Page 1

Part No. 312755-G Rev 00

May 2006

4655 Great America Parkway

Santa Clara, CA 95054

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 2

2

Copyright © 2006 Nortel Networks. All Rights Reserved.

The information in this document is subject to change without notice. The statements, configurations, technical data, and

recommendations in this document are believed to be accurate and reliable, but are presented without express or implied

warranty. Users must take full responsibility for their applications of any products specified in this document. The

information in this document is proprietary to Nortel.

Trademarks

*Nortel, the Nortel logo, and the Globemark are trademarks of Nortel.

Adobe and Acrobat Reader are trademarks of Adobe Systems Incorporated.

Statement of conditions

In the interest of improving internal design, operational function, and/or reliability, Nortel Inc. reserves the right to make

changes to the products described in this document without notice.

Nortel Inc. does not assume any liability that may occur due to the use or application of the product(s) or circuit layout(s)

described herein.

International regulatory statements of conformity

This is to certify that the Nortel 8000 Series chassis and components installed within the chassis were evaluated to the

international regulatory standards for electromagnetic compliance (EMC) and safety and were found to have met the

requirements for the following international standards:

• EMC - Electromagnetic Emissions – CISPR 22, Class A

• EMC - Electromagnetic Immunity – CISPR 24

• Electrical Safety – IEC 60950, with CB member national deviations

Further, the equipment has been certified as compliant with the national standards as detailed below.

National electromagnetic compliance (EMC) statements of compliance

FCC statement (USA only)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the Federal Communications Commission (FCC) rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy. If it is not installed and used in accordance with the instruction manual, it

may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case users will be required to take whatever measures may be necessary to correct

the interference at their own expense.

ICES statement (Canada only)

Canadian Department of Communications Radio Interference Regulations

This digital apparatus (8000 Series chassis and installed components) does not exceed the Class A limits for radio-noise

emissions from digital apparatus as set out in the Radio Interference Regulations of the Canadian Department of

Communications.

312755-G Rev 00

Page 3

Règlement sur le brouillage radioélectrique du ministère des Communications

Cet appareil numérique (8000 Series chassis) respecte les limites de bruits radioélectriques visant les appareils

numériques de classe A prescrites dans le Règlement sur le brouillage radioélectrique du ministère des Communications

du Canada.

CE marking statement (Europe only)

EN 55 022 statements

This is to certify that the Nortel 8000 Series chassis and components installed within the chassis are shielded against the

generation of radio interference in accordance with the application of Council Directive 89/336/EEC. Conformity is

declared by the application of EN 55 022 Class A (CISPR 22).

War nin g: This is a Class A product. In a domestic environment, this product may cause radio interference, in which

case, the user may be required to take appropriate measures.

Achtung: Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei Betrieb dieses Gerätes

Rundfunkstörungen auftreten, in welchen Fällen der Benutzer für entsprechende Gegenmaßnahmen verantwortlich ist.

Attention: Ceci est un produit de Classe A. Dans un environnement domestique, ce produit risque de créer des

interférences radioélectriques, il appartiendra alors à l’utilisateur de prendre les mesures spécifiques appropriées.

EN 55 024 statement

This is to certify that the Nortel 8000 Series chassis is shielded against the susceptibility to radio interference in

accordance with the application of Council Directive 89/336/EEC. Conformity is declared by the application of

EN 55 024 (CISPR 24).

3

EC Declaration of Conformity

This product conforms to the provisions of the R&TTE Directive 1999/5/EC.

VCCI statement (Japan/Nippon only)

This is a Class A product based on the standard of the Voluntary Control Council for Interference (VCCI) for

information technology equipment. If this equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective actions.

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 4

4

Denan statement (Japan/Nippon only)

National safety statements of compliance

CE marking statement (Europe only)

EN 60 950 statement

This is to certify that the Nortel 8000 Series chassis and components installed within the chassis are in compliance with

the requirements of EN 60 950 in accordance with the Low Voltage Directive. Additional national differences for all

European Union countries have been evaluated for compliance. Some components installed within the 8000 Series

chassis may use a nickel-metal hydride (NiMH) and/or lithium-ion battery. The NiMH and lithium-ion batteries are

long-life batteries, and it is very possible that you will never need to replace them. However, should you need to replace

them, refer to the individual component manual for directions on replacement and disposal of the battery

Nortel Inc. software license agreement

This Software License Agreement (“License Agreement”) is between you, the end-user (“Customer”) and Nortel

Corporation and its subsidiaries and affiliates (“Nortel”). PLEASE READ THE FOLLOWING CAREFULLY. YOU

MUST ACCEPT THESE LICENSE TERMS IN ORDER TO DOWNLOAD AND/OR USE THE SOFTWARE. USE

OF THE SOFTWARE CONSTITUTES YOUR ACCEPTANCE OF THIS LICENSE AGREEMENT. If you do not

accept these terms and conditions, return the Software, unused and in the original shipping container, within 30 days of

purchase to obtain a credit for the full purchase price.

“Software” is owned or licensed by Nortel, its parent or one of its subsidiaries or affiliates, and is copyrighted and

licensed, not sold. Software consists of machine-readable instructions, its components, data, audio-visual content (such

as images, text, recordings or pictures) and related licensed materials including all whole or partial copies. Nortel grants

you a license to use the Software only in the country where you acquired the Software. You obtain no rights other than

those granted to you under this License Agreement. You are responsible for the selection of the Software and for the

installation of, use of, and results obtained from the Software.

1. Licensed Use of Software. Nortel grants Customer a nonexclusive license to use a copy of the Software on only

one machine at any one time or to the extent of the activation or authorized usage level, whichever is applicable. To the

extent Software is furnished for use with designated hardware or Customer furnished equipment (“CFE”), Customer is

granted a nonexclusive license to use Software only on such hardware or CFE, as applicable. Software contains trade

secrets and Customer agrees to treat Software as confidential information using the same care and discretion Customer

uses with its own similar information that it does not wish to disclose, publish or disseminate. Customer will ensure that

anyone who uses the Software does so only in compliance with the terms of this Agreement. Customer shall not a) use,

copy, modify, transfer or distribute the Software except as expressly authorized; b) reverse assemble, reverse compile,

312755-G Rev 00

Page 5

reverse engineer or otherwise translate the Software; c) create derivative works or modifications unless expressly

authorized; or d) sublicense, rent or lease the Software. Licensors of intellectual property to Nortel are beneficiaries of

this provision. Upon termination or breach of the license by Customer or in the event designated hardware or CFE is no

longer in use, Customer will promptly return the Software to Nortel or certify its destruction. Nortel may audit by remote

polling or other reasonable means to determine Customer’s Software activation or usage levels. If suppliers of third

party software included in Software require Nortel to include additional or different terms, Customer agrees to abide by

such terms provided by Nortel with respect to such third party software.

2. Warranty. Except as may be otherwise expressly agreed to in writing between Nortel and Customer, Software is

provided “AS IS” without any warranties (conditions) of any kind. NORTEL DISCLAIMS ALL WARRANTIES

(CONDITIONS) FOR THE SOFTWARE, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND

ANY WARRANTY OF NON-INFRINGEMENT. Nortel is not obligated to provide support of any kind for the

Software. Some jurisdictions do not allow exclusion of implied warranties, and, in such event, the above exclusions may

not apply.

3. Limitation of Remedies. IN NO EVENT SHALL NORTEL OR ITS AGENTS OR SUPPLIERS BE LIABLE

FOR ANY OF THE FOLLOWING: a) DAMAGES BASED ON ANY THIRD PARTY CLAIM; b) LOSS OF, OR

DAMAGE TO, CUSTOMER’S RECORDS, FILES OR DATA; OR c) DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

PUNITIVE, OR CONSEQUENTIAL DAMAGES (INCLUDING LOST PROFITS OR SAVINGS), WHETHER IN

CONTRACT, TORT OR OTHERWISE (INCLUDING NEGLIGENCE) ARISING OUT OF YOUR USE OF THE

SOFTWARE, EVEN IF NORTEL, ITS AGENTS OR SUPPLIERS HAVE BEEN ADVISED OF THEIR POSSIBILITY.

The forgoing limitations of remedies also apply to any developer and/or supplier of the Software. Such developer and/or

supplier is an intended beneficiary of this Section. Some jurisdictions do not allow these limitations or exclusions and, in

such event, they may not apply.

4. General

a. If Customer is the United States Government, the following paragraph shall apply: All Nortel Software

available under this License Agreement is commercial computer software and commercial computer software

documentation and, in the event Software is licensed for or on behalf of the United States Government, the

respective rights to the software and software documentation are governed by Nortel standard commercial

license in accordance with U.S. Federal Regulations at 48 C.F.R. Sections 12.212 (for non-DoD entities) and

48 C.F . R. 227.7202 (for DoD entities).

b. Customer may terminate the license at any time. Nortel may terminate the license if Customer fails to comply

with the terms and conditions of this license. In either event, upon termination, Customer must either return

the Software to Nortel or certify its destruction.

c. Customer is responsible for payment of any taxes, including personal property taxes, resulting from

Customer’s use of the Software. Customer agrees to comply with all applicable laws including all applicable

export and import laws and regulations.

d. Neither party may bring an action, regardless of form, more than two years af ter the cause of the action arose.

e. The terms and conditions of this License Agreement form the complete and exclusive agreement between

Customer and Nortel.

f. This License Agreement is governed by the laws of the country in which Customer acquires the Software. If

the Software is acquired in the United States, then this License Agreement is governed by the laws of the state

of New York.

5

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 6

6

312755-G Rev 00

Page 7

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Text conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

How to get Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Physical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Back panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Accessing the alarm module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7

Getting Help from the Nortel Web site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Getting Help over the phone from a Nortel Solutions Center . . . . . . . . . . . . . 17

Getting Help from a specialist by using an Express Routing Code . . . . . . . . . 17

Getting Help through a Nortel distributor or reseller . . . . . . . . . . . . . . . . . . . . 17

Shelf circuit breakers (upper and lower shelves) . . . . . . . . . . . . . . . . . . . . . . 20

Alarm module display panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Front panel locking screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Shelf alarm connectors (upper and lower shelves) . . . . . . . . . . . . . . . . . . . . . 24

Central office alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Preparing to install the breaker interface panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Shipment contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Additional equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 8

8 Contents

Installing the breaker interface panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Verifying the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 3

Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DC input electrical requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connecting cables to the chassis power supplies . . . . . . . . . . . . . . . . . . . . . . . . . 38

Routing power supply cables to the BIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting the ground cables to the rack grounding strip . . . . . . . . . . . . . . . . . . 48

Connecting the power supply cables to the BIP . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Connecting DC input power feeds to the BIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Replacing covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Installing shelf alarm cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Initial power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Verifying the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Powering off the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Interpreting the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Diagnosing and correcting the problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Corrective actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix A

Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Physical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Electromagnetic emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Safety agency certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendix B

BIP external cable pin assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Shelf alarm connectors (J1 and J2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Office alarm connectors (J3 and J4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Standalone office alarm connector (J5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

312755-G Rev 00

Page 9

Contents 9

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 10

10 Contents

312755-G Rev 00

Page 11

Figures

Figure 1 Breaker interface panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2 Front panel components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 3 Shelf circuit breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 4 Alarm module display panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 5 Back panel components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 6 Shelf alarm connections (upper and lower shelves) . . . . . . . . . . . . . . . . . 25

Figure 7 Configuring multiple BIPs to aggregate office alarms . . . . . . . . . . . . . . . . 26

Figure 8 Configuring standalone BIPs to report alarm status . . . . . . . . . . . . . . . . . 27

Figure 9 Power terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 10 Power and grounding example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 11 Opening the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 12 Accessing the alarm module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 13 Default jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 14 8010co chassis configuration with BIP option . . . . . . . . . . . . . . . . . . . . . 32

Figure 15 Contents of the BIP shipping container . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 16 Removing the plastic back cover from the BIP . . . . . . . . . . . . . . . . . . . . . 37

Figure 17 Installing the BIP in the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 18 Removing the 8010co chassis bottom 312096-A bezel . . . . . . . . . . . . . . 39

Figure 19 Location of power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 20 Loosening the power supply retaining screws . . . . . . . . . . . . . . . . . . . . . 41

Figure 21 Disconnecting the power supply from the chassis backplane . . . . . . . . . 41

Figure 22 Removing the plastic safety cover from the power supply . . . . . . . . . . . . 42

Figure 23 Power supply input and ground stud location . . . . . . . . . . . . . . . . . . . . . . 42

Figure 24 Power supply cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 25 Attaching the ground lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 26 Attaching the positive lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 27 Attaching the negative lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 28 Replacing the plastic safety cover on the power supply . . . . . . . . . . . . . . 45

Figure 29 Replacing the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 12

12 Figures

Figure 30 Labeling cables for the BIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 31 Rack grounding strip example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 32 Attaching power supply cable leads to the BIP . . . . . . . . . . . . . . . . . . . . . 49

Figure 33 Upper and lower shelf power cables connected to the BIP . . . . . . . . . . . 50

Figure 34 Attaching the BIP ground cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 35 A and B feed example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 36 Locating the A and B -48 VDC input feeds . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 37 Connecting the A and B -48 VDC input feeds to the BIP (1 of 2) . . . . . . . 55

Figure 38 Connecting the A and B -48 VDC input feeds to the BIP (2 of 2) . . . . . . . 56

Figure 39 Connecting the A/B input feed returns (1 of 2) . . . . . . . . . . . . . . . . . . . . . 57

Figure 40 Connecting the A/B input feed returns (2 of 2) . . . . . . . . . . . . . . . . . . . . . 58

Figure 41 Replacing the plastic back cover on the BIP . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 42 Replacing the 8010co chassis 312096-A bezel . . . . . . . . . . . . . . . . . . . . 60

Figure 43 Installing shelf alarm cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 44 BIP LEDs and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 45 J1 and J2 9-pin standard D-sub connector . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 46 J1 and J2 shelf alarm connector pinouts . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 47 J3 and J4 high-density 26-pin D-sub connector . . . . . . . . . . . . . . . . . . . . 77

Figure 48 J3 and J4 office alarm connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 49 J5 high-density 26-pin D-sub connector . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 50 J5 standalone office alarm connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

312755-G Rev 00

Page 13

Tables

Table 1 Alarm module display LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 2 DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 3 Single chassis and dual chassis input options . . . . . . . . . . . . . . . . . . . . . 53

Table 4 BIP LEDs and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 5 Corrective actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 6 J1 and J2 shelf alarm connector pin assignments . . . . . . . . . . . . . . . . . . 76

Table 7 J3 and J4 office alarm connector pin assignments . . . . . . . . . . . . . . . . . . 78

Table 8 J5 standalone office alarm connector pin assignments . . . . . . . . . . . . . . 80

13

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 14

14 Tables

312755-G Rev 00

Page 15

Preface

The breaker interface panel (BIP) provides power distribution and alarm status

indications for one or two 8010co chassis in an equipment rack. The status

indications can be linked to other BIPs to provide total system status to the central

office (CO).

This guide describes how to install the breaker interface panel in an equipment

rack, connect cables, and interpret LEDs. It also includes technical specifications

for the breaker interface panel.

For a list of related publications, see the release notes that accompany your

software.

Before you begin

This guide is intended for qualified service personnel who need to install or

replace a breaker interface panel. A qualified service person must have

appropriate technical training and experience and be aware of hazards involved in

installing and replacing customer-replaceable units (CRUs).

15

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 16

16 Preface

Text conventions

This guide uses the following text conventions:

bold Courier text

italic text Indicates new terms, book titles, and variables in

plain Courier

text

How to get Help

This section explains how to get help for Nortel products and services.

Getting Help from the Nortel Web site

Indicates command names and options and text that

you need to enter.

Example: Use the

Example: Enter

command syntax descriptions. Where a variable is two

or more words, the words are connected by an

underscore.

Example: If the command syntax is

show at <valid_route>, valid_route is one

variable and you substitute one value for it.

Indicates command syntax and system output, for

example, prompts and system messages.

Example:

Set Trap Monitor Filters

dinfo command.

show ip {alerts|routes}.

312755-G Rev 00

The best way to get technical support for Nortel products is from the Nortel

Technical Support Web site:

http://www.nortel.com/support

This site provides quick access to software, documentation, bulletins, and tools to

address issues with Nortel products. More specifically, the site enables you to:

• download software, documentation, and product bulletins

• search the Technical Support Web site and the Nortel Knowledge Base for

answers to technical issues

Page 17

Preface 17

• sign up for automatic notification of new software and documentation for

Nortel equipment

• open and manage technical support cases

Getting Help over the phone from a Nortel Solutions Center

If you don’t find the information you require on the Nortel Technical Support Web

site, and have a Nortel support contract, you can also get help over the phone from

a Nortel Solutions Center.

In North America, call 1-800-4NORTEL (1-800-466-7835).

Outside North America, go to the following Web site to obtain the phone number

for your region:

http://www.nortel.com/callus

Getting Help from a specialist by using an Express Routing Code

To access some Nortel Technical Solutions Centers, you can use an Express

Routing Code (ERC) to quickly route your call to a specialist in your Nortel

product or service. To locate the ERC for your product or service, go to:

http://www.nortel.com/erc

Getting Help through a Nortel distributor or reseller

If you purchased a service contract for your Nortel product from a distributor or

authorized reseller, contact the technical support staff for that distributor or

reseller.

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 18

18 Preface

312755-G Rev 00

Page 19

Chapter 1

Overview

This chapter provides an overview of the BIP and covers the following topics:

• Physical description

• “Accessing the alarm module” on page 30

• “Configuration example” on page 32

Physical description

The BIP provides a central rack location where redundant input DC power feeds

are connected and routed to one or two 8010co chassis. The BIP also provides an

alarm module and display panel that monitors system components, generates

alarms, and controls LED status indicators (requires 8010co chassis configured

with an 8691SF or 8691omSF CPU Module). The alarm module provides total

system status to the central office.

19

Figure 1 shows the breaker interface panel. Descriptions of the front panel

components follow the figure.

Figure 1 Breaker interface panel

R

E

W

O

P

L

A

IC

IT

R

C

R

O

J

A

M

R

O

IN

M

10370FB

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 20

20 Chapter 1 Overview

Front panel

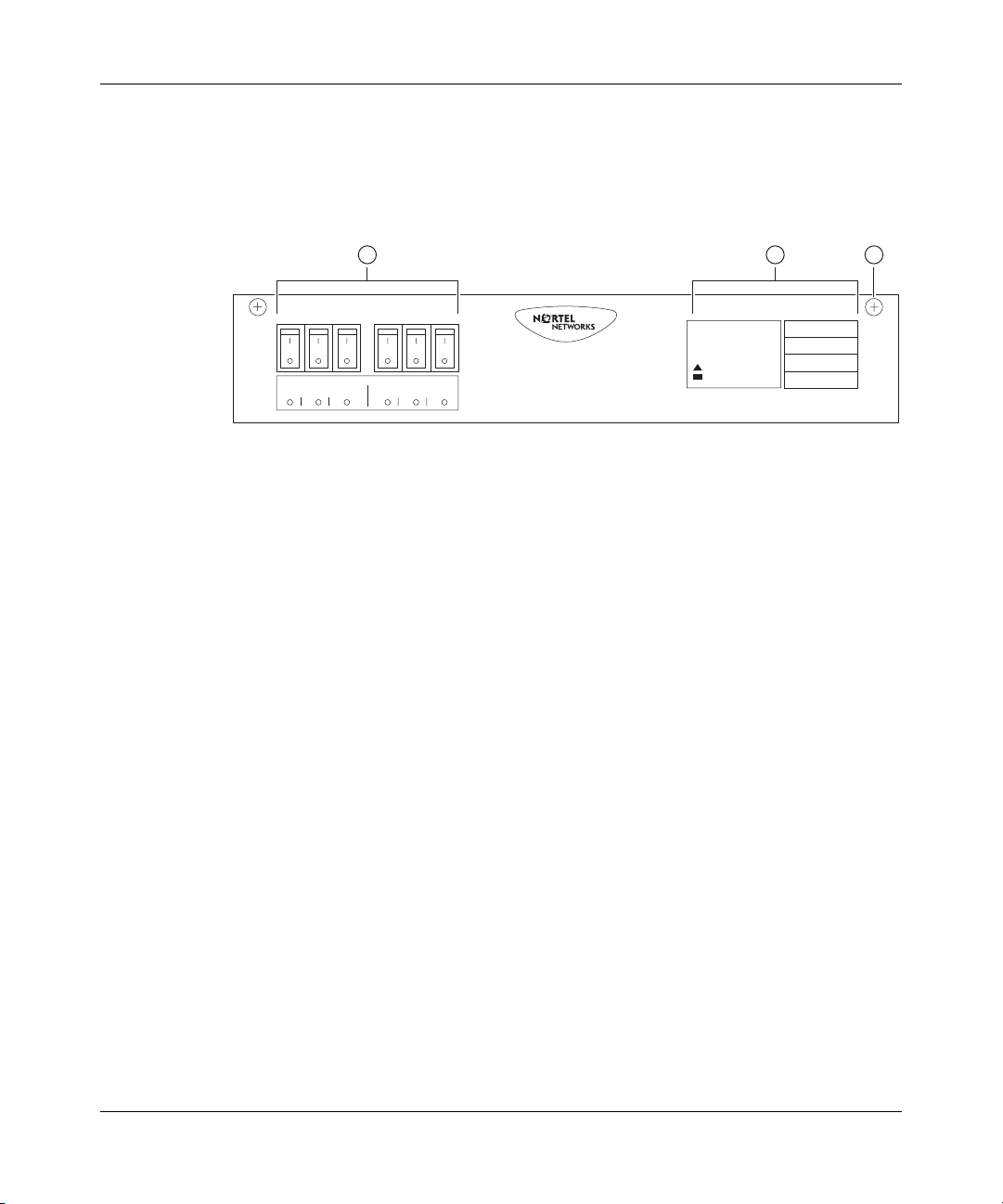

Figure 2 shows the BIP front panel components.

Figure 2 Front panel components

1 2

Upper Shelf

123 123

1 = Shelf circuit breakers (upper/lower shelves)

2 = Alarm module display panel

3 = Front-panel locking screws (x2)

Lower Shelf

Alarm Module

POWER

CRITICAL

MAJOR

MINOR

3

10376EB

Shelf circuit breakers (upper and lower shelves)

Two groups of three circuit breakers provide input power to the power supplies for

the upper and lower shelf 8010co chassis (Figure 3 on page 21):

• The first group, labeled “Upper Shelf,” provides input power to the upper

shelf power supplies.

• The second group, labeled “Lower Shelf,” provides input power to the lower

shelf power supplies.

312755-G Rev 00

If a power supply over current condition occurs, the associated circuit breaker

trips and indicates the fault by lighting the associated circuit breaker’s LED (red).

Each of the six circuit breakers is current limited to 30 amperes @80 volts direct

current. The circuit breakers are designed with internal auxiliary switches to

provide fault indications to the alarm module and to the associated circuit breaker

LEDs on the front panel. The alarm module reports circuit breaker fault conditions

by lighting the MAJOR indicator on the Alarm Module display panel.

No alarm is generated to the alarm module when the circuit breaker is manually

switched on (|) or off (O).

Page 21

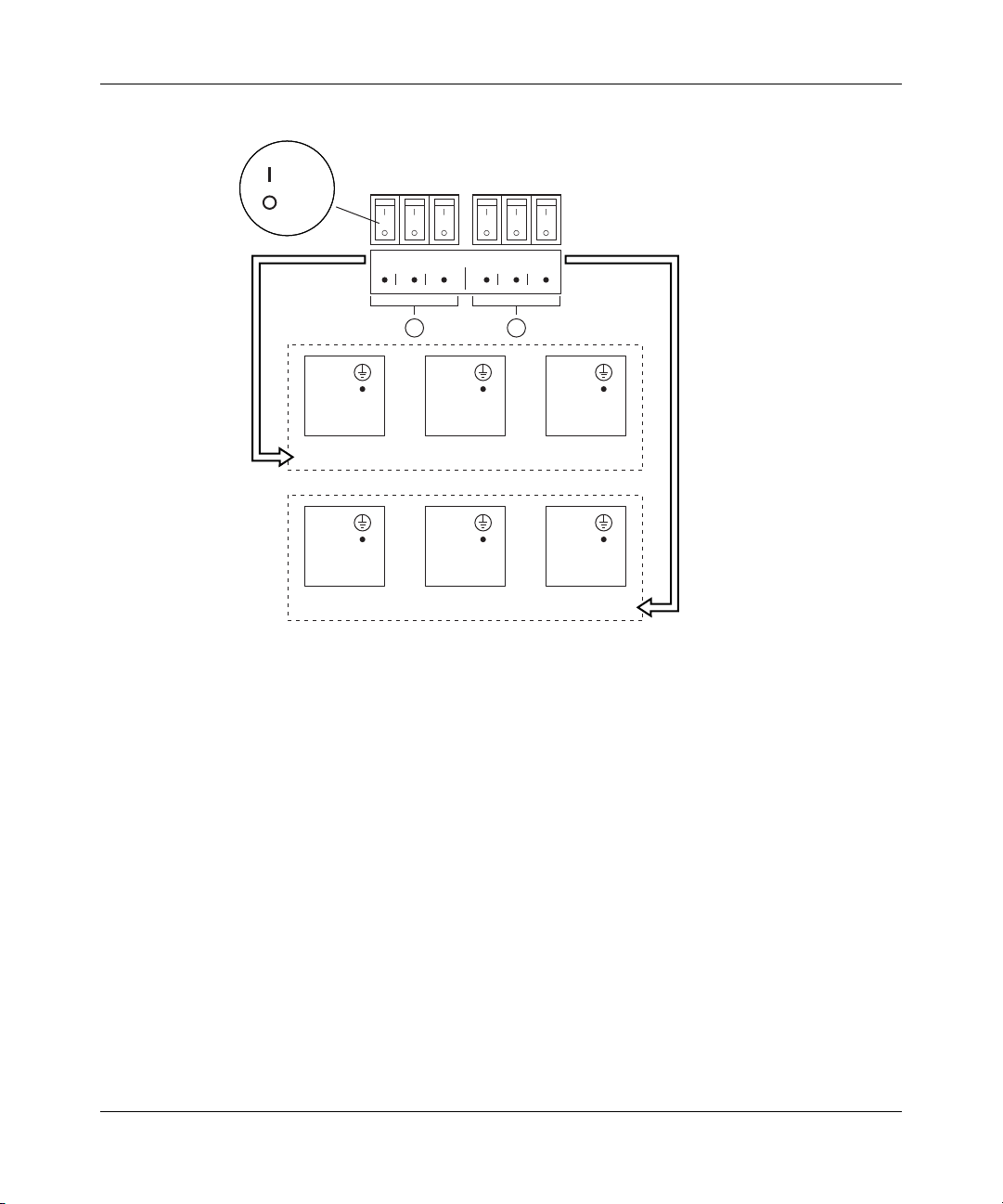

Figure 3 Shelf circuit breakers

= On

= Off

Chapter 1 Overview 21

Upper Shelf

123 123

PS 1

+ DC

– DC

Upper shelf power supplies

PS 1

+ DC

– DC

1 = Upper shelf LEDs

2 = Lower shelf LEDs

Lower Shelf

1

2

PS 2

+ DC

– DC

PS 2

+ DC

– DC

Lower shelf power supplies

Front of rack

PS 3

+ DC

– DC

PS 3

+ DC

– DC

10372EA

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 22

22 Chapter 1 Overview

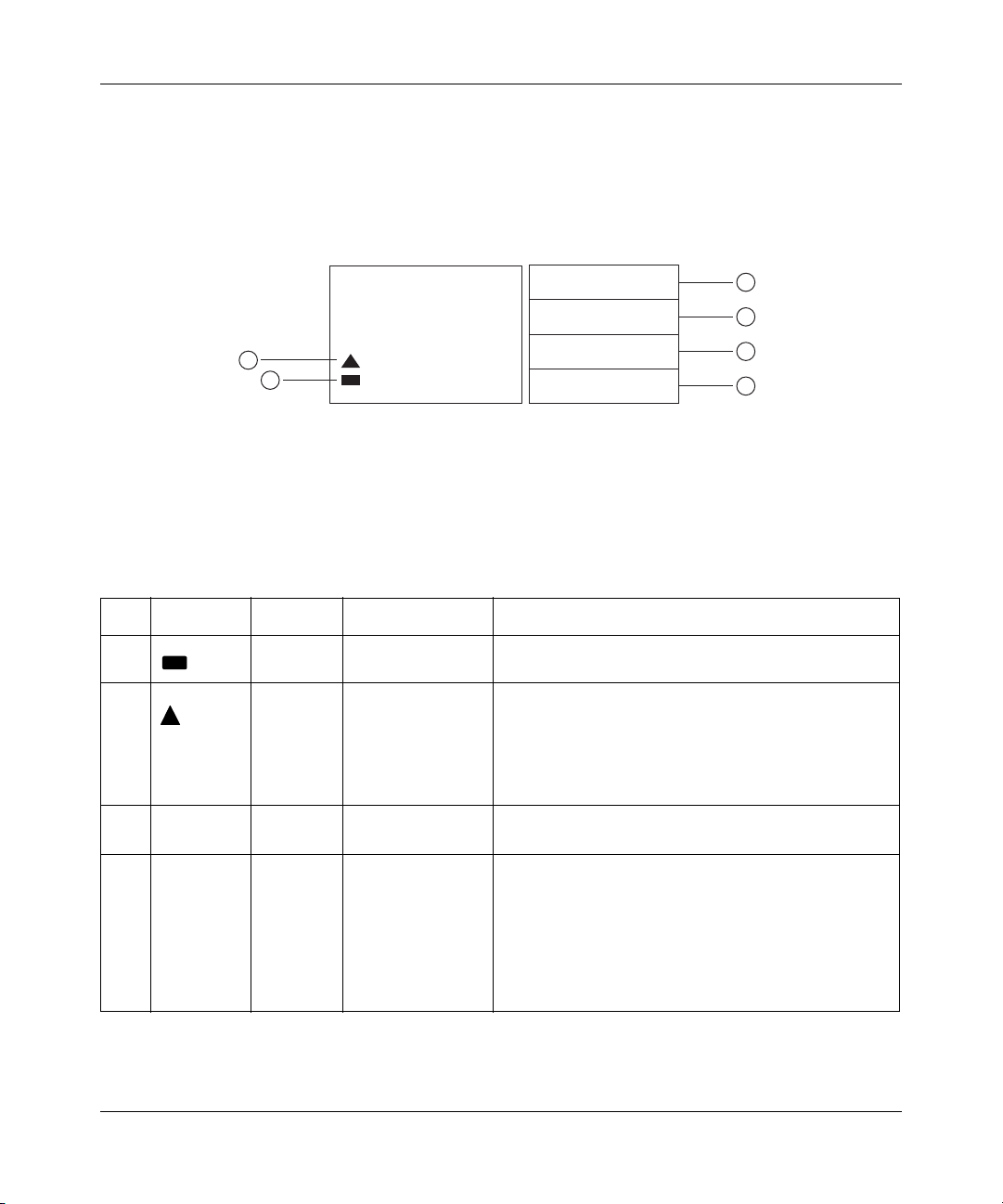

Alarm module display panel

The alarm module display panel (Figure 4), located on the BIP front panel,

provides visual status indications for one or two 8010co chassis in a single rack.

Figure 4 Alarm module display panel

3

4

5

6

10377EA

2

1

1 = Shelf alarm cable validation LED

2 = Shelf alarm cable fault LED

Alarm Module

POWER

CRITICAL

MAJOR

MINOR

3 = POWER indicator

4 = CRITICAL fault indicator

5 = MAJOR fault indicator

6 = MINOR fault indicator

See Tabl e 1 for a description of the LEDs.

Table 1 Alarm module display LEDs

Item Label/Icon Type Color/State Description

1 LED Green/On steady Shelf alarm cable validation LED—The alarm cables

are properly connected to the shelves.

2 LED Red/On steady Shelf alarm cable fault LED—The shelf alarm cables

3 POWER Indicator White/On steady Power indicator—The external DC power is available

4 CRITICAL Indicator Red/On steady Critical fault indicator—Indicates that a severe

are missing, not secured, or the shelf alarm jumpers

are not configured properly (see “Accessing the alarm

module” on page 30). This fault condition also lights

the MINOR fault indicator (see Minor fault description

in this table).

to the BIP.

service-affecting condition has occurred that requires

immediate corrective action. Common causes for this

type of fault condition include:

• Line card failure

• Temperature fault

• CPU fault when only one CPU is installed

312755-G Rev 00

Page 23

Chapter 1 Overview 23

Table 1 Alarm module display LEDs (continued)

Item Label/Icon Type Color/State Description

5 MAJOR Indicator Red/On steady Major fault indicator—Indicates that the system

hardware or software has identified a serious

disruption of service or that an important circuit failure

has occurred.

Common causes for this type of fault condition

include:

• CPU fault when two CPUs are installed

• Two fan trays are faulty

• Two power supplies are faulty

6 MINOR Indicator Yellow/On steady Minor fault indicator—Indicates a problem that does

not have a serious effect on customer service, or a

problem in circuits that are not essential to device

operation.

Common causes for this type of fault condition

include:

• Shelf alarm cables not installed or not connected

properly.

• Alarm module jumpers configured incorrectly.

• One power supply is faulty

• One fan tray is faulty

The alarm module can also be linked to other BIPs, and can provide visual and

audible alarms to aisle alarms and to the central office (see “Central office alarms”

on page 26).

Alarm support for the BIP is provided by the 8691SF or 8691omSF central

processing unit (CPU) in the 8010co chassis. The following conditions in the

8010co chassis generate alarms:

• Power supply failure

• Fan failure

• Overheating

• Line card error

•Master CPU failure

For details about the 8691SF or 8691omSF Central Processing Unit (CPU), see

the appropriate product chassis installation manual.

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 24

24 Chapter 1 Overview

Front panel locking screws

The front panel locking screws allow you to open the front panel to access the

alarm module. The alarm module contains jumpers that you use to configure your

system alarm parameters.

For information about configuring your system alarm parameters, see “Accessing

the alarm module” on page 30.

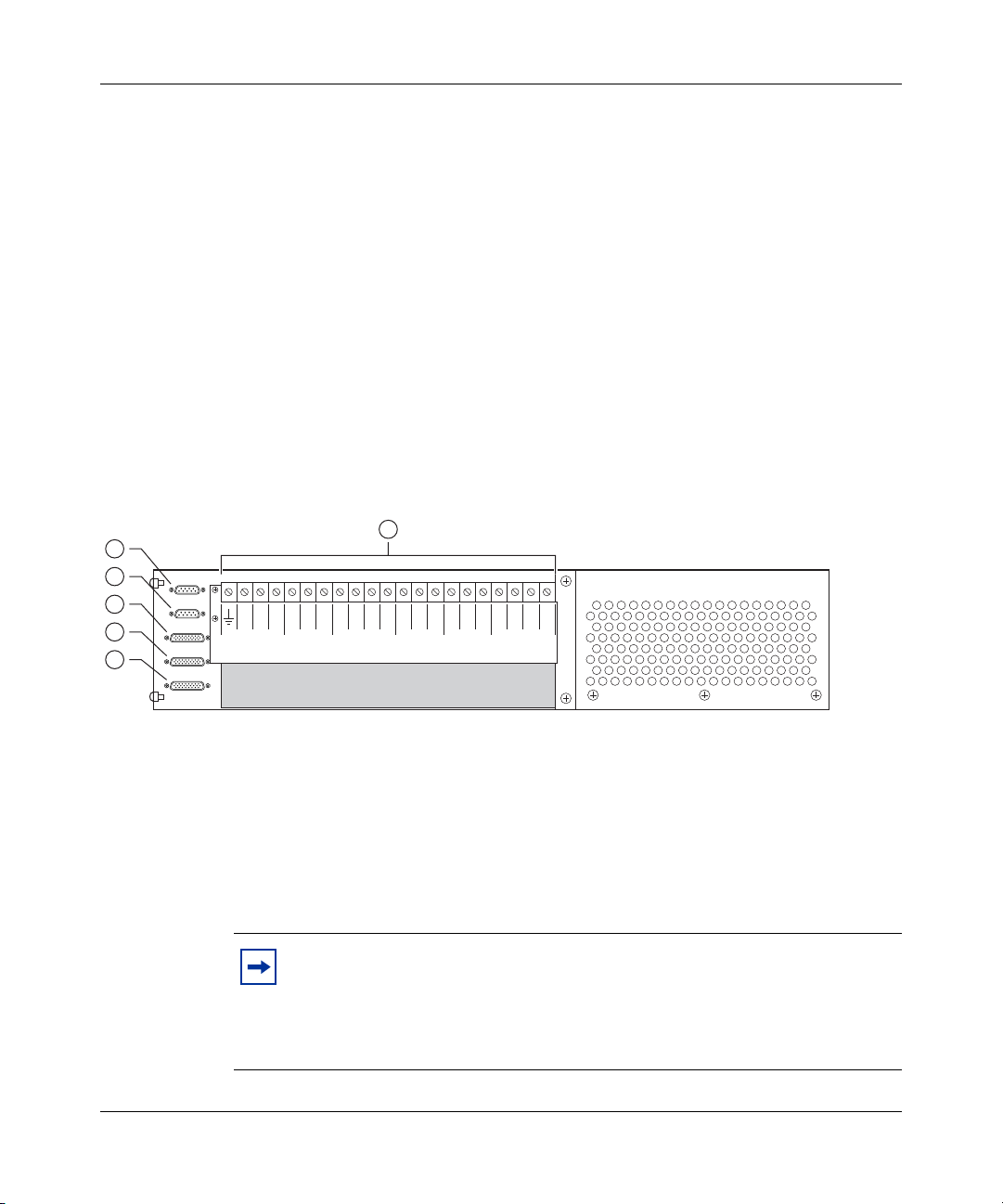

Back panel

Figure 5 shows the BIP back panel configuration (plastic back cover not shown).

Descriptions of the back panel components follow the figure.

Figure 5 Back panel components

1

2

3

4

5

32

1321 321321 A2A1B1B

PS (+)

PS (+)

Upper Shelf

A/B Input Feed

Returns

Lower Shelf

6

PS (-)

Lower Shelf

PS (-)

Upper Shelf

– 48 VDC

A/B Input Feeds

2

1 = J1 Upper shelf alarm connector

2 = J2 Lower shelf alarm connector

Shelf alarm connectors (upper and lower shelves)

The shelf alarm connectors allow you to configure the BIP to control more than

one 8010co chassis.

312755-G Rev 00

3 = J3 Central office alarm "in"

4 = J4 Central office alarm "out"

5 = J5 Standalone office alarm connector

6 = TB1 Power terminal block

10367EA

Note: The BIP ships from the factory with default alarm configurations

set for a single chassis in the lower shelf of the rack. If you install a

second chassis, you must also configure the jumper on the alarm module

to support that configuration. See “Accessing the alarm module” on

page 30 for information about jumper settings for your configuration.

Page 25

Chapter 1 Overview 25

Figure 6 shows the location of the shelf alarm connectors on the BIP and on two

8010co chassis (upper and lower shelves).

Figure 6 Shelf alarm connections (upper and lower shelves)

1

2

J1

J2

J3

J4

J5

3

4

1 = J1 (BIP upper shelf alarm connector)

2 = J2 (BIP lower shelf alarm connector)

3 = Upper shelf chassis alarm connector "out"

4 = Lower shelf chassis alarm connector "out"

10380EA

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 26

26 Chapter 1 Overview

Central office alarms

The central office alarm connectors allow you to aggregate alarms from multiple

BIPs and route them to an aisle alarm and to the central office. Figure 7 shows

three BIPs configured to aggregate alarms from three racks. You can configure up

to ten BIPs in a series configuration to aggregate alarms.

Central office alarm cables are not provided as part of your BIP shipment. To

build your own central office alarm cables, see Appendix B, “BIP external cable

pin assignments,” on page 75.

Figure 7 Configuring multiple BIPs to aggregate office alarms

1

2

J1

J2

J3

J4

J5

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

Upper Shelf

2

PS (-)

– 48 VDC

A/B Input Feeds

BIP 1

PS (-)

BIP 2

PS (-)

BIP 3

– 48 VDC

A/B Input Feeds

– 48 VDC

A/B Input Feeds

2

2

3

To central office

32

1321 321321 A2A1B1B

PS (+)

PS (+)

Lower Shelf

Upper Shelf

32

1321 321321 A2A1B1B

PS (+)

PS (+)

Lower Shelf

Upper Shelf

A/B Input Feed

Returns

A/B Input Feed

Returns

PS (-)

Lower Shelf

PS (-)

Lower Shelf

Upper Shelf

Upper Shelf

1 = J3 (central office alarm "in")

2 = J4 (central office alarm "out")

3 = Aisle alarm

10371EA

You can also configure one or more standalone BIPs to individually report alarm

status to the central office (Figure 8 on page 27).

312755-G Rev 00

Page 27

Chapter 1 Overview 27

This type of configuration allows you to independently monitor and control the

external audible and visual alarm status indications of the BIP at the central office.

Figure 8 Configuring standalone BIPs to report alarm status

J1

J2

J3

1

J4

J5

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

PS (-)

Upper Shelf

– 48 VDC

A/B Input Feeds

2

To central office

BIP 1

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

PS (-)

Upper Shelf

– 48 VDC

A/B Input Feeds

2

To central office

BIP 2

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

PS (-)

Upper Shelf

– 48 VDC

A/B Input Feeds

2

To central office

BIP 3

1 = J5 (standalone office alarm connector)

10419EA

Power terminal block

The power terminal block is located on the back panel of the BIP. As shown in

Figure 9 on page 28, the power terminal block provides 21 connection blocks for

DC input and output feeds.

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 28

28 Chapter 1 Overview

Figure 9 Power terminal block

1 10

2 3 5 64

7

8

9

32

1321 321321 A

PS (+)

Lower Shelf

1 = To frame (rack) ground

2 = To lower shelf power supplies (+DC terminals)

3 = To upper shelf power supplies (+DC terminals)

4 = Returns (A/B input feeds)

5 = To lower shelf power supplies (-DC terminals)

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

6 = To upper shelf power supplies (-DC terminals)

7 = -48 VDC input feed (Primary A feed)

8 = -48 VDC input feed (Secondary A feed)

9 = -48 VDC input feed (Primary B feed)

10 = -48 VDC input feed (Secondary B feed)

PS (-)

Upper Shelf

2A1B1B2

– 48 VDC

A/B Input Feeds

10379EA

Figure 10 on page 29 shows an example of the BIP power terminal block cabling

including ground connections for two 8010co chassis and installed power

supplies.

As shown in this example, both upper and lower chassis are each fully configured

with three power supplies (one is redundant) and require four 60 A direct current

input feeds to the BIP (two feeds are redundant).

For more information, see “Connecting DC input power feeds to the BIP” on

page 52.

Caution: All DC input feeds to the breaker interface panel must be

equipped with an overcurrent protection device that limits current to a

maximum of 60 A. The overcurrent protection device can be any

approved, standard-delay, 60 A fuse or circuit breaker with an

interrupting current rating of not less than 10,000 A.

312755-G Rev 00

Page 29

Figure 10 Power and grounding example

PS 3

+ DC

– DC

PS 3

+ DC

–

DC

PS 3

+ DC

– DC

Return Secondary B

Return Primary B

Return Secondary A

Return Primary A

+DC PS1 Upper

+DC PS2 Upper

+DC PS3 Upper

+DC PS1 Lower

Equipment

rack

+DC PS2 Lower

+DC PS3 Lower

Chapter 1 Overview 29

-DC PS3 Lower

-DC PS2 Lower

-DC PS1 Lower

-DC PS3 Upper

-DC PS2 Upper

-DC PS1 Upper

-48 VDC Primary A

-48 VDC Secondary A

-48 VDC Primary B

-48 VDC Secondary B

Rack

grounding strip

example

Gnd BIP

Gnd PS 1 upper

Gnd PS 2 upper

Gnd PS 3 upper

Gnd upper shelf

Gnd PS 1 lower

Gnd PS 2 lower

Gnd PS 3 lower

Gnd lower shelf

Legend:

= Chassis ground

32

1321 321321 A

PS (+)

Lower Shelf

PS (+)

Upper Shelf

Power terminal block (BIP)

Upper shelf

PS 1

+ DC

– DC

Lower shelf

PS 1

+ DC

– DC

A/B Input Feed

Returns

PS 1

PS 2

PS 1

PS 2

PS (-)

Lower Shelf

+ DC

+ DC

– DC

– DC

+ DC

+ DC

– DC

– DC

PS (-)

Upper Shelf

PS 3

2A1B1B2

– 48 VDC

A/B Input Feeds

DC

Chassis

ground stud

Cable not

supplied

Chassis

ground stud

Cable not

supplied

= Earth ground

= Redundant equipment

10760EB

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 30

30 Chapter 1 Overview

Accessing the alarm module

Danger: Ensure that the DC power source is off or disconnected at the

remote end before you perform any of the steps in this section. Be sure

that the DC input source power is locked out and tagged.

The alarm module contains jumpers that you can configure to allow the BIP to

monitor the shelf alarm cables for a single or dual chassis installation. The BIP

ships from the factory with default jumper configurations set for a single chassis

in the lower shelf of the rack. If you install a second chassis in the upper shelf, you

must configure the jumpers on the alarm module to support that configuration.

Note: The jumper configuration has no affect on the chassis status

alarms.

The BIP front panel opens to provide access to the jumpers on the alarm module.

To open the front panel:

312755-G Rev 00

1 Using a Phillips screwdriver, loosen the two front panel locking screws

(Figure 11).

Figure 11 Opening the front panel

1

R

E

W

O

P

L

A

IC

IT

R

C

R

O

J

A

M

R

O

IN

M

1 = Front panel locking screws (x 2)

10375FB

Page 31

Chapter 1 Overview 31

2 Gently lower the front panel to expose the alarm module (Figure 12).

Figure 12 Accessing the alarm module

1

1 = Alarm module

10365FB

Figure 13 shows a close-up view of the alarm module with jumpers J8 and J9

configured to monitor the shelf alarm cable for a single chassis in the lower shelf

only (default setting). Monitoring of the upper shelf alarm cable is disabled with

jumper J8, by default.

To enable the BIP to monitor the shelf alarm cable for a second chassis in the

upper shelf, you must place the upper shelf alarm jumper (J8) over pins 2 and 3.

Figure 13 Default jumper settings

2

3 2 1

J9

1

J9

3 2 1

J8

3

J8

1 = Alarm module

2 = J9 Lower shelf alarm jumper (enabled)

3 = J8 Upper shelf alarm jumper (disabled)

10366EB

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 32

32 Chapter 1 Overview

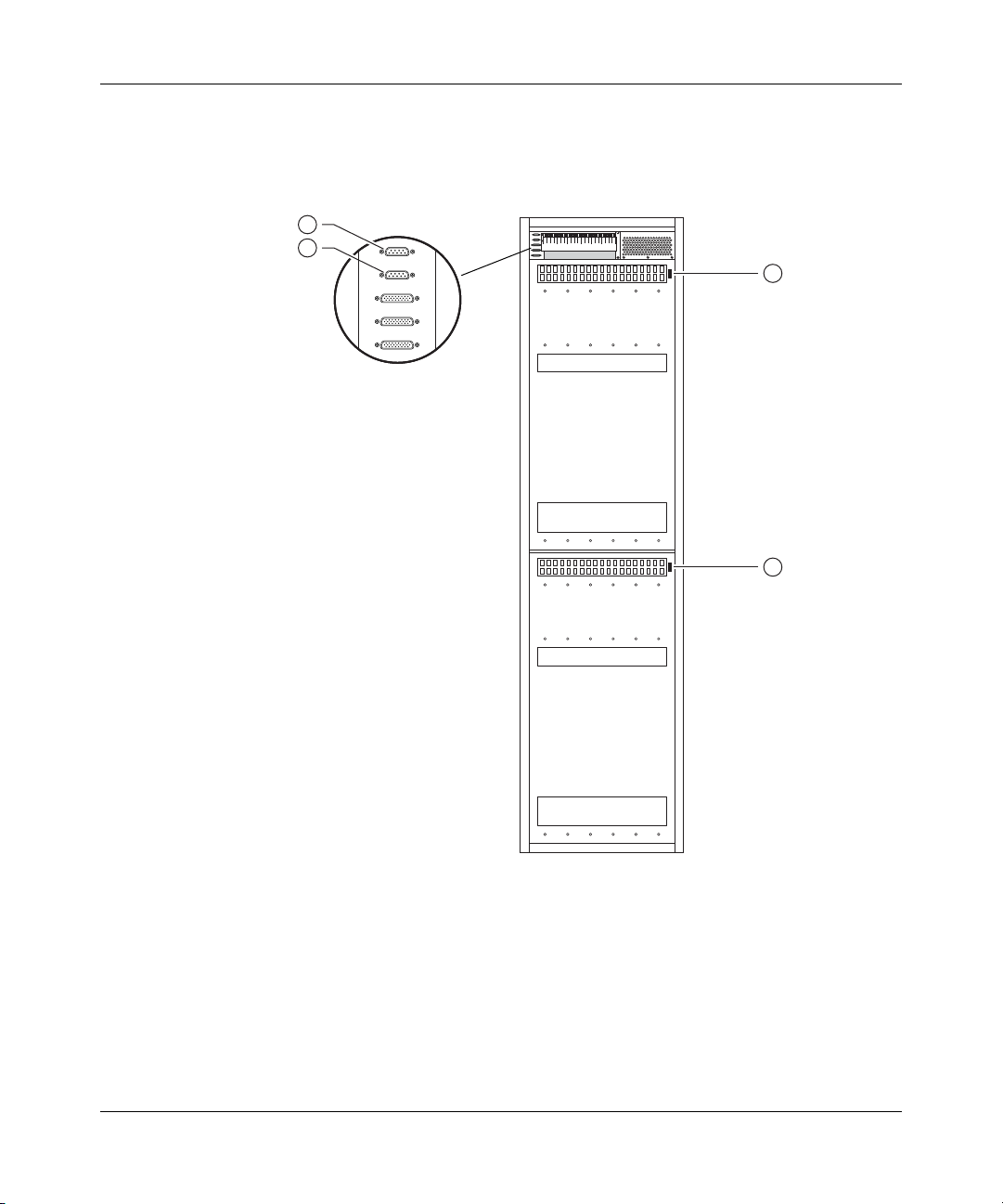

Configuration example

Figure 14 shows a typical configuration using the optional breaker interface panel.

Figure 14 8010co chassis configuration with BIP option

1

2

312755-G Rev 00

3

1 = Breaker interface panel

2 = 8010co Chassis (upper shelf position)

3 = 8010co Chassis (lower shelf position)

10420EB

Page 33

Chapter 2

Installation

This chapter describes how to install the breaker interface panel and covers the

following topics:

• “Preparing to install the breaker interface panel” next

• “Installing the breaker interface panel” on page 36

• “Verifying the installation” on page 62

Preparing to install the breaker interface panel

Before begin the installation, verify that:

• Your shipment is complete and undamaged.

• You have the cables, tools, and other equipment that you need.

• Your installation site meets the physical, electrical, and environmental

requirements (see Appendix A, “Technical specifications,” on page 73).

33

The sections that follow help you prepare for installation.

Note: For a list of requirements that must be met for the 8010co chassis,

see the appropriate product chassis installation manual.

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 34

34 Chapter 2 Installation

Shipment contents

Inspect all items for shipping damage. If you detect any damage, do not install the

BIP. Call the Nortel Technical Solutions Center in your area (see “How to get

Help” on page 16).

Your BIP shipment contains the following items (Figure 15):

Figure 15 Contents of the BIP shipping container

1

2

R

E

W

O

P

L

A

IC

IT

R

C

R

O

J

A

M

R

O

IN

M

312755-G Rev 00

3

4

5

6

1 = Breaker interface panel (BIP)

2 = BIP ground cable (x 1)

3 = 90-inch power supply ground cable (x 6)

4 = 125-inch power supply cable (x 6)

5 = 90-inch power supply cable (x 6)

6 = Shelf alarm cables (x 2)

10369FC

Page 35

Additional equipment

To install the BIP, you might need items that are not part of the BIP installation

kit. Before installing the BIP hardware, ensure that you obtain all the cables, tools,

and other equipment that you need. For information about office alarm cable pin

assignments, see Appendix B, “BIP external cable pin assignments,” on page 75.

Mounting hardware

You must install the BIP in an equipment rack. You need the following tools:

• Phillips screwdriver

• 7/16-inch hex wrench

You also need a rack that meets the following specifications:

• Heavy-duty steel construction

• Electronics Industries Association (EIA) standard hole-spacing

Chapter 2 Installation 35

You can install the BIP in the following 19-in. (48.26 cm) rack configurations:

• Standard 19-inch rack

• Hendry rack

You can install the BIP in a standard 23-inch rack using adapters provided by the

rack supplier. If your rack does not have threaded rail holes, you must use

cagenuts that are appropriate for the specific rack model you are using.

DC input electrical requirements

The installation site must meet the following electrical requirements for DC power

(Tabl e 2):

Table 2 DC power requirements

Nominal input voltage Maximum input current Physical

-48 VDC nominal 60 A Reinforced insulation

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

from the main DC power

Page 36

36 Chapter 2 Installation

Installing the breaker interface panel

Warning: Ensure that the DC power source is off or disconnected at the

remote end before you perform any of the steps in this section. You may

need to switch a circuit breaker off or turn off power at the DC input

source. Be sure that the DC input source power is locked out and tagged.

Note: The 8004DC power supply operates with the BIP. The BIP does

not support the 8005DC power supply.

This section covers the following topics:

• “Installing the hardware” next

• “Connecting cables to the chassis power supplies” on page 38

• “Routing power supply cables to the BIP” on page 47

• “Connecting the ground cables to the rack grounding strip” on page 48

• “Connecting the power supply cables to the BIP” on page 49

• “Connecting DC input power feeds to the BIP” on page 52

• “Replacing covers” on page 59

• “Installing shelf alarm cables” on page 61

Installing the hardware

312755-G Rev 00

Before beginning the BIP hardware installation, ensure that you:

• Always install the BIP in the uppermost position in the rack to allow for

maximum convection cooling requirements.

• Ground the rack to the same grounding electrode used by the power service in

the area.

The ground path must be permanent and must not exceed 1 ohm of resistance

from the rack to the grounding electrode.

Page 37

Chapter 2 Installation 37

To install the BIP:

1 Remove the plastic back cover from the BIP terminal block (Figure 16).

Figure 16 Removing the plastic back cover from the BIP

2

1

32

1321 321321 A2A1B1B

PS (+)

PS (+)

Upper Shelf

A/B Input Feed

Returns

Lower Shelf

Lower Shelf

PS (-)

PS (-)

Upper Shelf

2

– 48 VDC

A/B Input Feeds

2

1 = Back cover (plastic)

2 = Cover screws (x 4)

Caution: The BIP weighs 33.9 lbs (15.4 kg). The next step requires two

persons to mount the BIP in the rack.

2 Position the BIP in the uppermost position in the rack and align the holes in

the mounting bracket with the holes in the rack.

3 Insert 2 screws, appropriate for your rack type, into each mounting bracket

and tighten them (Figure 17).

Figure 17 Installing the BIP in the rack

R

E

W

O

P

L

A

IC

IT

R

C

R

O

J

A

M

R

O

IN

M

10378FB

4 After the BIP is secured in the rack, go to the next section, “Connecting cables

to the chassis power supplies” on page 38.

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 38

38 Chapter 2 Installation

Connecting cables to the chassis power supplies

This section describes how to connect the BIP power cables to the 8010co chassis

8004DC power supplies. These procedures assume that all required power

supplies were previously installed during the 8010co chassis installation.

Note: This guide does not describe how to remove or replace power

supplies in the 8010co chassis. For detailed instructions about adding

power supplies or modifying an existing configuration, see the

appropriate product chassis installation manual.

Before beginning the procedures in this section, note the following:

• A 8010co chassis configuration can consist of one or two chassis in a single

rack. If a single chassis is installed, it is always installed in the lower shelf

position.

Note: For a single chassis installation, always install the chassis in the

lower shelf position to stabilize the rack.

312755-G Rev 00

• Each chassis can be configured with up to three power supplies. The cabling

for each power supply comprises three conductors: the positive lead wire, the

negative lead wire, and the ground lead.

• To access the power supplies, you may have to remove the bottom front bezel

from both the upper shelf and lower shelf 8010co chassis.

Warning: Ensure that the DC power source is off or disconnected at the

remote end before you perform any of the steps in this section. You may

need to switch a circuit breaker off or turn off power at the DC input

source. Be sure that the DC input source power is locked out and tagged.

Note: The 321325-A bezel does not need to be removed to access the

power supplies.

Page 39

Chapter 2 Installation 39

To connect cables to the chassis power supplies:

1 Remove the 8010co chassis bottom bezels (if required).

a Using a Phillips screwdriver, loosen the 2 captive screws securing the

bezel to the chassis (Figure 18).

b Pull the top of the bezel forward and then lift the 312096-A bezel from the

two tabs on the bottom of the chassis.

c Repeat steps a and b for the second chassis, if installed.

Figure 18 Removing the 8010co chassis bottom 312096-A bezel

il

a

F

s

s

a

l

i

a

F

s

s

a

P

P

Bottom bezel

10422FA

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 40

40 Chapter 2 Installation

2 Locate the power supplies (Figure 19).

With the bezel removed, you can see the power supplies. The chassis can

contain up to three power supplies. (Power supplies reside in bay 1, bay 2, and

bay 3, viewed left to right from the front of the chassis.)

Figure 19 Location of power supplies

Fail

Pass

Fail

Pass

312755-G Rev 00

1 = Power supply (bay 1)

2 = Power supply (bay 2)

3 = Power supply (bay 3)

C

D

+

C

C

D

+

C

C

D

+

C

-D

-D

-D

3

2

1

10423FA

Page 41

Chapter 2 Installation 41

3 Loosen the 2 retaining screws on the power supply located in bay 1 in the

lower chassis (Figure 20).

Figure 20 Loosening the power supply retaining screws

+DC

+DC

+DC

-DC

-DC

-DC

10424FA

4 Lift the extractor lever to disconnect the power supply from the backplane

connector, and then pull the power supply partially out of the chassis

(Figure 21).

Figure 21 Disconnecting the power supply from the chassis backplane

+DC

+DC

-DC

C

+D

C

-D

-DC

10425FA

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 42

42 Chapter 2 Installation

5 Remove the Phillips screw securing the plastic safety cover to the power

supply, and then remove the cover (Figure 22).

Save the Phillips screw and the cover for replacement later.

Figure 22 Removing the plastic safety cover from the power supply

+DC

-DC

10426FA

312755-G Rev 00

6 Note the position of the ground stud and of the positive and negative power

supply inputs (Figure 23).

Figure 23 Power supply input and ground stud location

1

+DC

-DC

1 = Ground stud

2 = Positive power inputs

3 = Negative power inputs

2

3

10427FA

Page 43

Chapter 2 Installation 43

7 Locate the following items in the shipping container (Figure 24).

• 125-inch power cables—for power supplies located in the lower chassis

• 90-inch power cables—for power supplies located in the upper chassis

• 90-inch ground cables—for grounding of power supplies located in the

upper and lower chassis

Figure 24 Power supply cables

1

2

3

1 = 125-inch power supply cables (x 6)

2 = 90-inch power supply cables (x 6)

3 = 90-inch power supply ground cables (x 6)

10428FC

8 Attach one end of a 90-inch ground cable to the grounding stud on the power

supply. Use a 7/16-inch hex wrench to fasten the hardware in the correct order

(Figure 25).

The hardware (washers and nuts) are included with the power supply

shipment.

Figure 25 Attaching the ground lead

1

2

3

4

5

1 = Grounding stud

2 = Flat washer

3 = Crimp lug

4 = Lock washer

5 = Hex nut

6 = Earth ground lead

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

+DC

-DC

6

10297FA

Page 44

44 Chapter 2 Installation

9 Attach the lug end of a 125-inch power supply cable to the positive terminal

on the power supply (Figure 26).

Use a 7/16-inch hex wrench to fasten the hardware in the correct order.

Figure 26 Attaching the positive lead

1

2

3

+DC

-DC

312755-G Rev 00

1 = Two-hole crimp lug

2 = Lock washer (x 2)

3 = Hex nut (x 2)

4 = Positive lead wire

4

10429FA

Page 45

Chapter 2 Installation 45

10 Attach the lug end of a 125-inch power supply cable to the negative terminal

on the power supply (Figure 27).

Use a 7/16-inch hex wrench to fasten the hardware in the correct order.

Figure 27 Attaching the negative lead

1

+DC

-DC

2

3

1 = Two-hole crimp lug

2 = Lock washer (x 2)

3 = Hex nut (x 2)

4 = Negative lead wire

4

10430FA

11 Replace the plastic safety cover on the power supply (Figure 28).

Figure 28 Replacing the plastic safety cover on the power supply

+DC

-DC

10431FA

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 46

46 Chapter 2 Installation

12 Secure the power supply in bay 1 of the lower chassis (Figure 29).

a Use the power supply handle to push the power supply firmly into bay 1.

b Push the extractor lever down to lock the power supply in place.

c Tighten the two power supply retaining screws.

Figure 29 Replacing the power supply

+DC

+DC

-DC

C

+D

C

-D

-DC

312755-G Rev 00

10432FB

13 Perform steps 3 through 12 for each power supply in the system configuration,

including the upper shelf chassis, if installed.

Use the shorter, 90-inch power cables for upper shelf power supplies.

14 After all power supplies are cabled, go to the next section,“Routing power

supply cables to the BIP” on page 47.

Page 47

Routing power supply cables to the BIP

After you connect all cables to the chassis power supplies, you must route the

power supply cable leads from each chassis to the BIP. If you installed an upper

and lower shelf chassis, and each chassis has three power supplies, you have 18

separate cables to route to the BIP. For this reason, Nortel recommends that you

label the cables and loosely bundle and fasten them with tie-wraps along the path.

To route the cables to the BIP:

1 Label the unconnected ends of the cable leads for each power supply

according to their destination on the BIP (Figure 30).

Figure 30 shows an example of one set of power supply cables for a power

supply that is located in bay 1 of the upper shelf chassis. The cables were

preassembled with the appropriate crimp lugs.

Be sure to label the cable leads appropriately for the power supplies in both

the upper and lower shelves.

Figure 30 Labeling cables for the BIP

Chapter 2 Installation 47

1

2

1 = BIP ground cable (x 1)

2 = Power supply ground cable (x 6)

Rack Ground

Gnd PS 1 Upper

2 Use tie-wraps or cable ties to loosely bundle the cable leads for each power

supply into a single manageable cable.

3 Route the bundled cables under each chassis to the back of the rack.

4 Separate the green (with yellow stripe) ground cable leads from the bundled

cables, and route them to the base of the rack.

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Bip Ground

Rack Ground

3

4

5

3 = Power supply negative lead cable (x 6)

4 = Power supply positive lead cable (x 6)

5 = Label tags (optional, use as required)

-DC PS 1 Upper

+DC PS 1 Upper

-DC PS 1 Upper

+DC PS 1 Upper

10411EB

Page 48

48 Chapter 2 Installation

5 Route the remaining (black) power supply cables from the back of the lower

and upper shelf chassis to the back panel of the BIP, loosely fastening them

with tie-wraps along the path.

6 Loosely support the power supply cables with tie-wraps above the BIP power

terminal block.

7 Proceed to, “Connecting the ground cables to the rack grounding strip.”

Connecting the ground cables to the rack grounding strip

To connect the power supply ground cables to the rack grounding strip:

1 Locate the rack grounding strip at the back base of the rack (Figure 31).

Note: Figure 31 shows an example of a rack grounding strip. Your rack

grounding strip can look different than the one shown in this example.

2 Attach the lug ends of the power supply ground cables to the rack grounding

strip (Figure 31).

312755-G Rev 00

Use a 7/16-inch hex wrench to fasten the hardware in the correct order.

Figure 31 Rack grounding strip example

1

2

3

4

1 = Hex head bolt

2 = Lock washer

3 = Ground crimp lug

4 = Rack grounding strip

10433FA

3 Proceed to “Connecting the power supply cables to the BIP” on page 49.

Page 49

Connecting the power supply cables to the BIP

To connect the power supply cables to the BIP:

1 Locate one of the power supply cables.

2 Match the labeled tag on the power supply cable with the correct location on

the power terminal block (Figure 32).

The power terminal block label indicates a location for the positive and

negative power supply leads for both the upper shelf and lower shelf power

supplies.

3 Loosen the appropriate power terminal block screw, and then insert the cable

lead (item 1 in Figure 32). Tighten the screw securely.

Item 2 in Figure 32 shows the negative cable lead from power supply 1 in the

upper shelf correctly connected to the power terminal block.

Figure 32 Attaching power supply cable leads to the BIP

Chapter 2 Installation 49

1

+DC PS1 Upper

32

1321 321321 A2A1B1B

PS (+)

PS (+)

Upper Shelf

A/B Input Feed

Lower Shelf

3

1 = Positive lead wire from power

supply 1, upper shelf

2 = Negative lead wire from power

supply 1, upper shelf

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

2

-DC PS1 Upper

PS (-)

PS (-)

Returns

Lower Shelf

Upper Shelf

– 48 VDC

A/B Input Feeds

3 = Power terminal block label

2

10393FA

Page 50

50 Chapter 2 Installation

4 Repeat steps 1 through 3 for each remaining power supply in your

configuration (Figure 33).

Figure 33 Upper and lower shelf power cables connected to the BIP

1

2

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

1 = Positive lead wires

(lower shelf power supplies)

2 = Positive lead wires

(upper shelf power supplies)

5 Locate the BIP ground cable (see Figure 30 on page 47).

3

4

PS (-)

A/B Input Feed

Returns

Lower Shelf

PS (-)

Upper Shelf

A/B Input Feeds

3 = Negative lead wires

(lower shelf power supplies)

4 = Negative lead wires

(upper shelf power supplies)

2

– 48 VDC

10394FA

312755-G Rev 00

Page 51

6 Attach one end of the BIP ground cable to the power terminal block

(Figure 34).

a Loosen the power terminal block screw just enough to insert the ground

cable lead (item 1 in Figure 34).

b Insert the lead and tighten the screw securely.

Figure 34 Attaching the BIP ground cable

Chapter 2 Installation 51

1

+DC PS1 Upper

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

3

1 = Positive lead wire from power

supply 1, upper shelf

7 Route the other end of the BIP ground cable to the rack grounding strip near

the base of the rack (see Figure 31 on page 48).

Use a 7/16-inch hex wrench to fasten the hardware in the correct order.

8 Go to the next section, “Connecting DC input power feeds to the BIP” on

page 52.

2

PS (-)

A/B Input Feed

Returns

Lower Shelf

PS (-)

Upper Shelf

3 = Power terminal block label

-DC PS1 Upper

– 48 VDC

A/B Input Feeds

2

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 52

52 Chapter 2 Installation

Connecting DC input power feeds to the BIP

Danger: Due to high-energy hazards, only qualified service personnel

are permitted to connect the BIP to the DC power source.

Warning: Ensure that the DC power source is off or disconnected on the

remote end before you perform any of the steps in this section. You may

need to switch a circuit breaker off or turn off power at the DC input

source.

Nortel does not supply the cables for connecting the breaker interface panel to the

DC input power source. You must select cables that comply with the electrical

code of the country where you intend to use the DC-DC power supply.

Caution: As the installer, you have the sole responsibility for ensuring

that the connection cable used with the breaker interface panel is

appropriate for use with the DC power source to which the power supply

is connected. Consider gauge, flammability, and mechanical

serviceability when determining which cables to use.

312755-G Rev 00

You can connect up to two “A” feeds and two “B” feeds to your 8010co chassis

configuration for redundancy. Each chassis can require up to 60 A service for

maximum operating power.

As shown in Figure 35 on page 53, the primary B feed (B

1

for the primary A feed (A

for the secondary A feed (A

), and the secondary B feed (B2) provides redundancy

2

).

1

) provides redundancy

Note: An optional third power supply in the chassis provides redundancy

and high-availability operation. In the same way, the BIP provides

redundancy and high-availability operation by allowing two additional

“B” feeds to provide redundancy for single or dual chassis installations.

Page 53

Figure 35 A and B feed example

Chapter 2 Installation 53

BIP

Upper shelf chassis

60 A

60 A

60 A

60 A

A

2

B

1

A

1

B

= A feeds

30 A

30 A

30 A

30 A

30 A

30 A

30 A

PS1

30 A

PS2 PS3

Lower shelf chassis

30 A

PS1

30 A

PS2 PS3

= Redundant power supply

2

= B feeds

= Redundant feed

10400EC

Tabl e 3 lists input power options for single and dual chassis installations.

Table 3 Single chassis and dual chassis input options

Single chassis input

Non-redundant input power A

Redundant input power A1 and B

* For a single chassis installation, always install the chassis in the lower shelf position to stabilize

the rack.

1

1

*

Dual chassis input

A1 and A

2

A1 and B1, A2 and B

2

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

Page 54

54 Chapter 2 Installation

To connect the DC input feeds to the BIP:

1 Locate the DC power source for the DC input feed.

Warning: Ensure that the DC power source is off or disconnected on the

remote end before you perform any of the steps in this section. You may

need to switch a circuit breaker off or turn off power at the DC input

source.

2 Determine the power requirements for your configuration (see Figure 35 on

page 53).

3 Locate the A and B -48 VDC input feeds (Figure 36).

Note: Figure 36 shows an example of a site DC input conduit. Your DC

input conduit can look different or can be in a different location than the

one shown in the following examples.

The -48 VDC input feed cables should be tagged with source labels (for

example, -48 VDC Input feed or -48 VDC Return). If they are not labeled, and

you are not sure of the source, ask for assistance from a qualified electrician.

312755-G Rev 00

Figure 36 Locating the A and B -48 VDC input feeds

-48 VDC Feeds

-48VDC A feed 1

Return A feed 1

-48VDC A feed 2

Return A feed 2

-48VDC B feed 1

Return B feed 1

-48VDC B feed 2

Return B feed 2

10401EA

Page 55

Chapter 2 Installation 55

4 Connect the -48 VDC input feeds according to your configuration

requirements.

a Match the tagged -48 VDC input feed cable lead with the correct power

terminal block on the back of the BIP (Figure 37).

a Loosen the power terminal block screw just enough to insert the cable

lead (item 1 in Figure 37).

b Insert the lead and tighten the screw securely.

Figure 37 Connecting the A and B -48 VDC input feeds to the BIP (1 of 2)

-48 VDC Feeds

1

32

1321 321321 A2A1B1B

PS (+)

PS (+)

Upper Shelf

A/B Input Feed

Returns

Lower Shelf

1 = -48 VDC input feed (Primary A feed)

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

PS (-)

Lower Shelf

PS (-)

Upper Shelf

-48 VDC A feed 1

– 48 VDC

A/B Input Feeds

2

10406FA

Page 56

56 Chapter 2 Installation

5 Connect the remaining -48 VDC input feeds and returns as required

(Figure 38).

Note: Figure 38 shows the attachment of two “A” feeds and two “B”

feeds to the BIP. Note that there is a primary and a secondary A feed, as

well as a primary and secondary B feed (see Figure 35 on page 53 for

configuration details).

Figure 38 Connecting the A and B -48 VDC input feeds to the BIP (2 of 2)

-48 VDC Feeds

1

– 48 VDC

A/B Input Feeds

2

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

PS (-)

Upper Shelf

1 = -48 VDC input feeds (Primary A, Secondary A, Primary B, Secondary B)

312755-G Rev 00

10407FA

Page 57

6 Connect the A/B input feed returns.

Note: The total number (quantity) of Input feed return cable leads must

match the total number of Input feeds used for your installation.

a Locate the A/B Input Feed Returns section of the power terminal block.

b Loosen one of the four available A/B input feed return connection screws

just enough to insert the cable lead (item 1 in Figure 39).

You can use any of the four available input feed return connections.

c Insert the lead and tighten the screw securely.

Figure 39 Connecting the A/B input feed returns (1 of 2)

-48 VDC Feeds

Chapter 2 Installation 57

1

Return A feed 1

2

– 48 VDC

A/B Input Feeds

2

32

1321 321321 A2A1B1B

PS (+)

Lower Shelf

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

PS (-)

Upper Shelf

1 = -48 VDC input feed Return (Primary A feed Return)

2 = -48 VDC input feeds (Primary A, Secondary A, Primary B, Secondary B)

Installing the Breaker Interface Panel for the Ethernet Routing Switch 8010co Chassis

10408FA

Page 58

58 Chapter 2 Installation

7 Connect the remaining -48 VDC input returns as required (Figure 40).

Figure 40 shows the BIP with all power cables and returns installed.

Note: Be sure to properly support the cables with cable ties to avoid

undue stress to the power terminal block.

Figure 40 Connecting the A/B input feed returns (2 of 2)

-48 VDC Feeds

32

PS (+)

Lower Shelf

312755-G Rev 00

– 48 VDC

A/B Input Feeds

2

1321 321321 A2A1B1B

PS (+)

Upper Shelf

A/B Input Feed

Returns

PS (-)

Lower Shelf

PS (-)

Upper Shelf

8 Go to the next section, “Replacing covers” on page 59.

10409FA

Page 59

Replacing covers

After you complete all of the cabling requirements as described in the previous

sections, you must replace the plastic back cover on the BIP and the 8010co

chassis bezel(s) that were removed earlier in these procedures.

Before you replace the covers and bezels, be sure that all cables are routed

properly from under the chassis bays, through the rack, and up to the BIP power

terminal block. Check that all tie-wraps are secured, and give special attention to

the cables at the power terminal strip; the cable leads must be supported to avoid

undue stress on the terminal block.

1 Replace the plastic back cover on the BIP (Figure 41).

Figure 41 Replacing the plastic back cover on the BIP