Page 1

Important: Read and save these instructions. This guide to be left with equipment.

2530618-J | 10 NOV 2014

NH

Series

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for your NHRS Resistive

Element Steam Humidifier

Page 2

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

Thank you for choosing NORTEC.

Proprietary Notice

This document and the information disclosed herein are proprietary data of Nortec Humidity Ltd. Neither this

document nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorization of Nortec Humidity Ltd., except to the extent required for installation or maintenance of

recipient’s equipment.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel,

or the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2014, Nortec Humidity Ltd. All rights reserved.

Page 3

Contents

1 Introduction

2 Receiving and Unpacking

3 Humidifier Components

4 Description of Components

5 NHRS Models

8 Installation

9 Typical Humidifier Installation

10 Location

12 Mounting with Keyholes

13 Plumbing

14 Steam Distributor

15 Steam Lines and Condensate

Return

21 Electrical

22 External Controls

29 Optional Outdoor Temperature

Setback Sensor

30 Remote Fault Option Wiring

31 Options and Accessories

36 Start Up Procedure

38 Information Screens

45 How the Humidifier Works

47 Selecting an RH Setpoint

48 Maintenance and

Servicing

52 Troubleshooting

53 General Troubleshooting

55 Wiring Diagrams

57 Start Up Checklists

60 Maintenance Checklists

61 Spare Parts

62 NHRS Plumbing Parts

64 NHRS Electrical Parts

66 Warranty

33 Start Up

34 Installation Check

Page 4

CAUTION: Servicing

Disconnect main power before any servicing.

The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

During and following operation of the humidifier, the steam and components in

contact with the steam such as the cylinder, blower pack, steam lines, steam

distributors, and condensate lines can become hot and can burn if touched.

Nortec Humidity Ltd. does not accept any liability for installations of humidity

equipment installed by unqualified personnel or the use of parts/components /

equipment that are not authorized or approved by Nortec Humidity Ltd.

CAUTION: Electrical

All electrical work should be done according to local electrical code.

Electrical connection to be performed by a licensed electrician.

CAUTION: Plumbing

Plumbing to be performed by a licensed plumber.

Drain water from humidifier can be very hot. Do not drain to public sink.

All plumbing work should be done according to local plumbing code.

CAUTION: Installation

Do not mount on hot surfaces.

Do not mount in area where freezing can occur.

Do not mount on vibrating surface.

Do not mount on floor.

The NHRS produces steam at atmospheric pressure, no devices which could block

steam output should be connected to the steam outlet.

Steam lines must be installed so that no restriction can produce backpressure in

the humidifier. Failure to follow installation instructions will result in improper

operation and could void warranty.

Regardless of selecting On/Off or modulating control method, NORTEC humidifiers

must have a closed circuit across the On/Off security loop control terminal to

operate. NORTEC highly recommends the use of a high limit humidistat and an air

proving switch in series for this function.

Introduction

1 | Introduction

Page 5

Figure 1: Specification Label Location

Receiving and Unpacking

1 Check packing slip to ensure ALL material has been delivered.

2 All material shortages are to be reported to NORTEC within 48 hours from receipt of goods.

NORTEC assumes no responsibility for any material shortages beyond this period.

3 Inspect shipping boxes for damage and note damages on shipping waybill accordingly.

4 After unpacking, inspect equipment for damage. If damage is found, notify the shipper

promptly.

5 All NORTEC products are shipped on a Free-On-Board (FOB) factory basis. Any and all

damage, breakage or loss claims are to be made directly to the shipping company.

Before Installation

1 Ensure that available voltage and phase corresponds with humidifier voltage and phase as

indicated on humidifier specification label.

2 Ensure that the dedicated external fuse disconnect is of sufficient size to handle the rated

amps as indicated on the specification label. Refer to local codes.

3 Report any discrepancy immediately to the site engineer.

4 Ensure sufficient clearances will be available as described on pages 10 and 11.

5 Ensure steam lines can be routed to distributor or blower pack as described on pages 14-19

and 31.

Introduction | 2

Page 6

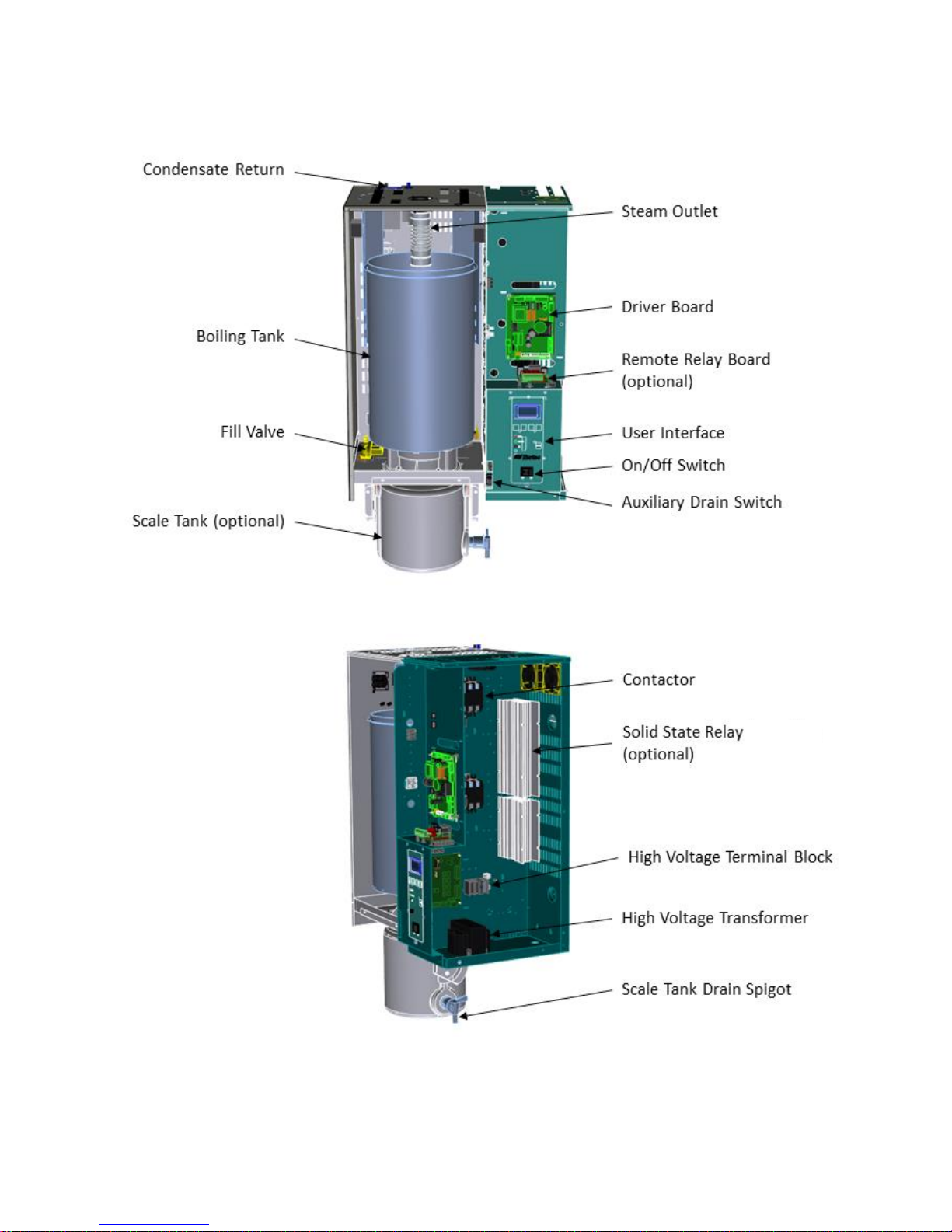

Humidifier Components

3 | Introduction

Figure 2: NHRS Humidifier Components

Page 7

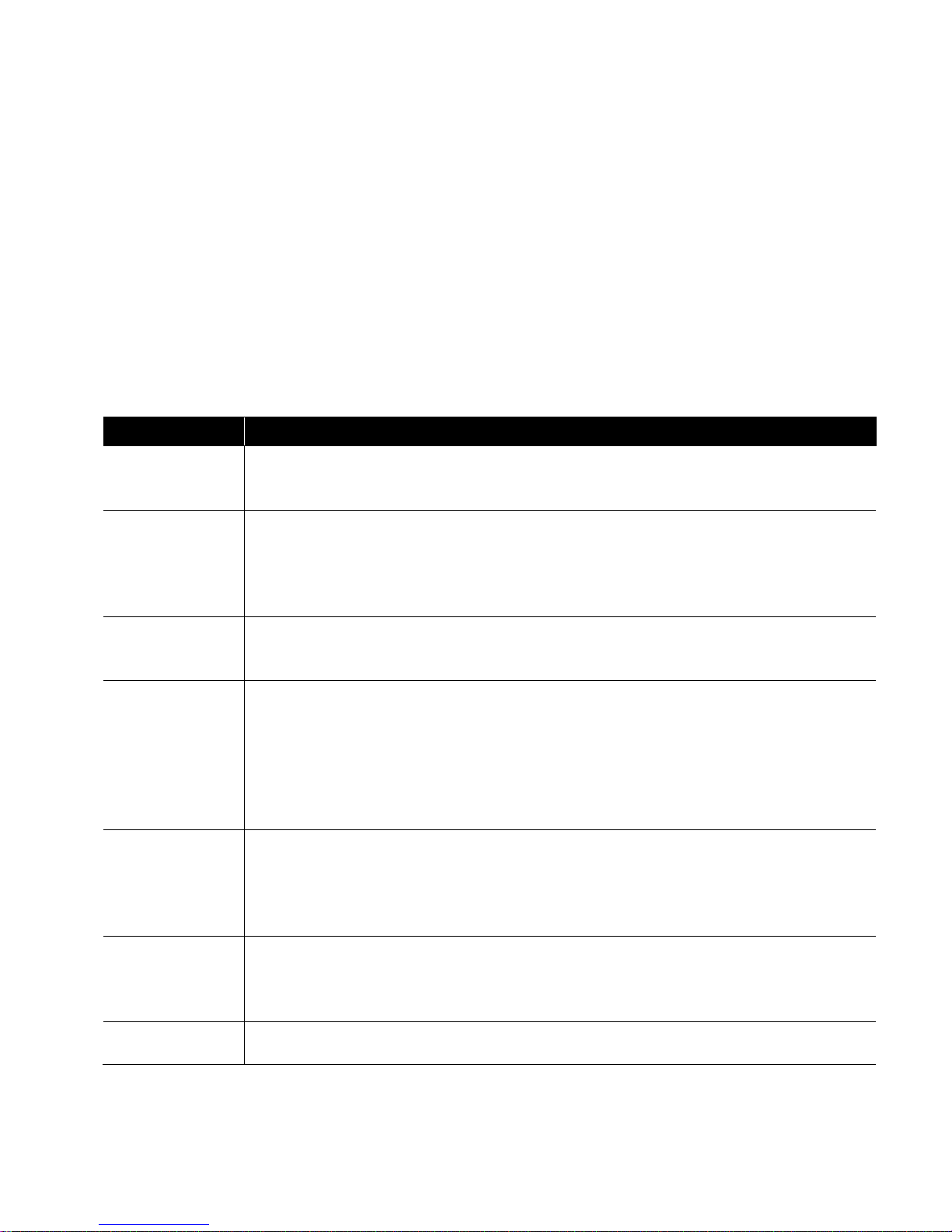

Component

Function of Component

Auxiliary Drain

Switch

Drains water from boiling tank by activating drain pump. Note that initiating a

drain in this manner will not induct Drain Water Cooling.

Boiling Tank

Holds resistive elements submerged in water. Current traveling along the

internal element wire generates heat which is used to generate steam.

Condensate

Return

Provides a connection to return condensate to humidifier.

Contactor

Turns On/Off power to boiling tank elements.

Drain Pump

Drains water from boiling tank.

Drain Water

Cooling Valve

Adds cold supply water to water draining from boiling tank to temper drain

water to a maximum of 140ºF (60ºC).

Driver Board

Provides input and output connections to humidifier components.

Fill Cup

Provides an air gap for backflow prevention.

Fill Valve

Controls flow of water into humidifier.

High Voltage

Terminal Block

Primary power connection from remote disconnect to humidifier.

High Voltage

Transformer

Steps primary voltage down to 24 VAC for the controller and internal

components such as the fill valve and drain pump.

On/Off Switch

Turns power On/Off to humidifier controller. Note: Turn off humidifier

disconnect to shut off primary power to the humidifier.

Remote Relay

Board (option)

Provides a terminal strip to dry contacts which open/close to indicate the

humidifier is on, humidifying, needs service, or is in a fault condition.

Scale Tank

Scale created inside the boiling tank (on the elements and the side walls)

breaks off and gravitates to the scale tank for easy disposal.

Scale Tank

Drain Spigot

Manually activated drain spigot used to empty the scale tank of water before

removing and emptying tank of collected scale.

Solid State

Relay (optional)

Solid State Relays offer shorter cycles when turning the resistive elements On

and Off. Recommended for humidification applications requiring high

accuracy.

Steam Outlet

Connect to steam line with steam hose.

User Interface

Controls all functions of the humidifier operation and provides user ability to

modify configuration of the humidifier.

Description of Components

Table 1: Humidifier Components

Introduction | 4

Page 8

NHRS Models

The NHRS is Nortec’s flagship resistive element electric humidifier. Since it can accept a variety

of supply water types (potable, Reverse Osmosis, De-Ionized), it is very robust and useful in a

wide set of applications. The NHRS is available in capacities ranging from 10 lb/hr (4.5 kg/hr)

to 180 lb/hr (81.6 kg/hr). NHRS humidifiers are packaged in two different cabinets, depending

on their capacity. Figure 3 shows the configuration and relative size of the different cabinets.

Table 3 on page 7 provides specifications for the NHRS product line.

Figure 3: NHRS Models

Double Unit (NHRS 135-180)

NHRS double units have two tanks to provide increased capacity. The construction and

installation of double units is identical to units with a single tank with the following exceptions:

In addition to having two tanks, double units also have two Driver Boards. One Driver

Board controls each tank.

Double units can operate both tanks in series or parallel from a single control signal

Parallel Operation – If configured for parallel operation, only one set of control wiring is

required. The tanks operate in parallel giving the advantage of even wear on both tanks.

Series Operation – One tank’s output range is 0-50% and the other tank’s output range

is 50-100%. An advantage is that a lower turndown ratio can be applied to one tank.

Hybrid Mode – One tank operates using Solid State Relay switching, the other tank

operates using contactor switching. See P/N 2530631.

Double units have one primary power connection, but have individual fill, drain, and

steam outlet connections for each tank.

5 | Introduction

Page 9

Component

Function of Component

Drain Water

Cooler, Low

Flow

Reduces drain rate from the humidifier by restricting the boiling tank drain

outlet diameter, as well as providing a lower-flow drain water cooling valve.

Dual Demand

Controller

Consists of a universal math module that compares two demand input signals

and outputs the lowest of the two to the humidifier. This option is useful

where a high limit modulating demand channel is desired (along with a

modulating demand channel humidistat), since the humidifier only allows one

modulating input. See P/N 2558776.

Keep Warm

(Outdoor

standard)

Maintains water temperature in boiling tank at 160ºF (70ºC) for quick

response of the unit to a call for humidity while minimizing health concerns

associated with standing water. See P/N 1504561.

Nortec

Online/LINKS2

Provides monitoring and control, allowing humidifier to communicate with a

Building Management System (BMS). Controller is factory installed and

located internally to the humidifier. At the time of ordering, customer must

specify the desired protocol: BACnet/IP, BACnet/MSTP, Johnson N2, or

LonWorks.

Nortec Online provides an internet-based monitoring and control system for

the humidifier.

Remote Relay

Board

Provides four built-in status relays for remote monitoring capabilities: steam

production, unit fault, maintenance/service, and unit power. Relays can

interface with a Building Management System (BMS). If one of the above

conditions is met, a relay will close which will complete a connection. A signal

will be provided to a wire terminal. See P/N 1508069.

Scale

Management

System

Provides a separate reservoir underneath boiling tank for scale collection.

Minerals removed from the boiling tank water during steam production will

collect in the scale reservoir rather than in the tank. When minor

maintenance is needed, the scale tank is easily removed and emptied.

Solid State

Relays

Allow for rapid response upon call for humidity, adapting instantly to humidity

demand, allowing for tight control of the in-space humidity.

Outdoor Model

The NHRS is available for outdoor use, providing a weatherproof enclosure that allows for

installation on rooftops in relatively extreme climates. Refer to the installation addendum that

is provided with the NHRS Outdoor model to ensure proper installation (P/N 2531550).

Options and Accessories

Nortec provides a complete line of options and accessories for every humidification application.

The following options and accessories are available and may have been delivered with your

NHRS humidifier. Refer to the installation instructions that came with the accessories for

proper installation and operation.

Table 2: Options and Accessories

Introduction | 6

Page 10

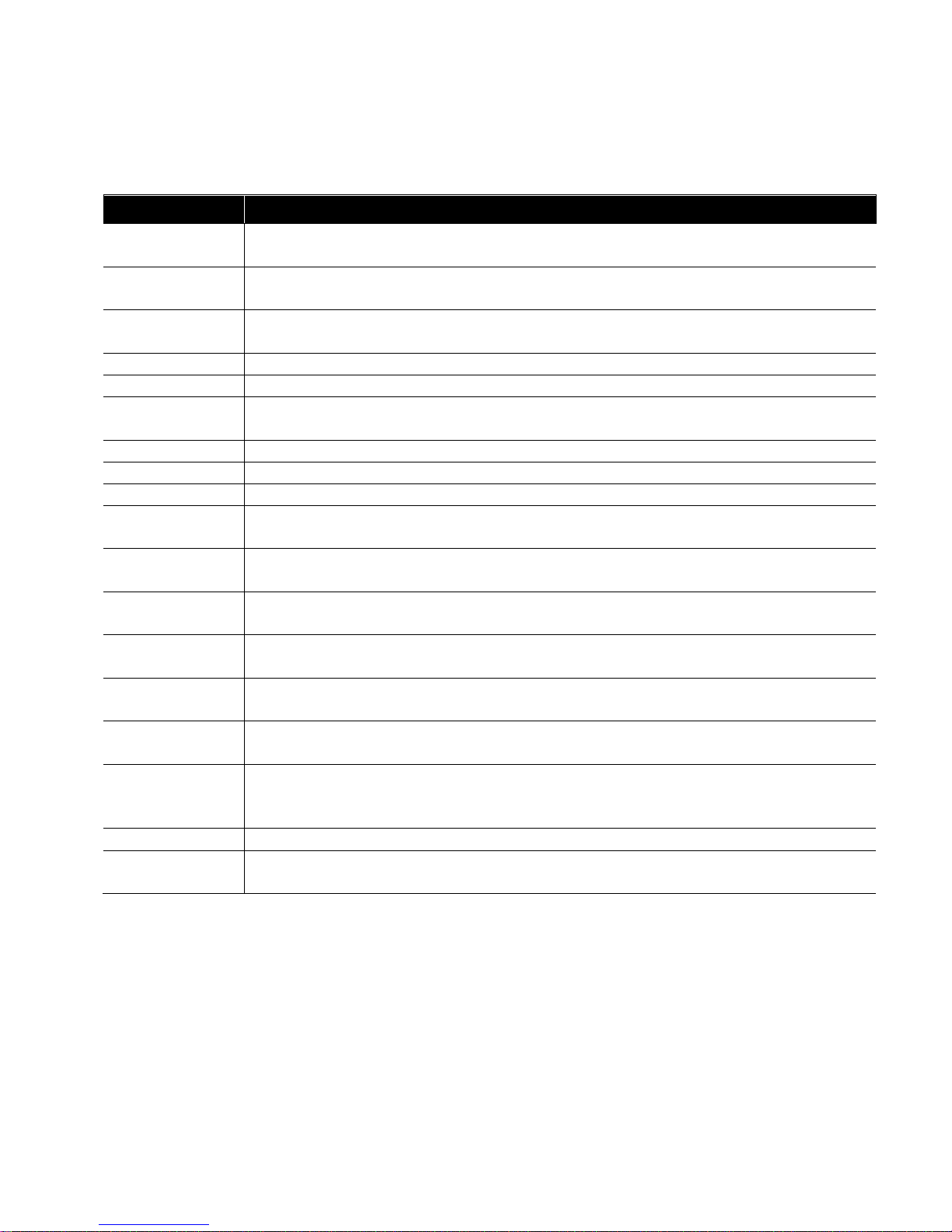

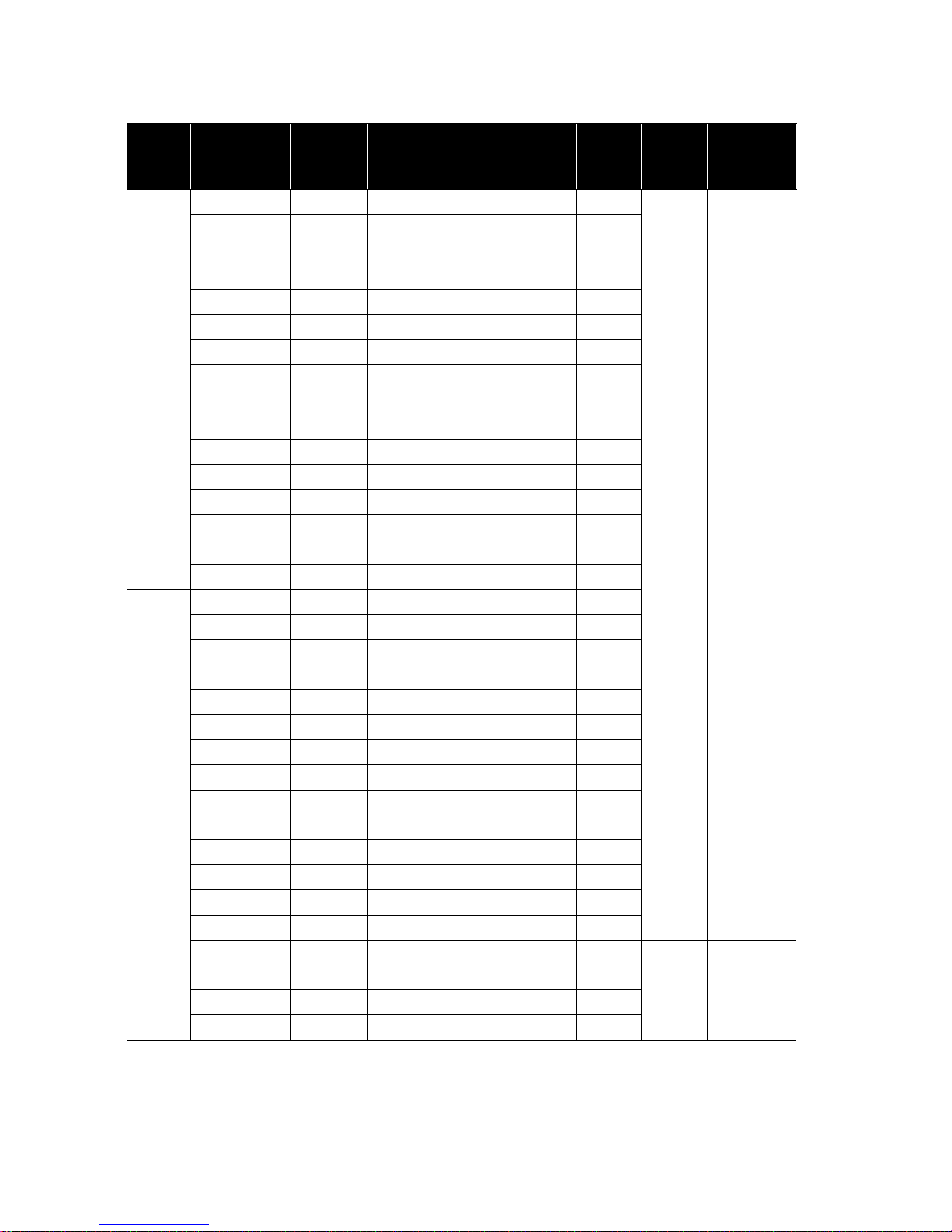

Phase

Capacity

lb/hr (kg/hr)

Volts

NHRS Part

No.

Amps

Max

Ext

Fuse

kW

Fill

gpm

(l/min)

Net/Full

Weight lb

(kg)

1

10 (4.5)

208

2530540

18.4

25

3.83

3.8

(14.4)

119/190

(54/86)

10 (4.5)

220-240

2530541

15.9

20

3.83

10 (4.5)

440-480

2530542

8.0

15

3.83

10 (4.5)

550-600

2530543

6.4

15

3.83

15 (6.8)

208

2530544

24.5

35

5.10

15 (6.8)

220-240

2530545

21.3

30

5.10

15 (6.8)

440-480

2530546

10.6

15

5.10

15 (6.8)

550-600

2530547

8.5

15

5.10

20 (9.0)

208

2530548

36.8

50

7.65

20 (9.0)

220-240

2530549

31.9

40

7.65

20 (9.0)

440-480

2530550

15.9

20

7.65

20 (9.0)

550-600

2530551

12.8

20

7.65

30 (13.6)

208

2530552

49.0

70

10.20

30 (13.6)

220-240

2530553

42.5

60

10.20

30 (13.6)

440-480

2530554

21.3

30

10.20

30 (13.6)

550-600

2530555

17.0

20

10.20

3

30 (13.6)

208

2530556

31.9

40

11.48

30 (13.6)

220-240

2530557

27.6

35

11.48

30 (13.6)

440-480

2530558

13.8

20

11.48

30 (13.6)

550-600

2530559

11.1

15

11.48

45 (20.4)

208

2530560

42.5

60

15.30

45 (20.4)

220-240

2530561

36.9

50

15.30

45 (20.4)

440-480

2530562

18.4

25

15.30

45 (20.4)

550-600

2530563

14.7

20

15.30

65 (29.4)

208

2530606

63.8

80

22.98

65 (29.4)

220-240

2530609

55.3

70

22.98

65 (29.4)

440-480

2530610

27.6

35

22.95

65 (29.4)

550-600

2530611

22.1

30

22.95

90 (40.8)

440-480

2530612

36.9

50

30.60

90 (40.8)

550-600

2530613

29.5

40

30.60

135 (61.2)

440-480

2530614

55.3

70

45.90

7.6

(28.8)

186/330

(85/150)

135 (61.2)

550-600

2530615

44.2

60

45.90

180 (81.6)

440-480

2530616

73.7

100

61.20

180 (81.6)

550-600

2530617

59.0

80

61.20

Table 3: NHRS Specifications

7 | Introduction

Page 11

Installation

9 Typical Humidifier

Installation

10 Location

11 Blower Pack Clearance

Requirements

12 Mounting with Keyholes

13 Plumbing

14 Steam Distributor

15 Steam Lines and

Condensate Return

21 Electrical

22 External Controls

29 Optional Outdoor

Temperature Setback

Sensor

30 Remote Fault Option

Wiring

31 Options and Accessories

32 Keep Warm (Outdoor Standard)

32 Nortec Online/LINKS2

32 Remote Relay Board

32 Scale Management System

32 Solid State Relays

22 Control Wiring

22 Duct Humidification

23 Space Humidification

24 On/Off Control Wiring

26 Modulating Control Wiring

28 Transducer Control Wiring

Installation | 8

Page 12

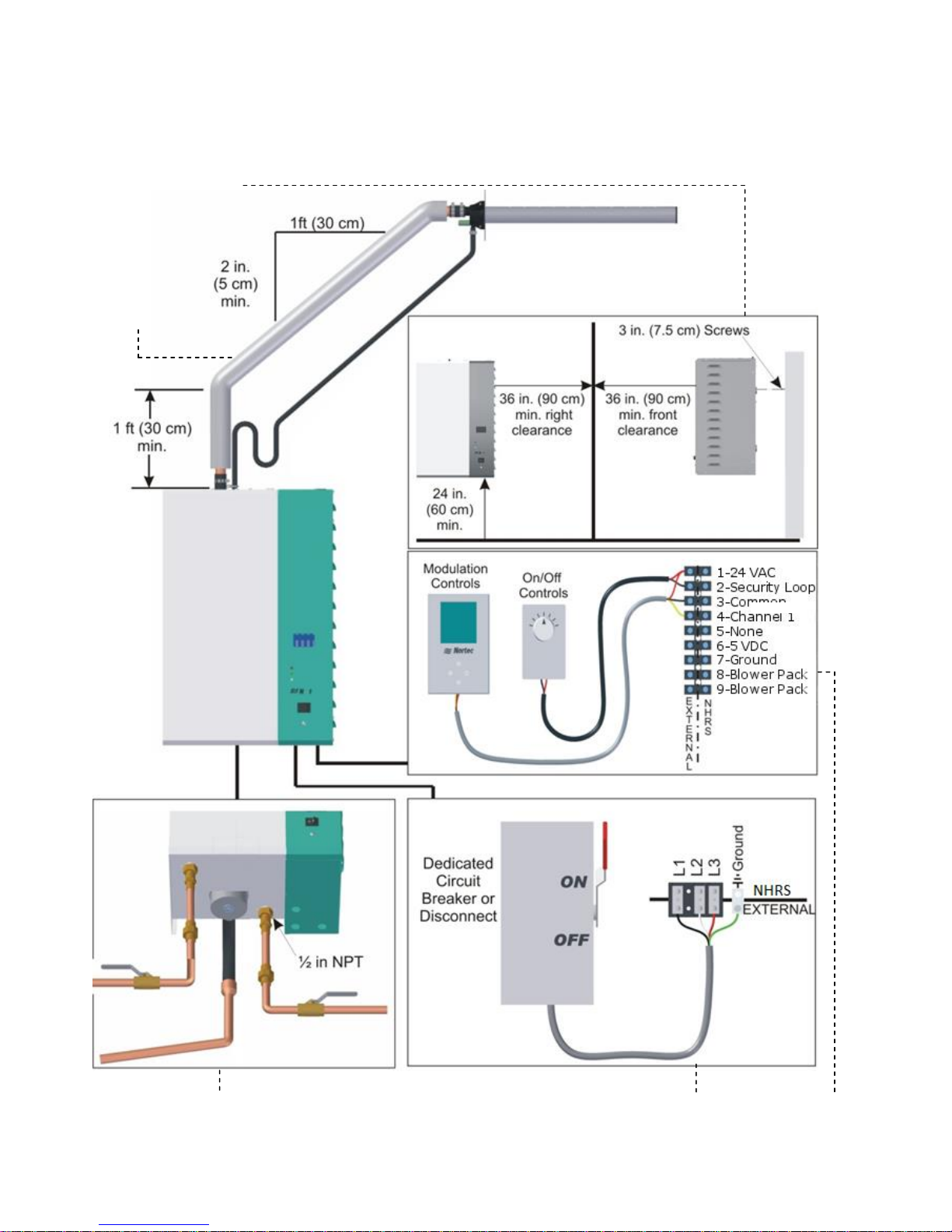

Mounting

Page 10

Steam

Distribution

Page 14

Controls

Page 21

Electrical

Page 20

Plumbing

Page 13

Typical Humidifier Installation

Figure 4: Typical Humidifier Installation

9 | Installation

Page 13

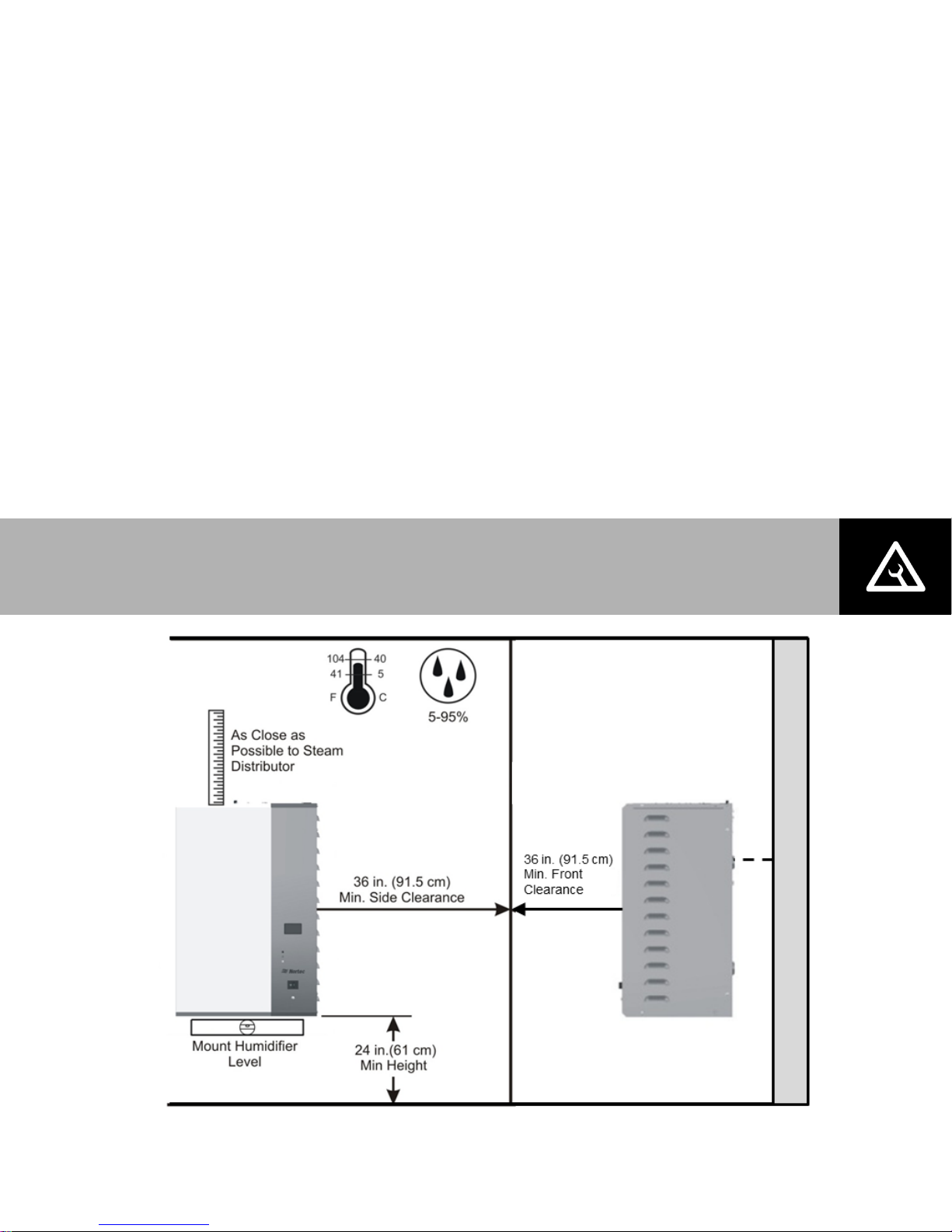

Figure 5: Mounting Location / Clearance

Note: Do not mount on hot surfaces, where freezing can occur, vibrating surfaces, or

floor.

Location

Mount on a suitable wall or vertical surface. Do not sit the unit on the floor to allow

clearances required for plumbing and electrical connections.

Clearance dimensions shown are for reference only and are the minimum required for

maintenance of the humidifier. Consult local and national codes before final location

and installation. Nortec does not accept responsibility for installation code violations.

Install only in areas with ambient temperatures between 41 and 104ºF (5 and 40ºC),

and relative humidity between 5 and 95% (non-condensing).

When possible, install the humidifier below the steam distributor. If mounted above the

steam distributor, take care to provide proper steam line routing and proper condensate

traps.

DO NOT locate the humidifier any further than absolutely necessary from the steam

distributor location as net output will be reduced as a result of heat loss through the

steam line.

When possible, mount the humidifier at a height convenient for servicing.

Installation | 10

Page 14

Humidifier

Capacity

lb/hr (kg/hr)

Min. Frontal

Clearance

Inches (cm)

Min. Overhead

Clearance

Inches (cm)

Min. Left Side

Clearance

Inches (cm)

Min. Right Side

Clearance

Inches (cm)

Up to 30 (13.6)

132 (336)

12 (31)

12 (31)

12 (31)

30-100

(13.6-45.4)

Not

recommended

Not

recommended

Not

recommended

Not

recommended

Humidifier

Capacity

lb/hr (kg/hr)

Min. Frontal

Clearance

Inches (cm)

Min. Overhead

Clearance

Inches (cm)

Min. Left Side

Clearance

Inches (cm)

Min. Right Side

Clearance

Inches (cm)

Up to 30 (13.6)

132 (336)

12 (31)

12 (31)

12 (31)

30-100

(13.6-45.4)

Not

recommended

Not

recommended

Not

recommended

Not

recommended

Blower Pack Clearance Requirements

For more information regarding the clearance requirements of the Remote Mounted Blower

Pack (P/N 2572615), refer to installation manual (document number 2572641).

Table 4: Clearances for Blower Packs on Low Speed*

Table 5: Clearances for Blower Packs on High Speed*

*NOTES:

Nominal Conditions: 72ºF (22.2ºC), 43% RH.

Low speed not recommended for 50-100 lb/hr humidifiers.

Blower Pack should not be installed near cold surfaces or where dew point may be reached.

Higher humidity or lower room temperature may result in longer absorption distances.

11 | Installation

Page 15

Note: Use screws longer than 3” (7.5 cm) if drywall or other spacer is present.

Mounting with Keyholes

1. The NHRS Series humidifier is wall mounted using keyholes located on the back of the

unit cabinetry.

2. Use #12 x 3” (7.5 cm) screws mounted into 2x4” studs or better. Two screws are

required for units with one tank (NHRS 10 to NHRS 90 lb/hr). Three screws are required

for units with two tanks (NHRS 135 and 180 lb/hr).

3. Keyholes are spaced 16” (40.6 cm) apart center to center as per UL certification

standard stud spacing dictates. Insert screws into the studs until there is ¼” (0.6 cm) of

screw exposed. Ensure the screws are level to each other.

4. Raise the unit and place the screws through the keyholes. Make sure the unit is level

before tightening the screws to secure the unit in place.

5. Place L-shaped brackets on top of the unit, ensuring the holes are in-line with the studs.

Using the appropriate sized wood screw, fasten the L-brackets to the studs, securing the

unit from any upwards motion. See Figure 6.

Figure 6: Mounting with Keyholes; A = B = 16” (40.6 cm)

Installation | 12

Page 16

Note: • Drain water is very hot, do not drain to public sink.

• Use material suitable for 212ºF (100ºC) for drain and condensate lines.

Figure 7: Water Supply and Drain Connection

Plumbing

All water supply and drain line connections should be installed in accordance with local

plumbing codes.

Supply water should have pressure between 30 and 80 psi

between 0 and 12 gr/gal. Various types of supply water may be used: soft water, deionized, reverse osmosis, or potable.

Install water shut-off valve and union before humidifier to facilitate servicing.

The drain line should not end in a sink used frequently by personnel, or where plumbing

codes prohibit. Route to a floor drain or equivalent for safety reasons.

Ensure drain line is adequately sized to provide free and easy draining. Ensure air gap is

installed as shown. A restricted drain can cause the boiling tank to become heavily

concentrated with minerals and may result in poor operation or water backing up at the

air gap.

and have a hardness

g

13 | Installation

Page 17

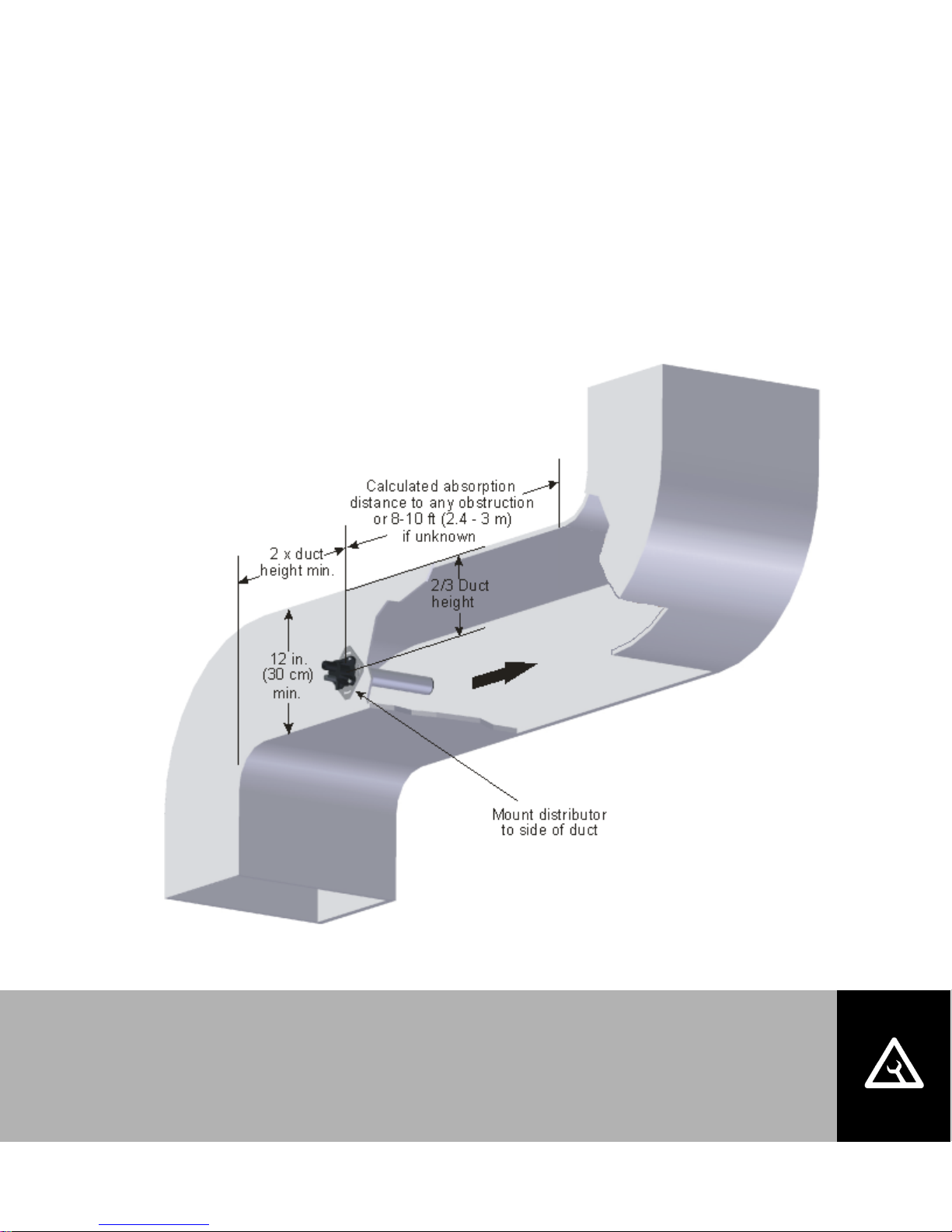

• Install the NHRS as close as possible to whatever steam distributor is used.

• Refer to distributor, SAM-e, or Remote Blower Pack installation manuals for detailed

installation instructions (2556592, 1507619, and 2572641, respectively)

Steam Distributor

Steam generated by the NHRS may be distributed directly into a conditioned

environment with a Remote Blower Pack (P/N 2572615), or into an air handling system

using either Nortec steam distributors or Nortec’s SAM-e steam distribution manifold.

The steam distributor should be installed as close as possible to the humidifier. Short

steam distribution lines minimize condensate losses and the possibility of generating

back pressure in the steam distribution line.

Figure 8 provides common guidelines for locating a steam distributor in a duct.

Figure 8: Distributor Location in Duct

Installation | 14

Page 18

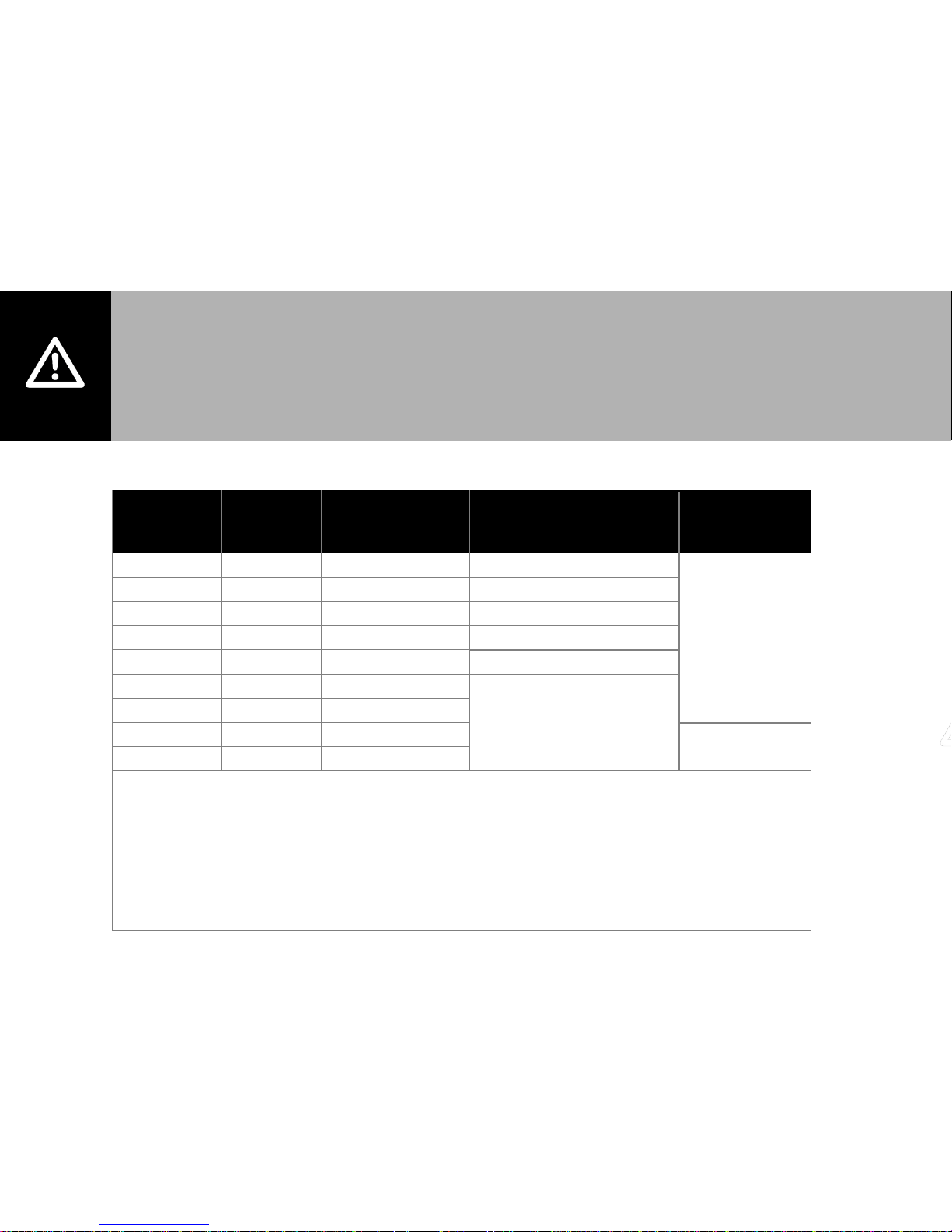

NHRS

Unit

Size

Steam

Output

(lbs/hr)

Distance

ft (m)

Possible

Loss

ft (m)

Steam

Line

Size

010

10

15 (4.5)

2 (0.6)

1.5”

015

15

17.5 (5)

2.25 (0.7)

020

20

20 (6)

2.5 (0.8)

030

30

25 (7.5)

3 (0.9)

045

45

35 (10.5)

4 to 5 (1.2 to 1.5)

065

65

45 (13.5)

5 to 10

(1.5 to 3.0)

090

90

50 (15)

135

135

50/tank (15)

2 x 1.5”

180

180

50/tank (15)

NOTES:

1) This chart gives the maximum length of recommended steam line by unit size.

2) The use of steam line other than copper, stainless steel, or Nortec steam hose will void the

warranty and may cause adverse effects regarding the operation of the humidifier.

3) Nortec steam line shall only be used for steam line runs of 10 ft (3m) or less.

4) Long steam runs affect accuracy of humidifier and its ability to quickly respond to changes in

demand. When tight control is required, ensure steam line run is as short as possible.

5) NHRS 135 and 180 have two tanks.

Danger:

The NHRS is an atmospheric humidifier that will only operate properly when its steam

distribution system is installed so that it provides no significant backpressure.

Installing the NHRS in such a way that backpressure can develop during operation

could result in serious injury or damage to property.

Steam Lines and Condensate Return

The following instructions must be followed for installation of steam lines for ASD, BSD, CSD,

SAM-e, and Remote Blower Packs. Failure to used material in Table 6 and Table 7 on page 16,

or failure to follow any other steam line installation instructions, will result in improper operation

and could void warranty.

Table 6: Recommended Maximum Length of Steam Line

15 | Installation

Page 19

Supply

Water

Type

Tank Size

(lbs/hr)

Steam Run

ft (m)

Steam Line

Material

Steam Line

Description

Potable

0-30

0-10 (0-3)

Copper Tube

1.5” MED-L Tubing

(1.625” OD)

0-30

10-30 (3+)

Copper Tube

2.0” MED-L Tubing

(2.125” OD)

RO or

DI

0-30

0-10 (0-3)

Stainless Steel Tube

1.75” Tube x

0.065” thick

0-30

10-30 (3+)

Stainless Steel Tube

2.0” Tube x

0.065” thick

Potable

45-90

0-20 (0-6)

Copper Tube

1.5” MED-L Tubing

(1.625” OD)

45-90

20+ (6+)

Copper Tube

2.0” MED-L Tubing

(2.125” OD)

RO or

DI

45-90

0-20 (0-6)

Stainless Steel Tube

1.75” Tube x

0.065” thick

45-90

20+ (6+)

Stainless Steel Tube

2.0” Tube x

0.065” thick

Table 7: Recommended Materials and Sizes for Steam Runs.

Installation | 16

Page 20

Ste

am

D

irectio

n

Ste

a

m Dir

ectio

n

S

t

e

a

m

D

i

r

e

c

t

i

o

n

2 in.

(5 cm)

1 ft (30 cm)

1ft (30 cm)

0.5 in.

(12 mm)

10 Degrees

2 Degrees

Use Appropriate Slope Insulate Pipe

1 in. (2.5 cm) pipe

insulation

Minimal Slope (up)

Minimal Slope (down)

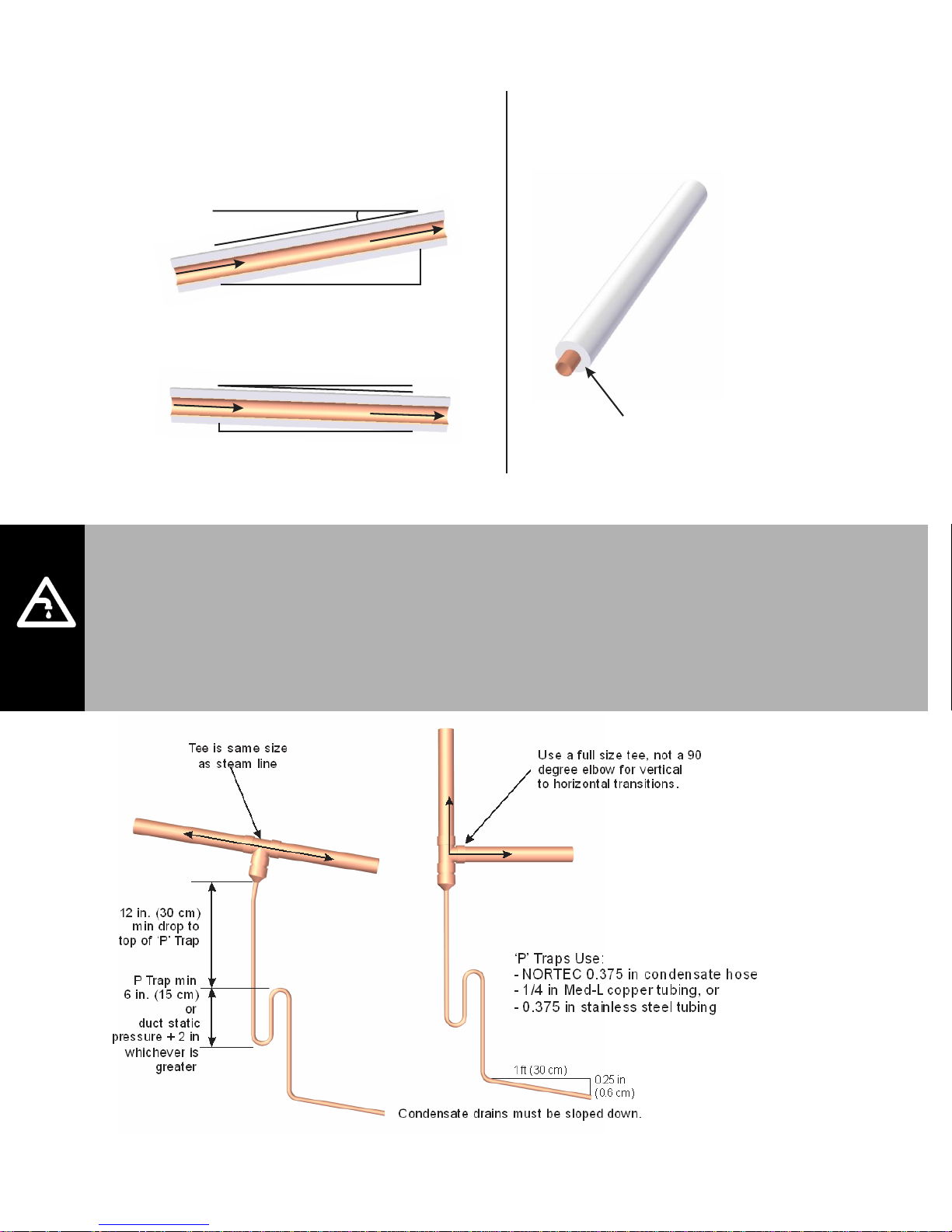

Figure 9: Steam Line Slope and Installation

• Trap at all low points and recommended intervals using full size ‘T’ for traps.

• Condensate should not be routed to a sink used frequently by personnel. Route to a floor

drain or equivalent. Condensate normally cools in traps but is still hot. A SAM-e or larger

steam line generates more condensate and water may not cool in the trap. A drain water

cooler option may be installed if required by code.

• Route condensate to floor drain or equivalent in multi-unit to single SAM-e installation.

Figure 10: Condensate Traps

17 | Installation

Page 21

Steam Line Rules

The following 10 points provide rules for installing steam lines connecting the NH

humidifier to ASD, BSD, CSD, SAMe and remote blower packs. In addition to these rules

never use unapproved material for steam lines.

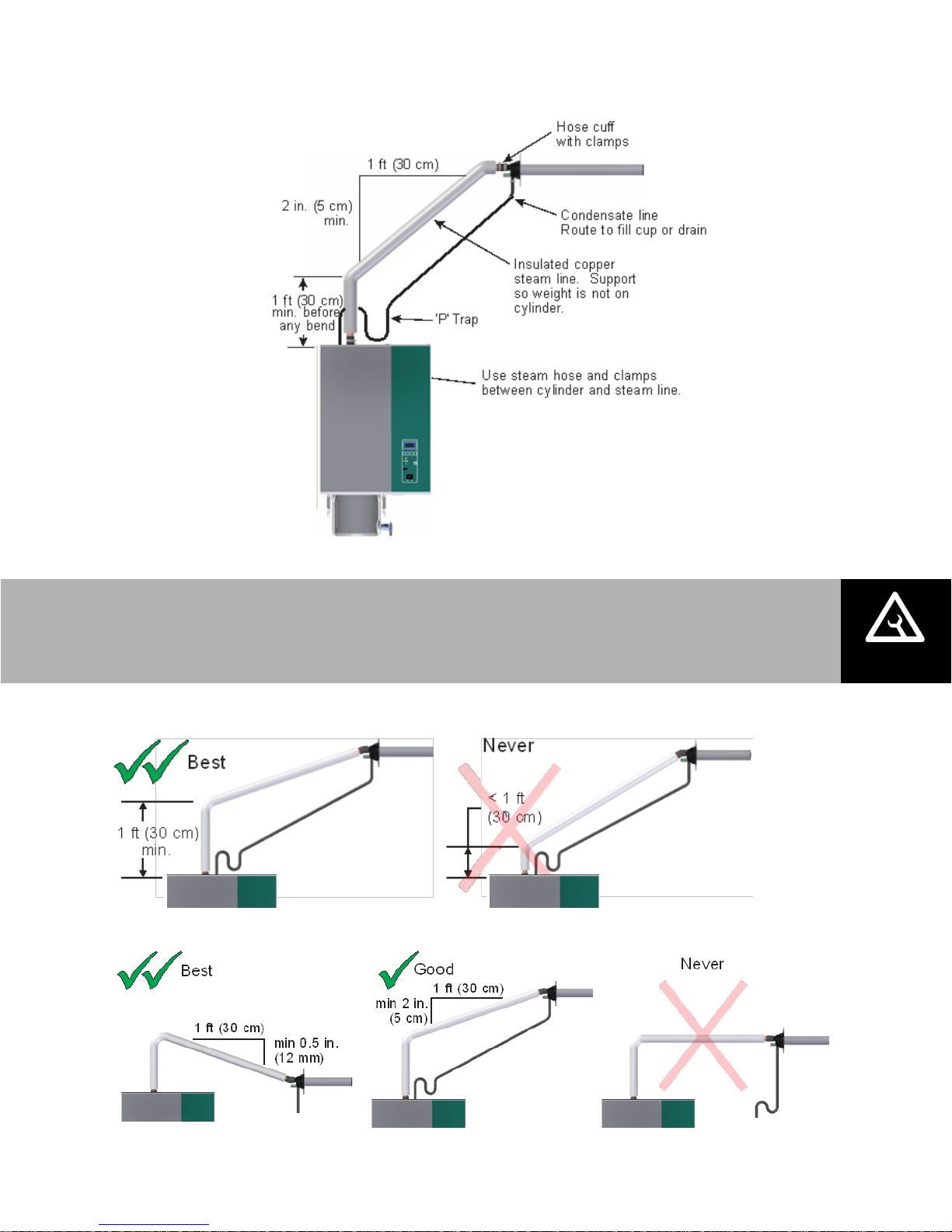

Figure 11: Typical Steam Line Installation

1. Allow a minimum of 12” (30 cm) before first bend in steam line.

2. Slope the steam lines.

Installation | 18

Page 22

3. Use steam hose only for short distances.

4. For steam hose, maintain minimum 12” (30 cm) bend radius.

5. Install traps on condensate lines at least 12” (30 cm) below connection.

6. Only combine steam lines at steam distributor with Nortec adapter.

7. Install condensate traps at low points and horizontal to vertical transitions.

19 | Installation

Page 23

After installation, always

Purge steam lines to remove any contaminants and installation materials.

Ensure all condensate lines/traps flow freely.

8. Increase diameter either on down slope or install condensate trap.

9. Install condensate traps if steam line > 15 feet (4.5 m).

10. In addition, never:

Installation | 20

Page 24

Caution: Wiring to be performed by a licensed Electrician.

To humidifier high

voltage terminal strip

Electrical

Figure 12: Primary Power Connection

21 | Installation

Page 25

Caution: Failure to wire the humidifier in accordance with the wiring instructions

could cause permanent damage. Such errors will void the warranty.

External Controls

Control Wiring

The following information is relevant to all controls, factory supplied or otherwise. For wiring use

a minimum of 18 AWG and keep as short as possible. The NHRS humidifier can be operated

with a modulating input or as On/Off.

Control Location

Duct Humidification

1 Air Proving Switch

Locate so that it can sense air flow, or lack thereof.

2 Duct High Limit

NHRS operates with On/Off control.

Locate at least 10 feet (3.0 m) from steam distributor, or far enough that steam is

fully absorbed under normal conditions.

3 Humidity Control

NHRS can be modulating, On/Off, or a humidity sensor.

Can be located either in return air duct (preferred) or in room being humidified.

Mount in area representative of room humidity (draft, doorways, sunlight, or

overhang such as shelf can affect reading). Avoid placing near discharge diffuser of

humidified air.

4 Outdoor Temperature Sensor

Mount in area representing outdoor air temperature (makeup air duct, outside).

Figure 13: Control Location (Duct Humidification)

Installation | 22

Page 26

1

Humidity

Control

(in location

representative

of the space)

1

Humidity

Control

(in location

representative

of the space)

1

Humidity

Control

(in location

representative

of the space)

Note: Regardless of selecting on/off or modulating control method, Nortec humidifiers must have a

closed circuit across its security loop control terminal to operate. Nortec highly recommends the use

of a high limit humidistat and an air proving switch in series for this function.

Space Humidification

Figure 14: Control Location (Space Humidification)

1 Humidity Control

NHRS can be modulating, On/Off, or a humidity transducer.

Locate in room being humidified but not in discharge zone of blower pack(s).

Mount on indoor wall in area representative of room humidity (draft, doorways,

sunlight, or overhang such as shelf can affect reading).

2 High Limit Humidistat (not shown)

Install a high limit On/Off humidistat in area representative of room humidity.

3 Outdoor Temperature Sensor (not shown)

Mount outside in area representing outdoor air temperature.

23 | Installation

Page 27

On/Off Control Wiring

Figure 15: On/Off Controls

Figure 16: Digital On/Off Humidistat

Installation | 24

Page 28

Figure 17: Duct Sensor Wiring

25 | Installation

Page 29

Modulating Control Wiring

Figure 18: Modulating Controls

Figure 19: Digital Modulating Humidistats

Installation | 26

Page 30

Figure 20: Digital Wall Humidistat - Remote Wall Sensor

27 | Installation

Page 31

Transducer Control Wiring

Figure 21: Transducers

Figure 22: Digital Transducers

Installation | 28

Page 32

Optional Outdoor Temperature Setback Sensor

Figure 23: Outdoor Temperature Setback

Each digital controller is equipped with an integrated reset function that can reduce the

setpoint during cold weather operation. This will prevent condensation on windows and

building structures. The above graph illustrates how the setpoint reset feature operates.

This feature is enabled by removing the jumper from terminals 8 and 1 on the humidistat

and wiring the outdoor temperature sensor to these terminals.

When the outdoor temperature setback feature is in effect, the humidistat will normally

display the calculated setpoint limit based on the outdoor air temperature. A snowflake will

also be displayed to indicate cold weather operation. When any key on the controller is

pressed, the LCD screen will display the customer specified setpoint for a short duration.

Figure 24: Outdoor Temperature Setback wiring

29 | Installation

Page 33

Remote Fault Option Wiring

The NHRS remote fault option (P/N 1508069) includes four relays that can provide remote

status indication. The relays are mounted to a remote fault board which is located as shown in

Figure 26. The PCB with the relays includes markings which indicate the function of each

terminal on the board. The relays indicate the following status:

1 Unit On – The normally open relay is closed when the humidifier has power and the On/Off

switch is set to on.

2 Steam – The normally open relay is closed when the control board detects that the cylinder

is drawing current and steam is being produced.

3 Service – The relay can be wired to open (NC) or close (NO) when a warning is displayed on

the humidifier display and the yellow service LED is illuminated.

4 Error – The relay can be wired to open (NC) or close (NO) when a fault is detected by the

humidifier controls.

Figure 25: Location of Remote Fault board

Installation | 30

Page 34

Note:

For installation of options and accessories follow the instructions that are provided with them.

Figure 26: Remote Mounted Blower Pack.

Options and Accessories

Blower Pack

Optional blower pack (part number 2572615) can be used to distribute steam to localized

areas, or in areas that do not have built-in air distribution systems. Blower packs are available

in remote configuration, are piped in the field, and are wired to the humidifier RMBP power

source (or a separate power source if the installation requires).

For detailed installation information, refer to the Blower Pack installation and operation manual

(document 2572641). Refer to Table 4 and Table 5 on Page 11 for clearance information.

31 | Installation

Page 35

Keep Warm (Outdoor Standard)

Menu configuration setup can be done at factory, which allows the water temperature in the

tank to be maintained at 160ºF (70ºC) for quick response of the unit to a call for humidity. This

aids in minimizing health concerns associated with standing water.

Part number 1504561.

Nortec Online/LINKS2

Nortec OnLine enables a humidifier to communicate and be monitored through the Internet.

Several configurations are available: Dynamic Host Configuration Protocol (DHCP), Dial-up,

General Packet Radio Service (GPRS), Slave, and Static IP. Consult factory for details.

Nortec LINKS provides monitoring and control allowing humidifier(s) to communicate to a

Building Management System (BMS). The controller is factory installed and is located internally

to the humidifier. Several communication protocols are available: BACnet MSTP, BACnet IP,

Johnson N2, and LonWorks. Consult factory for details.

Nortec LINKS2 is a package that includes both items above: a particular communication

protocol as well as Nortec OnLine.

Remote Relay Board

An optional remote fault kit is available that can provide remote indication of humidifier status.

The relays will activate upon the following humidifier conditions: steam production, unit fault,

maintenance/service, and unit power. The kit can be factory or field installed and can interface

with a BMS. See Page 30 for wiring and installation.

Part number 1508069.

Scale Management System

The Scale Management System provides a separate reservoir underneath the steam tank for

scale collection. The addition of this option reduces maintenance time significantly. Minerals

removed from the water during steam production will collect in the scale reservoir rather than in

the tank. When minor maintenance is needed, the scale reservoir is easily removed and

emptied. Without this option, the NHRS requires more effort during minor maintenance:

cleaning of the steam tank and heating elements. More humidifier downtime is required for this

maintenance. With the Scale Management System, minor maintenance simply requires the

scale reservoir to be emptied, which can be done in a matter of minutes.

Part number 2533179 (two must be ordered for units with two tanks, NHRS 135 & NHRS 180).

Solid State Relays

Solid State Relay Control (SSR Control) allow for rapid response upon a call for humidity by

replacing the standard contactors with a higher-performing component. The operating window

for the standard contactor is 2 minutes, but the SSRs will cycles in approximately 2 seconds.

This allow for quick response and tight control of the humidity. This option is essential where a

tight humidity tolerance is required.

Part number will vary according to the capacity and voltage of the unit.

Installation | 32

Page 36

Start Up

34 Installation Check

35 NHRS User Interface

35 Auxiliary Drain Switch

35 Door Interlock Switch

36 Start Up Procedure

36 Initial Start-Up Procedure

38 Information Screens

45 How the Humidifier Works

45 Start Up

45 Automated Operation

46 System Drains

47 Selecting an RH Setpoint

33 | Start Up

Page 37

Installation Check

Before turning on power to the NHRS, inspect the installation to ensure that it was carried out

correctly. Refer to figure below, the NHRS Pre-Start Up Checklist, and the preceding chapter on

installation.

Figure 27: Installation Check

Start Up | 34

Page 38

Door Interlock Switch

and

Auxiliary Drain Switch

NHRS User Interface

Figure 28: NHRS User Interface

Auxiliary Drain Switch

In addition to software controlled draining of the tank , the NHRS has a manual drain switch

which can be used to drain the tank even if software is not functioning. To drain the tank,

put the switch into the drain position. For normal operation the switch should be in the off

position. If the unit has multiple tanks, the switch will have both “Tank A” and “Tank B” settings.

This allows single-tank draining.

Door Interlock Switch

The door interlock switch cuts power to the contactor when the door is removed. It is an

additional safety device intended to prevent the possibility of service technicians coming into

contact with live electrical wiring while working on the humidifier. Pull the switch out with door

off to override.

Figure 29: Door Interlock Switch and Auxiliary Drain Switch

35 | Start Up

Page 39

Warning: Damaged units or improperly installed units must not be operated.

Damaged or improperly installed units may present a danger to persons and property.

Start Up Procedure

1. Examine the humidifier and installation for damage and/or improper installation.

2. Ensure that the doors are in place and secured with retaining screws.

NOTE: if the optional Scale Management System is installed, make sure the valve on the

scale reservoir is closed.

3. Open the supply water shut off valve.

4. Turn on the mains power using the installed disconnect.

5. Press the On/Off switch on the front of the humidifier to turn the humidifier on.

The NHRS humidifier will now carry out a system test. The display below appears and the three

LEDs light for approximately three seconds.

If a fault is detected during the system test, a corresponding fault message is triggered.

If the system test is successful, the steam tank fills up and a float test is carried out

(function check on the level unit). The display below appears.

If a fault is detected during the float test, a corresponding fault message is triggered.

When both tests are successful, the NHRS will enter normal operating mode. The display

below appears and the green LED lights.

Initial Start-Up Procedure

The following procedure should be carried out only on the first occasion that the unit is

operated:

1. Check the function of the humidifier:

a. Switch on the humidification by raising the set humidity value on the humidity

controller / humidistat / NHRS Display.

b. Switch off the humidification by lowering the set humidity value on the humidity

controller / humidistat / NHRS Display.

Start Up | 36

Page 40

LED

Action

Meaning

Green

Constant

Unit Producing Steam

Yellow

Flashing

Major or Minor Service Due.

Red

Flashing

The Unit is trying to self-correct a problem.

Red

Constant

Insoluble Problem

NOTE: Relevant data will be displayed on the NHRS LCD display during normal operation and

when in fault

Relay

Description

Notes

K1

Steam

(N/O) Normally open

K2

Error

(N/O) Normally open Or (N/C) Normally closed

K3

Service

(N/O) Normally open Or (N/C) Normally closed

K4

Unit On

(N/O) Normally open

c. Check for correct functioning of the monitoring equipment (external safety

network).

d. Set the desired humidity value on the humidity controller / humidistat.

e. Make sure no leaks are present.

The heating current switches on as soon as the humidity controller / humidistat

demands humidity. The yellow LED lights and steam is produced after a short delay

(approximately 5 minutes).

2. The operating status is displayed in the LED on the unit as follows:

Table 8: NHRS Operational Status LEDs

3. If the humidifier is equipped with the optional Remote Fault Indication, the operating

status will be shown as follows:

Table 9: Remote Fault Indication

37 | Start Up

Page 41

Information Screens

The NHRS has a “display menu” from which various operating parameters can be viewed. It is

not possible to change the values on the display level.

1. Display level operation

a. Call up the display level with <↑> or <↓>.

b. <↓> next operating parameter.

c. <↑> previous operating parameter.

d. Exit the display level with <Menu>.

2. Description of the operating parameters on the display level.

NOTE: The following describes the individual operating parameters that can be selected

using the keys <↑> and <↓>, after the display level has been called up.

a. Steam Production

1. Current, actual, and nominal value of steam production are displayed in

percentage of total output.

2. Nominal value: unit capacity x input signal value.

3. Actual value: max unit capacity x input signal value x capacity limitation

If the internal controller is activated, only the actual value is shown. Under the following

conditions the actual value may differ from the nominal value: upon activation of the

heating power, if capacity limitation is active during the filling cycle of the steam cylinder.

b. Analog Input

1. Current value of the signal applied to the analog input in [%] of its max value.

If the internal controller is active, the displayed value corresponds to the current air

humidity (% RH).

c. Internal Controller

1. Internal controller activated (“on”)/deactivated (“off”).

2. Activated with transducer signal.

3. De-activated with demand signal.

Start Up | 38

Page 42

S2 Position

Interval Minor

Maintenance

Interval Major

Maintenance

0

200 hours

600 hours

1

300

600

2

300

900

3

450

900

4

400

1200

5

600

1200

6

500

1500

7

750

1500

8

3000

3000

9

6000

6000

0 200 hours 600 hours

1 300 hours 600 hours

2 300 hours 900 hours

3 450 hours 900 hours

4 400 hours 1200 hours

5 600 hours 1200 hours

6 500 hours 1500 hours

7 750 hours 1500 hours

8 3000 hours 3000 hours

9 6000 hours 6000 hours

PositionS2Interval Minor

Maintenance

Interval Major

Maintenance

10 0

15 0

20 0

30 0

45 0

6 0

90 0

135 0

180 0

S2 Setting

NHRS

Model

Value Setting

Factory Setting

NHRS Main PCB

Maintenance Interval

Adjustment [S2]

d. Working Hours

1. Total of working hours elapsed since initial commissioning of the humidifier.

e. Time Remaining to minor/major service

1. Time remaining (in hours) before the next minor/major service.

Time to maintenance can be adjusted to suit water conditions.

The stated times are based on 100% steam capacity. If the operation is at a lower

capacity, the time should be extended accordingly. For example, average capacity of

50% would double the time to maintenance. Average capacity of 33% would triple the

time to maintenance. The servicing intervals are set up using the rotary switch “S2” on

the control board.

NOTE: S2 rotary switch is set at factory to “0”.

Table 10: Maintenance intervals with rotary switch S2

39 | Start Up

Figure 30: Maintenance interval adjustment S2

Page 43

S1 Position

Drain Intervals at

100% Steam Capacity

0

0 min

1

720

2

360

3

180

4

120 5 60

6

30 7 20

8

10 9 5

f. Drain Cycle

1. The following indications are provided for the set-flushing interval

Left: Switch setting on rotary switch “S1” (4 in example)

Right: Set flushing interval (120 in example)

The flushing interval is set on switch “S1” on the control board.

Table 11: Drain Cycle intervals with rotary switch "S1"

NOTE: S1 rotary switch is set at factory to “9”.

NOTE: Water quality conditions resulting in component failures are not covered

under Nortec’s standard warranty. The factory settings are based on the

following water conditions when the unit leaves the factory.

Should you have water conditions more aggressive that the stated parameters,

consult the factory for a new drain cycle setting to help improve your scale

management.

Figure 31: Drain Cycle adjustment S1

Start Up | 40

Page 44

Water

Parameters

Potable Water

Treated Water

Conductivity

0-1500 Siemens

0-50 Siemens

Hardness

12 grains per gallon

0 grains per gallon

Silica

12 ppm

0 ppm

pH

6.5-7.5

7

Chlorides

> 50 ppm

> 25 ppm

Table 12: Water quality

Nortec recommend performing a semi-annual water analysis to ensure optimal

performance.

g. Stand-by Heating (also known as “Keep Warm”)

1. Stand-by Heating activated (“on”) or deactivated (“off”).

NOTE: If stand-by heating is active, the water temperature in the steam tank is

constantly kept at approximately 158ºF (70ºC) by the control board.

h. Capacity Limitation

1. To change the Power Limit (Maximum Capacity), complete the following:

• Press both arrow keys simultaneously,

• Enter code “8808”,

• Change to desired value, and

• Press both arrow keys simultaneously.

i. Inlet Valve Correction

1. Set inlet valve correction (cycle ratio) in % of standard setting value to balance

out water pressure variations. Contact factory for more details.

j. Soft Start

1. Soft Start activated (“on”), consult factory. Deactivated (“off”), factory default.

41 | Start Up

Page 45

k. De-mineral Mode

1. De-mineral Mode activated (“on”), consult factory. Deactivated (“off”), factory

default.

l. Serial Interface

1. Serial Interface activated (“on”), consult factory. Deactivated (“off”), factory

default.

m. Full Drain Cycle

1. Full Drain Cycle activated (“on”), consult factory. Deactivated (“off”), factory

default.

n. Flush Cycle

1. Flush Cycle activated (“on”), consult factory. Deactivated (“off”), factory

default.

Start Up | 42

Page 46

S3 Position

Signal

0

No signal selected

1

Spare

2

0-5 VDC

3

0-10 VDC

4

Other

5

1-5 VDC

6

2-10 VDC

7

Other

8

4-20 mA

9

0-20 A

o. Control Signal

1. Range of the active analog signal in Volts or milliamps.

NOTE: The range of the analog signal may be adjusted using the rotary switch

“S3” on the control board.

Table 13: Control signal settings with rotary switch "S3"

Figure 32: Control signal setting S3

43 | Start Up

Page 47

p. Software Version

1. Displays software version for the steam humidifier.

q. Unit Type

Start Up | 44

Page 48

How the Humidifier Works

The NHRS is an isothermal humidifier that produces atmospheric steam at operational

pressures of -3 to +6 in. W.C. System operation is based upon regulating the operation of

Incoloy immersion resistive heating elements with pulse width modulation via contactor(s) or

optional solid state relay(s).

Start Up

1. Upon powering up the NHRS, a brief diagnostic process will be initiated, once this is

completed the humidifier will initiate a level sensing test. To initiate this test, it is

required that the operational water level be at level 1 or less. If the reservoir is above

this level the system will initiate a drain. If the water level is less than level 1, both

1.2 litre per min fill solenoids will be activated in order to recover water level quickly.

Once level 1 water level or greater is achieved, the system will fill with only a single

solenoid in order to increase the accuracy of the level sensing.

2. The level sensing test will perform a timed fill to water level 4 and initiate a drain

process to level 3. If both the fill and drain system successfully operate within the

allotted time requirements, the humidifier will assume automated operation.

Otherwise the system will generate a fault condition and display diagnostic

information.

Automated Operation

1. System operation is initiated by satisfying various control inputs that are specific to

the system configurations. Once the configured control inputs are satisfied, and

water levels are within operational requirements (level 1-4), steam production can

commence.

2. Steam production sequence will vary depending upon hardware configuration. Units

with the optional SSR relay kit should progress to step 2.2. Units with standard

contactors progress to step 2.1.

2.1. CONTACTORS: Once system demand exceeds 10% the contactors will close. The

contactor will pulse width modulate over 120 second cycles. At 11% demand the

contactor will be closed for 10 seconds and will increase the length of operation,

in relation to an increase in system demand in a linear fashion up to 98%

demand. At 98% demand and above the contactor will remain closed for the

maximum 120 seconds. Cylinders with multiple contactors will increment

operating time sequentially amongst all contactors in order to scale output to

demand.

2.2. SSR & CONTACTORS: Once system demand exceeds 4%, the contactors will

activate and pulse the SSR to modulate heat production up to 98% demand. At

98% demand and above the SSRs will remain constantly closed. For cylinders

with multiple solid state relays the system will increment operating time amongst

all SSRs sequentially in order to scale output to demand.

3. Once the contactors close, the fill system initiates pulse fill in order to anticipate

evaporation and maintain the operating water level. Operating pulses will increase as

the water level decreases, and conversely decrease the filling pulses as water level

45 | Start Up

Page 49

increases. This allows the humidifier to continuously evaporate without interruption

and prevents larger influxes of cold water that may otherwise interrupt system

operation by cooling the boiling chamber.

System Drains

1. System operation will continue in this state until the timer controlled flushing

(determined by the S1 dial selector switch on the processor board) is achieved. When

triggered, steam production will continue without interruption and the system will initiate

a drain of one water level.

2. The timer controlled flushing is based upon system operating at 100% capacity.

Operating at a lower system capacity will extend the drain interval by the factor of the

reciprocal of system demand (averaged for the length of the flush timer) to the flush

timer.

3. With very low demand this method can lead to exceedingly long intervals between

system flushes. In order to prevent the drain interval from becoming excessively long, a

function is used to limit maximum wait time before initiating the drain procedure. This

roughly equates to preventing the drain interval from exceeding 10 x the Flush Timer

setting.

4. Once triggered, the system will wait for a minimum water level of three, so as to not

interrupt steam production. If the system drain is triggered by the maximum wait time

the system will fill to level four and then evaporate to level three prior to draining. If the

level requirement is not achieved the filling pulses of the fill valve will be extended in

order to increase the water to levels permissible of initiating the system drain. Once

complete the fill valve operation will resume normal pulse control.

Start Up | 46

Page 50

Note: The job site design may have specified a setpoint chosen specifically for the site.

Refer to site documentation and where possible use setpoints specifically determined

for the site.

Selecting an RH Setpoint

The optimum humidity setpoint depends on the reasons that a conditioned environment is

being humidified. The “ASHRAE Handbook – HVAC Applications” recommends specific design

relative humidities for specific applications. Also see NORTEC publication “When You Need

Humidity” (Form 124A) for more information on humidity settings.

Health and Comfort - The benefit of humidity is most pronounced for health and comfort in the

40-60% range. A humidity setting of 40-50 % is recommended for this purpose to prevent over

humidifying.

Temperature Setback - In cold climates it is often necessary to reduce the humidity level in a

conditioned environment to prevent build-up of condensation on the inside of exterior walls,

windows, and trim. It is highly recommended that the temperature setback function of the

NORTEC digital controls be used under these conditions to prevent damage from condensation.

The digital control with an outdoor temperature sensor installed will automatically setback the

humidity setpoint to correspond with outdoor temperature.

Duct High Limit – The duct high limit is intended to prevent saturation and wetting in duct work

at high load conditions. NORTEC recommends a setting of 85% for the duct high limit. It may

be necessary to reduce this setting if the duct work is very cold or in contact with exterior cold

surfaces.

47 | Start Up

Page 51

Maintenance and Servicing

49 Minor Maintenance

51 Major Maintenance

Maintenance and Servicing | 48

Page 52

WARNING: A qualified service person should perform all maintenance on the

humidifier and any other equipment provided by Nortec that requires maintenance.

NOTE: Instruction and details concerning the maintenance of the Nortec equipment

must be observed and adhered to without fail. Only the maintenance documented

in this manual must be carried out.

WARNING: The NHRS brings water up to boiling temperatures. The steam tank and

plumbing components may be hot. Allow the unit an appropriate amount of time to

cool before performing service.

WARNING: High voltage! Disconnect main power before servicing the unit

Minor Maintenance

The NHRS will indicate “minor maintenance due” with a yellow flashing LED and a

message on the LCD.

1. Visual inspection must be performed before minor and major maintenance.

a. Inspect all water and steam installations for possible leakage or damage.

b. Inspect electrical installation for lose or frayed cables, as well as damaged

components.

c. Inspect the condition of the unit cabinetry for damage.

d. Survey the area surrounding the humidifier – make sure all clearances are met.

2. Maintenance

a. Manually drain the NHRS by pressing the drain button on the display.

b. Turn the unit power to the “off” position.

c. Switch the external electrical disconnect to the “off” position (open).

d. Remove the screw that holds the front door on the cabinetry in place.

e. Remove the Font Panel by sliding the panel upward and away from the unit.

f. Confirm that the high voltage feed to the unit is off, then remove the high voltage

wires that connect to the top of the steam tank.

The heating elements will not be affected if they are connected to different power lines

when re-installed. When re-connecting heating elements, ensure a tight engagement

with a “click” of the connectors.

g. Using a slotted screwdriver, loosen the gear clamps that hold the steam line in

place.

h. Remove the steam line.

49 | Maintenance and Servicing

i. Remove the zip-tie cylinder restraint.

j. Lift the cylinder upward, then out of the front of the unit.

Page 53

CAUTION: Be extremely careful when handling the steam cylinder. If it is

dropped and damaged, it will likely not seal properly and the entire cylinder

will need to be replaced.

Figure 33: Minor maintenance with optional Scale Management System

k. Remove the clamp at the top of the cylinder.

l. Remove the tank lid with the elements attached.

m. Remove all scale from the tank.

n. Inspect the heating elements for damage.

o. Re-install the equipment in reverse order.

p. Turn power and water supplied back on to the unit.

q. Turn on the unit and carry out the steps of the visual inspection once more.

No maintenance re-set is required for Minor Maintenance Interval.

Maintenance and Servicing | 50

Page 54

Maintenance Item

Unit has Scale

Management

System?

Minor

Maintenance

Interval

Major

Maintenance

Interval

Remove scale tank and empty

Yes

Required

Required

No

N/A

N/A

Remove steam tank - clean inside,

as well as heating elements

Yes

Optional

Required

No

Required

Required

WARNING: A qualified service person should perform all maintenance on

the humidifier and any other equipment provided by Nortec that requires

maintenance.

NOTE: Instruction and details concerning the maintenance of the Nortec

equipment must be observed and adhered to without fail. Only the

maintenance documented in this manual must be carried out.

Major Maintenance

Major maintenance items include all those for the minor maintenance service, with the

exception that the steam tank must be cleaned at this point. The differences in maintenance

requirements are shown below.

Table 14: Minor and major maintenance

Resetting Maintenance Indication (Major Maintenance Only)

1. Restore primary voltage to the unit.

2. With the unit in the “off” position, press and hold the drain activation switch.

3. Continue to hold the drain activation switch and turn the main power switch to the “on”

position.

4. Allow the unit to undergo initial startup diagnostics. When the diagnostics are complete,

release the drain activation switch. The unit maintenance should be cleared at this

point.

51 | Maintenance and Servicing

Page 55

Troubleshooting

53 General Troubleshooting

55 Wiring Diagrams

57 Start Up Checklists

57 NHRS Electric Steam Humidifier – Mandatory Pre-Start-Up Checklist (p1 of 3)

58 NHRS Electric Steam Humidifier – Mandatory Pre-Start-Up Checklist (p2 of 3)

59 NHRS Electric Steam Humidifier – Mandatory Pre-Start-Up Checklist (p3 of 3)

60 Maintenance Checklists

Troubleshooting | 52

Page 56

Malfunction / Indication

Cause

Remedy

Min. Filling time too short

Error code: 1A/1B

Alarm1A

fillingtime

Error1B

Fillingtime

Steam cylinder heavily calcified.

Level in steam cylinder and level

in the float chamber do not match.

Carry out major servicing.

Level sensing unit faulty.

Test the level sensing unit is

operational by activating a drain

and noting if the LED sequence

changes, indicating a drain.

Internal safety chain

interrupted Error code: 2A/2B

Alarm2A

Safetychainint Error2

safetychainint

Connection to over-temperature

switch on steam cylinder is

broken or over-temperature

switch faulty.

Check connections or replace

over-temperature switch.

Steam cylinder overheating, over-

temperature switch has

responded.

Inspect steam cylinder, clean if

necessary. Replace over-

temperature switch.

Flat-band cable between control

and power board interrupted or

not connected.

Inspect connections, connect or

replace flat-band cable.

Door switch is disengaged.

Door switch safety connection is

closed by either pushing the

switch (such as when the door is

installed), or by pulling the switch.

Max. Filling time exceeded

(alarm message only) Error

code: 3A/3B

Alarm3A

Water supply

Water feed blocked (main water

tap closed, filter valve closed or

blocked). Water pressure too low.

Inlet valve does not open, filter

sieve in Inlet valve blocked or

inlet valve faulty. Feed hoses into

the steam humidifier not

connected or kinked. Level unit

not connected. Float in the level

unit sticking or level unit faulty.

Check water feed, open main

water tap, open or clean filter

valve. Raise water pressure

(range 1-10 bar). Inspect

electrical connections and fuse F2

on supply module. Clean filter

sieve or replace Inlet valve.

Inspect hoses into unit and

connect if necessary. Replace

faulty hoses. Connect level unit.

Clean or replace level unit.

General Troubleshooting

Most operational malfunctions are not caused by faulty equipment but rather by improper

installation, or disregard for planning guidelines. Therefore, a complete fault diagnosis always

involves a thorough examination of the entire system. Often, the steam hose connection has not

been properly executed or the fault lies with the humidity control system. The following table

gives a list of possible malfunctions, the appropriate alarm or error message, details of their

cause, and notes on how to deal with each problem.

Table 15: Troubleshooting errors and warnings

53 | Troubleshooting

Page 57

Malfunction / Indication

Cause

Remedy

Max. Boil down rate too long

Error code: 4A/4B

Error4B

SteamtimeAlarm

4Asteamtime

Individual heating elements faulty.

Replace faulty heating elements.

Main voltage too low or failure of

a phase (L1, L2 or L3).

Replace fuses on power board.

Check main voltage and

connections.

Steam line too long or not

insulated.

Maintain maximum line lengths

(max. 15’). Insulate steam lines.

Max. Drain time exceeded

Error code: 5A/5B

Alarm5Adrain

Error5Bdrain

Drain pump not connected or

faulty.

Connect or replace drain pump.

Outlet line from unit kinked or

blocked.

Inspect outlet line from unit,

replace if necessary.

Water outlet blocked (external

outlet line or siphon blocked.

Clean water outlet line and

siphon.

Hose to level unit blocked.

Clean or replace hose.

Invalid level

Error code: 6A/6B

Alarm6A

Levelindicat

Error6B

levelindicat

Level unit faulty.

Replace level unit.

Magnetic field in vicinity of level

unit.

Eliminate magnetic field.

Steam pressure (error only)

Error code: 7A/7B

Alarm7A

communication

Steam hose blocked or restricted

(water trap).

Inspect steam hose, clean if

necessary and install correctly.

Pressure balance adapter into

steam connection fitting blocked.

Remove adapter and clean

opening with a needle.

Duct pressure too high

(>1500 Pa).

Inspect ventilation settings.

External safety chain

interrupted Error code: none

SafetychainexternalA

Mainsfailure B

Ventilator lock open.

Switch on ventilator/ventilation

system.

Automatic flow control has

responded.

Inspect ventilator/filter of

ventilation system.

Safeties are open.

Servicing, inspect system if

necessary.

Main failure on Unit B.

Inspect voltage supply to Unit B.

Table 14: Troubleshooting errors and warnings (continued)

Troubleshooting | 54

Page 58

Figure 34: Wiring Diagram (NHRS 010 to 090)

Wiring Diagrams

55 | Troubleshooting

Page 59

Figure 35: Wiring Diagram (NHRS 135 to 180)

Troubleshooting | 56

Page 60

WATER QUALITY:

Well water

City water

Softened water

Conductivity: _______mhmos

Hardness: _____gr.

Silica____ppm

HUMIDIFIER MOUNTING:

Clearances around the unit:

Acceptable

Obstruction

Front (door opens freely?)

3ft min

__________________

Top (steam lines)

1ft min

____________________

Bottom (fill, drain, controls)

1ft min

____________________

Right (main pwr)

3ft min

____________________

Left (main pwr)

2” min

____________________

Start Up Checklists

NHRS Electric Steam Humidifier – Mandatory Pre-Start-Up Checklist (p1 of 3)

Unit Serial #: ____________ # of humidifiers: ____________ Tag:_____________

Unit type: NHRS Voltage: _____V/___ph Steam output: ____lbs./hr

Customer/Job:_______________

Address: ____________________________________________________________________

Inspected by: ____________ Date of inspection: ___/___/___

Ensure the scale tank bracket is locked in place

STEAM LINES: CONDENSATE LINES:

Slope up 2” per 12” Slopped back to drain

Slope down ½” per 12” Trapped 2” more than static duct pressure

Traps Size _______

Insulated Length/Size ____________

90º elbows qty: ____ 45 deg. Elbows qty: ____

Can condensate be trapped anywhere in the steam line? Yes no

WATER LINES:

½” at max 4ft from the unit -3/8” connection at fill

Water pressure: 30-80psig

57 | Troubleshooting

Page 61

NHRS Electric Steam Humidifier – Mandatory Pre-Start-Up Checklist (p2 of 3)

DRAIN LINES:

Air gap located within 3ft of the unit Slopped to drain Size:______________

WIRING:

No loose wires around the unit or on the PC board? Yes no

CONTROLS:

Installed Location/Wiring/Setting

High limit: _________________

Air proving: _________________

Mod controller: _________________

Other: _________________

POWER:

Voltage, amperage rating and fuse corresponds to Spec Label

Disconnect switch located close to humidifier

Field contact:___________________________ Signature:_______________________________

Troubleshooting | 58

Page 62

NHRS Electric Steam Humidifier – Mandatory Pre-Start-Up Checklist (p3 of 3)

Unit Serial #: ____________ # of humidifiers: ____________ Tag:_____________

Unit type: NHRS Voltage: _____V/___ph Steam output: ____lbs./hr

Customer/Job:___________ Address: ___________________________________________

Start-up by: _____________ Date of Start-up: ___/___/___

PRELIMINARY:

Pre-start-up checklist completed? Yes No

If no, return to Pre-Start-up Checklist before going on with start-up procedure.

START-UP PROCEDURE:

The prerequisites for getting power and water into the steam cylinder is as follows:

1. Check that main breaker is on and power is at the unit.

2. Check that main water shut-off valve is open.

3. on/off switch must be switched on.

4. Control circuit 1 - 2 must be made.

5. Modulation humidistat, if present, must be calling.

6. Door interlock switch must be made (interlock switch can be pulled out to operate unit).

NOTE:

The unit will undergo a System Test to ensure integrity of all the components. If the test is successful,

the unit will fill and the float test will be carried out. If everything ok, the green light will come on and

the display will show NHRS Ready.

OPERATIONAL CHECK:

1. Switch on the humidification by raising the humidity set point on the humidistat/controller.

2. Switch off the humidification by lowering the humidity set point on the humidistat/controller.

3. Check for correct functioning of the external monitoring safeties such as air proving and high

limit.

4. When check complete: Set the desired humidity level.

REMARKS:

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

59 | Troubleshooting

Page 63

Maintenance Checklists

Unit Serial #: ____________ # of humidifiers: ____________ Tag:_____________

Unit type: NHRS Voltage: _____V/___ph Steam output: ____lbs./hr

Customer/Job:___________ Address: ___________________________________________

Maintenance by: _____________ Date of Maintenance: ___/___/___

TYPE OF MAINTENANCE*:

Minor maintenance, 2-3 times per year:

Inspect all water and steam installations for possible leakage or damage.

Inspect electrical installation for loose or frayed cables, as well as damaged components.

Inspect the condition of the unit cabinetry for damage.

Survey the area surrounding the humidifier – make sure all clearances are met.

If equipped with scale tank: remove scale tank and empty

If not equipped with scale tank: remove boiling tank, clean inside as well as heating

elements.

Major maintenance, at least once per year:

Inspect all water and steam installations for possible leakage or damage.

Inspect electrical installation for loose or frayed cables, as well as damaged components.

Inspect the condition of the unit cabinetry for damage.

Survey the area surrounding the humidifier – make sure all clearances are met.

Remove scale tank and empty

Remove boiling tank, clean inside as well as heating elements.

Reset maintenance indication

Seasonal maintenance, at the conclusion of the humidification season**:

All items from “Major maintenance” section.

Inspect boiling tank for pitting and/or corrosion due to harsh supply water.

Inspect drain pump to ensure there is no blockage.

* Note that the duration of the maintenance intervals can be set by the user. See Table 10 on

page 39 for details. For additional details on maintenance, see section Maintenance and

Servicing on page 48.

** The “humidification season” is typically the winter months, where cold outdoor air requires

heat and humidification before being delivered into a conditioned environment. There are

geographical areas where the humidification season is all year long i.e. locations where summer

months are very dry.

Troubleshooting | 60

Page 64

Spare Parts

62 NHRS Plumbing Parts

64 NHRS Electrical Parts

Part Ordering

The following illustrations and tables list the most commonly used NHRS parts.

First locate the part you require in the illustration corresponding to your NHRS unit.

Find the item number in the first column of the table adjacent to the illustration.

Read across the table to the column which corresponds to the number of phases,

voltage, and capacity of your unit.

To order parts, or help in identifying the part you need, contact your local Nortec

agent.

61 | Spare Parts

Page 65

NHRS Plumbing Parts

Figure 36: Exploded view, NHRS plumbing parts

Spare Parts| 62

Page 66

Table 16: Exploded view, NHRS plumbing parts

575

460

575

460

575

460

575

460

230

208

575

460

230

208

575

460

230

208

575

460

230

208

575

460

230

208

575

460

230

208

575

460

230

010/1 015/1 020/1 030/1 180/3135/3090/3065/3045/3030/3

208

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

123612

123612

1236

1236

123612

123612

123

123

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

1111111111111111111111111111112222

63 | Spare Parts

Spare Parts List NHRS Plumbing Section

Voltage

Capacity

Fill Cup Assembly

Drain Canal Assembly

Fill Valve Assembly

Drain Pump Assembly

Drain Water Cooling Valve Assembly

O-ring kit, units with scale tank (optional)

O-ring kit, units without scale tank

Tank Base

Tank Base for Scale Management Option

Tank

Plastick Liner with Funnel

Stainless Steel Liner

Steam Outlet

Steam Outlet Hose

Tank Clamp

1116483

1116482

Part Number Description

1 1508019

2 2526944

3 2573527

4 1502644

5 2541095

6 2573903

7 2573904

8

9 1113772

10 1117634

11 1119101

12 1509465

13 2557455

14 1109384

SP Heating Element, 11.25 lbs/hr 208V Assembly

SP Heating Element, 11.25 lbs/hr 240V Assembly

SP Heating Element, 11.25 lbs/hr 480V Assembly

SP Heating Element, 11.25 lbs/hr 600V Assembly

SP Heating Element, 15 lbs/hr 208V Assembly

SP Heating Element, 15 lbs/hr 240V Assembly

SP Heating Element, 15 lbs/hr 480V Assembly

SP Heating Element, 15 lbs/hr 600V Assembly

Tank Lid

Tank Gasket

Temperature Switch

Scale Tank Bracket (Scale Management Option)

Scale Tank (Scale Management Option)

Water Leveling Sensor

Float Chamber Mounting Bracket

Float Chamber

Fitting, Nylon Male, 1/2 NPT, Female GH

2578492

2578493

2578494

2578495

2578496

2578497

2578498

2578499

15

16 1119102

17 1110091

18 1502684

19 1505914

20 2573902

21 2511137

22 1113777

23 1114768

24 1509787

1113796 Drain Disk, NHRS 1111111111111111111111111111112222