Nortec RH2+ User Manual

RH2+

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for your RH2+ Electric

Steam humidifier

2568051-F| 28 OCT 2014

Important: Read and save these instructions. This guide to be left with equipment owner.

Thank you for choosing Nortec.

Proprietary Notice

This document and the information disclosed herein are proprietary data of Nortec Humidity Ltd. Neither this

document nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorization of Nortec Humidity Ltd., except to the extent required for installation or maintenance of

recipient’s equipment.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2014, Nortec Humidity Ltd. All rights reserved.

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Contents

1 Introduction

2 Receiving and Unpacking

3 RH2 Models

4 Options and Accessories

5 Installation

6 Typical RH2 Installation

7 Location

8 Mounting with Keyholes

9 Plumbing

10 Steam Distributor

12 Steam Lines and Condensate

Return Instructions

16 Electrical

17 External Controls

22 Options and Accessories

23 Start Up

24 Installation Check

25 On/Off or Modulating Operation

26 Start Up Procedure

27 Nortec Digital Controls

28 RH2 Pre-Start Up Checklist

31 Operation

32 LED Status Lights

32 Selecting a Relative Humidity

Setpoint

33 Humidifier Components

34 Description of Components

35 Humidifier Schematic

36 How the Humidifier Works

38 Humidifier Configuration

40 Maintenance and

Servicing

41 Required Maintenance

45 Extended Shutdown

46 RH2 Maintenance Checklist

47 Troubleshooting

49 General Troubleshooting

51 RH2 Faults

53 RH2 Wiring Diagrams

54 Spare Parts

58 Warranty

1 | Introduction

Introduction

CAUTION: Servicing

Disconnect main power before any servicing.

The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

During and following operation of the humidifier, the steam and components in

contact with the steam such as the blower pack, steam lines, steam distributors,

and condensate lines can become hot and can burn if touched.

Nortec does not accept any liability for installations of humidity equipment

installed by unqualified personnel or the use of parts/components/equipment

that are not authorized or approved by Nortec.

CAUTION: Electrical

All electrical work should be done according to local and national electrical code.

Electrical connection to be performed by a licensed electrician.

CAUTION: Plumbing

Plumbing to be performed by a licensed plumber.

Drain water from humidifier can be very hot. Do not drain to public sink.

All plumbing work should be done according to local plumbing code.

CAUTION: Installation

Do not mount on hot surfaces.

Do not mount in area where freezing can occur.

Do not mount on vibrating surface.

Do not mount on floor.

The RH2 produces steam at atmospheric pressure. No devices which could block

steam output should be connected to the steam outlet.

Steam lines must be installed so that no restriction can produce backpressure in

the humidifier.

Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to

operate. Nortec highly recommends the use of a high limit humidistat.

Introduction | 2

Receiving and Unpacking

1 Check packing slip to ensure ALL material has been delivered.

2 All material shortages are to be reported to Nortec within 48 hours from receipt of goods.

Nortec assumes no responsibility for any material shortages beyond this period.

3 Inspect shipping boxes for damage and note damages on shipping waybill accordingly.

4 After unpacking, inspect equipment for damage and if damage is found, notify the shipper

promptly.

5 All Nortec products are shipped on a Free-On-Board (FOB) factory basis. Any and all damage,

breakage or loss claims are to be made directly to the shipping company.

Before Installation

1 Ensure that available voltage and phase corresponds with humidifier voltage and phase as

indicated on humidifier’s specification label.

2 Ensure that the dedicated external fuse disconnect is of sufficient size to handle the rated

amps as indicated on the specification label. Refer to local codes.

3 Report any discrepancy immediately to the site engineer, if applicable.

4 Ensure sufficient clearances will be available as described in the Location section on pg 7.

5 Ensure steam lines can be routed to duct distributor or blower pack as described in Steam

Lines and Condensate Return Instructions on page 12.

Figure 1: Specification Label Location

MADE IN CANADA

MODEL:

VOLTS 1:

F.L.A:

KW:

XXXXXXXXXXXXXXXXXXXXXXXX S/N:XXXXXXX

XXXXXX XXX

PHASE:XXXX HZ:

XXXXX

XXXXXX

DATE:

XXXXXXXXX

VOLTS 3: XXXXXX XXX

VOLTS 2: XX XXXX XXX

F.L.A:XXXXX

F.L.A:XXXXX

XXXXXX

XXXXXX

KW:

KW:

3 | Introduction

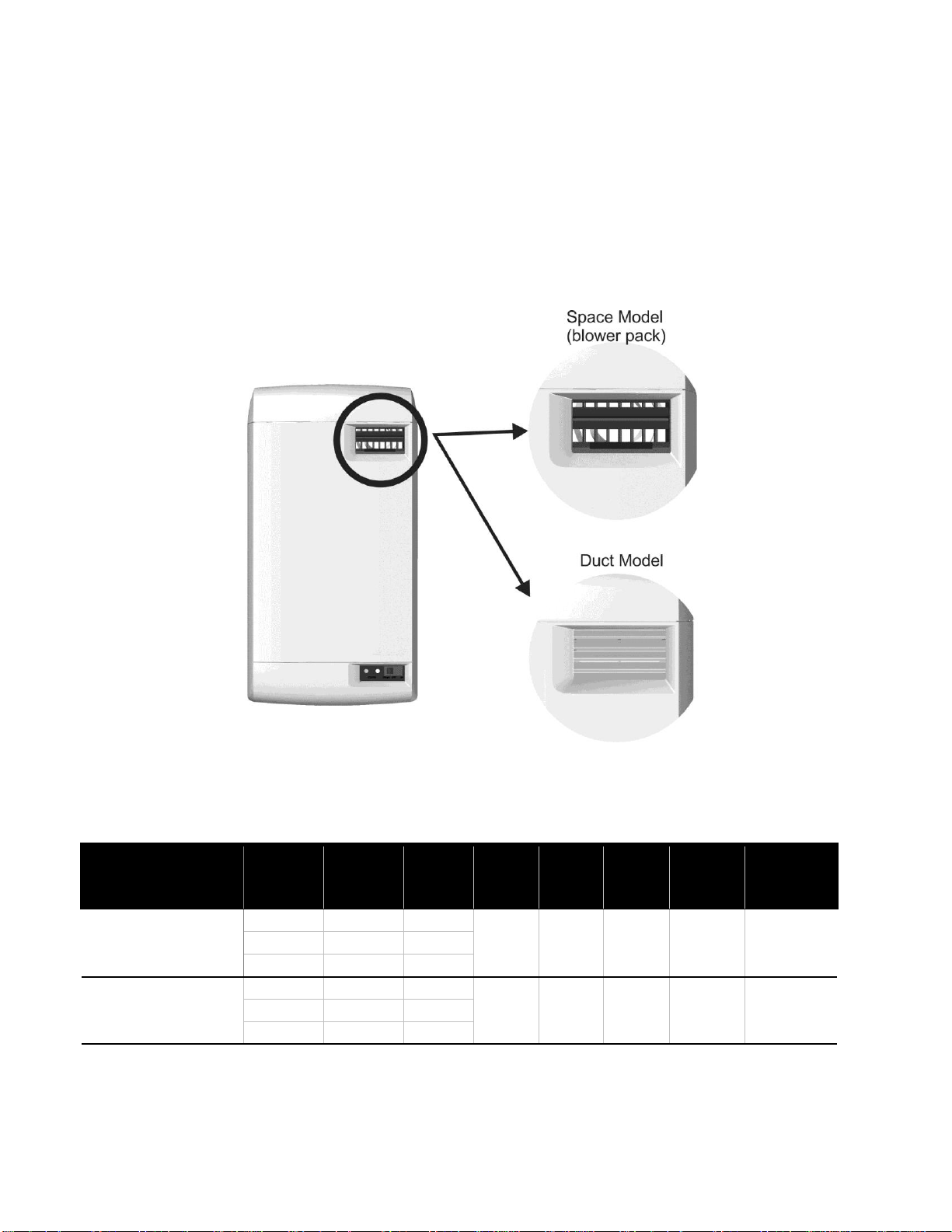

RH2 Models

The RH2 is the most advanced residential steam humidifier available and provides steady and

reliable humidification for a home using the same proven cylinder technology as Nortec’s

industrial electrode platform. The RH2 is available in 2 models: Duct, and Space. The duct

model is designed for connection to a steam distributor installed in a supply air duct, or for

connection to a remote blower pack. The space model is designed for applications where

humidity is to be introduced directly into the conditioned environment. The two models can be

differentiated by the grille in the humidifiers front cover, see Figure 2: RH2 Models.

.

Figure 2: RH2 Models

Table 1: RH2 Specifications

Model - Part No.

Volts

Capacity

lb (kg)

KW

Amps

Phase

Max Ext

Fuse

Standard

Cylinder

Net/Full

Weight

lb (kg)

RH2 Space - 2560952

110-120

4 (1.8)

1.5

1

20

202

16 / 22

(7.5 / 10.0)

208

6.9 (3.1)

2.6

12.7

220-240

8 (3.6)

3.0

RH2 Duct - 2560953

110-120

5 (2.3)

1.9

1

20

202

15 / 21

(7.0 / 9.5)

208

8.7 (4.0)

3.3

15.9

220-240

10 (4.6)

3.8

Introduction | 4

Options and Accessories

Nortec provides a complete line of options and accessories for every humidification application.

The following options and accessories are available and may have been delivered with your RH2

humidifier. Refer to the installation instructions that came with the accessories for proper

installation and operation.

Table 2: Options and Accessories

Option / Accessory

Application

Steam Distributors

Introducing steam into ventilation ducts.

Remote Blower Pack

Introducing steam into conditioned environments.

Digital or Modulating Control Humidistats

Controlling the output of the humidifier based on sensed RH.

Digital or Modulating High Limit

Humidistats

Preventing over-humidification in a duct by shutting down or

throttling down the humidifier when RH approaches saturation.

Air Proving Switches

Ensuring humidification only occurs when air is moving in a duct.

5 | Installation

Installation

6 Typical RH2 Installation

7 Location

8 Mounting with Keyholes

9 Plumbing

10 Steam Distributor

12 Steam and Condensate Returns

16 Electrical

17 External Controls

17 Control Wiring

17 Duct Humidification Control Location

18 Space Humidification Control Location

19 On/Off Control Wiring

20 Modulating Control Wiring

21 Fan Enable Wiring

21 RH2 Fan Control

21 Nortec On/Off Humidistat Fan Control

22 Options and Accessories

22 Remote Blower Pack

Installation | 6

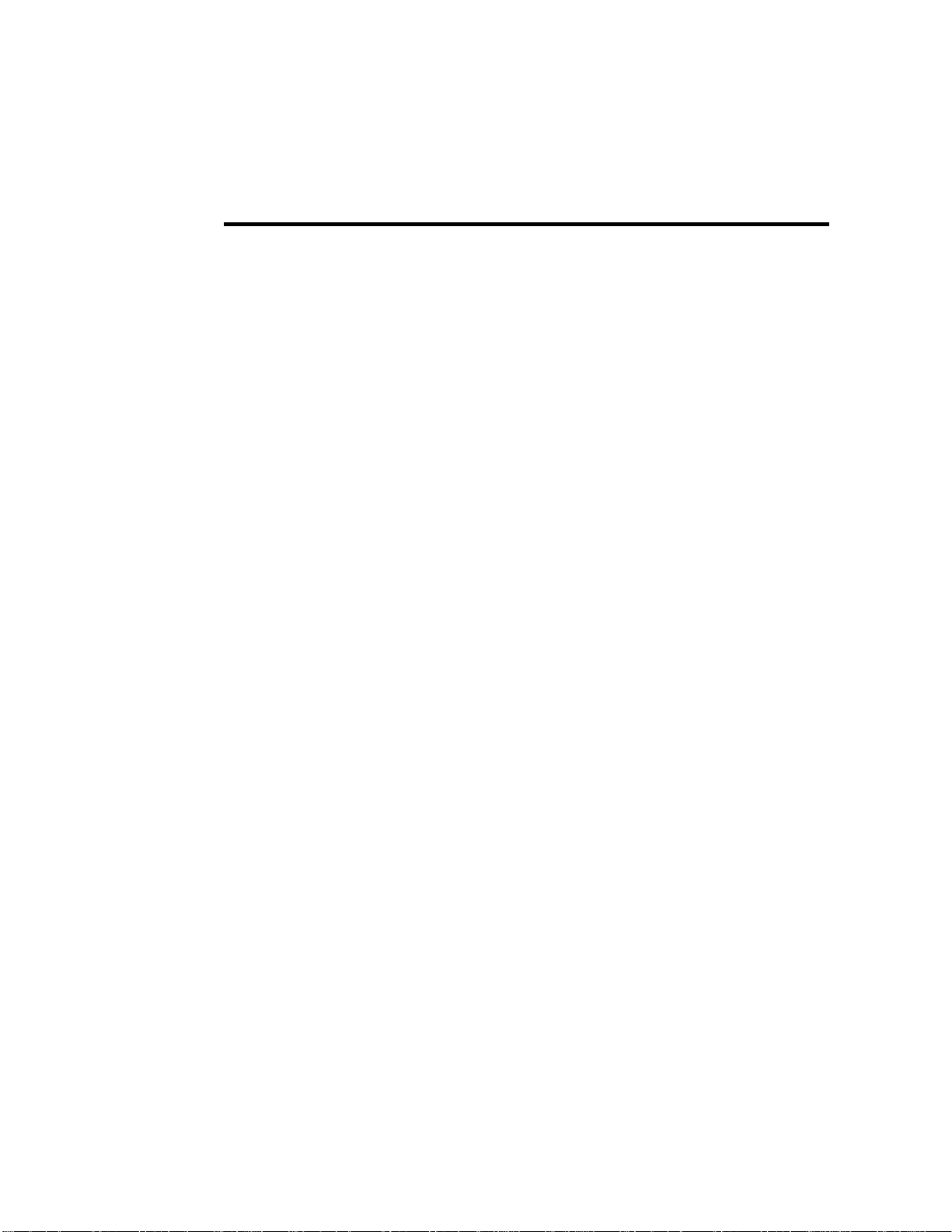

Typical RH2 Installation

Figure 3: Typical Humidifier Installation

2

7 | Installation

Location

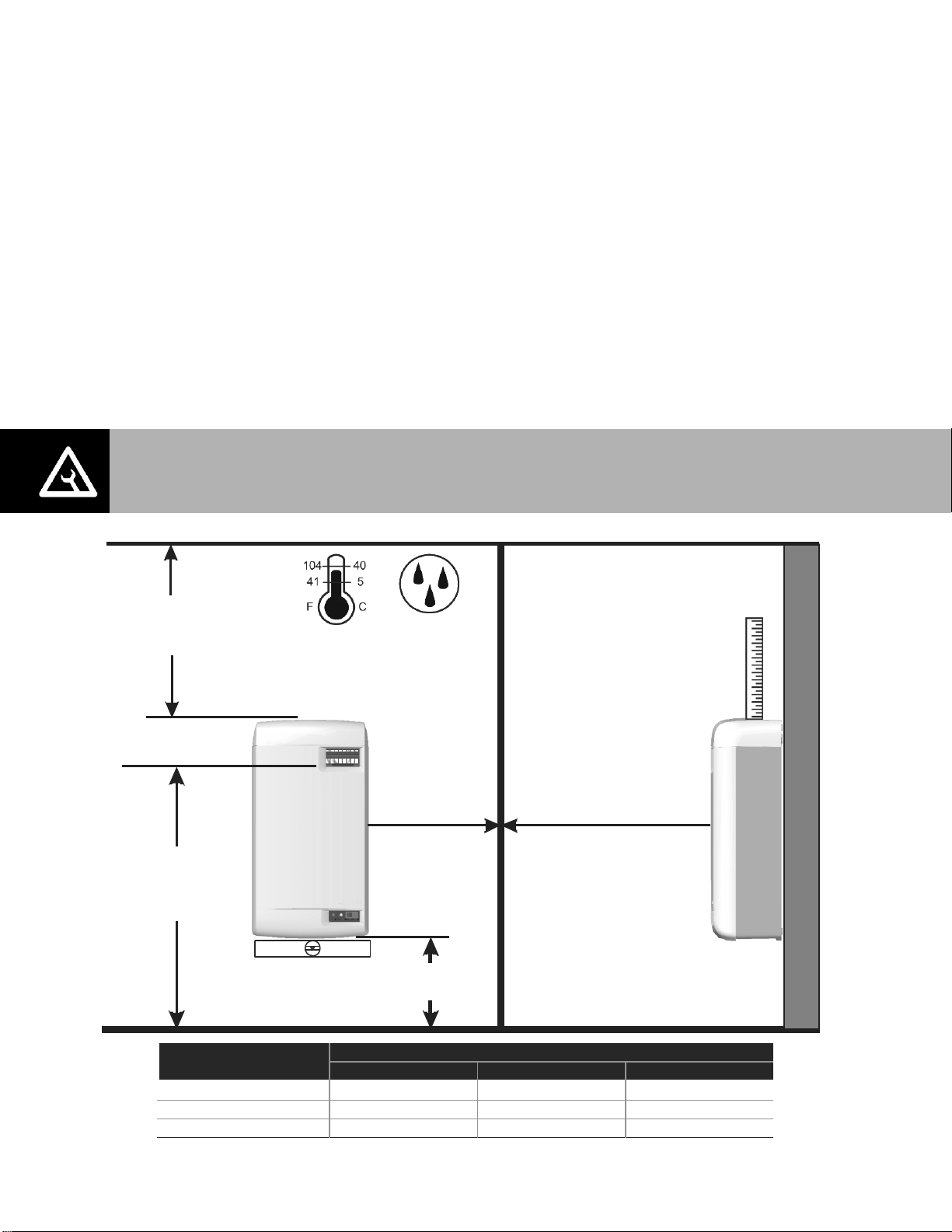

Mount on a suitable wall or vertical surface. Do not sit the unit on the floor. Allow clearances

required for plumbing and electrical connections. Clearance dimensions shown are for

reference only and are the minimum required for maintenance of the humidifier. Consult local

and national codes before final location and installation. Nortec does not accept responsibility

for installation code violations.

Install only in areas with ambient temperature 41-104°F (5 – 40°C) relative humidity

5 - 95%.

When possible install below the steam distributor. Take care to provide proper steam line

routing and proper condensate traps.

DO NOT locate the humidifier any further then absolutely necessary from the steam

distributor location as net output will be reduced as a result of heat loss through the steam

line.

When possible, mount the RH2 humidifier at a height convenient for servicing.

Figure 4: Mounting Location / Clearance

Side clearance

for space models

only, see table

36 in. (92 cm)

in. ront learance

duct model

m f c

Additional front clearance

for space models,

see table

24 in.(61 cm)

Min Height

Mount Humidifier

Level

As Close as

Possible to Steam

Distributor

5-95%

Overhead clearance

for space models

only, see table

Humidifier Output lb (kg) Side in. (cm)

<4 (1.8) 12 (30) 12 (30)

6 (2.7) 16 (40) 18 (46)

8 (3.6) 18 (46) 18 (46)

7 ft (2.1 m)

min. Height

for space

models only.

36 (92)

42 (107)

48 (120)

Additional Clearance for Space Models Only

Overhead in. (cm) Front in. (cm)

Note: Do not mount on hot surfaces, where freezing can occur, vibrating surface, or floor.

Installation | 8

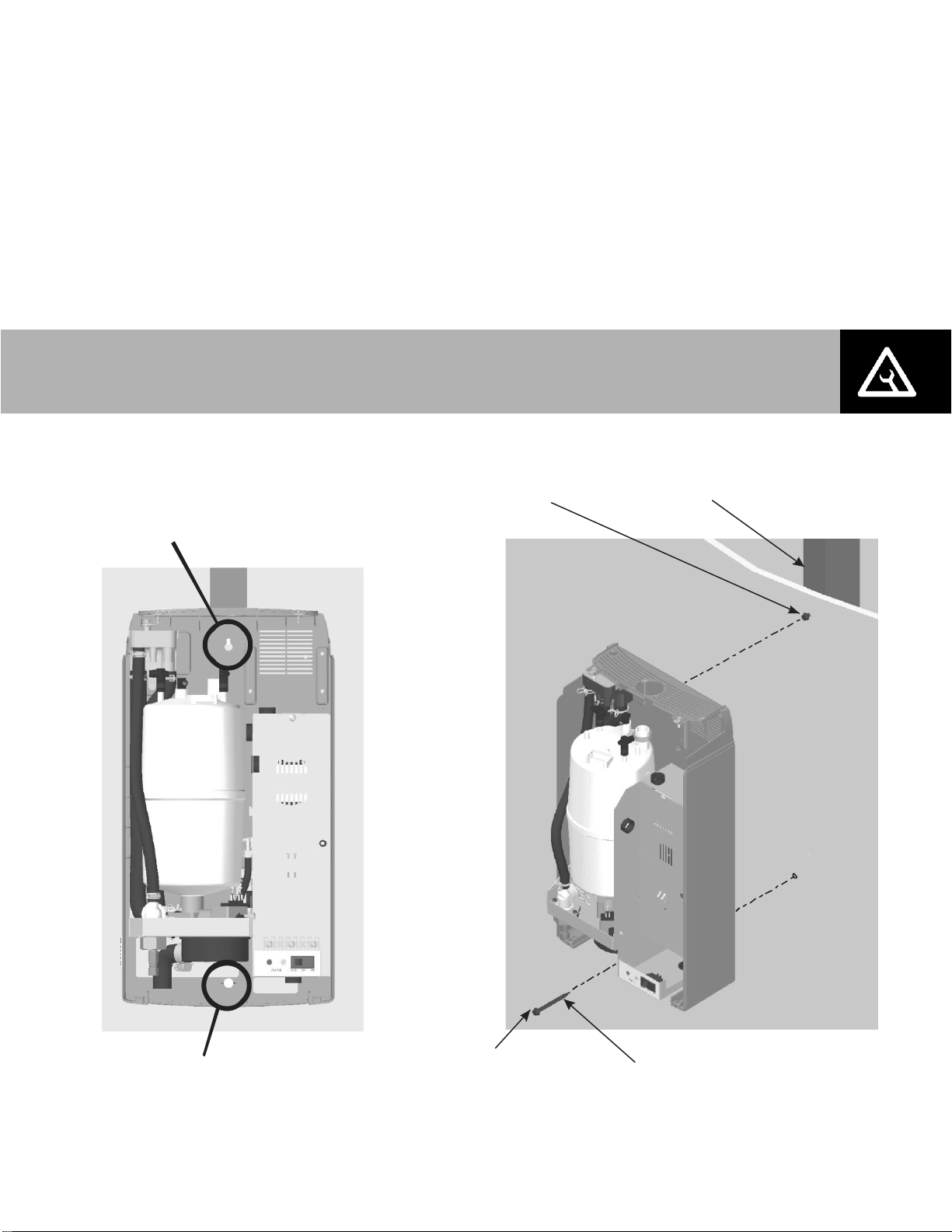

Mounting with Keyholes

1 The RH2 humidifier is wall mounted using a keyhole located on the back of the unit

cabinetry.

2 Use #8 x 2 in. (5 cm) screws mounted into 2x4 studs or better. 2 screws are needed, one for

hanging the unit and one for securing so it will not lift off the keyhole.

3 Install the top screw so that 1/4 in. (6 mm) is exposed. Raise the unit and place the screw

head through the keyhole.

4 Make sure the unit is level and then insert and tighten the second screw through the bottom

hole. Tighten the top screw. See Figure 5: Mounting With Keyholes.

Figure 5: Mounting With Keyholes

Note: Use screws longer than 2” (5 cm) if drywall or other spacer is present.

Install Second Screw

after hanging

humidifier

#8 x 2 in. (5 cm)

Wood Screws

Insert screw so that

1/4 in. (6 mm) exposed,

hang unit, tighten

screw.

2x4 or Other

Structural

Member

Keyhole

Hole

9 | Installation

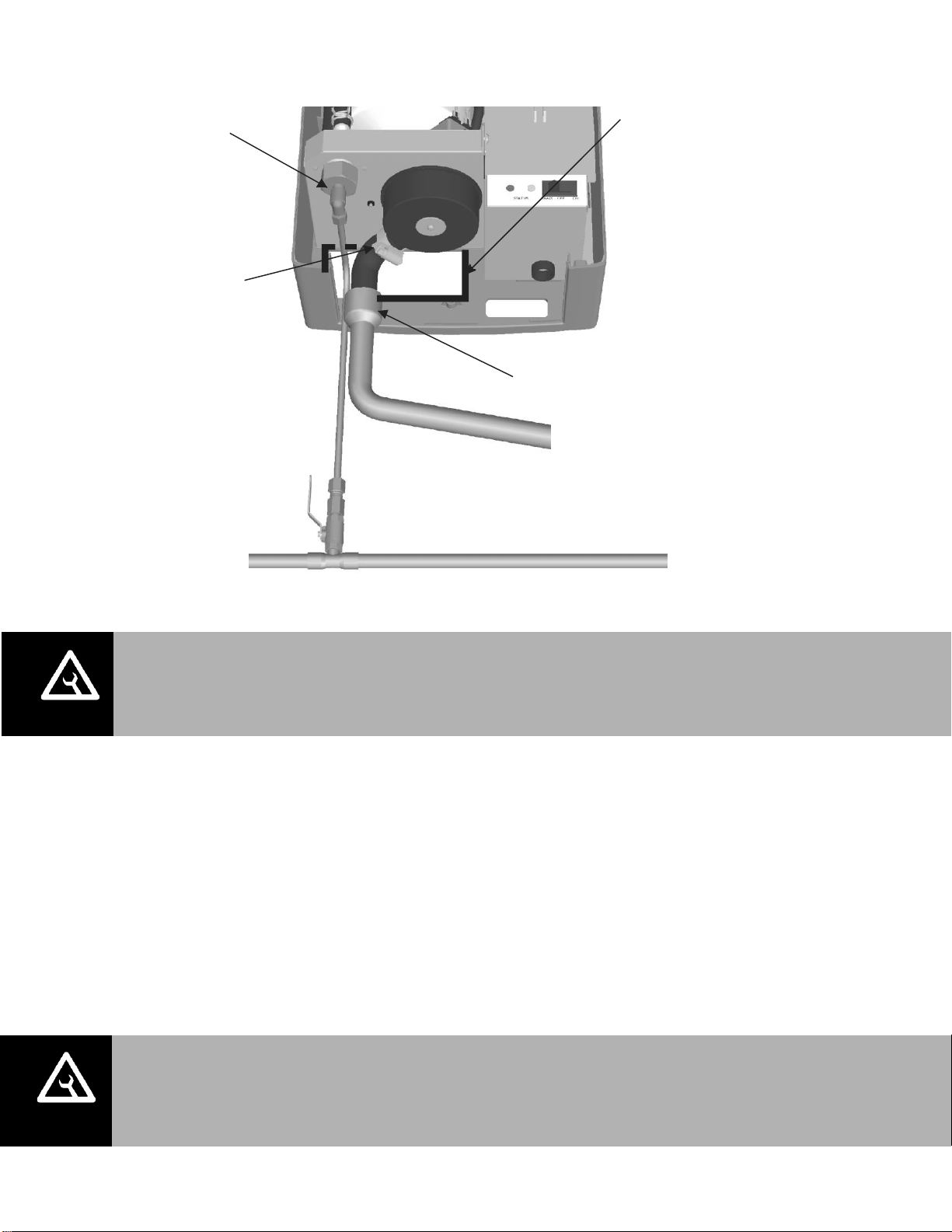

Plumbing

Figure 6: Water Supply and Drain Connection

Supply water should at 30 to 80 PSIG and be between 150-1200 Microsiemens

(330-670 S optimal range). Consult factory for water conditions outside of this range. Do

not use reverse osmosis or de-ionized water. Supply water should be cold (34-68ºF/1-20ºC).

Install water shut off valve before humidifier to facilitate servicing.

The drain line should not end in a sink used frequently by personnel, or where plumbing

codes prohibit it. Route to a floor drain or equivalent for safety reasons.

Ensure drain line is adequately sized to provide free and easy draining and that an air gap is

installed as shown. A restricted drain can cause cylinder water to over concentrate and

result in poor operation.

If a drain is not located near the humidifier use a condensate pump rated for hot drain water

such as Nortec’s Part Number 1429527.

1.2 in. (30 mm). OD

un-threaded outlet

with factory supplied

bent hose and clamp.

Always install a water

shut-off valve.

1/8 in. NPT

Use 1/4 in.

compression

fitting to connect

supply line to

unit.

*Pipe and water shut-off valve not supplied by Nortec.

Use 1/2 in. OD copper to within 4 ft (1.2 m) of humidifier

Note:

1 Fill and drain lines

can also be routed

through opening in

back of cabinet.

2 Optional cover

2548313 Is available

to conceal plumbing

connections.

Air gap required. 2 1/2 in. to 7/8 in.

Copper reducer is ideal. (NORTEC option

P/N 2522172) Hose must not

touch the bottom of the funnel.

Min. 7/8 in. OD drain line.

Keep as short as possible.

Slope down to floor

drain or main drain.

All water supply and drain line connections should be installed in accordance with

local plumbing codes.

Drain water is automatically cooled to 140°F (60°C). Drain material must be

rated for this temperature.

For humidifiers installed in some cities including the City of Los Angeles:

A city-approved spring-loaded double ball CHECK VALVE must be installed by

contractor on the potable water inlet to the humidifier. Recommended valve

manufacturer: Watts Regulator, phone number 508-688-1811, Size depending on

supply line 1/4”, 3/8”, or 1/2” NPT inlet and outlet, Model #7.

Installation | 10

Steam Distributor

Steam generated by the RH2 Space is blown directly into the space by the integrated blower

pack. The RH2 Duct requires a steam distributor, installed in the ventilation duct. The RH2

Duct can distribute steam into a ventilation duct using the following distributor options in

Table 3.

Table 3: RH2 Duct Steam Distributor Options

Nortec Part

Number

Option Description

Notes

1581820

Nozzle Distributor Kit

Includes a steam distribution nozzle, steam hose, condensate hose,

and installation hardware. See Figure 7.

2553708

RSD 10 Distributor Kit

Includes a steam distributor, steam hose, condensate hose, and

installation hardware. See Figure 8.

Select to duct

dimensions

ASD Duct Distributor

Used when duct width exceeds 12”. Refer to Distributor manual or

HELP software for selection.

Select to duct

dimensions

Mini SAM-e

Used when short absorption is necessary. Refer to SAM-e manual

or HELP software for selection.

2564776

RMBP for RH2 Duct

Remote Mounted Blower Pack, used with the RH2 Duct, adds steam

directly into the space. The blower pack is installed remote to the

humidifier.

Whichever method is used, the steam distributor should be installed as close as possible to

the humidifier. Short steam distribution lines minimize condensate losses and the

possibility of generating backpressure in the steam distribution line.

11 | Installation

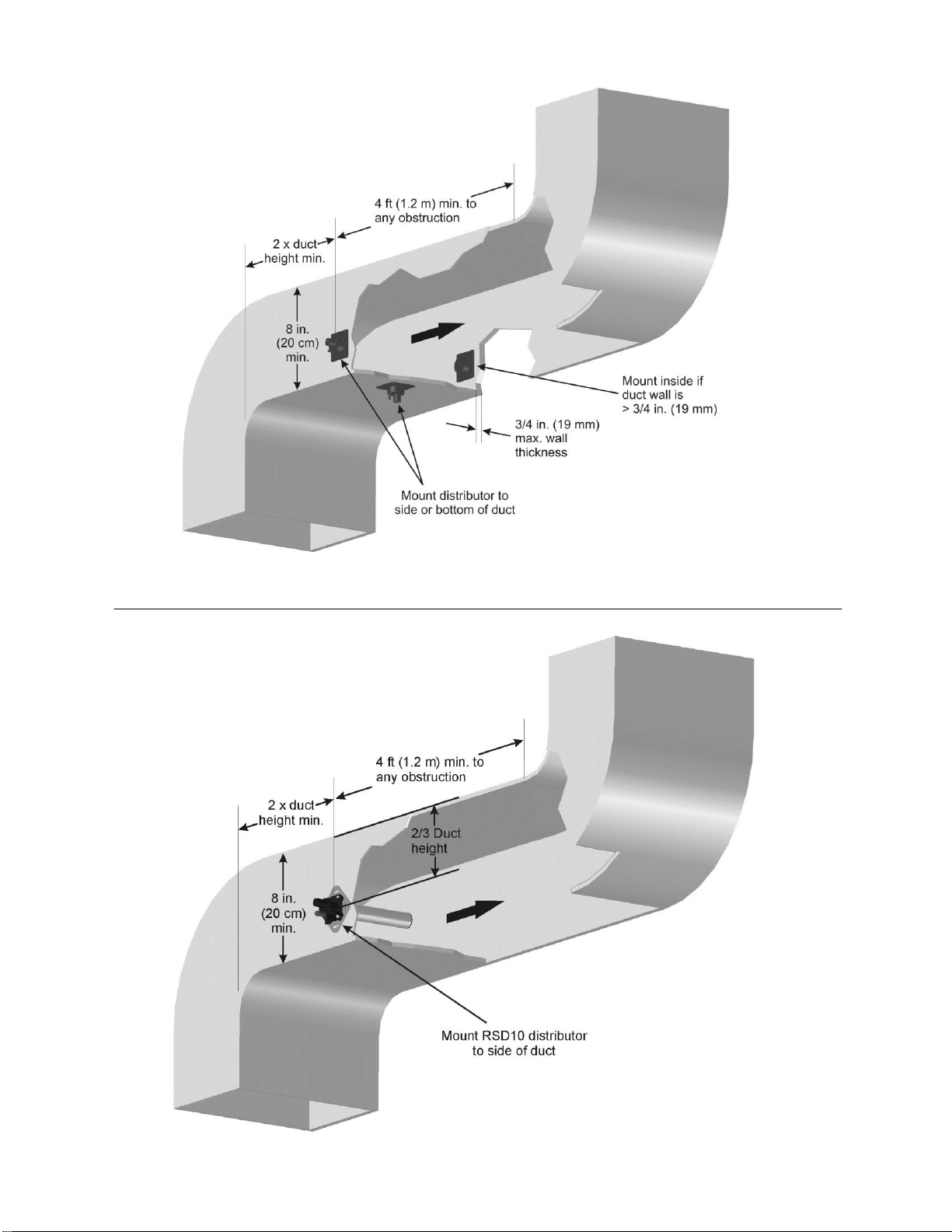

Figure 7: RH2 Duct Nozzle Distributor Installation

Figure 8: RH2 Duct RSD10 Distributor Installation

Installation | 12

Steam Lines and Condensate Return Instructions

The following instructions must be followed for installation of steam lines for the RH2 Duct.

Failure to use recommended material and exceeding maximum recommended length in Table

4, or failure to follow any other steam line installation instructions will result in improper

operation and could void the warranty.

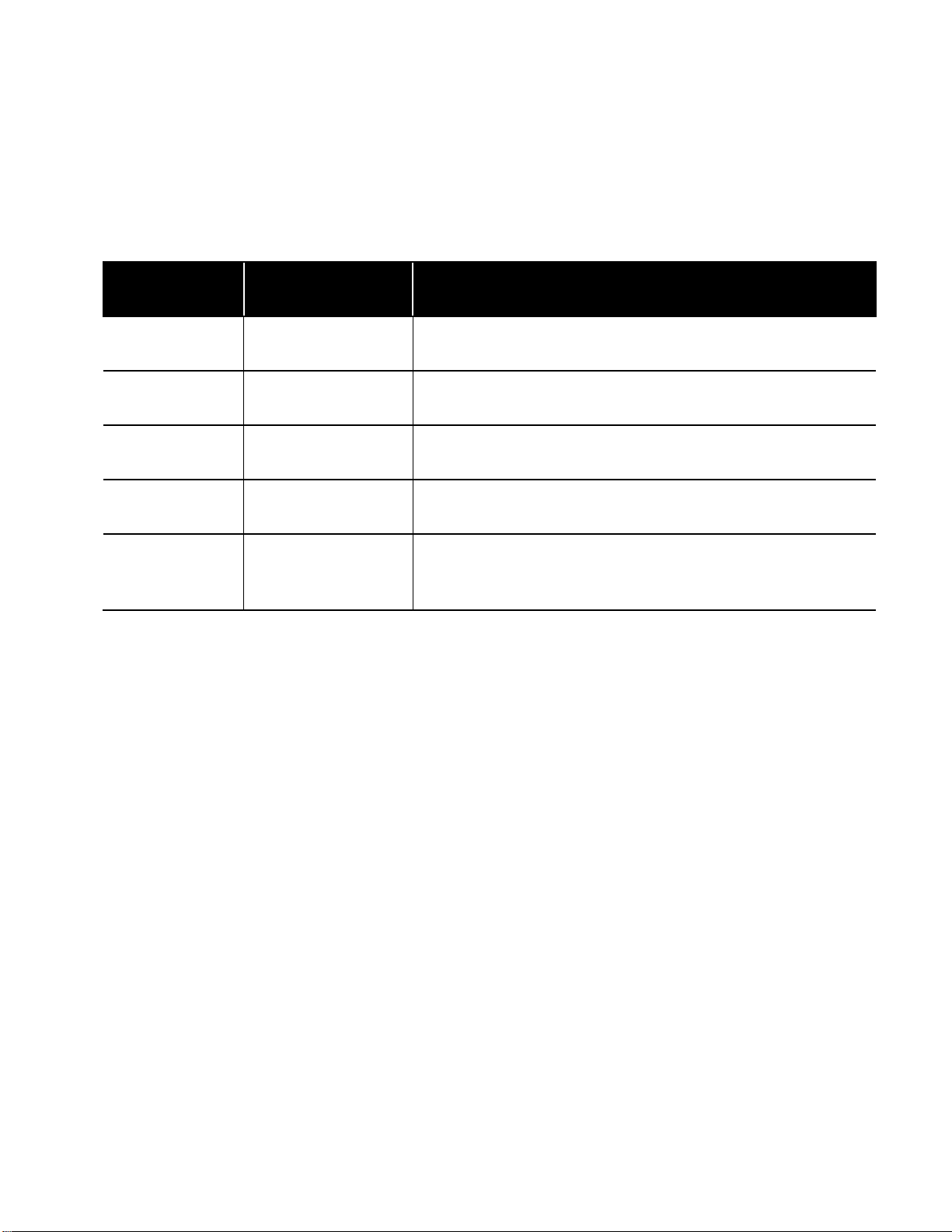

Table 4: Recommended Steam Line Material for RH2 Duct

Voltage

Steam Output

Material*

Maximum

Steam Line

Length

Possible Losses

lbs/hr

(kg/hr)

Nortec Steam

Hose

MED-L

Copper

Tube

Stainless

Steel

Tube

ft

(m)

lbs/hr

(kg/hr)

110-

120V

5

(2.3)

Part Number

1328810

(7/8”)

3/4”

0.875 X

0.049W

7

(2)

0.5

(0.2)

208V

8.7

(3.3)

10

(3)

1

(0.5)

220-

240V

10

(4.6)

12

(3.5)

1.5

(0.7)

Oversized Steam Line (used for longer steam runs)**

110-

120V

Not

Recommended

Not

Recommended

1”

1.125 X

0.049W

Not Recommended

208V

8.7

(3.3)

12

(3.5)

2

(0.9)

220-

240V

10

(4.6)

24

(7)

3

(1.4)

Note: * The use of steam line other than copper, stainless steel tube or Nortec supplied steam line will void the warranty and may adversely

affect the operation of the humidifier.

** These diameters require a reducer at humidifier and steam distributor connection. Use Nortec part number 1115444 at

humidifier to prevent backpressure caused by condensation collecting at the reduction.

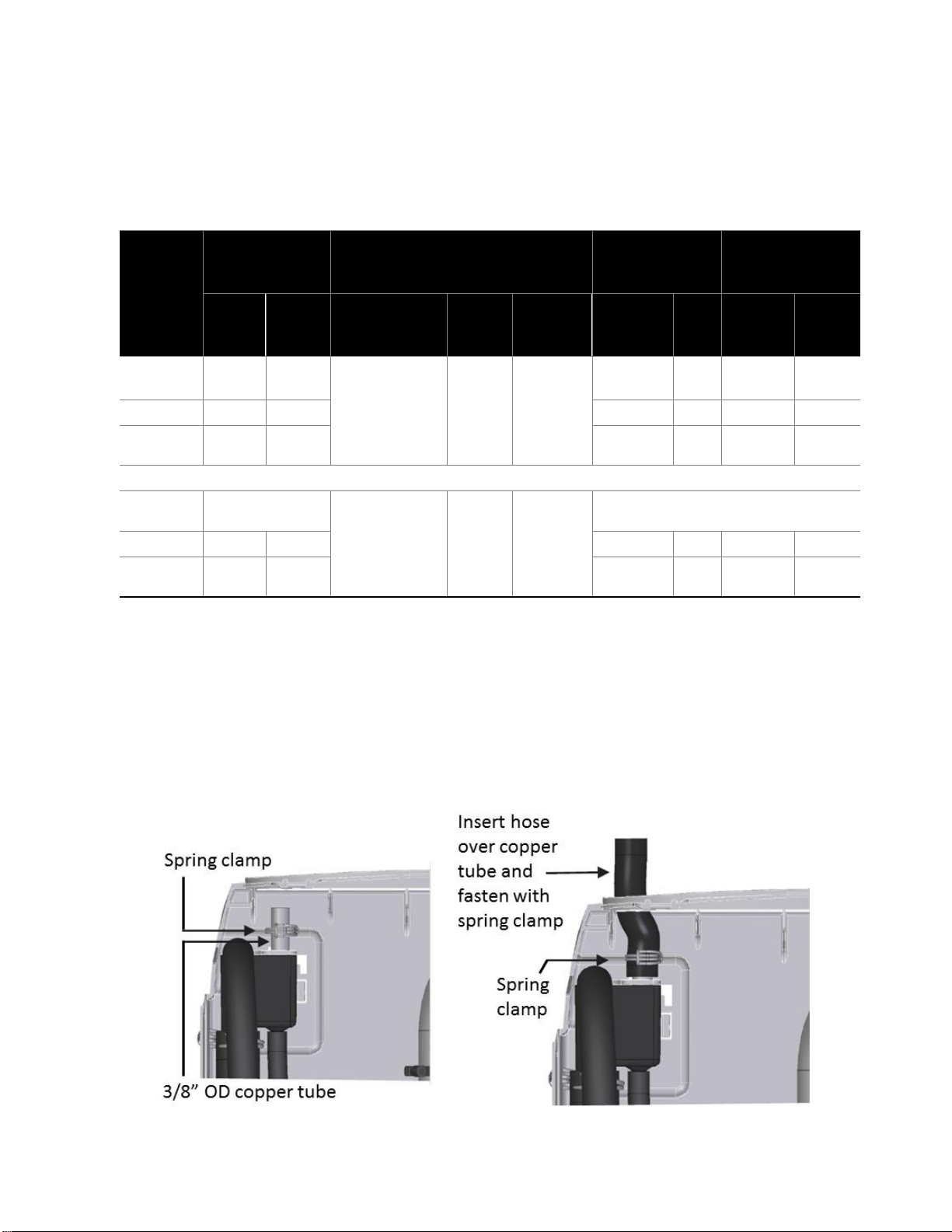

To return condensate for RH2+, insert copper tube (supplied with equipment) half way into the

condensate opening of the fill cup along with the spring clamp (supplied with equipment).

Insert the condensate hose into the condensate return hole at the top of the RH unit, and over

the copper tube. Fasten in place with the spring clamp.

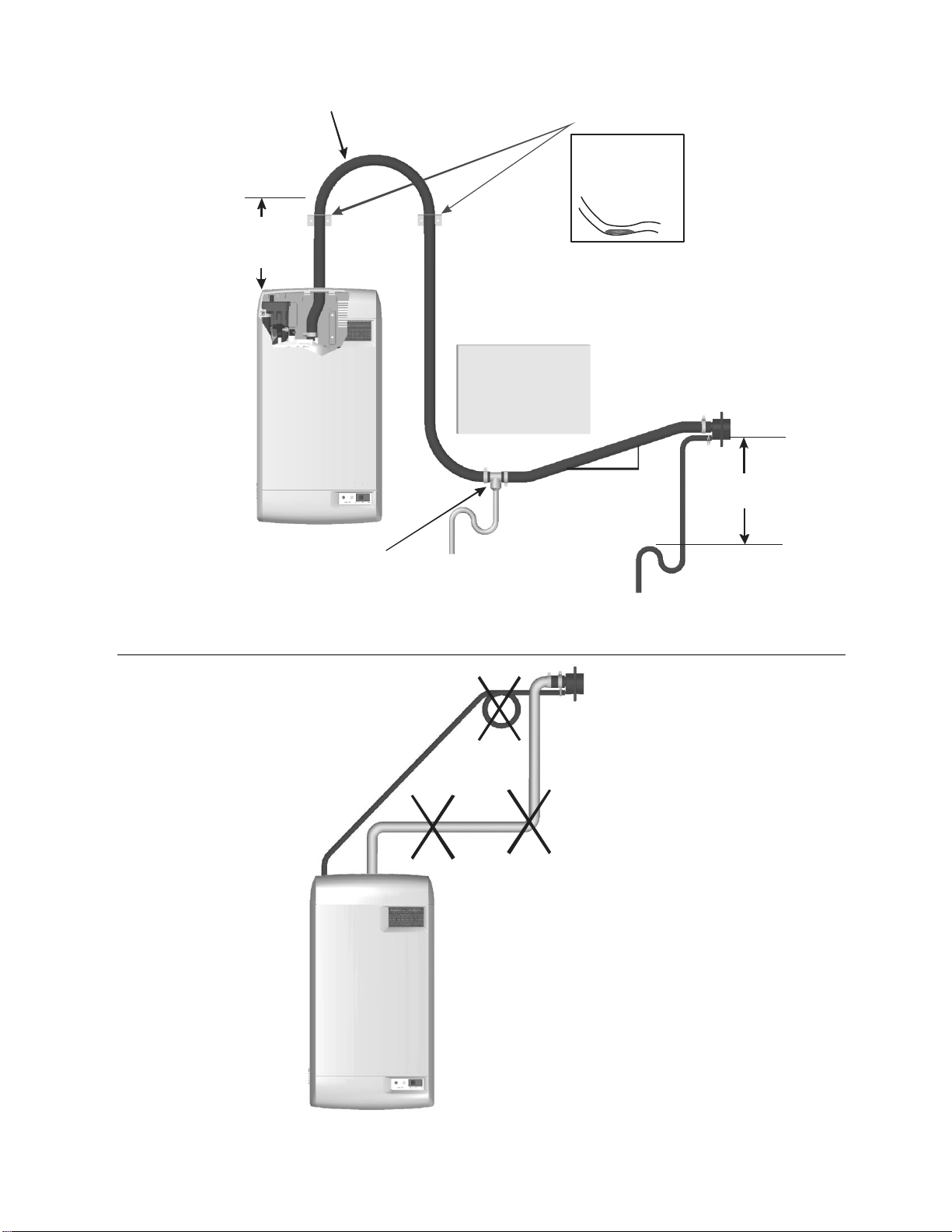

Figure 9: Condensate Return

13 | Installation

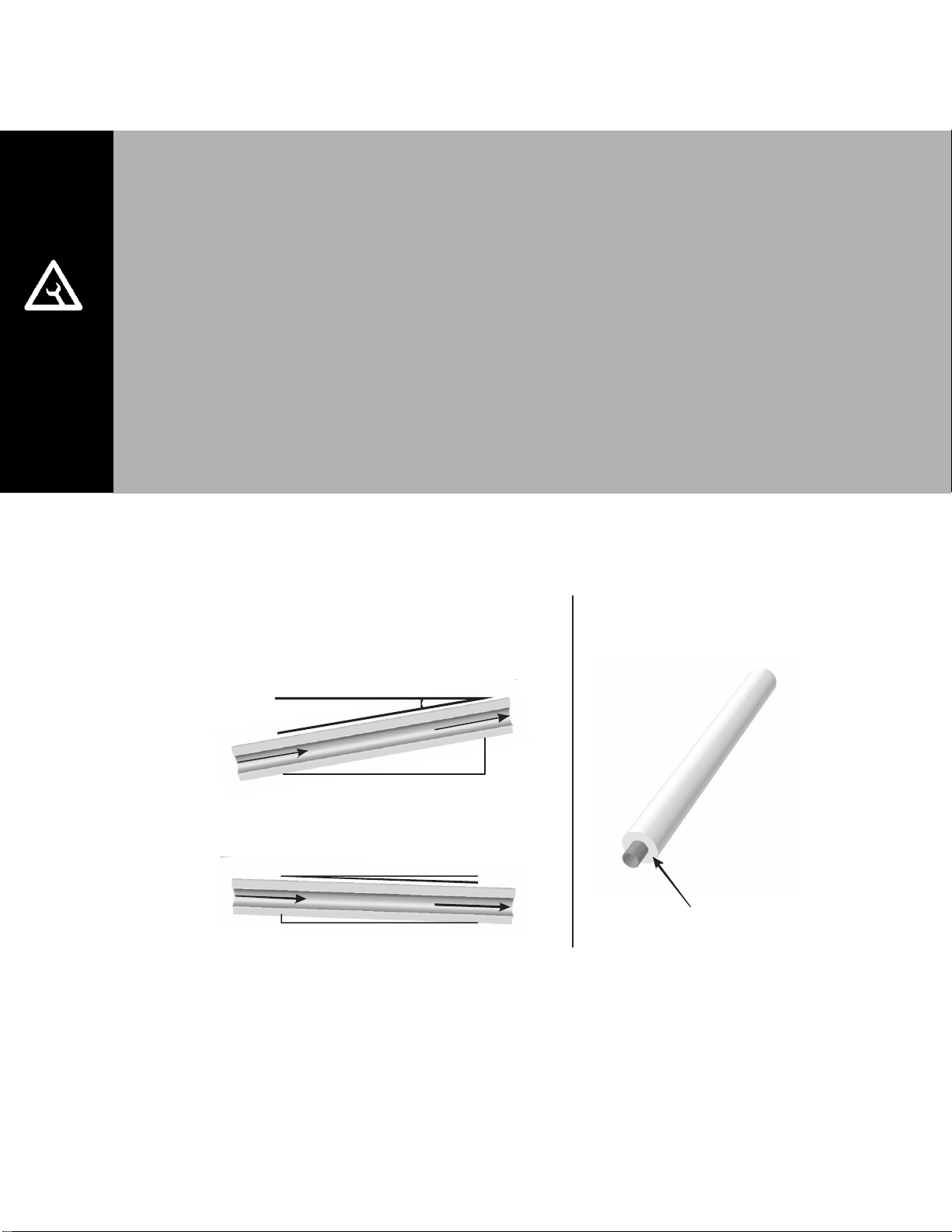

Figure 10: Main Steam Line Requirements

MAIN RULES FOR ATMOSPHERIC STEAM LINES

Steam lines must not have any restrictions which could result in back pressure.

Follow recommended materials, size and length, see tables.

Slope the steam lines.

Insulate with 1.0 in. (2.5 cm) pipe insulation

Trap condensate (Use full size ‘T’ for Traps)

Do not over tighten hose clamp at cylinder steam outlet. The maximum torque is 12

in-lbs.

Support steam line so weight is not on cylinder.

Condensate traps must be a minimum of 6 in. (15 cm) in height or duct static

pressure + 2 in. (5 cm), whichever is greater.

Trapping by P-trap or pigtail. Support line as necessary to ensure it remains free of

kinks.

S

t

e

a

m

D

i

r

e

c

t

i

o

n

S

t

e

a

m

D

i

r

e

c

t

i

o

n

S

t

e

a

m

D

i

r

e

c

t

i

o

n

2 in.

(5 cm)

1 ft (30 cm)

1ft (30 cm)

0.5 in.

(12 mm)

10 Degrees

2 Degrees

Use Appropriate Slope Insulate Pipe

1 in. (2.5 cm) pipe

insulation

Installation | 14

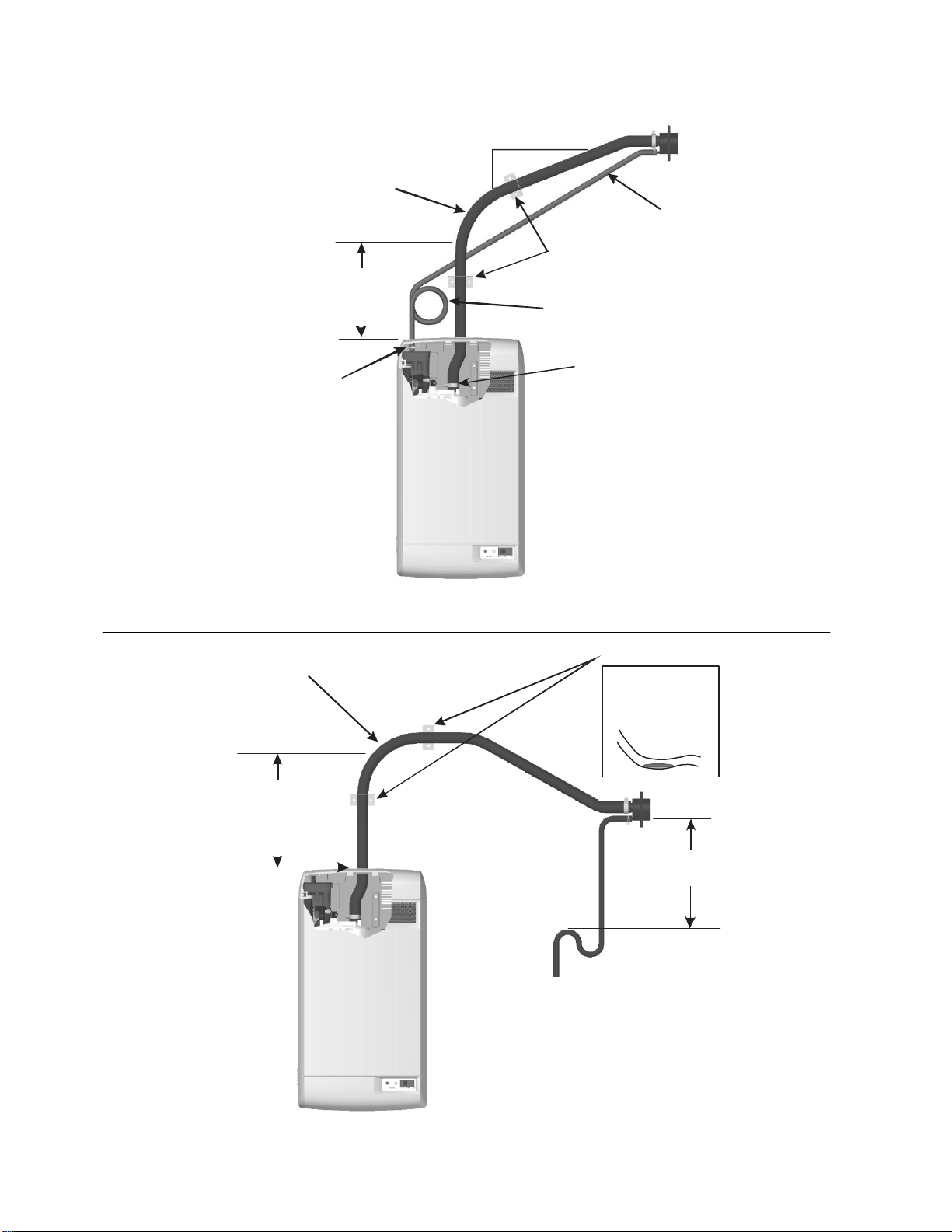

Figure 11: Steam Distributor Above Humidifier (Hose)

Figure 12: Steam Distributor Below Humidifier (Hose)

Condensate

Trap

1 ft (30 cm)

min. Before

any bend

Min 12 in.

(30 cm)

radius

Hose will soften

over time

proper support

Is necessary

Support Brackets

1 ft (30 cm)

min.

To Drain

1 ft (30 cm)

min. before

any bend

12 in.(30 cm)

min. Radius

Condensate

Trap

Condensate

line

Connect Steam

Hose to CylinderConnect Condensate

Hose to Fill Cup

2 in. (5 cm)

min.

1 ft (30 cm)

Support

Brackets

15 | Installation

Figure 13: Steam Distributor Below Humidifier With Obstruction (Hose)

Figure 14: Common Steam Line Errors

Steam line

not sloped

No condensate

trap at vertical

transition

Condensate trap

not 12 in (30 cm)

below distributor

1ft (30 cm)

min. before

any bend

12 in.

(30 cm)

min.

radius

Obstruction

Use full size condensate tee

at low point. Slope lines up

to “T” and immediately after it.

Hose will soften

over time

proper support

Is necessary

Support brackets

1 ft (30 cm)

min.

To drain

To drain

2 in.

(5 cm)

min.1 ft (30 cm)

Installation | 16

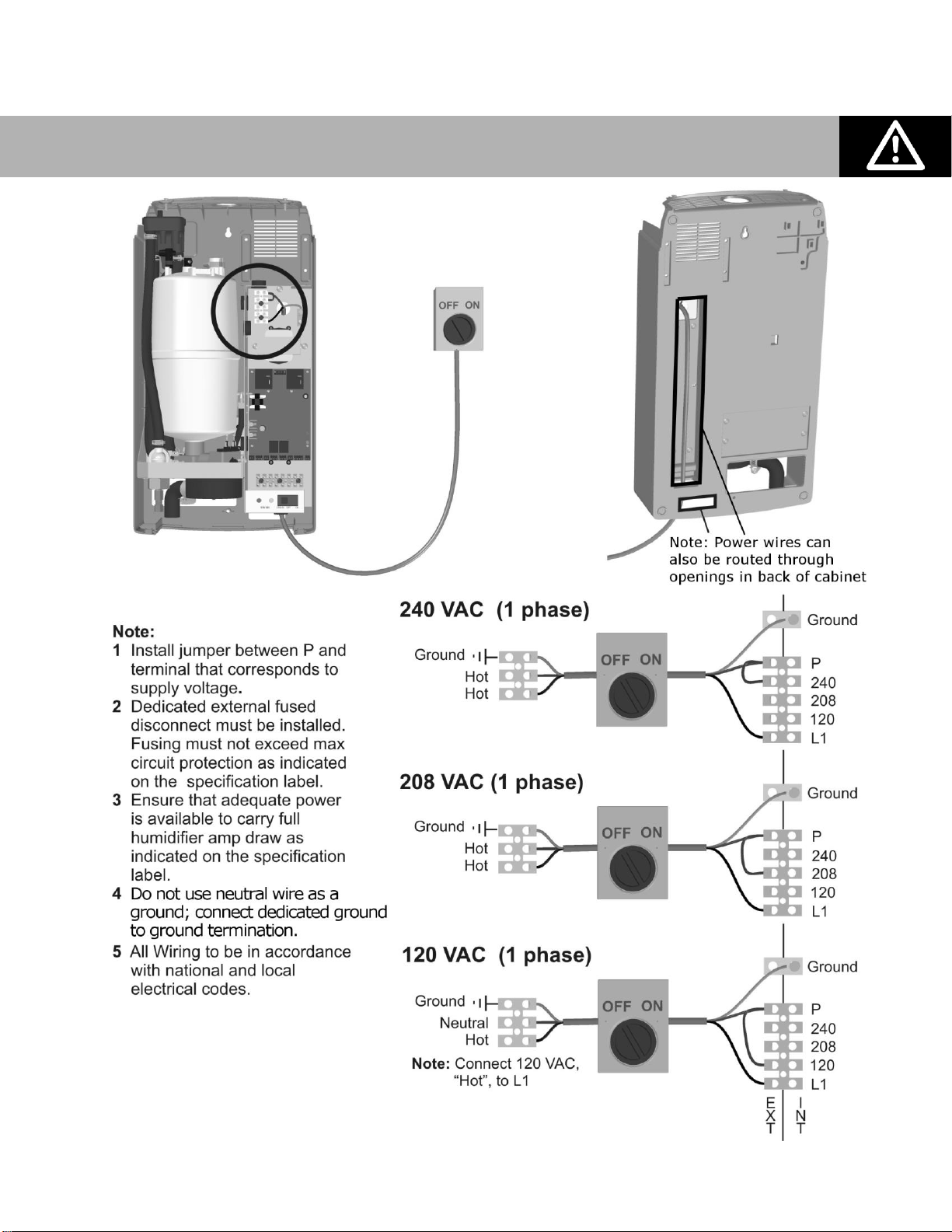

Electrical

Figure 15: Primary Power Connection

Caution: Wiring to be performed by a licensed Electrician.

Loading...

Loading...