Page 1

Important: Read and save these instructions. This guide to be left with equipment.

1507619-H| 10 SEP 2014

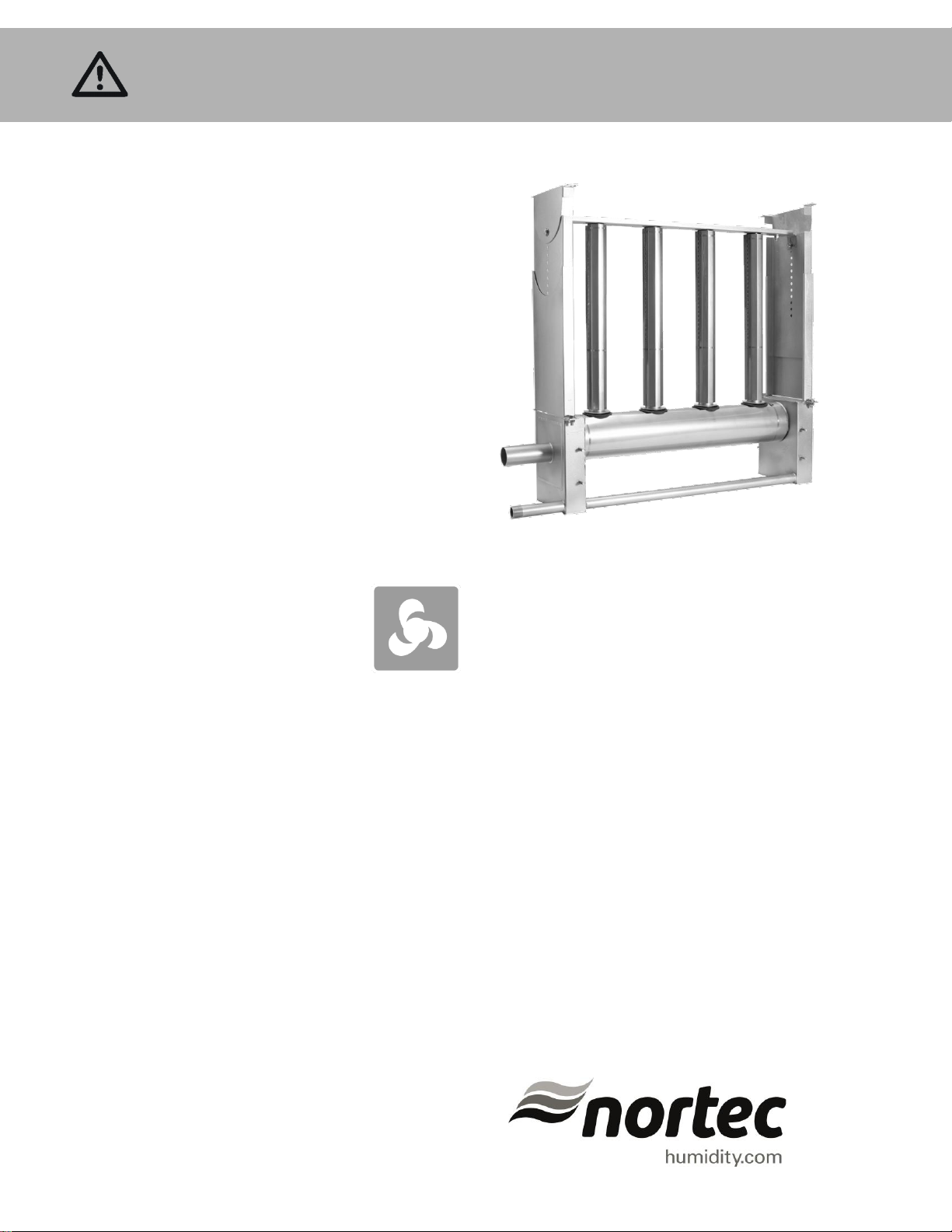

SAM-e

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for your SAM-e and Mini

SAM-e Short Absorption Manifold.

Page 2

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

Thank you for choosing Nortec.

Proprietary Notice

This document and the information disclosed herein are proprietary data of NORTEC HUMIDITY LTD. Neither

this document nor the information contained herein shall be reproduced, used, or disclosed to others without

the written authorization of NORTEC HUMIDITY LTD., except to the extent required for installation or

maintenance of recipient’s equipment. All references to the Nortec name should be taken as referring to

NORTEC HUMIDITY LTD.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2014, NORTEC HUMIDITY LTD. All rights reserved.

Page 3

Contents

2 Introduction

2 Location of Humidifier’s Manifold in an Air Conditioning System

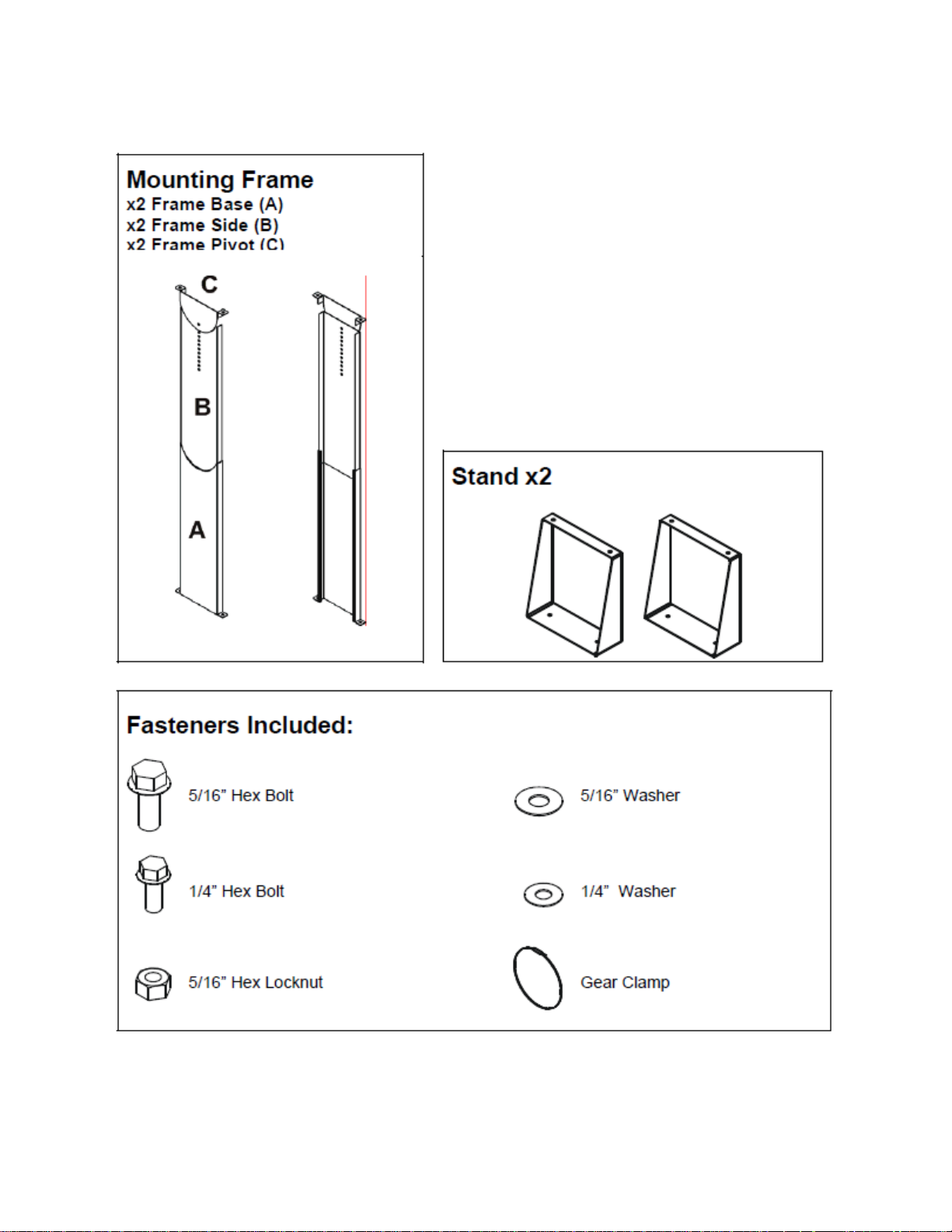

4 Identify your Components

5 How to Use this Manual

7 SAM-e In-Duct

15 Installation in Vertical Duct

17 Mini SAM-e Installation Procedures

21 Plumbing

22 SAM-e with Pressure Steam

24 Mini SAM-e with Pressurized Steam

29 SAM-e with Atmospheric Steam

31 Mini SAM-e with Atmospheric Steam

33 Atmospheric Steam Lines

34 Plumbing

34 Atmospheric SAM-e Steam Lines

39 Length of Steam Line Runs

39 Material for Steam Lines

40 Atmospheric SAM-e Condensate Drainage

41 Steam Lines and Condensate Returns

45 Insulated SAM-e & Mini SAM-e

46 Insulation

49 SAM-e Insulation Retrofit

52 Mini SAM-e Insulation Retrofit

55 Troubleshooting, Maintenance, Spare Parts

Page 4

CAUTION: Plumbing

All plumbing work should be done according to local plumbing code.

CAUTION: Installation

CAUTION: Servicing

Disconnect main power before any servicing.

During and following operation of the humidifier, the steam and components in

contact with the steam such as the blower pack, steam lines, steam distributors,

and condensate lines can become hot and can burn if touched.

Nortec does not accept any liability for installations of humidity equipment

installed by unqualified personnel or the use of parts/components/equipment

that are not authorized or approved by Nortec.

Plumbing to be performed by a licensed plumber.

Drain water from humidifier can be very hot. Do not drain to public sink.

Do not mount on hot surfaces.

Do not mount in area where freezing can occur.

Do not mount on vibrating surface.

Do not mount on floor.

The RH2 produces steam at atmospheric pressure no devices which could block

steam output should be connected to the steam outlet.

Steam lines must be installed so that no restriction can produce backpressure in

the humidifier.

1 | SAM-e Installation

Page 5

Introduction

Receiving and Unpacking Equipment

Check packing slip to ensure ALL material has been delivered. Each humidifier may be shipped

in more than one box.

All material shortages are to be reported to NORTEC within 48 hours from receipt of goods.

NORTEC assumes no responsibility for any material shortages beyond this period.

Inspect boxes for damage and note on shipping waybill accordingly.

After unpacking, inspect equipment for damage. If damage is found, notify the shipper promptly.

All NORTEC products are shipped on an F.O.B. factory basis. Any and all damage, breakage, or loss

claims are to be made to the shipping company.

Location of Humidifier’s Manifold in an Air Conditioning System

Although SAM-e distribution systems are designed to provide drip-less humidification, several operating

factors related to steam supply may result in excess moisture or water collecting in

steam-tube pipe with the potential for water damage. To ensure protection against water damage, best

practice includes either a sealed section of duct or, preferably a drip-pan with drain installed underneath

each unit. In addition, to facilitate maintenance checks and inspections, an inspection cover, inspection

glass or service opening should be installed downstream.

For more information, see SAM-e Engineering Manual [1503529-X].

Notes

Absorption distance: the distance between the SAM-e and the first obstruction (coil, elbow, damper, etc.)

that steam may encounter. Traces of steam may pass the obstruction, but will not condense, leaving

obstructions dry. If any of the duct or air-handling unit (AHU) conditions are changed between design

and installation, calculated absorption distance may change. It is advisable to re-calculate absorption

distance to ensure that SAM-e operates as intended. If changes are required, please contact factory for

assistance.

SAM-e Installation | 2

Page 6

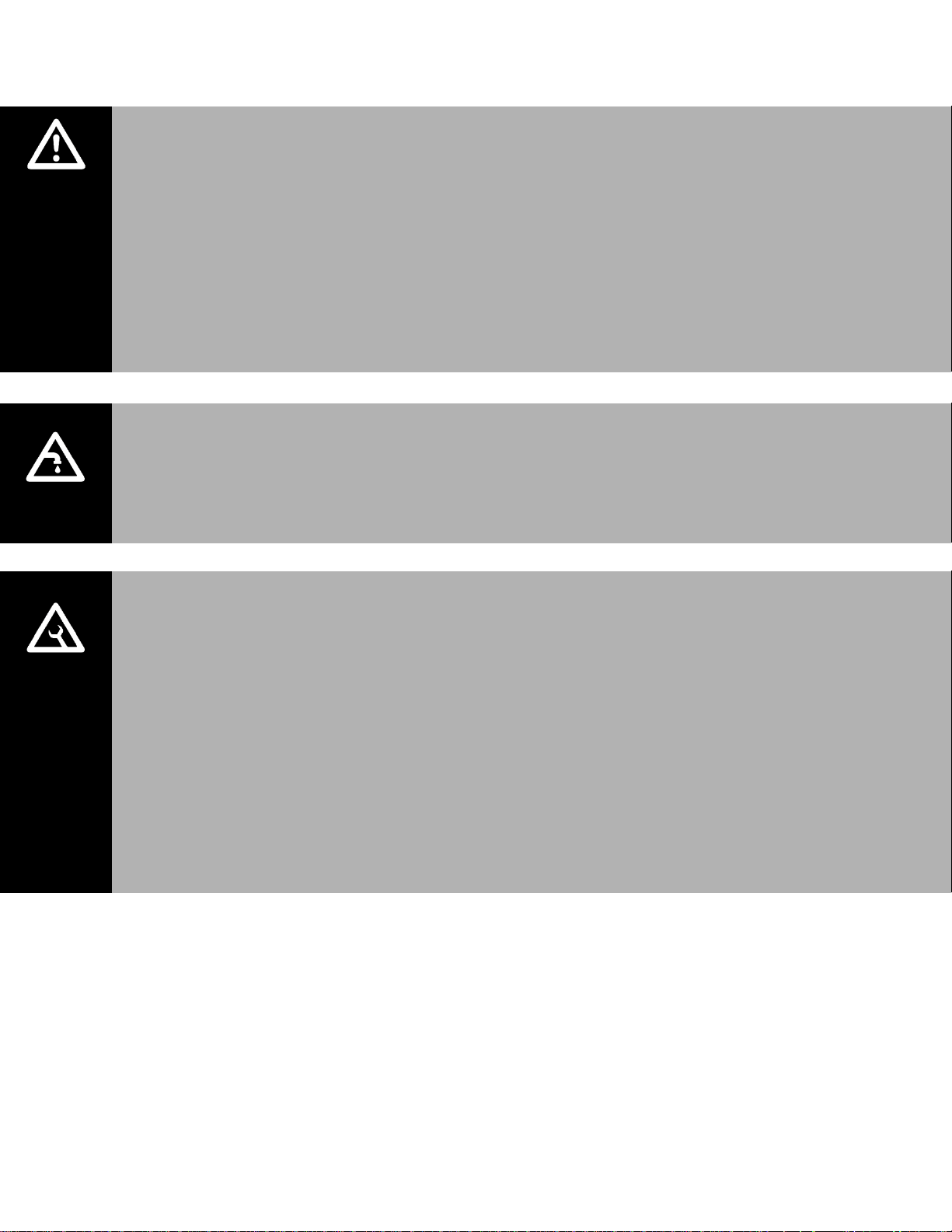

Identify your Components

3 | SAM-e Installation

Page 7

Identify your Optional Components

SAM-e Installation | 4

Page 8

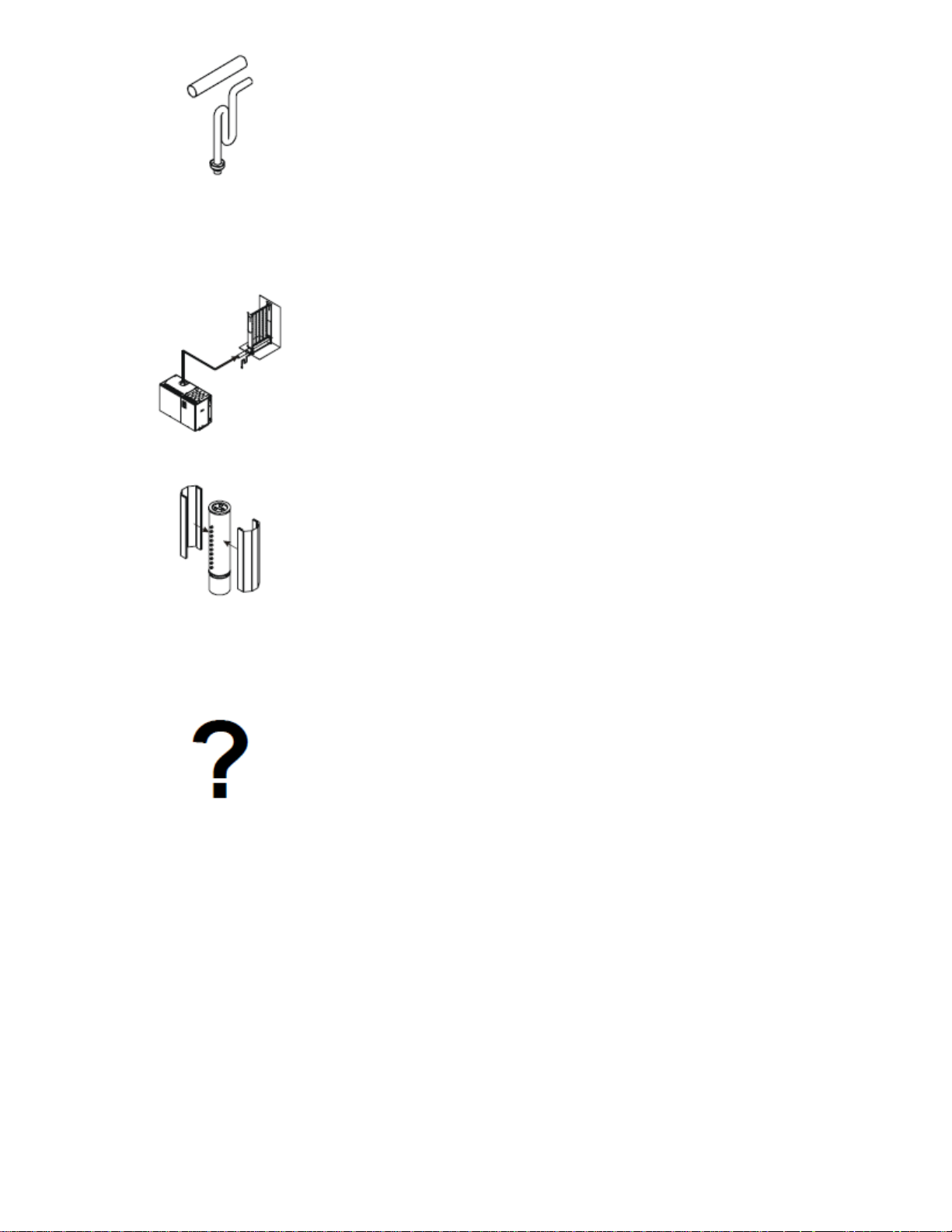

How to Use this Manual

SAM-e - In Duct

Section 2

Follow steps 1-9

SAM-e - Vertical Duct Installation

Section 4

Follow steps 1-8B

Then refer to Section 3.

mini SAM-e

Section 5

Follow steps 1-5

5 | SAM-e Installation

Page 9

Plumbing

Section 6

6A - SAM-e Pressure Steam

6B - mini SAM-e Pressure Steam

6C - SAM-e Atmospheric Steam

6D - mini SAM-e Atmospheric Steam

Steam Lines

Section 7

SAM-e Insulation

Section 8

8A - SAM-e Retrofit

8B - mini SAM-e Retrofit

Troubleshooting, Spare Parts & Warranty

Section 9

SAM-e Installation | 6

Page 10

SAM-e In-Duct

7 | Installation

Page 11

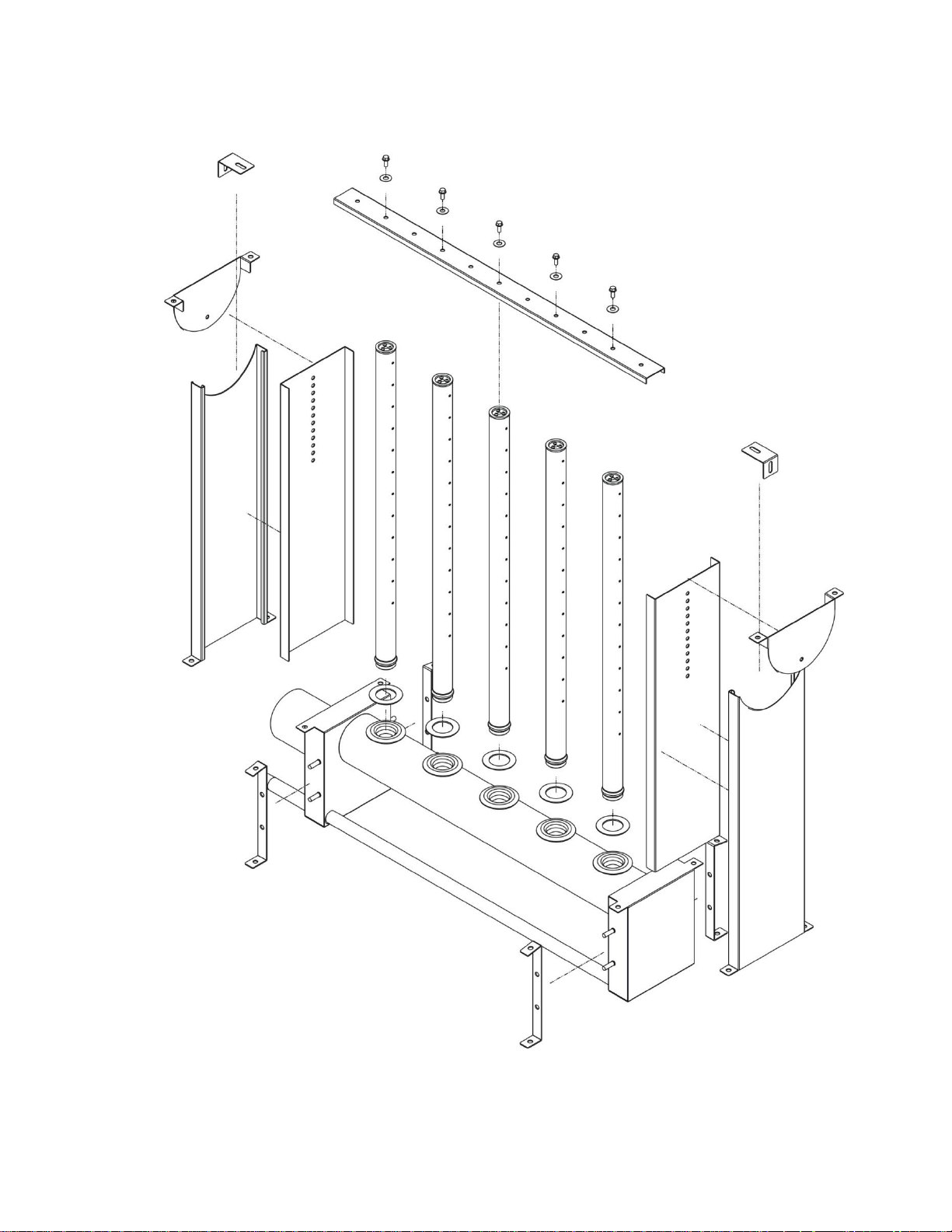

General SAM-e Assembly Diagram

Typical SAM-e Installation

SAM-e Installation | 8

Page 12

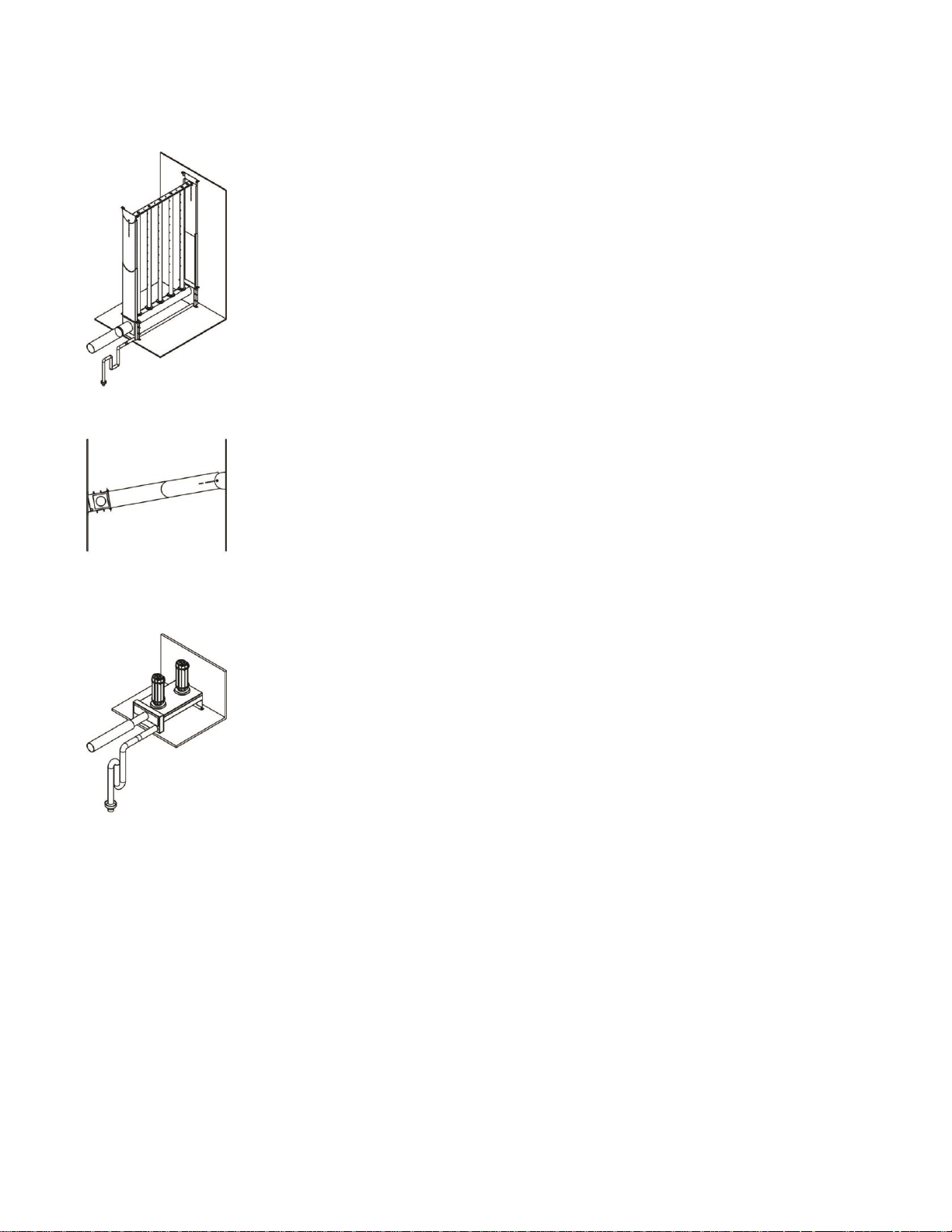

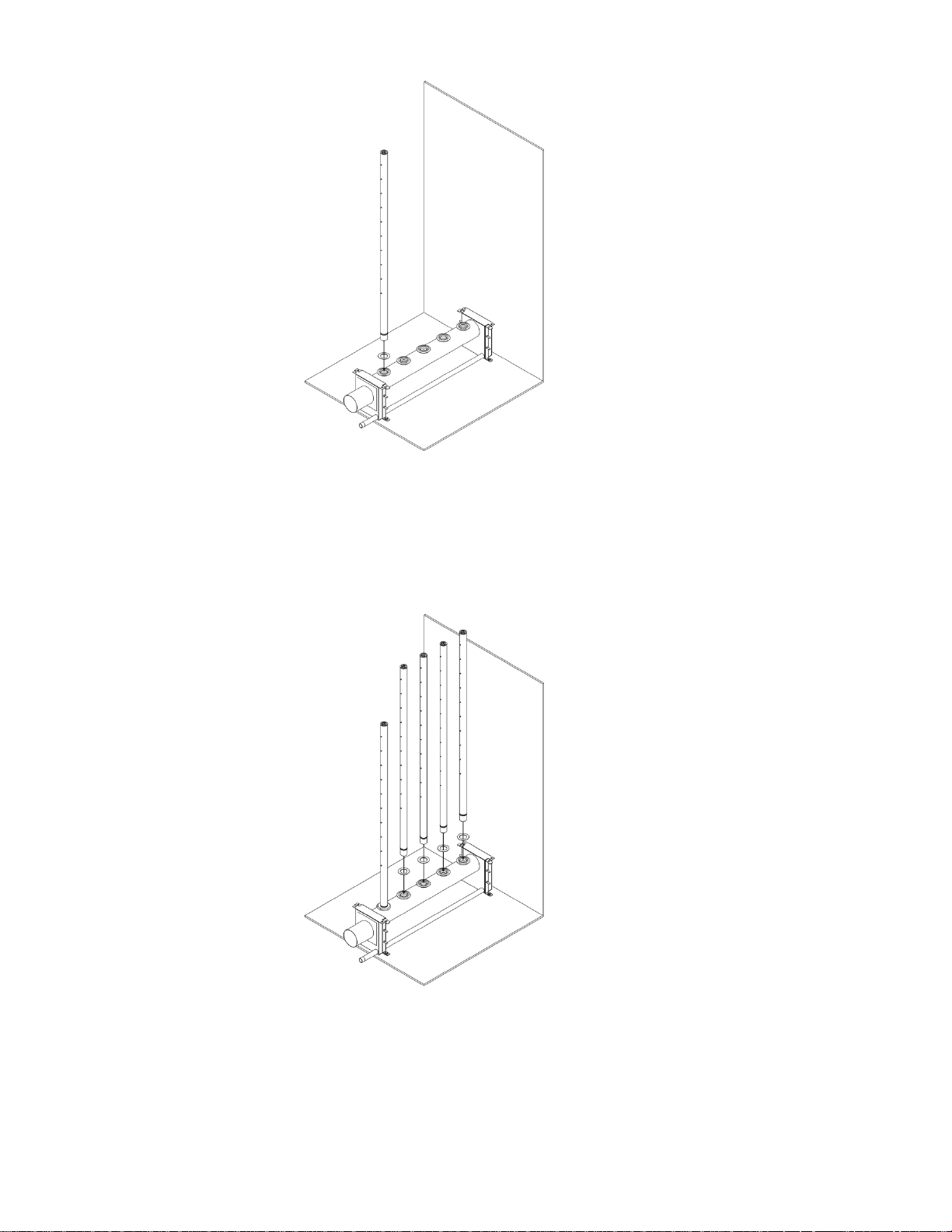

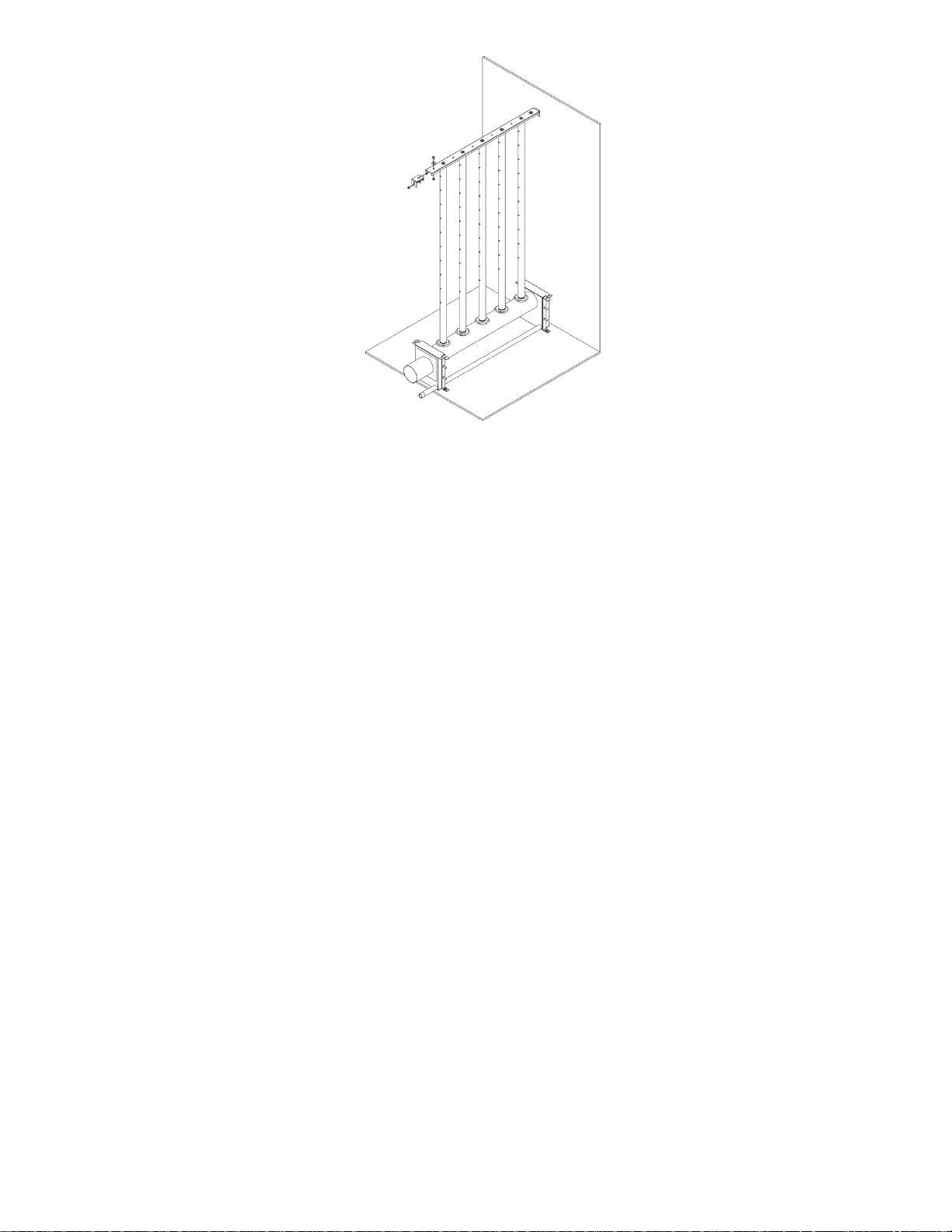

1

Fasten support brackets to header using 5/16” washers and 5/16” nylon lock-nuts.

2

Place header on duct floor and drill 4 x 1/2” (12.7 mm) holes through floor.

Secure header to floor using fasteners (by others).

Use caulking to seal holes in ductwork.

9 | SAM-e Installation

Page 13

3

Insert tube into insertion stop washer and then into grommet.

Wetting grommet with water will make assembly easier.

Ensure nozzles face the sides of the duct (perpendicular to air flow).

4

Assemble remaining tubes in same way.

SAM-e Installation | 10

Page 14

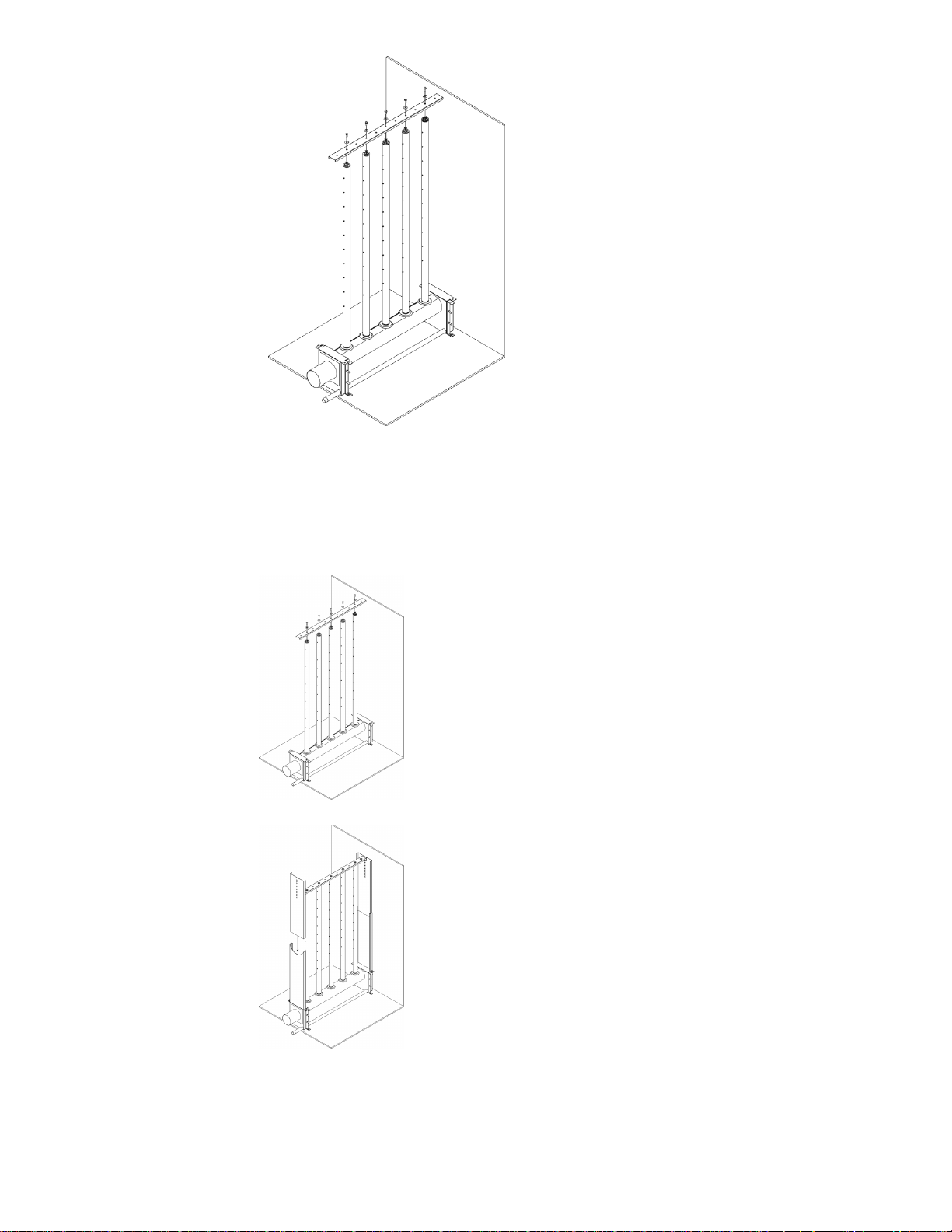

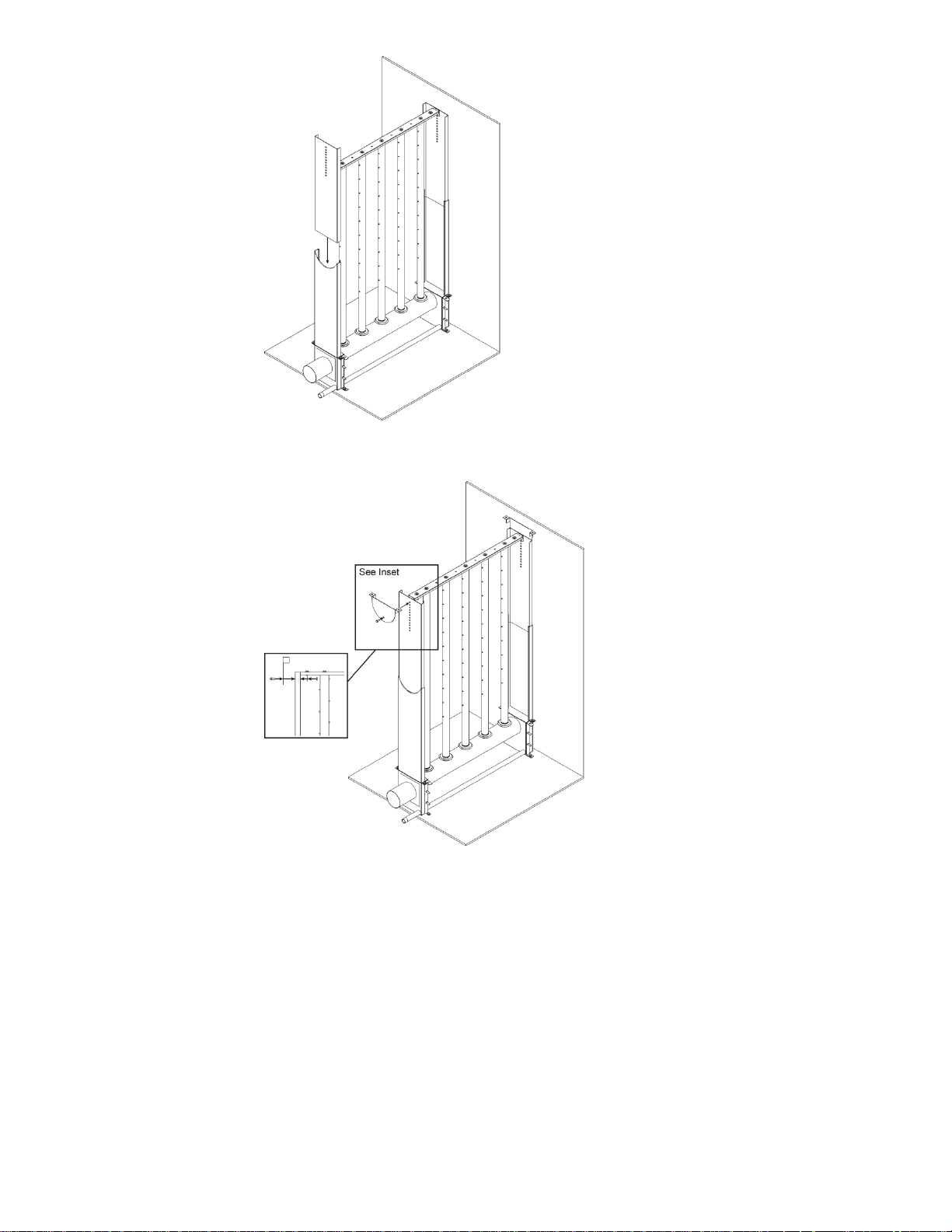

5

Attach tube support bracket using supplied 1/4” lock-washer and 1/4” hex

screws.

6

No mounting frame –

proceed to step 6A.

Mounting frame –

proceed to step 7

11 | SAM-e Installation

Page 15

6A

If no mounting frame is supplied:

Attach bracket flanges to tube support bracket using 5/16” screws,

washers, and nylon lock-nut.

Bolt flanges to duct wall using field-supplied 1/2”-fasteners.

SAM-e Installation | 12

Page 16

7

Slide frame sides into frame base.

8

Attach Frame Pivot using 5/16” bolt, washer, and nylon lock-nut.

Side View

13 | SAM-e Installation

Page 17

SAM-e Installation | 14

Page 18

Installation in

Vertical Duct

15 | SAM-e Installation

Page 19

1

Complete assembly following Steps 1 through 8 on pages 9

through 13.

Install complete assembly into duct at 10° angle. Fasten to

duct walls using field-supplied fasteners.

SAM-e Installation | 16

Page 20

Mini SAM-e

Installation Procedures

17 | SAM-e Installation

Page 21

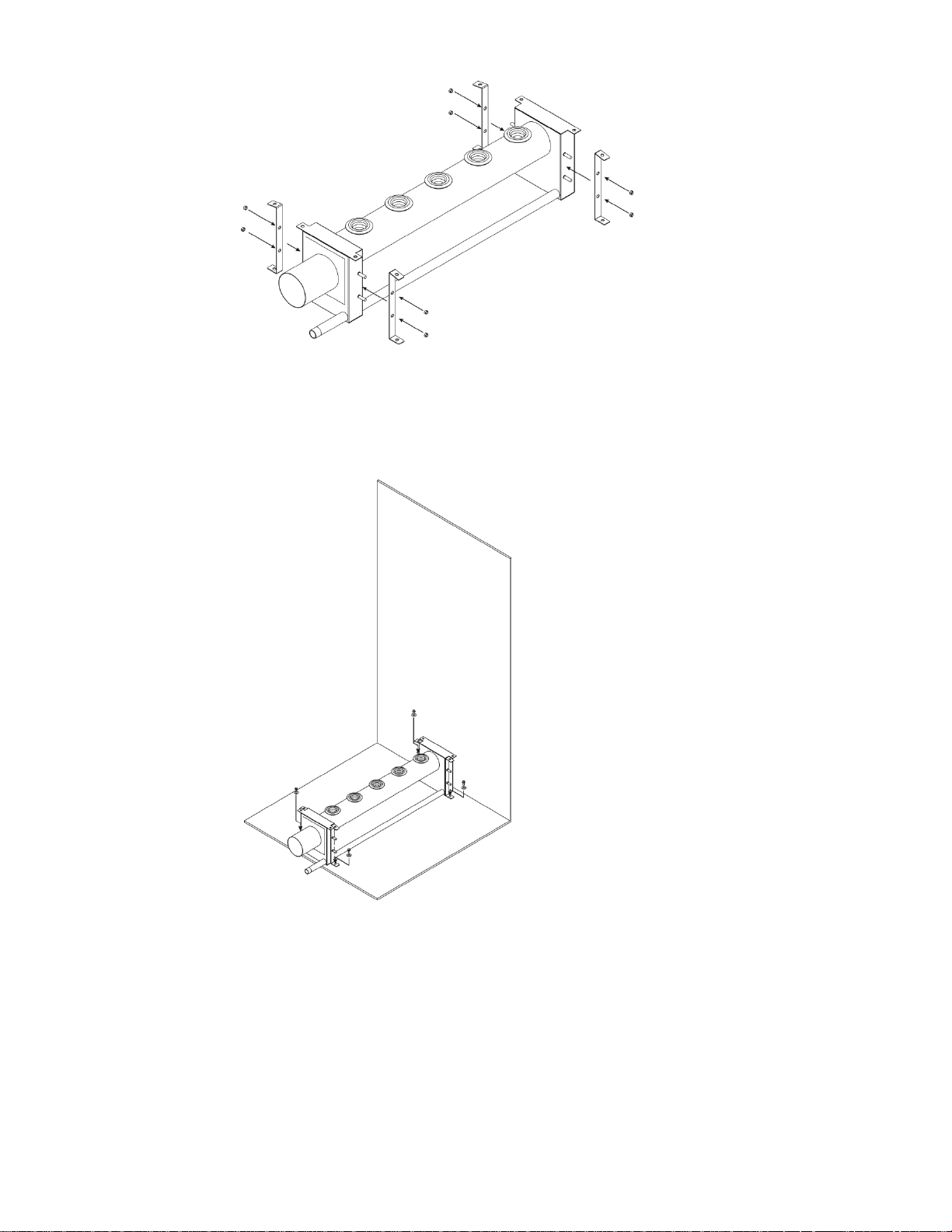

Mini SAM-e Assembly General Installation

SAM-e Installation | 18

Page 22

1

Place header into duct. Use supplied template to cut

holes for steam and condensate parts. Attach

header to duct using field-supplied fasteners.

2

Insert steam tubes with Insertion stop washers,

ensuring nozzles are perpendicular to airflow. Using

water to wet the rubber grommets will facilitate

installation. Seal all ductwork.

19 | SAM-e Installation

Page 23

SAM-e Installation | 20

Page 24

Plumbing

21 | SAM-e Installation

Page 25

• Steam components in grey provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from separator to be returned to pressurized condensate main.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters SAM-e, pressure drops down to almost atmospheric pressure.

Therefore, it must be drained atmospherically, and the use of a condensate pump (rated for 212ºF)

must be used to raise condensate to a higher elevation.

Strainer

Manual Shut-Off

Valve (By Others)

Pressurized

Steam Main

F & T Steam Trap

Duct/AHU Width

Duct/AHU

Height

Separator

Actuator & Valve

Pressurized condensate

return main

1” Air Gap

Drain

Manual Shut-Off

Valve (By Others)

6” min.

6” Min

Return to non-pressurized

condensate return main

Tap steam from top of

pressurized steam main

SAM-e with Pressure Steam

Pressurized Plumbing with External Separator

SAM-e Installation | 22

Page 26

Note: The SAM-e header functions as a steam separator, therefore an external steam

separator is not required.

• Steam components in grey provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters SAM-e, pressure drops down to almost atmospheric pressure.

Therefore, it must be drained atmospherically, and the use of a condensate pump (rated for 212ºF)

must be used to raise condensate to a higher elevation.

1” Air Gap

Drain

Strainer

Manual Shut-Off

Valve (By Others)

Pressurized

Steam Main

6” min.

Return to non-pressurized

floor drain

Pressurized condensate

return main

Tap steam from top of

pressurized steam main

Pressurized Plumbing without External Separator

23 | SAM-e Installation

Page 27

Internal Baffle Plate

SAM-e Installation | 24

Page 28

Condensate Pump Plumbing

When pressurized steam enters SAM-e, pressure drops down to almost atmospheric pressure.

Therefore, it must be drained atmospherically, and the use of a condensate pump (rated for 212ºF)

must be used to raise condensate to a higher elevation, or return to a pressurized condensate main.

6” min.

Condensate Pump

(By Others)

Pressurized Steam from Valve

Pressurized Condensate Main

25 | SAM-e Installation

Page 29

• Steam components in grey provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from separator to be returned to pressurized condensate main.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters SAM-e, pressure drops down to almost atmospheric pressure.

Therefore, it must be drained atmospherically, and the use of a condensate pump (rated for 212ºF)

must be used to raise condensate to a higher elevation.

Strainer

Manual Shut-Off

Valve (By Others)

Steam Main

F & T Steam Trap

Separator

Actuator & Valve

Pressurized condensate

return main

1” Air Gap

Drain

Steam from top of main

Manual Shut-Off

Valve (By Others)

6” min.

6” min

Return to non-pressurized

condensate return main

Duct Width

Duct

Height

Duct Floor

Mounting

bracket

Mini SAM-e with Pressurized Steam

Mini SAM-e Pressurized with External Separator

SAM-e Installation | 26

Page 30

• Max steam pressure of 15 psig when no separator is used.

• Steam components in grey provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from separator to be returned to pressurized condensate main.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters SAM-e, pressure drops down to almost atmospheric pressure.

Therefore, it must be drained atmospherically, and the use of a condensate pump (rated for 212ºF)

must be used to raise condensate to a higher elevation.

Strainer

Manual Shut-Off

Valve (By Others)

Steam Main

1” Air Gap

Drain

Steam from top of main

6” min.

Return to non-pressurized

condensate return main

Pressurized condensate

return main

Mini SAM-e Pressurized without External Separator

27 | SAM-e Installation

Page 31

When pressurized steam enters Mini SAM-e, pressure drops down to almost atmospheric pressure.

Therefore, it must be drained atmospherically, and the use of a condensate pump (rated for 212ºF)

must be used to elevate condensate to a higher point.

6” min.

Condensate Pump

(By Others)

Pressurized condensate

return main

Pressurized Steam

from Valve

Mini SAM-e Condensate Pump Plumbing

SAM-e Installation | 28

Page 32

Atmospheric steam inlet

Use Nortec supplied steam

hose and gear clamps

Drain

1" Air Gap To Prevent

Back Siphonage

6” min.

8” min.

2” plus duct

static pressure

Or

From Humidifier

SAM-e with Atmospheric Steam

Atmospheric Plumbing

29 | SAM-e Installation

Page 33

1" NPT to 3/4” NPT

Reducer

(Supplied By Others)

1" Air Gap To Prevent

Back Siphonage

Atmospheric steam inlet

Use Nortec supplied steam

hose and gear clamps

To drain

1/2” NPT Cold water inlet

3/4” NPT

Manual dump valve

6” min.

8” min.

2” plus duct

static pressure

Or

2” NPT Tempered

Water Drain

Plumbing with Drain Water Cooler

SAM-e Installation | 30

Page 34

Atmospheric steam inlet

Use Nortec supplied steam

hose and gear clamps

Drain

1" Air Gap To Prevent

Back Siphonage

6” min.

8” min.

2” plus duct

static pressure

Or

From Humidifier

Mini SAM-e with Atmospheric Steam

Mini SAM-e with Atmospheric Steam

31 | SAM-e Installation

Page 35

SAM-e Installation | 32

Page 36

Atmospheric Steam Lines

33 | SAM-e Installation

Page 37

Plumbing

Pressurized SAM-e

For pressurized steam line installation instructions, refer to LiveSteam Steam Injection

Humidifier Installation Manual.

Atmospheric SAM-e Steam Lines

Guidelines

1 Nortec steam hose should only be used on short steam runs of less than 10 feet.

2 Ensure that no condensate produced in steam line will remain trapped. Steam naturally

flows upward and condensate naturally flows downward.

3 See material recommended for use in below chart. To eliminate metal corrosion, Nortec

does not recommend the use of steel piping.

4 Consult below charts for steam and condensate sizing guidelines when using steam

distributors.

5 Be sure to include fitting equivalent lengths in total steam run lengths (see below).

In general, match steam-line size to outlet size of distributor.

When using an SETC with less than 15 psig steam supply pressure, a reducer (Nortec part

number 2526110 – 3” to 1.5” reducer or 2526111 – 4” to 3” reducer) is required to

prevent over-sizing of steam lines.

All steam lines should be insulated with at least 1”-thick steam insulation.

SAM-e Installation | 34

Page 38

Table 1: Electrode Steam-Line

Humidifier

Steam

output

[ lb ]

MED-L copper

tube nominal

steam line size

Stainless steel

tube diameter

(wall thickness

0.065”)

Steam loss per

foot in

condensation

[ lb/ft ]

Steam line

maximum

equivalent

length

RH Duct 120V

5

3/4"

7/8”

0.06

8 ft

RH Duct 240V

10

3/4"

7/8”

0.06

15 ft

NH 005

5

3/4"

7/8”

0.06

7 ft

NH 010

10

3/4"

7/8”

0.06

12 ft

NH 020

20

3/4"

7/8”

0.06

17 ft

NH 030

30

3/4"

7/8”

0.06

22 ft

NH 050

50

1-1/2”

1-3/4"

0.11

43 ft

NH 075

75

1-1/2”

1-3/4"

0.11

47 ft

NH 100

100

1-1/2”

1-3/4"

0.11

50 ft

NH 150 (2 outlets)

150

2 x 1-1/2”

1-3/4"

0.11

47 ft

NH 200 (2 outlets)

200

2 x 1-1/2”

1-3/4"

0.11

50 ft

Electrode Steam-Line

• Based on 3” duct static pressure.

• Maximum duct static pressure for electrode steam units is 6” w.c.

• A fill cup extension kit can be used on NH to overcome higher duct static pressure, or for

longer steam line runs. (Consult factory).

35 | SAM-e Installation

Page 39

Table 2: Gas Steam-Line

Humidifier

Steam

output

[ lb ]

MED-L copper

tube nominal

steam line size

Stainless steel

tube diameter

(wall thickness

0.065”)

Steam loss per

foot in

condensation

[ lb/ft ]

Steam line

maximum

equivalent

length

GS 100

100

1-1/2”

1-3/4”

0.11

90 ft

GS 200

200

3”

3”

0.16

90 ft

GS 300

300

3”

3”

0.16

180 ft

GS 400

400

4”

4”

0.22

180 ft

GS 500

500

4”

4”

0.22

220 ft

GS 600

600

4”

4”

0.22

260 ft

Gas Steam-Line

• Based on 3” duct static pressure.

• Maximum duct static pressure for GS is 12” w.c.

SAM-e Installation | 36

Page 40

Table 3: SE Steam-Line

Unit

No. of

Steam

Outlets

Steam

output

[ lb ]

MED-L copper

tube nominal

steam line size

Stainless steel

tube diameter

(wall thickness

0.065”)

Steam loss

per foot in

condensation

[ lb/ft ]

Steam line

maximum

equivalent

length

SE 050

1

50

1-1/2”

1-3/4”

0.11

37 ft

SE 100

1

100

1-1/2”

1-3/4”

0.11

90 ft

SE 175

1

175

3”

3”

0.16

90 ft

SE 250

1

250

3”

3”

0.16

180 ft

SE 375

1

375

4”

4”

0.22

180 ft

SE 575

1

575

4”

4”

0.22

220 ft

SE 750

2

750

2 x 4”

2 x 4”

0.44

260 ft

SE 1050

2

1050

2 x 4”

2 x 4”

0.44

260 ft

SE Steam Line

• Based on 3” duct static pressure.

• Maximum duct static pressure for SE is 12” w.c.

37 | SAM-e Installation

Page 41

Table 4: SE Steam-Line

Humidifier

Steam

output

[ lb ]

MED-L copper

tube nominal

steam line size

Stainless steel

tube diameter

(wall thickness

0.065”)

Steam loss per

foot in

condensation

[ lb/ft ]

Steam line

maximum

equivalent

length

NHRS 010

10

1-1/2”

1-3/4”

0.11

12 ft

NHRS 015

15

1-1/2”

1-3/4”

0.11

15 ft

NHRS 020

20

1-1/2”

1-3/4”

0.11

18 ft

NHRS 030

30

1-1/2”

1-3/4”

0.11

27 ft

NHRS 045

45

1-1/2”

1-3/4”

0.11

43 ft

NHRS 065

65

1-1/2”

1-3/4”

0.11

47 ft

NHRS 090

90

1-1/2”

1-3/4”

0.11

48 ft

NHRS 135

135

2 x 1-1/2”

2 x 1-3/4”

0.11

47 ft

NHRS 180

180

2 x 1-1/2”

2 x 1-3/4”

0.11

48 ft

NHRS Steam-Line

• Based on 3” duct static pressure.

• Maximum duct static pressure for resistive element units is 6”w.c.

SAM-e Installation | 38

Page 42

Table 5: Effective length of Typical Steam-Line Fittings

Nominal tube

size

Standard

90°-elbow

Standard

45°-elbow

Side-outlet

tee

Gate valve*

Globe valve*

3/4”

2 ft

1 ft

4 ft

0.4 ft

18 ft

7/8”

2 ft

1 ft

4 ft

0.4 ft

18 ft

1-1/2”

3.5 ft

1.75 ft

7 ft

0.8 ft

34 ft

1- 3/4”

3.5 ft

1.75 ft

7 ft

0.8 ft

34 ft

3”

5 ft

2.5 ft

11 ft

1.1 ft

54 ft

4”

8 ft

4 ft

15 ft

1.6 ft

80 ft

Table 6: Effective length of Typical Steam-Line Fittings

Material

Type

Note

Copper

MED-L Tube

Recommended.

Stainless steel

Tube wall thickness 0.065”

Recommended.

Required for RO/DI water.

Flex-hose

High-temperature rubber

hose

Nortec high-temperature flex-hose recommended only.

Nortec flex-hose to be checked every 5 years.

Other brands of steam hose may:

- Carry odors

- Kink or deform

- Create back-pressure and affect humidifier

performance

Black pipe

Schedule 40

Schedule 40

Not recommended

Oil seeps out.

Rusting.

Health hazard.

Larger pressure drop.

Plastic

-----

Not recommended

Effective Length of Typical Steam-Line Fittings

*Valve in full open position.

Material for Steam Lines

39 | SAM-e Installation

Page 43

Atmospheric SAM-e Condensate Drainage

1 SAM-e condensate outlet connection is male 3/4”-NPT.

2 Condensate from SAM-e must be plumbed to a P-trap. Trap must have center-to-center

height of at least 8”, or 2” more than duct static pressure, whichever is greater. Refer to

typical installation drawings.

3 Condensate from P-trap should drain into a funnel with air-gap prior to entering building

drain.

4 Condensate exits at 212°F (100°C). Local codes may require use of a drain water

cooler (Nortec part number 1710020 - electronic drain water cooler or 1710010 – selfactuated drain water cooler). Refer to installation manual that accompanies drain water

cooler for plumbing details.

5 When collecting condensate, ensure that each device has an air-gap prior to entering the

condensate collection system. Failing to incorporate an air-gap may cause backpressure

on SAM-e and result in poor performance.

6 Some humidifiers allow distributor condensate to be returned to the unit. Refer to

humidifier manual for details.

7 For systems using condensate pumps, a P-trap and air-gap are still required at SAM-e

outlet. Never connect SAM-e directly to a pressurized drain line.

SAM-e Installation | 40

Page 44

Use appropriate slope

Figure 1: Slope

Figure 2: Insulate pipe

Figure 3: Condensate Traps

MAIN RULES FOR ATMOSPHERIC STEAM LINES:

Follow recommended materials, size and length (see tables)

Steam Lines and Condensate Returns

Steam lines must be sloped

Condensate must be trapped (Use full-size ‘T’ for traps)

Steam lines must not have any restrictions that could cause back-pressure

Insulate with minimum 1” pipe insulation

41 | SAM-e Installation

Page 45

Figure 4: Distributor Above Humidifier (Copper Steam Line)

Figure 5: Distributor Above Humidifier (Hose)

SAM-e Installation | 42

Page 46

Figure 6: Steam Distributor Below Humidifier (Hose)

Figure 7: Steam Distributor Below Humidifier and Obstruction (Hose)

43 | SAM-e Installation

Page 47

Figure 8: Long Steam Run

SAM-e Installation | 44

Page 48

Atmospheric Steam Lines

45 | SAM-e Installation

Page 49

Insulation

Factory-Installed Insulation

1 Unpack tubes and headers. Inspect tubes to ensure that stainless insulation covers have not

shifted during shipping. Tube covers should not be obstructing nozzles, and should be aligned

with nozzles. Header covers should be aligned with grommets, and not obstructing tube holes.

Cut around drilled holes to create access port in side of duct. This port should be large enough

to accommodate Mini SAM-e.

2 After tubes and headers have been inspected, install tubes and header according to this chapter.

Insert all steam tubes into header such that flanges are flush with rubber gaskets. Rotate steam

tubes, as needed, to ensure all nozzles are perpendicular to airflow. Do not lift manifold by steam

tubes.

Field Retrofit of Insulation

1 Unpack insulation covers. Inspect insulating covers for shipping damage; covers should be

straight and all foam strips should be aligned with edge of covers and. After tubes and headers

have been inspected, install tubes and headers according to this chapter. Insert steam tubes

into header, until flanges are flush with rubber gaskets. Rotate steam tubes, as needed, to

ensure all nozzles are perpendicular to airflow. Do not lift manifold by steam tubes.

2 Install tube insulation; each tube shall receive two (2) stainless steel covers and two (2) metal

straps for every four (4) feet of tube length. Fit insulating shields around distributor tubes,

ensuring edges of shields are aligned with nozzles. Secure tubes in place with metal clamps at

top and bottom. Take care to not over-tighten. See Figure 1.

NOTE: Multiple covers may be required to completely insulate SAM-e tube. Please refer to

Table: “Number of Insulating Covers Required to Cover a SAM-e Tube”.

SAM-e Installation | 46

Page 50

Table 7: Quantity of Insulating Covers Required to Cover SAM-e Tubes

SAM-e Tube

Length

[in]

Insulation Length

6 in

12 in

18 in

24 in

30 in

36 in

42 in

48 in

6 2

18

2 24

2

30

2

36

2 42

2

48

2

54

2 60

2 2

66

4

72

2 2

78

4 84

2 2

90

4

96

2 2 102

4

108

2 4

114

6

120

4 2

126

2 4

132

6

138

4

2

Table 8: Quantity of Insulating Covers Required to Cover Mini SAM-e Tubes

Mini SAM-e

Tube Length

[in]

Insulation Length

5 in

7 in

9 in

11 in

13 in

15 in

17 in

19 in

5 2

7

2 9 2

11

2

13

2

15

2

17

2

19

2

21

Quantity of Insulating Covers Required to Cover SAM-e Tube

Quantity of Insulating Covers Required to Cover Mini SAM-e Tubes

47 | SAM-e Installation

Page 51

Header Installation

1 Install header insulation for SAM-e; expand header insulation to fit over header and slide on.

Ensure that edges tuck underneath synthetic grommets on top of header. Secure insulation in

place using metal straps. See Step 2.

2 Install header insulation for SAM-e Dual Inlet; expand insulation to fit over header and slide on.

Additionally, expand smaller metal cover for inlet leg and slide on. If inlet leg insulation conflicts

with inlet adapter, trim insulation to fit. Secure both covers in place with metal strapping. See

Step 3.

3 Install header insulation for Mini SAM-e; expand header insulation to fit over header and slide on.

Take care when installing to avoid permanently bending insulation. Inspect for a tight fit after

installation. See Step 4.

SAM-e Installation | 48

Page 52

1

Install header wrap around header.

2

Tuck header wrap underneath rubber grommets and secure with stainless wraps at

each end.

SAM-e Insulation Retrofit

49 | SAM-e Installation

Page 53

FOR DUAL INLETS; INSULATE HEADER AS SHOWN ON PREVIOUS PAGE.

INSULATE SECOND INLET AS SHOWN

ROLL SHIELD TO

CREATE OVERLAP

DETAIL D

USE TIE WRAP 2538347 TO

SECURE IN PLACE.

D

ALWAYS PLACE TIE WRAPS AT THE

ENDS OFTHE SHILED, 1/2 INCH IN.

WHEN 3 TIE WRAPS ARE NEEDE

POSITION ONE IN THE

APPROXIMATE MIDDLECUT OFF

EXCESS END.TIGHTEN UNTIL

SNUG. DO NOT CRUSH

ORIENT END AS SHOWN

Field Retrofit of Installation Dual Inlet Headers

SAM-e Installation | 50

Page 54

3

Apply shields to tubes and secure with stainless straps.

4

Completed Tube.

51 | SAM-e Installation

Page 55

1

Connect Top and Bottom heat shields together (snap fit) .

2

Completed header.

Mini SAM-e Insulation Retrofit

SAM-e Installation | 52

Page 56

3

Fit shields to tubes.

4

Secure with stainless straps.

53 | SAM-e Installation

Page 57

5

Completed tube.

SAM-e Installation | 54

Page 58

Troubleshooting, Maintenance,

Spare Parts

55 | SAM-e Installation

Page 59

Kit Part #

Kit description

Quantity in Kit

1503812

SAM-e coupling seal for steam tubes (1 per tube)

1

2546662

Insertion stop (1 per tube) (Galvanized)

10

2578156

Insertion stop (1 per tube) (Stainless Steel)

10

2546665

5/16” Locknuts, bolts, washers (Galvanized)

10

2546668

5/16” Locknuts, bolts, washers (Stainless Steel)

10

2546667

1/4" bolts, washers (1 per tube) (Galvanized)

10

2578157

1/4" bolts, washers (1 per tube) (Stainless Steel)

10

2538346

SAM-e insulated tube strapping

1

2538347

SAM-e insulated header strapping

1

2538344

SAM-e insulated dual-inlet header strap (for second inlet)

1

Troubleshooting

Steam tubes discharge water:

1 Steam supply pipe is not insulated.

2 Steam supply pipe not properly drained or sloped.

3 Manifold or adapter condensate drain is clogged or malfunctioning.

4 Excessive back-pressure in condensate drain pipe (due to pressure in secondary condensate

drain); must be piped to non-pressurized condensate return.

5 Primary and secondary condensate drains are both joined together.

6 Condensate line has been routed too high (causing static back pressure).

Maintenance

Inspect SAM-e at start-up.

1 For humidifier maintenance schedule, refer to Installation, Operation, and Maintenance

Manual for your humidifier.

Spare Parts

SAM-e Installation | 56

Page 60

Page 61

Warranty

Nortec Humidity Inc. and/or Nortec Humidity Ltd. (hereinafter collectively referred to as THE

COMPANY), warrant for a period of ten years after installation, that THE COMPANY’s

manufactured and assembled products, not otherwise expressly warranted (with the exception

of the tube coupling seals, two years only), are free from defects in material and workmanship.

No warranty is made against corrosion, deterioration, or suitability of substituted materials used

as a result of compliance with government regulations.

THE COMPANY’s obligations and liabilities under this warranty are limited to furnishing

replacement parts to the customer, F.O.B. THE COMPANY’s factory, providing the defective

part(s) is returned freight prepaid by the customer. Parts used for repairs are warranted for the

balance of the term of the warranty on the original humidifier or 90 days, whichever is longer.

The warranties set forth herein are in lieu of all other warranties expressed or implied by law. No

liability whatsoever shall be attached to THE COMPANY until said products have been paid for in

full and then said liability shall be limited to the original purchase price for the product. Any

further warranty must be in writing, signed by an officer of THE COMPANY.

THE COMPANY’s limited warranty on accessories, not of the companies manufacture, such as

controls, humidistats, pumps, etc. is limited to the warranty of the original equipment

manufacturer from date of original shipment of humidifier.

THE COMPANY makes no warranty and assumes no liability unless the equipment is installed in

strict accordance with a copy of the catalog and installation manual in effect at the date of

purchase and by a contractor approved by THE COMPANY to install such equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for consequential

damage or damage resulting directly from misapplication, incorrect sizing or lack of proper

maintenance of the equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for damage resulting

from freezing of the humidifier, supply lines, drain lines, or steam distribution systems.

THE COMPANY makes no warranty and assumes no liability whatsoever for equipment that has

failed due to ambient conditions when installed in locations having climates below 14°F (10°C) during January or above 104°F (40°C) during July.

THE COMPANY retains the right to change the design, specification and performance criteria of

its products without notice or obligation.

57 | SAM-e Installation

Page 62

U.S.A.

1860 Renaissance Blvd.

Sturtevant, WI 53177

826 Proctor Avenue

Ogdensburg, NY 13669

CANADA

2740 Fenton Road

Ottawa, Ontario K1T 3T7

TEL: 1.866.NORTEC1

EMAIL: nortec@humidity.com

WEBSITE: www.humidity.com

Loading...

Loading...