Page 1

Important: Read and save these instructions. This guide to be left with equipment owner.

2548006-A| 8 OCT 2009

RH

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for your RH Electric

Steam humidifier

Page 2

Thank you for choosing Nortec.

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Proprietary Notice

This document and the information disclosed herein are proprietary data of WALTER MEIER LTD. Neither this

document nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorization of WALTER MEIER LTD., except to the extent required for installation or maintenance of

recipient’s equipment. All references to the Nortec name should be taken as referring to WALTER MEIER LTD.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2008, WALTER MEIER LTD. All rights reserved.

Page 3

Contents

1 Introduction

2 Receiving and Unpacking

2 RH Models

3 Options and Accessories

5 Installation

6 Typical RH Installation

7 Location

8 Mounting with Keyholes

9 Plumbing

10 Steam Lines and Condensate

Returns

14 Electrical

15 External Controls

38 Maintenance and

Servicing

39 Required Maintenance

43 Extended Shutdown

44 Maintenance Checklist

45 Troubleshooting

47 General Troubleshooting

49 RH Faults

51 Wiring Diagrams

52 Spare Parts

56 Warranty

20 Options and Accessories

21 Start Up

22 Installation Check

23 RH User Interface

24 Start Up Procedure

26 Start Up Checklists

29 Operation

30 LED Status Lights

30 Selecting an RH Setpoint

31 Humidifier Components

34 How the Humidifier Works

36 Humidifier Configuration

Page 4

Introduction

CAUTION: Servicing

• Disconnect main power before any servicing.

• The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

• During and following operation of the humidifier, the steam and components in

contact with the steam such as the blower pack, steam lines, steam distributors,

and condensate lines can become hot and can burn if touched.

• Walter Meier does not accept any liability for installations of humidity equipment

installed by unqualified personnel or the use of parts/components/equipment

that are not authorized or approved by Walter Meier.

CAUTION: Electrical

• All electrical work should be done according to local electrical code.

• Electrical connection to be performed by a licensed electrician.

CAUTION: Plumbing

• Plumbing to be performed by a licensed plumber.

• Drain water from humidifier can be very hot. Do not drain to public sink.

• All plumbing work should be done according to local plumbing code.

CAUTION: Installation

• Do not mount on hot surfaces.

• Do not mount in area where freezing can occur.

• Do not mount on vibrating surface.

• Do not mount on floor.

• The RH produces steam at atmospheric pressure no devices which could block

steam output should be connected to the steam outlet.

• Steam lines must be installed so that no restriction can produce backpressure in

the humidifier.

• Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to

operate. Nortec highly recommends the use of a duct high limit humidistat.

1 | Introduction

Page 5

Receiving and Unpacking

1 Check packing slip to ensure ALL material has been delivered.

2 All material shortages are to be reported to Nortec within 48 hours from receipt of goods.

Nortec assumes no responsibility for any material shortages beyond this period.

3 Inspect shipping boxes for damage and note damages on shipping waybill accordingly.

4 After unpacking, inspect equipment for damage and if damage is found, notify the shipper

promptly.

5 All Nortec products are shipped on an FOB factory basis. Any and all damage, breakage or

loss claims are to be made directly to the shipping company.

Before Installation

1 Ensure that available voltage and phase corresponds with humidifier voltage and phase as

indicated on humidifier’s specification label.

2 Ensure that the dedicated external fuse disconnect is of sufficient size to handle the rated

amps as indicated on the specification label. Refer to local codes.

3 Report any discrepancy immediately to the site engineer.

4 Ensure sufficient clearances will be available as described in the Location section on page

7.

5 Ensure steam lines can be routed to distributor or blower pack as described in Steam Lines

and Condensate Returns on page 10.

MODEL:

XXXXXXXXXXXXXXXXXXXXXXXX

PHASE:

XXXX

VOLTS 1:

XXXXXXXXX

VOLTS 2:

XXXXXXXXX

VOLTS 3:

XXXXXXXXX

XXXXXXXXX

DATE:

HZ:

F.L. A:

F.L. A:

F.L. A:

XXXXX

XXXXX

XXXXX

MADE I N CANADA

S/N:

XXXXXXX

XXXXXX

KW:

XXXXXX

KW:

KW:

XXXXXX

Figure 1: Specification Label Location

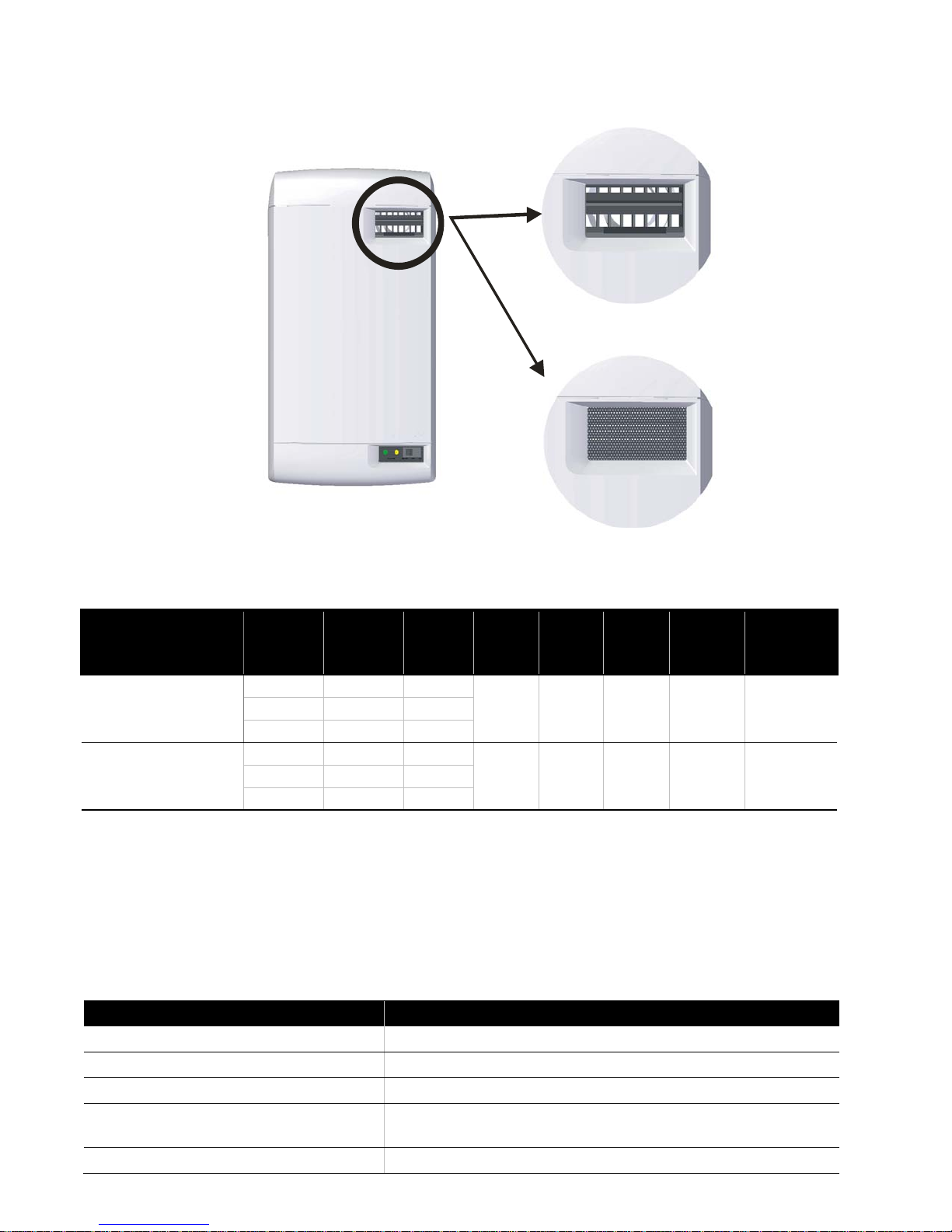

RH Models

The RH is the most advanced residential steam humidifier available and provides steady and

reliable humidification for a home using the same proven cylinder technology as Nortec’s

commercial NHTC. The RH is available in 2 models. The duct model is designed for connection

to a steam distributor installed in a supply air duct or for connection to a remote blower pack.

The space model is designed for applications where humidity is to be introduced directly into

the space being humidified. The two models can be differentiated by the grille in the

humidifiers front cover, see Figure 2: RH Models.

Introduction | 2

Page 6

Space Model

(blower pack)

Duct Model

Figure 2: RH Models

Table 1: RH Specifications

Model - Part No. Volts Capacity

lb (kg)

110-120 4 (1.8) 1.5

RH Space - 2548758

RH Duct - 2548759

208 6.9 (3.1) 2.6 12.7

220-240 8 (3.6) 3.0

110-120 5 (2.3) 1.9

208 8.7 (4.0)

220-240 10 (4.6)

KW Amps Phase Max Ext

Fuse

1 20 202

3.3 15.9

3.8

1 20 202

Standard

Cylinder

Net/Full

Weight

lb (kg)

16 / 22

(7.5 / 10.0)

15 / 21

(7.0 / 9.5)

Options and Accessories

Nortec provides a complete line of options and accessories for every humidification application.

The following options and accessories are available and may have been delivered with your RH

humidifier. Refer to the installation instructions that came with the accessories for their proper

installation and operation.

Table 2: Options and Accessories

Option / Accessory Used For

Steam Distributors Adding steam into air ducts.

Remote Blower Pack Adding steam into a space remote from the humidifier.

Digital or Modulating Control Humidistats Controlling the output of the humidifier based on sensed RH.

Digital or Modulating High Limit

Humidistats

Air Proving Switches Insuring humidification only occurs when air is moving in a duct.

3 | Introduction

Preventing over humidification in a duct by shutting down or

throttling down the humidifier when duct RH gets high.

Page 7

Introduction | 4

Page 8

Installation

6 Typical RH Installation

7 Location

8 Mounting with Keyholes

9 Plumbing

10 Steam Lines and Condensate Returns

14 Electrical

15 External Controls

15 Control Location

15 Control Wiring

16 On/Off Control Wiring

17 Modulating Control Wiring

19 Optional Outdoor Temperature Reset

20 Options and Accessories

20 Remote Blower Pack

5 | Installation

Page 9

Typical RH Installation

Figure 3: Typical Humidifier Installation

Installation | 6

Page 10

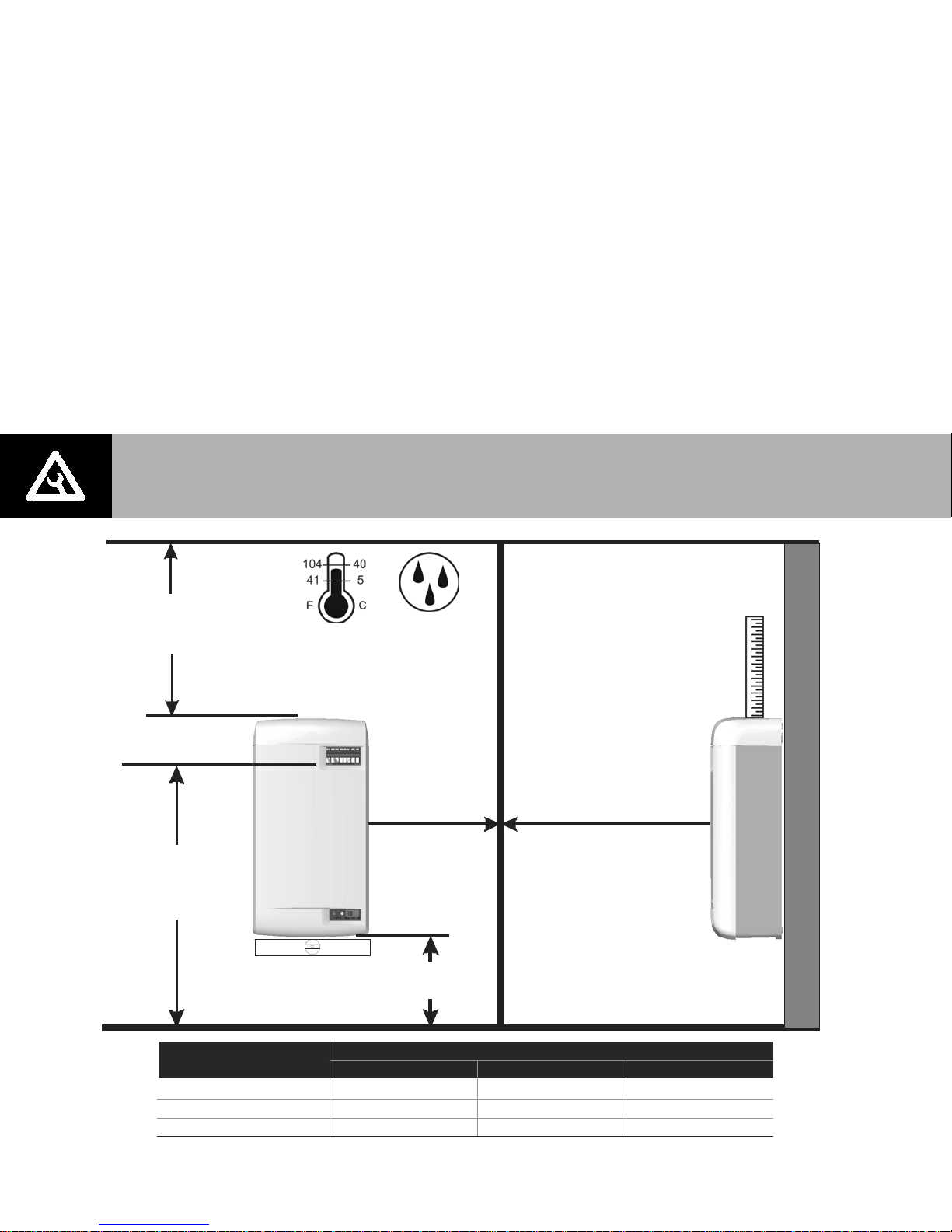

Location

Mount on a suitable wall or vertical surface. Do not sit the on the floor to allow clearances

required for plumbing and electrical connections. Clearance dimensions shown are for

reference only and are the minimum required for maintenance of the humidifier. Consult local

and national codes before final location and installation. Nortec does not accept responsibility

for installation code violations.

• Install only in areas with ambient temperature 41-104°F (5 – 40°C) relative humidity

5 - 95%.

• When possible install below the steam distributor. If mounted above the steam distributor

take care to provide proper steam line routing and proper condensate traps.

• DO NOT locate the humidifier any further then absolutely necessary from the steam

distributor location as net output will be reduced as a result of heat loss through the steam

line.

• When possible, mount the RH humidifier at a height convenient for servicing.

Note: Do not mount on hot surfaces, where freezing can occur, vibrating surface, or

floor.

Overhead clearance

for s pac e m odels

only , see table

7 ft (2.1 m)

min. Height

for space

models on ly.

5-95%

Side clearance

for s pac e models

only, se e table

As Close as

Possible to Steam

Distributor

36 in. ( 92 c m )

duct m odel

in. ront learance

mf c

Additional front c learance

for space models,

see t abl e

Mount Humidifier

Level

Humidifier Output lb (kg) Side in. (cm)

<4 (1.8) 12 (30) 12 (30)

6 (2.7) 16 (40) 18 (46)

8 (3.6) 18 (46) 18 (46)

7 | Installation

24 in. ( 61 cm)

Min Height

Additional Clearance for Space Models Only

Figure 4: Mounting Location / Clearance

Overhead in. (cm) Front in. (cm)

36 (92)

42 (107)

48 (120)

Page 11

t

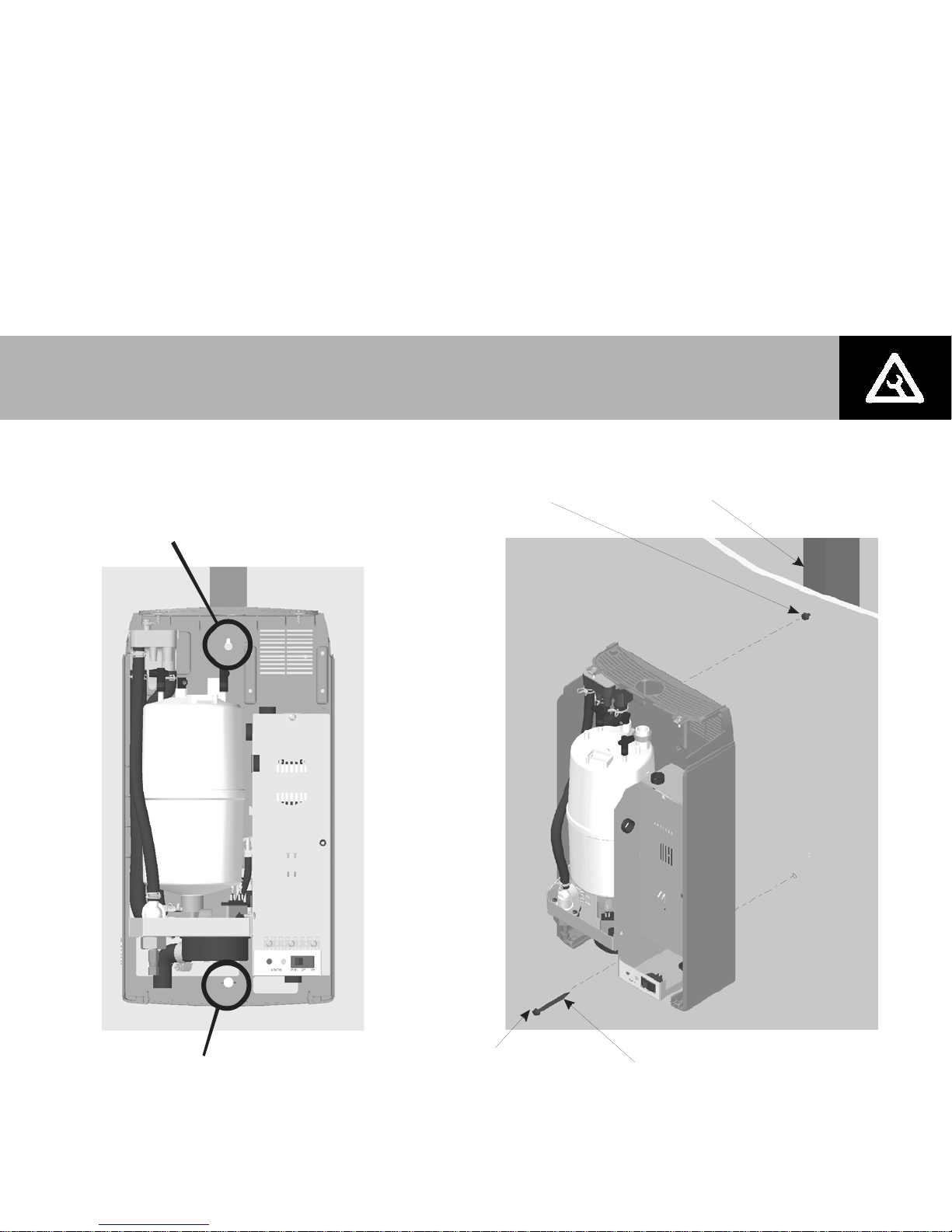

Mounting with Keyholes

1 The RH humidifier is wall mounted using a keyhole located on the back of the unit’s

cabinetry.

2 Use #8 x 2 in. (5 cm) screws mounted into 2x4 studs or better. 2 screws are needed, one for

hanging the unit and one for securing it so it will not lift off the keyhole.

3 Install the top screw so that 1/4 in. (6 mm) is exposed. Raise the unit and place the screw

head through the keyhole.

4 Make sure the unit is level and then insert and tighten the second screw through the bottom

hole. Tighten the top screw. See Figure 5: Mounting With Keyholes.

Note: Use screws longer than 2” (5 cm) if drywall or other spacer is present.

Keyhole

Insert screw so tha

1/4 in. (6 mm) ex pos ed,

hang unit, tighten

screw.

2x4 or Other

Structural

Member

Hole

Install Second Screw

after hanging

humidifier

Figure 5: Mounting With Keyholes

#8 x 2 in. ( 5 c m )

Wood Scr e w s

Installation | 8

Page 12

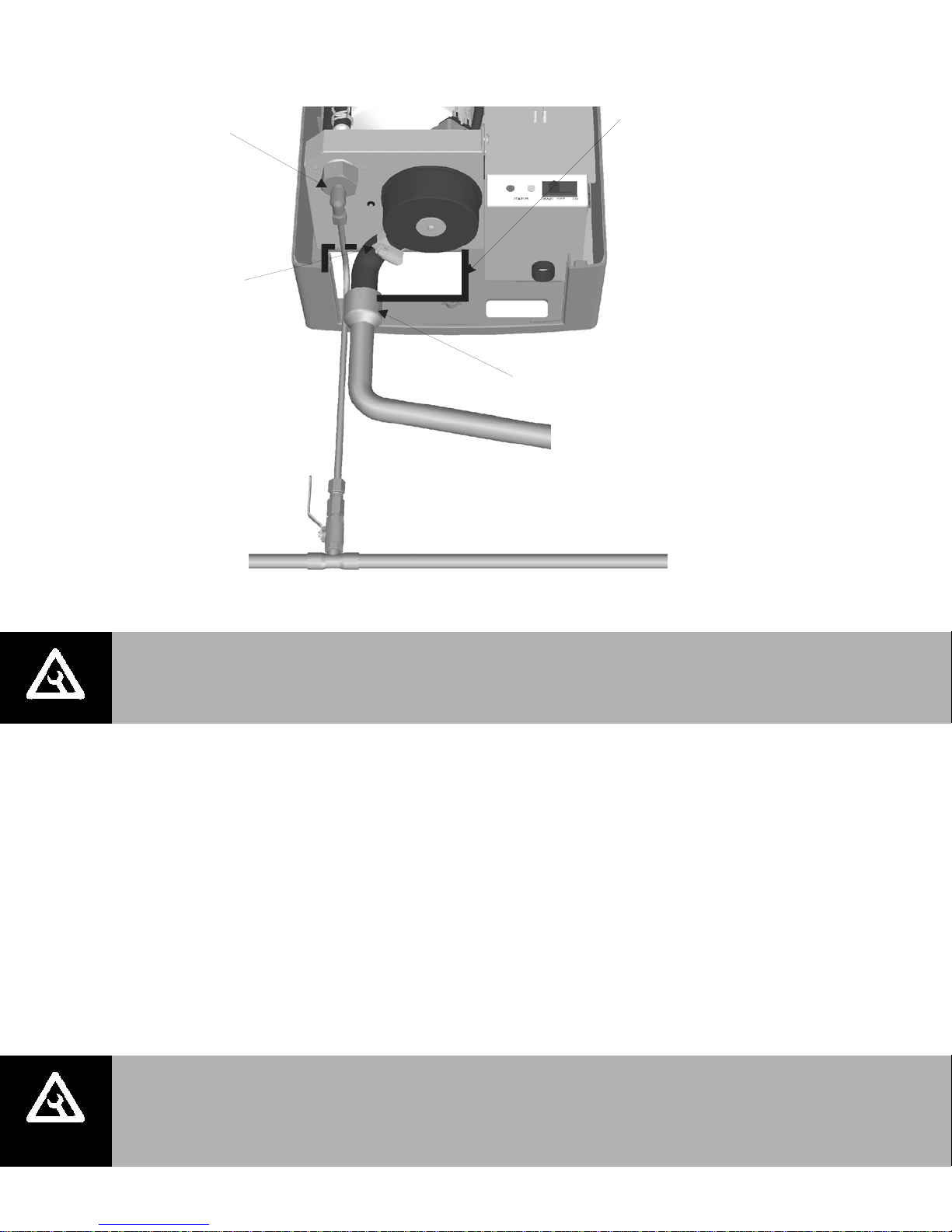

Plumbing

1/8 in. NP T

Use 1/ 4 in.

compression

fitting to c onnec t

supply line t o

1.2 in. (30 mm). OD

un-t hr eaded outlet

with factory s upplied

bent hos e and clam p.

Always ins tall a water

unit.

shut - off valv e.

Note:

1 Fill and drain lines

can also be routed

through opening in

back of cabinet.

2 Optional cov er

2548313 Is available

to c onceal plum bing

connect i ons.

Air gap requir ed. 2 1/2 in. to 7/8 in.

Copper reduc er is ideal. (NORTEC option

P/ N 2522172) Hos e m us t not

touc h the bottom of the funnel.

Min. 7/ 8 in. OD dr ain line.

Keep as shor t as possible.

Slope down t o f loor

drain or m ain drain.

Use 1/ 2 in. OD copper to within 4 ft ( 1.2 m) of hum idifier

Note:

• Drain water is very hot, do not drain to public sink.

• Do not use plastic pipe for drain.

*Pipe and water s hut-off v alv e not s upplied by Nor tec.

Figure 6: Water Supply and Drain Connection

• All water supply and drain line connections should be installed in accordance with local

plumbing codes.

• Supply water should at 30 to 80 PSIG and be between 150-1200 Microsiemens (Hardness

0-12 GPG). Consult factory for water conditions outside of this range. Water softener may

be used if conductivity remains in recommended range.

• Install water shut off valve before humidifier to facilitate servicing.

• The drain line should not end in a sink used frequently by personnel, or where plumbing

codes prohibit it. Route to a floor drain or equivalent for safety reasons.

• Insure drain line is adequately sized to provide free and easy draining and that an air gap is

installed as shown. A restricted drain can cause cylinder water to over concentrate and

result in poor operation.

• If a drain is not located near the humidifier use a condensate pump rated for hot drain water

such as Nortec’s Part Number 1429527.

For humidifiers installed in some cities including the City of Los Angeles:

A city-approved spring-loaded double ball CHECK VALVE must be installed by

contractor on the potable water inlet to the humidifier. Recommended valve

9 | Installation

manufacturer: Watts Regulator, phone number 508-688-1811, Size depending on

supply line 1/4”, 3/8”, or 1/2” NPT inlet and outlet, Model #7.

Page 13

Steam Lines and Condensate Returns

MAIN RULES FOR ATMOSPHERIC STEAM LINES

• Slope the steam lines

• Trap condensate (Use full size ‘T’ for Traps)

• Condensate traps must be a minimum of 3 in. (15 cm) in height or duct static

pressure + 2 in. whichever is greater.

• Steam lines must not have any restrictions which could cause back pressure.

• Insulate with 1.0 in. (2.5 cm) pipe insulation

• Follow recommended materials, size and length see tables.

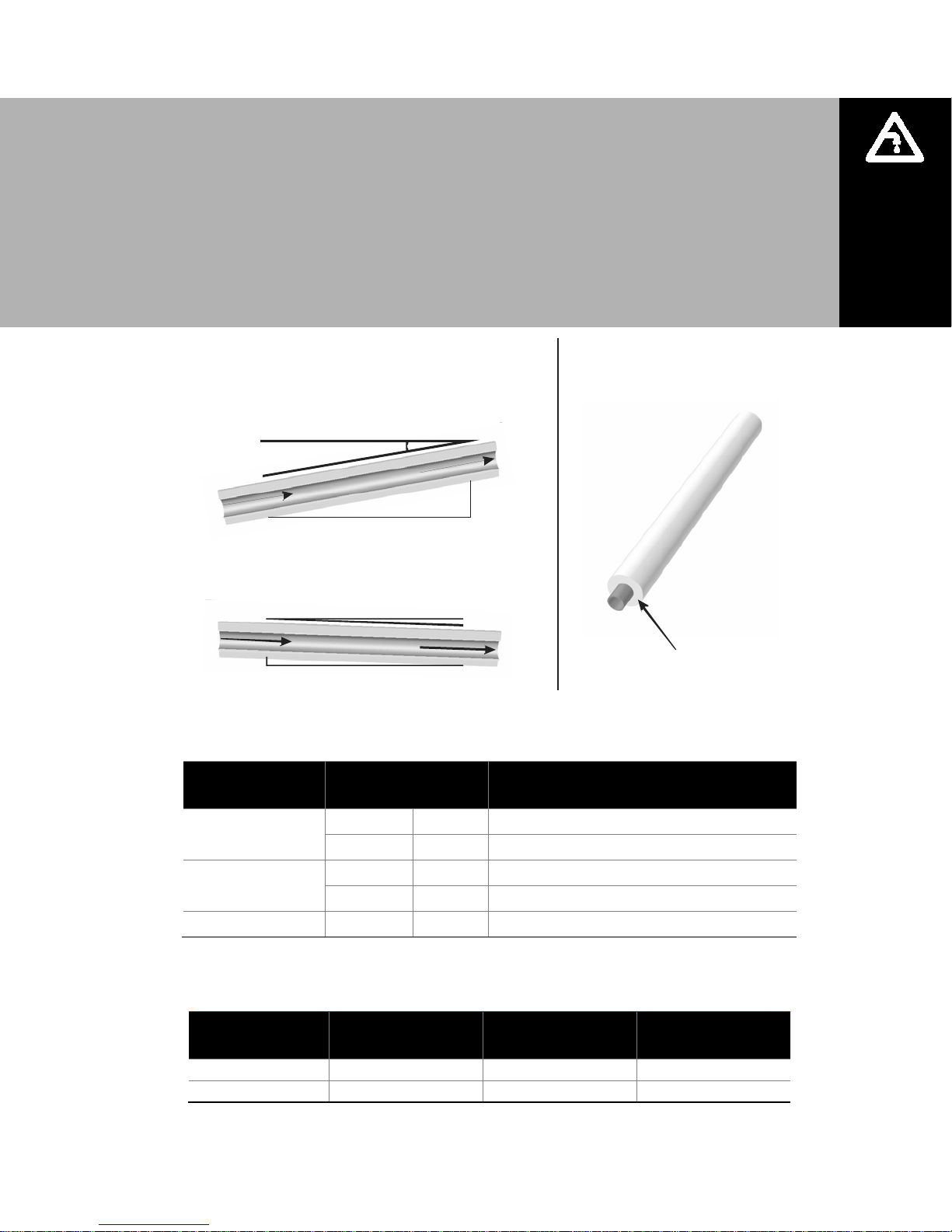

Use Appropriate Slope Insulate Pipe

10 D egrees

n

o

i

t

c

e

r

i

D

m

a

e

t

S

1 ft (30 c m )

2 in.

(5 c m )

2 Degrees

S

t

e

a

m

r

D

i

e

o

t

i

c

S

t

e

a

m

D

i

0.5 i n.

(12 mm )

Steam Line

Material

Copper Tube

Stainless Steel

Tube

Nortec Hose < 10 < 3

Note: * These diameters require a reducer at humidifier and steam distributor connection. Use Nortec part number 1115444 at

humidifier to prevent backpressure caused by condensation collecting at the reduction.

Steam Output

(lb/hr)

1ft (30 cm)

Figure 7: Main Steam Line Requirements

Table 3: Recommended Steam Line Material

Steam Line Length

0-10 0-3

10+ 3+

0-20 0-6

20+ 6+

Table 4: Maximum Recommended Length of Steam Line

n

r

e

c

t

i

o

n

ft m

Distance

(ft)

1 in. (2.5 cm) pipe

insulation

Steam Line Description

3/4 in MED-L Tubing (7/8 in. OD)

*1 in. MED-L Tubing (1 1/8 in. OD)

1 1/2 in. MED-L Tubing (1 5/8 in. OD)

*2 in. MED-L Tubing (2 1/8 in. OD)

Part Number 1328810 (7/8”)

Possible Loss

(lb/hr)

Steam Line Size

(in)

5 8 1.0 3/4

10 15 1.5 3/4

NOTE: 1 Use one inch copper steam line for longer runs.

2 The use of steam line other then copper, stainless steel tube or Nortec supplied steam line will void the

warranty and may adversely effect the operation of the humidifier

Installation | 10

Page 14

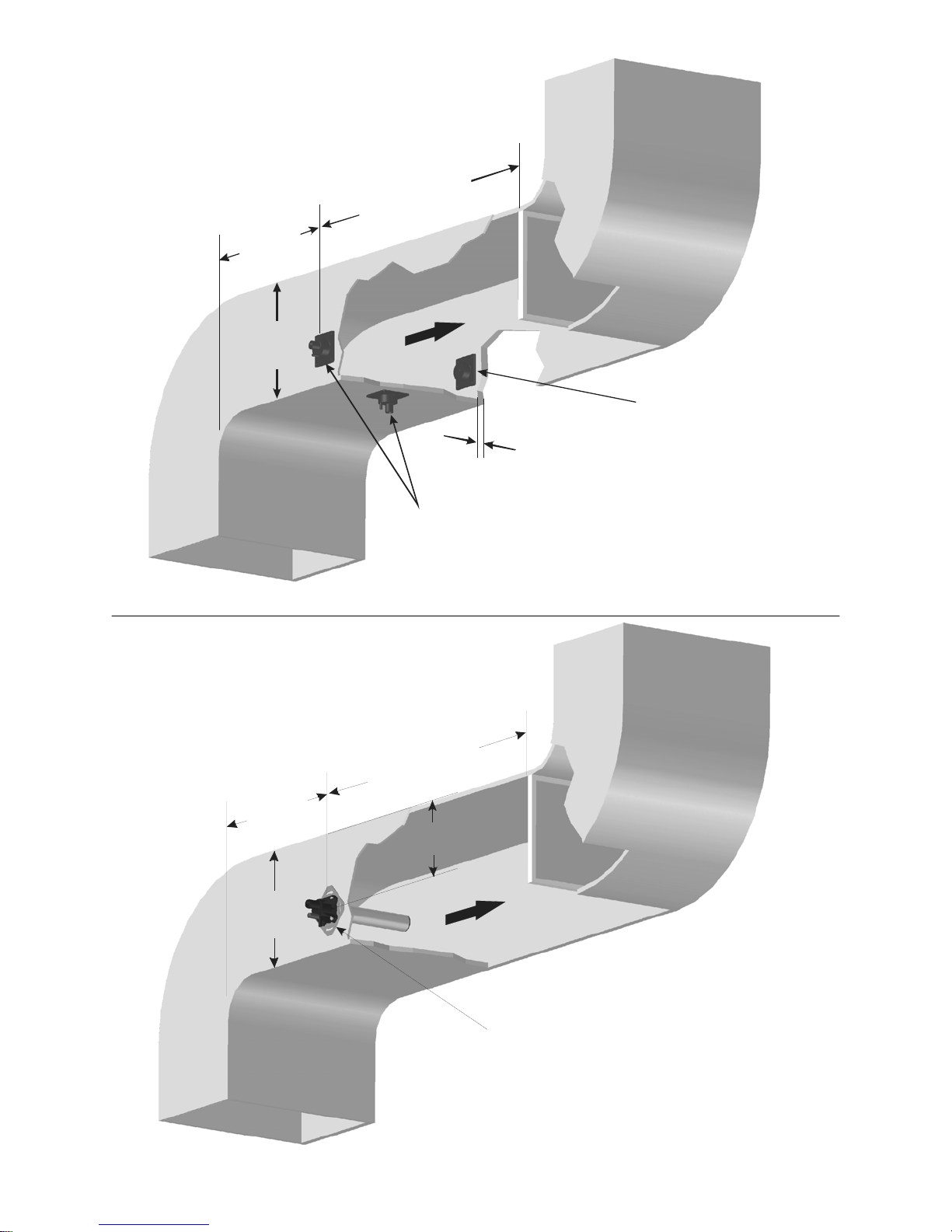

2 x duct

height min.

4 ft (1.2 m) min. to

any o b stru ction

12 in.

(30 cm)

min.

Mount inside if

du c t wall is

> 3/4 in. (19 mm)

3/4 in. (19 mm)

max. w all

thickness

Mount distributor to

side or bottom of duct

Figure 8: RH Distributor Installation

Figure 10: Steam Distributor Above Humidifier (Hose)

Figure 11: Steam Distributor Below Humidifier (Hose)

2 x duct

height min.

4 ft (1.2 m) min. to

any obstruction

2/3 Duct

Height

12 in.

(30 cm)

min.

Mount ASD distributor

to side of duct

11 | Installation

Figure 9: ASD10 Distributor Installation

Page 15

12 in.(30 c m)

min. Radi us

2 in. ( 5 c m )

min.

1 ft (30 cm)

min. bef ore

any bend

Connect Condensate

Hose t o Fill Cup

1 ft (30 cm)

Condensate

line

Support

Brackets

Condensate

Trap

Connect Steam

Hose t o Cy li nder

Figure 10: Steam Distributor Above Humidifier (Hose)

Min 12 in.

(30 cm)

radius

Support B rac k et s

Hose will s often

over time

proper s upport

Is necessary

1 ft (30 cm)

min. Before

any bend

1 ft (30 cm)

min.

Condensate

Trap

To Drain

Figure 11: Steam Distributor Below Humidifier (Hose)

Installation | 12

Page 16

.

12 in

(30 cm)

min.

radius

Suppor t brackets

Hose will sof ten

over t im e

proper support

Is necessary

1ft (30 cm)

min. bef ore

any bend

Obstruction

2 in.

(5 cm)

min.1 ft (30 cm)

1 ft (30 cm)

min.

Use full size condensate tee

at low point. Slope lines up

to “ T” an d imm e diately after it.

Figure 12: Steam Distributor Below Humidifier With Obstruction (Hose)

To drain

To drain

Condensate trap

not 12 in ( 30 cm )

below distributor

No condensate

tr ap at vertical

transition

Steam line

not sloped

13 | Installation

Figure 13: Common Steam Line Errors

Page 17

Electrical

Caution: Wiring to be performed by a licensed Electrician.

Figure 14: Primary Power Connection

Installation | 14

Page 18

External Controls

Control Wiring

Controls are available from Nortec as accessories. If controls were not ordered with humidifier,

they must be purchased or supplied by others. The following information is relevant to all

controls, factory supplied or otherwise. For wiring use minimum 18 AWG and keep as short as

possible.

The RH humidifier can be operated with either On/Off controls only or with On/Off controls and

one modulating input. The modulating input can be from a duct high limit or humidity control

humidistat. See Humidifier Configuration on page 36 to configure the RH for modulation.

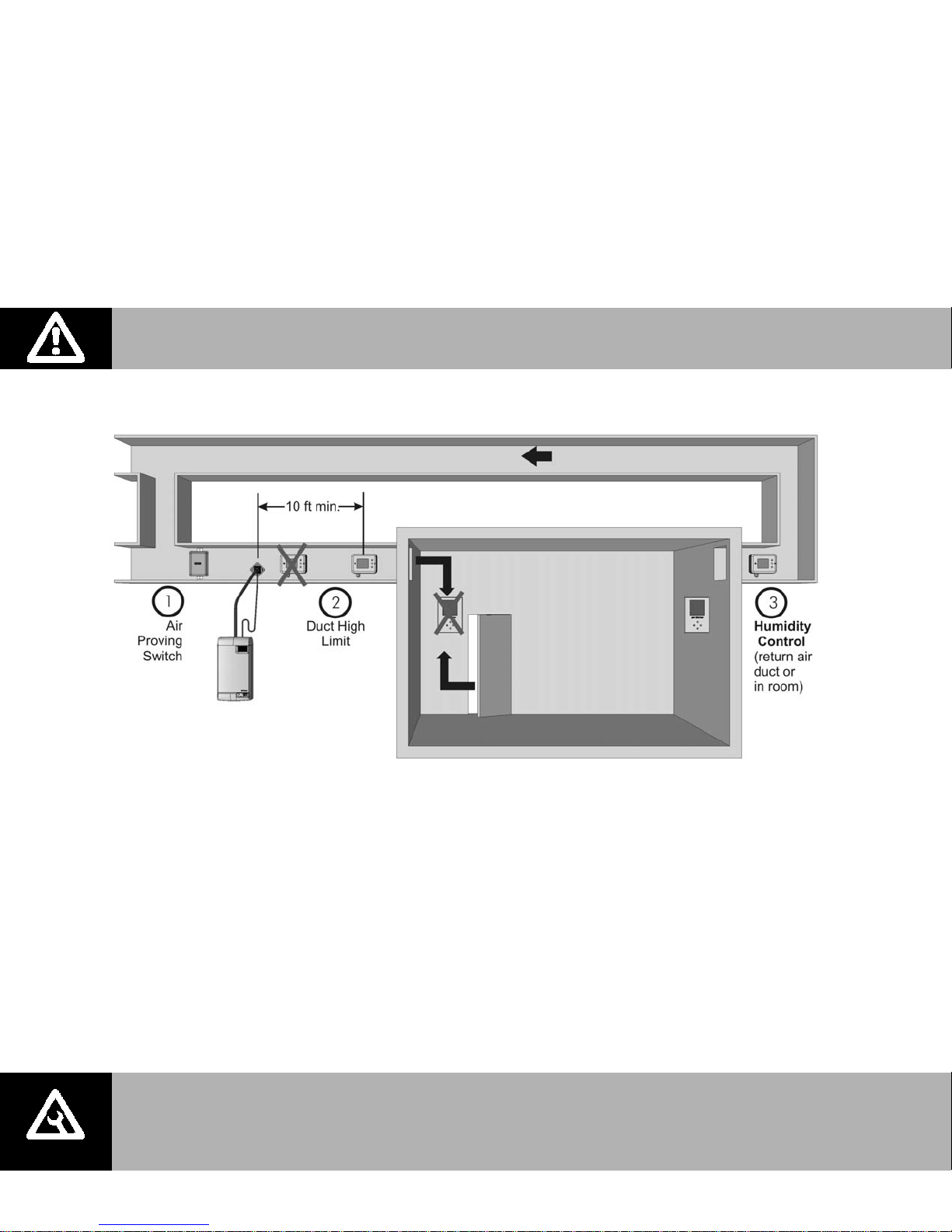

Control Location

Caution: Failure to wire the humidifier in accordance with the wiring instructions could

cause permanent damage. Such errors will void the warranty.

1 Air Proving Switch

• Locate so that it can sense air flow or lack of it.

2 Duct High Limit – Can be modulating or On/Off humidistat.

• Locate at least 10 feet from steam distributor or far enough that under normal conditions

steam is fully absorbed.

3 Humidity Control - Can be Modulating or On/Off humidistat

• Can be located either in return air duct (preferred) or in room being humidified.

• Avoid placing near discharge diffuser of humidified air.

• Mount in area representative of room humidity (draft, doorways, sunlight, or overhang such

as a shelf can affect reading).

15 | Installation

Note: Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to operate.

Nortec highly recommends the use of a high limit humidistat and an air proving switch

in series for this function.

Figure 15: Control Location

Page 19

On/Off Control Wiring

Figure 16: On/Off Controls

Figure 17: Digital On/Off Humidistat

Installation | 16

Page 20

Modulating Control Wiring

Figure 18: Modulating Controls

17 | Installation

Page 21

Figure 19: Modulating Control Wiring

Figure 20: Duct Sensor Wiring

Installation | 18

Page 22

Optional Outdoor Temperature Reset

Figure 21: Outdoor Temperature Reset

• Each Digital controller is equipped with an integrated reset function that can reduce the

setpoint during cold weather operation. This will prevent condensation on windows and

building structures. The above graph illustrates how the setpoint reset feature operates.

• This feature is enabled by removing the jumper from terminals 8 and 1 on the humidistat

and wiring the outdoor temperature sensor to these terminals.

• When the outdoor temperature setback feature is in effect, the humidistat will normally

display the calculated setpoint limit based on the outdoor air temperature. A snowflake will

also be displayed to indicate cold weather operation. When any key on the controller is

pressed, the LCD screen will display the customer specified setpoint for a short duration.

NOTE: Please refer to the Modulating Humidistat Installation Instructions for the Modulating Humidistat Wiring Diagram

19 | Installation

Figure 22: Outdoor Temperature Sensor

Page 23

Options and Accessories

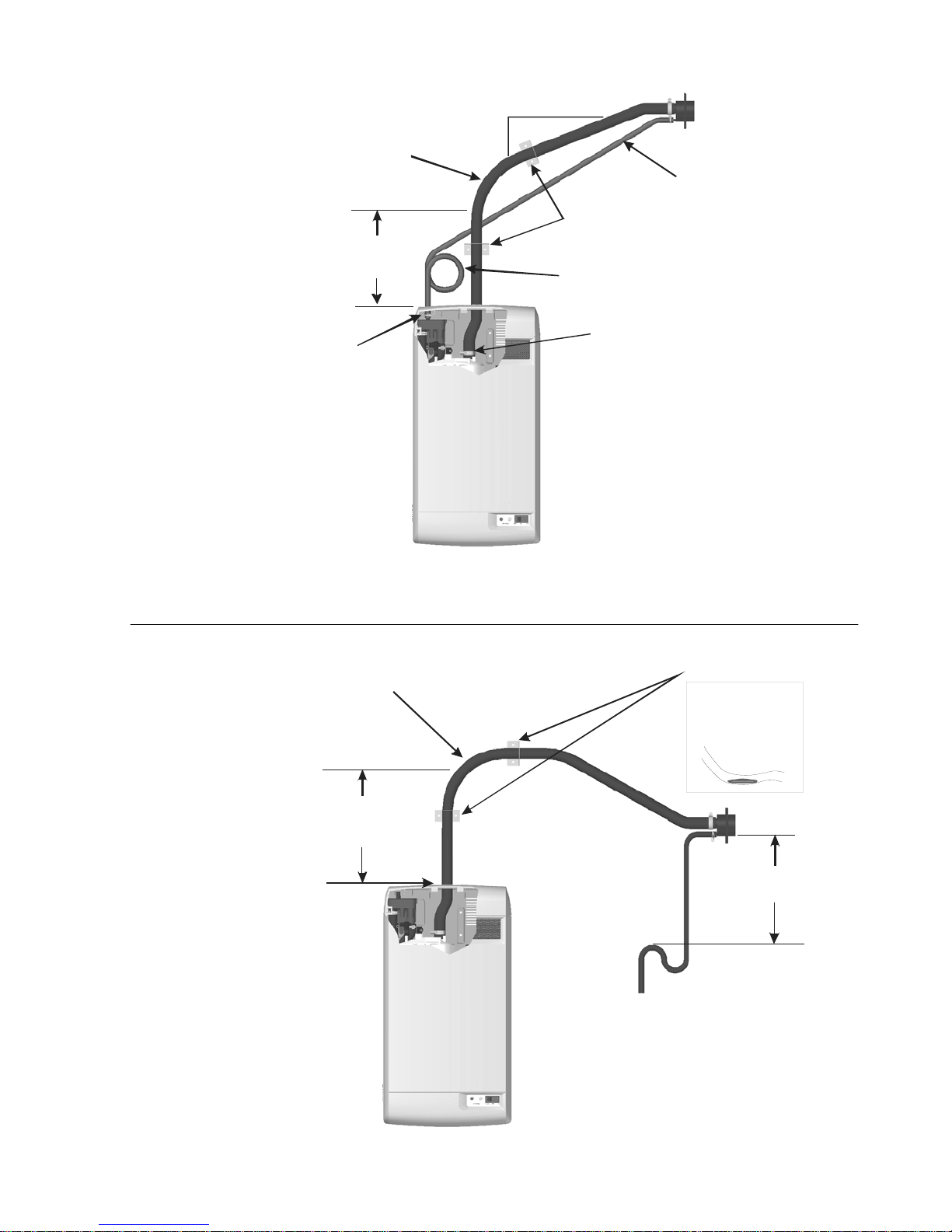

Remote Blower Pack

A remote blower pack is available for the RH for applications where steam for humidification

must be introduced directly into the space being humidified but the humidifier must be installed

in a different location.

• For instructions on installing the remote blower pack refer to the installation instructions

supplied with it.

• The steam line instructions in this manual are also applicable to remote mounted blower

packs except the slope must be larger because the blower pack does not have a separate

condensate line and the maximum allowable steam line length is 4 ft (1.2 m)

Note:

• The blower pack requires additional clearance see the instructions that came with it.

• The steam line slope for the blower pack is 4 in. / 1 ft (10 cm / 30 cm).

Figure 23: Remote Mounted Blower Pack

Installation | 20

Page 24

Start Up

22 Installation Check

23 RH User Interface

23 On/Off or Modulating Operation

24 Start Up Procedure

25 Nortec Digital Controls

25 Modulating Control

25 On/Off Control

26 RH Pre-Start Up Checklist

21 | Start Up

Page 25

Installation Check

Before turning on power to the RH inspect the installation to insure that it was carried out

correctly. Refer to, to RH Pre-Start Up Checklist on page 26, and to the chapter on installation.

12 in.

min.

10 ft (3 m) min.

Filter, bend or

any other

obstruction.

High Li m it

On/Off

- In series between

terminal1and 2

Mod ulating

- Wired to termina 4.

2 x duct height

On/Off

Controls

(Air Proving)

in series

between

terminal

1 and 2

from fan or

trans ition

4 ft (1.2 m) min.

2/3 duct

height

(30 cm)

- Adequate slope

- No restrictions

- no kinks (hose)

- Condensate

traps on long

Mounting

- Unit Level

- Screw s into

structural

Spec Label

Air Ga p

Steam Li ne

runs

member

1/2 in line min to w ithin 4 ft ( 1 .2 m)

30-80 PSI

P Trap with

12 in (30 cm)

min drop

.

Not Plastic Dr a in,

Not to s ink.

Fused

Disconne ct

Correct

voltage /

amps / phase

per spec label.

Note: if a modulating control

is connected to the RH

then jumpe r J1 0 must

be re mo ve d .

Humidity Control

- in return duct or

location wh ich

represents

space (no drafts,

not by door, not by

- Wired to Term 4.

- n series between

I

humidifie d

diffuse r) .

Modulating

On/Off

term 1 and 2.

Figure 23: Installation Check

Start Up | 22

Page 26

RH User Interface

The RH has a simple to use user interface that includes two status LEDs that provide

information on current humidifier status. The On/Off/Drain switch can be used to turn the

humidifier On/Off and drain it for servicing or replacing the cylinder. See Figure 26: LED Status

Lights on page 30 for information on the LEDs.

Status LEDs On/Off/Drain Switch

(Turns humidifier

On/Off and drains

the cylinder)

Figure 24: RH User Interface

Caution: Do not leave the On/Off/Drain switch in the drain position for extended

periods of time. The drain valve solenoid may heat up and result in damage to the

valve and its wiring.

On/Off or Modulating Operation

From the factory the RH is configured to operate as an On/Off humidifier. It will run when 24

VAC from terminal 1 is fed back into terminal 2 through an On/Off humidistat and other security

devices in series. See On/Off or Modulating Control (J10) on page 37 for instructions on

configuring the RH to operate as a modulating humidifier.

23 | Start Up

Page 27

Start Up Procedure

1 Examine the humidifier and installation for damage and or improper installation.

2 Ensure that the front cover is in place and secured with its retaining screws.

3 Open the supply water shut off valve.

4 Turn on the mains power using the installed disconnect.

Warning: Damaged Units or improperly installed units must not be operated. Damaged or

improperly installed units may present a danger to persons and property.

5 Turn the On/Off switch on the front of the humidifier to On.

The humidifier will perform a self-diagnostic sequence during which the LED’s and internal

components will be momentarily activated.

If an error is detected during the self-diagnostic sequence the humidifier will not start. The

yellow status LED will flash in sequence to indicate the detected fault. See RH Faults on

page 49 for information on diagnosing and correcting faults.

After the system test the humidifier is in normal operation mode.

6 Check and adjust the control setpoint on the control and high limit humidistat.

7 When the external humidistat generates a demand for humidity and the security loop is

closed the green humidifying LED on the front of the humidifier will light up, the power relay

on the control board will engage, the fill valve will activate (after a delay) and the cylinder will

slowly fill with water.

Note: While the cylinder is filling with water there should be no water flowing down the drain. If

water is flowing down the drain it can indicate excessive backpressure or a leaking drain

valve. See chapter on troubleshooting starting on page 45.

8 It can take 5 – 10 minutes for the water to be heated up by the submerged electrodes and

for steam to be produced.

Note: If operated on low conductivity water it may take several hours for the RH to reach

full output capacity. This is normal. During this time the humidifier will not perform any

drains and the conductivity of the water in the cylinder will increase.

Start Up | 24

Page 28

Nortec Digital Controls

Nortec provides optional On/Off and Modulating digital controls. Figure 25 show the function

and meaning of the Digital Control’s display and buttons. All controls are available either wall

mounted or with a remote sensor for duct mounting.

Humidity (RH %)

Indicates the

humidistat is on.

A half moon

indicates it is off.

Output signal is shown on

modulating controller

proportional to the demand.

State of On/Off humidistat

Snowflake indicates the

setpoint is being

overridden by outdoor

temperature.

Power button turns

off the humidiistat if

pressed for 2 seconds

Setpoint (RH%)

Option button accesses

sensor calibration.

See troubleshooting

Increase / Decrease Setpoint

Figure 25: Modulating and On/Off Digital Control Operation

Modulating Control

The modulating controls use a PI control algorithm to transmit a 0-10V control signal to the

humidifier. Adjust the setpoint to the desired setting by using the up/down arrow buttons on

the controller.

On/Off Control

The On/Off controls use a PI control algorithm to open and close a relay that opens and closes

the humidifier’s On/Off loop. Adjust the setpoint to the desired setting by using the up/down

arrow buttons on the controller.

Note: It is possible to field calibrate Nortec digital controls if the displayed humidity is found to

be different than a known trusted source. See chapter on Troubleshooting starting on

page 45.

25 | Start Up

Page 29

RH Pre-Start Up Checklist

Unit Serial #: _________________ No. of humidifiers: _______ Tag: _______________

Unit type: _______ __________ Voltage: ________V/_____ph

Cylinder type: Customer/Job: Address:

WATER QUALITY:

Well water F City water F Softened water F

HUMIDIFIER MOUNTING: (Clearances around the unit Acceptable Obstruction)

• Level Front Clearance 36 in. F

STEAM LINE(S):

• Material F Diameter / Size F

• Slope up (min 2 in/ft) F Slope down (min 0.500 in/ft) F

• Low point condensate traps F No hose kinks / Restrictions F

• Type of Insulation

CONDENSATE LINE(S):

• P Trap min 6 in or duct press + 2in F P Trap min 12 in drop F

WATER LINE:

• 1/2 in to within 4ft of unit F Water pressure: 30-80 psig F

DRAIN LINE:

• Air gap within 3 ft of the unit F Diameter / Size F

CYLINDER:

• Seated in drain valve and secured yes F no F

WIRING:

• Wiring connections and connectors secured yes F no F

CONTROLS:

• On / Off / Security loop devices working correctly yes F no F

• Jumper J10 set to

Modulating (removed) F

Or

On/Off (installed) F

• Control Location

• High Limit Location

POWER:

• Voltage, amp, fuse per Spec Label: yes F no F

• Disconnect switch located close to humidifier yes F no F

• Panel Number

Inspected by:

Date of inspection: ______/_______/______

Company:

Start Up | 26

Page 30

RH Start Up Checklist

Unit Serial #: _________________ No. of humidifiers: _______ Tag: _______________

Unit type: _______ __________ Voltage: ________V/______ph

Cylinder Type: Customer/Job: Address:

PRELIMINARY:

• Pre-start-up checklist completed? yes F no F

If no, perform Pre-Start-up Checklist before starting humidifier.

START-UP PROCEDURE:

The prerequisites for the humidifier filling and contactor pulling in to make steam are as follows:

• Front cover in place and secured with screws yes F no F

• Water supply valve opened yes F no F

• Mains disconnect switched on yes F no F

• Turn On/Off switch on yes F no F

• On/Off security loop (Terminal 1 and 2) closed. yes F no F

• Fan security (Terminal 8 and 9) closed yes F no F

CONTROLS:

• Installed controls match configuration yes F no F

• Control Setpoint: High Limit Setpoint:

• > 3 VDC on terminal 4 (Modulating Humidistat) yes F no F

or

• Terminal 1 and 2 closed (On/Off Humidistat) yes F no F

The Humidifier will undergo a self-test when the power is turned on activating the LED’s and other

internal components.

If the above listed prerequisites are fulfilled the humidifier will start filling the cylinder and begin

normal operation.

Note: Most water does not contain enough conductivity for full boil on initial start-up. Units

will need to concentrate the water over a time period (hours to days).

REMARKS:

Started by:

Company:

27 | Start Up

Date of Start Up: _______/_______/______

Page 31

Start Up | 28

Page 32

Operation

30 LED Status Lights

30 Selecting an RH Setpoint

31 Humidifier Components

32 Description of Components

33 Humidifier Schematic

34 How the Humidifier Works

34 Steam Generation

34 Drains

34 Steam Distribution

35 Steam Line

35 Condensate Return

36 Humidifier Configuration

29 | Operation

Page 33

LED Status Lights

The RH user interface includes 2 LED’s which provide information about the humidifier’s current

status.

Green LED On

Indicates steam is being produced

Green LED Blinking

Indicates humidifier is on but there is

no requirement for humidity..

Yellow LED On

Indicates that water level is high

Yellow LED Flashing

Indicates the contr oller has detected

a fault and he humidifier has shut

down. (See table 7 on page47

for meaning of flashes)

Figure 26: LED Status Lights

Yellow LED Steady On

When the yellow LED is steady on (not flashing) it indicates that the high water sensor

has interrupted filling of the cylinder. The LED is on for information only and unless it

persists for an extended period of time it does not require any action.

Selecting an RH Setpoint

The optimum humidity setpoint depends on the reasons that a space is being humidified. The

“ASHRAE Handbook. HVAC Applications” recommends specific design relative humidities for

specific applications. See also Nortec publication “When You Need Humidity” (Form 124A) for

more information on humidity settings.

Health and Comfort - The benefit of humidity is most pronounced for health and comfort in the

40-60% range. A humidity setting of 45-50% is recommended for this purpose to prevent over

humidifying.

Temperature Setback - In cold climates it is often necessary to reduce the humidity level in a

space to prevent build up of condensation on the inside of exterior walls, windows, and trim. It

is highly recommended that the temperature setback function of the Nortec Digital controls be

used under these conditions to prevent damage from condensation. The digital control with an

outdoor temperature sensor installed will automatically setback the humidity setpoint to

correspond with outdoor temperature.

Duct High Limit – The duct high limit is intended to prevent saturation and wetting in duct work

at high load conditions. Nortec recommends a setting of 85% for the duct high limit. It may be

necessary to reduce this setting If the duct work is very cold or in contact with exterior cold

surfaces.

Operation | 30

Page 34

t

r

h

Humidifier Components

Condensate Return

Fill Cu p

Cylinder Plug

Cylinder

High Water Senso

Plug

Steam Outle

Blowerpack

High Voltage

Terminal Block

Transformer

Power Relay

Control Boar d

Fill Va lve

Drain ValveDrain Canal

Control Terminal

Strip

On/Off/Drain Switc

Figure 27: RH Humidifier Components

31 | Operation

Page 35

Description of Components

Table 5: Humidifier Components

Component Function of Component

Blowerpack

Condensate Return

Control Terminal

Strip

Cylinder Plug

Cylinder

Drain Canal

Drain Valve

Control Board

Fill Cup

Fill Valve

High Voltage

Terminal Block

Disperses steam generated by the humidifier directly into a space being

humidified. Consists of a steam distributor, fan, power supply, and

mounting bracket.

Provides a connection to return condensate to humidifier.

Terminal strip for connecting external controls to humidifier and

interfacing with other equipment.

Power connectors to electrodes in cylinder.

Holds electrodes in water. Current between electrodes generates heat

used to generate steam.

Combines cylinder drain water and fill cup overflow into a single drain

outlet.

Drains water from humidifier.

Controls all functions of the humidifier’s operation and provides input

and output connections to humidifier components.

Provides an air gap for backflow prevention.

Controls flow of water into humidifier.

Primary power connection from remote disconnect to humidifier.

High Water sensor

Plug

On/Off/Drain Switch

Power Relay

Steam Outlet:

Transformer:

Used to detect max water level in cylinder.

Turns power on/off to humidifier controller and drains the cylinder for

servicing. Note: Turn off humidifier disconnect to shut off primary power

to the humidifier.

Turns on/off power to cylinder electrodes based on a signal from the

humidifier’s controller (mounted on control board).

Connect to steam line with steam hose (shown with steam hose to

blower pack).

Steps primary voltage down to 24 VAC for the controller and internal

components such as the fill valve and drain valve.

Operation | 32

Page 36

Humidifier Schematic

33 | Operation

Figure 28: Humidifier Schematic

Page 37

How the Humidifier Works

The RH is an atmospheric steam generator that uses heat generated by electrical current

flowing between submerged electrodes to generate heat and steam. The RH is designed for air

humidification via steam distributor or blower pack.

Steam Generation

• Once the unit receives a demand signal and the safety loop between terminal 1 and 2 is

closed the humidifier closes the contactor and measures the current.

• If the demand is lower than the actual output the inlet valve is kept closed and output is

reduced by letting the water level in the cylinder decrease by evaporation.

• If demand is higher than the actual output after a brief delay the fill valve is activated and

water flows into the fill cup. Water from the fill cup flows into the bottom of the cylinder

through a hose connected to the drain valve housing.

Note: The cylinder is gravity fed from the fill cup. If backpressure from the steam line is too

high it will cause water to back up in the fill cup and flow down the overflow line to the

drain.

• ·A soon as the water in the cylinder comes in contact with the energized electrodes current

flows through the water. The resistance of the water to the electrical current generates heat

and in turn steam. The more electrode is covered by water the higher is the current and

output. The unit continues to fill until the current matches demand or the high water sensor

detects a high water level.

• The RH repeats the fill and boil down cycle repeatedly to match output to demand.

• Over time minerals in the water will adhere to the cylinder’s electrodes. The humidifier will

automatically fill to a higher water level to maintain full capacity during the life of the

cylinder. Eventually because of scale formation it will no longer be possible for the

humidifier to reach its full capacity. The RH’s software monitors this condition and when

detected will stop operating and flash the yellow LED in a repeating sequence of 4 flashes.

Drains

• As steam is produced minerals are left behind increasing the conductivity of the water. The

RH’s patented auto adaptive cycle will monitor the water conductivity and perform drains to

maintain the water at optimal conductivity for peak performance.

• The auto adaptive cycle provides the longest cylinder life in combination with keeping the

tightest control and most efficient use of water during the entire cylinder life.

Steam Distribution

Steam generated by the humidifier may be introduced into the air in several different ways. The

most common method for adding the steam into the air is to mount a steam distributor tube in

a supply air duct as shown in Figure 35, Humidifier Schematic. For introducing steam directly

into a room humidifier built in or remote mounted blower packs are used see Figure 29: Remote

Blower Pack.

Operation | 34

Page 38

Steam Line

The steam line between the cylinder steam outlet and the distributor may be Nortec steam

hose, copper pipe, or stainless steel pipe or tube. The RH is an atmospheric steam generator

so it is very important no restrictions are present in the steam line and that the steam line is

sized properly to carry the full output capacity of the humidifier. See Steam Lines and

Condensate Returns on page 10 for information on selecting steam lines.

Condensate Return

Whenever steam is distributed condensate is formed in the distribution system and steam

distributor, manifold, or blower pack. Insulating steam lines is one important way to reduce the

amount of condensate formed. Steam lines are sloped so that condensate does not collect in

the lines and create a restriction to steam flow. The condensate must be collected and

removed from the system so that it does not build up and leak into the duct (or room if blower

pack is used). Condensate can be returned to the RH fill cup to reduce water waste or can be

fed to drain.

35 | Operation

Figure 29: Remote Blower Pack

Page 39

Humidifier Configuration

The RH is factory configured to operate under most conditions without the need for any changes

to its configuration. If required several settings can be made using jumpers on the RH’s control

board. The output of the RH can also be reduced by using a potentiometer on the RH’s control

board. See Figure 30: RH Control Board Jumpers for location of jumpers and the capacity

adjustment potentiometer.

Note: Nortec recommends not making any configuration changes unless they are required and

that any changes to the RH’s settings be performed by a qualified technician.

Figure 30: RH Control Board Jumpers

Caution: Never adjust jumpers other than those listed in this section. Other jumpers are

factory set and must not be changed.

Capacity Adjustment

The Capacity adjustment potentiometer can be accessed through the clearance hole in the

cover of the electrical compartment. It can adjust the capacity of the humidifier between 100%

and 30% of its rated output. (Factory setting = 100% output).

100%30%

Figure 31: Capacity Potentiometer Adjustment

Operation | 36

Page 40

A

A

On/Off or Modulating Control (J10)

The RH’s output can be controlled by either an On/Off humidistat or a modulating humidistat.

To set the RH to operate with a modulating humidistat remove Jumper J10. (Factory setting =

jumper Installed , On/Off operation)

J10 Removed– Modulating operation, the controller monitors the demand signal on

terminal point 4 of the control terminal strip and adjusts humidifier output to match it.

J10 Installed - The RH is configured for On/Off operation. The controller will ignore any

modulating signals even if they are connected.

Modulation Offset (J13)

The RH controller can be configured to work with a modulating humidistat with 4-20 mA or 2-10

VDC output. Modulation offset can be configured with jumper 13. (Factory setting = Jumper

Removed, 0-10 VDC or 0-20 mA control signal)

J13 Removed – Controller is configured for a 0-10 VDC or 0-20 mA control signal.

J13 Installed – Controller is configured for a 2-10 VDC or 4-20 mA control signal.

Note: For mA control a 500Ω register is required between terminals 3 and 4 on the low voltage

control terminal.

Table 6: Control Jumper Configuration

Resulting Control J10 J13

On/Off Installed No Affect

Modulating 0-10 VDC or 0-20 m

Modulating 2-10 VDC or 4-20 m

Removed Removed

Removed Installed

Ground Fault Interrupt (GFI) (J15)

Ground current leakage can occur when the humidifier performs drains. With jumper J15 the

RH can be configured to turn off the power to the electrodes whenever a drain takes place.

J15 Removed – The power relay is on during drains to control cylinder water concentration.

J15 Installed – The power relay is turned off during drains to control cylinder water

concentration.

37 | Operation

Page 41

Maintenance and

Servicing

39 Required Maintenance

39 Cylinder Spent Fault

39 Replacement Cylinder

40 Removing the Cylinder

41 Drain Valve Cleaning

42 Installing the New Cylinder

43 Extended Shutdown

43 Starting After Extended Shutdown

44 RH Maintenance Checklist

Maintenance and Servicing | 38

Page 42

Required Maintenance

The RH humidifier has been designed to require very little maintenance. Regular maintenance

consists of checking the humidifier to insure it is in good condition, replacing the cylinder when

the software advises that the cylinder is spent and cleaning out the drain valve whenever the

cylinder is replaced.

Cylinder Spent Fault

When the cylinder is spent the RH will stop operating and the yellow LED will flash in a repeating

pattern of 4 flashes. See Table 8: Troubleshooting RH Faults on page 49 for more information

on other flash sequences. At this time the cylinder must be replaced.

The steam cylinder is disposable and must be replaced at end of cylinder life. Cylinder life is

dependent on water supply conditions and humidifier usage.

Caution: Failure to replace the cylinder at the end of cylinder life will result in improper

operation and may result in damage to the humidifier. Nortec is not responsible for

any damages resulting from, or attributed to, the failure to replace a spent cylinder

(see Manufacturer’s Warranty).

Note: Nortec recommends keeping a replacement cylinder in stock throughout the

humidification season. This will prevent possible downtime when the humidifier

reports cylinder end of life.

Replacement Cylinder

The label on the existing cylinder identifies the cylinder type in its top left corner. When ordering

a cylinder always quote the three or five digit model number on the label, the humidifier’s serial

number and the humidifiers voltage. Serial number and voltage are located on the specification

label on the left side of the humidifier.

39 | Maintenance and Servicing

Figure 32: RH Cylinder

Page 43

.

Removing the Cylinder

Warning

• Disconnect main power at the external disconnect before any servicing.

• The inside of the humidifier’s cabinet contains high voltage components and wiring.

Access should be limited to authorized personnel.

1 Drain the existing cylinder by switching the On/Off/Drain switch to the Drain position. Let

the humidifier drain until no more water is flowing out to drain (usually not more than 10

minutes).

2 Turn the humidifier On/Off/Drain switch to off.

3 Close supply water shut off valve.

4 Turn off power to the humidifier with the external disconnect.

5 Remove the two screws securing the front cover.

6 Remove the cylinder plugs from the cylinder pins by pulling vertically.

7 Using a flat screwdriver loosen the hose clamp where the hose is connected to the cylinder.

8 Tip the top of the cylinder forward to pivot it out of the steam hose. When free of steam

hose lift the cylinder out.

Cy lin der P lug

lift v ertic a lly

Cylinder

Tilt cy lin der

forward to clear

hose and then

lift from drain

Hose Clamp

Cover Screws

valve.

Tilt cove r

forw a r d to

remove.

On /O ff/D ra in Switch

Figure 33: Cylinder Removal

Maintenance and Servicing | 40

Page 44

Drain Valve Cleaning

Always clean the drain valve before installing a new cylinder. Scale from the spent cylinder may

have fallen into the drain valve and could prevent its proper operation. To properly clean the

drain valve it must be removed and disassembled.

Note: Be sure to reattach the green ground wire to reduce the risk of electrical shock.

1 Disconnect spade terminals from the drain valve.

2 Remove the screw holding the green ground wire and the two screws holding the valve to

the drain pan.

3 Squeeze the tabs of the spring clamp holding the hose to the drain valve and slide it up the

hose. Pull hose from drain valve. Lift the drain valve from the drain pan.

4 Unsnap red coil cap on solenoid and remove the solenoid from the valve.

5 Loosen brass nut holding actuator to plastic housing with a wrench and disassemble

actuator.

6 Clean actuator components and valve housing (inlet port, outlet port, and cylinder port). Put

new o-ring that was supplied with new cylinder into valve.

7 Reassemble actuator making sure tapered end of spring is oriented as shown. Tighten

brass nut 1/4 turn past hand tight.

8 Clean out end of hose and reattach to valve. Slide hose clamp back in place and place valve

into drain pan.

9 Secure valve with 2 screws and attach green ground wire to solenoid.

Figure 34: Drain Valve

41 | Maintenance and Servicing

Page 45

Plunger

Spring

(Note Orientation)

Sleeve

and

Solenoid

Figure 35: Drain Valve Actuator Assembly

Installing the New Cylinder

CAUTION: Make sure the new cylinder is the same model as the one that was removed.

Model number is on top left corner of cylinder label.

1 Insert cylinder into drain valve. Tilt cylinder forward and fit end of steam hose to steam

outlet. Tip cylinder back into place.

2 Tighten hose clamp being careful not to over tighten and crush the plastic cylinder steam

outlet.

3 Attach color-coded cylinder plugs to the corresponding color-coded cylinder pin. Push down

completely. Connect high water sensor plug. Spring-loaded plugs should fit snuggly onto

the cylinder pin. Replace if they are loose or damaged.

4 Replace the humidifier cover and secure with two screws.

5 Turn on power to humidifier with the external disconnect.

6 Open supply water shut off valve.

7 Turn the humidifier On/Off /Drain switch to On.

Maintenance and Servicing | 42

Page 46

Extended Shutdown

Should it be required to disconnect power to the humidifier for a period of extended shut-down,

always drain the cylinder first.

1 Switch the On/Off/Drain Switch to the Drain position.

2 Wait until the humidifier is completely drained (usually takes less than 10 minutes).

3 Turn the On/Off /Drain switch to the off position.

4 Shut off power to the humidifier with the external disconnect.

5 Close the supply water shut-off valve.

Note: As long as the RH is powered, it will automatically drain the cylinder when there

has not been a call for humidity for an extended period of time. This feature will

reduce or prevent the possibility of corrosion of the electrodes and the accumulation

of algae and bacteria growing in the cylinder. The cylinder will remain empty until

there is a call for humidity at which time the fill valve will open and refill the cylinder.

The unit will go through its normal process for optimum operation.

Starting After Extended Shutdown

1 Check to see the humidifier has not been damaged and the installation has not been

altered. Refer to the Chapter on Start Up.

2 Turn on the power to the humidifier with the external disconnect.

3 Turn the On/Off/ Drain switch to the Drain position.

4 Wait until there is no water flowing to drain. It usually takes less than 10 minutes.

5 Follow the start up procedure in the chapter on Start Up.

43 | Maintenance and Servicing

Page 47

RH Maintenance Checklist

Model #: _________________

Serial #: _________________ Tag: ________

Cylinder #:

CHECK CYLINDER

• Cylinder spent), yellow LED flashing 4 times in sequence.

(If Yellow LED is On and cylinder is not new then cylinder will have to be replaced soon.)

REPLACE CYLINDER

Cylinder drained.

•

•

Disconnect open, On/Off/Drain switch off, water shut off valve closed, cover removed.

• Cylinder removed

• Drain valve removed / cleaned / new O-Ring

• Drain valve installed / ground wire attached.

New Cylinder Installed New cylinder model #

•

(Should be same as removed cylinder)

• Cylinder plug colors match cylinder dots.

• Cylinder plugs snug and in good condition.

• High Water Sensor plug snug and in good condition.

• Cover replaced, water shut off valve open, On/Off /Drain switch On, Disconnect Closed

SYSTEM CHECK

• Yellow Led flashing? No Yes Flash Sequence?

(See Troubleshooting Chapter for actions if yellow LED is flashing)

• Primary power disconnect turned off

Cylinder plugs snug and in good condition.

•

• Electrical wiring not loose and in good condition,

• Steam hoses and steam lines in good condition / No kinks in hose,

• No Signs of water leaking around humidifier, steam line, condensate returns,

Inspected by: Date of inspection: _______/_______/______

Company:

Maintenance and Servicing | 44

Page 48

Troubleshooting

46 Organization of Troubleshooting Chapter

46 Troubleshooting Requirements

47 General Troubleshooting

47 Humidifier

48 Steam Distributors

48 Blower Pack

48 Digital Humidistat

49 RH Faults

49 LED Flash Sequence

49 Clearing a Fault

51 RH Wiring Diagram

45 | Troubleshooting

Page 49

Organization of Troubleshooting Chapter

The troubleshooting chapter is broken down into 2 sections.

General Troubleshooting Deals with troubleshooting incorrect humidifier operation,

steam line and plumbing issues without any control

software faults.

Humidifier Warnings and Faults Deals with faults that are generated by the humidifier’s

control software.

CAUTION: Be aware, when troubleshooting, that the humidifier is powered by high voltage

and familiarity with both good practices and wiring of the humidifier is recommended.

Any troubleshooting that requires opening the cabinet should be done by qualified

personnel.

NOTE: Most humidifier faults are not caused by faulty equipment but rather by improper

installation. A complete fault diagnosis always involves a thorough examination of the

entire system. Often, the steam hose connection has not been properly executed, or the

fault lies with the humidity control system.

Troubleshooting Requirements

• Ensure the installation meets the installation requirements outlined in the Installation

Chapter of this manual.

• Familiarize yourself with the operation of the humidifier by reading the Operation Chapter of

this manual.

• Wiring diagram for specific for your humidifier is installed on the inside of the humidifier

door. A generic copy of the RH wiring diagram is also included at the end of this chapter for

reference purposes.

• When contacting your local representative or Nortec for troubleshooting assistance, please

ensure the serial number has been obtained for reference purposes.

Troubleshooting | 46

Page 50

General Troubleshooting

The following section provides general guidelines for troubleshooting the RH humidifier and

auxiliary components. For detailed troubleshooting information refer to the manuals that were

provided with the auxiliary equipment and to Table 8: Troubleshooting RH Faults after in this

chapter.

Humidifier

Table 7: General Troubleshooting

Symptom Cause Corrective Action(s)

Nothing happens when On/Off

switch is turned on.

Humidifier will not humidify or

not reaching RH setpoint

1 Fuse blown 1 Check inline fuse between transformer

and control board.

2 Incorrect Voltage 2 Check voltage against spec label and

correct.

3 Step Down Transformer not

outputting 24VAC

4 Incorrect primary power jumper 4 Check that jumper on high voltage

1 Safety loop open

2 No demand signal

3 Replace the transformer

terminal block is connected between P

and terminal corresponding to supply

voltage.

1a Check if there is 24 VAC at terminal

2.

1b Check wiring and operation of On/Off

devices connected to terminal 1 and

2.

1c Check jumper is installed in fan

safety loop, terminal 8 and 9.

2 Check voltage between terminal 3 and

4. For demand configuration 35% of

full-scale signal must be present for

humidifier to start.

3 Not configured correctly for

4 Capacity has been manually

5 Low conductivity water 5 Check if yellow LED is on. If operated

6 Incorrect configuration

Humidifier has faulted and

yellow LED is flashing

47 | Troubleshooting

1 Software has detected an

On/Off or modulating control

limited

(Modulating or On/OFF)

abnormal condition

3 Check that J10 on control board is

removed for modulating control and

installed for On/Off control.

4 Check Manual Capacity adjustment

potentiometer. Clockwise increases

capacity.

on low conductivity water it may take

several hours for the RH to reach full

output capacity. This is normal.

During this time the humidifier will not

perform any drains and the

conductivity of the water in the

cylinder will increase.

6 Check J10 on control board, remove if

a modulating humidistat is being used.

1 Refer to Table 8: Troubleshooting RH

Faults.

Page 51

Steam Distributors

Symptom Cause Corrective Action(s)

Distributor spitting out water

Condensation in duct 1 Installation clearances not

1 Distributor not level 1 Use support at end o distributor to

2 “P” Trap too close to distributor 2 “P” Trap must be a minimum of 12 in

3 Condensate line not sloped

sufficiently

4 Trap blocked 4 Check that water flows through trap.

5 Steam line not insulated 5 If steam line is long condensate build

6 Incorrect steam line installation 6 Check that steam line has been

observed

ensure it is level.

(30 cm) below the distributor to

ensure flow. Relocate if required.

3 Sufficient slope to insure flow is

required. Reinstall if required.

Clear out if blocked.

up could overload distributor

condensate port. Insulate line to

improve efficiency and install

additional condensate traps as

required.

installed with condensate traps and

slope per installation instructions on

page 10.

1 Refer to distributor installation manual

for required clearances. Relocate

distributor if required.

2 Design conditions changed 2 Check supply air temperature and

humidity to determine if conditions

have changed.

3 High limit not functioning 3 Check setting and operation of high

limit. Replace if defective.

Blower Pack

Symptom Cause Corrective Action(s)

Blower not operating 1 No power to blower pack 1a Check power connection to blower

pack.

1b Ensure unit is humidifying. The

blower will not operate if the

humidifier is not generating steam.

Digital Humidistat

Symptom Cause Corrective Action(s)

Humidistat Reading incorrectly 1 Sensor out of calibration 1 Check reading against known reliable

instrument. If out of calibration it can

be field calibrated ±10%. Refer to

humidistat documentation for

calibration instructions.

Troubleshooting | 48

Page 52

RH Faults

The self-diagnostic system built into the RH is continually monitoring the operation of the

humidifier. When an abnormal condition occurs that cannot be self corrected by the software

the RH will turn off power to the cylinder, drain the cylinder, and annunciate the fault using the

yellow status LED.

LED Flash Sequence

To differentiate between different fault conditions the yellow LED is flashed in different

sequences. Table 8 lists the fault sequences that can be displayed, their meaning, possible

cause and suggested corrective actions.

Clearing a Fault

• Check the flash sequence against the list of fault messages and take any necessary actions

to correct the cause(s) as outlined in Table 8: Troubleshooting RH Faults.

• Power cycle the humidifier with the On/Off switch waiting 10 seconds between turning it off

and on.

Table 8: Troubleshooting RH Faults

Yellow LED System Detected Cause Corrective Action(s)

1 flash

Excess Current

Current has exceeded

130% of max

1 Drain blocked water over

concentrated

2 Drain solenoid not energized,

water over concentrated

3 Filling too fast, fill valve

damaged

4 Filling too fast, wrong fill valve 4 Check for correct fill valve in

5 Water supply too conductive 5a Contact Nortec

6 Humidifier short cycling 6a Check if high limit or other

1 Clean the drain line

2 Check and correct wiring to

drain valve.

3 Replace the fill valve

parts list, replace if incorrect

representative for

recommendation on alternate

cylinder

5b Change the water supply

On/Off control is cycling

On/Off in less than 5

minutes. Check location and

setting of high limit.

6b Reduce the output by

turning down the capacity

potentiometer.

49 | Troubleshooting

7 Wrong cylinder installed 7 Install correct cylinder model

8 Cylinder Spent but not

detected by software

9 Condensate from other

source

10 Back pressure 10 Eliminate back pressure

8 Replace the cylinder (see

maintenance chapter)

9 Remove condensate returns

other than from steam line.

Page 53

Table 8: Troubleshooting RH Faults (Continued)

Yellow LED System Detected Cause Corrective Action(s)

2 flashes

No Current

Fill valve activated for

long time but high water

level not reached.

Fill should be faster than

1” per minute.

1 Drain valve leaking or stuck

open

2 Water shut off valve closed 2 Open shut off valve

3 Fill Valve strainer blocked 3 Clean out strainer on fill valve

4 High system back pressure 4a Check for kinked hose

5 High water sensor not

connected

6 Low water conductivity 6a Check conductivity of water.

1 Clean drain valve or replace

(see maintenance chapter)

inlet.

4b Check for proper

condensate removal (see

installation chapter)

4c Install fill cup extension

5 Check that cylinder plug with

white marker is connected to

short electrode with a plastic

well around it and to control

board.

If less than 150

microsiemens contact factory

for recommendation.

6b Add 1/4 teaspoon of salt to

fill cup and restart unit.

3 flashes

4 flashes

No Current, High Water

Water level at top of

cylinder with no current

Cylinder Spent

Electrodes covered with

scale.

1 Primary wire not looped

through current transformer.

2 High water sensor plug is on

an electrode pin.

3 Cylinder plugs installed

incorrectly

1 Cylinder electrodes are

covered with scale and

humidifier cannot meet

demand

1 Open disconnect, rewire

primary wire through current

transformer.

2 Install high water senor plug

on cylinder pin with shroud

around it.

3 Check that cylinder plugs

colors match markers next to

electrodes on cylinder and

that white marked cylinder

plug is connected to short

electrode located in plastic

well.

1 Replace cylinder with same

model number (see

maintenance chapter)

Troubleshooting | 50

Page 54

RH Wiring Diagram

K2

P8

High Water

K3

Capacity

adjust

P7

120 VAC

208 VAC

240 VAC

Hot

Hot

Hot

Cylinder

P1

P2

P3

P4 P5 P6

Install J10 for

On/Off

control only

J10

G

Y

Status

Lamps

On/Off/Drain

Switch

VAC

24 VAC

240/208/120

Transformer

208

120 P

240L1

Neutral

Ground

S

Internal

External

1.5 Amps

12

Note:

208

120 P

240L1

Hot

208

120 P

240L1

Hot

Install jumper

from P to

terminal

Ground

corresponding

to mains

voltage.

Ground

24 VAC

3

Security Loop

Fill V

8

919

4

24 VAC

Control Signal (+)

Control Ground (-)

Drain V

20

ROOM Steam Distributor

M

Fan Start (+)

Fan Start (--)

Fan Security

Note:

Room Steam Distributor

not included with RH

+

_

TB2

~

TB1

~

Duct humidifier

51 | Troubleshooting

Rh Humidifier 120/208/240 Vac

INTERNAL WIRING DIAGRAM

DIAGRAM No. 2548760 REV. B DATE: Sept. 9, 2009

Figure 36: RH Wiring Diagram

Page 55

Exploded View and Spare Parts List

Spare Parts| 52

Page 56

RH Spare Parts

53 | Spare Parts

Figure 37: RH Spare parts

Page 57

Table 9: RH Spare Parts List

Item Nortec Part No. Description

1 Reference Housing, Plastic Back, RH

2 2547403 Housing, Plastic front cover, RH

3 Reference Cabinet, Electrical Backplate, RH

4 2548001 Cabinet, Drain Pan, RH

5 2548000 Coverplate, Electrical, RH

6 2548313 Cover, bottom, RH

7 2548683 Distributor, Plastic, RH Blower

8 2548314 Fan, 80X80mm Tangential, 24Vdc

9 Reference Bracket, fan, RH

10 2548008 PWB, Power Supply, RH Blower Pack

11 Contact Factory Condensate Hose Kit, RH Blower Pa ck

12 1323020 GROUND CLAMP

13 2547999 Transformer Multi tap 120/208/240 to 24V

14

15 1323097 Switch Rocker SPDT 5A-250V

16 1583008 LENS CLEAR 1/4in - LED DISPLAY

17 1519002 Cylinder 202

18 2547963 Fill cup assembly, RH

19 2547964 Cylinder Plug kit, RH

20 1313244 VALVE, FILL ASSLY 005-020 LBS

21 1455000 GASKET FOR FILL THRU CAB

22 1639011 COMP FTTG 1/4in ELBOW ASSLY

23 1456000 VALVE DRAIN 93BEIGE+24V COIL

24 2547997 Gasket, Drain canal, round, RH

25 1102503 Drain Canal Round

26 2547998 Hose, 7/8" drain preformed 90deg, RH

27 2548118 Grill, built in blower, RH

28 1106649 Preformed Steam Hose to Blower Pack

2549518 PCB RH Duct 10 lbs/hr

2549519 PCB RH Space 8 lbs/hr

Spare Parts| 54

Page 58

55 | Warranty

Page 59

Warranty

Walter Meier Inc. and/or Walter Meier Ltd. (hereinafter collectively referred to as THE

COMPANY), warrant for a period of two years after installation or 30 months from

manufacturer’s ship date, whichever date is earlier, that THE COMPANY’s manufactured and

assembled products, not otherwise expressly warranted (with the exception of the cylinder), are

free from defects in material and workmanship. No warranty is made against corrosion,

deterioration, or suitability of substituted materials used as a result of compliance with

government regulations.

THE COMPANY’s obligations and liabilities under this warranty are limited to furnishing

replacement parts to the customer, F.O.B. THE COMPANY’s factory, providing the defective

part(s) is returned freight prepaid by the customer. Parts used for repairs are warranted for the

balance of the term of the warranty on the original humidifier or 90 days, whichever is longer.

The warranties set forth herein are in lieu of all other warranties expressed or implied by law. No

liability whatsoever shall be attached to THE COMPANY until said products have been paid for in

full and then said liability shall be limited to the original purchase price for the product. Any

further warranty must be in writing, signed by an officer of THE COMPANY.

THE COMPANY’s limited warranty on accessories, not of the companies manufacture, such as

controls, humidistats, pumps, etc. is limited to the warranty of the original equipment

manufacturer from date of original shipment of humidifier.

THE COMPANY makes no warranty and assumes no liability unless the equipment is installed in

strict accordance with a copy of the catalog and installation manual in effect at the date of

purchase and by a contractor approved by THE COMPANY to install such equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for consequential

damage or damage resulting directly from misapplication, incorrect sizing or lack of proper

maintenance of the equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for damage resulting

from freezing of the humidifier, supply lines, drain lines, or steam distribution systems.

THE COMPANY retains the right to change the design, specification and performance criteria of

its products without notice or obligation.

Warranty | 56

Page 60

U.S.A.

Walter Meier (Climate USA) Inc.

826 Proctor Avenue

Ogdensburg, NY 13669

CANADA

Walter Meier (Climate Canada) Ltd.

2740 Fenton Road

Ottawa, Ontario K1T 3T7

TEL: 1.866.NORTEC1

FAX: 613.822.7964

EMAIL: northamerica.climate@waltermeier.com

WEBSITE: www.humidity.com

Certificate No. 002419

Loading...

Loading...