Page 1

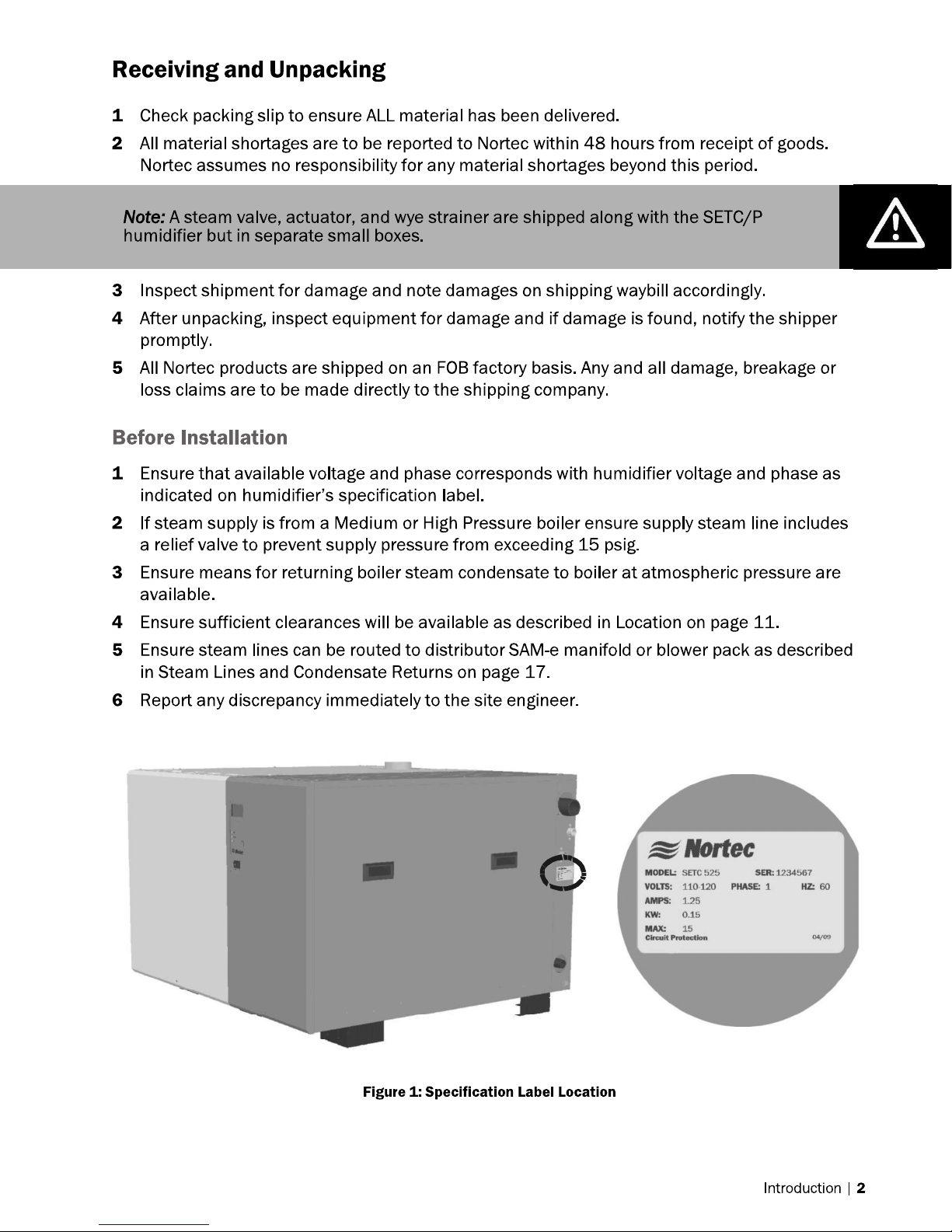

Page 2

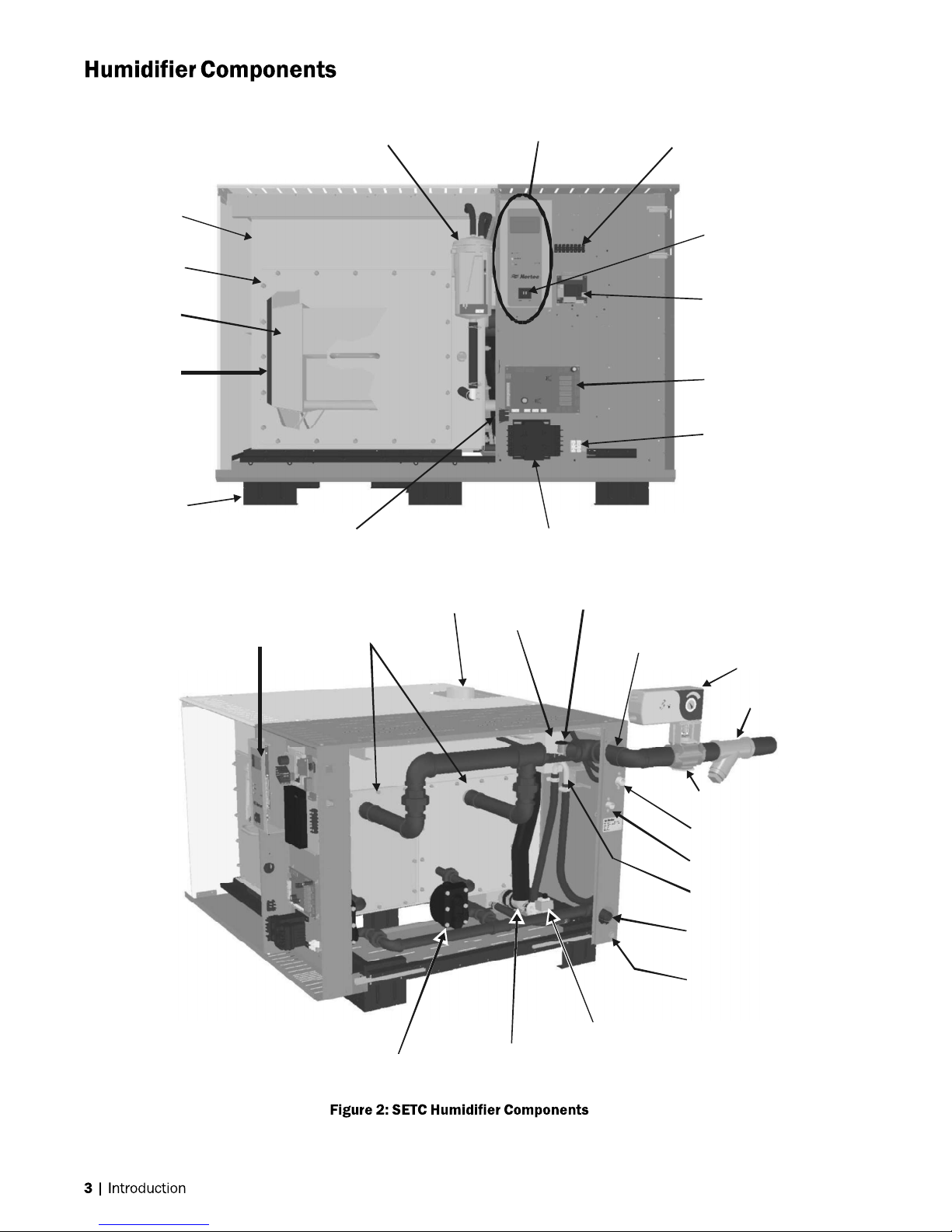

Page 3

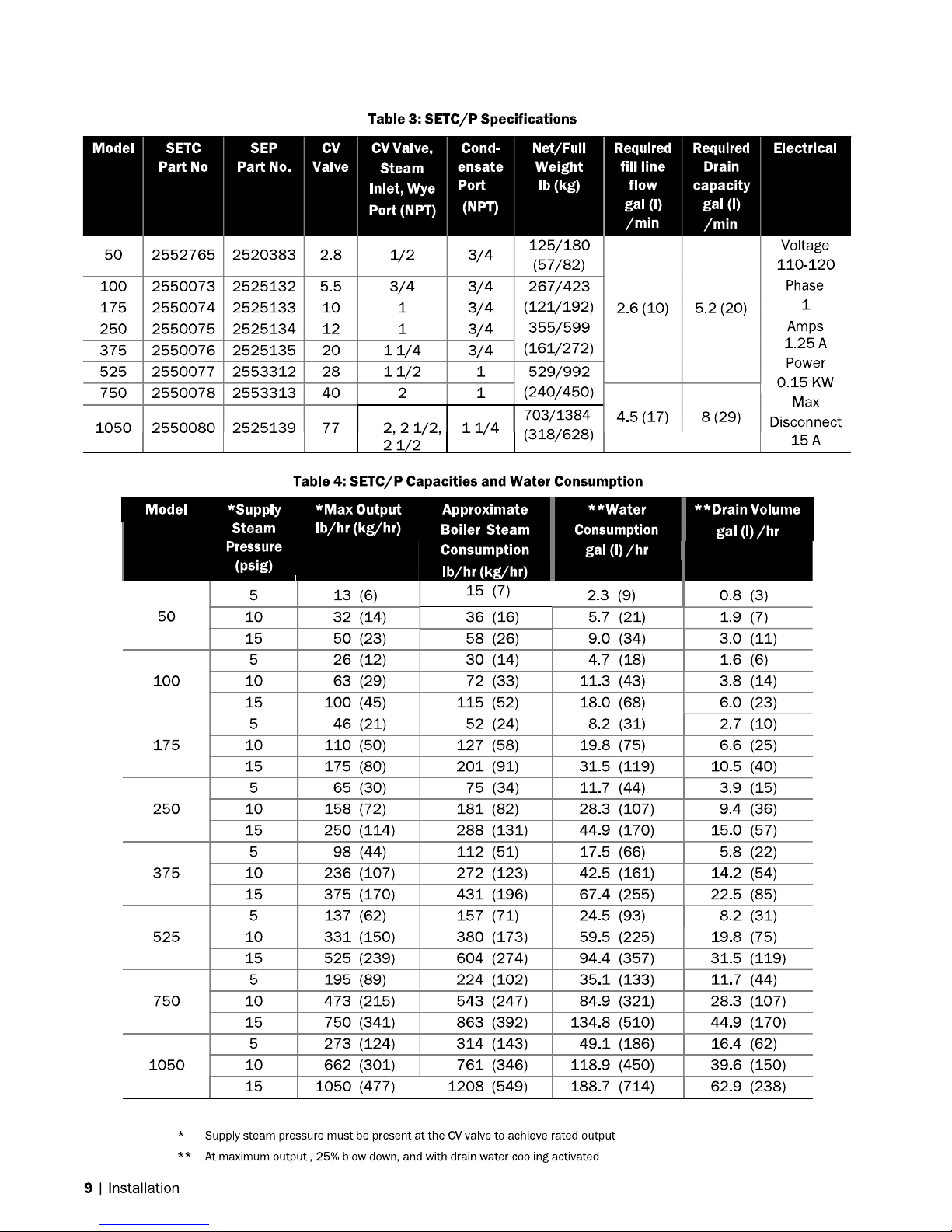

Page 4

Page 5

Page 6

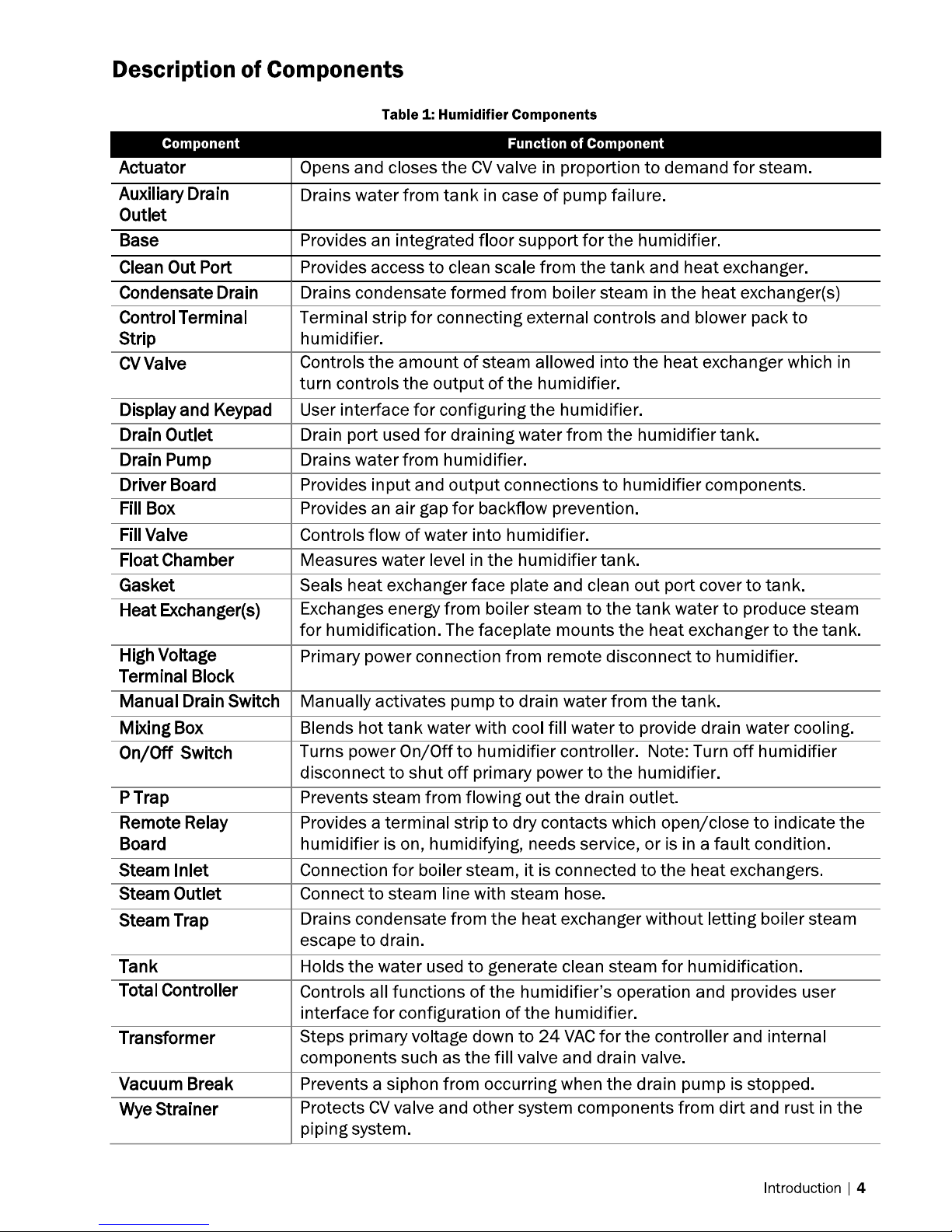

Tank

Clean Out

Port

Heat

Exchanger

Gasket

Base

Total Controller

Float Chamber

Manual Drain Switch

Heat

Exchangers

(Faceplate)

Display and Keypad

Steam Outlet

Transformer

Fill Box

Vacuum Break

Steam Inlet

(Boiler Steam)

Control Terminal Strip

On/Off Switch

Remote Relay

Board

Driver Board

High Voltage

Terminal Block

Actuator

Wye Strainer

Steam Trap

Drain Pump

Mixing Box

CV Valve

Fill Valve

Drain Outlet

P Trap

Condensate Drain

(Boiler Steam)

Auxiliary Drain

Outlet

Page 7

Page 8

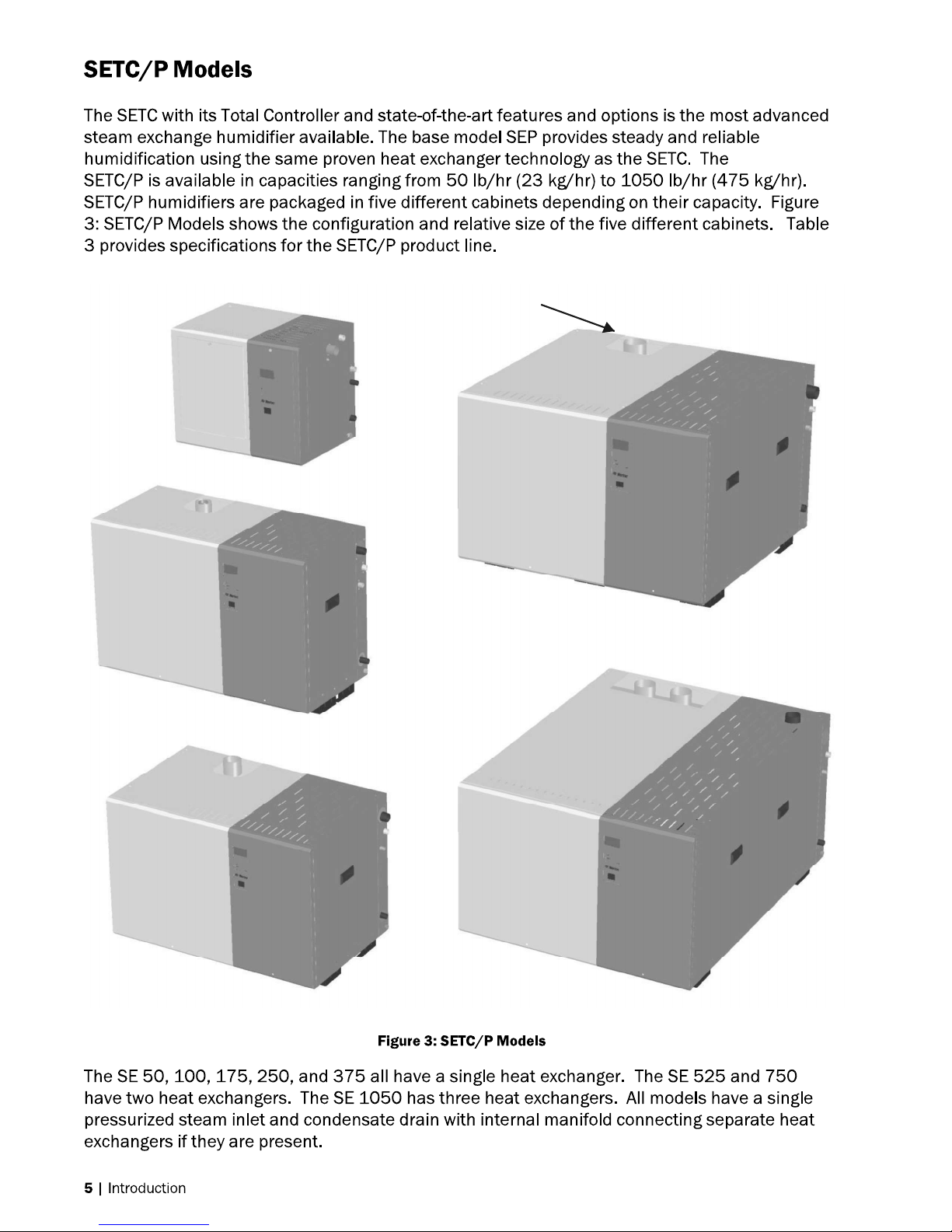

SETC50

Note:

SE 750 has

outlets

SE 525

-

750

SE

100

-

175

SE

1050

SE 250

-

375

2 steam

Page 9

Page 10

Page 11

Page 12

Page 13

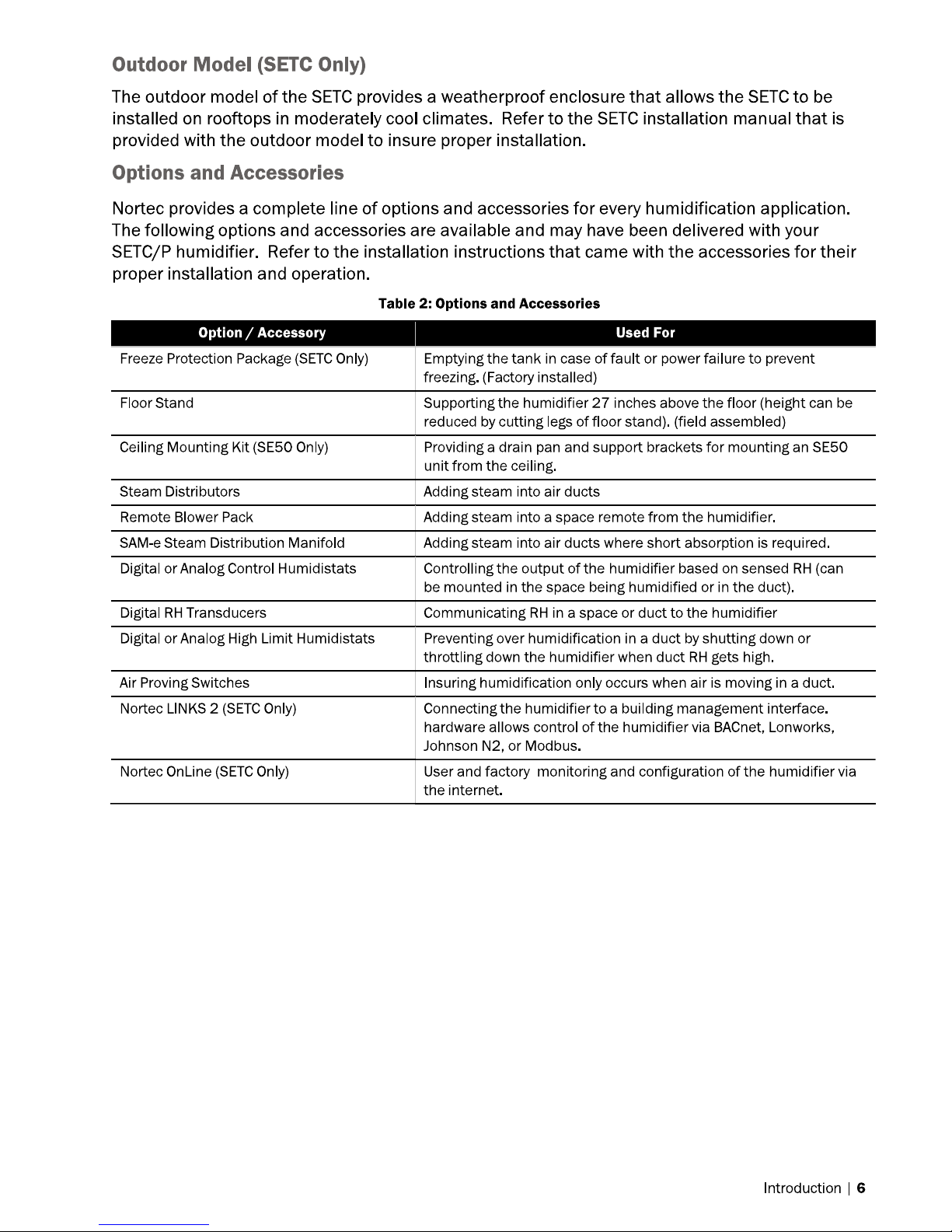

E

Ground

Location

Mounting

Pg 11

Steam

Distribution

Pg 17

1 ft (30 cm)

Plumbing

Pg 14

Boiler

Steam

Pg 15

Controls

Pg 23

Electrical

Pg 22

Modulation

Controls

2 in.

(5 cm)

min.

1ft (30 cm)

min.

On/Off

Controls

30 in.

(76 cm)

Min.

SE 1050

SAM-e Distribution Manifold

36 in. (91 cm)

Min. Top Clearance

(0 in SE 50)

30 in.

(76 cm)

Clearance

Min.

Side

30 in.

(76 cm)

Min.

Front

Clearance

Pressurized

steam supply

Water supply

30-80 psig

Tank drain

Air gap

Condensate

return to boiler

123- Ctrl Ground

45-

78-

9- Ground

10-

11-

12-

S

E

X T

T

C

/

P

24 VAC

On/Off Loop

Control Signal

Limit Signal

6-

5 VD C

Ground

Tank Blow Down

Actuator

Actuator

0-10 VDC Out

Dedicated

Circuit Breaker

or Disconnect

SETC/P

EXT

Page 14

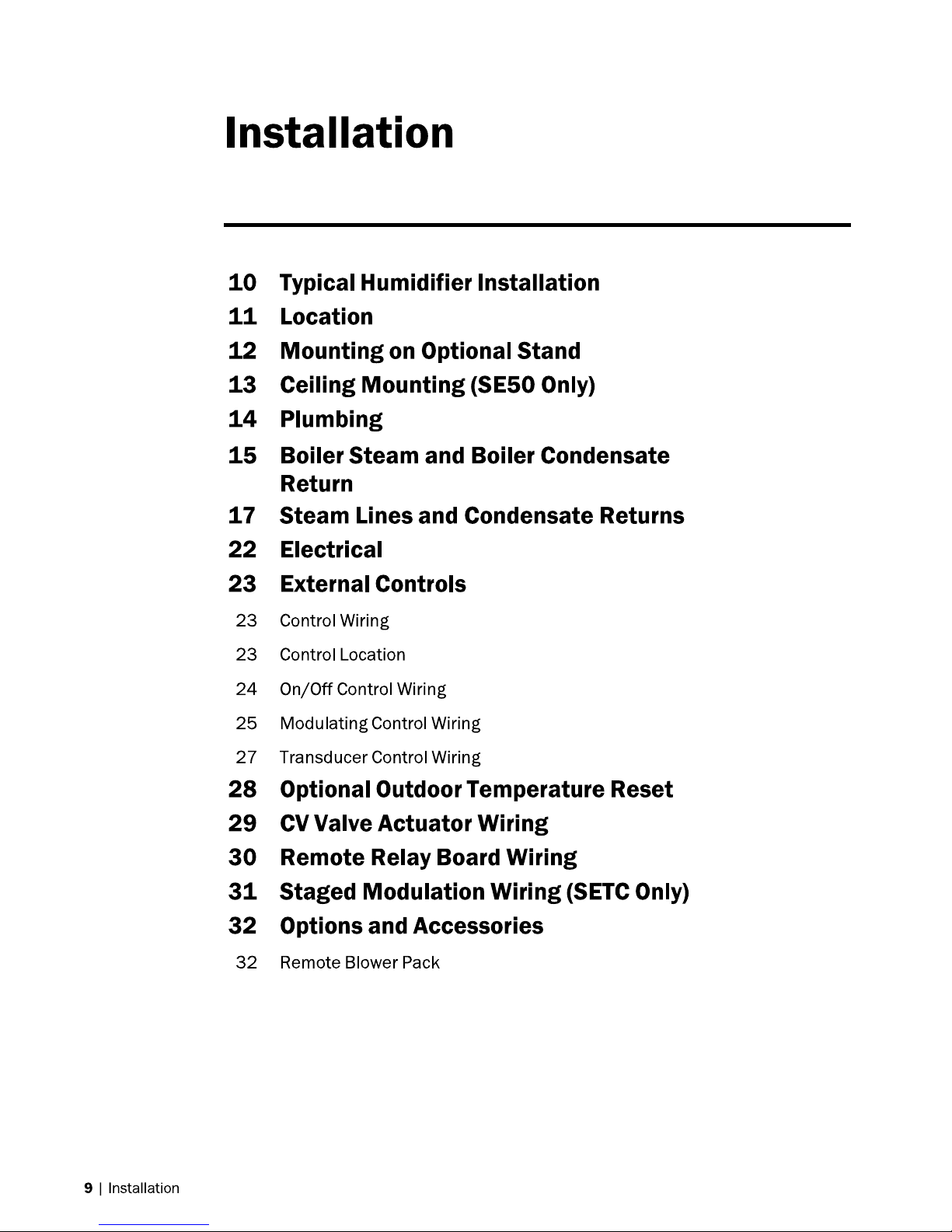

As Close as

Possible to Steam

Distributor

Mount

Humidifier

evel

5-95%

36 in. (91 cm) Min.

Top Clearance

(0 in. for SE50 only)

30 in.

(76 cm)

Min.

SE 1050

only

30 in.

(76 cm)

Min. Side

Clearance

Condensate drain

line must be

sloped down, do

not use to lift

condensate

30 in.

(76 cm)

Min. Front

Clearance

Page 15

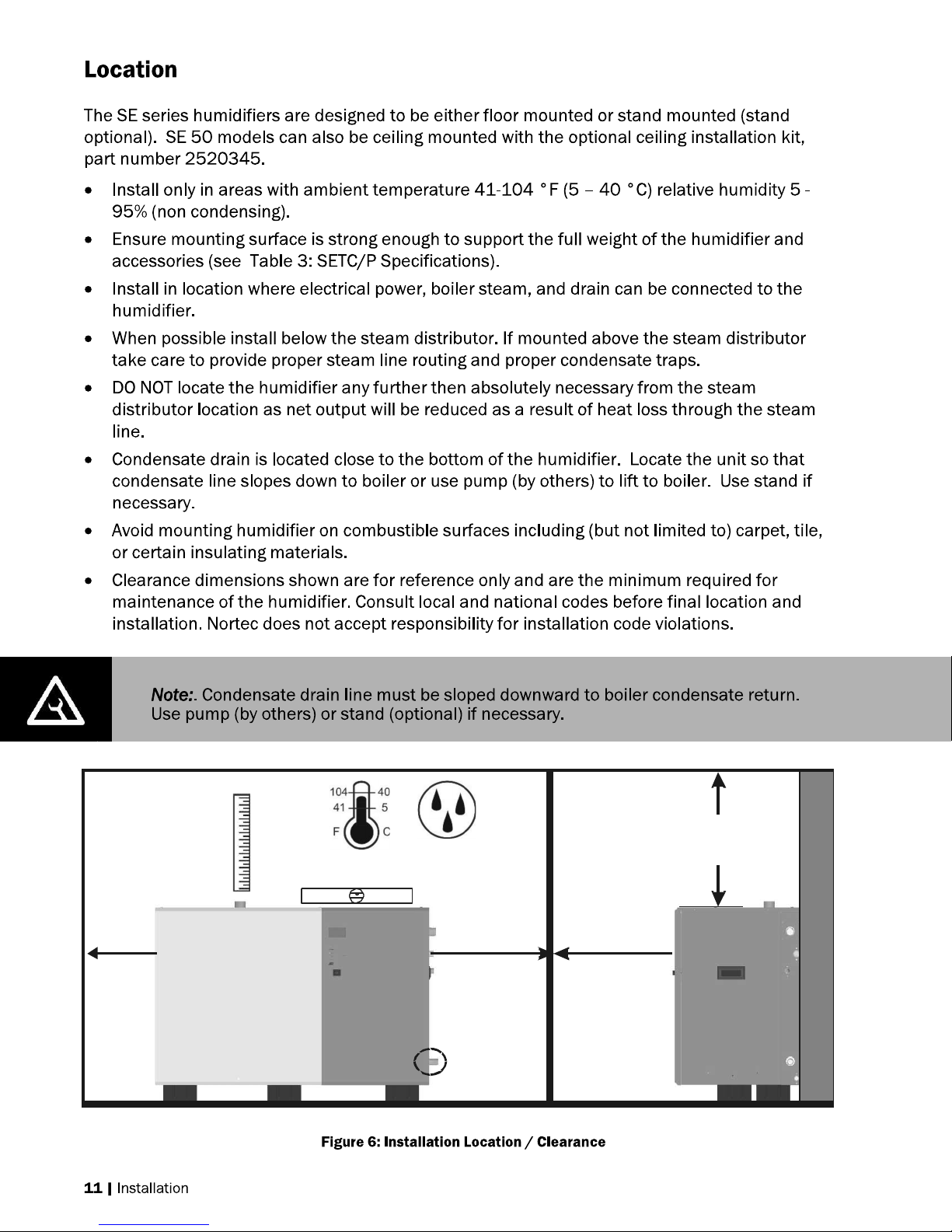

Fasten

SE

humidifier

nuts

Nm).

Note:

Center

support

only

and larger.

Secure

stand

to

floor

(hardware

by

others)

Mount stand on level surface

Ensure humidifier is Level

lock washers, and

to 200 in-lb (22.6

four places.

to stand with bolts,

provided. Tighten

present on SE 525

Page 16

Anchor 3/8 in (M10)

support rods to ceiling

(by others)

12.8 in.

(32.6 cm)

Sloped drain

1/2 in. pipe

(by others)

Support rods and hardware

(by others) must not extend

below support bracket flange.

Page 17

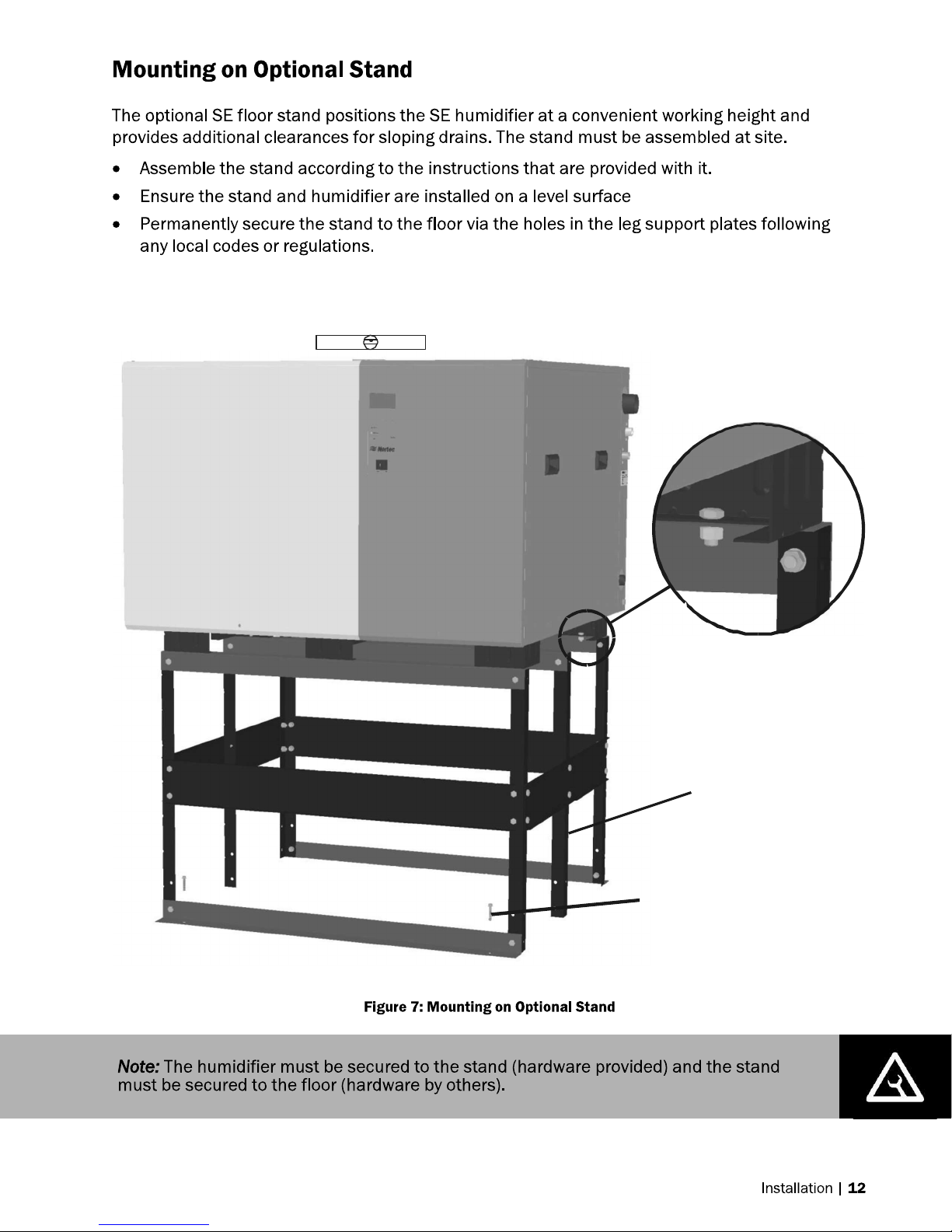

0.75 in. (19 mm). OD

un-threaded drain outlet

Connect with hose cuff

and hose clamps.

1/2 in. NPT

Use union to connect

supply pipe to unit.

Always install a water

shut-off valve.

Air gap required.

2 1/2 in. to 1 1/4 in. copper

reducer is ideal.

Hose/line must not touch

the bottom of the funnel.

Min. 1 1/4 in. OD drain line.

Slope down. Increase size

if combining multiple drains.

Axillary drain, 1/2 in. female NPT

For draining tank without pump. Leave

valve closed except if freeze protection is installed.

*Pipe, unions, and water shut-off valve not supplied by NORTEC.

Page 18

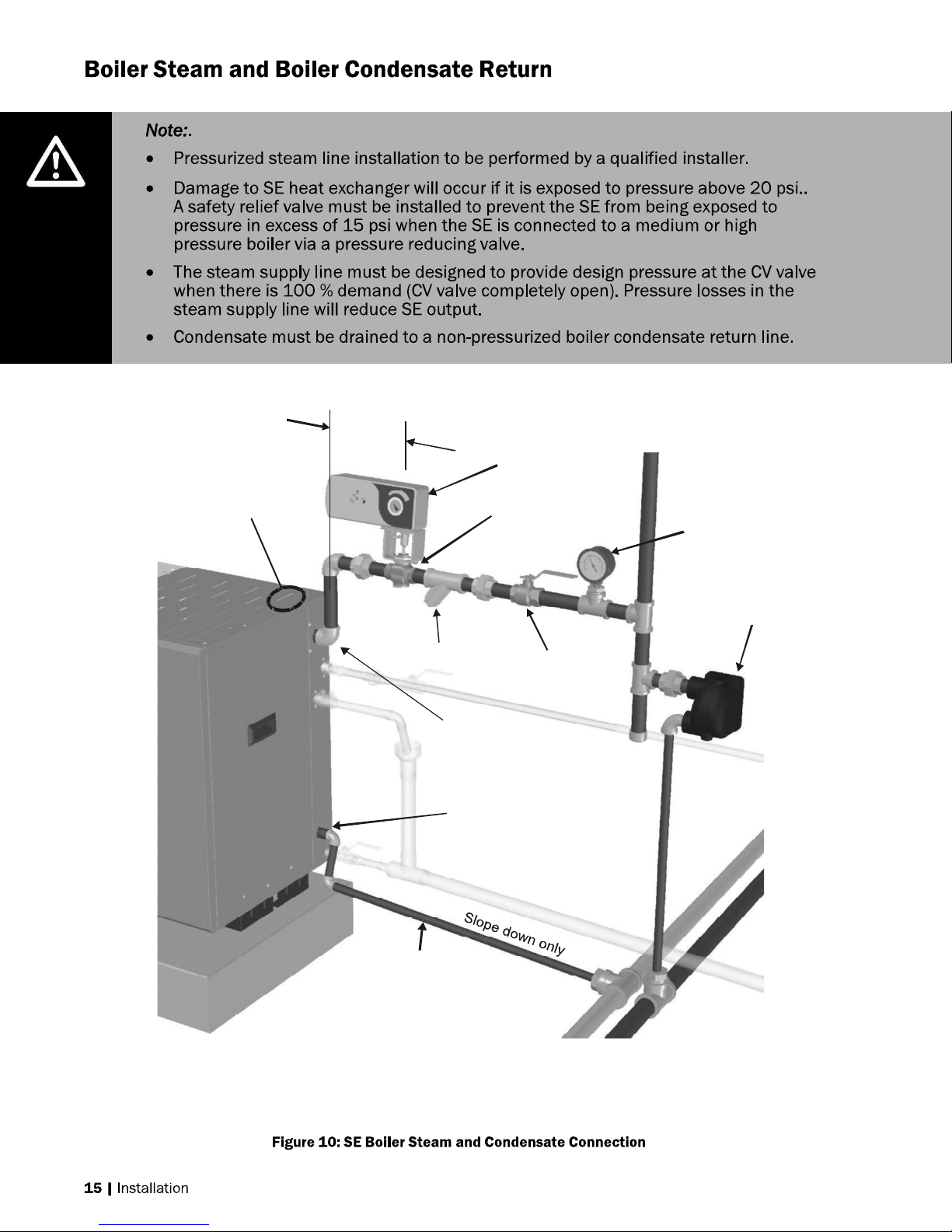

6 in.

cm)

Boiler

steam

supply

psi

measured

at CV

Valve

Actuator

(optional)

F&T Trap

Wye Strainer

Isolation

Valve

Boiler

steam

(see table 3)

Condensate

Drain

Condensate

drain

line.

must be lifted.

Boiler steam

inlet port location

on SE 1050

(15

Max

CV Valve

(see table 3)

inlet port

Port (see table 3)

line. Max 15 psi, Min 5

Pressure

gauge

Note: Nortec supplies CV valve, actuator

and wye strainer. All other

components and fittings by others.

Gravity feed to boiler.

Use pump if condensate

condensate header

Not pressurized

(slope down)

Pressurized condensate

header

Page 19

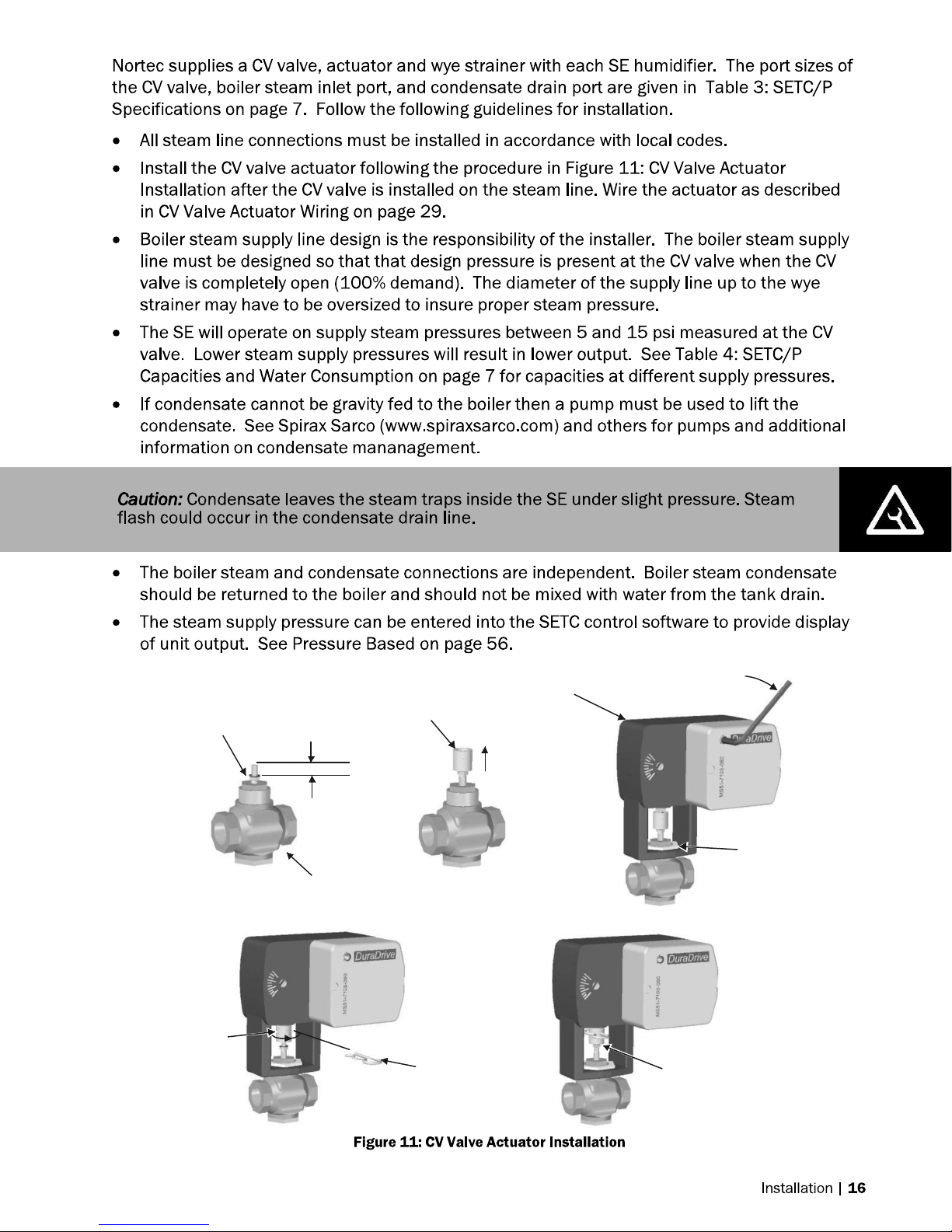

Install jam nut

and lock washer

Turn stem

extension

until holes

line up

1/2 in. (1.2 cm)

CV Valve

Install stem

extension

min.

Insert

connecting

pin

Actuator

Raise valve

stem to full up

2 turns then

push in and

1/8 turn to lock

Tighten jam nut

against stem extension

Install and

tighten

mounting nut

Page 20

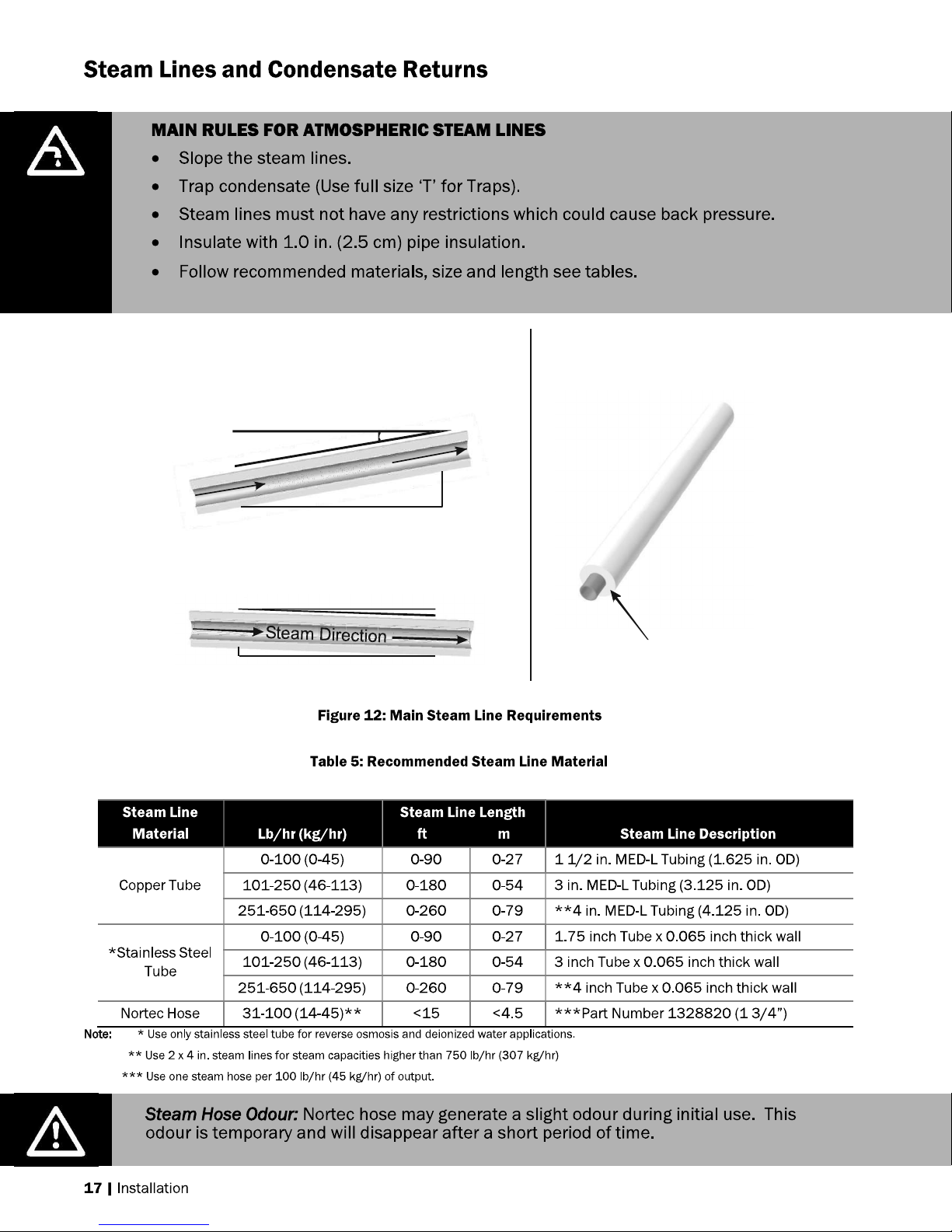

10 Degrees

2 in.

) 1 ft

(30 cm)

Use Appropriate Slope Insulate Pipe

(5 cm

0.5 in.

(12 mm)

St

eam

Dire

ction

1ft (30 cm)

2 Degrees

1 in. (2.5 cm) pipe

insulation

Page 21

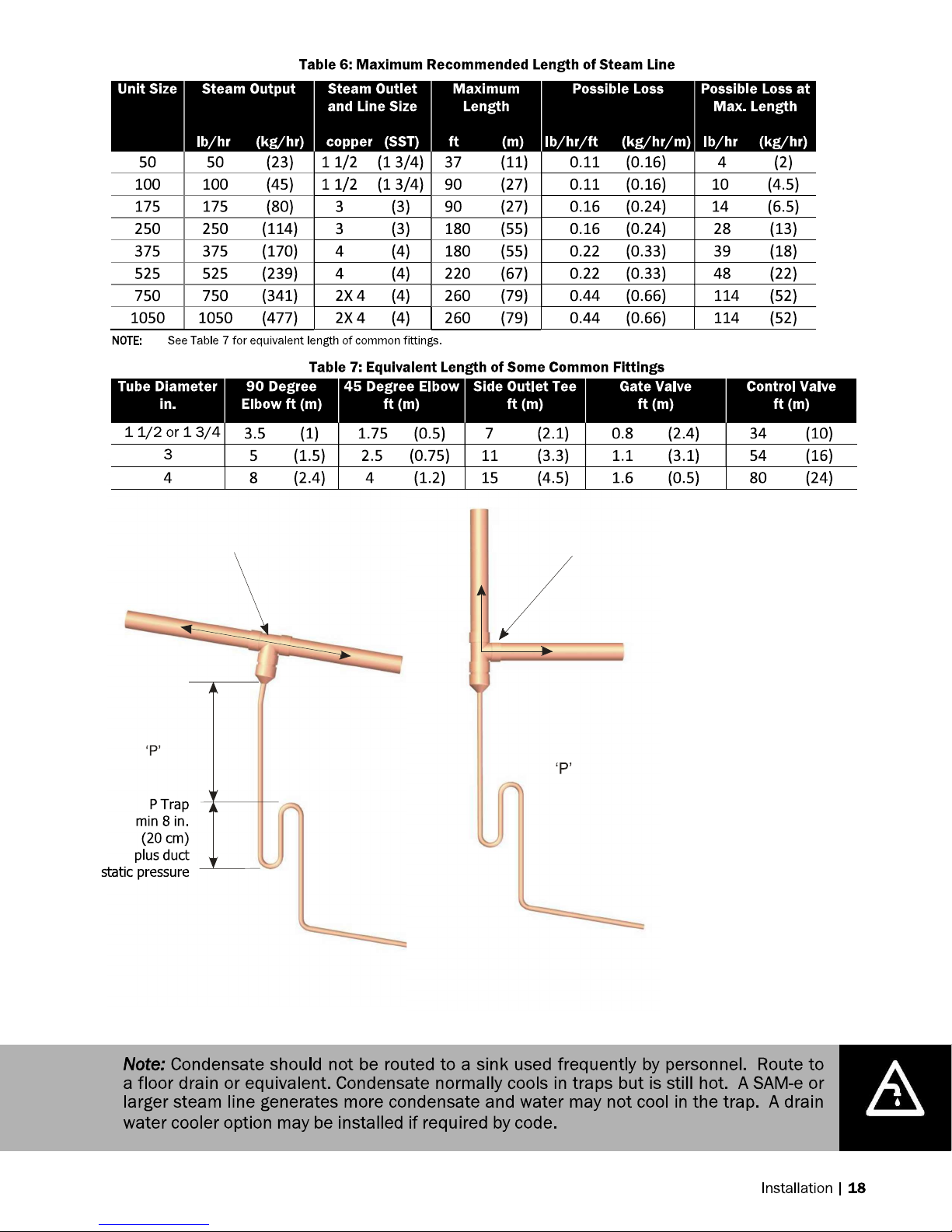

as steam

line

12 in. (30 cm)

min drop to

top of Trap

Tee is same size

Use a full size tee, not a 90

degree elbow for vertical

to horizontal transitions.

Traps Use:

-

NORTEC 0.375 in condensate hose .

-

1/4 in Med-L copper tubing, or

-

0.375 in stainless steel tubing

Condensate drains must be sloped down.

Route to humidifier fill cup if possible.

Page 22

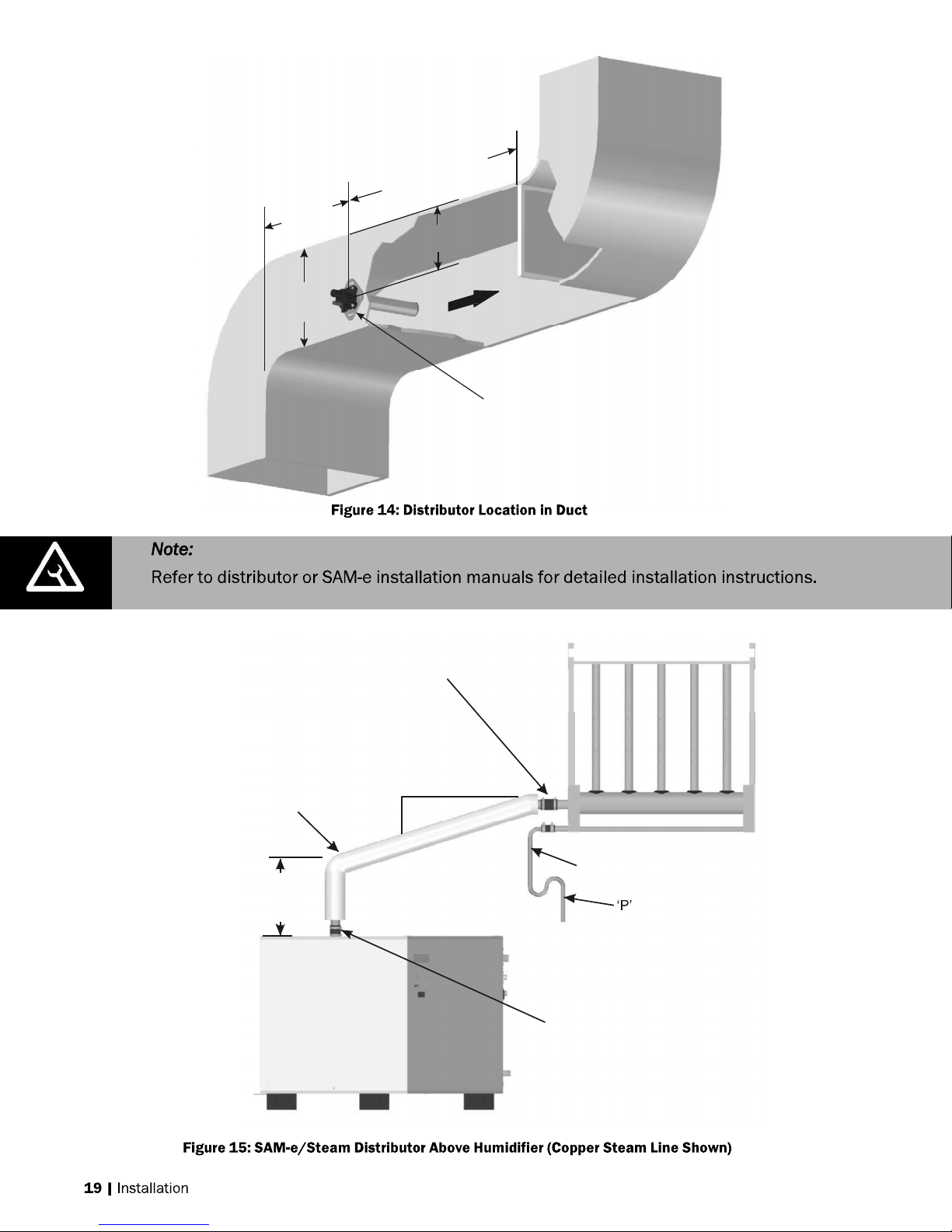

Calculated absorption

obstruction

if unknown

2 x duct

height min.

2/3 Duct

12 in.

(30

cm)

min.

Mount

distributor

to side of duct

distance to any

or 8-10 ft (2.4 - 3 m)

height

Insulated copper

steam line. Support

so weight is not on

steam outlet.

1 ft (30 cm)

min. before

anybend

2 in. (5 cm)

Hose cuff

with clamps

1 ft (30 cm)

min.

Condensate line

Trap

To drain

Use steam hose between

steam outlet and steam line.

Page 23

Min 12 in.

1 ft (30 cm)

0.5

in. (1.2 cm)

min.

1ft (30 cm)

re

Obstruction

1 ft (30 cm)

Use full s

ize condensate

tee

to

and immediately

after it.

Trap To drain

Trap To drain

(30 cm)

radius

Hose will soften

over time

proper support

Is necessary

1 ft (30 cm)

min. Before

any bend

Support Brackets

Install Condensate Tee

Before Distributor

Trap

1 ft (30 cm)

min.

Trap

To drain

To drain

min. befo

any bend

at low point. Slope lines up

min.

Page 24

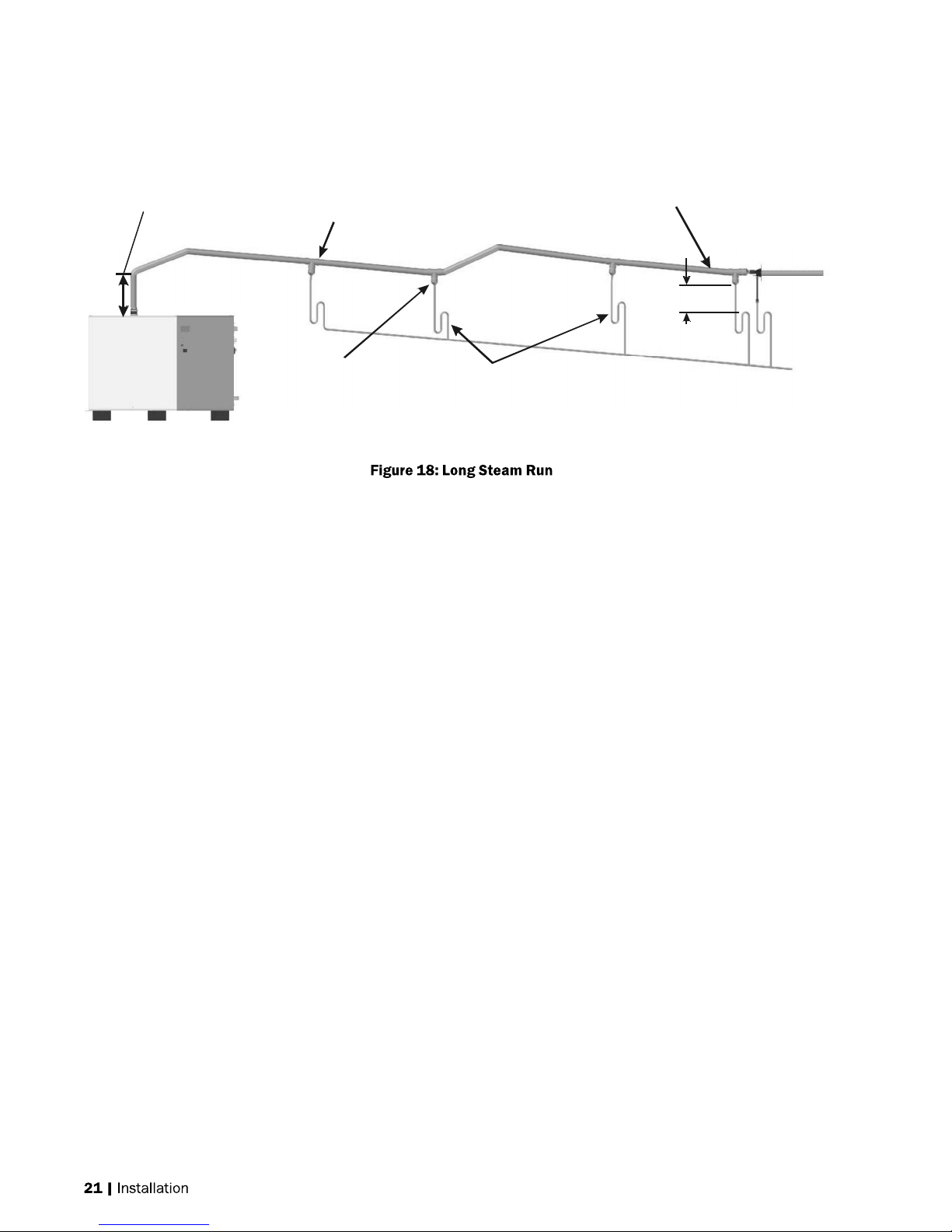

Method for Longer Runs With Limited Vertical Space

1 ft (30 cm)

min before turn

Condensate

tee every

15-20 ft

(4.5 - 6 m)

Install condensate tee

before distributor

Condensate

tee at low

points

Individually trap multiple condensate

returns before joining on common line.

1 ft (30 cm)

min.

To Drain

Page 25

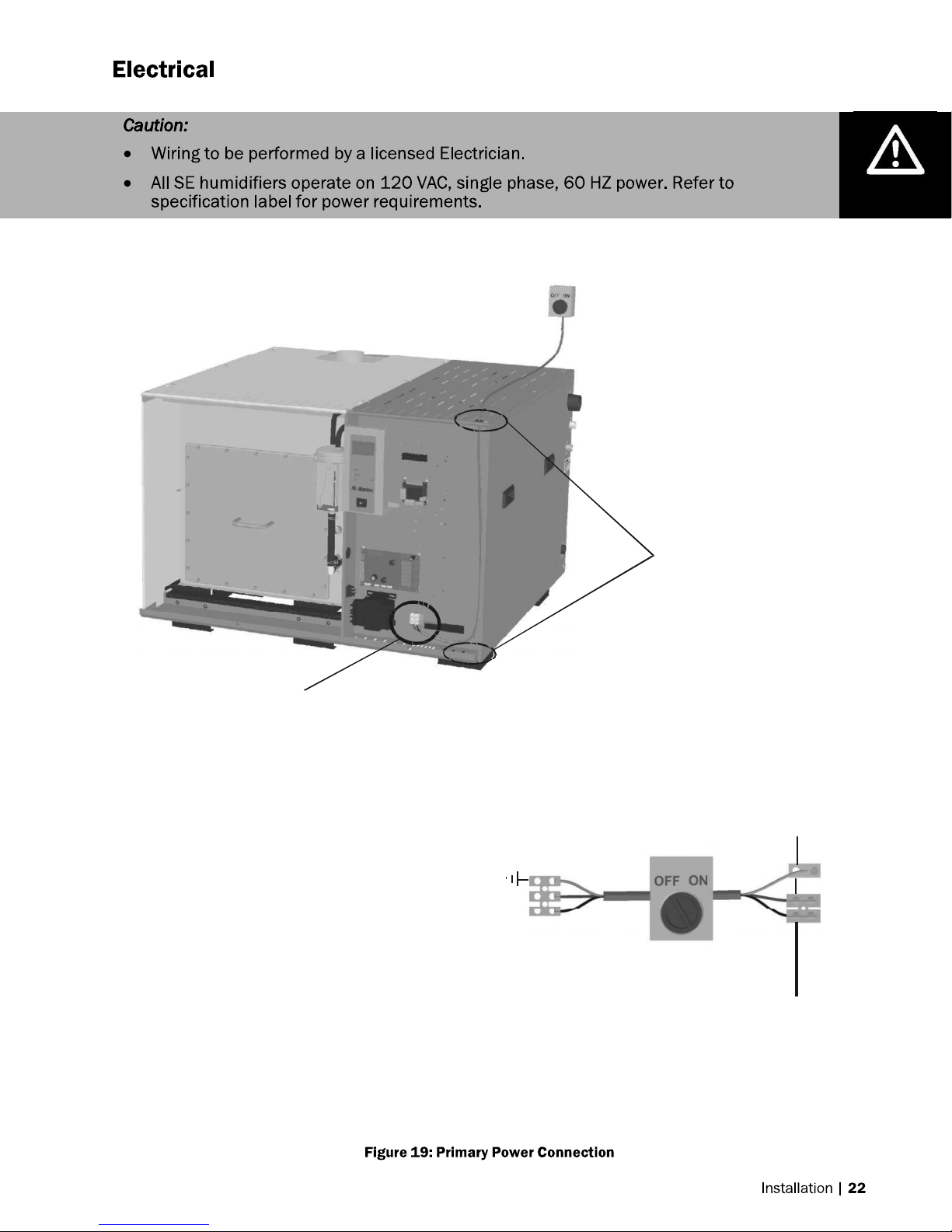

Knockouts provided

in top and bottom panels.

Install strain relief (by others)

High voltage

terminal block

Note:

1 Dedicated external fused

disconnect must be installed.

Fusing must not exceed max

circuit protection as indicated

on the specification label.

2 Ensure that adequate power is

available to carry full humidifier

amp draw as indicated on the

specification label.

3 All wiring to be in accordance

with national and local electrical

codes.

Single Phase Supply

Ground

L1

Neutral

SETC / P Primary Power

Dedicated circuit

breaker or fused

disconect.

E I

X N

Ground

L1

Neutral

T T

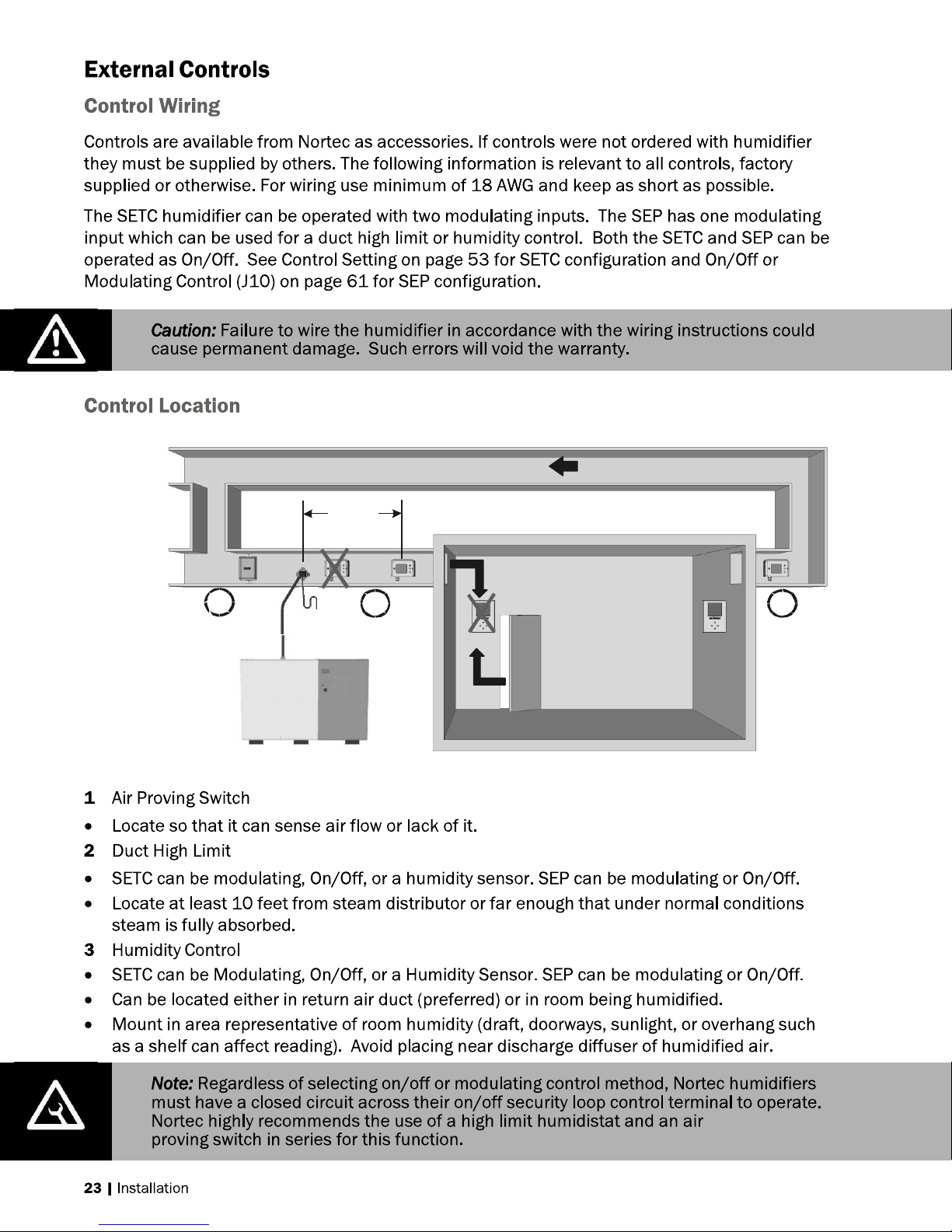

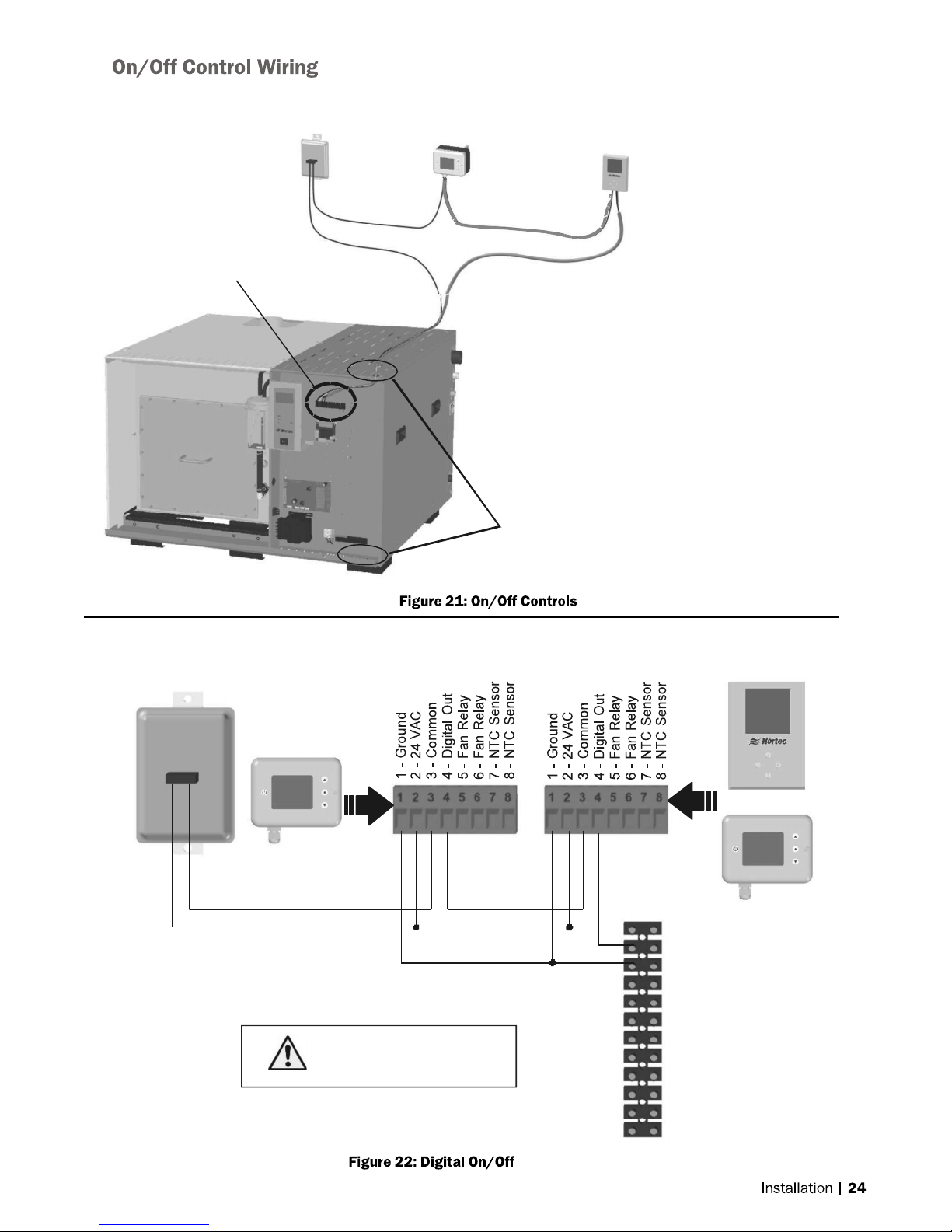

Page 26

10 ft min.

1

Air

Proving

Switch

2

Duct High

Limit

3

Humidity

Control

(return air

duct or

in room)

Page 27

Air Proving

Com

Humidifier Terminal Strip

Switch

Duct High Limit

2548732 -On/Off

Duct Humidistat

Humidity Control

2548731 - On/Off

Wall Humidistat

Air Proving Switch

Wire to make when

sensing air flow

N/O

Knockouts provided

in top and bottom panels.

Install strain relief (by others)

Duct High Limit

2548732 - On/Off Duct Humidistat

Wire to make on drop in humidity

Note: 1 Humidifier will run when circuit between

terminal 1 and 2 on humidifier is closed.

2

Terminal 1 is 24VAC Hot, turn unit off to

avoid shorting while wiring.

3

Digital Humidistats require 24 VAC power

from terminals 1 and 3 of humidifier.

4

Humidity Control can be wall mounted

as shown or return air duct mounted.

Humidity Control

2548731 - On/Off Wall Humidistat or,

2548732 - On/Off Duct Humidistat

Connect 24 VAC ,

term inal 1 of hum id ifie r to

term inal 2 of co n t rollers.

OR

E S

X E

T

1- 24 VAC

2 - On/Off Loop

3 - Ground

4 - Control Signal

5 - Limit Signal (SETC only)

6 - 5 VDC

7 - Grou nd

8 - Full Tank Blow Down

9 - Ground

10 - Actuator power

11 - Actuator power

12 - 0-10 VDC Out

Page 28

Air Proving

1

-

Ground

1 -

G

r

ou

n

d

Switch

High Limit Humidistat

Control Humidistat

Humidifier Terminal Strip

Note: 1

Install On/Off controls or jumper between

terminal 1 and 2 of humidifier in order to run.

2

Terminal 1 is 24 VAC Hot, turn unit off to

avoid shorting while wiring.

3

High Limit Humidistat must be duct mounted.

It can be On/Off or modulating.

4

Control Humidistat can be mounted in space

or in return air duct and can be On/Off or

modulating.

5

The SEP can only accept one modulating

signal.

Knockouts provided

in top and bottom panels.

Install strain relief (by others)

2520266 - Digital Duct Humidistat

Analog Out - 3

24 VAC - 2

Ground - 1

Package

2 - 24 VAC

6 - Analog Out

7 - Analog In

8 - Temperature

Connect 24 VAC, terminal

1 of SETC/P to terminal

2 of controllers.

1510142 - Digital Wall Humidistat

2 - 24 VAC

6 - Analog Out

8 - Temperature

Insert On/Off

controls or jumper

between 1 and 2

1- 24 VAC

2 - On/Off Loop

3 - Ground

4 - Control Signal

5 - Limit Signal (SETC only)

6 - 5 VDC

7 - Ground

8 - Full Tank Blow Down

9 - Ground

10 - Actuator power

11 - Actuator power

12 - 0-10 VDC Out

E

S

X

E

T

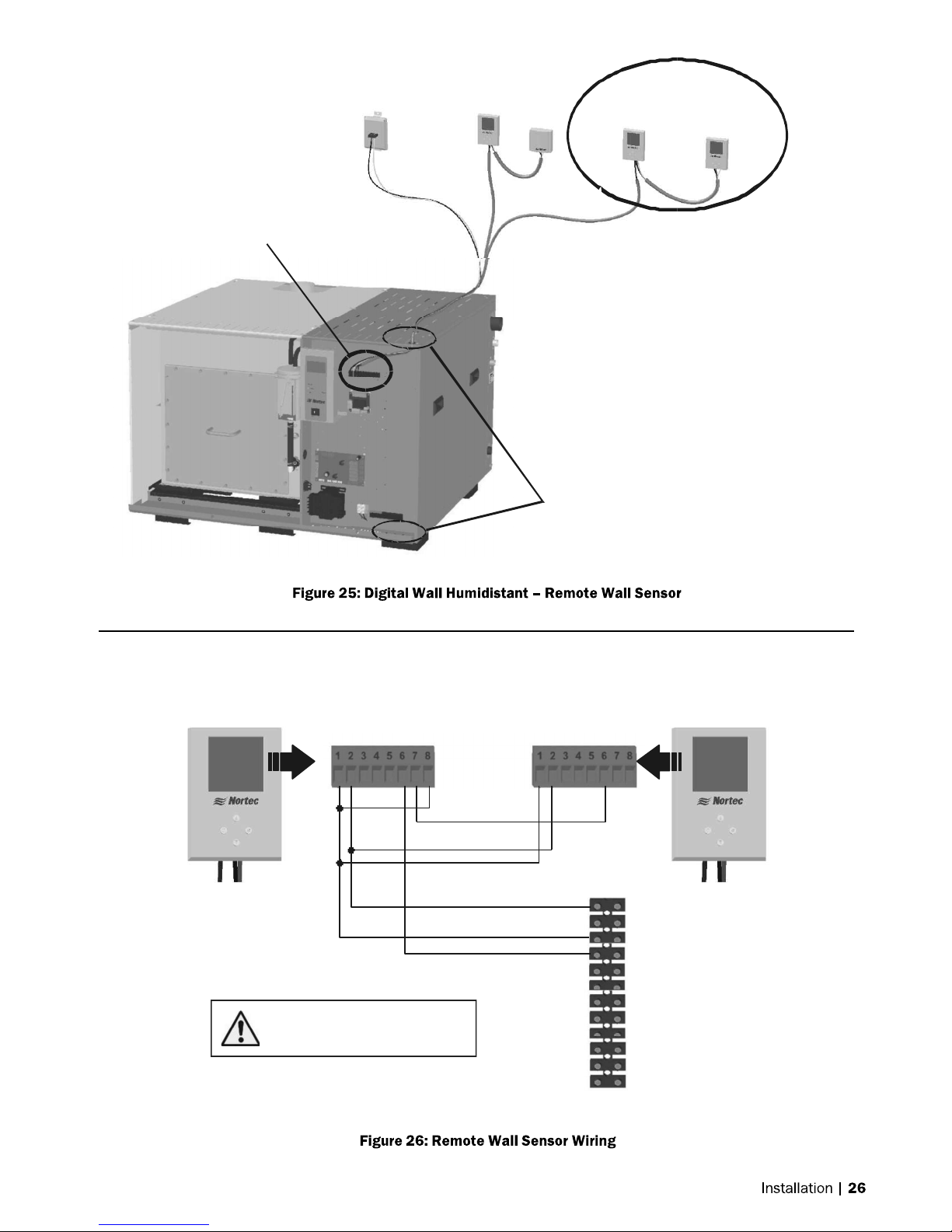

Page 29

1

-

Ground

Temperature

1

-

Ground

Out

Air Proving

only)

Switch

Duct High

Limit

2520261 - Digital

WallW/O Sensor

1509858 - Wall

Sensor

Humidifier Terminal Strip

2520261 - Digital

Wall W/O Sensor

Connect 24 VAC, terminal

1 of SETC/P to terminal

2 - 24 VAC

6 - Analog Out

2 of controllers.

2520261 - Digital Wall W/O Sensor

+

1509858 - Wall Sensor

Wire wall sensor to digital display as shown

below, wire digital display to humidifier as shown

for 151014 2 - Digital Wall Humidistat.

Knockouts provided

in top and bottom panels.

Install strain relief (by others)

7 - Analog In

8 -

2 - 24 VAC

6 - Analog

1509858 - Wall

Sensor

1- 24 VAC

2 - On/Off Loop

3 - Ground

4

- Control Signal

5

- Limit Signal (SETC

6

- 5 VDC

7

- Ground

8

- Full Tank Blow Down

9 - Ground

10 - Actuator power

11 - Actuator power

12 - 0-10 VDC Out

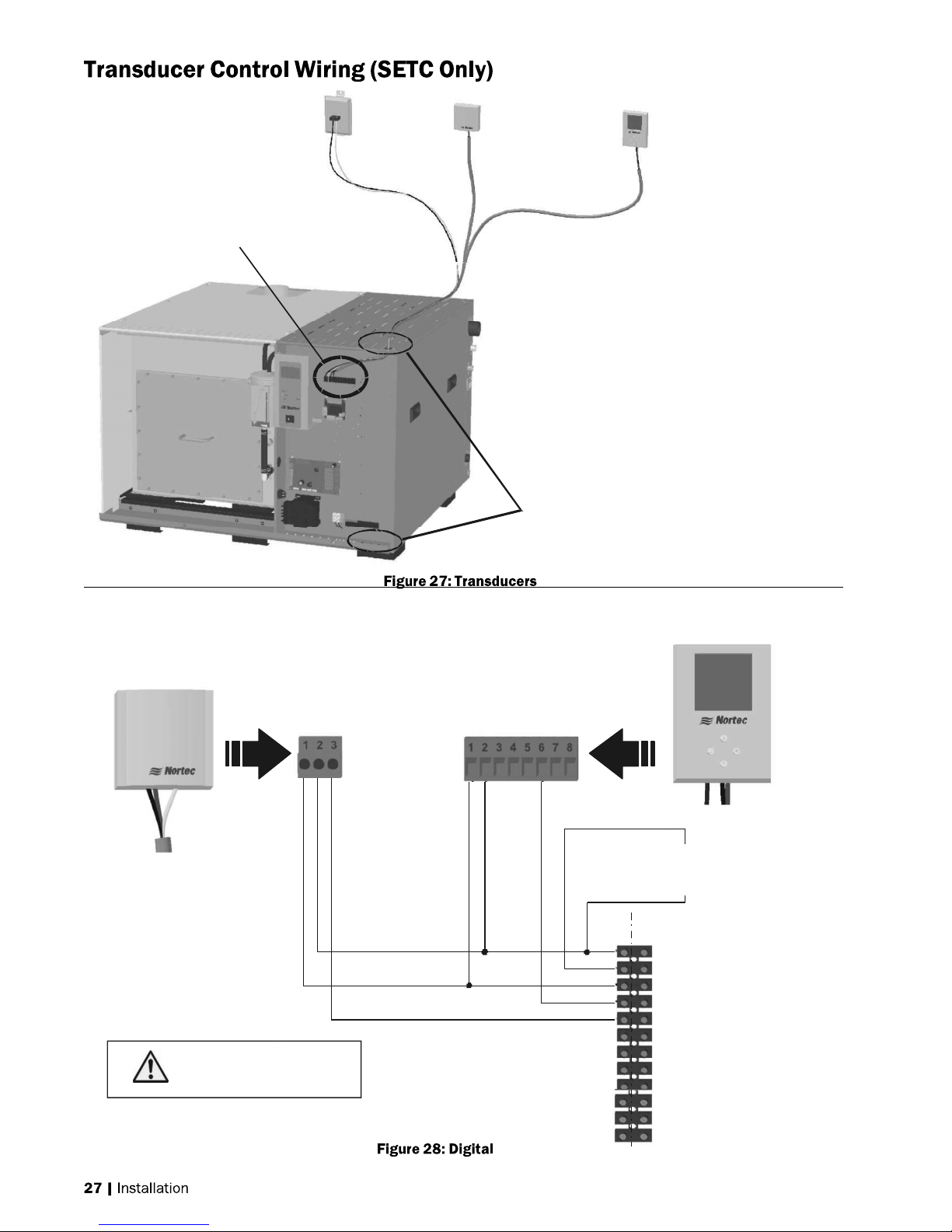

Page 30

1

- Ground

Out

Air Proving

1

-

Ground

Out

E

Switch

Duct High Limit

1509857 - 2-10V

Duct Humidity

Transducer

Humidity Control

1509858 - 2-10V Wall

Humidity Transducer

Humidifier Terminal Strip

1509857 - 2-10V Duct Humidity

Transducer

Note: 1

Install On/Off controls or jumper between

terminal 1 and 2 of humidifier .

2

Terminal 1 is 24 VAC Hot, turn unit off to

avoid shorting while wiring.

3

Duct High limit can be duct humidity

transducer as shown or duct On/Off

humidistat.

4

Humidity Control can be wall humidity

transducer as shown, duct humidity

transducer, or On/Off humidistat.

Knockouts provided

in top and bottom panels.

Install strain relief (by others)

1509858 - 2-10V Wall Humidity

Transducer

2 - 24 VAC

Co n n ect 24 VAC ,

term inal 1 of SETC to

term inal 2 of con tro llers

3 - Analog

2 - 24 VAC

6 - Analog

Insert On/Off

controls or jumper

between 1 and 2

E

S

X

T

1- 24 VAC

2 - On/Off Loop

3 - Ground

4

- Control Signal

5

- Limit Signal (SETC only)

6 - 5 VDC

7

- Ground

8

- Full Tank Blow Down

9 - Ground

10 - Actuator power

11 - Actuator power

12 - 0-10 VDC Out

Page 31

1

-

Ground

Sensor

Sensor

1

-

24

VAC

2548731 - On/Off Wall Humidistat or,

2548732 - On/Off Duct Humidistat

OR

Note:

1 The Temperature sensor is

intended for duct mounting.

2 Locate the temperature sensor

near the fresh air intake. This

will ensure accurate representation

of the outdoor air temperature.

Connect 24 VAC, terminal

1 of humidifier to terminal

2 of controllers.

2 - 24 VAC

3 - Common

4 - Digital Out

2520263 - Outdoor Temperature

5 - Fan Relay

6 - Fan Relay

7 - NTC

8 - NTC

Insert Other

On/Off

controls

in series

2 - Temperature

Sensor

E S

X

T

E

1- 24 VAC

2 - On/Off Loop

3 - Ground

4 - Control Signal

5 - Limit Signal (SETC only)

6 - 5 VDC

7 - Ground

8 - Full Tank Blow Down

9 - Ground

10 - Actuator power

11 - Actuator power

12 - 0-10 VDC Out

Page 32

2520263 - Outdoor Temperature

1

- 24

VAC

Ground

Out

Sensor

Note:

1

The Temperature sensor is

intended for duct mounting.

2

Loc ate the tem perature sensor

near the fresh air intake. This

will ensure accurate representation

of the outdoor air temperat ure.

Connect 24 VAC, terminal

1 of SE to terminal

2 of controllers.

1510142 - Digital Wall Humidistat or,

2520266 - Digital Duct Humidistat Package

2 - Temperature

1 -

2 - 24 VAC

6 - Analog

8 - Temperature

Insert On/Off

controls or jumper

bet ween 1 and 2

E S

X E

T

1- 24 VAC

2 - On/Off Loop

3 - Ground

4

- Control Signal

5

- Limit Signal (SETC only)

6 - 5 VDC

7

- Ground

8

- Full Tank Blow Down

9 - Ground

10 - Actuator power

11 - Actuator power

12 - 0-10 VDC Out

SE 50 - 750

Actuator

Note: 1 Wire the CV valve actuator

to the low voltage

terminal strip.

2 Use minimum of 18 AWG wire

and keep as short as possible.

3 After installation and powering

humidifier verify that travel of

actuator at full de mand is to the

fully open position.

Actuator

SE 10 50

SE 1050 low

volta ge terminal strip

Bk

R

Gr

Y/Bk

SE 50 - 750 Terminal Strip

9 - Gro u nd

R

Bk

Y/Bk

10 - Actuator 24 VAC

11 - Actuator Gr ound

12 - 0-10 VDC Out

9 - Gro u nd

10 - Actuator 24 VAC

11 - Actuator Gr ound

12 - 0-10 VDC Out

Page 33

Page 34

Daisy

Chain

up to 16

Slave

1

Slave

X

Master

Daisy

chain

pole 2 and 3

driver

board.

Humidifiers

of terminal

Note:

Do not reverse polarity.

Do not connect to pole 1 or 4.

J2a-RS485

of the

Page 35

Page 36

Page 37

2 x duct height

from fan or

On/Off Controls

(Air Proving)

in series between

terminal 1 and 2

Steam Line

- Adequate slope

- No restrictions

- No kinks (hose)

- Condensate traps

on long runs

Mounting

- Unit level

- Service clearance

- Properly anchored

if on stand

transition

Disconnect

Correct voltage,

amps, phase

Calculated absorption distance

to any obstruction or 8 - 10 ft

(2.4 - 3 m) if unknown.

P Trap(s) with 12 in .

(30 cm) min. drop(s)

.

Actuator,

- Opens CV Valve

fully at 100%

demand

- Closes fully at 0%.

Air gap

Spec label

Boiler Condensate

- Gravity fed to boiler

or lift pump

Min 10 ft (3 m)

Boiler Steam

- Max 15 psi

- Safety valve if from

med. or high press.

boiler.

- Design pressure

at 100% demand.

1/2 in line min

30-80 PSI

Not plastic drain,

Not to sink.

High Limit

- Wired to terminal 5

- On/Off in series

between terminal

1 and 2

Control

- Wired to terminal 4.

- On/Off in series

between terminal

1 and 2.

- In return duct or

location which

represents humidified

space (no drafts,

not by door, not

by diffuser).

Page 38

LCD Display and

Manual

Input Buttons

(Buttons used to navigate .

status screens and

configure the humidifier,

correspond to icons on

the display)

Status LEDs

Software Drain Button

(Initiates a software

controlled drain)

On/Off Switch

(Turns humidifier On/Off)

drain

switch

Page 39

Menu

Request

xx%

Idle 0 lb/hr

04/30/09

14:25:22

Security loop: Closed

Page 40

Menu

Request

100%

Idle

04/30/09

loop:

750 lb/hr

Menu

Request

xx%

Idle

loop:

0 lb/hr

Menu

CONTROL

: 100%

lb/hr

CONTROL

Pt

: 100%

lb/hr

Menu

HUMIDIFIER

: SETC

750

StandAlone

Security

14:25:22

Closed

04/30/09

Security

Man Cap.

Demand

Limit

Output

14:25:22

Closed

Man Cap.

: 55%

: 80%

: 0

RH CNT

CNT Set-

RH Limit

LIM Set-Pt

Output

Menu

: 55%

: 50%

: 100%

: 70%

: 0

Model

Capacity

Multimode

REG Mode

Software

Press. In

: 750 lb/hr

:

: Demand

: XVXX

: 15 psi

Page 41

Menu

Analog

Output

Output

Signal

:

X.X

VDC

Menu

100%

0%

-4

hrs 0 hrs

Demand:

45%

Menu

Menu

Menu

Menu

Capacity

Total O/P

Tank Monitor

Quick Warm

Press. Base

: xxx lb/hr

: xxx lb/hr

: On/Off

: On/Off

: On/Off

TANK STATUS

Fill Valve : ON/OFF

Drain Pump : ON/OFF

Float Level 5

Run Time : xxx hr

Serv. Time : xxx hr

Serv Due : xxx hr

SENSOR INPUTS

Sec. Loop : Closed

Tank Temp. : Closed

FEATURES LIST

Idle Mode : Idle Drain

FTBD : On/Off

Time Prop. : On/Off

BD Rate : 25%

Drain Cool :On/Off/Smart

Float Check : On/Off

FEATURES LIST

Idle Mode : Idle Drain

FTBD : On/Off

Time Prop. : On/Off

BD Rate : 25%

Drain Cool :On/Off/Smart

Float Check : On/Off

Page 42

Humidity (RH %)

Indicates the

humidistat is on.

A half moon

indicates it is off.

Snowflake indicates the

setpoint is being

overridden by outdoor

temperature.

Power button turns

off the humidiistat if

pressed for 2 seconds

Output signal is shown on

modulating controller

proportional to the demand.

State of On/Off humidistat

Setpoint (RH%)

Option button accesses

sensor calibration.

See troubleshooting

Increase / Decrease Setpoint

Page 43

Humidity (RH %)

Option button accesses

sensor calibration.

See troubleshooting

Adjust calibration

while in calibration

mode

Power button will

display if an

attempt is made to

turn off the transducer.

Page 44

Page 45

If no, perform Pre-Start-up Checklist before starting humidifier.

The prerequisites for the humidifier activating the CV valve actuator to make steam are as follows:

The Humidifier will undergo a self-test when the power is turned on activating the and other

internal components followed by a float test.

If the above listed prerequisites are fulfilled the humidifier will fill the tank, open the CV valve and

begin normal operation.

Page 46

Page 47

Fault LED On

Indicates the controller has detected a

fault condition and stopped humidifier.

Check display for fault information

Service LED On

Indicates that service may be required

or that a warning condition exists.

Check display for warning information

Service LED Blinking

Indicates drain button has been pushed

and unit is draining.

ON LED On

Indicates steam is being produced.

ON LED Blinking

Indicates demand with safety loop open.

DEMAND LED On

Indicates steam is being produced.

DEMAND LED Blinking

Indicates humidifier is in standby waiting

for a demand.

SERVICE LED Flashing

Indicates the controller has detected a

fault. The flash sequence of the LED

indicates which fault has been detected.

FAULT LED On

Indicates the controller has detected a

fault condition and stopped humidifier.

Read Service flash sequence to

determine fault detected.

DEMAND

SERVICE

FAULT

ON

OFF

DRAIN

Page 48

Heat Exchanger

Steam

Line Steam

Distributor

CV

Valve

Actuator

Trap Tank

Float Chamber

Fill Box Cooling

to

Valve

Boiler

Steam

Valve

Vacuum

Break

Steam

Trap

Trap /

Condensate

Boiler

Auxiliary

Drain

Lower

Mixing

Drain

Pump

Float Chamber

Dual Fill

CV

Return to

Drain

Outlet

Overflow

Box

Page 49

Page 50

Insulated copper

steam line. Support

so weight is not on

steam outlet.

SAMe Manifold

Condensate line

Trap

Page 51

Insulate

steam lines

Blower Pack Blower Pack

Balance steam

line length to all

blower packs

Blower pack

condensate dain

and Trap

Provide 120 V

disconect for

blower packs

power.

Wire blwoer pack safety loop

terminals in series with humidifier

safety loop.

Condensate

to drain

Oversize condensate

line to combine multiple

condensate returns

Page 52

5

Screen Displays

Press

to go

down

a

go left information

up a menu

increase/

accept

menu

level

/right one about

current

setting

and

screen

warning

or fault

value

go up a

Request

100%

Idle

: 150 lb/hr

Menu ?

?

Menu

Menu Set

Menu

Set

Request

100%

Password

Idle 30 lb/hr

Set

Screen

Displays

ESC S et

04/30/09

Security loop

14:25:22

Closed

Set P

45%

45%

45 %

Press to

04/30/09 14:25:22

Security loop:

Closed

?=Press for Press to go Press to

level decrease

message

0335

Enter Code

Confirm with

Press to

level

Main Menu

Service Level

Service Level

User Defined Settings

Control Settings

Diagnostics

Page 53

500 hr

Set No Yes Menu

Set No Yes Menu

Menu Menu Set

Service Level

Tank Drain

Reminder

Set

Service Reminder : 500

Service Reminder :500

Tank PreClean

Reset Error History

Reset Serv.

Tank Drain

Service Reminder

500 hr

500

Interrupt Operation

Tank PreClean

Reset Error History

Reset Serv. Reminder

Interrupt Operation?

(This Operation

Can Take >1 hr)

Reset Error History

Menu Yes No Set

Reset Serv. Reminder

No

Menu

Yes

Set

Page 54

Menu Set

Menu

Smart

User Defined Settings

BD Rate

Hours

: 25%

Drain

Set

100

Drain Cool : On

Drain Cool : Off

FTBD

FTBD Time

FTBD

Idle Mode

Idle Time

Fill Corr

Drain Corr

Float Ck

Date

Time

Unit

Language

Contrast

Leak Ck

: Off

: Off

: 100

: Idle

: 72 hr

: 100%

: 100%

: 23:30

: 06/27/09

: 13:22

: lb/hr

: English

: 10

: Off

BD Rate : 25%

Drain Cool

On

Off

On

On

Blowdown Rate

25%

FTBD : Off

FTBD Time : Off

Menu

Full Tank Blowdown

Off

On

On

Menu

FTBD Time

Hour 23

Hour 23

Menu

FTBD Hours

100

100

Set

Set

Set

FTBD Hours : 100f

Menu

Set

Page 55

Keep Warm

Idle Mode : Idle Drain

Menu Set

Menu Set

Menu Set

Idle Mode

Idle Drain

Idle Drain

Idle Drain

Idle Time : 72 hr

Fill Corr : 100%

Menu

Idle Time

72 hr

72 hr

72 hr

Menu

Fill Correction

100 %

100 %

100 %

Menu

Drain Correction

100%

Set

Set

Set

Drain Corr : 100%

Float Ck : 23:30

Date : 27/06/09

100 %

Float Ck

Hour 23

Hour 23

Minute 30

Date

Day 27

Day 27

Month 06

Page 56

10

Menu Set

Time : 13:22

Menu Set

lb/hr

Menu Set

Menu Set

Menu Set

On

Unit : lb/hr

Language : English

Time

Hour 13

Hour 13

Minute 22

Unit Steam

lb/hr

lb/hr

kg/hr

Language

English

English

English

French

Dutch

German

Contrast 10

Leak Ck : Off

Contrast

10

10

Leak Check

Off

Off

Off

Page 57

Menu Set

Control Setting

Short

CD : On

(PI)

Menu Set

Source

Analog

Menu Set

Demand

Menu Set

Menu Set

Source : Analog

Source : Analog

REG Mode : Demand

MOD Mode : Dual CH

Multi Mode : Standalone

CNT Type : 0-10

LIM Type : 0-10

Only present if Mod Mode set to Dual CH

Short CD Tm : 30 s

Time Prop. : Off

Manual Cap : 100%

Mulit Unit Op Range

Modbus Settings

Press Base : On

Supply Press. : 15 psi

RH Settings

REG Mode : Demand

Only present if Short CD set to On

Only present if Multimode set to Master or Slave

Only present if Press Base set to On

Only present if REG Mode set to RH (P) or RH

Analog

Analog

Digital

Regulation Mode

Demand

On/Off

RH (P)

RH (PI)

MOD Mode : Single CH

Multi Mode : Standalone

MOD Mode

Single CH

Single CH

Single CH

Multi Mode

StandAlone

Standalone

StandAlone

Slave

Page 58

Menu Set

CNT Type : 0-10

Menu Set

LIM Type : 0-10V

Short CD : Off

CNT Type

0-10 V

0-5 V

1-5 V

0-10 V

0-10V

2-10 V

0-16 V

32-16 V

0-20 mA

4-20 mA

LIM Type

0-10 V

0-5 V

0-10 V

0-10V

2-10 V

0-16 V

3.2-16 V

Menu

Set

Short Cycle Delay

Off

Off

Off

Short CD Tm : 30 s

Time Prop. : Off

Menu

Short Cycle Delay Time

30 s

30 s

Menu

Time Proportioning

Off

Off

Off

Menu

Manual Capacity

100%

Set

Set

Set

Manual Cap : 100%

100%

100%

Page 59

Menu Set

Menu

Set

Multi Unit Op. Range

Modbus Settings

Press. Based : On

Multi Unit Op. Range

Zero Out

Full Out

Full Out : 20%

: 20%

: 0%

Modbus Settings

Parity : Even

Parity : Even

Timeout : 300 s

Rem Disable : On

Pressure Based

On

Off

On

Menu

Set

Page 60

CNT Band : 15% RH

RH Alerts

: On

Menu Set

Supply Press. : 15 psi

Supply Pressure

15 psi

15 psi

15 psi

RH Settings

Menu

Set

RH Settings

CNT Set-P : 40% RH

CNT Set-P : 40%

CNT Itime : 5 min

LIM Set-P : 80% RH

LIM Band : 15% RH

LIM Damp : 5 s

RH High : 75% RH

RH Low : 33% RH

Only present if MOD Mode is set to Dual CH

Only present if RH Alerts is set to On

CNT Set-P : 40%

CNT Band : 15% RH

CNT Itime : 5 min

Control Set Point

40% RH

40% RH

40% RH

Menu

Control Band

15% RH

15% RH

Menu

Control Integral Time

5 min

5 min

Menu

Set

Set

Set

Page 61

Limit Set Point

On

80% RH

LIM Set-P : 80%

LIM Band : 15% RH

LIM Damp : 15% RH

80% RH

Menu

Limit Band

15% RH

15% RH

Menu

Limit Damping

5 s

5 s

Menu

RH Alerts

Set

Set

Set

RH Alerts : On

RH High : 75%

RH Low : 33% RH

On

On

Menu

RH High

75% RH

75% RH

Menu

RH Low

33% RH

33% RH

Menu

Set

Set

Set

Page 62

Menu Menu Set

Diagnostic Menu

Service

History

Fault History

Set

Menu Set

Menu

Set

Output

Test

Inlet Valve:

Remote

Test

Steam

Rel

ay:

Fault History

Fault History

Output Test

Remote Test

Service History

04.14.07 21:48 E19A

03.20.09 02:35 E19A

Service History

04.21.07 09:10

03.21.09 10:10

Output Test

Remote Test

Off

Off

Menu

Set

Page 63

Blowdown

Adjustment

Potentiometer

Jumpers

J11 to J18

25%

0% 50%

Jumper

J10

Page 64

Page 65

Page 66

Page 67

Service LED On

+

HMW - Humidifier

Maintenance

=

Service timer has

expired and humidifier

needs maintenance

+ 200 Hours

Fault LED On

HMF - Humidifier

Service timer + 200 hours

has passed. Maintenance

must be performed.

+

Maintenance

=

Humidifier has

shut down.

Request 68%

Warning

HMW - Humidifier Maintenance

Humidifying 134 lb/hr

04/30/09 14:25:22

Security loop: Closed

Menu

Request 68 %

Fault

HMF - Humidifier Maintenance

Fault 34 lb/hr

04/30/09 14:25:22

Security loop: Closed

Menu

?

?

Page 68

Page 69

Top Cover

Front Cover

Front Maintenance Door

Gaskets

Tank Door Locknuts.

Apply anti seize compound

to remove.

Do not crush gasket.

Max 5 ft-lbs torque.

Top Maintenance Door

(SE 525 - 1050 Only)

Page 70

F&T Trap

Union

Steam Connection Union

F&T Trap

F&T Trap

Union

Heat Exchanger

Heat Exchanger Gasket

Cabinet Cover

Heat Exchanger Locknuts

Apply anti seize compound

to remove.

Do not crush gasket.

Max. 5 in-lb torque

Page 71

Caution:

Do not

reverse

To tank To fill valve

Squeeze

tabs

assembly

humidifier

float chamber

hoses

to remove

from

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Clock Fault

Drain Ck Fault

Controller

failure.

The drain pump

is activated but

water level has

not decreased

clock

Page 80

Fill Check Fault

The fill valve has

been active for

an extended

time without

increasing a

float level.

FIF

Float Inconsist.

On startup, the

unit registers

that the float

levels do not

increase

logically from 1

to 5

Page 81

FLF

(Cont)

Float Level

More than one

Float Level is

registering at the

same time

FTF

FTW

HMF

HMW

Fill Fault /

Warning

Maint. Fault /

Warning

The fill valve has

been active for

an extended

time without

reaching level 1.

The Humidifier

Maintenance

interval and 72

hour window for

cleaning has

expired

The preset

service interval

time has

expired.

KWF

Keep Warm

Fault

Keep Warm

activated but

tank

temperature has

not increased

within time

allotted

Page 82

(Cont)

LKF

LKW

LMI

Leak Fault /

Warning

Limit Instable

Float level has

dropped multiple

times while no

steam is being

produced.

Limit signal

Is not stable.

MEM

Flash R/W Fault

MTW

ModBus

Timeout

Controller

Memory failure

No Modbus

signal

Page 83

(Cont)

NSW

RDW

RHW

RLW

RMW

No Signal

Warning

Remote

Disabled

Rh High

Warning

Rh Low

Warning

Rh Limit

Warning

No

communication

is detected from

Master unit.

(This unit is set

up as slave)

The unit has

been remotely

disabled through

modbus

communication

or Nortec

Online.

The measured

RH is above the

RH High alarm

setting.

The measured

RH is below the

RH Low alarm

setting.

Operation is

interrupted until

an input higher

than 3% is

received.

Page 84

TCF

TCW

Tank Cold Fault

The tank has not

become hot with

the steam valve

activated.

Page 85

Page 86

Page 87

Page 88

Page 89

Page 90

4 3 5

8

9 6 10 19 2 7

18

11 15

1

14

13

12

16

17

Page 91

Page 92

15 14 16 13 12

3 4

5 5

11

6

10

2 1

9

7

8

17

Page 93

Page 94

1 10 11 12

13

9 8

14

15

18

17 16

2

7

3 19 5 4

6

Page 95

Page 96

SETC

Electrical

SEP

Electrical

7

1

1 2 12 7 3 6

9 9 13

5 6 14

4

10

11

15 10 11

8

18

17

16

Page 97

Page 98

Page 99

Page 100

Certificate No. 002419

Loading...

Loading...