Nortec SynPur User Manual

Installation, Operating and Maintenance

Instructions

Conductivity Synthesizer

Model SynPur

Type LS 400

LS3400

LS3402

A WMH company

Table of Contents - Conductivity Synthesizer

1. Introduction ................................................................................................................................. 3

1.1 First Things First! ........................................................................................................................ 3

1.2 About this Technical Document .................................................................................................. 3

2. For Your Safety ........................................................................................................................... 5

2.1 Agreement on Appropriate Use .................................................................................................. 5

2.2 General Safety Information ......................................................................................................... 5

3. Product Overview ....................................................................................................................... 6

3.1 System variants .......................................................................................................................... 6

3.1.1 Basic System A ........................................................................................................................... 8

3.1.2 Basic System B ........................................................................................................................... 8

3.1.3 Conductivity Synthesizer with existing full deionization stage .................................................... 9

3.2 System description ................................................................................................................... 10

3.2.1 Functional description of the mounting rail ............................................................................... 11

3.2.2 Functional description of the SynPur ........................................................................................ 11

3.2.2.1 Display Symbols ....................................................................................................................... 14

3.3 Functional description of the Synthesizer cartridge .................................................................. 16

3.4 Functional description of the additive ....................................................................................... 17

4. Installation ................................................................................................................................. 18

4.1 Safety information concerning installation ................................................................................ 18

4.2 General placement and assembly information ......................................................................... 18

4.2.1 Support console SynPur ........................................................................................................... 19

4.2.2 Mounting rail ............................................................................................................................. 19

4.2.3 CO2 bottle .................................................................................................................................. 20

4.3 Electrical installation ................................................................................................................. 21

4.3.1 SynPur ...................................................................................................................................... 21

4.3.1.1 Linking of fault and service outputs .......................................................................................... 22

4.3.1.2 Linking to the HPS .................................................................................................................... 22

4.3.1.3 Linking to the remote fault reporting system............................................................................. 23

4.4 Material specification ................................................................................................................ 24

4.4.1 Electrical components ............................................................................................................... 24

4.4.2 Additive ..................................................................................................................................... 24

4.4.3 Pressure reducer ...................................................................................................................... 24

5. Operation .................................................................................................................................. 25

5.1 Start-up in daily operations ....................................................................................................... 25

5.2 Shutdown in daily operations .................................................................................................... 26

5.3 Checks/regular service ............................................................................................................. 27

6. Replacing components ............................................................................................................. 29

6.1 SynPur ...................................................................................................................................... 30

6.2 Synthesizer cartridge ................................................................................................................ 32

6.3 CO2 Bottle ................................................................................................................................. 33

7. Technical Data .......................................................................................................................... 34

7.1 Conductivity synthesizer SynPur .............................................................................................. 34

7.2 Synthesizing stage .................................................................................................................... 34

7.3 CO2 bottle ................................................................................................................................. 34

7.3.1.1 Gas ........................................................................................................................................... 34

7.3.1.2 Pressure reducer ...................................................................................................................... 34

8. Appendix ................................................................................................................................... 35

8.1 Spare parts ............................................................................................................................... 35

8.2 Replacement parts .................................................................................................................... 35

8.3 Accessories .............................................................................................................................. 35

8.4 Fresenius Test Certificate ......................................................................................................... 36

8.5 Statement of Conformity ........................................................................................................... 37

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 2 of 37

1. Introduction

1.1 First Things First!

Thank you for choosing the DRAABE SynPur.

The SynPur was designed in accordance with the latest level of technology and

generally accepted safety standards and regulations. Nevertheless, inappropriate

use of the system can result in the risk of injury to the user and/or others, as well

as damage to property and equipment.

Therefore, to ensure safe, appropriate, and economical operation of the system, all

of the information and particularly the safety-related information in this document

should be noted and followed.

For questions that are not addressed or not adequately answered in this document,

please contact your local NORTEC representative or our service +1 613 822 0335.

Our specialists will be happy to assist you.

1.2 About this Technical Document

Limitations

The subject of this Technical Document is the DRAABE SynPur. The system

components (e.g. SynPur, mounting rail, etc.) are described only to the extent

necessary for proper operation. Since the system offers various upgrading options,

this document relates to the basic system. Depending on the application and

specified capacity, various system components are available. Because the system

serves as the preliminary stage for a DRAABE air humidification system, a higher

humidification capacity has a direct influence on the different parts of the system

described in this document. Some accessories are not absolutely essential; others

are part of the standard configuration. For additional information on accessories

and or individualized solutions, please refer to the customer-specific diagram or

contact NORTEC.

The information in this Technical Document is limited to the:

- Installation, initial startup, operation, and maintenance of the SynPur.

The Technical Document is supplemented by various separate documents (order

forms, diagrams, etc.). Where applicable, cross-references to these publications

are contained in the Technical Document.

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 3 of 37

!

Agreement

This symbol identifies Safety and Hazard Information that could lead to personal

injury and/or property damage if it is ignored. Safety and Hazard Information is also

identified by the term ATTENTION.

This symbol identifies important information. This information is also identified by

the term IMPORTANT.

This symbol is found on the nameplates of all devices. It is intended to remind you

to read the Technical Document before handling any of the equipment. If anything

is still unclear after reading the document, please contact the Technical Customer

Support department of the manufacturer before handling the equipment in any

way.

Definitions

Untreated water:

Drinking water or tap water.

RO water:

Reverse osmosis water (or pure water) is water that has been partially

demineralized in the pure water system RO water is also necessary as a

preliminary stage for the smooth operation of the SynPur.

DI water:

Fully deionized water contains no minerals. In plants that produce deionized water,

this water can be connected to the SynPur.

DM water:

In the Synthesizer cartridge the last minerals are extracted from the RO water. This

demineralized water is conditioned in the SynPur with an additive and is suitable

for the humidification of „clean rooms,“ etc.

Additive:

The additive is a gas (carbon dioxide) used to condition the DM water to enable

humidification with DM water.

Synthesizer cartridge:

The Synthesizer cartridge contains a resin solution formulated especially for

DRAABE for the production of DM water.

Document Storage

Please keep this Technical Document readily accessible in a safe place. If the

document is ever lost, please contact NORTEC.

Languages

This Technical Document is available multiple languages. Please contact NORTEC

with related questions.

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 4 of 37

2. For Your Safety

2.1 Agreement on Appropriate Use

The SynPur is intended for use exclusively as a preliminary stage for DRAABE

air humidification systems within the specified operating conditions in non-

potentially explosive environments. It is used to condition the feed water (RO or DI

water) and deliver a product that is processed further by the downstream air

humidification system. Any other use is considered inappropriate and can result in

the system becoming a hazard.

The proper use of the system includes compliance with all of the information

contained in these instructions (particularly the safety information) and strict

adherence to the specified operating conditions.

2.2 General Safety Information

- Only persons who are familiar with the product and are adequately trained

for the respective work should install and operate the SynPur. The customer is

responsible for ensuring that the technical documentation is supplemented by

internal company instructions regarding supervisory and reporting obligations,

work organization, employee qualification, etc.

- Before beginning work on components of the SynPur, the system should be

shut down properly according to Chapter 5.2 and secured against accidental

restart (controller off, water supply closed, and system depressurized).

- Compliance is required with all local safety regulations concerning:

- The use of mains-supplied electrical and electronic equipment.

- The design of water and high-pressure systems.

- All safety regulations concerning the use of pressurized gas containers,

especially those filled with carbon dioxide (CO2), should be obeyed.

- Inadequately maintained air humidification systems can pose a health hazard.

Because this system is used as a preliminary stage in an air humidification

system, the following rule applies equally to it: maintenance activities must

be performed properly in the specified intervals.

- If it can be assumed that a non-hazardous operation is no longer possible,

the SynPur must be shut down immediately and secured against

accidental restart and NORTEC should be notified. Circumstances in which

this could be the case include the following:

- Components of the system are damaged.

- The system is no longer functioning properly.

- Connections or lines are not leak-tight.

- To avoid water damage, materials that are sensitive to water should not be

stored directly under the SynPur.

- Aside from the activities described in these instructions, no other interventions

are permitted on the Conductivity Synthesizer.

- Only original accessories and replacement parts from NORTEC should be

used.

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 5 of 37

- Changes to the Conductivity Synthesizer are prohibited without written

approval from NORTEC.

- After changes are made to the system, NORTEC Customer Service or agents

authorized by NORTEC should perform an acceptance inspection before the

initial startup.

3. Product Overview

3.1 System variants

The Conductivity Synthesizer system is very flexible. The customer-specific

systems are oriented on the humidification demand of the downstream air

humidification system. Parts of the system depend on the performance data of the

upstream water purification system. Essentially, a distinction is made between

Basic System A, Basic System B, and the Conductivity Synthesizer in use with an

already existing deionization stage. All variants discussed below have a maximum

conditioning capacity of 400 kg/h.

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 6 of 37

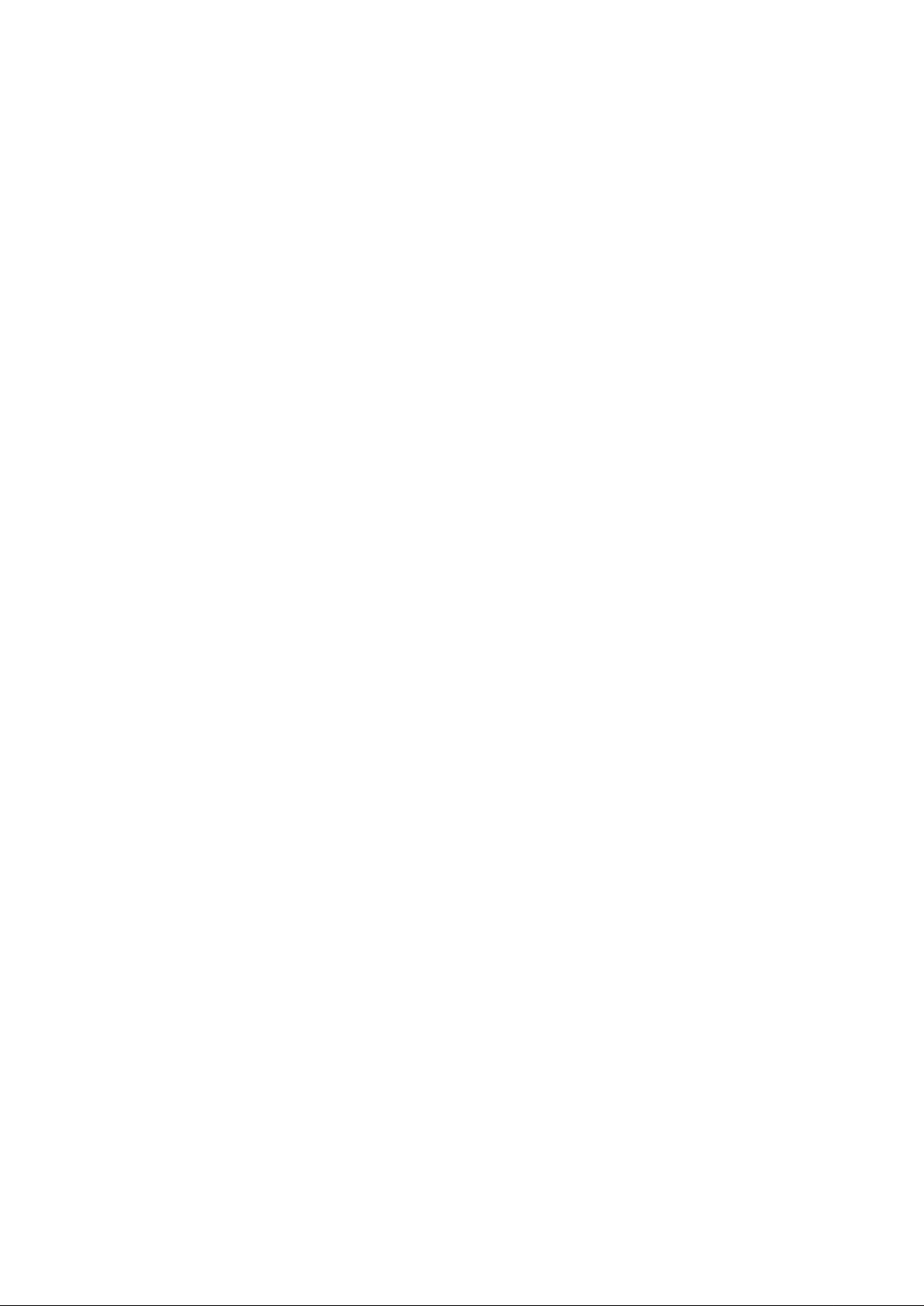

Inlet water

(raw water)

Water softener

Rinsing

120 V ~

Drain

Remote fault telemetrie

Pure Water System (PerPur)

120 V ~

Installation rail CSF

Product

HPS3202

230 V

HPS3208

208V

3~

3~

High Pressure System (HighPur)

Synthesis

cartridge

Additiv

Installation rail LS

TF 4 TF 4 TF 8.1 TF 8.1 TF 8.1

Remote fault unit

Groupe controller Unilog

Conductivity Synthesizer

GLT

120V ~

120 V ~

1

1

Potential free contact

Maintenance

Potential free contact

mal function

2

Remote fault telemetrie

HPS

2x potential free contacts

2

Figure 1: Complete air humidification system

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 7 of 37

bar

b

a

r

b

a

r

b

a

r

IN OUT

Patentierte

Reinraum-Befe uchtung

Prozessorge steuerte

Demineralisi erung

Automatisiert e

Hygienefunk tionen

ModemSchnittstelle

Ausbeute 10 0%

Anbindung

Gebäudetec hnik

Ein/Aus

Produkt

Gas

Synthese wasser

Synthese -

patrone

Reinwasse r

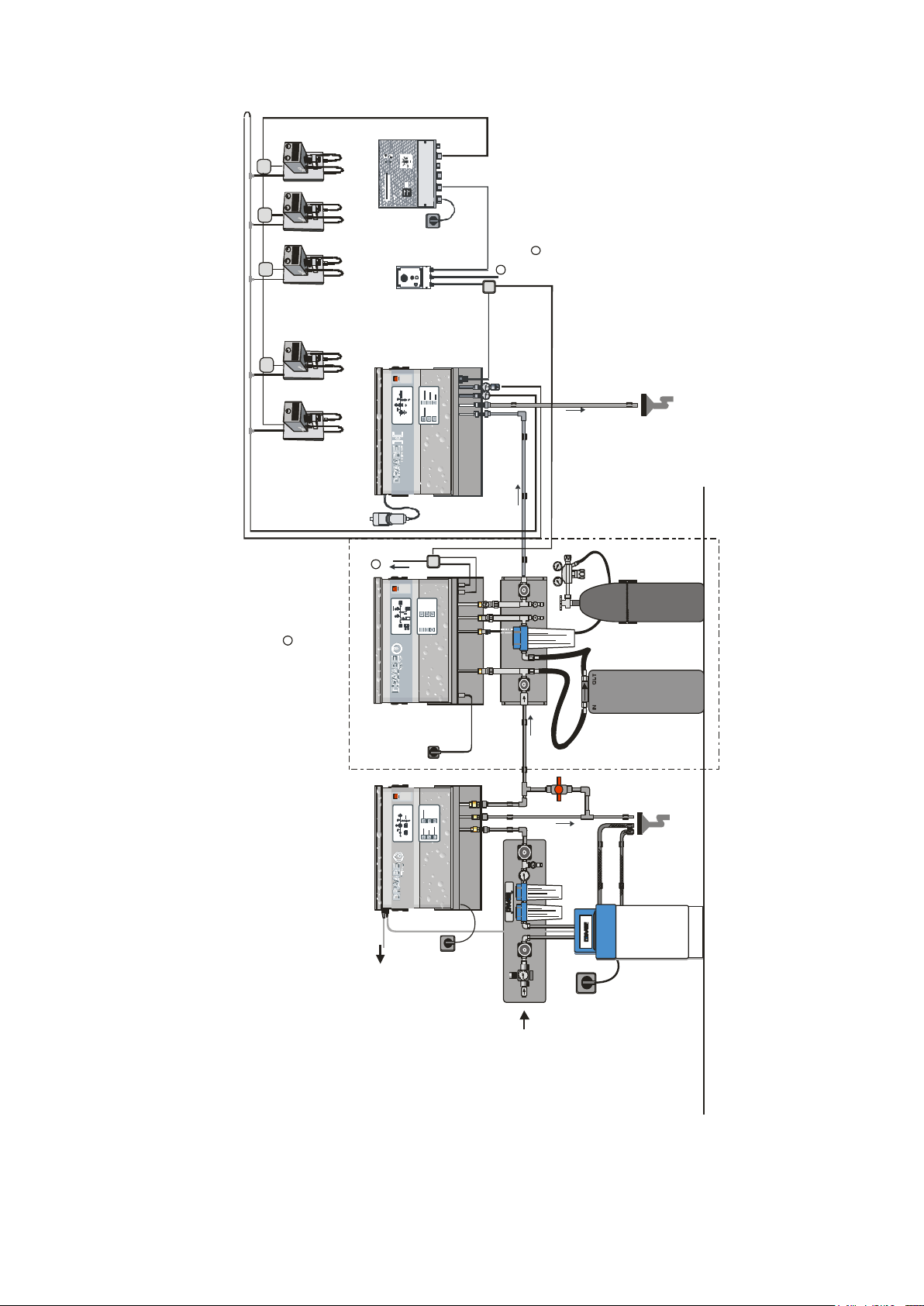

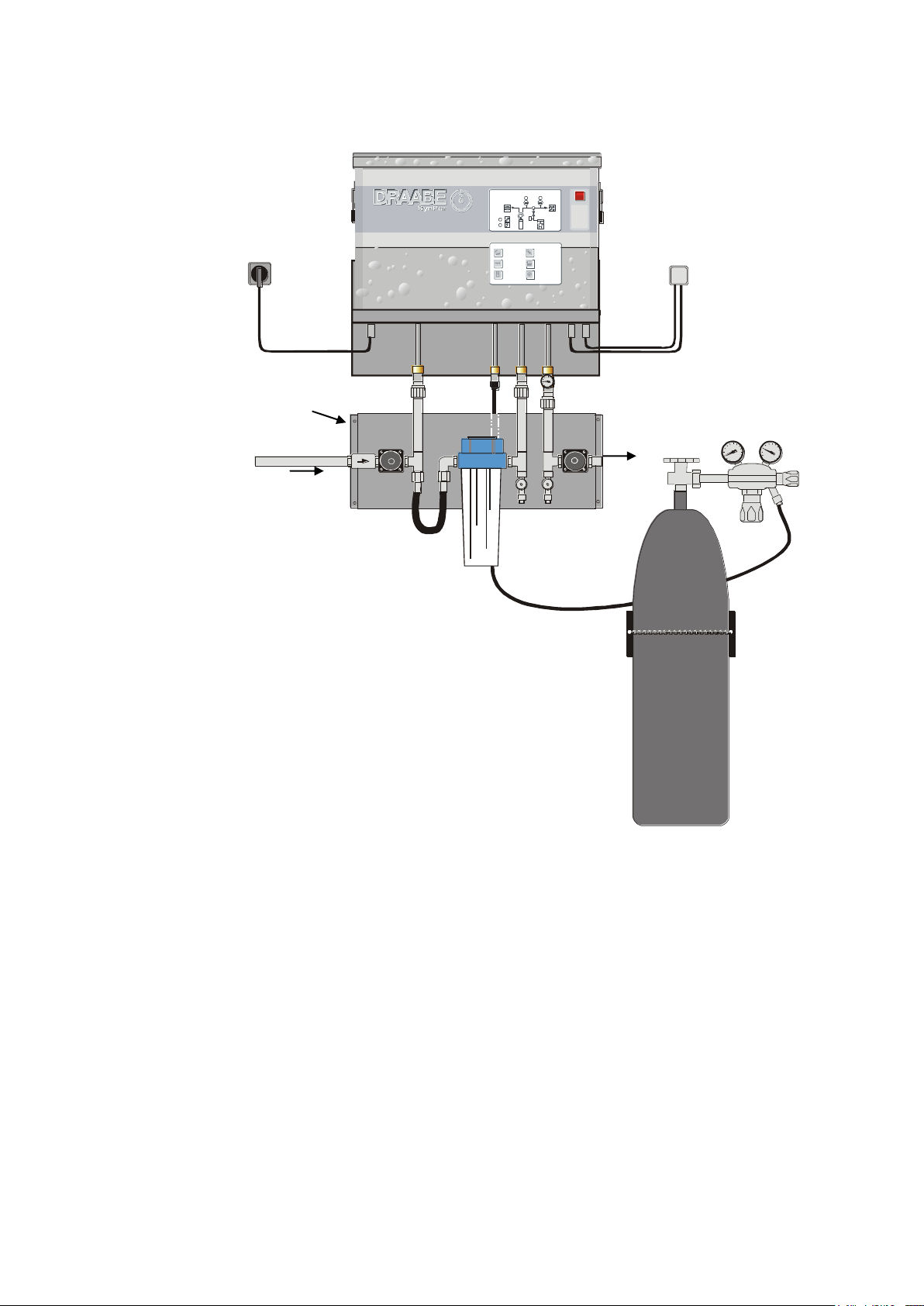

3.1.1 Basic System A

The Basic System A consists of a mounting rail, an SynPur, a Synthesizer

cartridge, and the additive. Basic System A is shown in the figure below.

Mounting rail

Product

Infeed

Synthesizing stage Additive

Figure 2: Basic System A

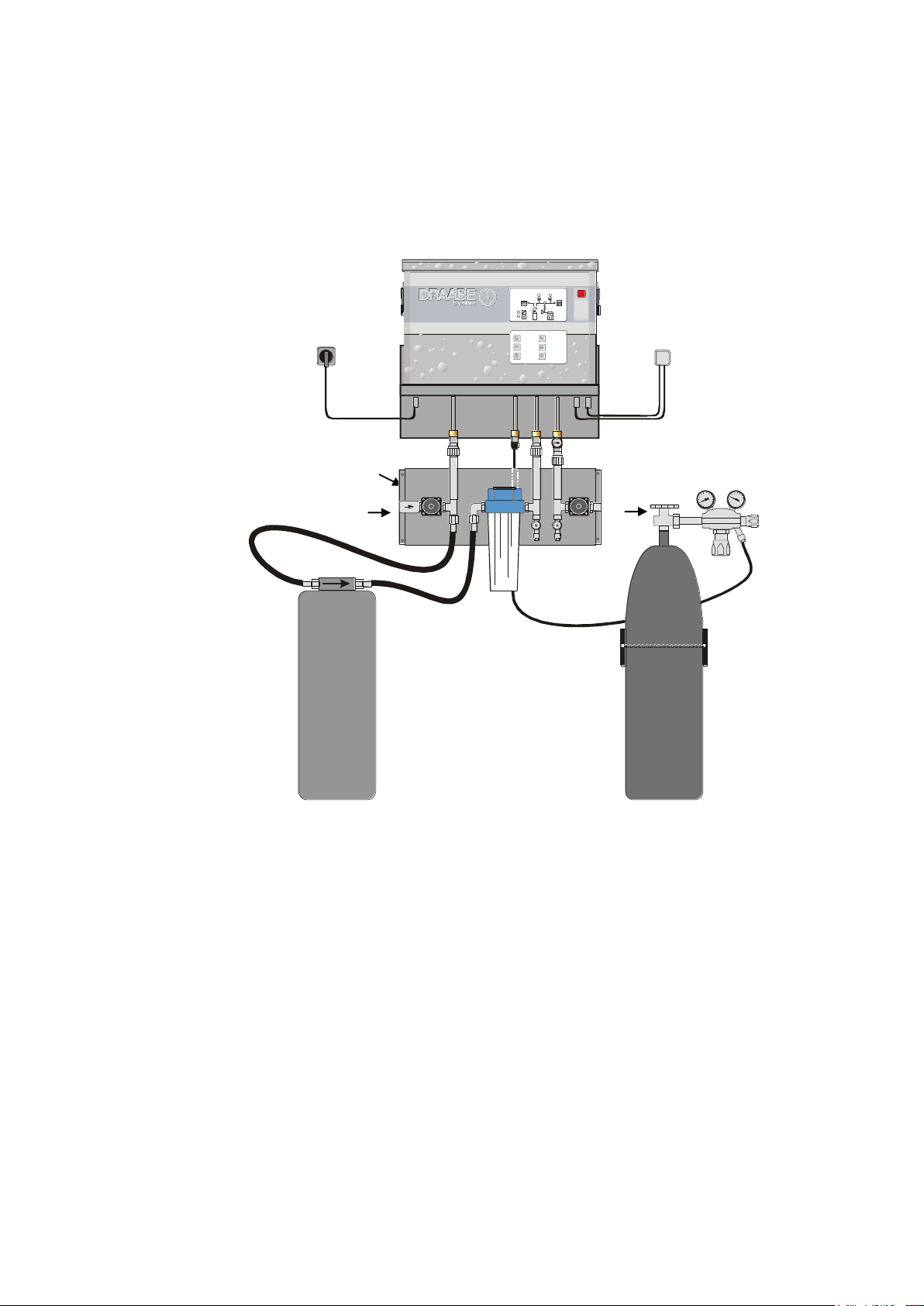

3.1.2 Basic System B

The Basic System B consists of a mounting rail, an SynPur, two to four synthesizer

cartridges, and the additive. Basic System B is shown in the figure below. The

higher the humidification demand, the faster the resins in the synthesizer cartridges

are depleted. To extend the replacement intervals, up to four cartridges can be

connected in sequence. As shown in the figure, the mounting rail is connected to

the inlet of the first cartridge. The outlet of the first cartridge is connected to the

inlet of the second cartridge, etc. The outlet of the last cartridge is connected again

to the mounting rail.

SynPur

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 8 of 37

bar

b

a

r

b

a

r

b

a

r

IN OUT IN OUT

Patentierte

Reinraum-Befeuchtung

Prozessorgesteuerte

Demineralisierung

Automatisierte

Hygienefunktionen

ModemSchnittstelle

Ausbeute 100%

Anbindung

Gebäudetechnik

Ein/Aus

Produkt

Gas

Synthesewasser

Synthesepatrone

Reinwasser

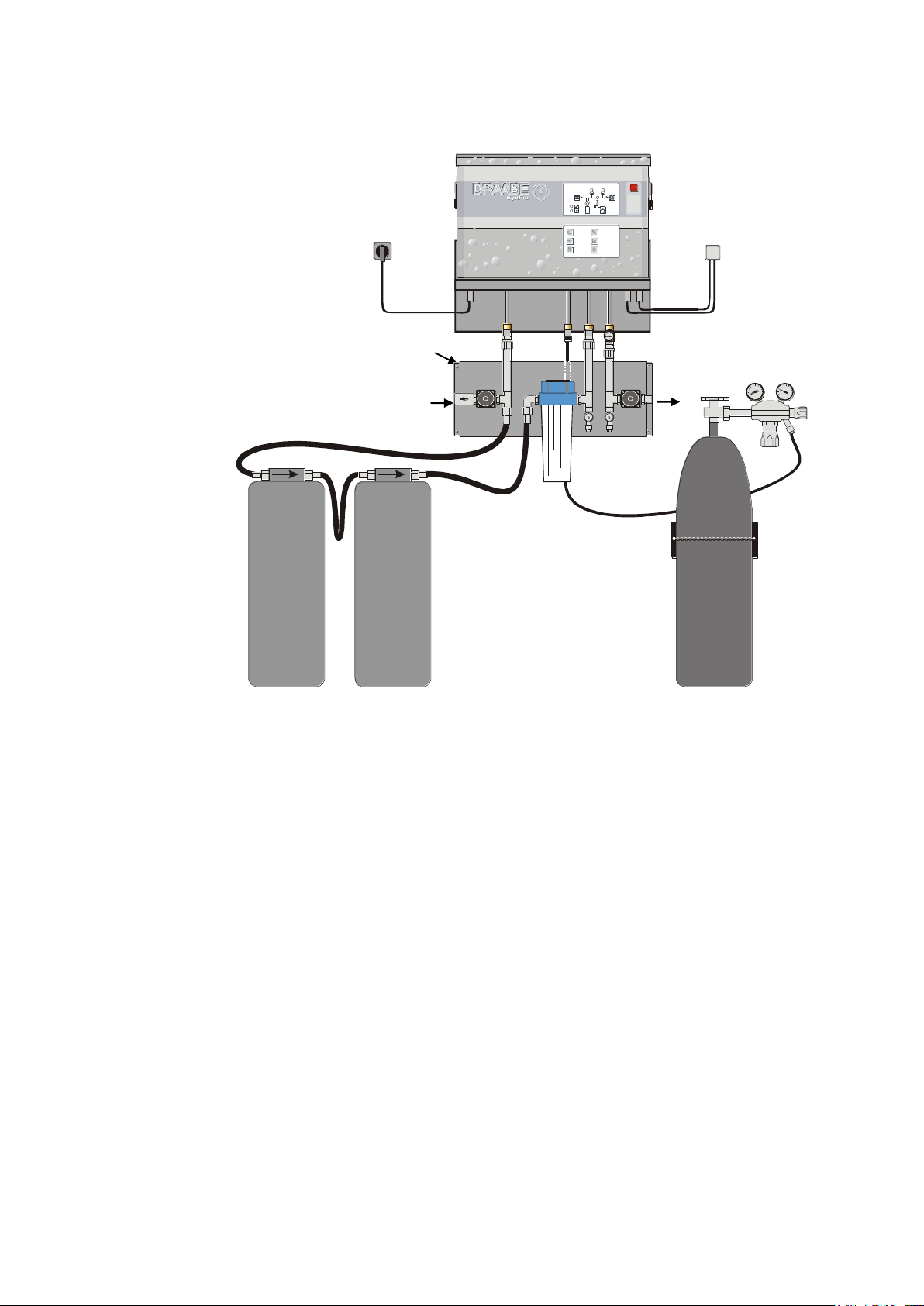

3.1.3 Conductivity Synthesizer with existing full deionization stage

SynPur

Mounting rail

Product

Infeed

Synthesizing stages Additive

Figure 3: Basic System B with two synthesizing stages

If a full deionization stage already exists in a plant for generating fully deionized

water (DI water), the DI water can be connected directly to the mounting rail. The

synthesizer cartridges are not required in this case. This system consists of a

mounting rail, an SynPur, and the additive. The connection to the synthesizer

cartridge should be jumpered on the mounting rail (see Figure 3).

Requirements of the DI water:

- Conductivity < 0.1µS

- Constant flow pressure of 2-3 bar (29-43.5 psi)

- Freedom from organic components (< 100 KBE)

Deionized water in untreated form is not suitable for use in a single-component air

humidification system. The SynPur conditions the DI water in such a way that it can

be used without reservation.

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 9 of 37

bar

b

a

r

b

a

r

b

a

r

Patentierte

Reinraum-Befeuchtung

Prozessorgesteuerte

Demineralisierung

Automatisierte

Hygienefunktionen

ModemSchnittstelle

Ausbeute 100%

Anbindung

Gebäudetechnik

Ein/Aus

Produkt

Gas

Synthese-

wasser

Synthesepatrone

Reinwasser

SynPur

Mounting rail

DI water Product

Additive

Figure 4: Conductivity Synthesizer with existing DI stage

3.2 System description

The DRAABE Conductivity Synthesizer is a compact conditioning unit that provides

maximum convenience and economic efficiency. It regulates the aqueous

properties of the product. The infeed water for the downstream air humidification

system represents the product. With the DRAABE single-component nozzle

systems (such as the TurboFog system) this water is brought to an operating

pressure of 85 bar (1232 psi) by means of high-pressure pulsation. At this

pressure, special jets deliver the water into the air in the room. The humidity in the

room is increased.

Consisting of the components synthesizing stage, additive, mounting rail, and the

SynPur, the system is connected between the water purification system and the

high-pressure pulsation system (HPS).

The basic design of the system is shown in the figure (see Sections 3.1.1 and

3.1.3).

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 10 of 37

1

2 3

4 5 6 2

7 98 10

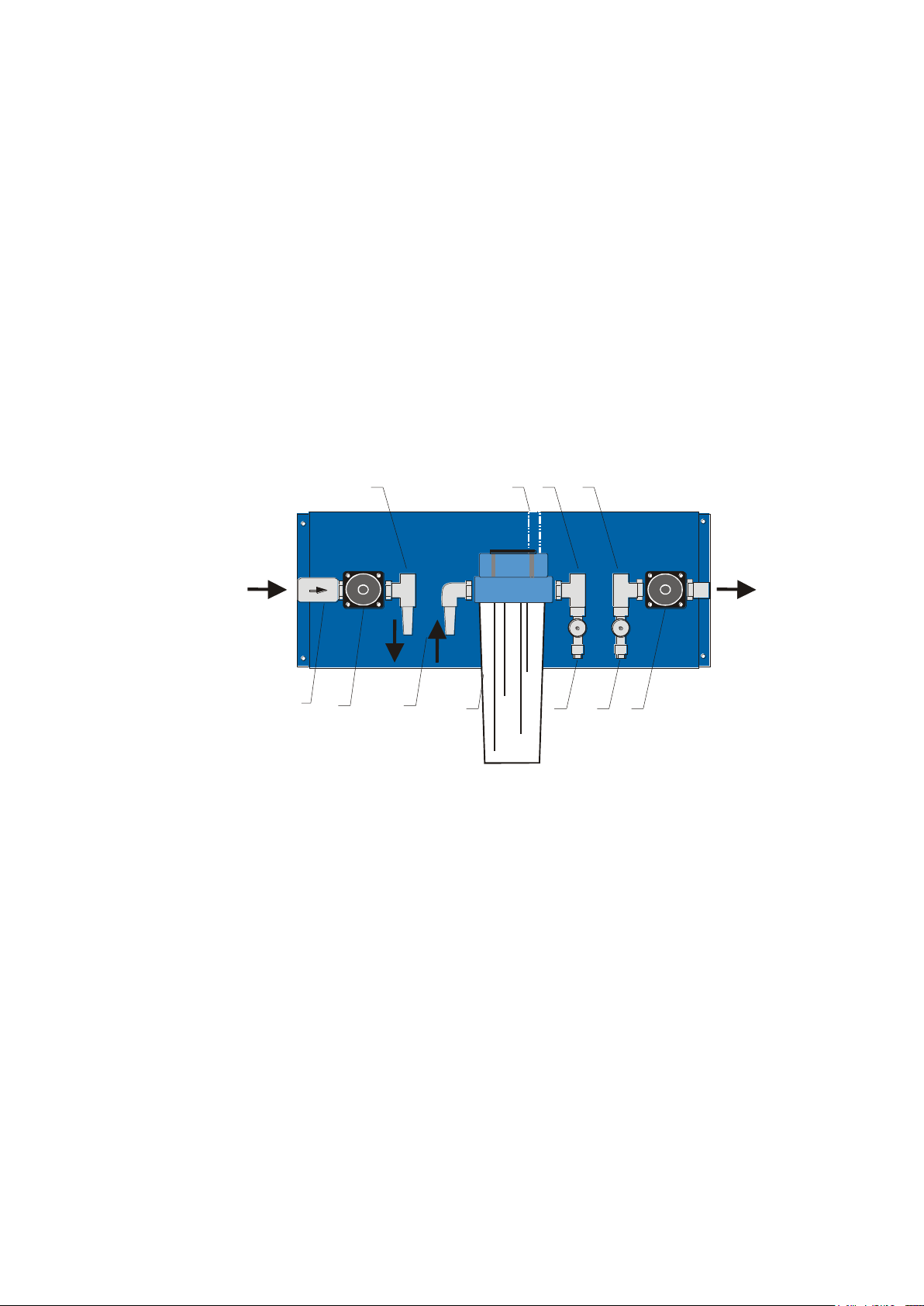

3.2.1 Functional description of the mounting rail

The mounting rail forms the interface between the water purification system, the

Conductivity Synthesizer, and the high-pressure pulsation system (HPS). A check

valve (1) prevents backflow of the conditioned water.

The synthesizer cartridge is connected to the mounting rail with quick couplings

(3). The shut-off valves (2) enable quick replacement of the cartridge or the filter

(e.g. during maintenance activities). From the support console, the circulation of

the Conductivity Synthesizer is connected from above (7).

A filter (4) protects the downstream Conductivity Synthesizer from possible

impurities in the water. After the filtration the DI water is connected to the

Conductivity Synthesizer (9) and the product is returned to the mounting rail (10).

The DI water (5) and the product (6) can be sampled at any time over the sampling

taps (5/6).

Infeed Product

Filter 20µ

Figure 5: Mounting rail

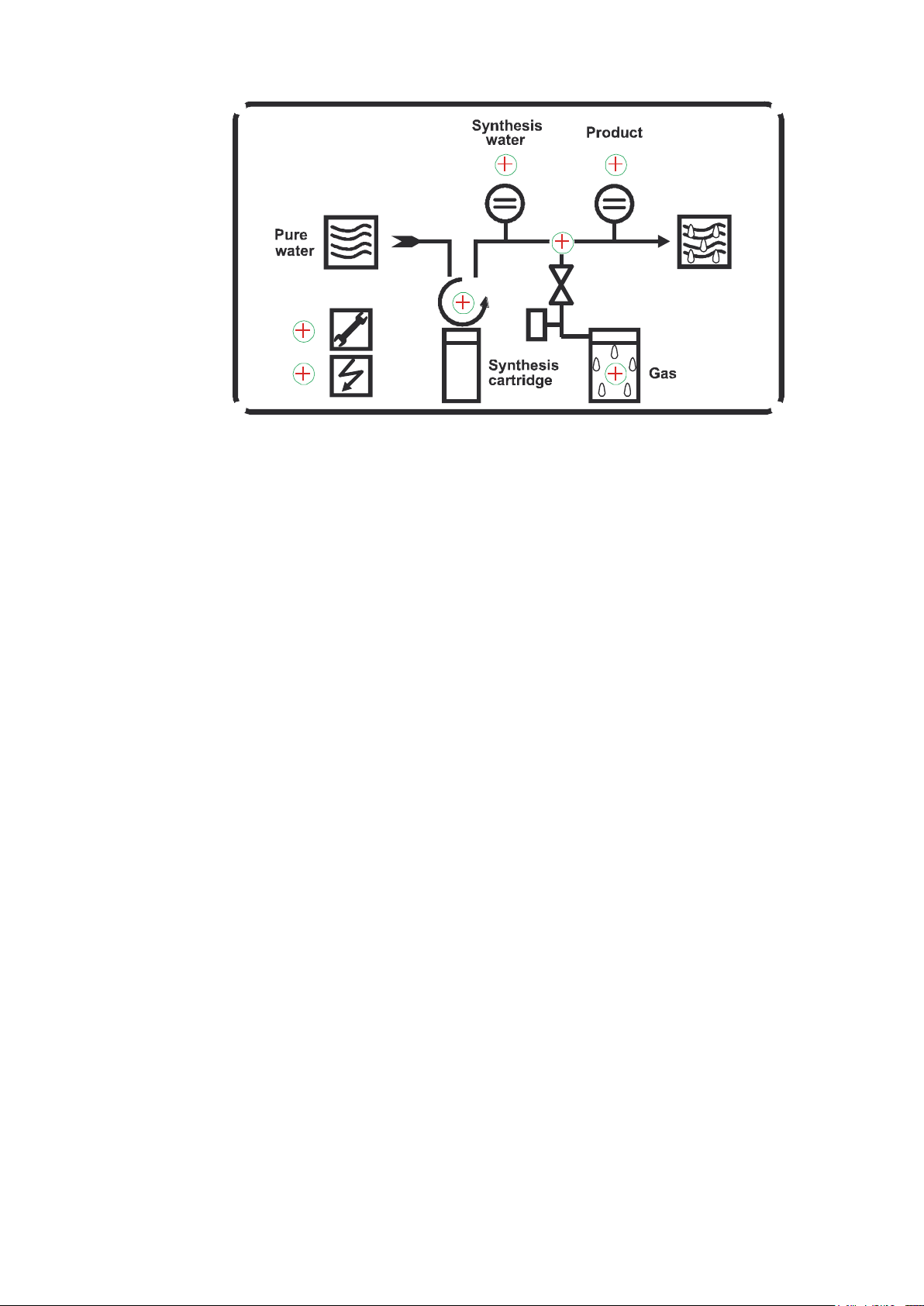

3.2.2 Functional description of the SynPur

In certain environments (e.g. „clean rooms“, ESD-protected areas, etc.), the water

to be atomized must be free of minerals (DI water = fully demineralized water). The

SynPur has the task of removing all of the minerals from the already purified water

in order to introduce minimum quantities of CO2. The product is a specially treated

(conditioned) water that is fed to the HPS to be atomized.

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 11 of 37

All internal processes of the SynPur are managed by a programmable logic

controller (PLC).

The function of the SynPur is explained below. The display shows the functional

status based on a stylized flow diagram and LED’s. A detailed description of the

display is found in Section 4.3.3.

Figure 6: Display of the SynPur

The SynPur is ready for operation when the supply voltage and the water supply

(with adequate water pressure) and the additive (with adequate gas pressure) are

connected. In addition, the lighted mains switch indicates that the device is turned

on.

The infeed pressure switch monitors the pressure of the water supply and shuts

the system off if the water supply malfunctions. In this case, the red LED „Fault“

lights up on the display.

Another pressure switch monitors the gas inflow. The LED „Additive“ lights up on

the display when gas is present. If the gas supply malfunctions the pressure switch

shuts the system off and the red LED „Fault“ lights up on the display. At the same

time, the LED „Additive“ turns off. Operation can be resumed after the bottle has

been replaced (for more information on replacing the bottle, see Section 6.3).

Because the resins in the synthesizer cartridges are depleted during the process of

extracting the minerals, the SynPur continuously monitors the quality of the

demineralized water. When a first threshold value is reached, the SynPur outputs a

service message indicating that the synthesizer cartridge should be replaced soon.

When the second threshold value is reached, the SynPur outputs a fault message

and the system– and therefore also the entire downstream air humidification

system – is shut off. To resume operation the synthesizer cartridge must be

replaced at this point (for more information on replacing the cartridge, see Section

6.2).

If there is no demand for humidification for an extended period, no product can be

accepted. In this case, there is a danger of germination during downtime. To avoid

this, the system should be equipped with extensive hygiene functions. The

DRAABE BioSafe System ensures a hygienically unobjectionable operation. The

SynPur directs the water cyclically from the synthesizer cartridge over a bioreactor

that disinfects the synthesizer cartridge, or the water from the cartridge, by means

of intensive UV-C radiation (it circulates). The unit responsible for this function is

referred to as the circulation.

If the circulation of the SynPur is shut off, the pump pressure and the motor current

are monitored as soon as the pump starts to run. The LED „Circulation“ lights up

on the display.

Created: 21.12.2006

Changed: 21.03.2007

Printed: 02.03.2009 page 12 of 37

Loading...

Loading...