a 230 VAC Inverter).

The secondary rack supports four servers and follows a similar scheme.

Part 2: 1001rp Server Hardware Installation 47

Page 48

Power supply installation Standard 1.0

About the Power Distribution Unit

Introduction

A Power Distribution Unit (PDU) is in stalled in a rac k that has DC-powe red

servers. Power from the DC supply source enters the PDU and can then be

distributed to one or more servers. A single PDU can supply DC power to

four DC power supply modules. A server can have either one or two power

supply modules installed. You can determine the number of PDUs to install

in a rack by counting the number of power supply modules in each rack.

Multiple PDUs

A server operates on a single power supp ly modul e. I ts t ota l capacity is two

installed power supply modules. The second power supply module is the

redundant power supply module.

A PDU can distribute power to a maximum of four power supply units that

can be installed in two or more servers. Therefore, if there are three or four

servers installed in a rack, then you must inst all a second PDU.

Note: The power supply module installs in the server. It does not refer to a

UPS, which is a separate unit on the rack.

48 CallPilot

Page 49

May 2003 Power supply installation

PDU terminal blocks and wiring diagram

A PDU consists of eight terminal blocks within a metal enclosure. Before

installing the PDU, connect the terminal blocks so that each output

connector receives power fr om a s epar at e - 48VDC branch circuit, as shown

in the following diagram. Use AWG 12 wires for these connections.

Single PDU wiring diagram

Output server 4 Output server 3 Output server 2 Output server 1

BAT-4 BAT-3 BAT-2 BAT-1 BR-4 BR-3 BR-2 BR-1

G101741

DC power input

DC power input into the distribution unit connects BAT-1 to BAT-4 and

BR-1 to BR-4. Refer to the preceding diagrams for the location of these

terminals. Connect the input wires before installing the PDU on the rack.

Part 2: 1001rp Server Hardware Installation 49

Page 50

Power supply installation Standard 1.0

Bringing power and ground into the PDU

Introduction

Install BAT/BATRTN wires in pairs. Each pair of wires supplies voltag es t o

a module through a power ha rness. The module h arnesses are installed i n the

cabinet PDU and connected to the modules at the factory.

See “About the Power Distribution Unit” on page 48 for a PDU wiring

diagram and description.

To bring DC power and ground into the PDU

1 If you are using a conduit, terminate the 1-1/4 or 3/4 conduit at the top

rear of the cabinet or at the bottom front of the cabinet using the

knockouts provided.

The number of wire pairs you can run in each conduit depends on the

wire gauge.

Note: To preserve ground integrity, the conduit must be insulated.

2 Select a power feed with a circuit breaker dedicated to each module, and

identify it with an appropriate tag.

3 Select a wire size to suit the required feed length from the power source

(see “DC wire gauge tables” on page 44).

4 Use pliers to strip one-quarter to one-half of the insulation from one end

of all power and ground feed wires.

5 Undo the terminal block screws at (-) positions 0, 1, 2, and 3.

6 Insert the red wires into terminal block positions 0, 1, 2, and 3.

7 Secure the wires in the terminal block by tightening the screws.

8 Undo the terminal block screws at (+) positions 0, 1, 2, and 3.

9 Insert the black wires into terminal block positions 0, 1, 2, and 3.

10 Secure the wires in the terminal block by tightening the screws.

50 CallPilot

Page 51

May 2003 Power supply installation

11 Select a #10 green wire safety ground and attach it to the cabinet.

12 Measure the module ground continuity by touching one multimeter lead

to any BATRTN terminal block connector and the other end to the GND

terminal block connector.

The measurement should be between 0–0.5 ohms.

Part 2: 1001rp Server Hardware Installation 51

Page 52

Power supply installation Standard 1.0

52 CallPilot

Page 53

Chapter 4

Installing the server and connecting the peripheral devices

In this chapter

Installing the server 54

Preparing the modem 55

Connecting peripherals to the server 59

Connecting the server to the ELAN 62

Connecting the server to the CLAN (optional) 64

Installing the Nortel Networks software feature key adapter 66

Connecting the server to power 68

Part 2: 1001rp Server Hardware Installation 53

Page 54

Installing the server and connecting the peripheral devices Standard 1.0

Installing the server

Introduction

Before you install the 1001rp server, ensure that the chosen location meets

the requirements iden tified on the “Site inspec tion checklist” provided in

Part 1 of the CallPilot Installation and Configuration binder.

To install the server

Place the 1001rp ser ver in i ts chosen location . If you ar e instal ling the server

in a rack cabinet, follow the instructions that are provided with the slide

rails.

Connect peripheral devices as described in the remainder of this chapter.

ATTENTION

54 CallPilot

Do not connect the server to power yet.

Page 55

May 2003 Installing the server and connecting the peripheral devices

Preparing the modem

Introduction

You require a modem to support remote dial-up access to the CallPilot

server. The modem also enables Nortel Networks technical support to

connect to your CallPilot server for troubleshooting purposes. Nortel

Networks connects to your server only when you request technical

assistance.

Required equipment

To install the modem, you need the following equipment:

an analog external modem that includes

an RJ-11 analog phone cord

a power adapter cord

One of the following modems may have been provided with your server:

U.S. Robotics 33.6 Kbps modem (NTRH9016)

U.S. Robotics 56 Kbps modem (NTRH9078)

a 25-pin male to 9-pin female shielded serial cable for your modem

Note: Ensure that you have the correct cable for you r modem, as fol lows:

33.6 Kbps modem: A0601464

56 Kbps modem: A0841984

an analog line jack

tweezers, or a screw driver small enough to use to adjust the DIP

switches

Part 2: 1001rp Server Hardware Installation 55

Page 56

Installing the server and connecting the peripheral devices Standard 1.0

Modem DIP switches

Set the modem DIP switches before you connect the modem to the CallPilot

server.

Note: This s ecti on appl ies only t o the US Robot ics 33 .6 o r 56 Kbps ext ernal

Sportster modem. If your mode m is d if fer ent, re fer t o the do cumen tati on for

your modem.

The following diagram shows the key components of the external modem,

including the location and required settings of the DIP switches:

RJ-11

connection

Switch positions:

OFF

DIP

switches

12345678

ON

12345678

Serial cable

(RS-232)

connection

Power

connection

G101445

56 CallPilot

Page 57

May 2003 Installing the server and connecting the peripheral devices

To set the modem DIP switches

Use a pair of tweezers or a small screw driver to set the DIP switches as

described in the “Change to” column of the following table:

Note: ON is down. OFF is up.

DIP

switch

Default

setting

Change

to Function

1 OFF OFF Data Terminal Ready (DTR) override

OFF: Normal DTR operations. (The

computer must provide a DTR sign al for the

modem to accept commands. If DTR is

dropped, the call is terminated.)

ON: The modem ignores DTR (override).

2 OFF OFF Verbal/numeric result codes

OFF: Verbal (word) results.

ON: Numeric results.

3 ON ON Result code display

OFF: Suppresses result codes.

ON: Enables result codes.

4 OFF OFF Command mode local echo suppression

OFF: Disp lays keyboard comm ands.

ON: Suppresses echo.

5 ON ON Auto answer suppression

OFF: The modem answers on the first ring,

or higher if specified in NVRAM.

ON: Disables auto answer.

Part 2: 1001rp Server Hardware Installation 57

Page 58

Installing the server and connecting the peripheral devices Standard 1.0

DIP

switch

Default

setting

Change

to Function

6 OFF OFF Carrier Dete ct (CD) override

OFF: The modem sends a CD signal when it

connects with another modem; it drops the

CD on disconnect.

ON: CD is always ON (override).

7 OFF OFF Power-on and ATZ reset software defaults

OFF: Loads Y or Y1 configuration from

user-defined non-volatile memory

(NVRAM).

ON: Loads &F0-Generic template from

read-only memory (ROM).

8 ON ON AT command set recognition

OFF: Disables command r ecognition (du mb

mode).

ON: Enables recognition (smart mode).

What’s next?

Continue with “Connecting peripherals to the server” on page 59.

58 CallPilot

Page 59

May 2003 Installing the server and connecting the peripheral devices

Connecting peripherals to the server

Rear panel connections

Slot 20

Video

card

CLAN

card

COM2COM1

ELAN

card

SBC

card

(slot 8)

PS/2

Keyboard

PS/2

Mouse

Parallel

port (LPT1)

Slot 1

Power

switch

Power

input

G101720

Note: The above picture shows the AC version of the server. The DC

version of the server has a different power input. For peripheral device

connections, this picture applies to both AC and DC servers.

Part 2: 1001rp Server Hardware Installation 59

Page 60

Installing the server and connecting the peripheral devices Standard 1.0

CAUTION

.

You can install or use only Nortel Networks approved

peripheral devices on your server. Installation or use of

unapproved peripheral devices can result in system failure.

To connect the mouse, keyboard, and monitor to the server

Risk of system failure

1 Place the monitor, keyboard, and mouse in the same location as the

server.

2 Plug the keyboard and mouse into the appropriate PS/2 connectors on

the SBC. See the “Rear panel connections” on page 59.

3 Plug in the monitor to the video connector on the video card. Tighten the

screws on the connector. See the “Rear panel connections” on page 59.

4 Connect the power cord to the monitor, and plug the other end into a wall

receptacle or power bar.

5 Turn on the monitor.

To connect the modem to the server

1 Ensure that the modem’s AC power cord is not plugged in.

2 Connect the large 25-pin male connector to the back of the modem.

Tighten the connector screws.

3 Connect the 9-pin female connector to COM1 at the rear of the server.

Tighten the connector screws.

4 Connect one end of the telephone cable to the modem RJ-11 jack

labeled LINE.

5 Connect the other end of the telephone cable to the RJ-11 jack in the

wall.

60 CallPilot

Page 61

May 2003 Installing the server and connecting the peripheral devices

6 Connect the power cord to the modem, and plug the other end into a wall

receptacle or power bar.

7 Turn on the modem.

What’s next?

Continue with “Connecting the server to the ELAN” on page 62.

Part 2: 1001rp Server Hardware Installation 61

Page 62

Installing the server and connecting the peripheral devices Standard 1.0

Connecting the server to the ELAN

Introduction

Connect the CallPilot server to the Meridian 1 switch or Succession

CSE 1000 system using the Embedded LAN (ELAN).

ATTENTION

For important con side ratio ns abou t usin g the EL AN in

your network, see “About the ELAN” in Part 1 of the

CallPilot Install ation and Config urat ion bi nder.

Media Access Control address

The Media Access Control (MAC) address is a unique number assigned to

network cards and controllers. The procedure below asks you to record the

MAC address from the label affixed to the ELAN network card faceplate.

The network card faceplate is visible through the slot openings in the back

of the chassis.

To connect the server to the ELAN

1 Refer to the diagram on page 59 to locate the ELAN Ethernet connector.

2 Locate the label on the ELAN network card faceplate that identifies the

ELAN controll er’s MAC address.

3 Record the MAC address on the Configuration Wizard worksheet that is

provided in Part 1 of the CallPilot Installation and Configuration binder.

You need the MAC address to identify the ELAN when running the

Configuration Wizard to configure the CallPilot server.

4 Connect an RJ-45 network cable from the ELAN hub to the ELAN

connector on the server.

Note: The ELAN hub is optional if you use a cross-over network cable to

make a direct point-to-point connection from the server to the switch.

62 CallPilot

Page 63

May 2003 Installing the server and connecting the peripheral devices

However, if you choose to establish a direct point-to-point ELAN

connection, no other device can connect to the ELAN.

5 At the switch, connect the ELAN network cable to an MAU (Ethernet)

transceiver. Then complete the connection from the transceiver to the

switch.

DANGER

.

What’s next?

IF the server will THEN

be connected to a CLAN continue with page 64.

not be connected to a CLAN continue with installing the software

Risk of fire hazard

MAU model NTRH9069 is not suitable for installation in

ducts, plenums, or o ther s paces u sed for envir onmen tal a ir. Do

not install it above a false ceiling or below a raised floor,

unless it can be confirmed that these spaces are not used to

convey environmental air.

feature key adapter (dongle). See page

66.

Part 2: 1001rp Server Hardware Installation 63

Page 64

Installing the server and connecting the peripheral devices Standard 1.0

Connecting the server to the CLAN (optional)

Introduction

This section provides instructions to connect the server to the Customer

LAN (CLAN).

Note: The CLAN is optional. However, a CLAN is required to support

desktop and web messaging users.

Media Access Control address

The Media Access Control (MAC) address is a unique number assigned to

network cards and controllers. The procedure below asks you to record the

MAC address from the label affixed to the CLAN network card faceplate.

The network card faceplate is visible through the slot openings in the back

of the chassis.

To connect the server to the CLAN

1 Refer to the diagram on page 59 to locate the CLAN network card.

2 Locate the label on the CLAN network card faceplate that identifies the

CLAN controller’s MAC address.

3 Record the MAC address on the Configuration Wizard worksheet that is

provided in Part 1 of the CallPilot Installation and Configuration binder.

You need the MAC address to identify the CLAN when running the

Configuration Wizard to configure the CallPilot server.

4 Connect an RJ-45 network cable from the CLAN hub to the CLAN

connector.

64 CallPilot

Page 65

May 2003 Installing the server and connecting the peripheral devices

What’s next?

Continue with “Installing the Nortel Networks software feature key adapter”

on page 66.

Part 2: 1001rp Server Hardware Installation 65

Page 66

Installing the server and connecting the peripheral devices Standard 1.0

Installing the Nortel Networks software feature key adapter

Introduction

The software feature key is a security device that stores the unique serial

number of the server. The feature key is embedded in the Nortel Networks

software feature key adapter, which plugs into the parallel port.

An illustration of the software featur e k ey embedded in the software f eat ure

key adapter is shown below:

Software

feature key

G101738

66 CallPilot

Page 67

May 2003 Installing the server and connecting the peripheral devices

Requirements

For instal lation, you require a Ph illips No. 1 s crewdriver.

To install the software feature key adapter

1 Ensure that there is no cable connected to the parallel port.

Note: The parallel port is also known as the printer port or LPT1. It is

located at the back of the server. See the diagram on page 59.

2 Plug the male end of the adapter into the parallel port.

3 Tighten the connector screws.

What’s next?

Continue with “Connecting the server to power” on page 68.

Part 2: 1001rp Server Hardware Installation 67

Page 68

Installing the server and connecting the peripheral devices Standard 1.0

Connecting the server to power

Before you begin

Ensure that proper power and grounding are available for all the power

outlets serving the CallPi lot server and its associated peripherals. Power for

these devices must be wired and fu sed indepe ndently of all other rece ptacles

and referenced to the same ground as the PBX system.

A qualified electrician must implement t he single-point groun d re ference as

required between the power outlets of the CallPilot server and the power

outlets of the switch.

Provide a sufficient number of properly grounded power outlets or power

bars for all equipment.

For more in formation, refer to Chapt er 2, “Grounding and power

requirements”, in the CallPilot Planning and Engineering Guide.

68 CallPilot

Page 69

May 2003 Installing the server and connecting the peripheral devices

Before you connect the server to the power source, review the following

diagram to ensure that all peripheral hardware devices are in place.

CallPilot

server

Keyboard

Monitor

AC

power

RJ-45

ELAN hub

(M1 or

CSE 1000

only)

AC

power

AC

power

source

RJ-45 RS-232

CLAN hub

(optional)

AC

power

ModemMouse

AC

power

Note: For details on the DC power source for 1001rp DC servers, see

Chapter 3, “Power supply installation.”

G101637

Part 2: 1001rp Server Hardware Installation 69

Page 70

Installing the server and connecting the peripheral devices Standard 1.0

To connect the 1001rp AC server to power

CAUTION

.

The power outlets that are used by the CallPilot server and its

peripheral devices must be connected to the same single-point

ground reference as the one used by the Meridian 1 switch or

Succession CSE 1000 system. If this requirement is not met,

power transients can cause personal injury and/or hardware

failure.

1 Plug the server’s AC power cord into the server’s rear panel.

2 Plug the other end of the server’s AC power cord into a properly

grounded power outle t or power bar.

Risk of personal injury and hardware failure

70 CallPilot

Page 71

May 2003 Installing the server and connecting the peripheral devices

To connect the 1001rp DC server to power

DANGER

.

Only qualified personnel can alter electrical connections.

Ensure the PDU is turned off until you are instructed to

turn it on.

1 Connect the DC power cable to the server, as shown below:

Receptacle for

positive and

negative plug

Risk of electrical shock

Negative

cable (black)

Ground wire

(green)

Positive

cable (red)

Posts for

ground wire

G101737

Part 2: 1001rp Server Hardware Installation 71

Page 72

Installing the server and connecting the peripheral devices Standard 1.0

2 Connect the other end of the DC power cable to the Power Distribution

Unit (PDU). See details below:

The following photograph shows the keyed plug of the DC power cable.

This plug connects to the PDU:

Note: If you are not using a Nortel Networks-supplied PDU, snip this

plug and connect the cable appropriately to your DC power plant.

Remember that a red cable is positive, a black cable is negative, and a

green cable is the ground.

3 Turn on the PDU.

To start the server

1 Press the server’s power switch to start the server.

2 Observe the Power-On Self-Test (POST) and initialization messages on

the monitor.

3 When the following menu appears on the monitor, select option 1 to boot

Windows NT:

Select one of the following:

--------------------------1 Windows NT 4.0 Server (Default within 30 secs)

2 Windows NT 4.0 Server (VGA mode)

Choose an option[1,2]?1

The Windows NT startup sequence begins.

4 Ensure that the Windows NT logon window appears on the monitor.

Note: If the Windows NT logon window does not appear, refer to Part 5

of the CallPilot Installation and Configuration binder for troubleshooting

instructions.

72 CallPilot

Page 73

May 2003 Installing the server and connecting the peripheral devices

What’s next?

If Windows NT started successfully, proceed with the switch and server set

up as described in Part 3 of the CallPilot Installation and Configuration

binder.

Part 2: 1001rp Server Hardware Installation 73

Page 74

Installing the server and connecting the peripheral devices Standard 1.0

74 CallPilot

Page 75

Index

A

adapter

software feature key, illustration

alarm board 11

assigned board label

CallPilot Manager

16

66

C

checklist

installation 26

CLAN

media access control address

CLAN network card faceplate 64

connecting peripherals to the server 59

connecting the server 68

connectivity

Ethernet

remote 23

Customer LAN

see CLAN

22

64

64

D

DC power 47

DC power and ground 50

DC power input 49

DC wire gauge tables 44

devices, peripheral

Ethernet hub

keyboard 24

modem 24

24

monitor 24

mouse 24

diagram

connection

network, M1 and CallPilot server

network, Succession CSE and CallPi-

lot server

front panel 11

PCI and ISA connectors 13

rear panel

slot locations

server connections for the power cord and

peripherals

DIP switches

modem, function 57

DIP switches, setting

modem

57

dongle 66

doors on the front bezel 31

21

12

59

E

ELAN

Media Access Control address

equipment

unpacking

Ethernet hub

description

29

24

62

F

fax modem

illustration

56

20

Part 2: 1001rp Server Hardware Installation 75

Page 76

Index Standard 1.0

required equipment 55

features

10

server

features, front panel

diagram

front bezel 31, 32

11

G

grounding guidelines 44

I

illustration

modem

software feature key adapter 66

TLAN 21

inspecting

server interior

installation checklist 26

IRQ mapping table 17

56

35

K

keyboard

connecting to the server

description 24

keylock 66

60

M

M1 and CallPilot server network diagram 20

MAC address

64

CLAN

ELAN 62

Metric wire conversion 45

modem

connecting to the server

description 24

DIP switches, setting 57

60

illustration 56

required equipment 55

monitor

connecting to the server

description 24

mouse

connecting to the server

description 24

MPB16-4 board

slot number for M1

slot number for Succession CSE 1000 16

60

60

16

N

network

protocols, supported

network interface cards 22

NIC

See network interface cards

22

P

part number

Ethernet hub

keyboard 24

modem 24

monitor 24

mouse 24

PCI and ISA connectors

diagram

PDU 48

multiple PDUs 49

single PDU wiring diagram 49

peripheral devices

Ethernet hub

keyboard 24

modem 24

monitor 24

mouse 24

peripherals

connecting to the server

power connection

24

13

24

59

76 CallPilot

Page 77

May 2003 Index

AC server 70

DC server 71

power distribution rationale 47

Power Distribution Unit

See PDU

power guidelines

power supply

bringing power and grou nd into the PDU

50

DC wire gauge tables 44

grounding guidelines 44

Metric wire conversion 45

module installation 42

module location 40

overview 40

PDU 48

power distribution rationale 47

protocols, supported network 22

44

R

remote access

connectivity

removing

front bezel

server cover 33

replacing

server cover

23

32

36

software feature key 66

Succession CSE 1000 and CallPilot server

network diagram

switches, setting DIP

modem

57

T

tables, slot assignment 14

telephony LAN

See TLAN

TLAN

illustration

21

21

U

unpacking

equipment

29

S

safety information 38

serial number of the server 66

server

connecting peripherals

power connection 68

serial number 66

setting

modem DIP switches

slot assignments 14

slot definition 14

slot numbering 14

Part 2: 1001rp Server Hardware Installation 77

59

57

Page 78

Index Standard 1.0

78 CallPilot

Page 79

Page 80

CallPilot

Installation and Configuration

Part 2: 1001rp Server Hardware Installation

Copyright © 2003 Nortel Networks, All Rights Reserved

Information is subject to change without notice. Nortel Networks reserves the right to make

changes in design or components as progress in engineering and manufacturing may

warrant.

The process of transmitting data and call messaging between the CallPilot server and the

Meridian 1 switch or Succession CSE 1000 system is proprietary to Nortel Networks. Any

other use of the data and the transmission process is a violation of the user license unless

specifically authorized in writing by Nortel Networks prior to such use. Violations of the

license by alternative usage of any portion of this process or the related hardware

constitutes grounds for an immediate termination of the license and Nortel Networks

reserves the right to seek all allowable remedies for such breach.

Publication number: 555-7101-217

Product release: 2.02

Document release: Standard 1.0

Date: May 2003

Printed in Canada

Loading...

Loading...