Page 1

NH

TM

Series

NHTC / NHPC

ELECTRODE

STEAM HUMIDIFIER

Engineering Manual

2538144-B

Page 2

PROPRIETARY NOTICE

This document and the information disclosed herein are proprietary data of WALTER MEIER LTD.

Neither this document nor the information contained herein shall be reproduced used, or disclosed to

others without the written authorization of WALTER MEIER LTD., except to the extent required for

installation or maintenance of recipient’s equipment. All re ferences to the NORTEC name should be

taken as referring to WALTER MEIER LT D.

LIABILITY NOTICE

NORTEC does not accept any liability for installations of humidity equipment installed by unqualified

personnel or the use of parts/components/equipment that are not authorized or approved by

NORTEC.

COPYRIGHT NOTICE

Copyright 2008, WALTER MEIER LTD. All rights reserved.

SPECIFICATION LABEL LOCATION

The Specification Label for your NH Series humidifier is located on the bottom of the unit. You will

find it attached to the skirt that separates the electrical and plumbing comp ar tments on the electrical

compartment side.

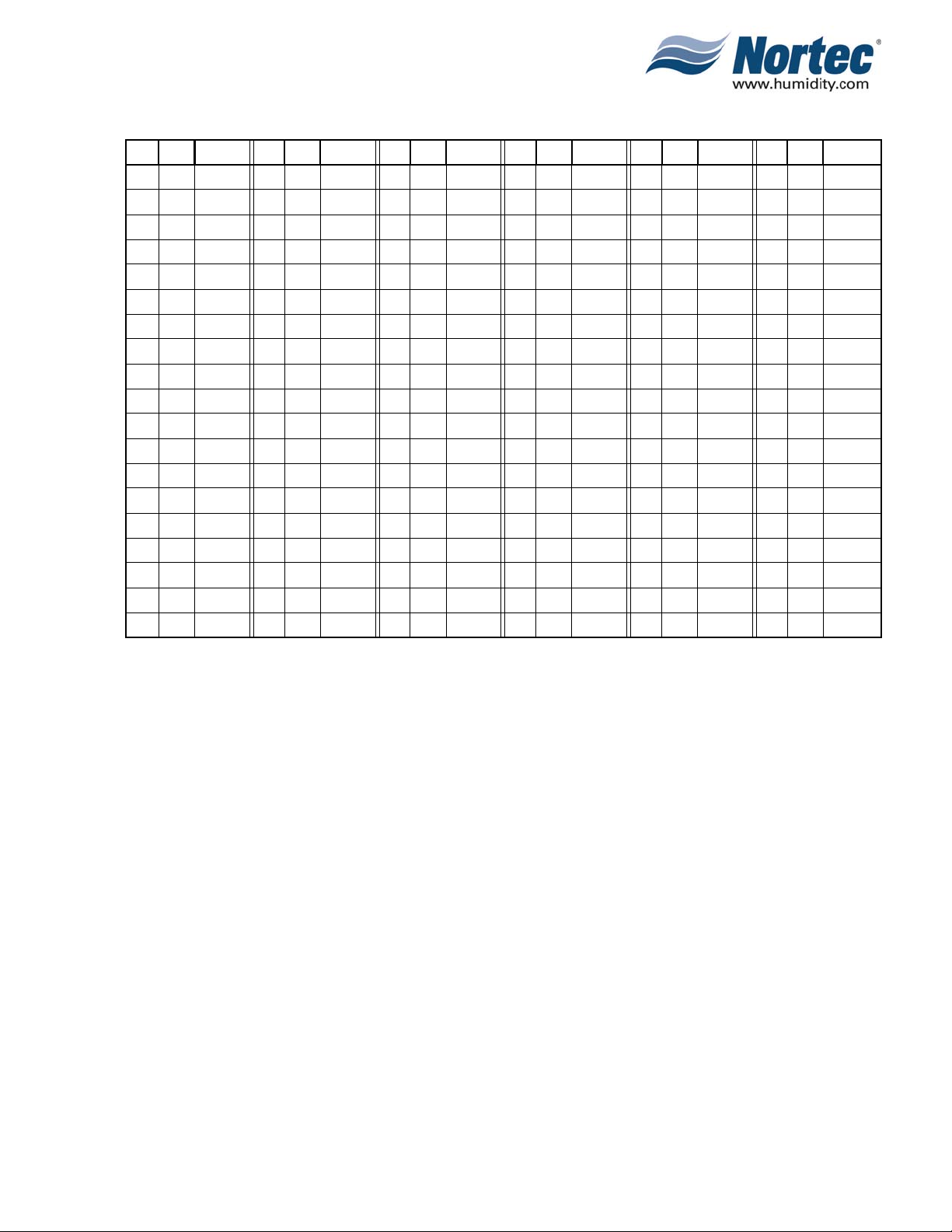

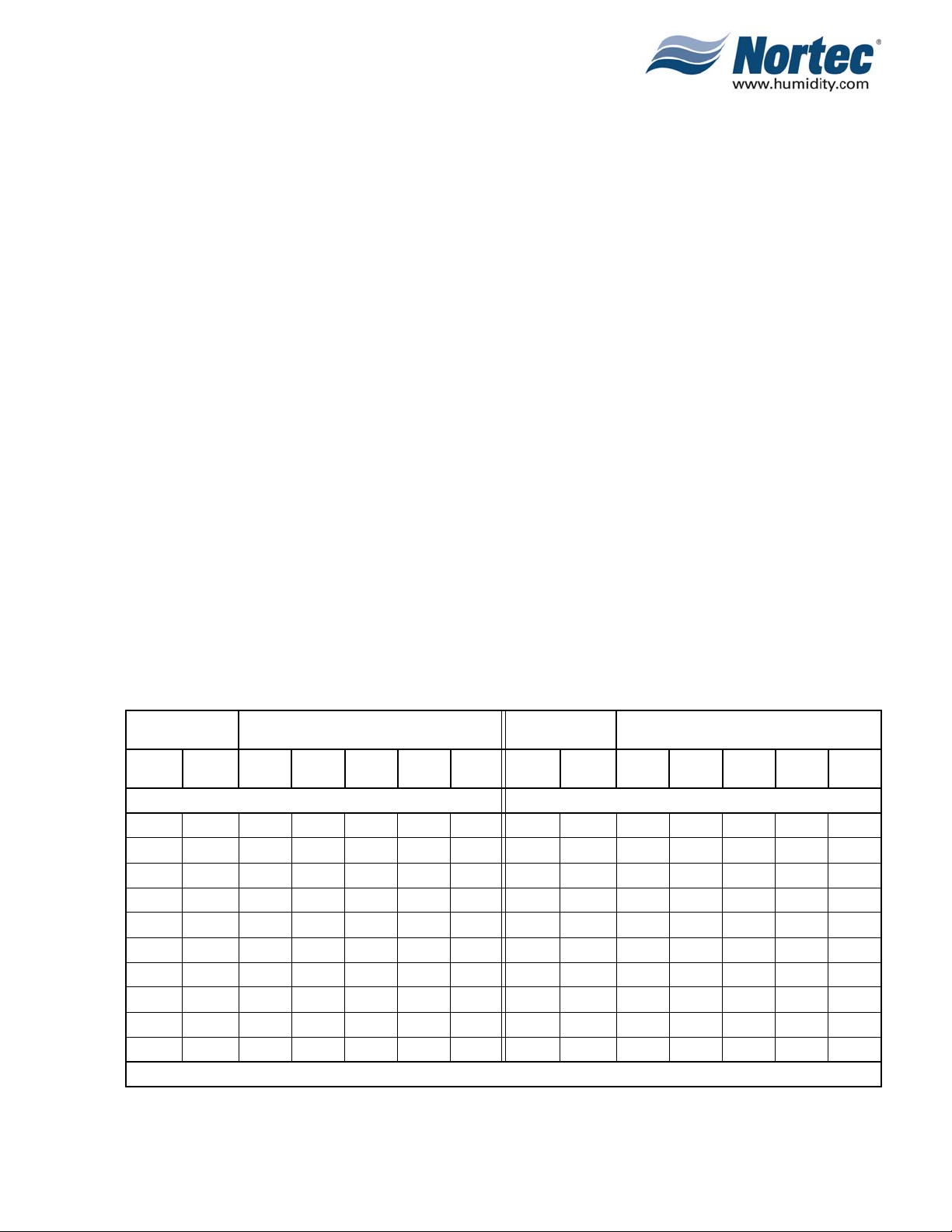

RECORD OF REVISIONS

For each revision, put the revised pages in your manual and disca rd the superseded pages. W rite the

revision number and revision date, date put in manual, and the incorporator’s initials in the applicable

columns on the Record of Revisions.

Revision

Number

Revision

Date

Date Put

In Manual By

Revision

Number

Revision

Date

Date Put

In Manual By

2008-10-01

Page 3

TABLE OF CONTENTS

Subject Page

10-00 ELECTRODE STEAM ENGINEERING

1. INTRODUCTION WHY ELECTRODE STEAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

A. PROPORTIONAL + INTEGRAL AUTO-ADAPTIVE CONTROL SYSTEM FOR

THE NHTC/NHPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

B. NH CAPACITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

C. DRAIN CYCLE AND CYLINDER LIFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. PRE-INSTALLATION EQUIPMENT VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

A. GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

10-10 HUMIDITY, STEAM ABSORPTION AND DISTRIBUTION

1. HUMIDITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

A. ESTIMATING THE HUMIDIFICATION LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

B. LOAD CALCULATION SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

C. TEMPERATURE AND HUMIDITY REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

D. TEMPERATURE AND HUMIDITY AVAILABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

E. INCOMING AIR VOLUME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2. STEAM ABSORPTION AND DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

A. VARIABLES THAT AFFECT ABSORPTION DISTANCES. . . . . . . . . . . . . . . . . . . .28

B. CALCULATING THE DOWN STREAM HUMIDITY LEVEL . . . . . . . . . . . . . . . . . . .30

C. CONTROL OF DUCT OR PLENUM SATURATION. . . . . . . . . . . . . . . . . . . . . . . . . 31

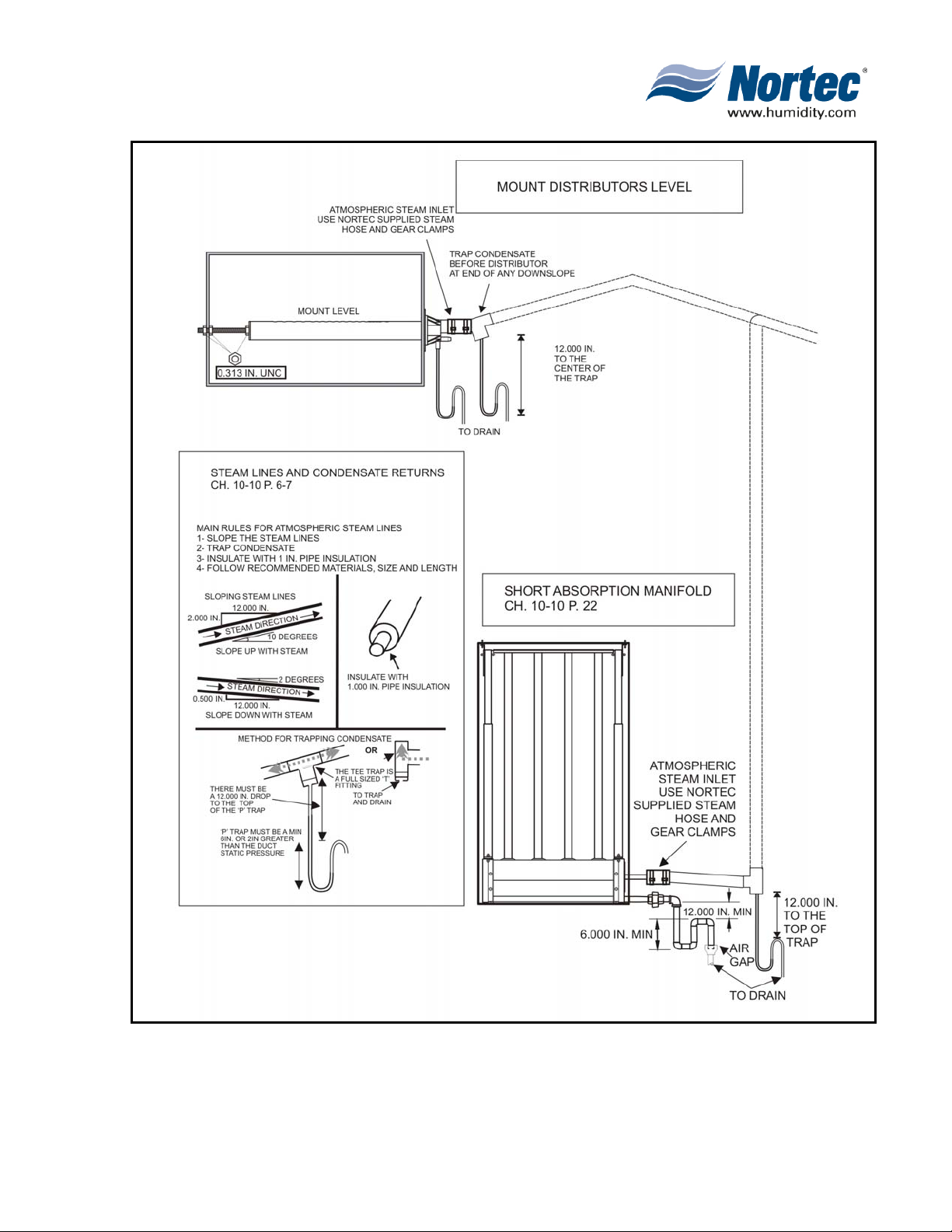

3. STEAM RUNS AND CONDESNATE RETURNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

A. STEAM RUNS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

B. CONDENSATE RETURN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4. STEAM DISTRIBUTORS (ASD, BSD, CSD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

A. STEAM DISTRIBUTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

B. DISTRIBUTOR CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

C. DISTRIBUTOR LOCATIONS AND MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

D. MULTIPLE DISTRIBUTOR APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

E. LOCATION OF STEAM DISTRIBUTORS WITHIN AN AIR HANDLER . . . . . . . . . . 40

F. DISTRIBUTOR ABSORPTION DISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

G. TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

H. DISTRIBUTOR DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5. SHORT ABSORPTION MANIFOLD (SAM-e) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

B. DETERMINING THE STEAM ABSORPTION DISTANCE . . . . . . . . . . . . . . . . . . . . 43

C. STATIC AIR PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

D. CONDENSATE LOSSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

E. CORRECT CHOICE OF PRODUCT APPLICATIONS (WITHIN SAM-e) . . . . . . . . 46

F. SAM-e DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

G. SAM-e HEADER SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

H. SAM-e STEAM TUBE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

I. SAM-e STEAM INLET CONFIGURATION SELECTION . . . . . . . . . . . . . . . . . . . . .48

J. MINI SAM-e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

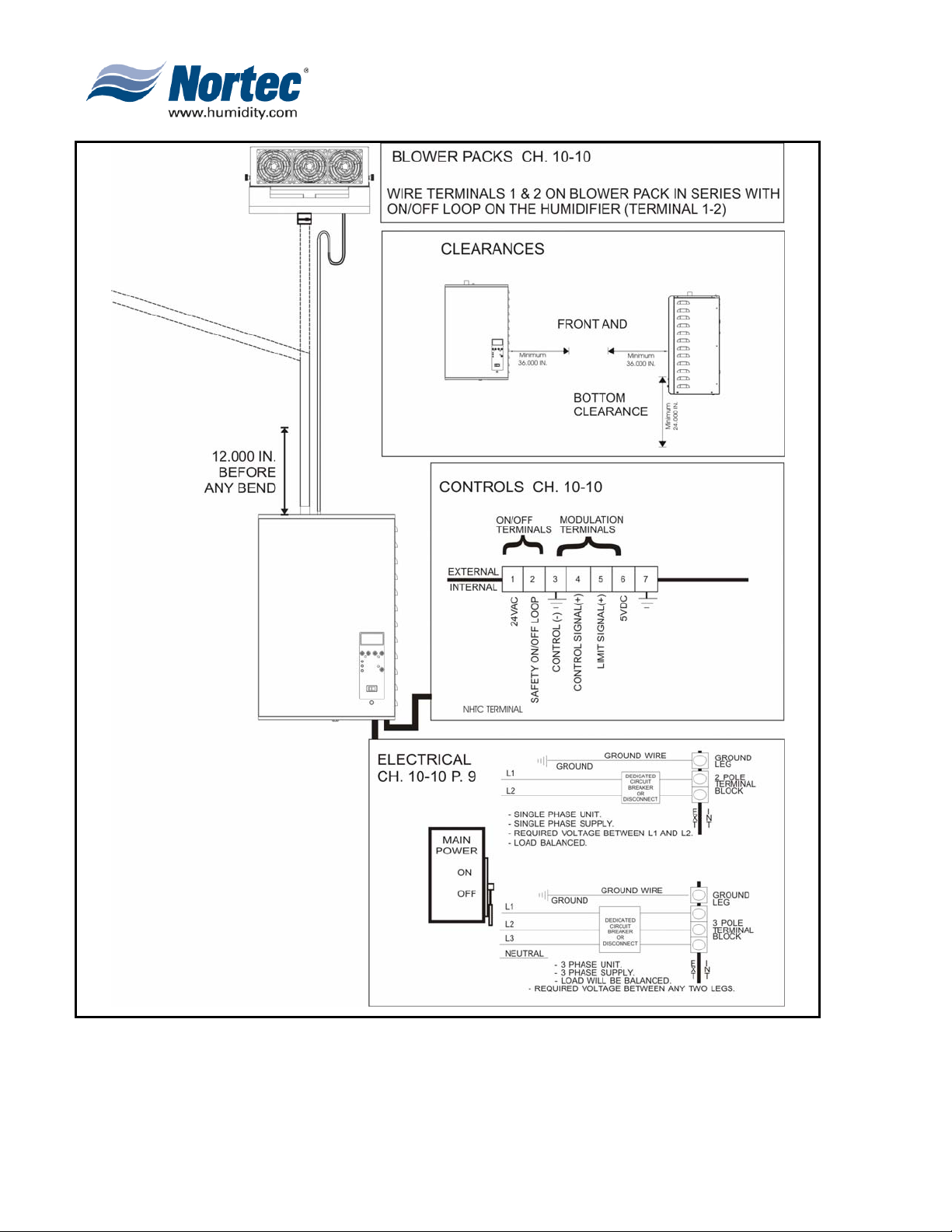

6. BLOWER PACKS (BOBP, RMBP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

A. BLOWER PACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2008-10-01

Page 4

Subject Page

7. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B. ON/OFF CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

C. MODULATING CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

D. OUTDOOR TEMPERATURE SETBACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

E. TRANSDUCER SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

F. POSITIONING CONTROLS AND SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

G. NORTEC ONLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

H. NORTEC LINKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

I. TYPICAL INSTALLATION LAYOUT FOR NHTC/NHPC . . . . . . . . . . . . . . . . . . . . . 58

J. NORTEC CONTROLLER DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10-20 SPECIFICATIONS

1. HUMIDIFIERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

B. PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

C. EXECUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10-30 SUBMITTALS

1. SUBMITTAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

A. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

B. NH UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

C. DISTRIBUTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

D. SAM-e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

E. BLOWER PACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

F. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

WARRANTY

2008-10-01

Page 5

LIST OF FIGURES

Figure Page

10-00 ELECTRODE STEAM ENGINEERING

Figure 1. NHTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Figure 2. Optimum Boiling Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 3. Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 4. Typical Auto-Adaptive Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

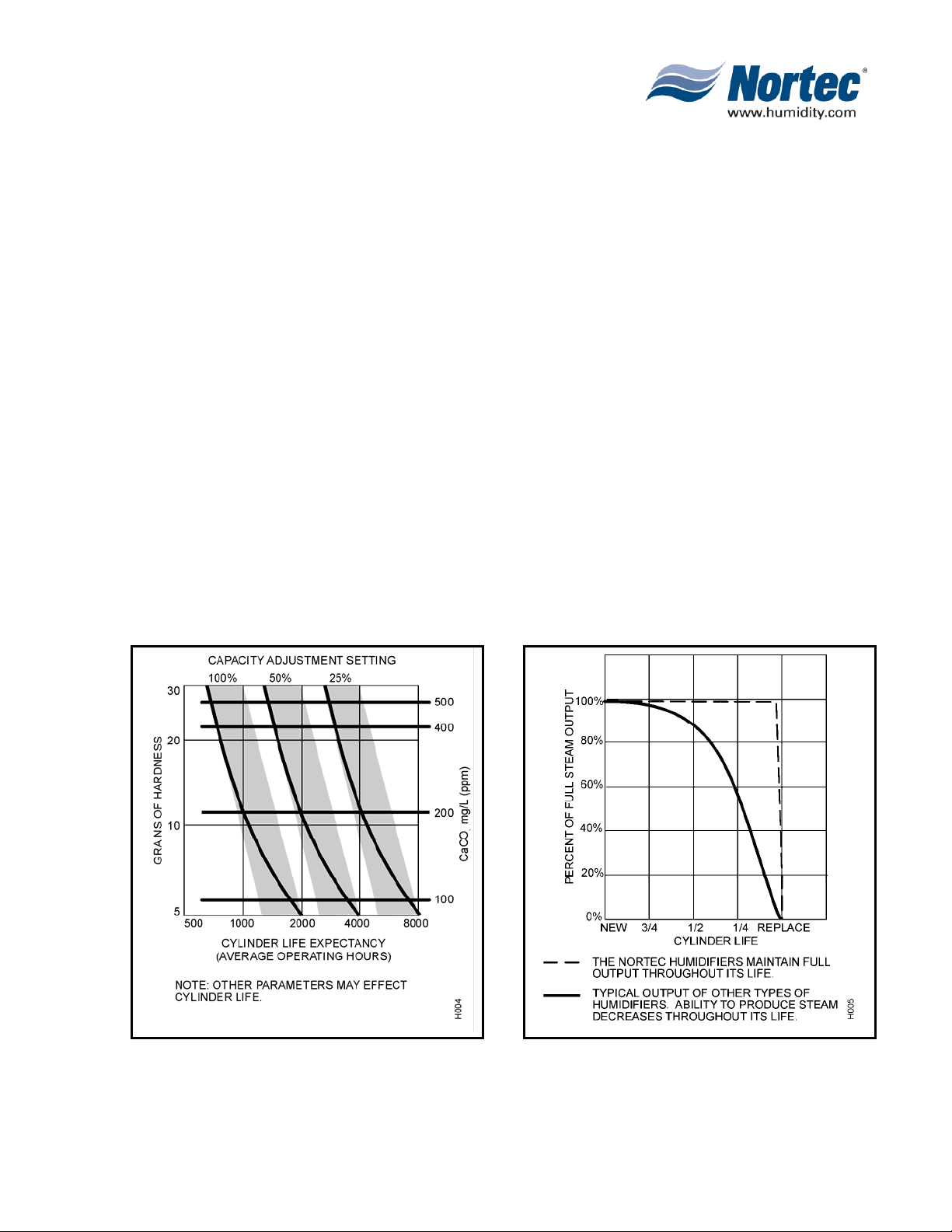

Figure 5. Capacity Setting & Cylinder Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 6. Output vs Service Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 7. Typical NHRS Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

10-10 HUMIDITY, STEAM ABSORPTION AND DISTRIBUTION

Figure 1. Schematic of a Typical Print Shop HVAC System . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2. Psychrometric Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 3. Steam Distributor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 4. Condensate Drain Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5. Proper Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 6. Drain Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 7. Steam Line Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 8. Condensate Tee At Any Low Point In Steam Line . . . . . . . . . . . . . . . . . . . . . . .35

Figure 9. Trap To Prevent Steam In Condensate Line . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 10. Levelling the Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 11. Single Steam Distributor Installation – Minimum Clearance . . . . . . . . . . . . . . .38

Figure 12. Cutting Duct For Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Figure 13. Humidification Distance Nomogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 14. Best Location for Multiple Steam Distributors . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 15. Roof Top Units 2-20 Tons – Typical Location . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 16. Small Units On Residential Furnaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 17. SAM-e Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 18. Cross-Section of Distributor Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 19. Absorption Distance – 3" Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 20. Absorption Distance – 6" Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 21. Absorption Distance – 9" Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 22. Absorption Distance – 12" Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 23. SAM-e Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 24. SAM-e Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 25. Steam Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Figure 26. Typical SAM-e Installation for Atmospheric Steam Applications . . . . . . . . . . . .50

Figure 27. NH Series Humidifier With Built-On Blower Pack . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 28. NH Series Remote Mounted Blower Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 29. Set Point Versus Outdoor Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 30. NORTEC OnLine Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Figure 31. NORTEC Online Configuration Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 32. NORTEC Links Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

2008-10-01

Page 6

Figure Page

Figure 33. Humidifier Controlled by Air Proving, On/Off Duct Mounted High Limit and

Modulating Wall Mounted Space Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 34. Humidifier Controlled by Air Proving, Modulating Duct Mounted High Limit

and Modulating Wall Mounted Space Controller . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 35. Humidifier Controlled by Air Proving, Modulating Duct Mounted High Limit

and Modulating Wall Mounted Return Air Sensor with Wall Mounted

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 36. Humidifier Controlled by Air Proving, Duct Mounted High Limit Sensor

and Modulating Duct Mounted Return Air Sensor with Networking Option . . . . 62

10-30 SUBMITTALS

Figure 1. Low Voltage Control Terminal Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 2. Primary (Line) Voltage Wiring to Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 3. Physical Data - NHTC/NHPC 005-030 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 4. Physical Data - NHTC/NHPC 050-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 5. Physical Data - NHTC/NHPC 150-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 6. Distributor Dimensions (3 Sheets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 7. SAM-e General Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 8. General Mini SAM-e Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 9. In-Duct/AHU Installation Without Mounting Frame Installation . . . . . . . . . . . . . 87

Figure 10. In-Duct/AHU Installation With Mounting Frame Installation . . . . . . . . . . . . . . . . 88

Figure 11. Outside Duct Installation Without Mounting Frame Installation . . . . . . . . . . . . . 89

Figure 12. Outside Duct Installation With Mounting Frame Installation . . . . . . . . . . . . . . . . 90

Figure 13. Vertical Duct Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 14. Outside Duct Mounting Cover Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 15. Atmospheric SAM-e Adapter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 16. Atmospheric Steam Header and Adapter Configuration . . . . . . . . . . . . . . . . . . 93

Figure 17. Physical Data for Remote Mounted Blower Pack . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 18. Physical Data Units With Optional Built-On Blower Packs . . . . . . . . . . . . . . . . . 95

Figure 19. Wall Digital Humidistat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 20. Duct Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2008-10-01

Page 7

LIST OF TABLES

Table Page

10-00 ELECTRODE STEAM ENGINEERING

Table 1. Features Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. NHTC/NHPC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10-10 HUMIDITY, STEAM ABSORPTION AND DISTRIBUTION

Table 1. Outdoor/Indoor Relative Humidity Conversion Chart . . . . . . . . . . . . . . . . . . . . 14

Table 2. Load Calculation Summary Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 3. Grains of Water Per Cubic Foot – Saturated Air (100% rh) . . . . . . . . . . . . . . . 15

Table 4. Design Outdoor Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. Inside Relative Humidities At Which Moisture Will Condense On Windows . . 21

Table 6. Regain of Hygroscopic Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Table 7. Design Indoor Conditions For Various Places, Products and Processes . . . . . . 23

Table 8. Variables That Affect Absorption Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 9. Typical Absorption Distances, Single Distributor, 100 lbs/hr Humidifier . . . . . . .29

Table 10. Water (lbs/hr) Contained in 1000 CFM of Air . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 11. Steam Line Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 12. Recommended Material and Size for Steam Run . . . . . . . . . . . . . . . . . . . . . . .33

Table 13. Recommended Condensate Line at Distributor(s) . . . . . . . . . . . . . . . . . . . . . . . 33

Table 14. Maximum Recommended Length of Steam Runs . . . . . . . . . . . . . . . . . . . . . . . 34

Table 15. Air Pressure Loss in AHU/Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 16. Condensate Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Table 17. SAM-e Tube Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 18. Mini SAM-e Headers – 3" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 19. Mini SAM-e Headers – 6" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 20. Mini SAM-e Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 21. Mini Inlet Configurations – For Atmospheric Steam Unit . . . . . . . . . . . . . . . . . . 49

Table 22. Ceiling and Frontal Clearances for Blower Packs . . . . . . . . . . . . . . . . . . . . . . .52

10-30 SUBMITTALS

Table 1. NH Series Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Table 2. Common Accessories Universal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Table 3. Steam Distributors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Table 4. Steam Distributor Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Table 5. SAM-e Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Table 6. Adjustable Mounting Frame for SAM-e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Table 7. SAM-e Tube Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Table 8. SAM-e Inlet and Adapter Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Table 9. Remote Blower Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Table 10. Built-On Blower Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 11. Controls – ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Table 12. Modulating Control By NORTEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

2008-10-01

Page 8

Table Page

Table 13. Modulating Demand Signal By Others Single Channel. . . . . . . . . . . . . . . . . . . 113

Table 14. Modulating Demand Signal By Others Dual Channel. . . . . . . . . . . . . . . . . . . . 113

Table 15. Modulating By Other Transducer Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 16. NORTEC OnLine Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 17. NORTEC Links Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 18. NH Series Fusing Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

2008-10-01

Page 9

10-00

INTRODUCTION

10-00

Page 1

2008-10-01

Page 10

Figure 1. NHTC

10-00

Page 2

2008-10-01

Page 11

1. INTRODUCTION

The NHTC humidifier is controlled by Nortec’s Patented Auto adaptive Water Management

Control System. This system allows the humidifiers to adapt to basically any potable

incoming water and changes that occur to the water supply. This eliminates the need to

readjust drain timers, changes complete cylinders or time consuming adjustment of

electrode spacing’s. The system also adjusts the drain rate of the humidifier to reduce the

amount of drain water exiting the humidifier as water conditions change. This reduces

energy loss due to excessive draining of hot water and extends cylinder life since less water

and minerals enter the humidifier.

The following is a brief description of how the Auto-Adaptive water Management System

works.

The electrode steam system produces pure uncontaminated steam with variable output

through electronic power control of the electrodes. Water borne minerals remain in the

cylinder and are periodically flushed out through the automatic cylinder drain. On NHTC and

NHPC models the drain automatically empties the steam cylinder if it is not operated for

three days. Solid mineral scale sinks to the bottom of the cylinder which, when filled with

residue, is easily removed and replaced.

A. PROPORTIONAL + INTEGRAL AUTO-ADAPTIVE CONTROL SYSTEM FOR THE

NHTC/ NHPC

(1) NORTEC’s patented P+I Auto-Adaptive control system allows the unit to operate at

an optimal low water level using the same fixed electrode spacing regardless of the

incoming water conditions. Boiling of the water allows the minerals in the water to

remain behind in the cylinder. This raises the contained water conductivity to a

value higher than the incoming water. The P+I Auto-Adaptive control system

monitors and adjusts the contained water conductivity as these changes occur.

(2) The humidifiers are designed to produce full steam output at the lowest possible

electrode coverage to obtain maximum cylinder life.

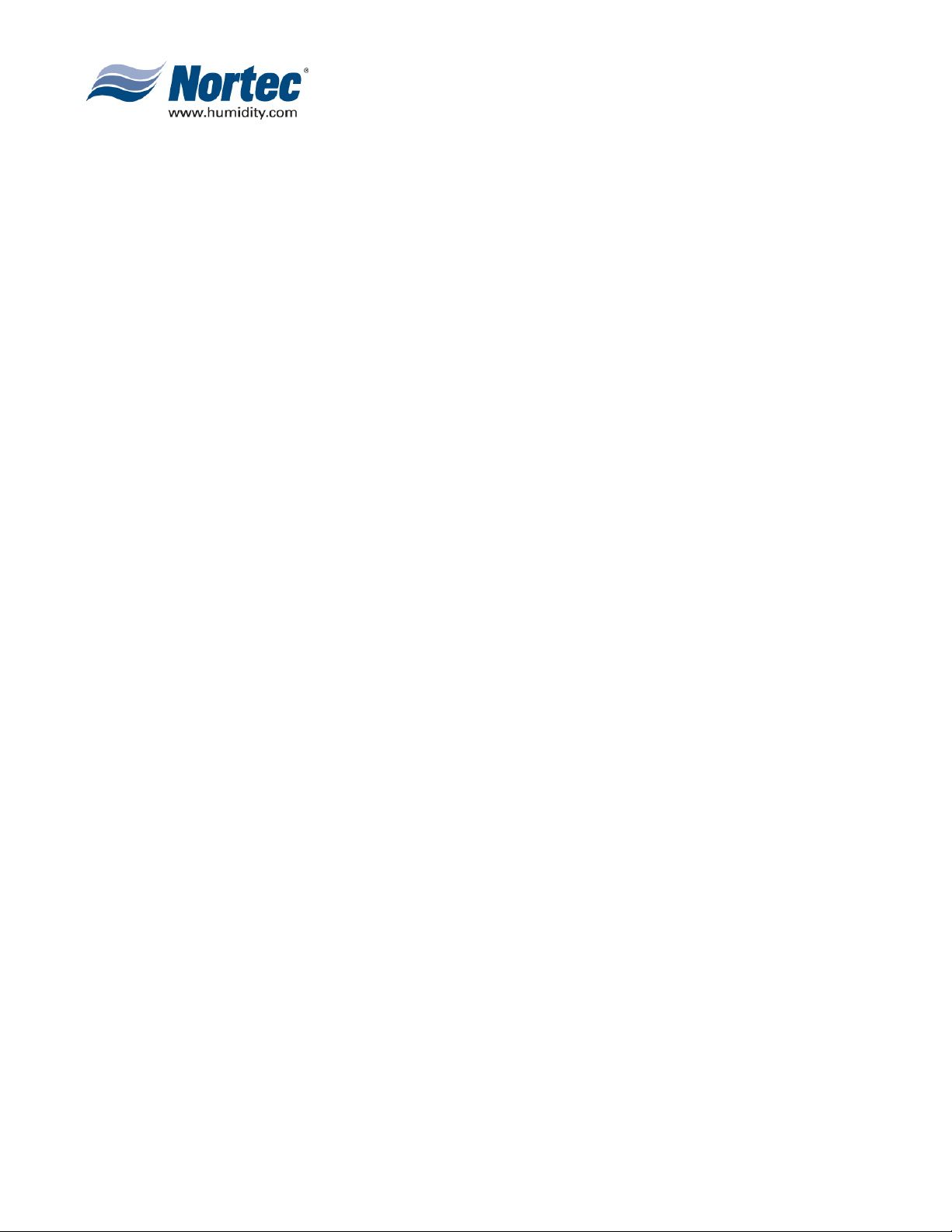

(3) The units operate between A and D of the main steam output demand.

Accordingly, the current flow between the electrodes in the cylinder is maintained

between these pre-established limits programmed into the P+I Auto-Adaptive

control system.

(4) As the water boils away and the electrode coverage is reduced, the steam output is

also reduced slightly. A pre-determined design parameter of every NORTEC

cylinder is the known time (To) (time optimum) that it takes to boil down from A to

D of output (also referenced to as amp trigger points) at a pre-designed contained

water conductivity. (See Figure 2.)

(5) Whenever the conductivity in the cylinder water is lower than the designed

conductivity, the (Ta) (time actual) to boil down from A to D will be longer than the

To. (See Figure 3.)

10-00

Page 3

2008-10-01

Page 12

(6) As the water is boiled away, the minerals left behind increase the conductivity of

the water in the cylinder. As soon as the conductivity is greater than design, the Ta

to boil from A to D will be shorter than To and a drain cycle is initiated.

(7) The fill valve always opens during timer drains, adding cold water to mix with the

hot water from the cylinder during automatic drain cycles. This tempering process

is required to meet plumbing codes.

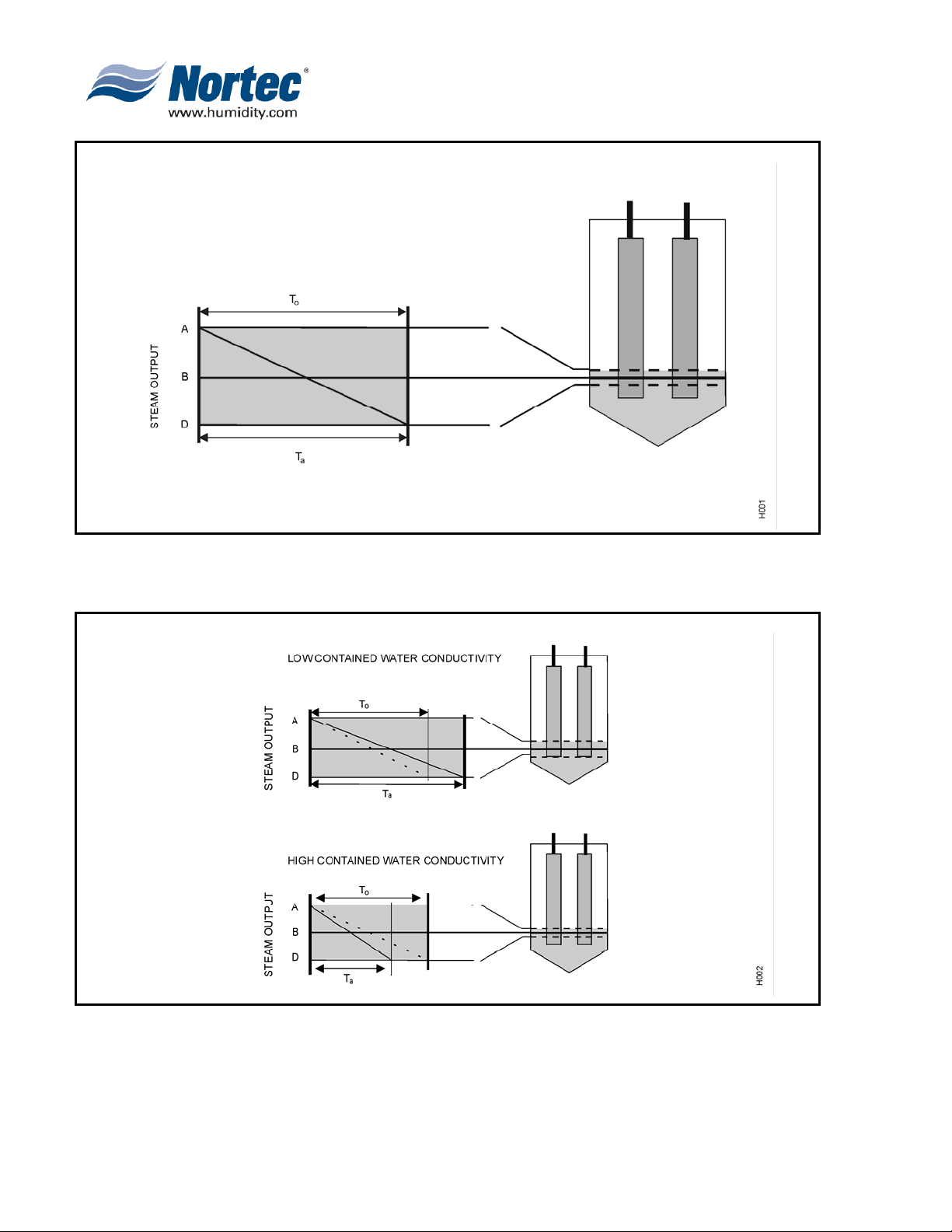

(8) As can be seen from a typical sequence depicted in Figure 4, the P+I Auto-

Adaptive system allows the unit to be self-regulating. It drains only when necessary

and only the amount of water to maintain optimum operating conditions.

(9) Relying on the proportional (P) feedback only to decide how much to drain is like

guessing what is happening based on a ‘snapshot’ only. By taking into

consideration a series of “snapshots”: (one from each of the past ten cycles for

example), the control system has more data on which to base its decision to drain.

The integral (I) part of the P+I Auto-Adaptive system provides this added feedback.

(10) The proportional (P) and integral (I) factors have been weighted as to the relative

influence each will have when the NHTC/NHPC calculates a drain. The

preprogrammed weighing was derived through extensive field and laboratory tests.

When supply water conductivity is extremely high (requiring substantially more

drains), the NHTC/NHPC will see the pattern developing in cycles stored in

memory. It will then initiate additional drains to adjust the contained water

conductivity.

(11) If low conductive water conditions occur, the P+I control will reduce the drains

necessary to maintain optimum operating conditions within the cylinder. If extreme

water conditions are encountered, the NHTC/NHPC can be reprogrammed with

factory instructions to compensate.

(12) NORTEC’s P+I Auto-Adaptive control system has been designed to benefit users

who demand very tight control of the relative humidity. It maintains steam output

above the B level, even during auto drains. (See Figure 4.)

(13) The P+I Auto-Adaptive control system allows the humidifier to maintain tighter

humidity control without the problem of rh depression during drain cycles that occur

with other humidifiers. This results in more consistent space rh levels, even with a

simple on/off control system.

10-00

Page 4

2008-10-01

Page 13

Figure 2. Optimum Boiling Time

Figure 3. Conductivity

10-00

Page 5

2008-10-01

Page 14

B. NH CAPACITY ADJUSTMENT

(1) Each NORTEC NH Series humidifier is rated at its maximum output capacity. By

means of the alphanumeric display and keypad on the NHTC/NHPC, the

humidifiers can be adjusted to obtain an output between 20% and 100% of its rated

capacity.

C. DRAIN CYCL E AND CYLINDER LIFE

(1) Water Type Used (Potable or Softened)

(a) The electrode steam product line is one of the most efficient humidifier

systems since it uses the minerals in the water to conduct electricity. If no

minerals are present no current can pass from one electrode to another, thus

no steam production can occur.

(b) Although the electrode steam humidifier is ideal for potable water, it should

not be used with pure reverse osmosis or deionized water since the

conductivity is too low.

(2) Water Conditions vs Cylinder Life

(a) The NH Series is designed to adapt to most potable or softened water

supplies. Since the output of all NH Series humidifiers is pure, clean steam,

minerals originally in the incoming water are left behind in the steam cylinder.

Many of these minerals will be removed during short flush cycles within the

cylinder. Therefore, the water chemistry, the unit running time, and output

capacity setting ultimately determines the cylinder life. (See Figure .)

(3) Output vs Cylinder Life

(a) As minerals build-up on the electrodes in the cylinder of the NORTEC NH

Series humidifier, the patented P+I Auto-Adaptive control system

automatically raises the water level slightly in the cylinder. This exposes fresh

electrode surface to the water and maintains peak output and efficiency from

the humidifier. Once the

(b) electrode surface is completely encrusted by the minerals, the user is alerted

to change the cylinder. Other humidifiers’ performance degrades gradually as

the minerals build-up. The NH Series maintains maximum efficiency then the

cylinder is replaced. (See Figure .)

(4) Water Conditions vs Drain Rate

(a) The P+I Auto-Adaptive control system automatically adjusts the drain rate to

maintain the design water conductivity required for proper operation. This

ensures regular flushing of minerals which become concentrated in the water,

and minimizing wastage of hot water. The humidifier automatically adjusts it’s

drain rate with changes in incoming water conductivity through the Autoadaptive water management system.

10-00

Page 6

2008-10-01

Page 15

0. Store previous cycle’s drain decision in integral (l) memory.

1. Fill to A trigger (use all places below 1-10).

2. Boil to C trigger without timing to allow previous fill water to mix thoroughly during boiling.

3. Boil from C to D while monitoring time (T actual).

4. Decide how long (how much) to drain, then fill to B.

5. Drain according to the P+I calculated drain time, fill on to control outlet temperature.

6. At D, stop draining and postpone remaining drain, fill to B.

7. Continue remaining drain.

8. With drain finished, fill to A.

9. Boil to D, timing from C to D.

10. Decide how long to drain (in this case zero) based on present and past cycles.

Figure 4. Typical Auto-Adaptive Operation

10-00

Page 7

2008-10-01

Page 16

It is important to note that the drain rate shown includes the make-up water,

mixed with the drain water, which tempers the drain water to 140°F (60°C) or

less.

NOTE

The electrode steam process provides optimum efficiency because all resistance to

current passage is converted to usable energy. Unlike cal-rod or infrared humidifiers

which convert some of their capacities into unusable heat.

Figure 5. Capacity Setting & Cylinder Life

Figure 6. Output vs Service Life

10-00

Page 8

2008-10-01

Page 17

3. PRE-INSTALLATION EQUIPMENT VERIFICATION

A. GENERAL

(1) Ensure the available voltage and phase correspond with humidifier voltage and

phase as indicated on the humidifier’s specification label.

(2) Ensure that the external fuse disconnect is sufficient size to handle the rated

amperage as indicated on the humidifier’s specifications label. Refer to local building

codes.

(3) Report any discrepancy immediately to the site engineer.

(4) Location and mounting is described in Chapter 10-10.

(5) For typical installation see Figures 6 & 7.

10-00

Page 9

2008-10-01

Page 18

Figure 6. Typical NHRS Installation (Sheet 1 of 2)

10-00

Page 10

2008-10-01

Page 19

10-00

Page 11

2008-10-01

Figure 7. Typical NHRS Installation (Sheet 2 of 2)

Page 20

10-10

HUMIDITY,

STEAM ABSORPTION

AND

DISTRIBUTION

10-10

Page 12

2008-10-01

Page 21

HUMIDITY, STEAM ABSORPTION AND DISTRIBUTION

1. HUMIDITY

A. ESTIMATING THE HUMIDIFICATION LOAD

Note: The humidification load can easily be calculated by using Nortec’s Humidification Engineering

and Load-sizing Program (HELP). The softward can be downloaded at www.humidity.com

(1) Relative humidity is the percentage of moisture in the volume of air at a given

temperature, compared to the maximum amount of moisture that the volume of air can

hold at the same temperature and atmospheric pressure. As air becomes warmer, it

can absorb more moisture per unit volume. Therefore a quantity of air containing a

specific amount of moisture will have different values of relative humidity as the

temperature changes.

(2) It is this process that causes dry air in building. As cold incoming air is heated, its

relative humidity value drops. Therefore moisture must be added to attain an

acceptable level of humidity within the building. Determining how much moisture must

be added is the object of this brochure. Table 2 simplifies the calculations which are

described here in detail.

B. LOAD CALCULATION SUMMARY

(1) In order to determine the humidification load three basic values need to be known:

(a) The design conditions of the humidified space, i.e., the temperature and humidity

required.

(b) The conditions of the incoming air, i.e., the temperature and humidity available.

(c) Incoming air volume and secondary conditions that can affect the humidification

load.

(2) Data and calculations required to estimate humidification load are described in

Tables 1, 2 and 3.

C. TEMPERATURE AND HUMIDITY REQUIRED

(1) The design temperature and humidity of a space depends mostly upon the job being

performed. Once the design temperature and humidity have been established, the

required moisture can be found in gr/ft

worst case (highest temperature, highest humidity).

(2) Formula 1

For example:

The press room of a printing plant should be kept at 76 - 80

Therefore, the worst case is 80

From Table 3 the required moisture is 11.04 gr/ft

D. TEMPERATURE AND HUMIDITY AVAILABLE

(1) The outdoor conditions tell us the moisture available in the incoming air. Approximate

values can be obtained from Table 4 and combined with Table 3 to find moisture

available. Once again we must take the worst case (here, it is lowest temperature,

lowest humidity). As can be seen, the contribution of moisture from the outside air is

almost zero.

3

from Table 3. Remember always to take the

°F with 43% - 47% rh

°F, 47% rh.

3

x 47% = 5.19 gr/ft

3

10-10

Page 13

2008-10-01

Page 22

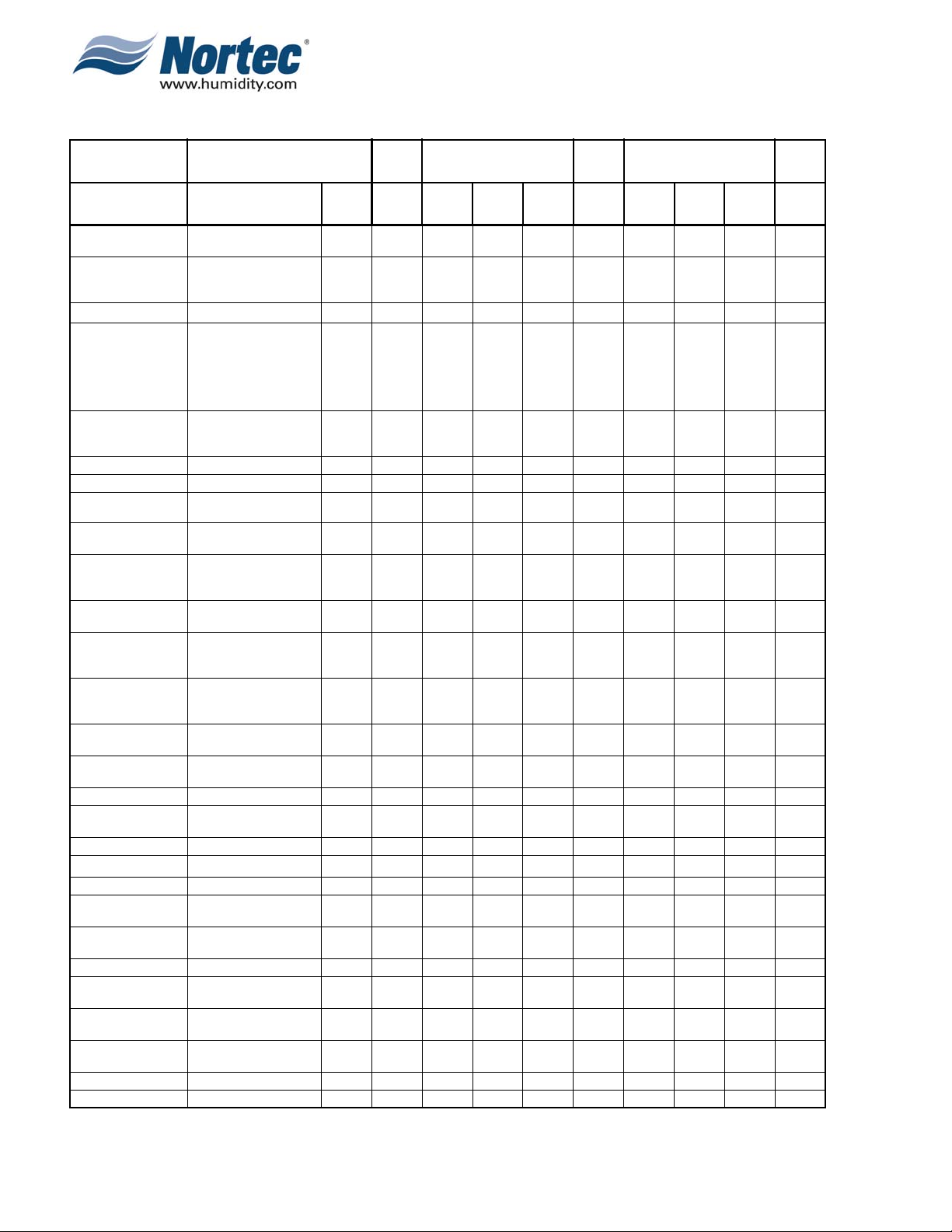

Table 1. Outdoor/Indoor Relative Humidity Conversion Chart

100%2456791217192329364352

95%2346791216172228344150

90%2345681115162126313948

85%2345681114152024293745

80%2345671013151923273542

75%2344571012141822263339

70%123456911131720243136

65%123445810121519232934

60%12334579111417212631

55%11334478101316192429

50%1123346891214182226

45%1123346781113162024

40%1122345771012141821

35%112224566910121518

Outdoor relative humidity

30%01222345679111315

25%0111233455791113

20%011122334557910

15%00111123344568

10%00011122233346

5%00000011122233

0%00000000000000

-20° -10° -5° 0° +5° +10° +15° +20° +25° +30° +35° +40° +45° +50°

Chart shows what the residual indoor RH would be at 70°F under varying outdoor conditions if a proper humidification

system were not installed in the building. Studies indicate that the recommended RH should be between 40% and 60%

for optimum benefits to the occupants.

Outdoor temperature

Table 2. Load Calculation Summary Sheet

Determine the moisture required in the space (Table 3)

Grains from Table 3 at space temp. ______ x Indoor RH

Determine the moisture level of incoming air (Table 4)

Grains from Table 4 at space temp. ______ x Outdoor RH

Therefore: moisture to be added: (moisture) M - A - B ______ gr/ft3 →M ______ gr/ft

Determine the volume of air to be humidified. Choose the largest

value.

1. Natural ventilation: Volume x number of air changes.

2. Exhaust air: CFM x 60 min/hr

3. Make-up air: CFM x 60 min/hr

Therefore: Gross humidification load = L (load) = MxC = ______ lbs/hr →L ______ lbs/hr

7,000

NOTES: 1. 7,000 grains = 1 pound

2. If HVAC system uses economizer cycle, check load using formula 6.

= A ______ gr/ft

= B ______ gr/ft

______ ft

______ ft

______ ft

3

3

3

/hr

3

/hr

3

/hr →C ______ ft3/hr

10-10

Page 14

2008-10-01

3

Page 23

Table 3. Grains of Water Per Cubic Foot – Saturated Air (100% rh)

°C °F Grains °C °F Grains °C °F Grains °C °F Grains °C °F Grains °C °F Grains

-23 -10 .29 4 40 2.86 58 5.41 76 9.75 35 95 17.28 1 14 29.34

-5 .35 41 2.97 59 5.60 77 10.06 96 17.80 115 30.13

-18 0 .48 42 3.08 16 60 5.80 78 10.40 97 18.31 49 120 34.38

8 .61 43 3.20 61 6.00 79 10.80 98 18.85 125 39.13

-12 10 .78 44 3.32 62 6.20 27 80 11.04 99 19.39 54 130 44.41

-9 15 .99 7 45 3.44 63 6.41 81 11.40 38 100 19.95 135 50.30

-7 20 1.24 46 3.56 64 6.62 82 11.75 101 20.52 60 140 56.81

-4 25 1.56 47 3.69 18 65 6.85 83 12.11 102 21.11 145 64.04

-1 30 1.95 48 3.83 66 7.07 84 12.49 103 21.71 66 150 72.00

31 2.04 49 3.97 67 7.31 29 85 12.87 104 22.32 155 80.77

32 2.13 10 50 4.11 68 7.57 86 13.27 41 105 22.95 71 160 90.43

33 2.21 51 4.26 69 7.80 87 13.67 106 23.60 165 101.00

34 2.29 52 4.41 21 70 8.10 88 14.08 107 24.26 77 170 112.60

2 35 2.38 53 4.56 71 8.32 89 14.51 108 24.93 175 125.40

36 2.47 54 4.72 72 8.59 32 90 14.94 109 25.62 82 180 139.20

37 2.56 13 55 4.89 73 8.87 91 15.39 43 110 26.34 185 154.30

38 2.66 56 5.06 74 9.15 92 15.84 111 27.07 88 190 170.70

39 2.76 57 5.23 24 75 9.45 93 16.31 112 27.81 195 188.60

94 16.79 113 28.57

(2) Formula 2

Assume our printing plant is located in Denver, Colorado. From Table 4, the worst

case is -10

From Table 3:

0.29 gr/ft

°F with 37% rh

3

x 37% rh - 0.11 gr/ft

3

Combining this result with that of Moisture Required (A) we see that we will need

5.19 - 0.11 = 5.08 grains of moisture for every cubic foot of outside air brought in.

E. INCOMING AIR VOLUME

(1) The following outlines the steps necessary to determine the amount of outside air being

brought into the humidified space and the corresponding amount of moisture required.

There are three basic means by which outside air is introduced into the humidified

space. These are:

(a) Through natural ventilation, for example, opening and closing doors and windows,

and by infiltration through cracks and openings in the building construction.

(b) Through mechanical ventilation, for example, the introduction of make-up air, or

the exhausting of stale air by the building HVAC system.

(c) Through the economizer section of the HVAC system - if this feature is included in

the system.

(2) For maximum accuracy, all three should be estimated and the largest chosen.

10-10

Page 15

2008-10-01

Page 24

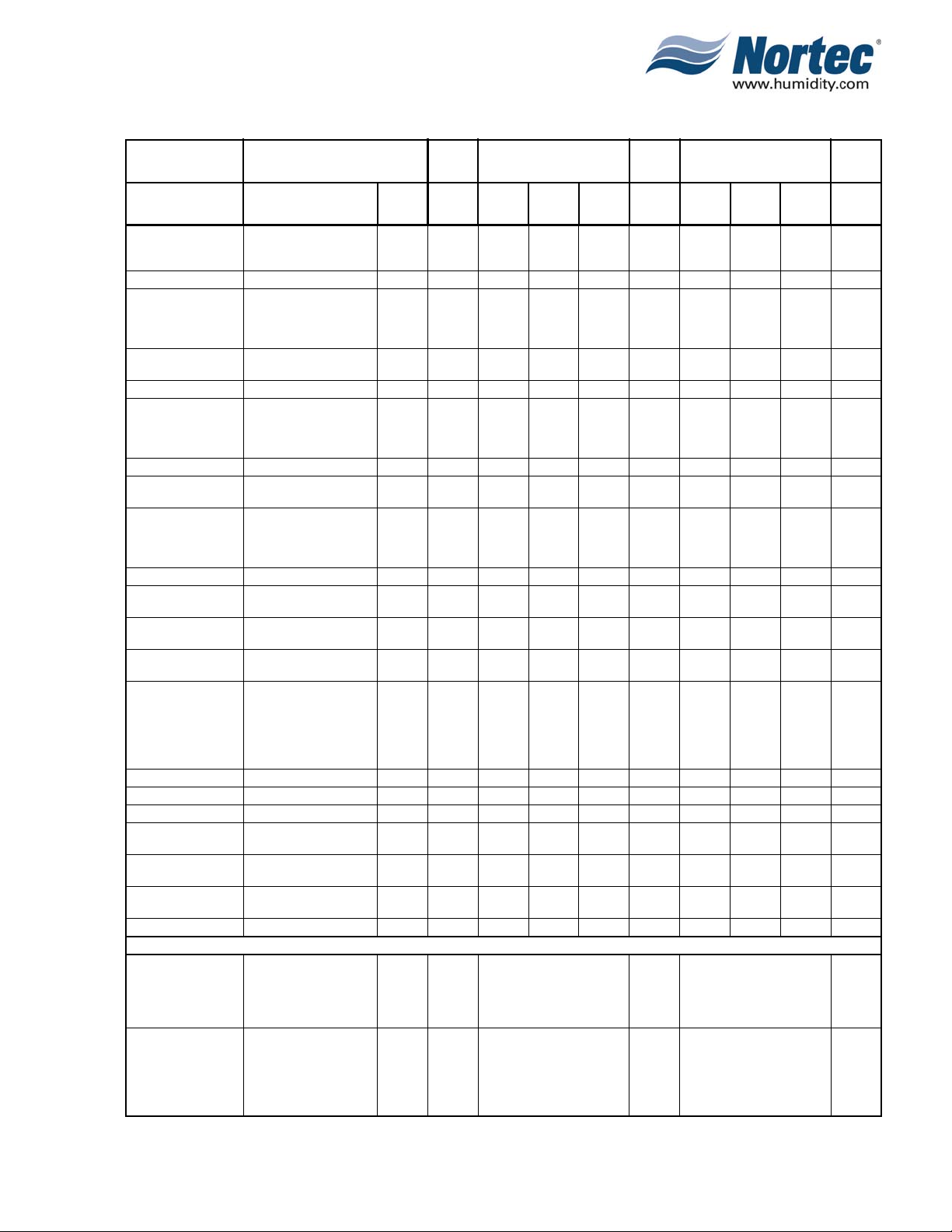

Table 4. Design Outdoor Conditions

JANUARY

Relative Humidity

(% RH)

State City °C

Alabama Birmingham

Arizona Flagstaff

Arkansas Little R o ck -15 5 80 67 68 95 85 55 59 35

California Eureka

Colorado Denver

Connecticut New Haven -18 0 75 65 69 95 77 64 74 35

Delaware Wilmington -18 0 77 62 70 95 80 52 69 35

District of

Columbia

Florida Jacksonville

Georgia Atlanta

Idaho Boise

Illinois Cairo

Indiana Fort Wayne

Iowa Davenport

Kansas Dodge City

Kentucky Louisville -18 0 78 68 69 95 77 52 57 35

Louisiana New Orleans

Maine Portland -21 -58165749078587632

Maryland Baltimore -18 07268569571526535

Massachusetts Boston -18 0 72 59 67 92 72 55 70 33

Michigan Detroit

Minnesota Duluth

Mississippi Vicksburg -12 10 82 65 67 95 87 61 70 35

Missouri

Montana Billings

Nebraska North Platte

Nevada Reno -21 -58267549572252035

New HampshireConcord -26-157860699080496932

Mobile

Phoenix

Yuma

Fresno

Los Angeles

Sacramento

San Diego

San Francisco

Grand Junction

Pueblo

Washington -18 0 73 56 64 95 78 52 64 35

Miami

Augusta

Savannah

Lewiston

Chicago

Peoria

Indianapolis

Terre Haute

Sioux City

Topeka

Shreveport

Grand Rapids

Minneapolis

Kansas City

St. Louis

Butte

Omaha

Dry

Bulb

-12

-12

-23

-4

-1

-1

-4

2

-1

2

2

-23

-26

-29

-4

2

-12

-12

-7

-23

-20

-18

-23

-23

-23

-23

-18

-26

-29

-23

-23

-7

-7

-23

-23

-32

-29

-23

-18

-32

-29

-29

-23

°F

10

10

-10

25

30

30

25

35

30

35

35

-10

-15

-20

25

35

10

10

20

-10

-10

-10

-10

-10

-15

-20

-10

-10

20

20

-10

-10

-25

-20

-10

-25

-20

-20

-10

7:30

A.M.

-5

0

0

0

81

83

75

56

87

93

63

90

76

84

54

77

67

89

87

80

84

83

82

79

81

81

83

84

83

82

78

78

78

85

83

82

85

78

82

78

77

67

76

80

82

1:30

P.M.

--

--

61

58

47

37

80

46

82

58

68

37

64

44

56

59

64

59

58

75

73

69

70

72

75

72

70

67

57

64

67

67

71

78

74

72

64

65

73

70

62

68

7:30

P.M.

--

--

--

Dry

Bulb

°F

66

39

27

77

66

51

70

60

70

41

64

48

75

75

69

69

72

74

71

75

77

81

78

76

72

61

6795100

73

6695100

77

80

74

75

6668100

60

71

66

73

95

--

95

--

90

105

110

90

105

90

100

85

85

95

95

95

95

91

95

98

95

95

95

--

98

95

96

95

95

95

--

95

95

95

95

93

95

95

90

95

85

95

7:30

A.M.

JULY

Relative Humidity

(% RH)

84

90

77

53

51

92

61

85

76

86

92

55

48

73

85

83

83

83

85

54

64

83

78

81

84

84

77

86

77

85

84

86

74

76

87

82

76

73

65

82

84

80

1:30

P.M.

--

56

64

36

31

31

36

50

46

68

75

27

27

34

57

64

57

55

61

34

37

57

51

53

53

54

50

55

45

54

64

56

50

51

61

54

48

50

40

36

50

51

7:30

P.M.

--

--

68

78

23

23

80

20

54

28

65

78

30

22

35

76

76

68

69

80

23

25

55

58

58

60

56

54

52

54

72

62

56

54

66

54

47

55

33

33

46

51

°C

35

35

--

32

41

44

32

41

32

38

29

29

35

35

35

35

33

35

37

35

35

35

--

37

35

35

35

35

35

--

35

35

35

38

35

38

35

35

33

35

38

35

32

35

29

35

10-10

Page 16

2008-10-01

Page 25

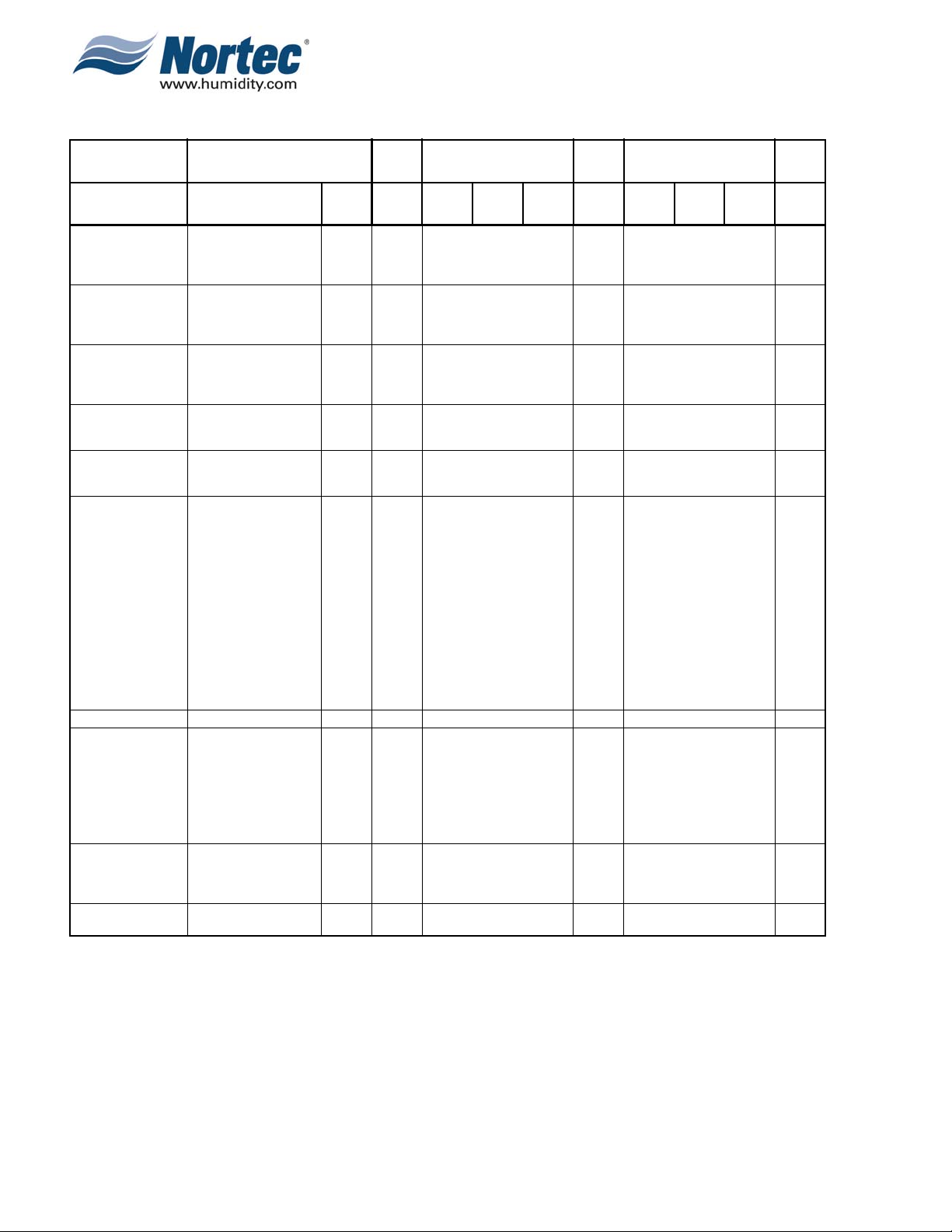

Table 4. Design Outdoor Conditions (cont)

JANUARY

Relative Humidity

(% RH)

74

65

68

71

78

66

79

69

69

74

79

76

75

78

78

65

68

63

76

65

76

67

69

73

52

75

62

39

73

59

74

78

70

74

73

73

Dry

Bulb

--

°F

95

95

95

93

93

95

95

93

95

95

95

95

95

90

90

95

95

95

95

95

95

95

95

95

95

100

95

100

100

95

100

85

95

95

95

95

95

87

86

84

91

96

87

94

85

73

80

80

7:30

A.M.

State City °C

New Jersey Atlantic City

Newark

Trenton

New Mexico Albuquerque -18 0 68 51 46 95 59 33 28 35

New York Albany

Buffalo

New York

Rochester

North Carolina Asheville

Raleigh

North Dakota Bismarck -34 -30 77 71 75 95 85 52 49 35

Ohio Cincinnati

Cleveland

Columbus

Toledo

Oklahoma Oklahoma City -18 0 79 62 65 101 80 49 51 38

Oregon Baker

Portland

Pennsylvania Harrisburg

Philadelphia

Pittsburgh

Scranton

Rhode Island Providence -18 0 73 60 67 93 79 57 73 34

South Carolina Charleston

Columbia

South Dakota Huron

Rapid City

Tennessee Knoxville

Memphis

Texas Amarillo

Corpus Christi

Dallas

El Paso

Houston

San Antonio

Utah Salt Lake City -23 -10 80 71 72 95 56 27 23 35

Vermont Burlington -23 -10 81 69 78 90 76 54 67 32

Virginia Richmond -9 15 84 60 68 95 81 57 72 35

Washington Seattle

Walla Walla

West Virginia Charleston

Parkersburg

Wisconsin Green Bay

Milwaukee

Wyoming Cheyenne -26 -15 59 48 55 95 73 36 40 35

Province City

Alberta Calgary

Edmonton

Grande Prairie

Lethbridge

Medicine Hat

British Columbia Estevan Point

Fort Nelson

Penticton

Prince George

Prince Rupert

Vancouver

Dry

Bulb

-15

-18

-18

-23

-21

-18

-21

-18

-12

-18

-18

-23

-23

-21

12

-18

-18

-18

-21

-9

-12

-29

-29

-18

-18

-23

-7

-12

-12

-7

-7

-9

-21

-18

-23

-26

-26

-34

-34

-42

-36

-34

-8

-40

-18

-38

-12

-9

°F

-10

10

-10

-10

10

15

10

-20

-20

-10

20

10

10

20

20

15

-10

-15

-15

-29

-29

-43

-32

-30

17

-40

-37

11

15

7:30

A.M.

5

0

0

-5

0

-5

0

0

0

-5

0

0

0

-5

0

0

-5

0

0

79

72

73

75

79

72

81

82

82

82

81

83

79

83

87

72

74

77

80

87

81

79

71

83

82

71

88

81

63

85

82

86

80

79

82

75

76

1:30

P.M.

71

75

80

66

73

84

79

81

82

87

87

68

79

62

63

72

61

73

59

57

70

72

71

72

81

82

49

65

67

67

55

57

72

69

65

67

51

66

62

45

66

60

80

74

64

66

68

70

7:30

P.M.

JULY

Relative Humidity

(% RH)

81

75

77

79

78

75

80

88

86

84

79

78

76

69

86

78

78

80

77

88

83

86

71

83

85

77

93

79

60

90

88

86

50

88

80

85

81

1:30

P.M.

34

42

38

30

31

32

32

44

53

54

41

72

51

55

52

53

58

50

56

55

52

52

52

52

68

63

51

52

52

50

64

56

52

42

55

55

43

58

50

37

58

49

63

33

53

52

58

58

7:30

P.M.

82

65

68

64

63

68

60

73

72

60

58

60

59

36

48

62

64

63

82

68

49

40

66

59

42

68

47

30

66

45

47

22

67

65

64

64

°C

35

35

35

34

34

35

35

34

35

35

35

35

35

32

32

35

35

35

35

--

35

35

35

35

35

35

38

35

38

38

35

38

29

35

35

35

35

35

31

30

29

33

36

31

34

29

23

27

27

10-10

Page 17

2008-10-01

Page 26

Table 4. Design Outdoor Conditions (cont)

JANUARY

Relative Humidity

(% RH)

Province City °C

Manitoba Brandon

Churchill

The Pas

Winnipeg

New Brunswick Campbellton

Fredericton

Moncton

Saint John

Newfoundland Corner Brook

Gander

Goose Bay

St. John’s

N.W.T. Frobisher

Resolute

Yellowknife

Nova Scotia Halifax

Sydney

Yarmouth

Ontario Thunder Bay

Hamilton

Kaspuskasing

Kingston

Kitchener

London

North Bay

Ottawa

Peterborough

Sioux Lookout

Sudbury

Timmins

Toronto

Windsor

Sault St. Marie

P.E.I. Charlottetown -21 -6 86 84 57 29

Quebec Knob Lake

Mont Joli

Montreal

Port Harrison

Quebec City

Sept-Iles

Sherbrooke

Trois Rivieres

Saskatchewan Prince Albert

Regina

Saskatoon

Swift Current

Yukon Territory Dawson

Whitehorse

Dry

Bulb

-34

-40

-37

-34

-28

-27

-24

-24

-23

-21

-32

-17

-43

-45

-45

-18

-17

-15

-33

-18

-34

-24

-19

-18

-29

-27

-25

-36

-29

-36

-19

-16

-29

-40

-24

-27

-39

-28

-33

-28

-28

-41

-37

-37

-34

-49

-43

°F

-29

-40

-35

-29

-18

-16

-12

-12

-10

-26

-45

-49

-49

-27

-30

-11

-20

-17

-13

-33

-20

-33

-20

-40

-11

-16

-39

-19

-27

-18

-18

-41

-34

-34

-29

-56

-45

7:30

A.M.

-5

1

0

1

5

0

-3

0

-3

-3

1:30

P.M.

73

76

77

78

77

72

82

82

84

76

85

77

71

82

83

84

83

80

75

79

84

80

77

77

78

81

79

82

79

75

76

81

77

81

76

79

76

80

7:30

P.M.

Dry

Bulb

°F

90

79

85

90

87

89

88

81

84

85

86

79

63

54

78

83

84

76

86

91

87

85

88

90

87

90

90

65

89

90

90

92

88

55

62

88

86

80

87

88

88

92

90

93

57

78

7:30

A.M.

JULY

Relative Humidity

(% RH)

1:30

P.M.

50

57

54

50

54

47

52

62

47

45

42

60

67

81

50

50

56

70

52

52

52

69

58

53

46

50

53

69

44

45

56

51

48

70

71

58

60

47

58

58

60

40

7:30

P.M.

°C

32

26

29

32

31

32

31

27

29

29

30

26

17

12

26

28

29

24

30

33

31

29

31

32

31

32

32

18

32

32

32

31

29

13

17

31

30

27

31

31

31

33

32

34

14

26

10-10

Page 18

2008-10-01

Page 27

(3) Using the natural ventilation method requires knowing the volume of the humidified

space and the type of construction. A tightly constructed building will have a least one

air change per hour. A loosely constructed building will have at least one and one half

changes per hour, and this same building with a large a amount of incoming or exiting

traffic will have at least two air changes per hour.

(a) Formula 3

Assume our print shop has a floor area of 100'

large amount of traffic. This requires

100' x 100' x 20' x 2 = 400,000 ft

Using our example, the moisture required is

400,000 x 5.08

_______________

7000 grains/lb

(4) Using make-up air:

(a) Formula 4

Assume our print shop has a 15,000 CFM HVAC system and uses 10%

make-up air during winter. The amount of outside make-up air entering the

HVAC system will, therefore, be 10% of 15,000 CFM = 1,500 CFM. The

moisture required will be

1,500 x 5.08 x 60 min/hr

_________________________

7,000 grains/lb

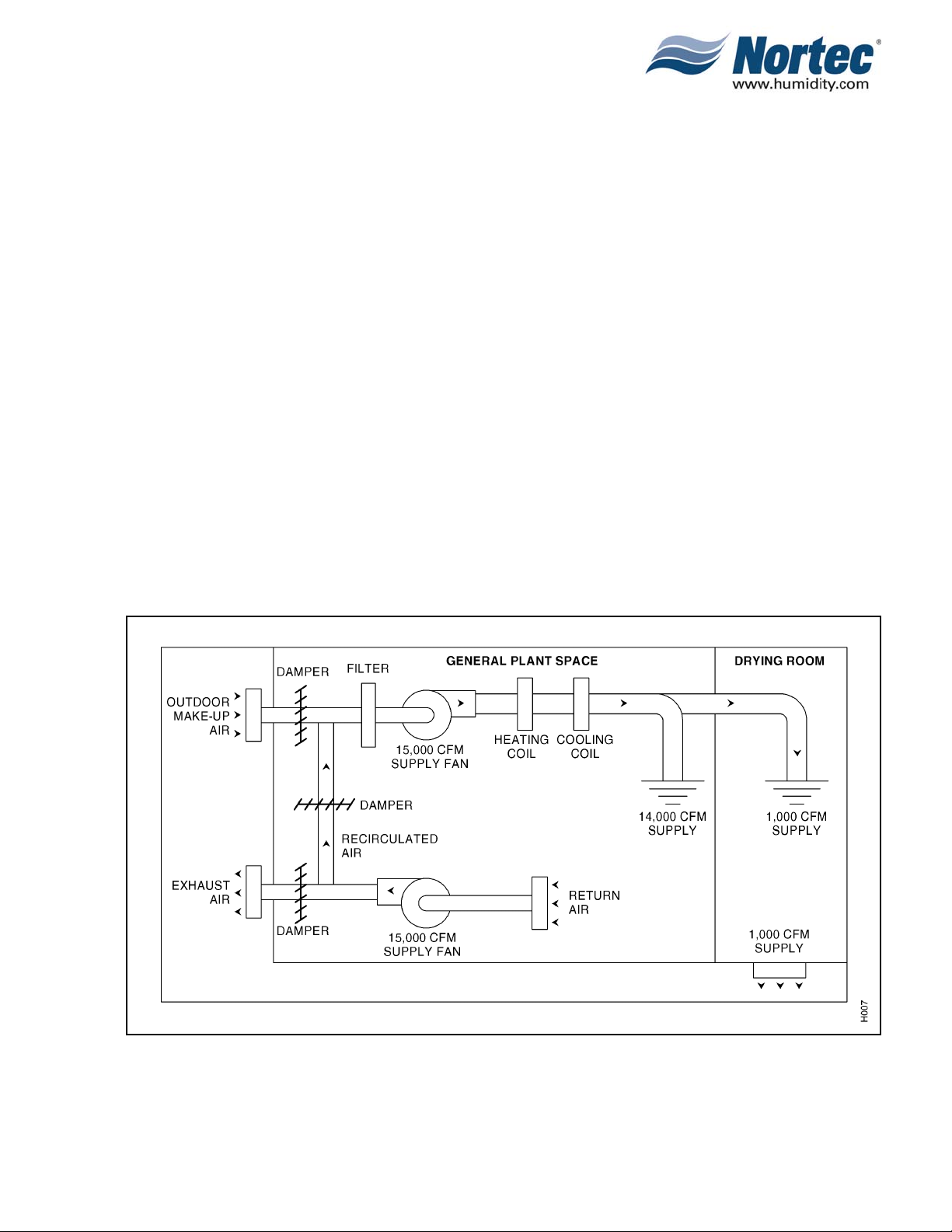

(Refer to Figure 1.)

= 290 lbs/hr

= 65 lbs/hr

3

x 100' with a 20' ceiling with a

/hr.

Figure 1. Schematic of a Typical Print Shop HVAC System

10-10

Page 19

2008-10-01

Page 28

(5) Using an exhaust air fan:

(a) Formula 5

Assume the print shop has a 1,000 CFM fan to exhaust a drying room. The

moisture required to humidify the drying room only is

1,000 x 5.08 x 60 min/hr

_________________________

7,000 grains/lb

= 44 lbs/hr

(Refer to Figure 1.)

(6) Using an economizer cycle:

(a) Care should be taken in sizing humidification load when an economizer cycle is

incorporated into a building HVAC system. The purpose of an economizer cycle is

to provide building cooling using outside air, rather then the building refrigeration

system when outside air conditions permit.

(b) The economizer cycle senses and compares outdoor air temperature and return

air temperature during the cooling season.

(c) W hen the HVAC system calls for cooling and the outdoor air temperature is low

enough – typically 55°F or lower – the outside air and exhaust air dampers are

positioned to provide the required supply air temperature to maintain cooling, and

the recirculated air damper is positioned to maintain the required supply air

volume. When the outdoor air temperature is higher than the supply air

temperature required to maintain cooling but is lower than the return air

temperature, the make-up air and exhaust air dampers are 100% open. The

recirculation air damper closes, and the building refrigeration system provides the

portion of cooling load that cannot be provided by outside air intake.

(d) From this it can be seen that it is possible to introduce 100% outside air into a

building during the cooling season.

(e) Formula 6

For example, if out print shop were using 100% outdoor air at 55°F and

40% rh, then the moisture required is

5.19 - (4.89 x 40% rh) = 3.23 gr/ft

3

Therefore, on a 15,000 CFM system, the humidification load will be

15,000 x 3.23 x 60 min/hr

__________________________

7,000 grains/lb

= 415 lbs/hr

(f) In the above examples, the largest humidification load was due to the economizer

cycle at 415 lbs/hr.

(7) Using cooling or refrigeration loads:

(a) As air is cooled, it loses it’s ability to hold moisture. If it is cooled enough, some of

the moisture will condense out. This is known as cooling load. Cooling load

calculations can be important for process applications or refrigeration applications

to product dehydration.

10-10

Page 20

2008-10-01

Page 29

(b) Formula 7

Assume that during the summer the HVAC system is in the cooling mode. The

air leaving the cooling coil is at 55°F and 90% rh. In order to maintain the

desired 47% rh in the space, moisture must be added using the following

formula:

Desired space 80°F 47% rh= 5.19 gr/ft

3

(Formula 1)

55°F 90% = 4.89 x 0.90 = 4.40 gr/ft

________________________ __________

3

Grains to add = 0.79 gr/ft3

15,000 x 0.79 x 60 min/hr

_________________________

7,000 grains/lb

= 101.57 lbs/hr

(8) In considering Process and Environment, in Tables 5 through 7 you will find conditions

and processes that may affect your calculation and should be addressed.

(a) Table 5 shows the outdoor temperature at which the rh would cause condensation

on the windows to the outside. Should your outdoor conditions make this a

possibility, an outdoor setback sensor may be a solution.

(b) Table 6 describes the moisture gain of various material and if your process or

environment includes a great amount of these materials that are constantly

introduced to the area, its affects must be considered.

(c) Table 7 identifies many recommended indoor conditions for various locations and

processes, these can be of use when deciding what conditions would be most

beneficial in your application.

(d) In Figure 2, you will find the ASHRAE physchrometric chart describing the

enthalpy of dry air and the effects to and from rh in the air.

Table 5. Inside Relative Humidities At Which Moisture Will Condense On Windows

Outside

T emperature

°F °C

Single Windows, Still Air Single Windows, Wind

-50-4599988-50-4543332

-40-401212111010-40-4054443

-30-341614141313-30-3476665

-20 -29 20 18 18 17 16 -20 -29 10 9 9 8 7

-10 -23 25 23 22 21 20 -10 -23 14 13 12 11 10

0 -18 32 29 27 25 24 0 -18 20 18 16 15 13

10-12393633312910-122824222018

20 -7 47 43 40 37 35 20 -7 36 32 30 26 24

30 -1 57 52 50 45 42 30 -1 48 41 38 34 30

40 4 70 63 60 53 50 40 4 62 54 49 43 40

NOTE: Bold areas indicate that moisture will be in the form of frost on windows.

Inside Temperature (°F/°C)

60/

15.5

65/

18.3

70/

21

75/

23.8

80/

26.6

Outside

Temperature

°F °C

Inside Temperature (°F/°C)

60/

15.5

65/

18.3

70/

21

75/

23.8

80/

26.6

10-10

Page 21

2008-10-01

Page 30

Table 5. Inside Relative Humidities At Which Moisture Will Condense On Windows (cont)

Outside

T emperature

°F °C

Double Windows, Still Air Double Windows, Wind

-50 -45 34 34 34 33 32 -50 -45 23 26 26 26 25

-40 -40 38 38 36 36 35 -40 -40 32 30 30 29 28

-30 -34 42 42 41 40 38 -30 -34 36 34 34 32 31

-20 -29 47 46 46 44 42 -20 -29 41 39 38 35 35

-10 -23 52 50 49 48 46 -10 -23 46 45 42 42 39

0 -18 57 55 55 52 50 0 -18 52 49 47 46 44

10 -12 62 60 59 57 54 10 -12 58 56 53 52 49

20 -7 69 66 63 62 59 20 -7 65 63 59 58 54

30 -1 76 73 71 68 65 30 -1 72 70 66 64 60

40 4 84 80 79 74 71 40 4 80 78 73 70 67

NOTE: Bold areas indicate that moisture will be in the form of frost on windows.

Inside Temperature (°F/°C)

60/

15.5

65/

18.3

70/

21

75/

23.8

80/

26.6

Outside

Temperature

°F °C

Inside Temperature (°F/°C)

60/

15.5

65/

18.3

70/

21

75/

23.8

80/

26.6

Table 6. Regain of Hygroscopic Materials

Industry Materials

Baking Crackers

Flour

White Bread

Leather Sole Oak, Tanned 5.0 8.5 11.2 13.6 16.0 18.3 20.6 24.0 29.2

Printing Paper – Comm. Ledger – 75% Rag

1% Ash

Paper M.F. Newsprint – 24% Ash

Paper White Bond Rag – 1% Ash

Paper Writing – 3% Ash

Textile Cotton – Absorbent

Cotton – American-cloth

Cotton – Sea Isle-roving

Hemp – Manila and Sisal

Jute – Average Grade

Linen – Dried Spun – Yarn

Rayon – Celulose – Acetate – Fibre

Rayon – Cupramonium – Average

Skein

Rayon – Viscose Nitrocel

Silk – Raw Chevennes-Skein

Wool – Australian-Marino-Skein

Tobacco Cigarette 5.4 8.6 11.0 13.3 16.0 19.5 25.0 33.5 50.0

Wood Timber – Average

Glue – Hide

Miscellaneous Charcoal-Steam Activated

Gelatin

Silica Gel

Soap

Starch

NOTE: Moisture content expressed in per cent of dry weight of the substance at various relative humidities –

Temperature 75°F.

10 20 30 40 50 60 70 80 90

2.1

2.8

2.6

4.1

0.5

1.7

3.2

4.2

2.1

3.2

2.4

3.7

3.0

4.2

9.0

4.8

3.7

2.6

3.7

2.5

4.7

2.7

5.2

3.1

5.4

3.6

1.1

0.8

5.7

4.0

5.7

4.0

5.5

3.2

7.0

4.7

3.0

4.4

3.4

4.8

7.1

14.3

0.7

1.6

5.7

9.8

1.9

3.8

2.2

3.8

Relative Humidity - %

3.3

3.9

5.0

5.3

6.5

4.5

5.6

4.7

5.5

6.2

5.2

5.6

7.2

8.5

7.3

1.9

7.9

7.9

8.0

7.6

6.6

3.8

7.6

6.4

8.0

6.2

6.2

6.1

6.5

7.2

18.5

5.9

6.6

8.5

10.2

8.1

2.4

9.2

9.2

8.9

12.8

9.3

7.6

28.3

4.9

17.2

10.0

7.4

3.1

5.0

4.0

4.7

5.2

12.5

4.4

4.6

6.0

6.9

6.5

1.4

6.8

6.8

6.9

8.9

5.9

5.8

22.8

2.8

12.7

5.7

5.2

15.7

10.8

26.2

15.2

6.5

9.9

8.5

6.9

7.2

7.5

8.3

20.8

6.8

7.9

9.9

12.2

8.9

3.0

10.8

10.8

10.2

14.9

11.3

9.0

29.2

6.1

18.6

12.9

8.3

8.3

12.4

11.1

8.1

8.7

8.8

9.9

22.8

8.1

9.5

11.6

14.4

9.8

3.6

12.4

12.4

11.9

17.2

14.0

10.7

30.0

7.6

20.2

16.1

9.2

10.9

15.4

14.5

10.3

10.6

10.8

11.9

24.3

10.0

11.5

13.6

17.1

11.2

4.3

14.2

14.2

14.3

19.9

17.5

11.8

31.1

9.3

21.5

19.8

10.6

14.9

19.1

19.0

13.9

13.2

14.2

25.8

14.3

14.1

15.7

20.2

13.8

5.3

10.0

16.0

18.8

23.4

22.0

12.5

32.7

11.4

22.6

23.8

12.7

10-10

Page 22

2008-10-01

Page 31

Table 7. Design Indoor Conditions For Various Places, Products and Processes

Product and/or Process

Abrasives Manufacturing 78 25 50

Bowling Alleys 73 – 75 23 – 24 50 – 55

Billiard Rooms 73 – 75 23 – 24 40 – 50

Bread

Flour and Powdered Product Storage

Fermentation (Bread Dough)

Retarding of Doughs

Final Proof

Counterflow Cooling

Brewing

Hop Storage

Yeast Culture Room

Candy

Chocolate Pan Supply Air

Enrober Room

Chocolate Cooling Tunnel Supply Air

Hand Dippers

Moulded Goods Cooling

Chocolate Packing Room and Finished Stock Storage

Centers Tempering Room

Marshmallow Setting Room

Grained Marshmallow (deposited in starch) Drying

Gum (deposited in starch) Drying

Sanded Gum Drying

Gum Finished Stock Storage

Sugar Pan Supply Air (engrossing)

Polishing Pan Supply Air

Pan Rooms

Nonpareil Pan Supply Air

Hard Candy Cooling Tunnel Supply Air

Hard Candy Packing

Hand Candy Storage

Caramel Rooms

Raw Material Storage

Nuts (insect)

Nuts (rancidity)

Eggs

Chocolate (flats)

Butter

Dates, Figs, etc.

Corn Syrup

Liquid Sugar

Comfort Air Conditioners

Ceramics

Refractory

Molding Room

Clay Storage

Decalcomania Production and Decorating room

Cereal Packaging

Cheese Curing

Cheddar

Swiss

Blue

Brick

Limburger

Camembert

Temperature

°F °C

70 – 80

80

32 – 40

95 – 120

75

29 – 32

--

55 – 62

80 – 85

40 – 45

62

40 – 45

65

75 – 80

75 – 78

110

125 – 150

100

50 – 65

85 – 105

70 – 80

75 – 80

100 – 120

60 – 70

70 – 75

50 – 70

70 – 80

45

34 – 38

30

65

20

40 – 45

90 – 100

75 – 80

75 – 80

110 – 150

80

60 – 80

75 – 80

75 – 80

45 – 55

60

48 – 50

60 – 65

60 – 65

53 – 59

21 – 27

27

0 – 4

35 – 49

24

2 – 0

--

13 – 17

27 – 29

4 – 7

17

4 – 7

18

24 – 27

24 – 26

43

52 – 66

38

10 – 18

29 – 41

21 – 27

24 – 27

38 – 49

16 – 21

21 – 24

10 – 21

21 – 27

7

1 – 3

-1

18

-7

4 – 7

32 – 38

24 – 27

24 – 27

43 – 66

27

16 – 27

24 – 27

24 – 27

7 – 13

16

9 – 10

16 – 18

16 – 18

12 – 15

Relative

Humidity

%RH

60

75

85

85 – 90

80 – 85

50 – 60

80

45 – 55

25 – 30

70 – 85

45

70 – 85

50

30 – 35

40 – 45

40

15 – 25

25 – 40

65

20 – 30

40 – 50

30 – 35

20

40 – 55

35 – 40

40

40

65 – 75

65 – 75

85 – 90

50

65 – 75

–

30 – 40

50 – 60

50 – 90

60 – 70

35 – 65

48

45 – 50

85 – 90

80 – 85

95

90

95

90

10-10

Page 23

2008-10-01

Page 32

Table 7. Design Indoor Conditions For Various Places, Products and Processes (cont)

Product and/or Process

Clean Rooms – Computer Rooms

Computer Room

Clean Room – General

Clean Room – Critical

Distilling

Grain Storage

General Manufacturing

Aging

Electrical Products

Coil and Transformer Winding

X-ray Tube Assembly

Instruments Manufacture and Laboratory

Thermostat and Humidistat Assembly and Calibration

Close Tolerance Assembly

Meter Assembly and Test

Fuse and Cutout Assembly, Capacitor Winding and Paper Storage

Conductor Wrapping with Yarn

Lightning Arrestor Assembly

Thermal Circuit Breaker Assembly and T est Water Wheel Generators

Thrust

Runner Hopping

Processing Selenium and Copper Oxide Plates

Fruit Storage

Apples

Apricots

Grapefruits (California)

Grapefruits (Florida)

Grapes (Eastern)

Grapes (Western)

Lemons

Oranges (California)

Oranges (Florida)

Peaches and Nectarines

Plums

Specialty Citrus Fruit

Fur Storage 40 – 50 4 – 10 55 – 65

Gum

Manufacture

Rolling

Stripping

Breaking

Wrapping

Hospitals

Operating, Cystoscopic and Fracture Rooms

Patient Rooms

Intensive Care Unit

Administrative and Service Areas

Leather

Drying

Storage, Winter Room Temperature

Lenses (Optical)

Fusing

Grinding

Temperature

°F °C

70 – 80

70 – 74

71.5 – 72.5

60

0 – 75

65 – 72

72

68

70

76

72

76

73

75

68

76

70

74

30 – 40

31 – 32

58 – 60

50

31 – 32

30 – 31

58 – 60

40 – 44

32 – 34

31

30 – 32

38 – 40

77

68

72

74

74

68 – 76

75

75

70 – 80

70 – 120

50 – 60

75

80

21 – 27

21 – 23

22 – 22.5

16

16 – 24

18 – 22

22

20

21

24

22

24

23

24

20

24

21

23

-1– 4

-1 – 0

14 – 16

10

-1 – 0

-1

14 – 16

4 – 7

0 – 1

-1

-1 – 0

3 – 4

25

20

22

23

23

20 – 24

24

24

21 – 27

21 – 49

10 – 16

27

27

Relative

Humidity

%RH

40 – 60

40 – 60

43 – 47

35 – 40

45 – 60

50 – 60

15

40

50 – 55

50 – 55

40 – 45

60 – 63

50

65 – 70

20 – 40

30 – 60

30 – 50

30 – 40

90

90 – 95

85 – 90

85 – 90

85

90 – 95

86 – 88

85 – 90

85 – 90

90

90 – 95

90 – 95

33

63

53

47

58

50

40 – 50

40

30 – 50

75

40 – 60

45

80

10-10

Page 24

2008-10-01

Page 33

Table 7. Design Indoor Conditions For Various Places, Products and Processes (cont)

Product and/or Process

Libraries and Museums

Normal Reading and Viewing Rooms

Rare Manuscript Storage Vaults

Art Storage Areas

Matches

Manufacture

Drying

Storage

Meat and Fish

Beef (Fresh)

Beef, Fish, Lamb and Pork (Frozen)

Fish (Fresh)

Lamb and Pork (Fresh)

Mushrooms

Sweating-out Period

Spawn Added

Growing Period

Storage

Oil Paints: Paint Spraying 60 – 90 16 – 32 80

Pharmaceuticals

Manufactured Powder Storage and Packaging Area

Milling Room, Table Compressing and Coating

Effervescent Tablets and Powders

Hypodermic Tablets

Colloids

Cough Drops

Glandular Products

Ampoule Manufacturing

Gelatin Capsules and Storage

Microanalysis

Biological Manufacturing and Liver Extracts

Serums

Animal Rooms

Plastics

Manufacturing Areas Thermosetting

Molding Compounds

Cellophane Wrapping

Plywood

Hot Pressing (Resin)

Cold Pressing

Printing

Platemaking

Lithographic Press Room

Letterpress and Web Offset Press Rooms and Paper Storage

Paper Storage (Multicolor Sheet Feed Lithography)

Rubber Dipped Goods

Cementing

Dipping Surgical Articles

Storage Prior to Manufacture

Laboratory (ASTM Standard)

Tea Packaging 65 18 65

Temperature

°F °C

70 – 74

70 – 72

65 – 72

72 – 74

70 – 75

60 – 62

32 –34

-10 – 0

33 – 35

32 – 34

120 – 140

60 – 75

48 – 60

32 – 35

75

75

75

75

70

80

76

75

76

76

76

76

75 – 80

80

75 – 80

90

90

75 – 80

76 – 80

76 – 80

76 – 80

80

75 – 90

60 – 75

73.4

21 – 23

21 – 22

17 – 22

22 – 23

21 – 24

16 – 17

0 – 1

-23 – -18

1 – 3

0 – 1

49 – 60

16 – 24

9 – 16

0 – 2

24

24

24

24

21

27

24

24

24

24

24

24

24 – 27

27

24 – 27

32

32

24 – 27

24 – 27

24 – 27

24 – 27

27

24 – 32

16 – 24

23

Relative

Humidity

%RH

40 – 50

45

50

50

60

50

88 – 92

90 – 95

90 – 95

85 – 90

–

Nearly Sat.

80

80 – 85

35

35

20

30

30 – 50

40

5 – 10

35 – 50

35

50

35

50

50

35 – 30

45 – 65

60

15 – 25

45 Max

43 – 47

50

5 – 8

Higher than

Press Room

25 – 30

25 – 30

40 – 50

50

10-10

Page 25

2008-10-01

Page 34

Table 7. Design Indoor Conditions For Various Places, Products and Processes (cont)

Product and/or Process

Textiles

Opening and Picking

Cotton

Man-Made

Carding

Cotton

Wool

Man-Made

Silver and Ribbon Lapping

Cotton

Man-Made

Combing

Cotton

Wool

Man-Made

Drawing

Cotton and Wool

Man-Made

Roving

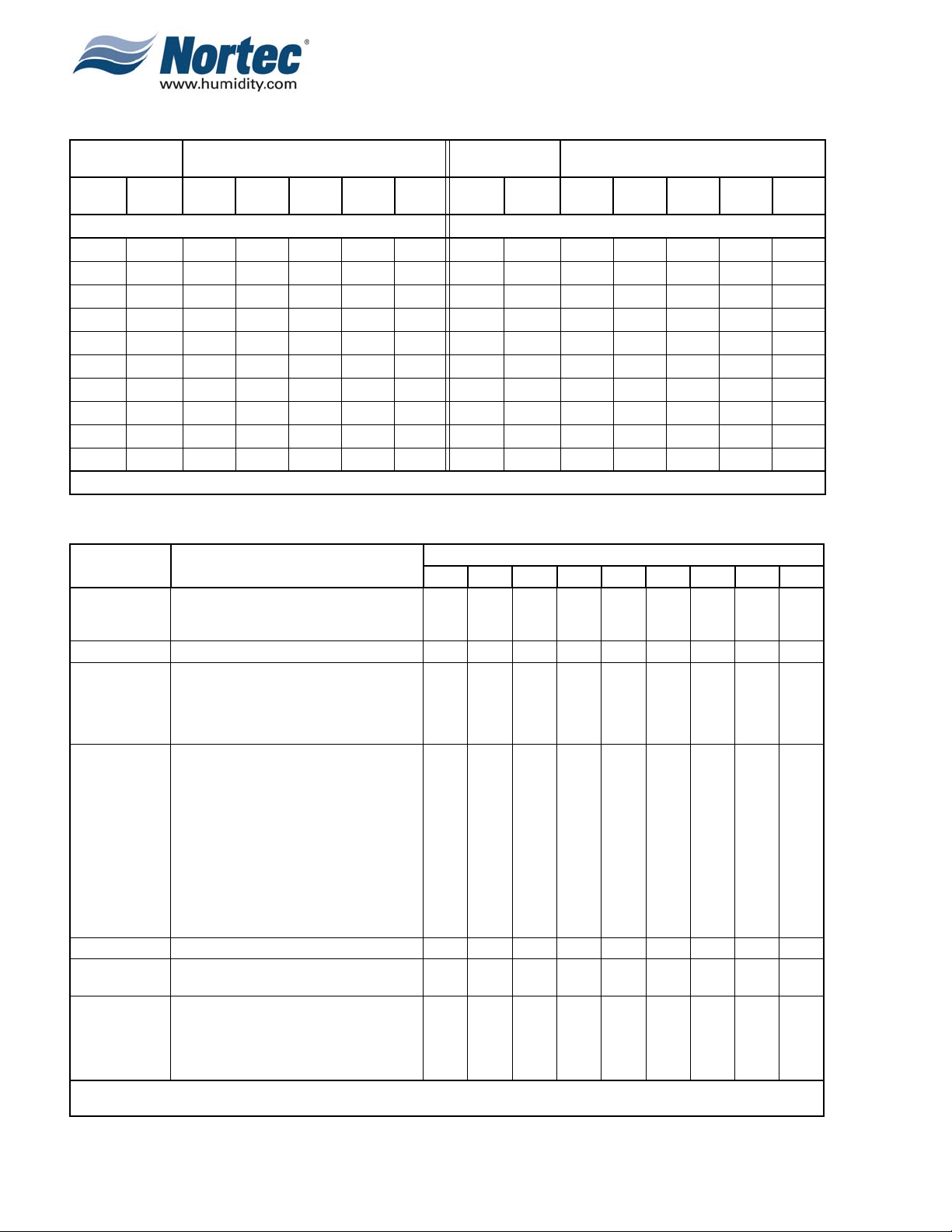

Cotton